文章信息

- 高鑫, 周凡, 周永东.

- Gao Xin, Zhou Fan, Zhou Yongdong.

- 高温热处理木材吸湿特性

- Sorption Isotherms Characteristics of High Temperature Heat-Treated Wood

- 林业科学, 2019, 55(7): 119-127.

- Scientia Silvae Sinicae, 2019, 55(7): 119-127.

- DOI: 10.11707/j.1001-7488.20190713

-

文章历史

- 收稿日期:2017-05-09

- 修回日期:2017-07-07

-

作者相关文章

木材是一类重要的可再生材料,具有优异的强重比、易加工性和优良的环境学特性,广泛用于建筑工程和室内装饰领域(Wacker,2010;Walker,2006);同时,也由于木材的干缩和湿胀,一定程度上限制了其使用环境(顾炼百,2011)。特别是随着原材料结构调整,人工速生林木材用量占比越来越高,这些木材尺寸稳定性往往较差,有的必须经改性处理(Mattos et al., 2015)。木材改性常用方法包括浸渍树脂、乙酰化、高温热处理等(Xie et al., 2013),其中高温热处理是一种环境友好型改性方法,可使木材中的半纤维素、木质素降解,降低木材中的亲水基团,增加纤维素的结晶区和结晶度,从而降低木材吸湿性,提高尺寸稳定性(Esteves et al., 2009)。目前,科研中大多通过选取特定温、湿度环境对木材进行平衡处理,分析处理温度对木材平衡含水率的影响,并以平衡含水率下降情况评价高温热处理改性木材效果,但未系统对高温热处理材水蒸气吸湿机制和连续动态过程进行分析(丁涛,2010;丁涛等,2015;2016)。

木材吸附特性研究一般采用BET模型、GAB模型、GDW模型和Hailwood-Horrobin模型等分析吸附过程水分构成,相较于常用的BET模型及在BET模型基础上衍生的GAB模型和GDW模型,Hailwood-Horrobin模型中单层分子吸附水含量可在全相对湿度波动范围内变化,符合木材干缩湿胀特性(Simpson,1980;Zaihan et al., 2009;Papadopoulos,2005a;2011;2012;Hill et al., 2010),在木材化学改性、纳米粒子改性等研究中广泛应用(Papadopoulos,2003;2005b;Mantanis et al., 2010;Hill et al., 2012;Popescu et al., 2014)。鉴于此,本研究运用Hailwood-Horrobin模型,探讨高温热处理对人工林樟子松(Pinus sylvestris var.mongolica)、杉木(Cunninghamia lanceolata)、美洲黑杨(Populus nigra)木材平衡含水率和吸湿特性的影响,以期为科学评价热处理木材吸湿特性提供理论基础,为人工林木材高附加值利用和实际高温热处理木材生产提供参考。

1 材料与方法 1.1 试验材料樟子松材产自黑龙江大兴安岭,锯材尺寸为4 000 mm(L)×300 mm(T)×25 mm(R),由浙江南浔某地板加工企业提供;杉木材产自广东,锯材尺寸为2 000 mm(L)×200 mm(T)×25 mm(R),由广东清远某木材加工企业提供;美洲黑杨材产自安徽阜阳,锯材尺寸为2 000 mm(L)×200 mm(T)×25 mm(R),由安徽阜阳某木材加工企业提供。锯材经窑干至含水率12%左右,热处理试验前将其加工成900 mm(L)×100 mm(T)×25 mm(R)规格试验板。

1.2 高温热处理工艺高温热处理设备由江苏星楠干燥设备有限公司生产,外置蒸汽发生器,提供蒸汽环境以隔绝氧气。试验设定180、200和220 ℃3个处理温度,试验过程包括高温干燥阶段、升温阶段和高温热处理阶段。高温干燥阶段(120 ℃)使木材含水率降至3%左右,升温阶段蒸汽发生器处于常开状态,升温速率为每小时干球温度上升10 ℃,至设定温度后保持2 h,停止加热自然冷却(丁涛,2010)。

1.3 水蒸气等温吸附采用双室温、湿度控制法精确控制试样水蒸气等温吸附过程,选取8种盐类配制饱和盐溶液,吸湿试验环境温度恒定为25 ℃,每种盐溶液对应的环境相对湿度如表 1所示(Oiml,1996)。从热处理后的试验板上锯取20 mm×20 mm×5 mm(厚度方向为纵向)水蒸气吸附试片,每一热处理温度制备5片,另取相同尺寸的素材吸湿试片,以103 ℃将高温热处理材和素材试片烘至绝干后同步进行等温吸附,每一相对湿度阶段木材试样吸湿平衡后更换饱和盐溶液进行下一阶段等温吸湿。

|

|

Hailwood-Horrobin模型是由Hailwood等(1946)提出的,用于解释纤维类材料水分吸附机制,尤其针对植物纤维(木材、棉花)和动物纤维(羊毛)等。Hailwood-Horrobin模型基于理想溶液理论,对于木材而言,其等温吸附可视为3组分体系动态平衡的物理过程,3组分分别对应木材基质、水合水(water of hydration,等效于单层分子吸附水,monolayer water)以及溶解水(dissolved water,等效于多层分子吸附水,polylayer water)(Hill,2006;Walker,2006)。木材在不同相对湿度环境中达到的平衡含水率可表达为:

| $ M=M_{\mathrm{h}}+M_{\mathrm{d}}=\frac{18}{W}\left(\frac{K_{1} K_{2} H}{1+K_{1} K_{2} H}+\frac{K_{2} H}{1-K_{2} H}\right)。$ | (1) |

式中:M为试样平衡含水率;Mh为单层分子吸附水含量;Md为多层分子吸附水含量;W为含有单位摩尔数吸附位的绝干木材质量(g·mol-1);H为相对湿度;K1为单层分子吸附水与多层分子吸附水之间的平衡常数;K2为多层分析吸附水分与环境温、湿度之间的平衡常数。

式(1)可以整理成如下多项式形式:

| $ \frac{H}{M}=A+B H-C H^{2}。$ | (2) |

式中:A、B、C为多项式的拟合参数。

拟合参数与W、K1、K2的关系如下:

| $ A=\frac{W}{18}\left[\frac{1}{K_{2}\left(K_{1}+1\right)}\right]; $ | (3) |

| $ B=\frac{W}{18}\left[\frac{K_{1}-1}{K_{1}+1}\right]; $ | (4) |

| $ C=\frac{W}{18}\left[\frac{K_{1} K_{2}}{K_{1}+1}\right]。$ | (5) |

通过不同相对湿度环境试样的等温吸湿曲线数据分析可得到拟合参数,进而可以求解W、K1和K2。本研究采用OriginPro 8分析软件,以最小二乘法进行等温吸附试验数据拟合。

2 结果与分析 2.1 高温热处理材吸湿平衡含水率樟子松、杉木、美洲黑杨3个树种素材和高温热处理材试样不同相对湿度环境的吸湿平衡含水率如表 2所示。可以看出,高温热处理可明显降低3个树种试样的吸湿平衡含水率,且处理温度越高,平衡含水率下降越明显。180、200和220 ℃处理后,试样吸湿平衡含水率均值相当于素材含水率均值的80%、70%和50%左右。以220 ℃处理试样在相对湿度93.6%环境中的平衡含水率均值对比相应素材的平衡含水率为例,樟子松、杉木和美洲黑杨试样平衡含水率均值分别为9.58%、9.09%和8.81%,相应素材试样平衡含水率均值分别为18.06%、15.98%和18.19%,可见高温热处理材相较于素材平衡含水率大幅降低。不同树种试样之间平衡含水率存在一定差异,经高温热处理后不同树种试样之间的平衡含水率差异性(标准偏差)减小,且随热处理温度升高呈减小趋势。

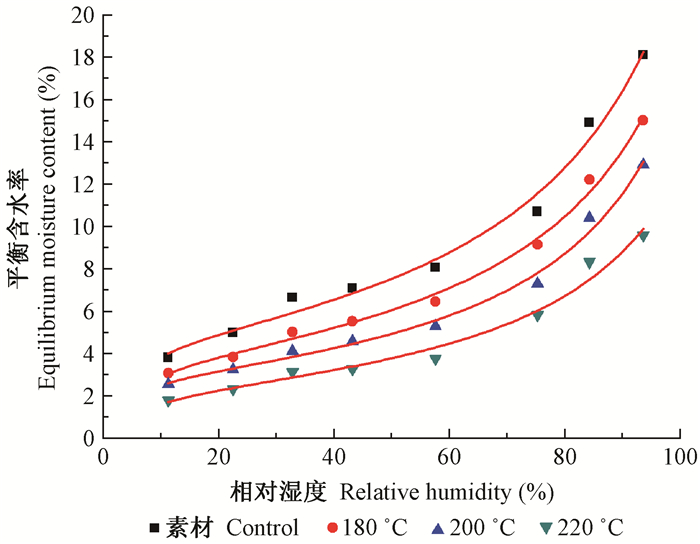

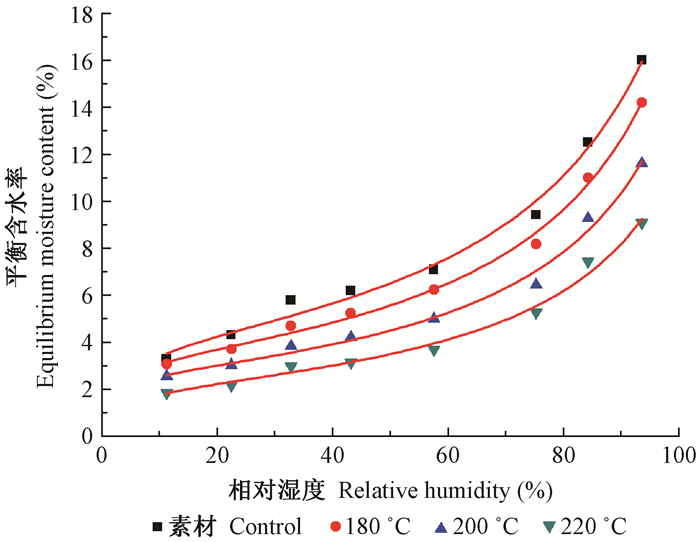

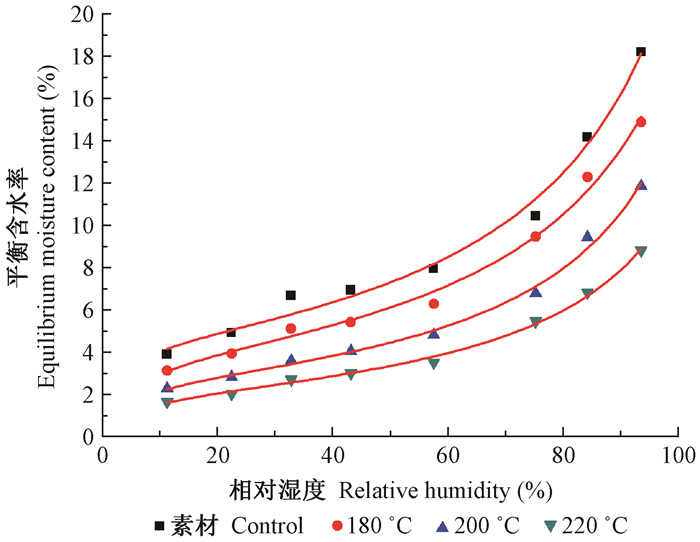

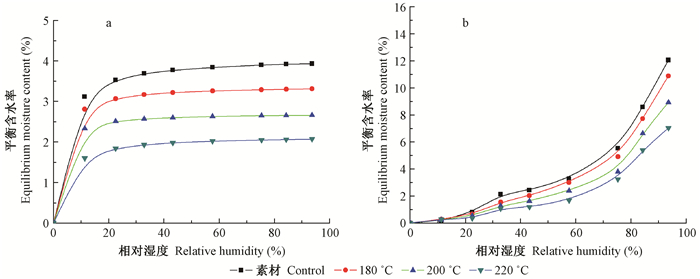

2.2 高温热处理材Hailwood-Horrobin等温吸附曲线拟合根据表 2等温吸附过程试样吸湿平衡含水率结果,结合Hailwood-Horrobin模型,采用Origin分析软件进行等温吸附试验数据拟合,拟合后的等温吸附曲线如图 1、2和3所示,等温吸附曲线参数如表 3所示。可以看出,不同热处理条件试样等温吸附曲线的拟合度(R2)均高于0.980 0,说明Hailwood-Horrobin模型能够较好描述高温热处理材等温吸附过程平衡含水率的变化规律。表 3中各树种素材拟合参数A、B、C的数值范围与Hill(2006)、Hill等(2012)、Papadopoulos(2003;2005a;2005b;2011;2012)、Zaihan等(2009)报道接近,通过A、B、C计算得到素材吸附模型平衡常数K1和K2的数值范围也与上述报道接近。樟子松、杉木和美洲黑杨素材含有单位摩尔数吸附位的绝干木材质量参数(W)分别为378.9、441.7和402.3 g·mol-1,与以往研究得到的松杉类、杨木木材等温吸附曲线拟合结果接近。对于吸附过程,W在300~400 g·mol-1之间(Okoh et al., 1980;Papadopoulos,2003)。高温热处理材W明显增大,说明热处理能够显著降低木材基质的吸湿能力,分析其原因主要是热处理可使半纤维素发生较多改变,造成羟基数量减少(Hill,2006)。同样以220 ℃处理试样为例,樟子松、杉木和美洲黑杨的W分别为738.8、834.9和853.0 g·mol-1,可见经高温热处理后试样至少需要2倍的基质质量才等价于素材的吸附位数量,这一规律与热处理对木材平衡含水率的影响相近。

|

|

|

图 1 樟子松热处理材等温吸湿平衡含水率变化曲线 Fig. 1 Sorption isotherms for heat-treated Pinus sylvestris var. mongolica |

|

图 2 杉木热处理材等温吸湿平衡含水率变化曲线 Fig. 2 Sorption isotherms for heat-treated Cunninghamia lanceolata |

|

图 3 美洲黑杨热处理材等温吸湿平衡含水率变化曲线 Fig. 3 Sorption isotherms for heat-treated Populus nigra |

|

|

将图 1、2和3的等温吸附曲线与国际纯粹与应用化学联合会(IUPAC)发布的常见吸附曲线类型(Donohue et al., Aranovich, 1998)进行对比,3个树种素材试样和高温热处理材试样均表现为第2类等温吸附曲线形态特征,但随着处理温度升高,曲线线形有改变趋势,特别在高相对湿度吸湿阶段,试样平衡含水率与相对湿度曲线斜率明显降低。Hill(2006)、丁涛等(2015)研究表明,热处理会使木材等温吸附曲线向直线线性变化,且处理温度越高,该趋势越明显。热处理材在高相对湿度环境中等温吸附曲线线形改变也与热处理导致的木材细胞壁吸湿性降低有关,由于吸湿基团数量减少,细胞壁基质吸收的水分含量明显降低,从而造成细胞壁吸湿润胀性下降,不利于新孔隙形成。在高相对湿度环境中,微毛细管吸附作用越来越明显,未处理材由于干缩湿胀现象形成的新孔隙在此阶段毛细吸附作用也更明显,导致平衡含水率极快上升(Hill,2006)。高温热处理材则由于吸湿润胀性下降,无法像素材一样润胀形成新孔隙,因此毛细吸附作用减弱,热处理温度越高,改性效果越明显,从而导致吸湿曲线线形朝着“直线”形转变。

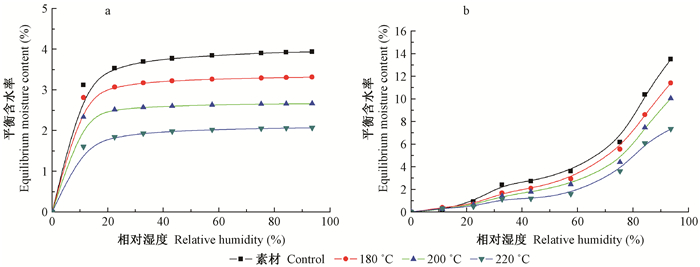

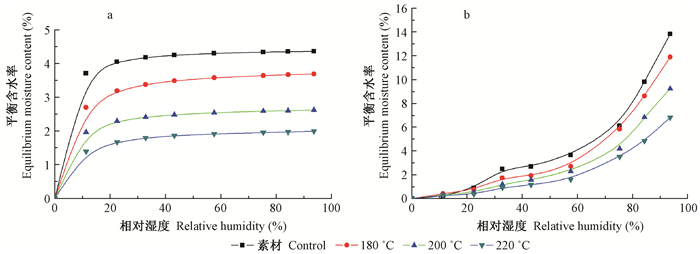

2.3 高温热处理对不同组分吸着水含量的影响Hailwood-Horrobin模型能够便捷分析计算木材等温吸附过程不同组分的吸附水(单层分子吸附水和多层分子吸附水)变化情况,根据式(1)和表 3数据计算高温热处理材和素材等温吸附过程不同组分的吸附水含量,其结果如图 4、5和6所示。可以看出,与高温热处理能够显著降低吸湿平衡含水率相似,热处理也可显著降低等温吸附过程形成的单层分子吸附水和多层分子吸附水含量。在相对湿度93.6%环境中,樟子松素材和高温热处理材(180、200和220 ℃)单层分子吸附水含量分别为4.56%、3.63%、2.91%和2.25%,杉木素材和高温热处理材单层分子吸附水含量分别为3.93%、3.31%、2.66%和2.07%,美洲黑杨素材和高温热处理材单层分子吸附水含量分别为4.36%、3.69%、2.62%和1.99%,180、200和220 ℃处理后,试样单层分子吸附水含量相较于素材下降20%、30%和50%左右,其余不同相对湿度环境热处理材单层分子吸附水含量降低相比素材也具有相似规律,与热处理对参数W的影响相对应。在相对湿度93.6%环境中,樟子松素材和高温热处理材(180、200和220 ℃)多层分子吸附水含量分别为13.50%、11.40%、10.03%和7.33%,杉木素材和高温热处理材多层分子吸附水含量分别为12.05%、10.88%、8.92%和7.02%,美洲黑杨素材和高温热处理材多层分子吸附水含量分别为13.83%、11.90%、9.23%和6.82%,可见经高温热处理后,木材试样多层分子吸附水含量下降规律与单层分子吸附水含量下降规律相近。

|

图 4 樟子松热处理材单层分子吸附与多层分子吸附曲线 Fig. 4 Monomolecular and polymolecular adsorption isotherms for heat-treated Pinus sylvestris var. mongolica a.单层分子吸附曲线Adsorption isotherms of monomolecular;b.多层分子吸附曲线Adsorption isotherms of polymolecular.下同The same below. |

|

图 5 杉木热处理材单层分子吸附与多层分子吸附曲线 Fig. 5 Monomolecular and polymolecular adsorption isotherms for heat-treated Cunninghamia lanceolata |

|

图 6 美洲黑杨热处理材单层分子吸附与多层分子吸附曲线 Fig. 6 Monomolecular and polymolecular adsorption isotherms heat-treated Populus nigra |

采用外推法,以相对湿度100%代入式(1),通过计算可获得单层分子吸附水、多层分子吸附水和吸附水总量极限,结果如表 4所示。樟子松、杉木和美洲黑杨素材单层分子吸附水最大含量分别为4.57%、3.94%和4.37%,与Walker(2006)、Hill(2006)、Hill等(2009)研究结果相近。经高温热处理后,不同树种木材试样单层分子吸附水最大含量发生明显改变,180、200和220 ℃处理后,樟子松单层分子吸附水最大含量分别为3.65%、2.91%和2.27%,杉木单层分子吸附水最大含量分别为3.32%、2.66%和2.08%,美洲黑杨单层分子吸附水最大含量分别为3.70%、2.62%和1.99%。樟子松、杉木和美洲黑杨素材多层分子吸附水最大含量分别为18.19%、16.07%和18.61%,其数值相较于Walker(2006)、Hill(2006)、Hill等(2009)报道的多层分子吸附水含量极限20%均值偏低,其主要原因是木材吸湿滞后及试样等温吸附试验前绝干处理造成的,木材在相同温、湿度环境中达到的吸湿平衡含水率低于由解吸过程达到的平衡含水率,其平均差值约为2.5%(顾炼百,2011)。试样经103 ℃绝干,细胞壁基质上羟基失水后可部分相互形成连接,后续吸湿过程很难再次打开,降低了吸湿平衡含水率(Walker,2006)。经高温热处理后多层分子吸附水最大含量也发生明显改变,樟子松多层分子吸附水最大含量分别为15.55%(180 ℃)、14.10%(200 ℃)和10.38%(220 ℃),杉木多层分子吸附水最大含量分别为14.90%(180 ℃)、12.50% (200 ℃)和9.93%(220 ℃),美洲黑杨多层分子吸附水最大含量分别为15.33%(180 ℃)、13.09%(200 ℃)和9.50%(220 ℃)。

|

|

分析不同组分吸附水水分构成,根据不同组分吸附水含量对细胞内孔隙大小进行估算,可提供木材细胞壁微观孔隙尺度信息。通过Hailwood-Horrobin模型计算出单层分子吸附水和多层分子吸附水最大含量,可估算多层分子吸附水等效水分子层厚度[用多层分子吸附水最大含量除以单层分子吸附水最大含量,即Md(Max.)/Mh(Max.)](Hill,2006;Walker,2006),结果见表 4。可以看出,3个树种不同热处理条件木材试样多层分子吸附水分子层厚度之间差异不大,均在4~5个水分子层厚度范围,与Walker(2006)报道接近。如果将细胞壁孔隙假设成裂隙结构,则裂隙宽度可等效认为包含2个吸附层,吸附层厚度约为10层水分子。1个水分子直径约为0.19 nm(Takai et al., 2014),由此可知吸附水层等效厚度约为2 nm,也可说明木材细胞壁孔隙孔径也在此范围,高温热处理后虽然木材吸湿平衡含水率明显下降,但并未明显影响木材细胞壁的孔隙孔径范围,原因与处理温度选择有关。根据Hill(2006),当处理温度超过240 ℃时,木材会发生较大质量和强度损失,而在此之前多数情况是细胞壁羟基数量减少,因此本研究选取的热处理温度应该不会形成明显质量损失,产生较大的细胞壁孔隙。估算得到的细胞壁微观孔隙情况也可进一步用于研究和生产实际,特别是近年来出现的高温热处理木材后再浸渍树脂进行增强的相关研究(徐康等,2015;黄文娟等,2016;陈敏杰等,2017),通过分析不同组分吸附水含量估算细胞壁孔隙分布,可为浸渍树脂分子质量、功能化纳米增强颗粒粒径选择及浸渍工艺优化提供指导。

由表 4可知,樟子松、杉木和美洲黑杨细胞壁吸附水最大含量分别为22.76%、20.01%和22.98%,明显低于普遍认为的纤维饱和点均值30%,主要原因如下:首先,本研究采用的吸附水最大含量分析方法为外推法,通过曲线拟合,将相对湿度100%代入式(1)计算得到吸附水最大含量,并非实际水分含量,基于溶剂排出法、示差量热法、核磁共振法测定的细胞壁水分含量最大值明显高于外推法计算值(Babiak et al., 1995;Telkki et al., 2013;Gao et al., 2015);其次,通过等温吸附曲线线形变化可看出等温吸附线在高相对湿度阶段呈现斜率急剧增大现象,特别在相对湿度高于95%~100%阶段,Skaar(1988)、Walker(2006)认为利用低相对湿度环境拟合的等温吸附曲线参数计算高相对湿度环境试样含水率时会产生偏差;第三,随着相对湿度升高,毛细凝结作用增强,特别在相对湿度98%以上环境中,按照Kelvin方程小于等于50 nm的孔隙均会出现毛细凝结,一些较大的细胞壁裂隙可能因此出现微毛细管吸附水,导致平衡含水率迅速上升。从表 4还可以看出,高温热处理可显著降低吸附水含量极限,3个树种木材经最高220 ℃热处理后吸附水含量极限下降50%左右,与Kekkonen等(2014)研究结果相近。周凡丁等(2017)基于低温NMR技术等测定木材经热处理后纤维饱和点变化情况,结果发现,220 ℃热处理后纤维饱和点下降也接近50%。

3 结论1) 高温热处理可明显降低3个树种试样的吸湿平衡含水率,处理温度越高,平衡含水率下降幅度越大,且高温热处理可降低不同树种之间平衡含水率差异性。

2) Hailwood-Horrobin模型能够较好描述高温热处理材的等温吸附过程,等温吸附曲线拟合度高,高温热处理会一定程度改变木材等温吸附曲线线形。

3) 高温热处理显著影响3个树种试样等温吸附过程单层分子吸附水和多层分子吸附水含量,且处理温度越高影响越明显,单层分子吸附水和多层分子吸附水最大含量均明显降低,进而影响吸附水总量最大值。

陈敏杰, 张振伟, 涂登云, 等. 2017. 热处理浸渍杨木性能研究. 西北农林科技大学学报:自然科学版, 45(1): 99-104. (Chen M J, Zhang Z W, Tu D Y, et al. 2017. Effects of heat treatment on properties of resin impregnated poplar. Journal of Northwest A & F University:Nautral Science Edition, 45(1): 99-104. [in Chinese]) |

丁涛. 2010.压力蒸汽热处理对木材性能的影响及其机理.南京: 南京林业大学博士学位论文. (Ding T. 2010. Properties of pressurized-steam-treated wood-a theoretical research. Nanjing: PhD thesis of Nanjing Forestry University.[in Chinese]) http://cdmd.cnki.com.cn/Article/CDMD-10298-2010253255.htm |

丁涛, 顾炼百, 蔡家斌. 2015. 热处理对木材吸湿特性及尺寸稳定性的影响. 南京林业大学学报, 39(2): 143-147. (Ding T, Gu L B, Cai J B. 2015. Effects of heat treatment on the moisture adsorption characteristic and dimensional stability of wood. Journal of Nanjing Forestry University, 39(2): 143-147. [in Chinese]) |

丁涛, 王长菊, 彭文文. 2016. 基于拉曼光谱分析的热处理松木吸湿机理研究. 林业工程学报, 1(5): 15-19. (Ding T, Wang C J, Peng W W. 2016. A theoretical study of moisture sorption behavior of heat-treated pine wood using Raman spectroscopic analysis. Journal of Forestry Engineering, 1(5): 15-19. [in Chinese]) |

顾炼百. 2011. 木材加工工艺学. 2版. 北京: 中国林业出版. (Gu L B. 2011. Wood processing technology. 2nd edtion. Beijing: China Forestry Publishing House. [in Chinese]) |

黄文娟, 武亚峰, 赵紫剑, 等. 2016. 热处理温度与浸渍方式对竹丝质量增加率的影响. 东北林业大学学报, 44(8): 65-67. (Huang W J, Wu Y F, Zhao Z J, et al. 2016. Effect of heat treatment temperature and impregnation on mass gain of bamboo. Journal of Northeast Forestry University, 44(8): 65-67. DOI:10.3969/j.issn.1000-5382.2016.08.013 [in Chinese]) |

徐康, 吕建雄, 李贤军, 等. 2015. 高温热处理对杨木PF浸渍材尺寸稳定性的影响. 北京林业大学学报, 37(9): 70-77. (Xu K, Lü J X, Li X J, et al. 2015. Effect of heat treatment on dimensional stability of phenolic resin impregnated poplar wood. Journal of Beijing Forestry University, 37(9): 70-77. [in Chinese]) |

周凡丁, 高鑫, 蔡家斌, 等. 2017. 利用低温NMR技术测定木材及其热处理材纤维饱和点. 波谱学杂志, 34(1): 108-114. (Zhou F D, Gao X, Cai J B, et al. 2017. Determination of treated and control wood on fiber saturation point by low-field NMR technology. Chinese Journal of Magnetic Resonance, 34(1): 108-114. [in Chinese]) |

Babiak M, Kúdela J. 1995. A contribution to the definition of the fiber saturation point. Wood Science and Technology, 29(3): 217-226. |

Ding T, Gu L B, Li T. 2011. Influence of steam pressure on physical and mechanical properties of heat-treated Mongolian pine lumber. European Journal of Wood and Wood Producs, 69(1): 121-126. DOI:10.1007/s00107-009-0406-1 |

Donohue M D, Aranovich G L. 1998. Classification of Gibbs adsorption isotherms. Advances in Colloid and Interface Science, 76(98): 137-152. |

Esteves B M, Pereira H M. 2009. Wood modification by heat treatment:a review. BioResources, 4(1): 370-404. |

Gao X, Zhuang S Z, Jin J W, et al. 2015. Bound water content and pore size distribution in swollen cell walls determined by NMR technology. BioResources, 10(4): 8208-8224. |

Hailwood A J, Horrobin S. 1946. Absorption of water by polymers:analysis in terms of a simple model. Transactions of the Faraday Society, 42: B084-B092. |

Hill C A S. 2006. Wood modification: chemical, thermal and other processes. John Wiley, Chichester, UK.

|

Hill C A S, Norton A J, Newman G. 2009. The water vapor sorption behavior of natural fibers. Journal of Applied Polymer Science, 112(3): 1524-1537. DOI:10.1002/app.29725 |

Hill C A S, Norton A J, Newman G. 2010. The water vapour sorption properties of Sitka spruce determined using a dynamic vapour sorption apparatus. Wood Science and Technology, 44(3): 497-514. DOI:10.1007/s00226-010-0305-y |

Hill C A S, Ramsay J, Keating B, et al. 2012. The water vapour sorption properties of thermally modified and densified wood. The Journal of Materials Science, 47(7): 3191-3197. DOI:10.1007/s10853-011-6154-8 |

Kekkonen P M, Ylisassi A, Telkki V V. 2014. Absorption of water in thermally modified pine wood as studied by nuclear magnetic resonance. Journal of Physical Chemistry C, 118(4): 2146-2153. DOI:10.1021/jp411199r |

Mantanis G I, Papadopoulos A N. 2010. The sorption of water vapour of wood treated with a nanotechnology compound. Wood Science and Technology, 44(3): 512-522. |

Mattos B D, Lourençon T V, Serrano L, et al. 2015. Chemical modification of fast-growing Eucalyptus wood. Wood Science and Technology, 49(2): 273-288. DOI:10.1007/s00226-014-0690-8 |

Oiml R. 1996. The scale of relative humidity of air certified against saturated salt solutions. The International Organization of Legal Metrology.

|

Okoh K I A, Skaar C. 1980. Moisture sorption isotherms of the wood and inner bark of southern U.S. hardwoods.. Wood and Fiber Science, 12(2): 98-111. |

Papadopoulos A N. 2003. The sorption of water vapour by anhydride modified softwood. Wood Science and Technology, 37(3): 221-231. |

Papadopoulos A N. 2005a. Moisture adsorption isotherms of two esterified Greek hardwood. Holz als Roh-und Werkstoff, 63(2): 123-128. DOI:10.1007/s00107-004-0551-5 |

Papadopoulos A N. 2005b. The sorption of water vapour by chemically modified softwood:analysis using various sorption models. Wood Science and Technology, 39(2): 99-112. DOI:10.1007/s00226-004-0272-2 |

Papadopoulos A N. 2011. Sorption studies of chemically modified elm wood with acetic or maleic anhydride. Journal of Indian Academy of Wood Science, 8(1): 32-36. DOI:10.1007/s13196-011-0020-9 |

Papadopoulos A N. 2012. Sorption of acetylated pine wood decayed by brown rot, white rot and soft rot:different fungi-different behaviours. Wood Science and Technology, 46(5): 919-926. DOI:10.1007/s00226-011-0450-y |

Popescu C M, Hill C A S, Curling S, et al. 2014. The water vapour sorption behaviour of acetylated birch wood:how acetylation affects the sorption isotherm and accessible hydroxyl content. Journal of Materials Science, 49(5): 2362-2371. DOI:10.1007/s10853-013-7937-x |

Simpson W. 1980. Sorption theories applied to wood. Wood and Fiber Science, 12(3): 183-195. |

Skaar C. 1988. Wood-water relations. Berlin, Heidelberg: Springer-Verlag.

|

Takai M, Nagasawa D, Azuma T, et al. 2014. Water molecule structure on material interface related to protein adsorption. Hyomen Kagaku, 35(9): 492-497. DOI:10.1380/jsssj.35.492 |

Telkki V V, Yliniemi M, Jokisaari J. 2013. Moisture in softwoods:Fiber saturation point, hydroxyl site content, and the amount of micropores as determined from NMR relaxation time distributions. Holzforschung, 67(3): 291-300. |

Wacker J P. 2010.Wood handbook: wood as an engineering material. Centennial edition. Madison, Wisconsin: United State Department of Agriculture Forest Service.

|

Walker J C F. 2006. Primary wood processing principles and practice. Second edition. New Zealand, Christchurch: University of Canterbury, Springer.

|

Xie Y, Fu Q, Wang Q, et al. 2013. Effects of chemical modification on the mechanical properties of wood. European Journal of Wood and Wood Products, 71(4): 401-416. DOI:10.1007/s00107-013-0693-4 |

Zaihan J, Hill C A S, Curling S, et al. 2009. Moisture adsorption isotherms of Acacia mangium and Endospermum malaccense using dynamic vapour. Journal of Tropical Forest Science, 21(3): 277-285. |

2019, Vol. 55

2019, Vol. 55