| A dual-antenna global positioning system (GPS) receiver based automated leveling system for tuber harvesters of Ophiopogon japonicus |

2. Ningbo Microagri Technology Ltd., Ningbo 315100, Zhejiang, China;

3. The 38th Institute of China Electronic Science and Technology Group, Hefei 230088, China

2. 宁波市鄞州麦谷农业科技有限公司,浙江 宁波 315100;

3. 电子科技集团第38所,合肥 230088

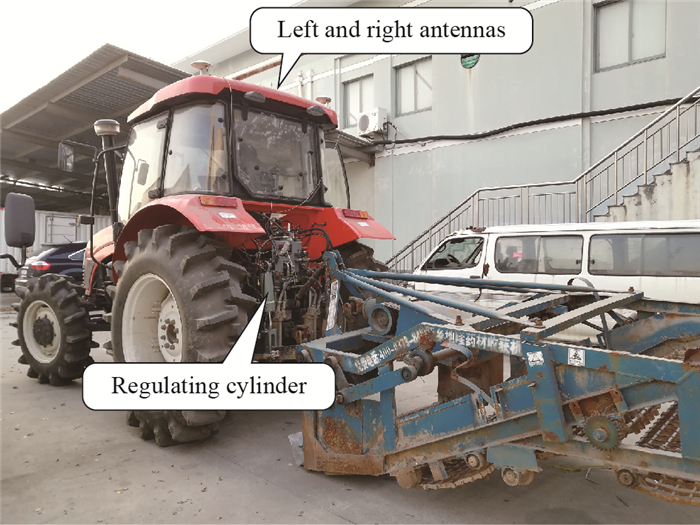

Ophiopogon japonicus is a kind of local herbal remedies in Cixi City, Zhejiang Province, which takes three years growing from a seedling to a mature plant. Harvesting of this genus is a laborious and skilled physical work. A person should dig out the root while keeping the green plants on the ground, which will be cut apart and used as seedlings in the next turn. A tuber harvester, hitched behind a tractor by a three- point suspension mechanism, was used to dig out O. japonicus. In the first harvest season, it suffered from several mechanical failures, such as fracture of connecting rod and heavy wear of chainwheels as shown in Fig. 1. The main reason was serious roll of the tractor when its tires in one side fell into a furrow in the field and the connecting rod of this side undertook nearly the whole strain. Thus it is important to keep the harvester horizontal in this situation.

|

| A: Structural fracture; B: Fatigue wear. Fig. 1 The 1st-generation harvester |

Automated leveling system for agricultural machines had been developed for more than 10 years. The common approach is that one linkage rod of a tractor was replaced by a cylinders[1], which was governed by a control circuit according to the signal from the rolling angle sensor mounted on the harrow to maintain level. This kind of sensor and regulating cylinder was also used in our first-generation leveling system. Initial experiments showed that the sensor could not output correct and stable value due to violent jitter of the harvester. Literatures show that there are two other schemes to solve the issue. One scheme is to measure rolling angle of the tractor and displacement of the regulating cylinder, and then establish a conversion function to evaluate the rolling angle of the implement[2-3]. The other scheme is to use two ultrasonic sensors[4], mounted on each end of the sprayer to detect the height of spray boom, thereby controlling the hydraulic cylinders to keep level. Multi-antenna or dual-antenna global positioning system (GPS) was used to measure the attitude angles of aircraft early in the 1990s[5-6]. In the last 10 years, Chinese scholars had begun to research application of dual-antenna GPS, such as measurement of yaw angle of vehicle[7-8], ship's attitude[9], missile attitude[10]. In the missile test, the results showed the pitch angle error was less than 0.8°, and the yaw angle error was less than 0.7°, when the distance between the two antennas was 0.36 m. As a dual-antenna GPS had already been a part in previously developed guidance systems, we attempt to realize leveling control of agricultural implements by a dual-antenna GPS instead of inclination sensor.

1 Materials and methods 1.1 Leveling measurement and control methodThe 2nd-generation of tuber harvester was a lengthened, double-layer vibrating machine (YJS-1, Dilong, China). A wheeled tractor (1204, Xingguang, China) was used as the power of the harvester. The harvester was connected with the tractor in a three-point suspension mode, as shown in Fig. 2. The leveling system consisted of a field computer, an electronic control unit (ECU), a dual-antenna GPS receiver (382, Beiyun, China), a rope-type sensor, and a hydraulic system. The left straight rod was replaced by the cylinder, whose action was controlled by the ECU. Two GPS antennas were mounted, which were one left and one right on the driver's cab. The GPS receiver output rolling angles with precision of 0.08° per 2 m, where the precision was 0.15° in this application. The field computer received rolling angles from the GPS and sampled the displacement of cylinder from the rope-type sensor.

|

| Fig. 2 Tractor, harvester, and leveling regulation system |

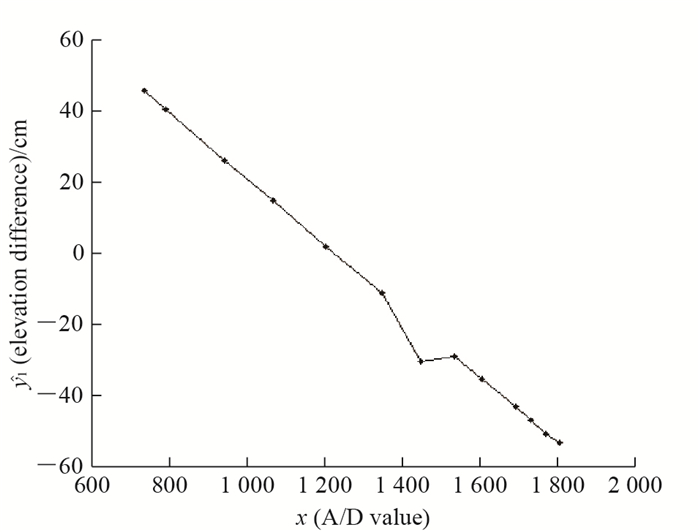

A linear functional relationship of the elevation difference between pairs of the left and right end points of the implement and the data of rope sensor were established through an experiment. Before the experiment, the harvester was lifted from horizontal posture to a height of about 30 cm, and then the left end of the harvester was lifted to its highest position. An optical level, standing 5 m far behind, was used to read numbers on a ruler standing on the left or right end of the implement. The left end of the implement dropped bit by bit. The numbers on the ruler and the analog-to-digital (A/D) value of the rope sensors were read once every drop. When the left side reached to the nadir, a set of elevation differences and A/D values were obtained, as shown in Fig. 3, which showed a linear relationship between these two data. Using the least square method, the relationship was established, as shown in formula (1):

| $ {\hat y_1} = 0.933x-1140.07. $ | (1) |

|

| Fig. 3 Measured relationship between elevation differences and A/D values |

Where,

The elevation difference caused by tractor rolling could be calculated as the following equation:

| $ {{\hat y}_2} = W \cdot \tan \gamma . $ | (2) |

Where,

These above two items constituted the total estimated elevation difference. The field computer calculated the elevation difference in every 200 ms, and produced the control quantity and moving direction of the cylinder through a proprotion integration differentiation (PID) algorithm. Finally, the ECU controlled the solenoid valve to adjust the expansion of the cylinder.

1.2 The hydraulic systemThe hydraulic system was composed of a directional valve (FW-02, Hoyea, China), a spool-type cartridge relief valve (LADRV2-10, Ketai, China), and a cylinder (Shengli, China). Fig. 4 shows the hydraulic schematic diagram, where the directional valve controls lifting or dropping action.

|

| A and B: Utilization ports; P: Pressure inlet; T: Return port. Fig. 4 Hydraulic system |

Farmland condition: a dryland with ridges of 1.5 m wide was selected for testing.

Test processing: The machine was used for harvesting from May 4 to 10, 2017. In the first two days, we recorded the control effect. Because it was difficult to measure the rolling attitude of the harvester directly, the leveling effect of the machine was evaluated by the land horizontal before and after harvesting. On the first day, the right tires fell into furrows, and the left tires fell into other furrows on the second day. Thus, the elevation measurements of each day were distinctly different, but this did not affect the elevation differences. Before harvesting, 40 pairs of points were measured by the optical level at 3 m interval; after harvesting, the elevation was measured again with the level.

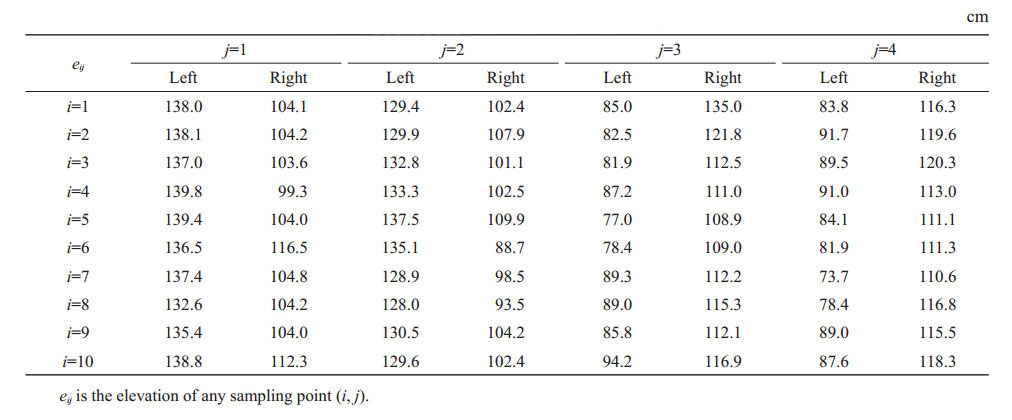

Data processing and analysis: Matlab software was used for data processing and graphic representation. The average value of the elevation difference represented the elevation difference, and the standard deviation represented the fluctuation degree of the elevation difference. Table 1 shows elevations before the harvest experiment, where the area is 40 m×20 m, and the sampling interval is 3 m.

| Table 1 Sampling data before harvesting |

|

| 点击放大 |

Before harvesting, the average elevation difference and standard deviation were as follows:

| $ \sum\limits_{i = 1, j = 1}^{i = 10, j = 4} {{f_{{{\rm{e}}_{ij}}}}/40} = 30.66\;{\rm{cm, }}\;{\mathit{S}_{\rm{d}}} = 6.32\;{\rm{cm}}{\rm{.}} $ |

Where feij is the elevation difference of the (i, j) pair of left and right points; Sd is the standard deviation of all feij data.

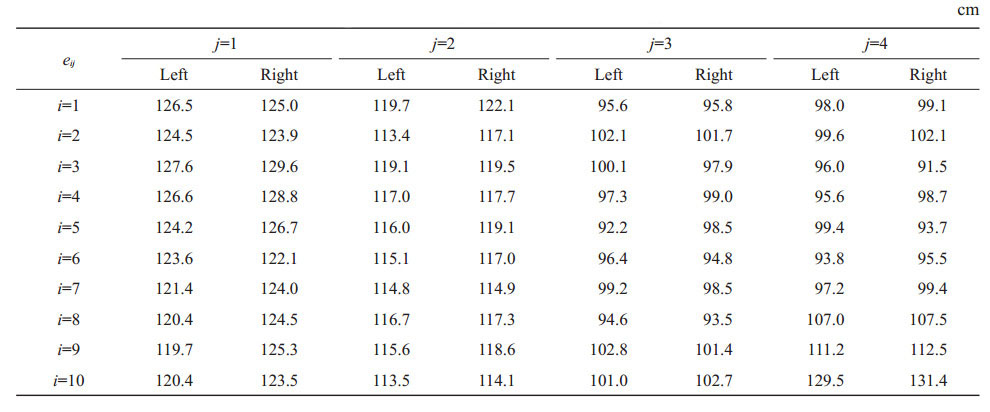

After harvesting, the 40 point-pairs were measured again, whose data were shown in Table 2.

| Table 2 Sampling data after harvesting |

|

| 点击放大 |

The average elevation difference and standard deviation were as follows:

| $ \sum\limits_{i = 1, j = 1}^{i = 10, j = 4} {{f_{{{\rm{e}}_{ij}}}}/40} = 1.01\;{\rm{cm, }}\;{\mathit{S}_{\rm{d}}} = 2.39\;{\rm{cm}}. $ |

According to the data, the average elevation difference was improved significantly, and the rolling angle of the harvester was well controlled by this leveling system, thus the system greatly reduced the risk of structural fracture when harvesting. However, the elevation of land surface after balanced treatment was still a little fluctuating, which was caused by fluctuating surface in the moving direction. The next step is to measure the pitch angle of vehicle and the displacement of lifting cylinder in the whole suspension mechanism to estimate the elevation of the suspension and control this cylinder.

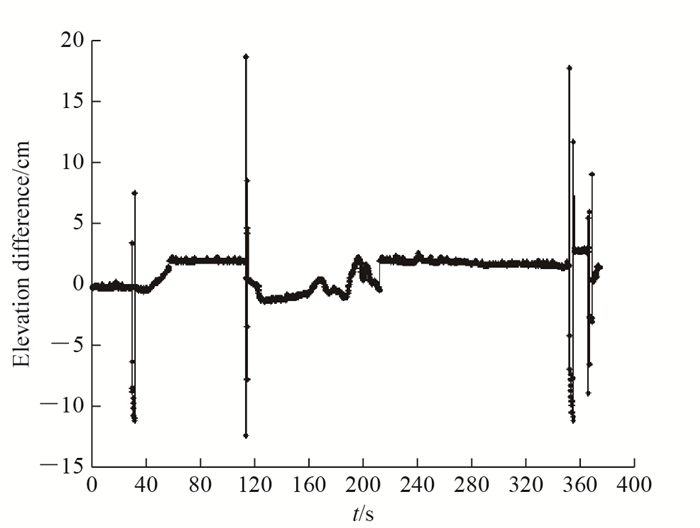

The PID algorithm used here only worked in the range of small elevation difference, which was set from-3 to 3 cm. When the difference was greater than 3 cm and less than 10 cm, the control output was 150 ms; and it was 200 ms when the difference was greater than 10 cm. Fig. 5 shows a curve of the elevation difference estimated by the system. In most cases, the fluctuation range of the elevation difference was less than 3 cm; but when the rolling angle of the vehicle was obviously large, the elevation difference might be 5-20 cm in a short time. However, it could be controlled back to the level state in 5-10 sampling periods, or 1-2 s.

|

| Fig. 5 Continuously estimated elevation difference |

During the field experiments, there were some cases out of control, which were caused by dust particles blocking the slide valve. After the slider was cleaned with diesel oil, the control system was restored. The hydraulic oil, obtained from hydraulic quick joint, was a kind of hydraulic transmission dual purpose oil. It might contain some dust after a long time use. Therefore, the cleanliness of oil is very important for the electromagnetic control system.

4 ConclusionsAn automated leveling control system was added to the three-point suspension mechanism of a tractor for harvesting O. japonicus. The conclusions can be drawn:

1) The rolling posture of the harvester was no longer a rigid body with the tractor. Regardless of the rolling motion of tractor, the harvester can remain horizontal. The average elevation difference of the left and right points reduced from 30.66 to 1.04 cm, and the standard deviation was reduced from 6.32 cm to 2.39 cm.

2) The control frequency of 5 Hz can meet the requirement of leveling control. The dual-antenna GPS receiver can reliably and accurately measure the rolling angle of the tractor.

3) Failure of connecting rod did not occur again in this harvest season.

If the system is to be used in an 8 m wide paddy rake machine, a PWM (pulse width modulation) module will be used to control the solenoid valve to achieve more precise control.

| [1] |

李庆, 罗锡文, 汪懋华, 等.采用倾角传感器的水田激光平地机设计.

农业工程学报,2007,23 (4):88–93.

LI Q, LUO X W, WANG M H, et al. Design of a laser land leveler for paddy field. Transaction of the CSAE, 2007,23 (4):88–93. (in Chinese with English abstract) DOI: 10.3321/j.issn:1002-6819.2007.04.017. |

| [2] |

胡炼, 林潮兴, 罗锡文, 等.农机具自动调平控制系统设计与试验.

农业工程学报,2015,31 (8):15–20.

HU L, LIN C X, LUO X W, et al. Design and experiment on auto leveling control system of agricultural implements. Transaction of the CSAE, 2015,31 (8):15–20. (in Chinese with English abstract) |

| [3] |

李革, 章铁成, 王益新. 前置式拖拉机悬挂机组水平自动控制装置: CN205179666U. 2016-02-24. LI G, ZHANG T C, WANG Y X. Automatic leveling control device for suspension unit of tractor: CN205179666U. 2016- 02-24. (in Chinese) |

| [4] |

魏新华, 邵菁, 缪丹丹, 等.喷杆式喷雾机喷杆高度及平衡在线调控系统.

农业机械化学报,2015,46 (8):66–71.

WEI X H, SHAO J, MIAO D D, et al. Online control system of spray boom height and balance. Transactions of the Chinese Society for Agricultural Machinery, 2015,46 (8):66–71. (in Chinese with English abstract) |

| [5] |

LU G, LACHAPELLE G, CANNON M E, et al. Attitude determination in a survey launch using multi-antenna GPS technology.

Proceedings of the 1993 National Technical Meeting of the Institute of Navigation, San Francisco, CA. [S. l.]:[s. n.], 1993 :251–259. |

| [6] |

HAYWARD R, MARCHICK A, POWELL J D, et al. Two antenna GPS attitude and integer ambiguity resolution for aircraft application.

Proceedings of the 1999 National Technical Meeting of the Institute of Navigation, San Diego, CA.[S. l.]:[s. n.], 1999 :155–164. |

| [7] |

胡晓清, 尚修香.采用双天线GPS/INS系统的汽车侧偏角和轮胎侧偏刚度估测法.

河北科技大学学报,2011,32 (1):92–97.

HU X Q, SHANG X X. Estimation of sideslip angle and tire cornering stiffness of vehicle with two-antenna GPS/INS measurement system. Journal of Hebei University of Science and Technology, 2011,32 (1):92–97. (in Chinese with English abstract) |

| [8] |

张建霞.基于GPS双天线测量的旋偏角自动纠正系统设计.

江南大学学报(自然科学版),2011,10 (2):188–191.

ZHANG J X. System design of auto-rectify of the yaw angle based on GPS surveying with double- antennas. Journal of Jiangnan University (Natural Science Edition), 2011,10 (2):188–191. (in Chinese with English abstract) DOI: 10.3969/j.issn.1671-7147.2011.02.013. |

| [9] |

阎肖鹏, 王海涛.基于两台双天线GPS测向单元的靶船测姿方法.

舰船电子工程,2012,32 (5):65–67.

YAN X P, WANG H T. Method of target ship's attitude determination based on double two-antenna GPS vector module. Ship Electronic Engineering, 2012,32 (5):65–67. (in Chinese with English abstract) DOI: 10.3969/j.issn.1627-9730.2012.05.023. |

| [10] |

丁传炳, 卞伟伟, 李海滨.基于GPS双天线的弹体姿态测量方法.

探测与控制学报,2017,39 (5):26–30.

DING C B, BIAN W W, LI H B. Missile attitude measurement method based on GPS double antenna. Journal of Detection and Control, 2017,39 (5):26–30. (in Chinese with English abstract) |

2018, Vol. 44

2018, Vol. 44