| 铸态共晶高熵合金的研究进展 |

对于高强度、高塑性、高熔点等优异性能材料的需求,推动了新材料的研发与制备。2004年叶均蔚教授和CANTOR教授分别提出了高熵合金的概念[1-2],区别于传统金属材料,高熵合金一般由4种以上合金元素作为主元素[3-11]。高熵合金多形成一种固溶体,单一FCC(face-centered cubic)固溶体虽然塑性高,但强度低;单一BCC(body-centered cubic)固溶体虽然强度高,但塑性差。同时,单一固溶体因流动性差而导致可铸造性差。直到2014年,大连理工大学卢一平教授等提出了共晶高熵合金(Eutectic high-entropy alloys, EHEAs)的概念,并设计出FCC与B2结构的AlCoCrFeNi2.1 EHEA[12]。EHEAs的铸造性能较好,并且在强度、塑性等力学性能的匹配上比单相高熵合金更有优势,使其工业应用前景更为广阔,引发了广泛的研究[13-22]。研究不同化学成分的EHEAs在铸态时的力学性能与微观组织的关系,是设计满足服役要求的EHEAs的重要依据。

本文调研了近年来关于EHEAs的相关文献,按化学元素组成和相组成进行了分类,即AlCoCrFeNi系、CoCrFeNi-M系和其他类别的EHEAs。从化学组成出发,探讨了微观组织的演化机制及其对力学性能的影响。最后,对EHEAs未来的发展趋势和前景进行了展望。

1 共晶高熵合金的化学成分、微观组织和力学性能EHEAs化学组成复杂,常见的组成元素有Co、Al、Cr、Fe、Ni、Mo、Ta和Hf等。其中,Co、Cr、Fe和Ni因混合焓几乎为零和原子半径相差不大而可以形成FCC结构的固溶体,而Al、Mo、Ta和Hf等与Cr/Fe/Ni之间具有较大的混合焓,并且它们原子半径相差较大,混合在一起容易促进BCC、HCP或Laves等相的形成。

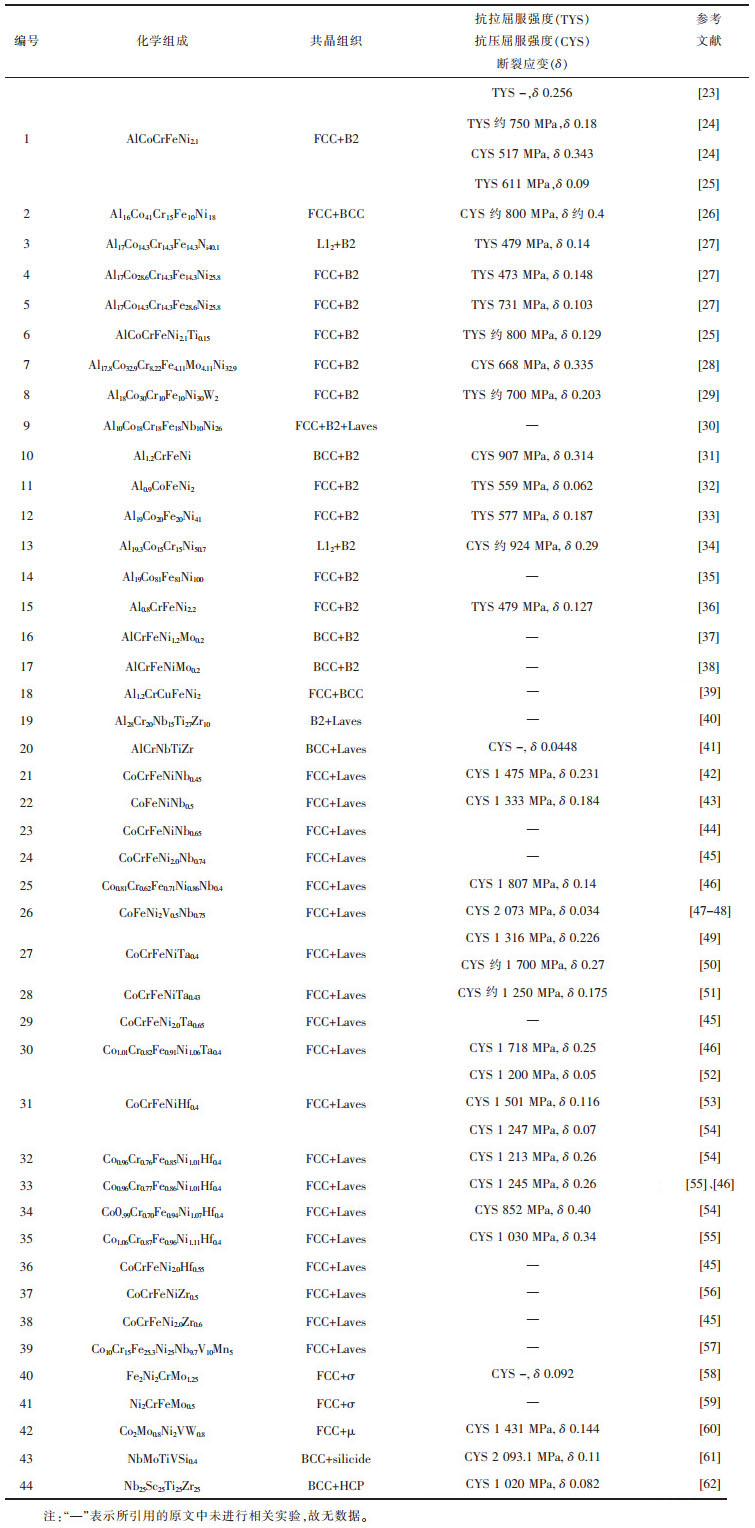

表 1列举出了近年来报道的EHEAs的化学成分、相组成和力学性能。可以看出,化学组成不同,导致共晶组织的相组成不同,进而使得力学性能也各不相同。如何通过设计化学成分来调控微观组织和优化力学性能,是当前研究的难点和热点。根据相组成的特点,将表 1中的EHEAs分为3类分别介绍,即主要由FCC相+B2/BCC相组成的AlCoCrFeNi系、主要由FCC相+Laves相组成的CoCrFeNi-M系(M=Hf、Ta、Nb等)和其他相组成的EHEAs。

| 表 1 铸态共晶高熵合金的微观组织和力学性能 Table 1 As-cast microstructures and mechanical properties of selected EHEAs |

|

| 点击放大 |

1.1 FCC+BCC AlCoCrFeNi系共晶高熵合金

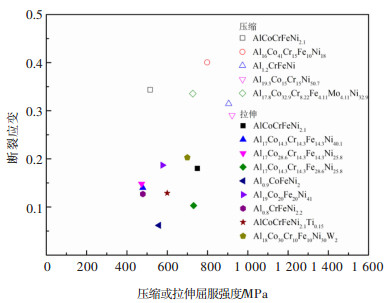

自2014年大连理工大学卢一平教授等提出AlCoCrFeNi2.1 EHEA以来,AlCoCrFeNi系EHEAs得到了最为广泛的研究[12]。通过改变Al、Co、Cr、Fe和Ni 5种元素的相对化学计量比,可以获得不同的共晶成分,如Al16Co41Cr15Fe10Ni18[26]、Al17Co14.3Cr14.3Fe14.3Ni40.1[27]、Al17Co28.6Cr14.3Fe14.3Ni25.8[27]和Al17Co14.3Cr14.3Fe28.6Ni25.8[27]等。同时,在共晶成分的基础上添加微量的过渡族元素,如Mo、W、Ti等,不仅可以保持原有的共晶组织,而且可以调整微观组织形态并改善力学性能。图 1所示为AlCoCrFeNi系的EHEAs的拉压屈服强度和断裂应变的关系图,可以看出,EHEAs的压缩屈服强度和断裂应变普遍比拉伸时高,其中Al18Co30Cr10Fe10Ni30W2具有较好的拉伸屈服强度和塑性的匹配,而Al16Co41Cr15Fe10Ni18具有较好的压缩屈服强度和塑性的匹配。

|

| 图 1 AlCoCrFeNi系EHEAs的拉压屈服强度和断裂应变关系 Fig. 1 The compressive or tensile yield stress as a function of fracture strain of AlCoCrFeNi EHEAs |

1.1.1 AlCoCrFeNi化学计量比的影响

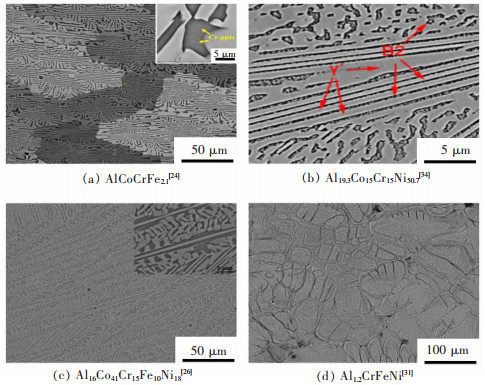

图 2(a)—图 2(d)所示依次为AlCoCrFeNi2.1[24]、Al19.3Co15Cr15Ni50.7[34]、Al16Co41Cr15Fe10Ni18[26]和Al1.2CrFeNi[31]EHEAs在扫描电子显微镜(scanning electron microscope,SEM)下的背散射电子图。如图 2(a)所示,AlCoCrFeNi2.1具有明显的层片状结构,且两相具有明显的对比度。通过透射电子显微镜(transmission electron microscope,TEM)和能谱仪(energy dispersive spectrometer,EDS)的分析,可知浅色区域为L12相(FCC结构,富含Co、Cr和Fe元素),深色区域为B2相(有序BCC结构,富含Al和Ni元素),其中FCC相占比约71%,B2相占比约29%[24],此外,CHEN等研究表明,在AlCoCrFeNi2.1的共晶组织中,FCC相与B2相形成严格的K-S位相关系,即{011}FCC//{111}B2,< 111 > FCC//< 011 > B2[25]。FCC相和B2相在强度和塑性上的互补,使其具有较好的强度和塑性匹配,拉伸时的屈服强度为750 MPa,伸长率为18%[24];压缩时的屈服强度为517 MPa,断裂应变为0.34[24]。此外,熊婷等通过多尺度地表征指出,AlCoCrFeNi2.1的两相中均存在纳米析出相[63],这也可能是其具有较好强塑性的原因。

|

| 图 2 4种EHEAs的SEM微观组织 Fig. 2 SEM microstructure of four EHEAs |

在AlCoCrFeNi2.1的基础上,减少Fe并增加Ni的含量同样可以获得共晶组织,如Al19.3Co15Cr15Ni50.7为FCC+B2的层片相间结构(图 2(b))。但由于Ni含量的增加,NiAl型的B2相比例大幅度提高,其体积分数达到了约90%;同时由于Fe的去除,FCC相的含量只有约10%。通过对比图 2(a)与图 2(b)可以发现,虽然两相的含量变化张大,但仍未改变共晶的形貌特点,却对力学性能影响较大,压缩时的屈服强度提高到924 MPa,而压缩应变减小至0.29[34]。

相比于增加Ni的含量,增加Co的含量对组织性能的影响大为不同。Al16Co41Cr15Fe10Ni18的组织形貌如图 2(c)所示,浅色区域依然为FCC相,而深色区域则由B2相转变为无序BCC相。由于Co含量较多,富含Co、Al、Fe的FCC相体积分数达到61%,而BCC相仅占39%。可能是由于两相的体积分数相差较少,导致其晶粒比AlCoCrFeNi2.1更为细小。从而使得强塑性均优于AlCoCrFeNi2.1,其压缩时的屈服强度约800 MPa,压缩应变约0.40[26]。

与图 2(c)正好相反,图 2(d)去除Co元素,制备了Al1.2CrFeNi EHEA。Co的缺失使得FCC相难以生成,取而代之的是FeCr型的无序BCC相,与AlNi型的B2相一起构成共晶组织。虽然BCC和B2相均为强度较高的脆性组织,但塑性并未有太大的损失,其压缩屈服强度达到907 MPa,压缩应变仍保持0.31[31]。相比于典型的片层状结构,Al1.2CrFeNi的组织不具有明显的方向性,BCC和B2较为随机的取向分布使得其在变形过程中受力均匀,不易导致应力集中,使其可以承受较大的变形。

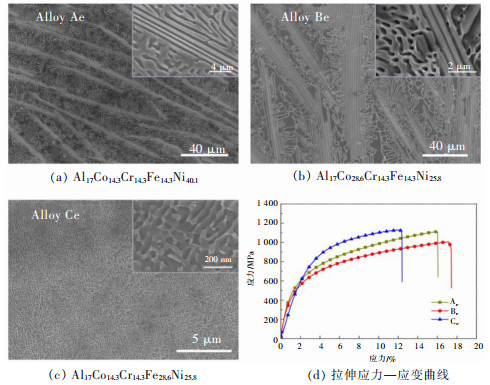

由此可见,改变Al、Co、Cr、Fe、Ni的比例可以改变相的结构、相的比例和组织形貌,进而影响到力学性能。如Al19.3Co15Cr15Ni50.7[34],Ni含量的增加可以使得NiAl型的B2相含量增加,导致强度提高和塑性下降。因此,通过设计不同成分的AlCoCrFeNi系EHEAs,对组织性能的调控具有重要意义。Jin等提出了伪二元法,利用价电子浓度(VEC)和混合焓(ΔHmix)来计算Al、Co、Cr、Fe、Ni这5种元素的配比,成功制备出3个由B2相和FCC相组成的EHEAs[27]。如图 3(a)— 图 3(c)所示,富Ni的Al17Co14.3Cr14.3Fe14.3Ni40.1和富Co的Al17Co28.6Cr14.3Fe14.3Ni25.8的微观组织具有明显的取向性,而富Fe的Al17Co14.3Cr14.3Fe28.6Ni25.8微观组织均匀。

|

| 图 3 伪二元法设计的EHEAs的微观组织和拉伸应力-应变曲线[27] Fig. 3 Microstructures and tensile stress-strain curves of EHEAs designed by pseudo-binary method[27] |

此外,WU等利用机器学习来设计AlCoCrFeNi系的共晶成分,设计制备的Ni30Co30Fe10Cr10Al18W2、Ni36Co24Fe10Cr10Al18W2和Ni40Co20Fe10Cr10Al18W2具有共晶组织的特点[64]。而张仰庆等通过去除Cr元素和改变Al的含量,制备得到Al0.95FeCoNi2.05同样具备共晶高熵合金的特点[65]。

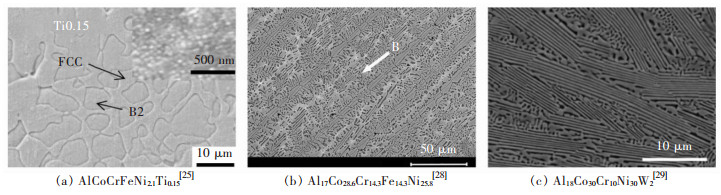

1.1.2 微量过渡族元素的影响除了Al、Co、Cr、Fe、Ni这5种基础元素外,过渡族元素如Ti[25]、Nb[30]、Mo[28]和W[29]等也被微量添加来调控共晶组织,从而改善力学性能。Ti的引入使得AlCoCrFeNi1.2Ti0.15 EHEA[25]的B2相和FCC相并非层片耦合生长,而是呈现出由FCC相近似连续地包围B2相的花瓣状形貌特点(图 4(a))。相比于AlCoCrFeNi1.2,AlCoCrFeNi1.2Ti0.15 EHEA的拉伸屈服强度可达到800 MPa,断裂应变达到0.129,均有所提高,这是由于组织形貌的变化和Ti固溶强化导致的。W和Mo的引入也会引起组织性能的变化,Al17.8(Co40Cr10Fe5Ni40Mo5)82.2 EHEA[28]和Al18Co30Cr10Fe10Ni30W2 EHEA[29],Mo和W的引入也没有改变原本FCC+B2的相组成,如图 4(b)—图 4(c)所示,但Mo的引入使原本层片状结构不再明显,而W的引入也使得原本层片状结构中多出一些不规则的共晶组织。Mo和W元素主要固溶于FCC软相中,引起晶格畸变,从而使得强度提高,而对塑性影响不大。

|

| 图 4 3种EHEAs的SEM微观组织 Fig. 4 SEM microstructures of three EHEAs |

由此可见,引入微量的过渡族金属元素,可以在保持共晶组织的前提下,对组织形貌起到一定的调控作用。微量元素的添加不会使强塑性发生特别大的变化,但可以牺牲较少的塑性使强度有较大的提升,甚至使得强度和塑性均有所改善。因此,选择恰当的、适量的过渡族元素进行添加,也是一种有效的调控EHEAs组织性能的方式。

1.2 FCC+Laves CoCrFeNi-M系共晶高熵合金在AlCoCrFeNi系共晶高熵合金的基础上,用另外一种金属元素M(M=Nb、Ta、Zr、Hf等IVB或VB族元素)取代Al的位置并控制其化学计量比,也可获得共晶组织,如CoCrFeNiNb0.45[43]、CoCrFeNiTa0.43[51]、CoCrFeNiHf0.4[52-54]和CoCrFeNiZr0.5[56]等。

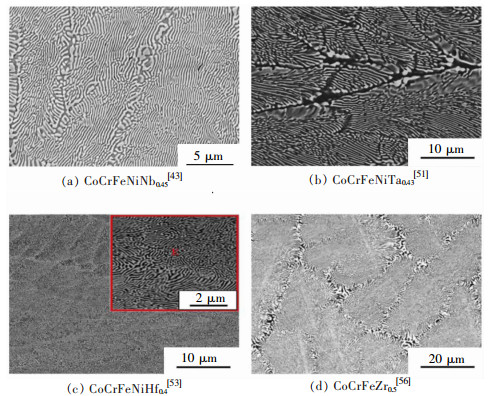

1.2.1 Nb、Ta、Hf、Zr的引入在Co、Cr、Fe和Ni相对化学计量比均为1的基础上,添加不同量的Nb、Ta、Hf和Zr,可以获得不同的EHEAs。如图 5所示,4种共晶组织均为典型的层片状结构,深色区域为FCC相(富含Cr和Fe),浅色区域为Laves相(富含Ni和Nb、Ta、Hf或Zr等)。Huo等指出,C14型的Laves相和FCC相的共格关系为[1210]Laves//[011]FCC[50],C15型的Laves相和FCC相的共格关系为(111)Laves//(111)FCC,[011]Laves//[211]FCC[56]。区别于AlCoCrFeNi2.1 FCC+B2的相组成,在Nb/Ta/Hf/Zr置换Al后, 虽然未改变层片状的形貌特点,但B2相被Laves相所取代。

|

| 图 5 CoCrFeNiM EHEAs的SEM微观组织 Fig. 5 SEM of CoCrFeNiM EHEAs |

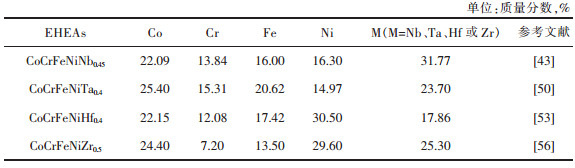

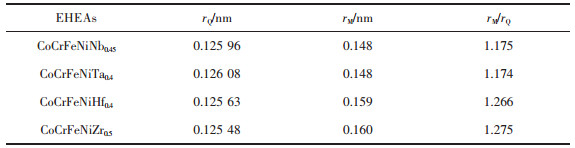

Nb、Ta、Hf、Zr的原子半径较大,分别为0.148、0.148、0.159、0.160 nm;与Ni的混合焓分别为-30、-29、-42、-49 kJ/mol。当加入Nb和Ta时,FCC相中富含Cr、Fe,同时也含有少量的Nb和Ta;当加入Hf和Zr时,FCC相中依然富含Cr、Fe,但几乎不存在Hf或者Zr元素[56]。这是由于Hf和Zr比Nb和Ta具有更大的混合焓,也使得Laves相主要由Ni和M(M=Nb、Ta、Hf或Zr)组成,如表 2所示,同时可以看出Co在FCC相和Lave相中具有较为均匀的分布。TSAI等指出CoCrFeNiM中金属间化合物的种类,主要与M的原子半径(rM)和Co、Cr、Fe、Ni原子的加权平均半径(rQ)的比值有关[66]。rQ按式(1)进行计算:

|

(1) |

| 表 2 共晶高熵合金中Laves相Co、Cr、Fe、Ni、M元素的占比 Table 2 Proportion of Co, Cr, Fe, Ni and M in Laves phase of different EHEAs |

|

| 点击放大 |

其中,ri为第i种原子的半径,xi为第i种元素所占比例。基于表 2的4种EHEAs中Laves相的化学成分,计算得到rQ和rM/rQ(表 3)。当M原子半径rM/rQ的比值大于1.156时,倾向于形成Laves C14、C15和C36相等;当比值小于1.156时,倾向于形成A15、μ和σ相等[66]。由表 3可以看出,rM/rQ比值均大于1.156,与观察到的Laves相一致,CoCrFeNiNb0.45和CoCrFeNiTa0.4的Laves相为C14型,CoCrFeNiHf0.4为C36型[53],CoCrFeNiZr0.5为C15型[66]。

| 表 3 共晶高熵合金中Laves相的rM与rQ比值 Table 3 The ratio of rM/rQ of Laves phase in different EHEAs |

|

| 点击放大 |

与由FCC+BCC组成的AlCoCrFeNi系EHEAs相比,由FCC+Laves相组成的CoCrFeNiM系(M=Nb、Ta、Hf和Zr)具有较高的压缩屈服强度和较低的塑性,这是由于Laves为脆性较大的金属间化合物导致的。CoCrFeNiNb0.45的压缩屈服强度为1 475 MPa,压缩应变为0.231[42];CoCrFeNiTa0.43的压缩屈服强度为1 250 MPa,压缩应变约0.24[51]。两者的压缩性能相近,这是由于两者的Laves相的晶格参数相似导致的。即,在CoCrFeNiNb0.65中,a=0.484 9 nm,c=0.790 7 nm[44];在CoCrFeNiTa0.43中,a=0.479 7 nm,c=0.782 7 nm[51]。这也说明了Ta和Nb在一定程度上具有可替代性。CoCrFeNiHf0.4 的压缩屈服强度可达1 501 MPa,比Nb和Ta更高,但压缩应变仅有0.116[53]。而CoCrFeNiZr0.5则由于脆性太大而无法进行拉伸试验[56]。

由此可见,M原子半径大小对EHEAs组成相的类型有重要的影响,因此,在一定程度上可以通过M原子与其他原子(Co、Cr、Fe、Ni)半径比的大小来判断CoCrFeNi-M系EHEAs在铸态下力学性质的好坏,如Nb、Ta最优,Hf次之,Zr最差。

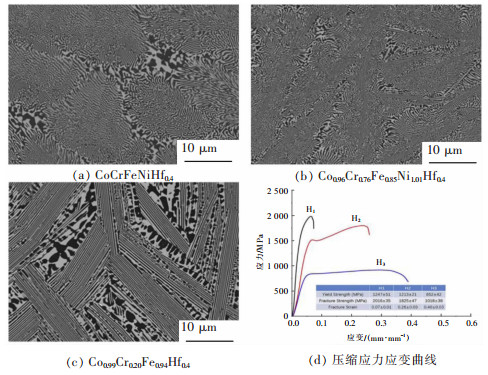

1.2.2 CoCrFeNi-M系共晶高熵合金的化学成分调节与AlCoCrFeNi系高熵合金一样,CoCrFeNiM系也可以通过调节化学成分,来获得不同的共晶点和微观组织。XIE等在引入Hf的基础上,通过改进的简单混合法来调控各主元化学计量比,成功制备了Co0.96Cr0.76Fe0.85Ni1.01Hf0.4和Co0.99Cr0.70Fe0.94Ni1.07Hf0.4 EHEAs[54]。由于化学成分的改变,使得微观组织和力学性能也得到了改变。如图 6(a)—图 6(c)所示,三者均为FCC相和Laves相构成的层片状结构,和CoCrFeNiHf0.4一致,这两种共晶成分下的FCC相富含Cr、Fe,Laves相富含Ni、Hf[52-54]。这主要受合金元素间的混合焓影响,而受化学计量比影响较小。CoCrFeNiHf0.4在多边形共晶团内部包含不规则片层,Co0.99Cr0.70Fe0.94Ni1.07Hf0.4由直片层构成,而Co0.96Cr0.76Fe0.85Ni1.01Hf0.4的共晶组织居于前两者之间。不同于CoCrFeNiHf0.4含有约30%(体积分数)的FCC相,Co0.96Cr0.76Fe0.85Ni1.01Hf0.4和Co0.99Cr0.70Fe0.94Ni1.07Hf0.4分别具有45.7%和55.8%(体积分数)的FCC相结构[54],这导致它们具有不同的力学性能。从图 6(d)中可以看出,Co0.96Cr0.76Fe0.85Ni1.01Hf0.4的压缩屈服强度为1 213 MPa,压缩应变为0.26[54],相比于CoCrFeNiHf0.4而言,强度变化不大,但塑性得到极大改善,这是由于微观结构的变化导致的。而Co0.99Cr0.70Fe0.94Ni1.07Hf0.4的压缩屈服强度仅为852 MPa,压缩应变却可达到0.40[54],这种强度严重下降而塑性显著升高的现象可能是由于其共晶组织中FCC相比例较大导致的。

|

| 图 6 3种EHEAs的微观组织和压缩应力-应变曲线[54] Fig. 6 Microstructures and compressive stress-strain curves of three EHEAs[54] |

由此可见,通过改变CoCrFeNiM系的化学成分相对含量,可以实现对FCC相和Laves相体积分数以及组织形貌特征的调控,进而改变力学性能。

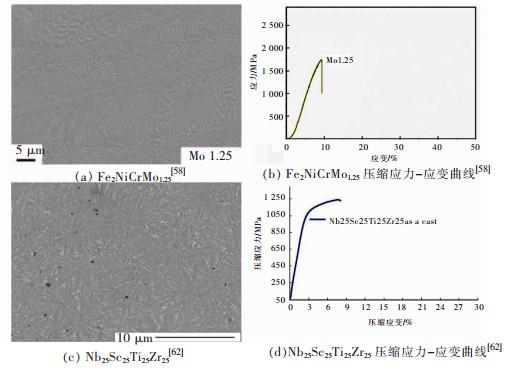

1.3 其他共晶高熵合金除了前述AlCoCrFeNi系和CoCrFeNiM(M=Nb、Ta、Hf、Zr等)系的EHEA被广泛研究外,JIAO等设计了FCC+σ相组成的Fe2Ni2CrMo1.25 EHEA[58],梁维中等设计出同样相组成的CrFeNiMo0.2 EHEA[67],而Rogal等设计了BCC+HCP相组成的Nb25Sc25Ti25Zr25 EHEA[62]。如图 7(a)所示,Fe2Ni2CrMo1.25具有细小的片层状结构,其中FCC相缺乏Mo元素,σ相(FeMo型)富含Mo元素,而Fe、Ni、Cr则按照化学计量数2∶2∶1分配在两相中[58],虽然Fe2Ni2CrMo1.25的共晶组织由塑性较好的FCC相和强度较高的σ相组成,但其整体的力学性能却不尽人意,其抗压极限仅为1 745 MPa,压缩应变也只有0.09[58],这可能是由于FCC相和σ相变形不协调导致的。如图 7(c)所示,Nb25Sc25Ti25Zr25不同于典型的层片状结构,并非两相协同生长,而是在成核位置向四周呈放射状生长,其中一相为HCP结构的α-(Sc,Zr)相,另一相为BCC结构的β-NbTiZr相(基体相)[62]。由于BCC相和HCP相可开动的滑移系较少,其屈服强度较高, 达到1 020 MPa,但断裂应变较低,仅有0.08[62]。

|

| 图 7 EHEAs的微观组织和压缩应力-应变曲线 Fig. 7 Microstructures and compressive stress-strain curves of EHEAs |

除上述共晶组织外,JIN等成功地设计了由FCC+B2+Laves三相组成的Al10Co18Cr18Fe18Nb10Ni26 EHEA[30],但遗憾的是文中并未提到其相关的力学性能特点;KIM等设计了双峰组织AlTa0.76CoCrFeNi2.1 EHEA,其中较粗的片层状共晶组织区域为B2和Laves相,较细的片层状共晶区域为FCC和Laves相[68]。虽然其他共晶组织报道较少,但是其力学性能特点和变形机理仍有待探究。

2 总结与展望EHEAs因化学成分的可调节使得组织形态多样化,从而导致力学性能的差异化,有望满足各种各样的工程化应用的要求。塑性较好的FCC相和强度较高的BCC/B2相构成的共晶组织具有较好的强塑性匹配,如Al、Co、Cr、Fe、Ni这5种主要元素所构成的一系列EHEAs。类似的,在Co、Cr、Fe、Ni的基础上添加一定量IVB或VB族元素,可以构造出由FCC相和硬质Laves相构成的共晶组织,也具有较好的强塑性匹配。通过改变共晶成分,或在共晶成分的基础上添加某种微量元素,可以调控EHEAs的微观组织和力学性能。因此,如何快速准确地设计EHEAs的成分亟待研究;进一步,各元素对微观组织的调控机理尚需明晰,微观组织对强塑性的影响规律也需要深入研究。最终,实现以特定力学性能为目标的EHEAs的成分设计。

| [1] |

YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J].

Advanced Engineering Materials, 2004, 6(5): 299–303. DOI: 10.1002/adem.200300567. |

| [2] |

CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys[J].

Materials Science and Engineering: A, 2004, 375/376/377: 213–218. |

| [3] |

HSU C Y, YEH J W, CHEN S K, et al. Wear resistance and high-temperature compression strength of Fcc CuCoNiCrAl0.5Fe alloy with boron addition[J].

Metallurgical and Materials Transactions A, 2004, 35(5): 1465–1469. DOI: 10.1007/s11661-004-0254-x. |

| [4] |

TONG C J, CEHN Y L, YEH J W, et al. Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements[J].

Metallurgical and Materials Transactions A, 2005, 36(4): 881–893. DOI: 10.1007/s11661-005-0283-0. |

| [5] |

SENKOV O N, SCOTT J M, SENKOVA S V, et al. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy[J].

Journal of Alloys and Compounds, 2011, 509(20): 6043–6048. DOI: 10.1016/j.jallcom.2011.02.171. |

| [6] |

MANZONI A, DAOUD H, VOLKL R, et al. Phase separation in equiatomic AlCoCrFeNi high-entropy alloy[J].

Ultramicroscopy, 2013, 132: 212–215. DOI: 10.1016/j.ultramic.2012.12.015. |

| [7] |

HE F, WANG Z, NIU S, et al. Strengthening the CoCrFeNiNb0.25 high entropy alloy by FCC precipitate[J].

Journal of Alloys and Compounds, 2016, 667: 53–57. DOI: 10.1016/j.jallcom.2016.01.153. |

| [8] |

HE F, WANG Z, SHANG X, et al. Stability of lamellar structures in CoCrFeNiNbx eutectic high entropy alloys at elevated temperatures[J].

Materials & Design, 2016, 104: 259–264. |

| [9] |

JIANG L, LU Y P, SONG M, et al. A promising CoFeNi2V0.5Mo0.2 high entropy alloy with exceptional ductility[J].

Scripta Materialia, 2019, 165: 128–133. DOI: 10.1016/j.scriptamat.2019.02.038. |

| [10] |

HUO W, FANG F, ZHOU H, et al. Remarkable strength of CoCrFeNi high-entropy alloy wires at cryogenic and elevated temperatures[J].

Scripta Materialia, 2017, 141: 125–128. DOI: 10.1016/j.scriptamat.2017.08.006. |

| [11] |

ZHU Z G, MA K H, WANG Q, et al. Compositional dependence of phase formation and mechanical properties in three CoCrFeNi-(Mn/Al/Cu) high entropy alloys[J].

Intermetallics, 2016, 79: 1–11. DOI: 10.1016/j.intermet.2016.09.003. |

| [12] |

LU Y P, DONG Y, JIANG H, et al. Promising properties and future trend of eutectic high entropy alloys[J].

Scripta Materialia, 2020, 187: 202–209. DOI: 10.1016/j.scriptamat.2020.06.022. |

| [13] |

CHOUDHURI D, JANNOTTI P A, MUSKERI S, et al. Ballistic response of a FCC-B2 eutectic AlCoCrFeNi2.1 high entropy alloy[J].

Journal of Dynamic Behavior of Materials, 2019, 5(4): 495–503. DOI: 10.1007/s40870-019-00220-z. |

| [14] |

WANI I S, BHATTACHARJEE T, SHEIKH S, et al. Tailoring nanostructures and mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy using thermo-mechanical processing[J].

Materials Science and Engineering: A, 2016, 675: 99–109. DOI: 10.1016/j.msea.2016.08.048. |

| [15] |

WANI I S, BHATTACHARJEE T, SHEIKH S, et al. Cold-rolling and recrystallization textures of a nano-lamellar AlCoCrFeNi2.1 eutectic high entropy alloy[J].

Intermetallics, 2017, 84: 42–51. DOI: 10.1016/j.intermet.2016.12.018. |

| [16] |

ZHANG L J, YU P F, FAN J T, et al. Investigating the micro and nanomechanical properties of CoCrFeNi-Cx high-entropy alloys containing eutectic carbides[J].

Materials Science and Engineering: A, 2020, 796: 140065. DOI: 10.1016/j.msea.2020.140065. |

| [17] |

VO T D, TRAN B, TIEU A K, et al. Effects of oxidation on friction and wear properties of eutectic high-entropy alloy AlCoCrFeNi2.1[J].

Tribology International, 2021, 160: 107017. DOI: 10.1016/j.triboint.2021.107017. |

| [18] |

GAO X, LU Y, ZHANG B, et al. Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy[J].

Acta Materialia, 2017, 141: 59–66. DOI: 10.1016/j.actamat.2017.07.041. |

| [19] |

WANG Y, CHEN W, ZHANG J, et al. A quantitative understanding on the mechanical behavior of AlCoCrFeNi2.1 eutectic high-entropy alloy[J].

Journal of Alloys and Compounds, 2021, 850: 156610. DOI: 10.1016/j.jallcom.2020.156610. |

| [20] |

郭娜娜, 高绪杰, 李肖逸, 等. 共晶高熵合金的研究进展[J].

稀有金属, 2021, 45(6): 728–739.

|

| [21] |

李肖逸, 高绪杰, 史程程, 等. 共晶高熵合金研究进展[J].

特种铸造及有色合金, 2021, 41(1): 32–37.

|

| [22] |

杨恬, 许军锋, 李卓. 高强韧共晶高熵合金的研究进展[J].

金属热处理, 2021, 46(2): 1–7.

|

| [23] |

LU Y P, DONG Y, GUO S, et al. A Promising new class of high-temperature alloys: eutectic high-entropy alloys[J].

Scientific Reports, 2014, 4(1): 6200. |

| [24] |

MUSKERI S, HASANNAEIMI V, SALLOOM R, et al. Small-scale mechanical behavior of a eutectic high entropy alloy[J].

Scientific Reports, 2020, 10(1): 2669. DOI: 10.1038/s41598-020-59513-2. |

| [25] |

CHEN X H, XIE W Y, ZHU J, et al. Influences of Ti additions on the microstructure and tensile properties of AlCoCrFeNi2.1 eutectic high entropy alloy[J].

Intermetallics, 2021, 128: 107024. DOI: 10.1016/j.intermet.2020.107024. |

| [26] |

SHAFIEI A, RAJABI S. A cobalt-rich eutectic high-entropy alloy in the system Al-Co-Cr-Fe-Ni[J].

Applied Physics A, 2019, 125(11): 783. DOI: 10.1007/s00339-019-3084-9. |

| [27] |

JIN X, ZHOU Y, ZHANG L, et al. A new pseudo binary strategy to design eutectic high entropy alloys using mixing enthalpy and valence electron concentration[J].

Materials & design, 2018, 143: 49–55. |

| [28] |

GASAN H, OZCAN A. New eutectic high-entropy alloys based on Co-Cr-Fe-Mo-Ni-Al: design, characterization and mechanical properties[J].

Metals and Materials International, 2020, 26(8): 1152–1167. DOI: 10.1007/s12540-019-00515-9. |

| [29] |

WU Q F, WANG Z J, ZHENG T, et al. A casting eutectic high entropy alloy with superior strength-ductility combination[J].

Materials Letters, 2019, 253: 268–271. DOI: 10.1016/j.matlet.2019.06.067. |

| [30] |

JIN X, BI J, LIANG Y X, et al. Triple-phase eutectic high-entropy alloy: Al10Co18Cr18Fe18Nb10Ni26[J].

Metallurgical and Materials Transactions A, 2021, 52(4): 1314–1320. DOI: 10.1007/s11661-021-06165-0. |

| [31] |

CHEN X, QI J Q, SUI Y W, et al. Effects of aluminum on microstructure and compressive properties of Al-Cr-Fe-Ni eutectic multi-component alloys[J].

Materials Science and Engineering: A, 2017, 681: 25–31. DOI: 10.1016/j.msea.2016.11.019. |

| [32] |

JIANG H, QIAO D, JIAO W, et al. Tensile deformation behavior and mechanical properties of a bulk cast Al0.9CoFeNi2 eutectic high-entropy alloy[J].

Journal of Materials Science & Technology, 2020, 61: 119–124. |

| [33] |

JIN X, ZHOU Y, ZHANG L, et al. A novel Fe20Co20Ni41Al19 eutectic high entropy alloy with excellent tensile properties[J].

Materials Letters, 2018, 216: 144–146. DOI: 10.1016/j.matlet.2018.01.017. |

| [34] |

LIU D J, YU P F, LI G, et al. High-temperature high-entropy alloys AlxCo15Cr15Ni70-x based on the Al-Ni binary system[J].

Materials Science and Engineering: A, 2018, 724: 283–288. DOI: 10.1016/j.msea.2018.03.058. |

| [35] |

ZHANG X K, CHOU T H, LI W P, et al. Microstructure and mechanical properties of (FeCoNi)100-x(NiAl)x eutectic multi-principal element alloys[J].

Journal of Alloys and Compounds, 2021, 862: 158349. DOI: 10.1016/j.jallcom.2020.158349. |

| [36] |

JIN X, BI J, ZHANG L, et al. A new CrFeNi2Al eutectic high entropy alloy system with excellent mechanical properties[J].

Journal of Alloys and Compounds, 2019, 770: 655–661. DOI: 10.1016/j.jallcom.2018.08.176. |

| [37] |

DONG Y, QIAO D, ZHANG H, et al. Microstructure evolution and hardness of AlCrFeNixMo0.2 high entropy alloy[J].

Materials Sience Forum, 2016, 849: 40–44. DOI: 10.4028/www.scientific.net/MSF.849.40. |

| [38] |

DONG Y, JIANG L, JIANG H, et al. Effects of annealing treatment on microstructure and hardness of bulk AlCrFeNiMo0.2 eutectic high-entropy alloy[J].

Materials & Design, 2015, 82: 91–97. |

| [39] |

GUO S, NG C, LIU C T. Anomalous solidification microstructures in Co-free AlxCrCuFeNi2 high-entropy alloys[J].

Journal of Alloys and Compounds, 2013, 557: 77–81. DOI: 10.1016/j.jallcom.2013.01.007. |

| [40] |

YURCHENKO N, PANINA E, ZHEREBTSOV S, et al. Design and characterization of eutectic refractory high entropy alloys[J].

Materialia, 2021, 16: 101057. DOI: 10.1016/j.mtla.2021.101057. |

| [41] |

ZHU M, YAO L J, LIU Y Q, et al. Microstructure evolution and mechanical properties of a novel CrNbTiZrAlx(0.25≤x≤1.25) eutectic refractory high-entropy alloy[J].

Materials Letters, 2020, 272: 127869. DOI: 10.1016/j.matlet.2020.127869. |

| [42] |

LU J L, WANG Z J, WANG W, et al. Superior slurry erosion behavior of a casting NiCoCrFeNb0.45 eutectic high entropy alloy[J].

Acta Metallurgica Sinica (English Letters), 2020, 33(8): 1111–1116. DOI: 10.1007/s40195-020-01070-8. |

| [43] |

JIANG H, JIANG L, QIAO D, et al. Effect of Niobium on microstructure and properties of the CoCrFeNbxNi high entropy alloys[J].

Journal of Materials Science & Technology, 2017, 33(7): 712–717. |

| [44] |

HE F, WANG Z J, CHENG P, et al. Designing eutectic high entropy alloys of CoCrFeNiNbx[J].

Journal of Alloys and Compounds, 2016, 656: 284–289. DOI: 10.1016/j.jallcom.2015.09.153. |

| [45] |

JIANG H, HAN K, GAO X, et al. A new strategy to design eutectic high-entropy alloys using simple mixture method[J].

Materials & Design, 2018, 142: 101–105. |

| [46] |

XIE T B, XIONG Z P, XU Z Q, et al. Another eutectic point of Co-Cr-Fe-Ni-M (Hf, Ta, Nb) high-entropy system determined using a simple mixture method correlated with mixing enthalpy[J].

Materials Science and Engineering: A, 2021, 802: 140634. DOI: 10.1016/j.msea.2020.140634. |

| [47] |

JIANG L, LU Y P, DONG Y, et al. Effects of Nb addition on structural evolution and properties of the CoFeNiV high-entropy alloy[J].

Applied Physics A: Materials Science & Processing, 2015, 119(1): 291–297. DOI: 10.1007/s00339-014-8964-4. |

| [48] |

JIANG L, LU Y P, WU W, et al. Microstructure and mechanical properties of a CoFeNi2V0.5Nb0.75 eutectic high entropy alloy in as-cast and heat-treated conditions[J].

Journal of Materials Science & Technology, 2016, 32(3): 245–250. |

| [49] |

JIANG H, HAN K M, QIAO D X, et al. Effects of Ta addition on the microstructures and mechanical properties of CoCrFeNi high entropy alloy[J].

Materials Chemistry and Physics, 2018, 210: 43–48. DOI: 10.1016/j.matchemphys.2017.05.056. |

| [50] |

HUO W Y, ZHOU H, FANG F, et al. Microstructure and properties of novel CoCrFeNiTax eutectic high-entropy alloys[J].

Journal of Alloys and Compounds, 2018, 735: 897–904. DOI: 10.1016/j.jallcom.2017.11.075. |

| [51] |

AI C, HE F, GUO M, et al. Alloy design, micromechanical and macromechanical properties of CoCrFeNiTax eutectic high entropy alloys[J].

Journal of Alloys and Compounds, 2018, 735: 2653–2662. DOI: 10.1016/j.jallcom.2017.12.015. |

| [52] |

XU Z Q, MA Z L, XIA G H, et al. Microstructures and mechanical properties of CoCrFeNiHfx high-entropy alloys[J].

Materials Science and Engineering: A, 2020, 792: 139820. DOI: 10.1016/j.msea.2020.139820. |

| [53] |

MA H, SHEK C H. Effects of Hf on the microstructure and mechanical properties of CoCrFeNi high entropy alloy[J].

Journal of Alloys and Compounds, 2020, 827: 154159. DOI: 10.1016/j.jallcom.2020.154159. |

| [54] |

XIE T B, XIONG Z P, XU Z Q, et al. Varying the eutectic composition of Co-Cr-Fe-Ni-Hf high-entropy system using a modified simple mixture method[J].

Materials Science and Engineering: A, 2020, 786: 139420. DOI: 10.1016/j.msea.2020.139420. |

| [55] |

XIE T B, XIONG Z P, LIU Z, et al. Excellent combination of compressive strength and ductility of (CoCrFeNi)x(Co0.26Cr0.07Fe0.16Ni0.31Hf0.4) high-entropy alloys[J].

Materials & Design, 2021, 202: 109569. |

| [56] |

HUO W Y, ZHOU H, FANG F, et al. Microstructure and mechanical properties of CoCrFeNiZrx eutectic high-entropy alloys[J].

Materials & Design, 2017, 134: 226–233. |

| [57] |

RAHUL M R, PHANIKUMAR G. Design of a seven-component eutectic high-entropy Alloy[J].

Metallurgical and Materials Transactions A, 2019, 50(6): 2594–2598. DOI: 10.1007/s11661-019-05210-3. |

| [58] |

JIAO W N, JIANG H, QIAO D X, et al. Effects of Mo on microstructure and mechanical properties of Fe2Ni2CrMox eutectic high entropy alloys[J].

Materials Chemistry and Physics, 2021, 260: 124175. DOI: 10.1016/j.matchemphys.2020.124175. |

| [59] |

HE F, WANG Z J, ZHU M, et al. The phase stability of Ni2CrFeMox multi-principal-component alloys with medium configurational entropy[J].

Materials & Design, 2015, 85: 1–6. |

| [60] |

JIANG H, ZHANG H Z, HUANG T D, et al. Microstructures and mechanical properties of Co2MoxNi2VWx eutectic high entropy alloys[J].

Materials & Design, 2016, 109: 539–546. |

| [61] |

XU Q, CHEN D Z, TAN C Y, et al. NbMoTiVSix refractory high entropy alloys strengthened by forming BCC phase and silicide eutectic structure[J].

Journal of Materials Science & Technology, 2021, 60: 1–7. |

| [62] |

ROGAL Ł, MORGIEL J, SWIATEK Z, et al. Microstructure and mechanical properties of the new Nb25Sc25Ti25Zr25 eutectic high entropy alloy[J].

Materials Science and Engineering: A, 2016, 651: 590–597. DOI: 10.1016/j.msea.2015.10.071. |

| [63] |

熊婷, 郑士建, 马秀良. 高熵合金AlCoCrFeNi2.1的共晶组织及析出相研究[J].

电子显微学报, 2020, 39(5): 470–475.

DOI: 10.3969/j.issn.1000-6281.2020.05.003.

|

| [64] |

WU Q F, WANG Z J, HU X B, et al. Uncovering the eutectics design by machine learning in the Al-Co-Cr-Fe-Ni high entropy system[J].

Acta Materialia, 2020, 182: 278–286. DOI: 10.1016/j.actamat.2019.10.043. |

| [65] |

张仰庆, 要玉宏, 侯永昌. AlxFeCoNi2.05近共晶高熵合金组织和力学性能研究[J].

西安工业大学学报, 2020, 40(1): 88–94.

|

| [66] |

TSAI M H, FAN A C, WANG H A. Effect of atomic size difference on the type of major intermetallic phase in arc-melted CoCrFeNiX high-entropy alloys[J].

Journal of Alloys and Compounds, 2017, 695: 1479–1487. DOI: 10.1016/j.jallcom.2016.10.286. |

| [67] |

梁维中, 吴万东, 陈永生, 等. 铌对铸态CrFeNiMo0.2Nbx共晶高熵合金微观组织的影响[J].

黑龙江科技大学学报, 2021, 31(3): 373–377.

DOI: 10.3969/j.issn.2095-7262.2021.03.018.

|

| [68] |

KIM M J, KANG G C, HONG S H, et al. Understanding microstructure and mechanical properties of (AlTa0.76)xCoCrFeNi2.1 eutectic high entropy alloys via thermo-physical parameters[J].

Journal of Materials Science & Technology, 2020, 57: 131–137. |

2022, Vol. 13

2022, Vol. 13