FV520B-I钢由于高强度、良好的韧塑性、较好的耐腐蚀性和焊接性能等特点在工业领域中广泛应用,主要用于制造各种回转类构件,例如叶片、转子等。尤其是作为离心压缩机叶轮叶片用材料,在服役过程中需要长期承载高频低应力幅的载荷作用。疲劳破坏成为其主要失效形式,实际的使用寿命已经远远超过107循环周次,甚至达到了1010周次。为提高离心压缩机叶轮服役可靠性,有必要对叶轮材料FV520B-I高强度钢的超离周疲劳行为与机理进行研究。大量的实验研究表明[1-3],高强钢疲劳性能表现为表面缺陷与内部缺陷竞争。处于中高周疲劳区域的裂纹主要萌生于表面缺陷,在超高周区域裂纹主要由内部缺陷引发,其中非金属夹杂物是造成高强钢超高周疲劳失效的主要原因。在内部疲劳破坏的试样断面上,裂纹整体显示出鱼眼的形状,通常夹杂物附近会出现粗糙的granular bright facet即GBF区域[4]。对于GBF的形成与裂纹扩展,研究人员提出了一些科学合理的解释。Murakami等[5]指出GBF的形成很可能与氢导致的氢脆有关,Otsuka等[6]和Murakami等[7]也在夹杂物周围通过实验确切的观察到氢的富集;王清远[8]基于夹杂物裂纹萌生和扩展过程的定量分析提出了一个确定性超高周疲劳寿命预测的模型,这个模型结合实验数据能够很好地预测寿命,并且提供了分析夹杂物对超高周疲劳性能影响的可靠方法。杨振国[9]和李永德[10]考虑氢对应力强度因子、裂纹扩展速率的影响,在寿命模型中引入与氢含量有关的系数,结合Paris方程建立了一个预测更为精确的超高周疲劳寿命公式。王金龙[11]参考王清远[8]和Tanaka[12]的工作建立了Fv520b-I钢的超高周疲劳寿命公式,结合实验数据拟合出式中的参数,成功地预测超高周疲劳寿命;并在此基础上分析了超高周次内表面缺陷与内部缺陷(非金属夹杂物)之间的竞争关系[13],实现2种失效机制的定量描述。

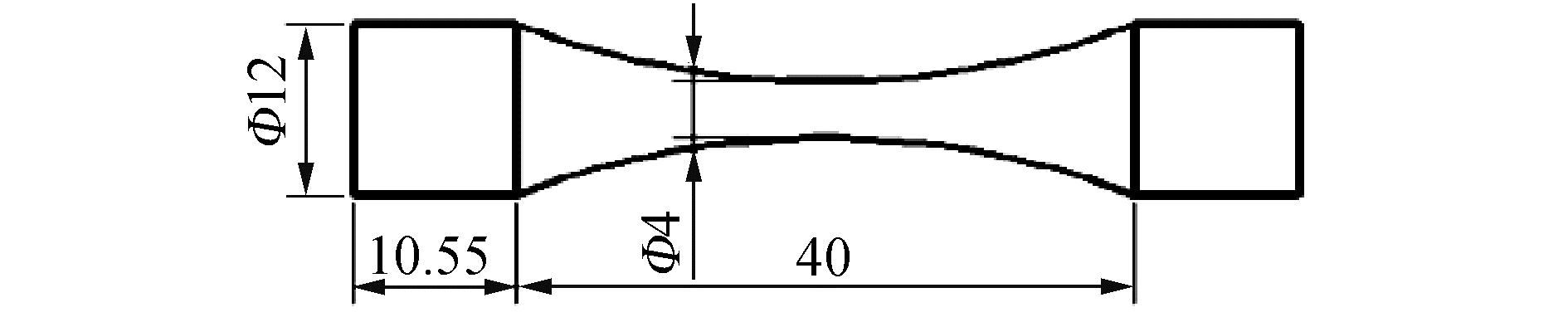

1 实验材料和方法本次超高周疲劳实验所用材料是离心压缩机常用材料FB520B-I。其化学成分的质量分数为0.07%C,1.0%Mn,0.07%Si,0.025%S,0.03%P,13.0%Cr,5.0%Ni,1.3%Mo,0.25%Nb,1.3%Cu。其热处理工艺条件为(1050±10)℃固溶处理1.5~2.5 h,空冷;(850±10)℃调质处理1.5~2.5 h,油冷;(480±10)℃时效处理2~3 h,空冷。热处理后钢材基体微观组织为马氏体板条,抗拉强度为1 078 MPa,屈服强度为1 029 MPa,硬度为380 HV,试样形状加工成如图 1的形状尺寸。

|

Download:

|

| 图 1 试样的形状尺寸 Fig. 1 Shape and dimensions of specimen | |

室温下利用岛津USF-2000超声疲劳试验机对试样进行实验,频率为20 kHz,R=-1。在扫描电镜和光学显微镜下对试样断口表面特征区域进行观察,并且利用电镜自带的EDX (energy dispersive X-ray)光谱仪对裂纹源附近的夹杂物进行成分分析。

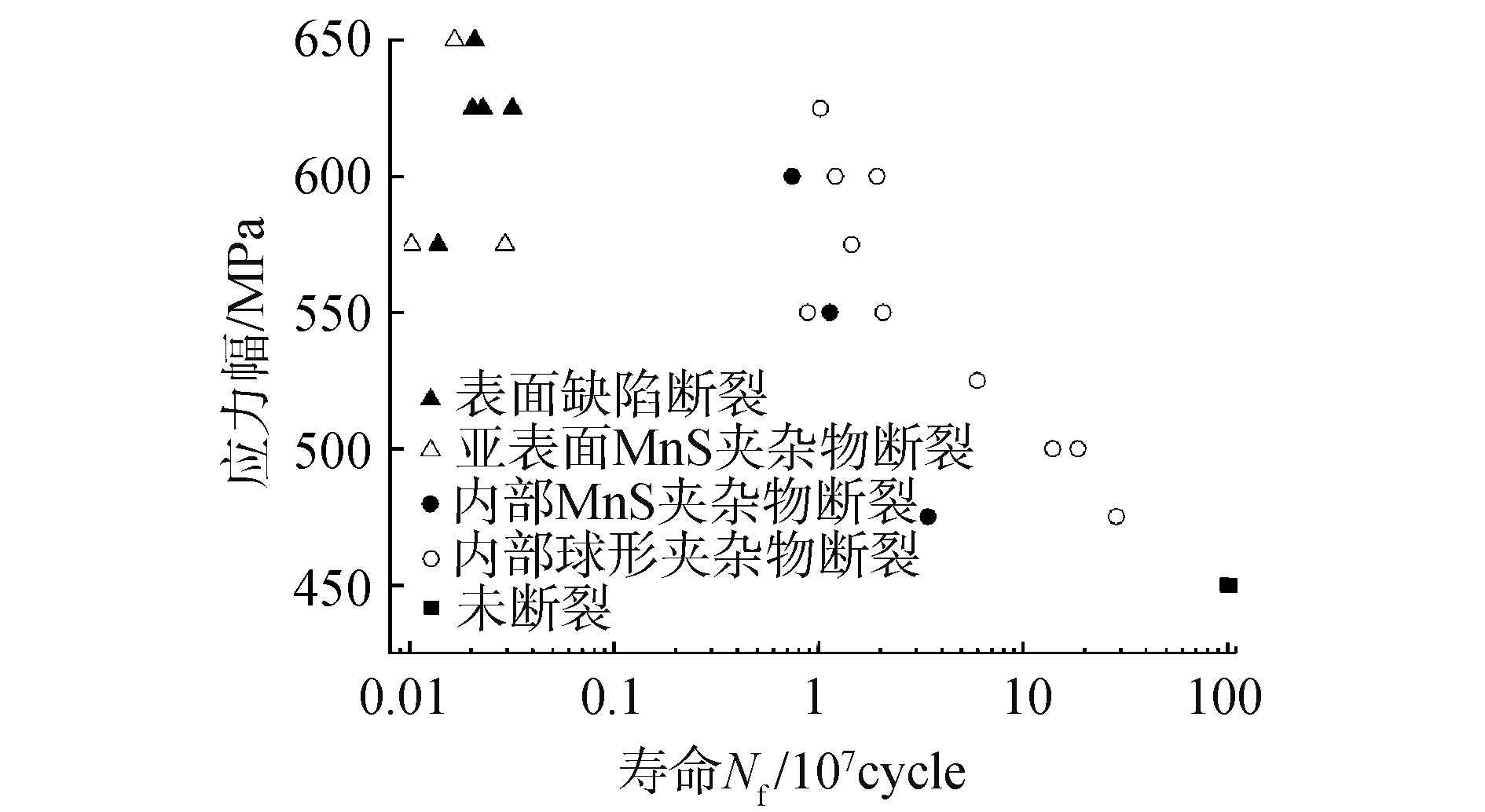

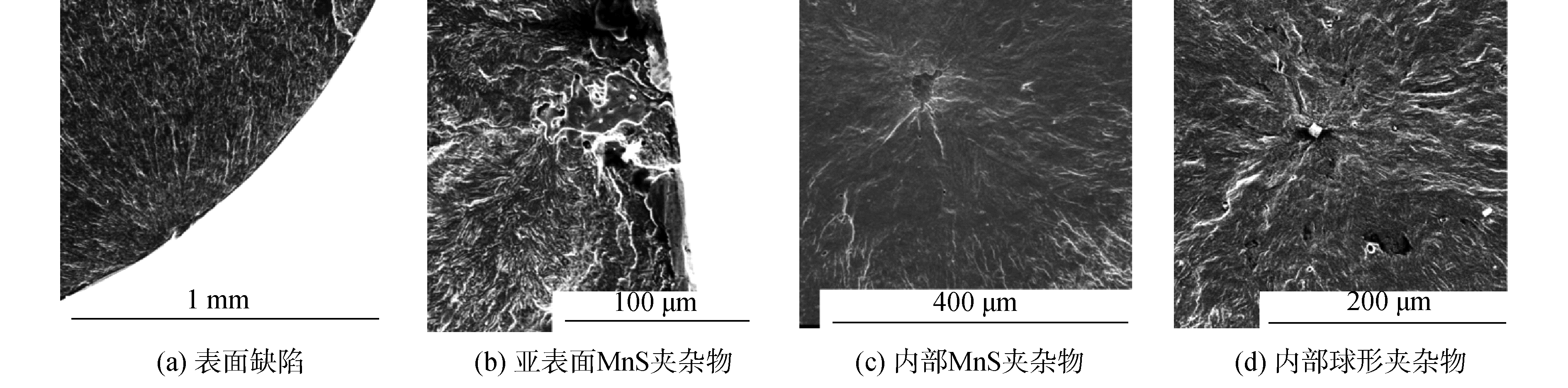

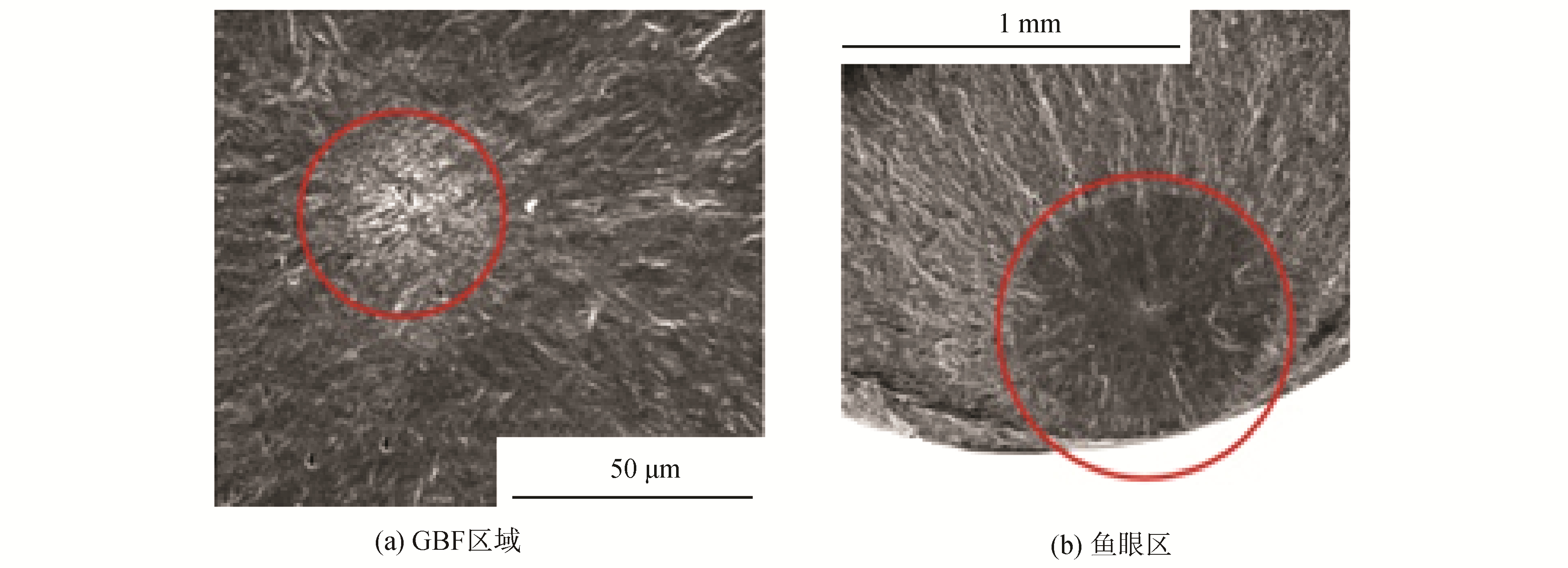

2 实验结果和讨论 2.1 S-N曲线和断口的电镜观察图 2为在拉压载荷下FV520B-I的超高周疲劳S-N曲线。整个曲线呈现应力幅-寿命下降趋势,并且106~107周次存在一段过渡区域,对应于传统疲劳极限(107)。在这个范围,裂纹源从表面划痕,到亚表面MnS再过渡到内部非金属夹杂物,各个缺陷之间存在着竞争。图 3为本实验中4种典型的失效模式。对于内部夹杂物引起的断口表面,可以在夹杂物附近观察到相应的GBF区域(如图 4(a)),其中大部分GBF区域外有明显鱼眼区(如图 4(b))。

|

Download:

|

| 图 2 疲劳试样S-N曲线 Fig. 2 S-N curve of fatigue testing specimens | |

|

Download:

|

| 图 3 FV520B-I钢4种典型疲劳裂纹源 Fig. 3 Four typical patterns of crack origin of FV520B-I steel | |

|

Download:

|

| 图 4 GBF区域和鱼眼区 Fig. 4 SEM observation of GBF and fish-eye region GBF region and fish-eye region | |

在对试样断口裂纹源进行观察时,发现主要有2种夹杂物引起失效。一种是MnS夹杂物(如图 3(b)、(c)),这中夹杂物由于其较低的弹性模量在钢基体中可以视为二维裂纹,并且与基体紧密贴合,形状不规则,近夹杂物处存在着解理形貌和特定的滑移特征。一种是球形夹杂物(含铝、铬、锰的氧化物),如图 3(d)、4(a),这种夹杂物在垂直于受力方向上的投影一般呈规则的多边形或圆形。在分析夹杂物对超高周疲劳的影响时,根据实验数据可得图 5。图 5显示距离试样表面距离越大,造成试样破坏的非金属夹杂物的尺寸越小,试样寿命增大。这一结论证实了夹杂物的属性(尺寸、位置等)对超高周疲劳的重要影响。

|

Download:

|

| 图 5 裂纹源深度Dinclu、寿命Nf以及夹杂物尺寸Rinclu之间的关系 Fig. 5 The relationship between radii of inclusion Rinclu, depth of crack origin Dinclu and fatigue life Nf | |

断裂力学是研究含缺陷(或裂纹)材料和结构的重要理论工具,在线弹性断裂力学中,常用应力强度因子来表示裂纹尖端应力场的强弱,并以应力强度因子幅值ΔK作为裂纹扩展的主要控制参量和裂纹扩展的主要驱动力。在超高周疲劳研究当中,日本学者Murakami[14]等结合线弹性断裂力学理论及超高周疲劳裂纹的典型特征,提出了计算高强度钢超高周疲劳裂纹萌生位置处应力强度因子幅值ΔK的计算公式(1)、(2),也得到了国内外众多学者[15-17]的认可并被广泛采用。

对于亚表面夹杂物:

| $ \Delta K_{\text {sub-surt }}=0.65 \sigma_{a} \sqrt{\pi \sqrt{A_{0}}} $ | (1) |

对于内部夹杂物:

| $ \Delta K_{\mathrm{int}}=0.5 \sigma_{a} \sqrt{\pi \sqrt{A_{0}}} $ | (2) |

式中:σa为应力幅值,MPa;A0为缺陷尺寸,μm。

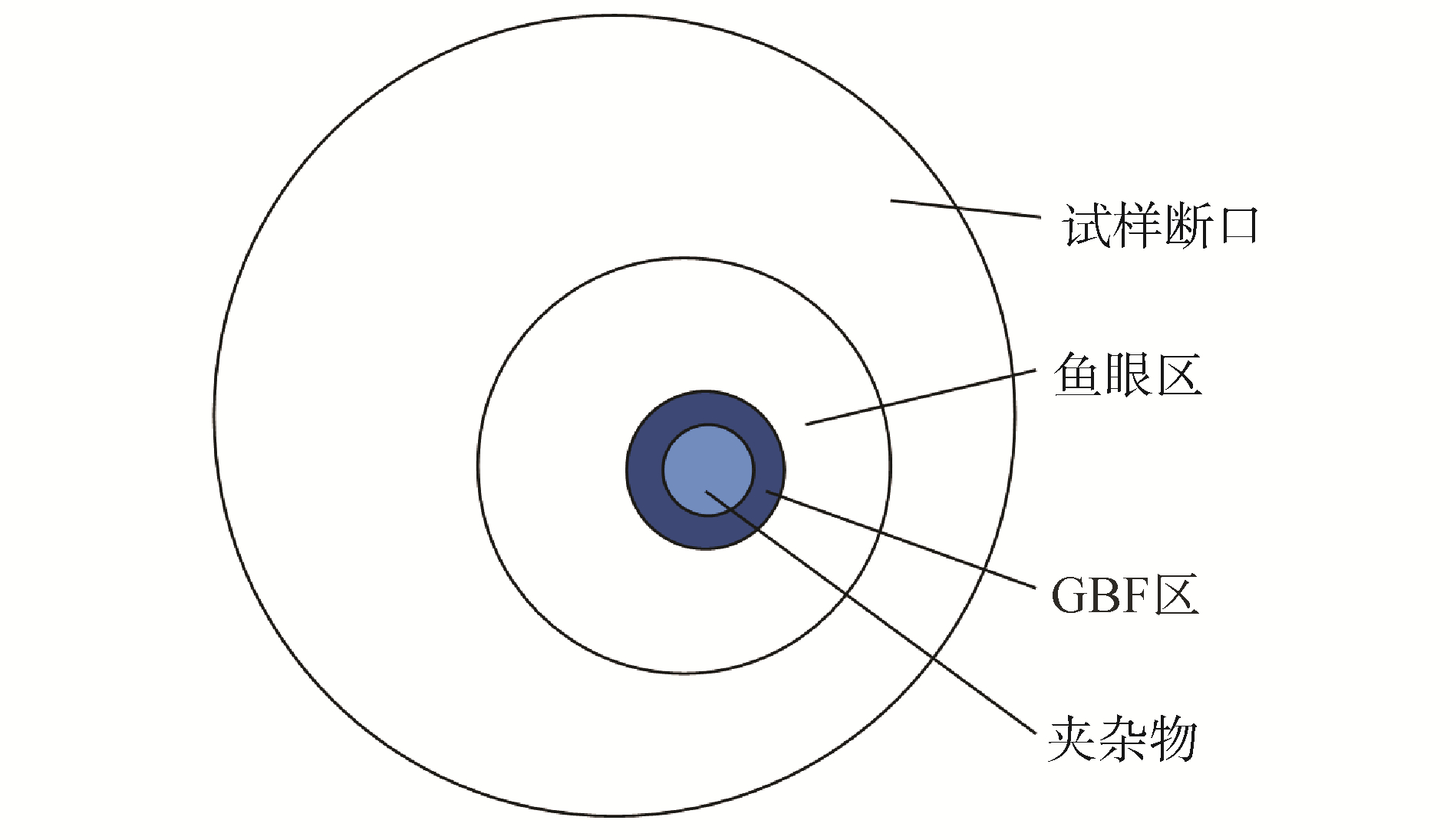

在对超高周疲劳(>107)试样断口观察中,可以发现裂纹源区有3个特征区域(如图 6):夹杂物、GBF和鱼眼区。利用式(1)、(2)对特征区域边界处的的应力强度因子幅值进行计算,可得图 7。

|

Download:

|

| 图 6 典型超高周断口形貌示意 Fig. 6 Typical schematic diagram of VHCF fracture morphology | |

|

Download:

|

| 图 7 夹杂物、GBF边界、鱼眼区边界应力强度因子与寿命的关系 Fig. 7 The relationship between Nf and ΔK at the periphery of inclusions, GBF areas and fish-eye areas | |

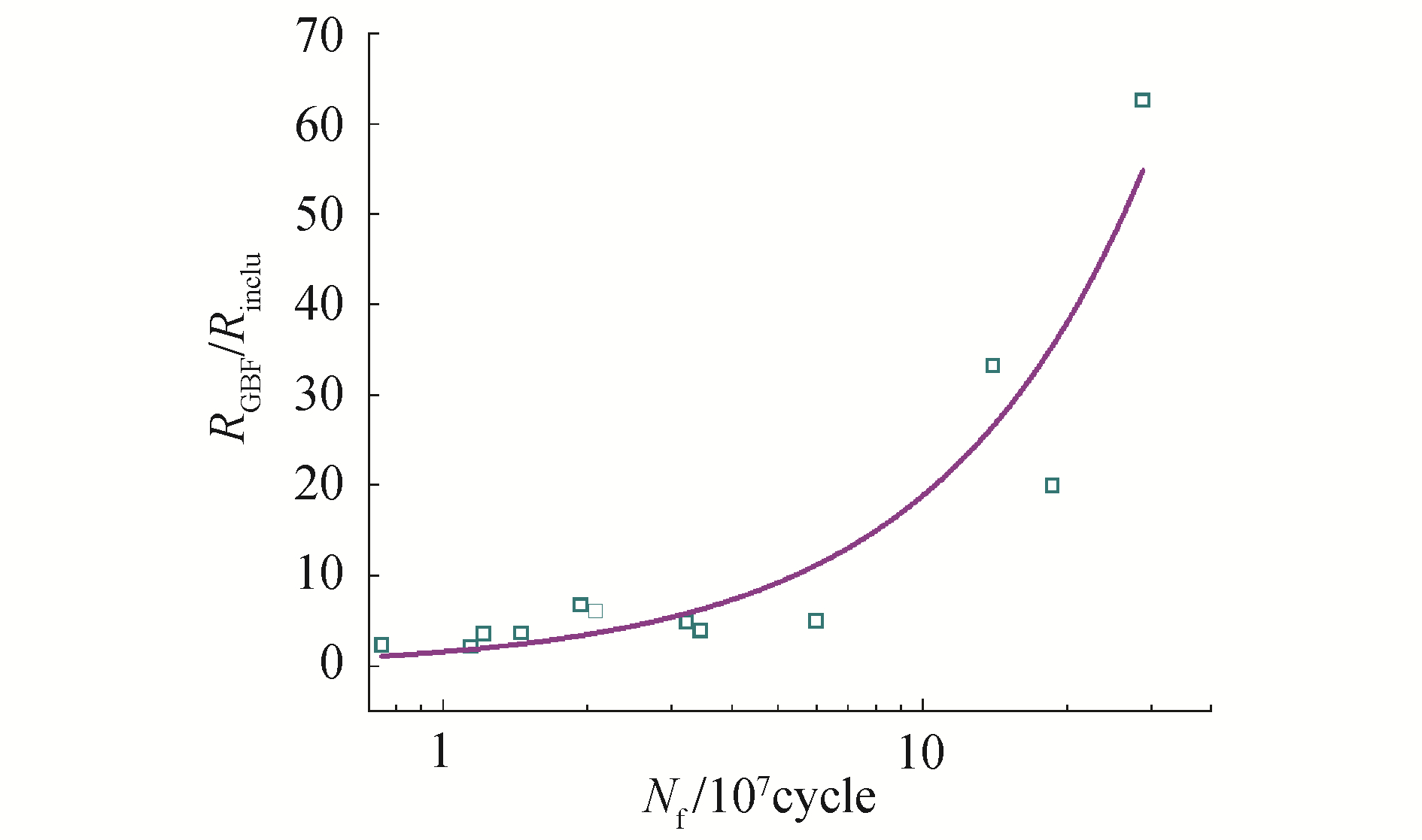

从图 7中可以看出,随着夹杂物造成的初始应力强度因子ΔKinclu降低,试样疲劳寿命增大,并且裂纹源位置逐渐变化,从亚表面MnS到内部MnS再迁移到内部球形夹杂。这现象既与夹杂物尺寸大小、应力幅度有关,也与不同的夹杂物与基体相互作用造成应力集中有关。GBF边界裂纹应力强度因子幅值经过计算平均值约为4.312 MPa·m1/2,基本可以视为一常数。已有的研究表明,ΔKGBF近似等于表面裂纹扩展的应力强度因子门槛值ΔKth[18-19], 这与本实验结果一致。对于萌生于内部非金属夹杂物与基体界面的裂纹,其在扩展到GBF区边界以前,如图所示,相应的应力强度因子幅值ΔK总是小于表面裂纹扩展的门槛值,这表明内部裂纹在低于门槛值的情况下仍然会发生扩展,而且扩展所需要的驱动力要小于表面裂纹裂纹扩展所需的驱动力。对于本实验中裂纹萌生于亚表面夹杂物的试样,其夹杂物所造成的应力强度因子ΔK≥ΔKGBF, 试样断口没有GBF区域;许多实验结论认定超高周疲劳95%的寿命消耗在GBF区域内[20-22]加之有学者发现GBF的形成是由ΔK的变化造成的[23-24],因此可以推断对于ΔKinclu≥ΔKGBF的试样, 裂纹扩展越过GBF区直接进入鱼眼区域,其速率要比GBF快,试样寿命短,换言之有GBF区域的试样寿命更长,这一结论与图 8一致。

|

Download:

|

| 图 8 RGBF/Rinclu与寿命的关系 Fig. 8 The relationship between Nf and RGBF/Rinclu | |

Tanaka等[25-26]把孔洞和脱离基体的夹杂物看做是缺陷,把用于解释表面粗糙化和延滑移带开裂的平行层模型加以推广,用来说明在高强度钢和铝合金中裂纹如何从夹杂物处萌生,并且这种裂纹萌生模型受制于能量准则。Wang等[27]简化后的裂纹萌生模型:

| $ N_{i}=A W s /\left(\Delta \tau-2 \tau_{f}\right)^{2} $ | (3) |

在此基础上又建立了包含裂纹萌生和扩展的全寿命模型:

| $ N_{i}=\frac{9 G W_{s}}{\left(\Delta \sigma-\Delta \sigma_{D}^{R}\right)^{2} a_{0}}+\frac{a_{0}^{1-n / 2}}{C \Delta \sigma^{n} \beta^{n} \pi^{\frac{n}{2}}\left(\frac{n}{2}-1\right)} $ | (4) |

王金龙[11]参考王清远的寿命模型,采用了合适的算法拟合出合适的C、n,成功地预测了FV520B-I钢试样超高周疲劳寿命。

利用式(3)计算本实验的试样裂纹萌生寿命发现,萌生寿命公式并不适用于FV520B-I钢超高周疲劳寿命预测。

| 表 1 式(3)预测部分试样寿命 Table 1 Predicted life of part samples by equation (3) |

于是,结合第3部分的工作,考虑到夹杂物和GBF区域对超高周疲劳寿命的重要影响,参考文献[9]的工作,可以将裂纹在GBF区域扩展的寿命近似等于试样全部寿命,即:

| $ N_{f} \approx N_{\mathrm{GBF}} $ | (5) |

Paris[28]也认为由夹杂物起裂的短裂纹在极低速扩展的速率da/dN(m/cycle)也遵从Paris方程:

| $ \frac{\mathrm{d} a}{\mathrm{d} N}=C(\Delta K)^{m} $ | (6) |

式中:

| $ \Delta K=\frac{2}{\pi} \lambda \sigma \sqrt{\pi a} $ | (7) |

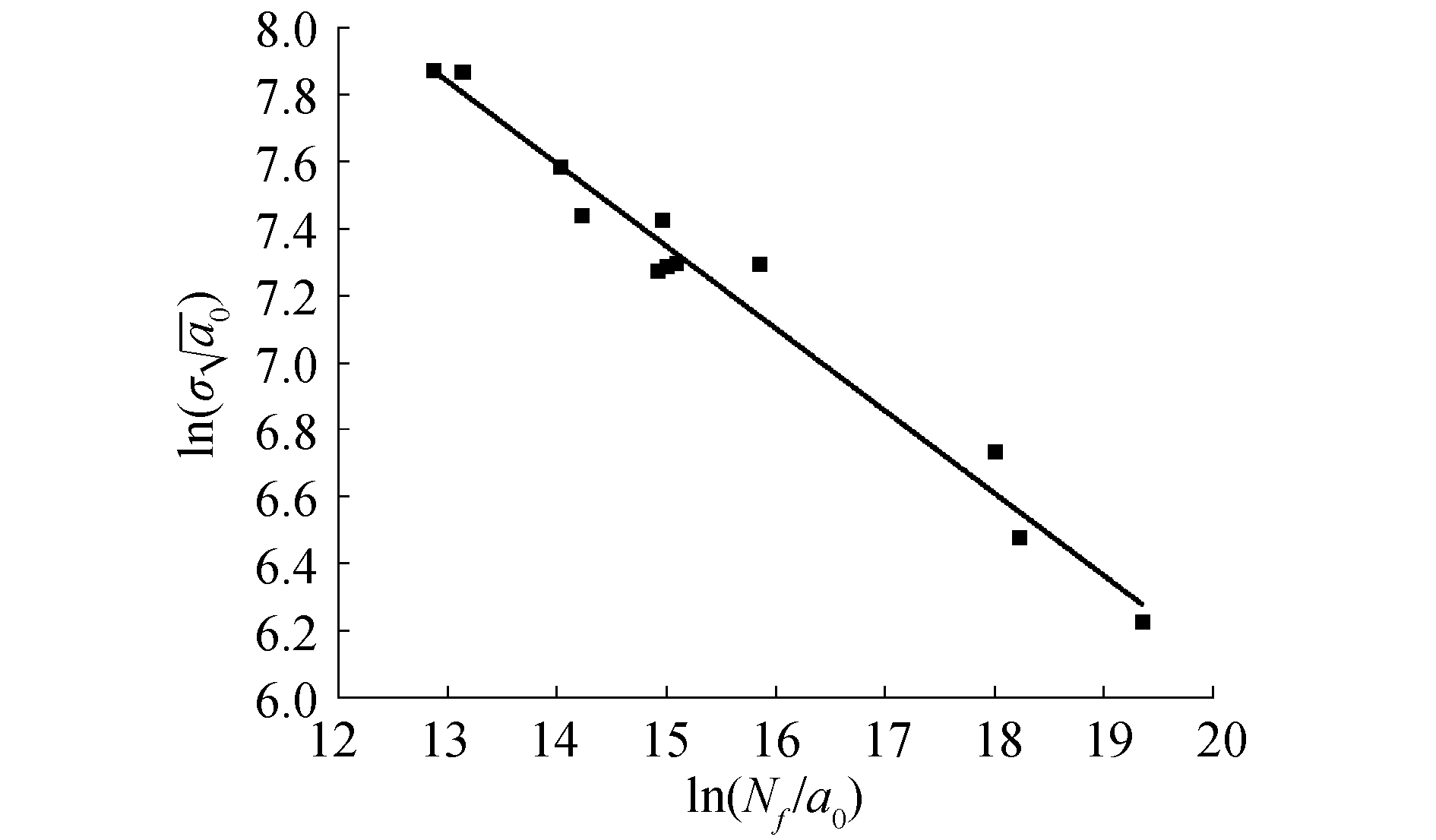

于是将(7)代入到(6)并进行积分、略去极小项得:

| $ N_{f}=\frac{1}{a_{0}^{\frac{m}{2}-1}} \times \frac{1}{\lambda^{m}}\left[\frac{2}{(m-2) C}\left(\frac{\sqrt{\pi}}{4}\right)^{m}\right] \frac{1}{\sigma^{m}} $ | (8) |

整理,得:

| $ \sigma \sqrt{a_{0}}=\frac{A}{\lambda}\left(\frac{N_{f}}{a_{0}}\right)^{-1 / m} $ | (9) |

式中:

| $ N_{f}=\frac{\mathrm{e}^{44.89}}{a_{0}^{1.035} \sigma^{4.07}} $ | (10) |

|

Download:

|

|

图 9 |

|

根据式(10)求得本实验中超高周疲劳试样的预测寿命(如表 2),平均误差在26.9%。

| 表 2 疲劳寿命预测值与实验值的对比 Table 2 Comparison between experimental data and life prediction |

1) FV520B-I钢在一定应力幅下存在着内部缺陷和表面缺陷的竞争,且超高周疲劳(循环次数大于107)裂纹源均为内部缺陷;断口观察及寿命分析发现,二维夹杂物MnS与球状夹杂物两类内部缺陷之间也存在竞争。

2) 内部夹杂物由于与基体相互作用产生的应力强度因子幅值ΔK对超高周疲劳寿命具有显著影响,裂纹萌生过程中ΔK变化导致FV520B-I钢超高周失效模式分为有GBF失效和无GBF失效,且两者均为内部夹杂物引起的失效。该规律间接说明了夹杂物和GBF尺寸对于超高周疲劳的重要影响。

3) 超高周疲劳寿命大部分消耗在裂纹从夹杂物到GBF边界的扩展过程,结合机理分析、实验数据,建立了FV520B-I的寿命预测公式,其寿命预测精度高于裂纹萌生寿命公式。

| [1] |

ITOGA H, TOKAJI K, NAKAJIMA M, et al. Effect of surface roughness on step-wise S-N characteristics in high strength steel[J]. International journal of fatigue, 2003, 25(5): 379-385. (  0) 0)

|

| [2] |

CHAPETTI M D, TAGAWA T, MIYATA T. Ultra-long cycle fatigue of high-strength carbon steels part Ⅰ:review and analysis of the mechanism of failure[J]. Materials science and engineering:A, 2003, 356(1/2): 227-235. (  0) 0)

|

| [3] |

FURUYA Y, MATSUOKA S. Improvement of gigacycle fatigue properties by modified ausforming in 1600 and 2000 MPA-class low-alloy steels[J]. Metallurgical and materials transactions A, 2002, 33(11): 3421-2431. (  0) 0)

|

| [4] |

SHIOZAWA K, MORⅡ Y, NISHINO S, et al. Subsurface crack initiation and propagation mechanism in high-strength steel in a very high cycle fatigue regime[J]. International journal of fatigue, 2006, 28(11): 1521-1532. (  0) 0)

|

| [5] |

MURAKAMI Y, NOMOTO T, UEDA T. Factors influencing the mechanism of superlong fatigue failure in steels[J]. Fatigue & fracture of engineering materials & structures, 1999, 22(7): 581-590. (  0) 0)

|

| [6] |

OTSUKA T, HANADA H, NAKASHIMA H, et al. Observation of hydrogen distribution around non-metallic inclusions in steels with tritium microautoradiography[J]. Fusion science and technology, 2005, 48(1): 708-711. (  0) 0)

|

| [7] |

MURAKAMI Y, MATSUNAGA H. The effect of hydrogen on fatigue properties of steels used for fuel cell system[J]. International journal of fatigue, 2006, 28(11): 1509-1520. (  0) 0)

|

| [8] |

王清远, 刘永杰. 结构金属材料超高周疲劳破坏行为[J]. 固体力学学报, 2010, 31(5): 496-503. WANG Qingyuan, LIU Yongjie. Understanding fatigue failure in structural metals in ultra-high cycle regime[J]. Chinese journal of solid mechanics, 2010, 31(5): 496-503. (  0) 0)

|

| [9] |

YANG Z G, LI S X, LI Y D, et al. Relationship among fatigue life, inclusion size and hydrogen concentration for high-strength steel in the VHCF regime[J]. Materials science and engineering:A, 2010, 527(3): 559-564. (  0) 0)

|

| [10] |

李永德, 李守新, 杨振国, 等. 氢对高强弹簧钢50CrV4超高周疲劳性能的影响[J]. 金属学报, 2008, 44(1): 64-68. LI Yongde, LI Shouxin, YANG Zhenguo, et al. Influence of hydrogen on ultrahigh cycle fatigue properties of high strength spring steel 50CrV4[J]. Acta metallurgica sinica, 2008, 44(1): 64-68. (  0) 0)

|

| [11] |

WANG Jinlong, ZHANG Yuanliang, SUN Qingchao, et al. Giga-fatigue life prediction of FV520B-I with surface roughness[J]. Materials & design, 2016, 89: 1028-1034. (  0) 0)

|

| [12] |

TANAKA K, MURA T. A dislocation model for fatigue crack initiation[J]. Journal of applied mechanics, 1981, 48(1): 97-103. (  0) 0)

|

| [13] |

王金龙, 张元良, 赵清晨, 等. 再制造毛坯疲劳损伤临界阈值及可再制造性判断研究[J]. 机械工程学报, 2017, 53(5): 41-49. WANG Jinlong, ZHANG Yuanliang, ZHAO Qingchen, et al. Study of fatigue defect critical threshold of remanufacturing cores and judgment of re-manufacturability based on fatigue defect[J]. Journal of mechanical engineering, 2017, 53(5): 41-49. (  0) 0)

|

| [14] |

MURAKAMI Y, KODAMA S, KONUMA S. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. Ⅰ:Basic fatigue mechanism and evaluation of correlation between the fatigue fracture stress and the size and location of non-metallic inclusions[J]. International journal of fatigue, 1989, 11(5): 291-298. (  0) 0)

|

| [15] |

LI Wei, YUAN Huang, SUN Zhenduo, et al. Surface vs. interior failure behaviors in a structural steel under gigacycle fatigue:failure analysis and life prediction[J]. International journal of fatigue, 2014, 64: 42-53. (  0) 0)

|

| [16] |

HUI W J, ZHOU C, ZHANG Y J, et al. Very high cycle fatigue properties of high-strength spring steel 60SiCrV7[J]. Fatigue & fracture of engineering materials & structures, 2016, 39(9): 1081-1091. (  0) 0)

|

| [17] |

OGAWA T, STANZL-TSCHEGG S E, SCHÖNBAUER B M. A fracture mechanics approach to interior fatigue crack growth in the very high cycle regime[J]. Engineering fracture mechanics, 2014, 115: 241-254. (  0) 0)

|

| [18] |

LI W, SAKAI T, LI Q, et al. Reliability evaluation on very high cycle fatigue property of GCr15 bearing steel[J]. International journal of fatigue, 2010, 32(7): 1096-1107. (  0) 0)

|

| [19] |

鲁连涛, 张卫华. 高碳铬轴承钢的超长寿命疲劳行为的研究[J]. 机械工程学报, 2005, 40(10): 143-148, 152. LU Liantao, ZHANG Weihua. Fatigue behaviour of a high carbon-chromium bearing steel in super-long life region[J]. Chinese Journal of mechanical engineering, 2005, 40(10): 143-148, 152. (  0) 0)

|

| [20] |

NAKAJIMA M, KAMIYA N, ITOGA H, et al. Experimental estimation of crack initiation lives and fatigue limit in subsurface fracture of a high carbon chromium steel[J]. International journal of fatigue, 2006, 28(11): 1540-1546. (  0) 0)

|

| [21] |

SPRIESTERSBACH D, GRAD P, KERSCHER E. Influence of different non-metallic inclusion types on the crack initiation in high-strength steels in the VHCF regime[J]. International journal of fatigue, 2014, 7(64): 114-120. (  0) 0)

|

| [22] |

MARINES-GARCIA I, PARIS P C, TADA H, et al. Fatigue crack growth from small to long cracks in VHCF with surface initiations[J]. International journal of fatigue, 2007, 29(9/10/11): 2072-2078. (  0) 0)

|

| [23] |

LIU Y B, YANG Z G, LI Y D, et al. On the formation of GBF of high-strength steels in the very high cycle fatigue regime[J]. Materials science and engineering:A, 2008, 497(1/2): 408-415. (  0) 0)

|

| [24] |

SPRIESTERSBACH D, GRAD P, KERSCHER E. Influence of different non-metallic inclusion types on the crack initiation in high-strength steels in the VHCF regime[J]. International journal of fatigue, 2014, 64: 114-120. (  0) 0)

|

| [25] |

TANAKA K, MURA T. A dislocation model for fatigue crack initiation[J]. Journal of applied mechanics, 1981, 48(1): 97-103. (  0) 0)

|

| [26] |

TANAKA K, MURA T. A theory of fatigue crack initiation at inclusions[J]. Metallurgical transaction A, 1982, 13(1): 117-123. (  0) 0)

|

| [27] |

WANG Q Y, BATHIAS C, KAWAGOISHI N, et al. Effect of inclusion on subsurface crack initiation and gigacycle fatigue strength[J]. International journal of fatigue, 2002, 24(12): 1269-1274. (  0) 0)

|

| [28] |

PARIS P C, MARINES-GARCIA I, HERTZBERG R W, et al. The relationship of effective stress intensity, elastic modulus and Burgers-vector on fatigue crack growth as associated with 《Fish Eye》 Gigacycle phenomena[C]//Proceedings of the International Conference on Very High Cycle Fatigue Ⅲ. Kusatsu, Japan: Ritsumeikan University, 2004.

(  0) 0)

|

2019, Vol. 40

2019, Vol. 40