Review of the IMO Initiatives for Ship Energy Efficiency and Their Implications

https://doi.org/10.1007/s11804-023-00374-2

-

Abstract

This paper presents a review of the different International Maritime Organization (IMO) initiatives to improve the ship energy efficiency of new and existing ships, which is considered one of the essential tasks to reduce Greenhouse Gas (GHG) in the maritime industry. First, the IMO effort and initiatives and the different indices suggested by the IMO are presented till the last version of the Marine Environment Protection Committee (MEPC), showing the effect of different technologies on reducing the level of indices and the suggested improvement of the terms of indices in the next years. Second, the short- and long-term strategies suggested by the IMO are presented, showing that the effect of indices will be noticed in the short term, while the new fuels will show a significant improvement in the long term. Finally, several examples of cooperation between the different organizations are presented, showing that transferring knowledge and experience will significantly impact the maritime industry and thus lead to the concept of green ships in the near future. This paper shows that the combination of different solutions, the cooperation between stakeholders and the sharing of the data and information are important to achieve the required goal.-

Keywords:

- Energy efficiency ·

- IMO ·

- Decarbonization ·

- Design index ·

- Operational index ·

- Classification societies

Article Highlights● The different IMO initiatives are reviewed for improving the ship energy efficiency of new and existing ships.● The effect of different technologies is presented on reducing the level of indices.● The short- and long-term strategies suggested by the IMO are presented.● The new fuels will show a significant improvement in the long term.● Cooperation between the different organizations must be performed to lead the concept of green ships in the near future. -

1 Introduction

According to international statistics, global trade is performed through the ocean, where 90% of goods are transported by ships (Equasis, 2019). This process requires cooperation between the different stakeholders, either private or public, within the maritime logistics chain operation to ensure a smooth transition in terms of technical and environmental aspects (DNV, 2020a).

Due to the large number of ships sailing worldwide ensuring the continuous operation of trading, more energy is required to operate the ships, especially the largest ones, thus increasing the amount of fuel consumed and exhaust emissions. Still, the fuel consumption and emissions levels are not comparable to the other types of transportation. However, it attracts attention from international organizations to mitigate global warming by finding an alternative type of fuel that can be used on board to reduce the harmful effect of carbon dioxide (CO2) emissions as well as the significant increment in fuel prices (EEA, 2021).

The main international organization associated with the shipping industry is the International Maritime Organization (IMO), which was established in Geneva in 1948. It has played an important role in improving safety at sea by developing restricted international regulations (IMO, 2019b) to improve the energy efficiency of the ships. Energy efficiency can be achieved through measures addressing the design of the ships and their operations (Wang et al., 2017; Feng et al., 2021). IMO has been addressing recommendations and promoting international standards on these issues, which have already influenced the industry.

As a part of the system, ship owners began reorganizing their fleets' schedules to achieve the best performance and improve the maritime industry's profit level (Zhu et al., 2020; Bui-Duy and Vu-Thi-Minh, 2021; Karatuğ et al., 2022b). One of the main and effective solutions that showed a fast impact on the maritime industry and was applied a few years ago is the reduction of ship speed (Tadros et al., 2022d; Armstrong, 2013; Dere and Deniz, 2019; Nzualo et al., 2021; Psaraftis, 2019b). This technique allows the ship to reduce the level of engine loading to achieve lower speeds, thus making beneficial effects in reducing fuel consumption and cutting the level of emissions by more than 20% (Tadros et al., 2021d; Elkafas and Shouman, 2021; Chang and Wang, 2014; Psaraftis, 2019a; Tillig et al., 2020).

Applying the technique of slow speed was an initial step towards mitigating global warming, especially for old ships (Goicoechea and Abadie, 2021; Taskar et al., 2023; Wu, 2020). At the same time, IMO took the lead through its technical arms to issue different stringent regulations and promote the enforcement of a series of measures in that direction, forcing the maritime stakeholders to reduce the level of emissions to the lowest possible levels; as otherwise, more penalties will be applied in the near future to ship owners (DNV, 2020a). The companies can be charged with some fines and can be compelled to cancel the sailing licenses of the ships according to the level of damage that their fleet can do (Wang et al., 2021).

Recently, the maritime industry has implemented several measures; however, because of the fast development of the technologies and the stringent regulations towards decarbonization, these measures must be updated every period to ensure suitability for every type of ship and keep the retrofitting procedures with new systems to reduce the level of emissions, especially to use new clean fuels towards achieving the level of sustainability (Sherbaz and Duan, 2012; Tadros et al., 2023c).

According to the Scopus database, several papers reviewed comprehensively and in detail the current technologies available in the maritime industry to improve energy efficiency and reduce exhaust emissions according to the reduction of fuel used. For instance, Wang et al. (2017) reviewed carbon capture and storage (CCS) systems as a new technology to reuse CO2 emissions and not go into the atmosphere. Mallouppas and Yfantis (2021) focused on presenting the technical measures of different strategies to improve energy efficiency, while Majumder and Maity (2023) and Stark et al. (2022) reviewed the development in energy-saving devices (ESDs) in the field of marine propeller. Also, the bibliometric analysis presented by Romano and Yang (2021) helps to understand the emerging research trends towards sustainability numerically.

From this point, this paper contributes to the research community by focusing on presenting the IMO effort, cooperation and initiatives and their implications in the maritime industry towards reducing exhaust emissions and thus improving the fleet's energy efficiency to achieve a fast transition towards zero emissions by 2050. Therefore, the IMO initiatives for ship energy efficiency and their implications are discussed by presenting the technical and operational measures until the last Marine Environment Protection Committee (MEPC (79)) to evaluate the energy efficiency of ships and the plans suggested for 2023 in section 2. Then, section 3 presents the short and long-term strategies applied to ensure the level of reduction of GHG by following the level of reduction by 2030 and 2050. Section 4 describes the effort performed by the recognized organization toward decarbonization in collaboration with other parties to achieve a specific target. After that, the concept of green ship is presented in Section 5, showing the main categories to reduce the amount of emissions. Finally, Section 6 presents some important conclusions to improve energy efficiency.

2 IMO initiatives in the maritime industry

2.1 Various initiatives of IMO

The IMO Convention entered into force ten years after its establishment to provide the highest possible standards for maritime safety, navigation efficiency and control of ships' marine pollution.

The International Convention for the Safety of Life at Sea (SOLAS) is the main instrument of IMO to ensure the maritime safety of the different parts of the ship (IMO, 2019d). It can specify the minimum standard of safety for the construction, equipment and operation of ships, where the flag states or other contracting states take the responsibility to ensure the ship's compliance with all the requirements of the convention.

After the Torrey Canyon disaster in 1967, spilling around 94-164 million litres of crude oil (SAFETY4SEA, 2021), IMO began to adopt the International Convention for the Prevention of Pollution from Ships, 1973, which has been updated by the Protocol of 1978 and namely "MARPOL 73/78" (IMO, 2019c). It consisted of six annexes to cover the different areas of pollution from ships from operational or accidental causes, including oil, chemicals, goods in packaged form, sewage, garbage and air pollution.

In 1970, the International Mobile Satellite Organization (IMSO) was established as a global search and rescue system, improving the provision of radio and other messages to ships as well as overseeing the performance of the mobile satellite communication systems (IMSO, 2022). Also, in 1988, the Global Maritime Distress and Safety System (GMDSS) was adopted to ensure the assistance of a ship in distress anywhere, even without requesting help from the ship's crew (FCC, 2022).

In 1993, the International Safety Management (ISM) Code was adopted and entered into force in 1998 (IMO, 2019f) to provide international and general guidelines for the safe management and operation of ships as well as to prevent pollution. This code is based on the assessment of all identified risks that face the maritime industry. Several amendments were introduced in 2000 and updated till 2013 according to the needs.

In 1997, the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW) entered into force to improve seafarer standards, which has been revised and improved by the adoption of the "Manila amendments to the STCW Convention and Code" (IMO, 2019e).

Since 2000, several conventions have been adopted to improve the safety of the ship. For instance, the International Ship and Port Facility Security (ISPS) Code (IMO, 2019g) entered into force in 2004 to determine the responsibilities and the roles of all parties in ports and on board to ensure maritime security. Other conventions were also adopted to improve the anti-fouling systems (IMO, 2019a) to control the harmful anti-fouling materials and ensure the hull's safety from unwanted organisms, not to increase fuel consumption and not harm the environment and the sea life. The management of the ballast water system is another convention adopted to prevent the invasion of alien species worldwide, which can destroy the marine environment (MEPC. 279(70), 2016). New guidelines have been presented in MEPC 80 to improve the recording and provide clarity to detect the performance of the ballast system, for instance, the use of an electronic record book (ERB).

Furthermore, the safety of ship breaking or ship recycling industry took the concern of IMO through the Hong Kong International Convention (IMO, 2009) to reduce human risk and environmental safety by providing guidelines to use suitable types of equipment and deal with the hazardous materials (Welaya et al., 2012; Alam and Faruque, 2014).

Since 1997, high levels of greenhouse gases (GHG) have been reported by the United Nations Framework Convention on Climate Change (UNFCCC) due to the adverse effects on the atmosphere, mainly from maritime and aviation industries, especially with the increase in global temperature by 1.5 ℃ nowadays and the expectation to reach 2.3 ℃ by the end of the century (DNV, 2020b). This is why the 2015 Paris Climate Agreement (COP21) results are to keep the global average temperature below 2.0 ℃.

Therefore, it was required to provide some conventions to include CO2 emissions, as the main GHG emissions, for further control. Unfortunately, while MARPOL 73/78 has become an important convention, which amendments that have been updated through the years to reduce the level of emissions from the marine industry, the CO2 emissions are not included. Thus, the MEPC of the IMO began to consider some new technical and operational measures to evaluate the level of CO2 from ships.

2.2 IMO initiatives for ship energy efficiency

Since 1997, the vision of IMO has been clear to reduce GHG and protect the climate system for the benefit of present and future generations. This was presented in MEPC 40 in resolution eight and considered a first initial step toward ship energy efficiency. In 2009, technical and operational measures were presented to evaluate the energy efficiency of ships. This includes the energy efficiency design index (EEDI), Ship Energy Efficiency Management Plan (SSEMP) and Energy Efficiency Operational Index (EEOI) and are presented in MEPC.1/Circ.681 to MEPC.1/Circ.684.

2.2.1 Energy efficiency design index

EEDI entered into force on the 1st of January 2013, where new ship designs must meet the reference level according to the ship type, as shown in Figure 1. This reference line is still under investigation and updated based on the new technologies and will be reduced by at least 30% in the third phase by 2025 and there are some possibilities to be extended to phase 4. This index evaluates the amount of CO2 emissions from all the installed engines according to the ship capacity and speed as computed using the following equation. All information about the ship, such as the power, speed, capacity, and fuel used, is defined in EEDI technical file to calculate the attained EEDI for this specific ship and then verified by the flag administration according to the guidelines presented in MEPC. 254(67) and as shown in Figure 2.

$$ \text { EEDI }=\frac{\mathrm{CO}_2 \text { emissions }}{\text { Transport work }} $$ (1)  Figure 1 EEDI reference lines for container ships (Vladimir et al., 2018)

Figure 1 EEDI reference lines for container ships (Vladimir et al., 2018) Figure 2 Overall process of EEDI verification (IMO, 2016b)

Figure 2 Overall process of EEDI verification (IMO, 2016b)where the summation of CO2 emissions is computed from the main engine, auxiliary engine(s), innovative power generation and subtracted from the innovative technologies that provide any mechanical power for propulsion of ship.

As this index is related to the new designs, implementing new techniques during the design stages is easier than in the existing designs from both technical and economic points of view. There is no single solution to achieve the best energy efficiency, but combining the different techniques will yield significant results (Mallouppas and Yfantis, 2021).

As presented in Figure 3, five categories can be considered to reduce CO2 emissions and thus improve the ship's energy efficiency.

Figure 3 Effect of individual measures on the CO2 emissions reduction potential (Bouman et al., 2017)

Figure 3 Effect of individual measures on the CO2 emissions reduction potential (Bouman et al., 2017)Most of the research work has been performed numerically and validated by experimental data. This kind of simulation assists in the analysis of complex systems and processes.

The development of advanced numerical models and computational tools has made it possible to perform more accurate and efficient simulations than traditional experimental methods, which can be expensive and time-consuming. This has led to a greater reliance on numerical computation in the maritime field.

These categories include first, the improvement of hull design to reduce the ship resistance and thus reduce the required power and fuel consumption (Zhao et al., 2021; Feng et al., 2021; Jung and Kim, 2019; Zhang et al., 2021; Liu et al., 2021; Zakerdoost et al., 2013). In these papers, detailed computational fluid dynamics (CFD) models have been developed and coupled with several optimizers, such as genetic algorithm (GA) (Mahmood and Huang, 2012). As a result, they could generate new hull forms according to the objective and the constraints defined in each study to find the optimal form of the hull that reaches the lowest resistance in calm water and in waves and ensure the safety of the motion of the ships. Also, optimizing the hull compartment is considered to maximize the amount of cargo and facilitate loading and unloading procedures while ensuring ship stability (Jafaryeganeh et al., 2019; Jafaryeganeh et al., 2020).

The second category is optimizing the propulsion system by selecting the optimum key configurations to reduce the fuel consumption at each engine operating point and ensure an efficient combustion process (Tadros et al., 2019; Stoumpos and Theotokatos, 2020; Tadros et al., 2022a; Altosole and Figari, 2011; Altosole et al., 2017; Benvenuto et al., 2021; Wang et al., 2020; Figari et al., 2022). These developed models vary between the use of 0D and 1D simulation to define the optimal parameters of the turbocharger, intercooler and injection systems to ensure better combustion of the diesel oil or any alternative fuel to reduce the amount of exhaust emissions and comply with the international regulations. The engine model can be validated using real data from the test bed or the project guide of the manufacturer. With the existence of real operational data, the model can be used to predict the amount of fuel consumption and exhaust emissions along the ship trip (Mocerino et al., 2021).

This can help to select an optimum propeller based on the system configurations to operate at the engine operating point with minimum fuel consumption, which can help to reduce the amount of fuel consumed along the ship trip with different weather conditions while complying with the cavitation, strength and noise issues (Tadros et al., 2021a; Ghaemi and Zeraatgar, 2021; Tavakoli et al., 2021; Tadros et al., 2022e; Tadros et al., 2022b; Tadros et al., 2023b). The use of empirical formulas shows its effectiveness in reaching the optimal solution in a few minutes with high accuracy. The computed results can be considered preliminary studies to estimate the propeller geometry and operation conditions. These results can be easily integrated into 3D models to compute the behaviour of the flow as well as the wake field around the propeller, ensuring more improvement in the design of propeller blades and the boss cap fins (Xiong et al., 2013; Najafi and Pourmostafa, 2022; Stark and Shi, 2021; Stark et al., 2021).

The use of alternative fuels is the third category that has a significant effect on reducing the amount of emissions, in particular on the long-term strategy to use a free sulphur fuel while reducing the other type of emissions (Chiong et al., 2021; Law et al., 2021; Elkafas et al., 2021; Liu et al., 2022; Ejder and Arslanoğlu, 2022; Sapra et al., 2020). El-Gohary (2013) presented the utilization of hydrogen as a clean fuel in marine power plants, with emphasizing on the gas turbine and fuel cell to be considered in the near future. He concluded that these two power plants are cleaner than the common diesel engines, although they use the same fuel. While the fuel cell is not feasible in the maritime field, several research projects have been carried out to support the development of this technology (Elkafas et al., 2023).

Another category is the use of energy sources to generate an additional amount of electricity to serve the hotel of the ship (Tadros et al., 2021c; Altosole et al., 2020; Mohammed et al., 2020; Yang and Yeh, 2017; Zhu et al., 2018; Dere and Deniz, 2019; Feng et al., 2020). The generation of additional electricity from the exhaust gas of the main and auxiliary marine engines directly affects the reduction of CO2 emissions compared to the power produced and thus improves the ship's energy efficiency. These studies depend on the thermodynamic and chemical properties of the fluid used, and the 0D models used show the ability to easily estimate the behaviour of the system and the total power computed from the rotary devices (Cherednichenko and Mitienkova, 2020).

The final category to be considered is the ship operation (Vettor et al., 2016; Vettor et al., 2018; Tadros et al., 2022e; Zaccone et al., 2018), where the path of the ship can be optimized based on the opinion of the ship master to use the less amount of fuel, ensure the safety of the ship in high weather conditions and reach the destination at the required time. These models require a combination of several types of data in terms of fuel consumption as approved by MEPC 79 and different types of computational models in addition to the multi-objective optimization technique to achieve optimal solutions intelligently.

Each category has a different potential for reducing CO2 emissions; it can vary between 1% to 85%. This depends on the design and operation of each ship, the feasibility of each technique to be integrated during the design and along the ship's life cycle, as well as the initial budget that is considered.

2.2.2 Ship Energy Efficiency Management Plan and Energy Efficiency Operational Index

SEEMP is an operational measure applied for a ship with more than 400 GT to improve the ship's energy efficiency in a cost-effective manner. It helps to manage the ship or a fleet over time through four main steps: planning, implementation, monitoring, and self-evaluation and improvement (IMO, 2016a). A specific plan is developed by the shipowner, operator or any other party concerned to ensure the continuous cycle to improve ship energy management. The solutions can be evaluated using multicriteria decision analysis (MCDA) to assess the energy efficiency of ship operations (Im et al., 2019).

EEOI monitors the results of these plans to evaluate their effectiveness over a specific period of time. It depends on the measurement of cargo carried or the transport work done and computed using the following expression:

$$ \mathrm{EEOI}=\frac{\sum\limits_i \mathrm{FC} \times C_F}{\sum\limits_i m_{\text {cargo }} \times D} $$ (2) where, i is the voyage number, FC is the fuel consumption at the voyage, CF is the emission factor, mcargo is the cargo weight and D is the distance of the voyage in nautical miles corresponding to the cargo carried. These plans can consider some categories, as presented in Figure 3, while these solutions can be limited regarding the economic situation.

Thus some solutions can be applied and show their effectiveness for an existing ship, such as the optimization of voyage planning while sailing in weather conditions (Vettor and Guedes Soares, 2016; Prpić-Oršić et al., 2016). The characteristics of the numerical model can be well-defined for each ship to achieve the safest trip and less consumption. This model has the ability to be integrated into an on-board decision support system to provide useful information to the ship master to easily take a decision during the trip (Perera et al., 2012; Uyanık et al., 2020; Karatuğ et al., 2023b).

Optimizing a suitable speed while selecting an efficient propeller is another solution to reduce the fuel consumed, cavitation and noise, particularly when applying engine power limitation level to avoid engine overloading (Tadros et al., 2022d). Optimizing the trim conditions of the ship, so the ship can be trimmed by stern which is more effective than by trim bow in terms of resistance and therefore reduce fuel consumption accompanied by an increase in energy efficiency (Elkafas, 2022). This kind of selection allows the ship master to ensure lower resistance along the route. Ballast tanks can control the ship trim through a ballast water management system which must be designed for shipboard operation (Kuroshi and Ölçer, 2017).

The selection of the optimum shaft power based on the combination between the main engine's operation and generators becomes an effective solution to reduce the main engine load and thus reduce fuel consumption (Sui et al., 2019). The model provides control and management of energy systems, especially with the existence of the controllable pitch propeller (CPP)

In addition, ensuring a clean hull and propeller, as well as maintaining their periodical maintenance (Wang et al., 2018; Farkas et al., 2020; Andersson et al., 2020a; Sanz et al., 2022) are essential to ensure the sustainability of the energy efficiency along the life cycle (Tadros et al., 2022c). More detailed about the technologies used to clean the hull can be found in (Song and Cui, 2020)

Also, installing a suitable waste heat recovery system (Altosole et al., 2020; Akman and Ergin, 2021) to produce additional power by recycling the exhaust gas flow is another parameter considered in the previous equation that helps to improve energy efficiency in the operational mode. Finally, the use of different types of fuel (Altosole et al., 2017; Tadros et al., 2018; Hansson et al., 2019) can effectively reduce the amount of GHG for the same power and thus directly affect the energy efficiency of the ship.

However, EEOI did not show effectiveness as a monitoring tool due to the significant differences in its values in the different conditions and was incompatible with the IMO Data Collection System (DCS) (Psaraftis, 2021).

3 Short and long-term strategies

Due to the significant increment in GHG by around 9.6% in 2018 compared to 2012, the international regulators have applied stringent regulations to achieve a reduction in carbon intensity by at least 40% by 2030 and the total annual GHG by at least 50% by 2050 compared to 2008 (IMO-MEPC, 2020). Therefore, short and long-term strategies are proposed to achieve this significant reduction within the required time, as shown in Figure 4.

Figure 4 Indicative timeline for developing and implementing possible global policy measures (Tadros et al., 2023d).

Figure 4 Indicative timeline for developing and implementing possible global policy measures (Tadros et al., 2023d).Regarding the new buildings, MEPC 75 adopted new amendments to strengthen the third phase of EEDI, which entered into force on the 1st of April 2022 instead of 2025 (IMO, 2020). This means a lot of improvements in energy efficiency must be performed for the new ships. The regulators approved some percentage of energy efficiency according to the ship size; for instance, at least 50% must reduce the EEDI of large container ships above 200, 000 DWT. This percentage is reduced to reach 30% while reducing the ship size when the ship is above 15, 000 DWT and less than 40, 000 DWT. Till now, this index will be considered for the short and long term.

3.1 Short term strategies

In MEPC 76, new measures have been presented to be applied to all ships to calculate their Energy Efficiency Existing Ship Index (EEXI) for the concept of design (IMO, 2021a). At the same time, an annual operational carbon intensity indicator (CII) has been proposed to improve the energy efficiency of the ships during operations. These two indices are applied as a short-term strategy for the existing ships. The EEXI is required to be calculated for ships with more than 400 GT, while the CII is applied to ships with 5 000 GT and above.

The EEXI is computed based on the guidelines provided in MEPC. 333(76) 2021 to MEPC. 335(76) 2021. The EEXI, a design index for the existing ships, follows the same concept used in EEDI, considering the engine power, transport capacity and ship speed. The EEXI calculation does not consider the rated engine power, 75% of the maximum continuous rate (MCR) or 83% of MCR in case of power engine limit (DNV, 2019).

The CII, as an operational index, comes into force on the 1st of January 2023, and the first rating will be available in 2024. It depends on providing a rate to the ship that varies from "A" to "E", where "A" is the best. In case the ship is located in the last two rankings, "D or E", SEEMP must be considered to re-evaluate the ship's performance and provide the optimal retrofit solution so the energy efficiency of the ship can be improved to have a high ranking (from "A" to "D") (DNV, 2021a).

Some comments have been provided by Psaraftis (2021) after the committee emphasized the unclear procedures that must be taken to evaluate ship performance worldwide, particularly in the EU region. At the end of 2021, MEPC 77 approved using wind for propulsion as an innovative energy efficiency technology, where the wind matrix was updated for more realistic results (IMO, 2021b).

In June 2022, MEPC 78 approved the applicability of the short-term measure to reduce GHG and enter into force in November 2022 (IMO, 2022b). The short-term measure introduces the EEXI, CII and SEEMP as the main indices to improve energy efficiency as well as the reporting procedures of these values to the DCS. In MEPC 80, the committee agree on a plan for reviewing the short-term GHG reduction measures, the CII and EEXI. The plan stipulates a data-gathering phase until MEPC 82 in autumn 2024 before analysing the data and finalizing any amendments to the measures by MEPC 83 in summer 2025 (DNV, 2023).

Some examples have been presented in (Green Ship of the Future, 2020) to perform retrofit procedures to the existing ships and improve energy efficiency. The main concept of retrofitting is to reduce the amount of energy used on-board, reducing the fuel consumed and thus CO2 emissions as the main parameter in EEXI and CII. Different companies have been involved in this study to present their solutions. These solutions depend on the target value's length; less or more than three years.

If the target value is less than three years, keeping the hull clean, optimizing the ship route and using an emulsified fuel system are the main solutions and a significant reduction in CO2 emissions of a tanker is achieved with more than 5, 000 tons/year.

Suppose the target value is more than three years. In that case, the instalment of the Flettner rotor, using power take-off (PTO) with an efficient propeller and using organic Rankine cycle (ORC) are other proposed solutions that can significantly reduce the CO2 emissions of the same ship by more than 4, 000 tons/year. The return on investment (ROI) varies according to the selected solutions between less than one year and up to 12 years.

Further improvement is presented in MEPC 79 to ensure the life cycle assessment (LCA) of the GHG and carbon intensity for the different marine fuels (Andersson et al., 2020b; Sarathy et al., 2022; Kallis et al., 2022; Huang et al., 2022). In addition, this study will allow the Well-to-Wake calculation. This type of calculation will include Well-to-Tank and Tank-to-Wake emission factors during the production and combustion of alternative marine fuels (Mio et al., 2022) and covers all fuels and other energy carriers used on-board ships. The LCA guidelines will be kept under review to reduce the risk of Carbon stock-Indirect Land Use Change (ILUC) for biomass used for fuel feedstocks (BIMCO, 2023). The guidelines of these procedures are clearly presented in MEPC 80.

3.2 Long term strategies

Long-term strategies are the measures proposed and will be considered by the IMO beyond 2030. These strategies include pursuing the sector's development towards zero-carbon or fossil-free fuels, which means improving the decarbonization procedure in the second half of the century. Also, it will consider any type of emission reduction mechanism.

Starting with the emission reduction mechanisms, there are several in the market to treat emissions, while not mainly concerning carbon reduction. However, they have a significant role in reducing the level of other types of emissions, in particular nitrogen oxides (NOx) and sulfur oxides (SOx) emissions, so the ship can have permission to operate in emission control areas (ECAs) smoothly. These types of ECAs have been selected and entered into force since 2006 and were extended over the last ten years to cover different areas such as the Baltic Sea, North Sea, North America, United States Caribbean Sea as mentioned in (IMO - MEPC, 2018) and as shown in Figure 5.

Figure 5 Emission control areas (ECAs) around the world (Tadros et al., 2020)

Figure 5 Emission control areas (ECAs) around the world (Tadros et al., 2020)ECA areas have been extended to include the Mediterranean Sea from 2025, where the ships must fulfil the requirements of both NOx and SOx emissions (IMO, 2022a). Also, the Red Sea and the Gulf of Aden will be considered special areas by the same year, as suggested by MEPC 80. The level of NOx reduction in ECA is around 80% compared to tier 1 (IMO, 2017a), while the SOx emissions have been reduced by around 94% compared to the first level suggested in tier 1 (IMO, 2017b).

These techniques are summarized by (El-Gohary et al., 2015), including the type of mechanism and the level of reduction. Regarding the NOx emissions, the selective catalytic reduction is the first one to mainly cut the NOx emissions by up to 95%, followed by humid air by 70%, engine tuning by up to 60%, then exhaust gas recirculation (EGR) by up to 30% and the emulsification by 25%. Regarding the SOx emissions, the scrubber is the effective solution to reduce the level of SOx emissions by 95%, followed by the fuel switching process by around 60 to 90%.

Nowadays, CCS attracts attention to catch the CO2 emissions from ships and store them for reuse in other applications (Wärtsilä, 2021; Güler and Ergin, 2023). This technique was installed on offshore platforms to store the CO2 emissions directly under the deep sea (IPCC, 2005; Watanabe et al., 2011). As this technology is new, it is still under investigation as it did not lead to the independence of fossil fuels (Irena et al., 2021), but it can help to save 17% of CO2 emissions. Buirma et al. (2022) presented a techno-economic study covering the different aspects of the technology on-board, including the corresponding benefits; for instance, the CO2 emissions can be used in agriculture. Also, the barriers have been presented, including the problem associated with the type of fuel used on-board, for instance, the occurrence of methane slip in liquefied natural gas (LNG) engines and the cost of CO2 transportation. More information will be presented in MEPC 80 to verify the use of CCS on-board.

The second part of the long-term strategy is developing alternative sulphur-free fuels to be used on-board so that the emissions can be significantly reduced (Karatuğ et al., 2022a). The first alternative fuel type is biofuel, which has the same characteristics as diesel oil and can be easily integrated into the power system (Tadros et al., 2021b; Tadros et al., 2022a; Korberg et al., 2021). However, biofuels depend on the availability of raw materials for each country, which can affect the amount of food required for human use (Estevez et al., 2022; Kolakoti et al., 2023). Therefore, advanced biofuels are under investigation to be derived from non-food-based feedstocks and reduce GHG by at least 50% (Panoutsou et al., 2021). An MEPC circular on interim guidance on the use of biofuels in relation to IMO DCS and the CII framework is approved and the approval of the interim guidance should not, in any case, prejudge future decisions on the application of LCA frameworks to any kind of fuels, including biofuels, following further development of the LCA guidelines.

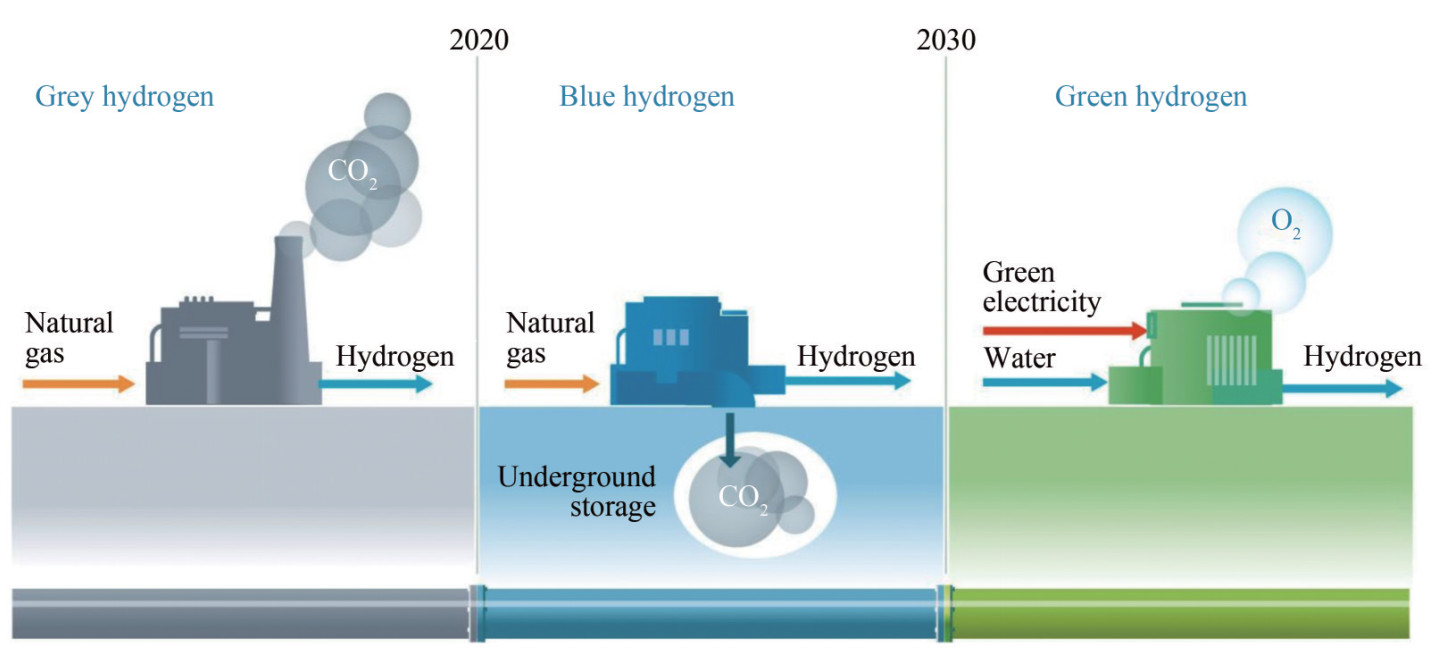

Other types of alternative fuels will be switched from grey fuel to green fuel passing through the process of blue fuel. The main alternative fuels considered for development are hydrogen, LNG, methanol and ammonia.

Figure 6 shows the difference between the three types of fuels for hydrogen production. The same concept is applied to the other types of mentioned fuels. The main difference between the three types is the source of energy and the management of CO2 emissions from production.

Figure 6 Schematic diagram showing the difference between the production of grey, blue and green hydrogen (Saracco, 2021)

Figure 6 Schematic diagram showing the difference between the production of grey, blue and green hydrogen (Saracco, 2021)From Figure 6, grey hydrogen is produced from fossil fuels such as natural gas using steam methane reforming and coal gasification as production methods, which produce plenty of CO2 emissions to the air. Blue hydrogen is similar to the production of grey hydrogen, while the CO2 emissions have been captured and stored using CCS and thus can be reused in other applications. Green hydrogen is the cleanest fuel produced as it is formed from water and from electricity provided by renewable sources; however, it is still very expensive but environmentally friendly compared to the first two types (El-Gohary et al., 2014).

Regarding hydrogen, it has gained considerable attention as a potential fuel source due to its lower emissions and high energy density and can be used in several marine applications, while the hydrogen infrastructure, including production, storage, and distribution, is still under development through 2030 (McKinsey & Company, 2022). Hydrogen has become used in internal combustion engines as a clean fuel which can help reduce GHG and achieve the limits of 2050. It is like any other type of fuel, and it requires attention to ensure the quality of combustion, mainly focusing on the four-stroke engines. In addition, hydrogen production, transportation, and storage costs are still under investigation as it requires a special atmosphere (El-Gohary, 2013; Man Energy Solutions, 2022). Also, it can be used in a fuel cell as a source of electricity and heat; however, it is still not ready to replace diesel engines as a main source of power as well as sustain the severe weather conditions along the ship route (Vedachalam et al., 2022).

Regarding LNG, it remains a promising fuel option in the near term, and it is suggested for the long term due to the process of production using renewable energies at a very low cost. LNG offers a relatively high energy density, and its infrastructure is more developed compared to other alternative fuels. Therefore, it has been used on-board several ships fitted with two or four-stroke engines due to the reduction of CO2 by more than 10%, while NO x and SOx and Particulate matter (PM) emissions by more than 85% (Man Energy Solutions, 2022; Pagonis et al., 2016). However, some limitations still exist; for instance, it requires an expensive installation, and it is preferred in new vessels with LNG engines than in older vessels due to the complexity of the system and the space required on-board, which makes the retrofitting process more difficult and other solutions such as the installation of after-treatment systems can be more economical. In addition, not all the ports can support the LNG loading facilities due to the high cost (Ammar and Seddiek, 2017; Balcombe et al., 2021).

Regarding methanol, it will fuel both two- and four-stroke engines due to its high-octane rating, making it suitable for use in high-performance engines. It is a clean fuel that can reduce PM, NOx and SOx and be stored in ambient conditions (Cordero-Lanzac et al., 2022). It will be available on ports due to the different feedstock from which the methanol can be produced. The existing dual-fuel engine will be adapted to support the use of methanol as a fuel, with the calibration of engine parameters to ensure better combustion, high power and lower emissions (Man Energy Solutions, 2022; Methanex, 2022; Fridell et al., 2021). The infrastructure for methanol production, distribution, and refuelling is less established than the LNG.

Regarding ammonia, it will support two-stroke engines, according to Man Energy Solutions (2022). Ammonia attracts attention due to its higher production worldwide (Hansson et al., 2020). In the long term, the cost of production of ammonia and, in particular, green ammonia will be reduced, which can be a carbon-neutral fuel and will be available for bunkering in ports. Ammonia has a high energy density, which makes it suitable for long-haul shipping. The combustion process is still under investigation to ensure highly efficient combustion with lower exhaust emissions (Wärtsilä, 2022). The first engine fuelled by ammonia is expected to be delivered by 2024. The infrastructure for ammonia production, storage, and transportation is limited compared to other fuels. Also, it is toxic and poses safety challenges in handling, storage, and refuelling.

To better select the optimal fuel based on the ranking process, MCDA has been used to evaluate the type of fuel based on several criteria. Karatuğ et al. (2023a) applied a technique for order of preference by similarity to ideal solution (TOPSIS) and found that ammonia is determined as the best alternative, while LNG and methanol share highly close similarity values. This study approved the same concept presented by Hansson et al. (2020). However, no generic fuel can be better used and there must be some evaluation procedures based on the type of ships, the installed propulsion system and the defined route, especially with the interest of integrating electric systems in marine vessels (Korberg et al., 2021). In the next few years, these kinds of fuels will be expanded to synthetic drop-in fuels and approved by MEPC 79, such as e-methanol and e-ammonia, thus facilitating their use as low- and zero-carbon fuels.

4 Recognized organizations

IMO has adopted the Code for Recognized Organizations (RO Code) by resolutions MEPC. 237(65) and MSC.349(92), in order to provide the minimum standards to the flag states (where the ships are registered) and ensure consistent global implementation of requirements established by the IMO and its instruments. Also, the RO clarifies the responsibilities of authorized organizations and their scope.

The performance level of several flag states, such as the Marshall Islands, Greece, Singapore and Hong Kong, continues to be very positive and ensures the implementation of the new regulations for the new and existing ships based on MARPOL requirements. These procedures can be performed using surveys or inspection of vessels, monitoring the oil discharge process and applying punishments to the vessels that fail to comply with requirements. Through the help provided by the flag states, EEDI and SEEMP will be improved, and this requires the transfer of the technologies to these RO to be up to date; thus, the collected information will be clear, and the decision-making will be realistic to improve the ship energy efficiency (Winkel et al., 2015).

In collaboration with the classification societies, flag states have launched the Maritime Technologies Forum (MTF, 2021) to bridge the fast progress in new technologies and regulatory processes. This will help to ensure a fast track towards sustainability and economic-friendly technologies in the maritime sector. The forum was founded by three flag states and four classification societies, without the existence of any of the large flag states mentioned before. However, it is supposed to be an extension of the members of the forum from both sides over the next few years.

By following the concept of collaboration to achieve a fast transition in decarbonization and reach net zero emissions, Det Norske Veritas (DNV) is one of the very active classification societies in this field. DNV supports several projects, either locally or worldwide. Green Shipping Programme (GSP) is a project funded by DNV so Norway can meet the country's emission targets by reducing the emission level by 50% by 2030 (DNV, 2015). The use of hydrogen as the main fuel as well as the electrification technologies in cooperation with ABB company, are the most used techniques to reduce emissions. Launching the Global Centre for Maritime Decarbonization (GCMD) in Singapore is another project that will support the research and development projects in collaboration with higher education and research institutes to reduce GHG emissions (DNV, 2021b). This project is one of the very supported projects by the Maritime and Port Authority of Singapore due to the effective location of the country in relation to the ship routes. This project will support Singapore in providing a multi-low-carbon fuel bunkering transition for the future of international shipping.

The Nordic Green Ammonia Powered Ships (NoGAPS) is another important project that ensures the applicability of ammonia as an alternative fuel in the maritime industry. This project is considered cooperation between the regulatory organizations, shipping lines and engine manufacturers, ensuring the suitability of the fuel from the techno-economic aspects (Nordic Innovation, 2020). Furthermore, there are other projects related to the suitability of the batteries as the main source of ship power, such as DDD-Batman (MarTERA, 2020), the zero-emission wind-assisted propulsion technology (Cargill, 2020) as well as the CCS technologies to store and reuse carbon (CETO) (DNV, 2022).

Lloyd's Register (LR) is interested in providing a techno-economic assessment of a combination of zero-carbon fuels to be used along the ship route (Lloyd's Register, 2022). Three criteria have been considered: technology readiness (TRL), investment readiness (IRL) and community readiness (CRL). Each fuel has been evaluated and ranked based on progress, from just an idea to achieve the production and development level. No standard solution is approved, but it mainly depends on several factors such as the ship type, route, fuel prices and availability. Furthermore, there are several barriers to achieving zero-carbon fuels as more development are required to the fuel quality standards, on-board storage, bunkering infrastructure and conversion equipment (Lloyd's Register and UMAS, 2020).

American Bureau of Shipping (ABS) cooperated with Siemens Energy Marine to provide digital solutions to the marine sector by capturing, consolidating, managing and visualizing essential emissions data (ABS, 2021). SISHIP EcoMAIN Suite is the result of this cooperation to optimize fleet performance and thus improve energy efficiency by giving ship operators assistance in taking the optimal decision. Furthermore, ABS supported the conversion of the marine systems to be operated by liquefied petroleum gas (LPG) and LNG to reduce the carbon footprint of the vessels and can be applicable by 2030. Furthermore, they ensure that the fuel selection will depend on the ship type and the operating profile (ABS, 2020).

Bureau Veritas assigned cooperation with Marlink as a smart network group to improve the cyber-secure digital tools ensuring safety services in the maritime industry (Marlink, 2022). The results from this cooperation will support the remote and digital operation modes to achieve intelligently zero-emission targets. Furthermore, another cooperation with Total Energies began to ensure the suitability of ammonia to power engines and marine propulsion systems, as ammonia shows positive health effects compared to other types of fuel, such as LNG (BV, 2022).

This section presents part of the collaboration work between the RO and other organizations as examples to achieve a fast pathway toward decarbonization without diminishing the other organizations' efforts to improve the maritime industry's development.

5 Green ship technologies

Based on the previous points, the concept of the green ship occurs and is already implemented in the maritime industry to achieve a ship that complies with the limitations of emission levels and leaves the lowest amount of carbon footprints. As shown in Figure 7, several solutions are proposed. Some of them are implemented to achieve the goal of green shipping, as mentioned before, while others are under development and will be available in the market in the coming years. These can be classified into two categories to serve the main goal of energy efficiency.

Figure 7 Different solutions towards green ship (Marine Digital GmbH, 2020)

Figure 7 Different solutions towards green ship (Marine Digital GmbH, 2020)The first category is to reduce the ship resistance significantly; therefore, the power transmitted to the ship hull will be reduced, thus significantly reducing fuel consumption. This concept can be achieved by optimizing the hull lines to improve the ship resistance and improving the wake field into the propeller and rudder, thus increasing the propeller efficiency to produce the required thrust of the ship. Also, it is essential to ensure the cleaning of the hull and the propeller and the use of suitable paints to decrease the hull roughness, which already increases over the years (ITTC, 2017; Sezen et al., 2021; Tadros et al., 2023a; Ravenna et al., 2022), and thus the ship can sustain to operate with the lowest fuel consumption. Another benefit of optimizing the hull is maximizing the amount of cargo affecting the design indices while ensuring a suitable trim level to reduce ship resistance. Some technologies can be considered, such as the air lubrication system to produce a layer of air under the keel to reduce the friction between the ship and the water and thus reduce the ship's resistance (Giernalczyk and Kaminski, 2021; Yanuar et al., 2018).

The second category directly reduces emissions by operating with a type of fuel alternative to fossil fuel and producing fewer emissions from CO2, NOx and SOx, as mentioned before. The production of green fuel from natural resources is the main target to be fully applicable in the industry by 2050, where the engine performance will be adapted to be operated using this kind of new fuel. Also, the use of wind-assisted propulsion, such as the kite-sail system (Bigi et al., 2020; Brandon, 2022) and the rotor system (Ammar and Seddiek, 2021; Kume et al., 2022; Nfnr Alkhaledi et al., 2023), will be a good choice to provide more power to the ship from wind and thus reduce the level of emissions. Finally, collecting and storing emissions or performing a treatment procedure will be effective in decreasing the intensity of emissions into the atmosphere, especially in the short term.

6 Conclusions

This paper comprehensively reviews the IMO initiatives toward ship energy efficiency and their implications on the maritime industry. The energy efficiency of the ship or the reduction of exhaust emissions is considered one of the important tasks on the agenda of the IMO. There is an importance related to this field nowadays to reduce the level of GHG and not reach an increase in the earth's temperature. From the paper, it has been concluded that:

1) The different types of indices developed will show a positive effect on the energy efficiency of the new or existing ships.

2) Updating the terms of indices according to the new technologies in the market will provide a real overview of the ship's performance and thus take the right decision to improve energy efficiency.

3) No single solution is suitable for all ships, but it differs for each type as well the combination of several solutions will achieve high-impact results.

4) These indices will play a great role in the short term, while the new fuels, mainly green ones, will significantly impact the long term.

5) Hydrogen, LNG, methanol and ammonia are the most suggested alternatives to fossil fuels, and they show more effectiveness in internal combustion engines than in electrical parts such as fuel cells.

6) LCA and MCDA will effectively define the optimal fuel in the next few years to be used on-board based on the real data collected.

7) Cooperation between several organizations is essential to achieve a fast pathway toward decarbonization and improve energy efficiency.

8) The availability of ship performance data along the route in different weather conditions will help achieve optimal decision-making solutions.

Nomenclature 0D Zero dimensional 1D One dimensional 3D Three dimensional ABS American Bureau of Shipping CCS Carbon capture and storage CF Emission factor CFD Computational fluid dynamics CII Carbon intensity indicator CO2 Carbon dioxide COP21 Paris Climate Agreement CPP Controllable pitch propeller CRL Community readiness D Distance of voyage DCS Data Collection System DNV Det Norske Veritas ECA Emission control areas EEDI Energy efficiency design index EEOI Energy Efficiency Operational Index EEXI Energy Efficiency Existing Ship Index EGR Exhaust gas recirculation ERB Electronic record book ESDs energy-saving devices FC Fuel consumption GA Genetic algorithm GCMD Global Centre for Maritime Decarbonization GHG Greenhouse Gas GMDSS Global Maritime Distress and Safety System GSP Green Shipping Programme i Voyage number ILUC Indirect Land Use Change IMO International Maritime Organization IMSO International Mobile Satellite Organization IRL Investment readiness ISM International Safety Management LCA Life cycle assessment LNG Liquefied natural gas LPG Liquefied petroleum gas LR Lloyd's Register MARPOL International Convention for the Prevention of Pollution from Ships mcargo Cargo weight MCDA Multicriteria decision analysis MCR Maximum continuous rate MEPC Marine Environment Protection Committee NoGAPS Nordic Green Ammonia Powered Ships NOx Nitrogen oxides ORC Organic Rankine cycle PM Particulate Matter PTO Power take-off RO Recognized Organizations ROI Return on investment SEEMP Ship Energy Efficiency Management Plan SOLAS International Convention for the Safety of Life at Sea SOx Sulfur oxides STCW International Convention on Standards of Training, Certification and Watchkeeping for Seafarers TOPSIS Technique for order of preference by similarity to ideal solution TRL Technology readiness UNFCCC United Nations Framework Convention on Climate Change Competing interestC. Guedes Soares is one of Editors for the Journal of Marine Science and Application and was not involved in the editorial review, or the decision to publish this article. All authors declare that there are no other competing interests.Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author (s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. -

Figure 1 EEDI reference lines for container ships (Vladimir et al., 2018)

Figure 2 Overall process of EEDI verification (IMO, 2016b)

Figure 3 Effect of individual measures on the CO2 emissions reduction potential (Bouman et al., 2017)

Figure 4 Indicative timeline for developing and implementing possible global policy measures (Tadros et al., 2023d).

Figure 5 Emission control areas (ECAs) around the world (Tadros et al., 2020)

Figure 6 Schematic diagram showing the difference between the production of grey, blue and green hydrogen (Saracco, 2021)

Figure 7 Different solutions towards green ship (Marine Digital GmbH, 2020)

Nomenclature 0D Zero dimensional 1D One dimensional 3D Three dimensional ABS American Bureau of Shipping CCS Carbon capture and storage CF Emission factor CFD Computational fluid dynamics CII Carbon intensity indicator CO2 Carbon dioxide COP21 Paris Climate Agreement CPP Controllable pitch propeller CRL Community readiness D Distance of voyage DCS Data Collection System DNV Det Norske Veritas ECA Emission control areas EEDI Energy efficiency design index EEOI Energy Efficiency Operational Index EEXI Energy Efficiency Existing Ship Index EGR Exhaust gas recirculation ERB Electronic record book ESDs energy-saving devices FC Fuel consumption GA Genetic algorithm GCMD Global Centre for Maritime Decarbonization GHG Greenhouse Gas GMDSS Global Maritime Distress and Safety System GSP Green Shipping Programme i Voyage number ILUC Indirect Land Use Change IMO International Maritime Organization IMSO International Mobile Satellite Organization IRL Investment readiness ISM International Safety Management LCA Life cycle assessment LNG Liquefied natural gas LPG Liquefied petroleum gas LR Lloyd's Register MARPOL International Convention for the Prevention of Pollution from Ships mcargo Cargo weight MCDA Multicriteria decision analysis MCR Maximum continuous rate MEPC Marine Environment Protection Committee NoGAPS Nordic Green Ammonia Powered Ships NOx Nitrogen oxides ORC Organic Rankine cycle PM Particulate Matter PTO Power take-off RO Recognized Organizations ROI Return on investment SEEMP Ship Energy Efficiency Management Plan SOLAS International Convention for the Safety of Life at Sea SOx Sulfur oxides STCW International Convention on Standards of Training, Certification and Watchkeeping for Seafarers TOPSIS Technique for order of preference by similarity to ideal solution TRL Technology readiness UNFCCC United Nations Framework Convention on Climate Change -