| 晶界扩散Dy60Co35Ga5合金对烧结钕铁硼磁体磁性能及热稳定性的影响 |

b. 江西理工大学,江西省稀土磁性材料及器件重点实验室,江西 赣州 341000

b. Jiangxi Key Laboratory for Rare Earth Magnetic Materials and Devices (IREMMD), Jiangxi University of Science and Technology, Ganzhou 341000, China

自1983年烧结钕铁硼磁体问世后,由于其具有优异的磁性能被称为“磁王”,因此广泛运用于传感器、音响、节能电梯等领域[1-2].尽管如此,烧结钕铁硼磁体相对较低的矫顽力和温度稳定性限制了其在某些特殊环境下的应用,包括混合动力汽车、伺服电机和风力发电机等方面[3].因此,寻求高矫顽力、高热稳定性的烧结钕铁硼磁体迫在眉睫.烧结钕铁硼磁体主要由Nd2Fe14B主相和富Nd相组成,Nd2Fe14B主相主导了磁体的内禀磁性能.此外,晶界处的富Nd相主要在液相烧结过程中隔离相邻的主相晶粒,从而来提高磁体的内禀矫顽力.烧结钕铁硼磁体的矫顽力通常通过在熔化过程中添加Dy或Tb元素来提高,因为Dy2Fe14B和Tb2Fe14B的磁晶各向异性场要比Nd2Fe14B高[4].然而,由于Dy原子和Tb原子会与Fe原子发生反铁磁耦合,剩磁将不可避免地降低[5-7].据文献[8-11]表明,在Nd2Fe14B主合金粉中加入Dy2O3,DyF3,DyHx辅合金粉,可以在保持剩磁基本不降低的情况下提高烧结钕铁硼磁体矫顽力.但是,烧结后却难以除去磁体中残留的氢,氧和氟元素.另据文献[12-18]报道,通过掺杂Cu、Al、Ga、Nb、Zr、Ni等元素可以提高磁体的磁性能,特别是元素Ga在磁体中能够以Nd2Fe14-XGaXB及GaNd的形式存在,在烧结过程中增加磁体液相的体积分数,起到助烧结的作用,增加磁体的密度,有利于矫顽力的提高.为了提高烧结钕铁硼磁体在高温环境下的稳定性,Matsuura和Tokunage等[19-20]在实验中用Co原子部分取代Fe原子来提高烧结钕铁硼磁体2:14:1主相的居里温度,从而提高磁体的使用温度.传统的单合金法及双合金法都会使得添加的非磁性元素进入主相,减少主相的体积分数,导致剩磁大幅度下降.而晶界扩散技术可以在保证磁体剩磁基本不降低的基础上,有效提高磁体的矫顽力.

在本次实验中,选择价格相对低廉的Co元素和Ga元素来部分替代Dy元素,熔合成成分为Dy60Co35Ga5的合金薄带作为扩散源来替代传统的,成本相对较高的Dy2O3、DyF3、DyHx粉末及Dy单质进行晶界扩散来提高磁体的磁性能和热稳定性,并对磁体的微观结构变化、磁性能和热稳定性增强原因进行分析.值得一提的是,此方法为降成本的同时实现工业化批量生产提供了可能.

1 实验方法本实验运用电弧熔炼的方法将成分Dy60Co35Ga5(at %,指原子数百分含量)反复熔炼4~5遍成合金铸锭,确保铸锭的均匀性.再在高真空快淬甩带设备中以8 m/s的速度将铸锭甩成宽为10 mm,厚约0.1 mm的快淬带.用400 #、800 #、1 000 #、1 500 #、2 000 #的砂纸将磁体上下表面打磨干净,然后将裁剪规整后的快淬带分别贴敷于名义成分为(PrNd)29..5Dy0.3FebalCo0.6Cu0.1Al0.15Zr0.18Ga0.2B0.98(wt %,指质量分数),尺寸为10 mm×10 mm×5 mm,牌号为50M的烧结钕铁硼磁体的上表面和下表面,随后将其放置在刚玉坩埚中,并在卧式高真空烧结炉中以840~940 ℃扩散3 h,480 ℃回火5 h的工艺进行热处理.使用NIM-500C高温永磁测量仪测试磁体在常温及高温下的磁性能,MLA650F型扫描电子显微镜观察样品扩散前后微观组织形貌变化,(DSC250,TA)型差示扫描量热仪测试样品的Tc,采用提拉法在亥姆霍兹线圈中测试磁体在不同温度下保温2 h的不可逆磁通损失,并使用CuKα射线通过XRD表征磁体的相结构衍射峰变化.

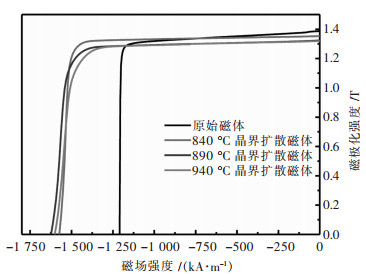

2 结果与讨论 2.1 晶界扩散Dy60Co35Ga5合金对磁体磁性能及微观组织形貌的影响图 1所示为原始磁体及不同温度晶界扩散Dy60Co35Ga5合金磁体在室温下的退磁曲线,从图 1可以明显看出,随着扩散温度升高,磁体的矫顽力呈现出先增加后减少的趋势,并在890 ℃扩散3 h,480 ℃回火5 h的工艺条件下,矫顽力达到较优,从1 209 kA/m提高到1 624 kA/m,而剩磁只有轻微的下降,从1.38 T降到1.32 T.进一步把扩散温度提高到940 ℃,磁体的矫顽力有所下降,可能是由于温度过高,晶粒长大,磁体的微观结构遭到破坏所致.因此,在890 ℃下晶界扩散Dy60Co35Ga5合金可以在保证磁体剩磁基本不降低的情况下,大幅度提高磁体的矫顽力.

|

| 图 1 原始磁体及不同温度晶界扩散Dy60Co35Ga5合金磁体在室温下的退磁曲线 Fig. 1 Demagnetization curves of original magnet and different temperature grain boundary diffusion Dy60Co35Ga5 alloy magnet at room temperature |

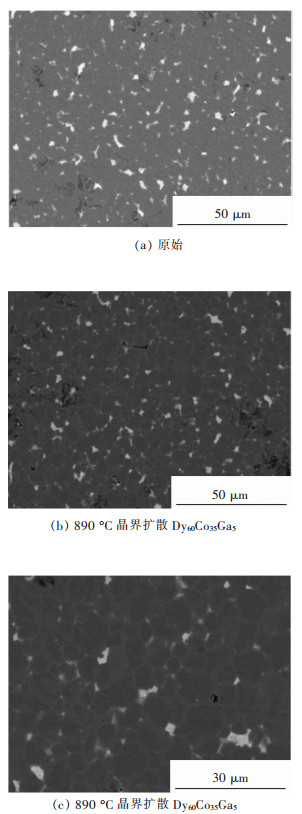

为了探究磁体矫顽力提升的原因,原始磁体和890 ℃晶界扩散Dy60Co35Ga5合金磁体SEM背散射下的微观组织形貌如图 2所示.其中图 2(a)、图 2(b)分别为原始磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体的微观组织形貌,图 2(c)为890 ℃晶界扩散Dy60Co35Ga5合金磁体的微观组织形貌.其中白色区域对应烧结钕铁硼的富Nd相,黑色区域对应烧结钕铁硼的2:14:1主相.从图 2(a)、图 2(b)中可以清楚的看出,原始磁体的富Nd相主要呈块状分布在磁体的三角交隅处,这种组织对磁体的性能是不利的.而890 ℃晶界扩散Dy60Co35Ga5合金磁体的富Nd相呈薄状连续、均匀、光滑地分布在磁体的晶界处,将相邻的主相晶粒隔开,达到去磁耦合作用,从而提升磁体的矫顽力. 图 2(c)中可进一步观察到在主相晶粒的外延层有介于白色和黑色之间的灰色区域.据文献[21]报道,灰色区域为(Nd,Dy)2Fe14B核壳结构,其磁晶各向异性场(HA)要高于Nd2Fe14B的磁晶各向异性场,可以有效抑制反磁化畴的形核,进而提升矫顽力.因此,晶界相的结构优化及磁晶各向异性场的提高是Dy60Co35Ga5合金扩散磁体矫顽力大幅度提升的主要原因.

|

| 图 2 烧结钕铁硼磁体SEM背散射微观组织 Fig. 2 Back-scattered SEM micrographs of sintered NdFeB magnet |

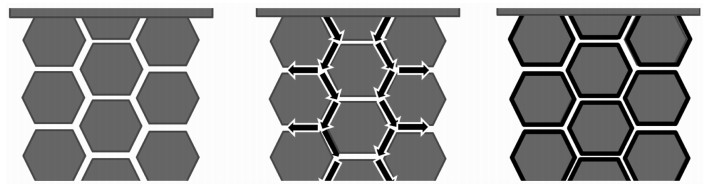

图 3所示为晶界扩散Dy60Co35Ga5合金在磁体矫顽力升高中起到的作用示意图,浅色正多面体代表Nd2Fe14B晶粒,黑色箭头代表Dy元素在扩散过程中的走向,黑色正多边形为(Nd,Dy)2Fe14B核壳结构.在磁体的表面贴敷成分为Dy60Co35Ga5的合金薄带,在890 ℃扩散温度下,合金薄带已经熔化成液态.而此时由于共晶反应,富Nd相也为液态,均匀分布在磁体的晶界处,这为Dy60Co35Ga5合金能够扩散进磁体内部打开了通道.随着保温时间的延长,越来越多的合金元素沿晶界进入到磁体的内部,由于Dy2Fe14B的生成焓要比Nd2Fe14B的生成焓更低,所以Dy元素会和Nd2Fe14B中的Nd元素发生置换反应,从而在主相晶粒的外延层形成(Nd,Dy)2Fe14B核壳结构,提高主相晶粒的磁晶各向异性场,抑制反磁化畴的形核,提高矫顽力.而Co元素和Ga元素同样会扩散进磁体的晶界处,达到修饰晶界缺陷以及细化晶粒的效果.再者,少部分的Co元素也会取代Nd2Fe14B中的Fe元素,对磁体居里温度升高具有重要作用.

|

| 图 3 烧结钕铁硼磁体晶界扩散Dy60Co35Ga5合金示意 Fig. 3 Schematic diagram of grain boundary diffusion Dy60Co35Ga5 alloy of sintered NdFeB magnet |

2.2 晶界扩散Dy60Co35Ga5合金对磁体热稳定性的影响

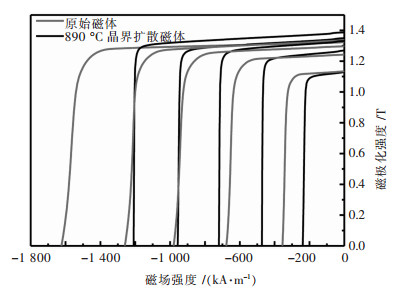

原始烧结钕铁硼磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体在20 ℃、50 ℃、80 ℃、120 ℃、180 ℃下分别保温5 min的退磁曲线如图 4所示.从图 4中可以看出,随着温度升高,不管是原始磁体还是晶界扩散Dy60Co35Ga5合金磁体的矫顽力都呈现出不断下降的趋势,但在同一温度,晶界扩散Dy60Co35Ga5合金磁体的矫顽力要明显高于原始磁体的矫顽力.因此,晶界扩散Dy60Co35Ga5合金可以有效提高磁体的热稳定性.

|

| 图 4 原始磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体在20 ℃、50 ℃、80 ℃、120 ℃、180 ℃下的退磁曲线 Fig. 4 Demagnetization curves of original magnet and 890 ℃ grain boundary diffusion Dy60Co35Ga5 alloy magnet at 20 ℃、50 ℃、80 ℃、120 ℃、180 ℃ |

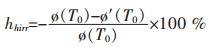

根据不可逆磁通损失公式[22]:

|

(1) |

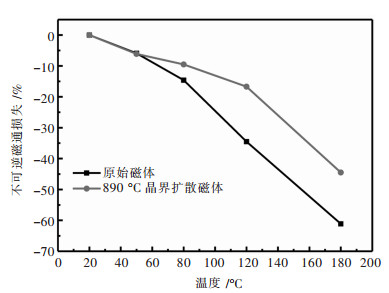

其中Φ(T0)为室温下的不可逆磁通损失,Φ′(T0)为环境温度下的不可逆磁通损失,并采用提拉法在亥姆霍兹线圈中测试原始磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体在20 ℃、50 ℃、80 ℃、120 ℃、180 ℃下分别保温2 h的不可逆磁通损失如图 5所示,在50 ℃左右,原始磁体及晶界扩散磁体的不可逆磁通损失几乎保持一致.随着温度升高,原始磁体的不可逆磁通损失幅度要远远高于晶界扩散磁体的不可逆磁通损失.当温度升高到180 ℃,原始磁体的不可逆磁通损失为63 %,而晶界扩散Dy60Co35Ga5合金磁体的不可逆磁通损失仅为45 %,远低于原始磁体.因此,晶界扩散Dy60Co35Ga5合金可以有效降低磁体的不可逆磁通损失,从而改善磁体的热稳定性.

|

| 图 5 原始磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体在20 ℃、50 ℃、80 ℃、120 ℃、180 ℃分别保温2 h的不可逆磁通损失 Fig. 5 Irreversible flux loss of original magnet and 890 ℃ grain boundary diffusion Dy60Co35Ga5 alloy magnet at 20 ℃、50 ℃、80 ℃、120 ℃、180 ℃ |

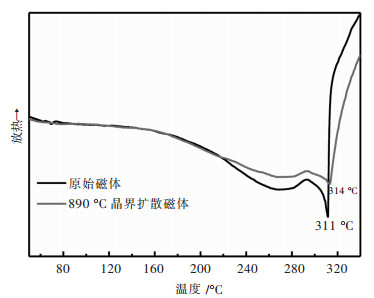

为了研究890 ℃晶界扩散Dy60Co35Ga5合金对磁体居里温度的影响,使用差示扫描量热仪来测试原始磁体及晶界扩散Dy60Co35Ga5合金磁体的DSC曲线,升温速率为10 ℃/min.如图 6所示,随着温度从20 ℃上升至311 ℃以及314 ℃的时候,DSC曲线出现了2个明显的吸热峰,这是由于原始磁体及晶界扩散Dy60Co35Ga5合金磁体从铁磁性转变为顺磁性需要更高的能量所致,这表明原始磁体的居里温度为311 ℃,而晶界扩散Dy60Co35Ga5合金磁体的居里温度为314 ℃.根据文献[23]报道,Co原子更加倾向于占据钕铁硼化合物的8j1晶位.这是因为Fe原子间距在8j1及8j2晶位间的间距比较小,8j1-8j2原子对的交换作用为负.由于Co原子占据了8j1晶位,有效降低了负的交换作用.因此,晶界扩散Dy60Co35Ga5合金磁体的居里温度得到有效提高.而居里温度的提高同样说明磁体的热稳定性得到了增强.

|

| 图 6 原始磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体的DSC曲线 Fig. 6 DSC curves of original magnet and 890 ℃ grain boundary diffusion Dy60Co35Ga5 alloy magnet |

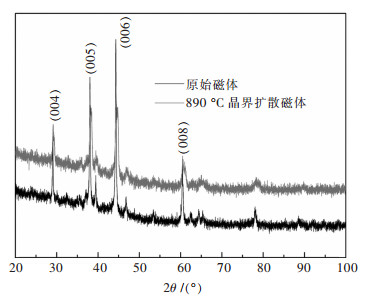

图 7所示为原始磁体及890 ℃晶界扩散Dy60Co35Ga5合金磁体的XRD图谱.衍射峰显示,原始磁体和晶界扩散Dy60Co35Ga5合金磁体2:14:1相是样品的主要相,没有检测到其它峰.晶界扩散磁体RE2Fe14B相的衍射峰相比较与原始磁体来说,略微向高2θ方向移动,表明2:14:1主相单胞的晶格参数发生变化.这种变化可能是由于少部分的Dy原子取代了2:14:1主相中的Nd原子导致的,因为在室温下,Nd2Fe14B化合物的晶格常数要比Dy2Fe14B化合物的晶格常数要大.也有可能是由于Co原子扩散进入基体相导致的[24].

|

| 图 7 原始磁体及890 ℃晶界扩散Dy60Co35Ga5磁体的XRD图谱 Fig. 7 XRD patterns of original magnets and 890 ℃ grain boundary diffusion Dy60Co35Ga5 magnets |

3 结论

通过烧结钕铁硼磁体晶界扩散Dy60Co35Ga5合金,得出以下结论:

1)烧结钕铁硼磁体晶界扩散Dy60Co35Ga5合金可以改善磁体的微观结构,提高磁体的磁晶各向异性场,从而有效提高磁体的矫顽力,在890 ℃扩散3 h,480 ℃回火5 h工艺下矫顽力达到较优,从1 209 kA/m提高到1 624 kA/m,磁体的剩磁只有轻微的下降,从1.38 T降低到1.32 T.

2)烧结钕铁硼磁体晶界扩散Dy60Co35Ga5合金可以有效提高磁体的居里温度,降低磁体的不可逆磁通损失,热稳定性增强.

3)通过改善磁体的微观组织结构,提高磁体的磁晶各向异性场及居里温度是提高磁体矫顽力及热稳定性的重要方法.

| [1] |

HIROSAWA S, MATSUURA Y, YAMAMOTO H, et al. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals[J].

Journal of Applied Physics, 1986, 59: 873–879. DOI: 10.1063/1.336611. |

| [2] |

雷伟凯, 曾庆文, 胡贤君, 等. 高丰度稀土永磁材料的研究现状与展望[J].

有色金属科学与工程, 2017, 8(5): 7–12.

|

| [3] |

LIU Q B, TANG X, CHEN R J, et al. Effect of Tb-Fe diffusion on magnetic properties and thermal stability of hot-deformed magnets[J].

Journal of Alloys and Compounds, 2019, 773: 1108–1113. DOI: 10.1016/j.jallcom.2018.09.205. |

| [4] |

郭诚君, 李家节, 饶先发, 等. 烧结Nd-Fe-B磁体腐蚀动力学行为[J].

有色金属科学与工程, 2016, 7(1): 59–63.

|

| [5] |

SAGAWA M, FUJIMURA S, TOGAWA N, et al. New material for permanent magnets on a base of Nd and Fe[J].

Journal of Applied Physics, 1984, 55: 2083. DOI: 10.1063/1.333572. |

| [6] |

GUTFLEISCH O, WILLARD M A, BRUCK E, et al. Magnetic materials and devices for the 21st century:stronger, lighter, and more energy efficient[J].

Advanced Materials, 2011, 23: 821. DOI: 10.1002/adma.v23.7. |

| [7] |

ZHOU B B, LI X B, LIANG X L, et al. Improvement of the magnetic property, thermal stability and corrosion resistance of the sintered Nd-Fe-B magnets with Dy80Al20 addition[J].

Journal of Magnetism and Magnetic Materials, 2017, 429: 257–262. DOI: 10.1016/j.jmmm.2017.01.025. |

| [8] |

CUI X G, CUI Y C, CHENG X D, et al. Effect of Dy2O3 intergranular addition on thermal stability and corrosion resistance of Nd-Fe-B magnets[J].

Intermetallics, 2014, 55: 118–122. DOI: 10.1016/j.intermet.2014.07.020. |

| [9] |

LIU P, MA T Y, WANG X H, et al. Role of hydrogen in Nd-Fe-B sintered magnets with DyHx addition[J].

Journal of Alloys and Compounds, 2015, 628: 282–286. DOI: 10.1016/j.jallcom.2014.12.177. |

| [10] |

LIU Y H, GUO S, LIU X M, et al. Magnetic properties and microstructure of Nd-Fe-B sintered magnets with DyHx addition[J].

Journal of Applied Physics, 2016, 111: 7–12. |

| [11] |

KIM T H, LEE S R, KIM H J, et al. Magnetic properties and microstructure of Nd-Fe-B sintered magnets with DyHx addition[J].

Journal of Applied Physics, 2014, 115: 17–21. |

| [12] |

PHAM T T, NGUYEN V D, NGUYEN H Y, et al. Effect of adding non-ferromagnetic nanoparticles to grain boundary on coercivity of sintered Nd-Fe-B magnet[J].

Current Applied Physics, 2018, 18: 329–334. DOI: 10.1016/j.cap.2017.12.014. |

| [13] |

GRIGORAS M, LOSTUN M, URSE M, et al. Nd-Fe-B/Sm-M/Nd-M (M=Fe, Co, Ti, Cu, Zr) hybrid magnets with improved thermal stability[J].

Journal of Magnetism and Magnetic Materials, 2018, 447: 68–72. DOI: 10.1016/j.jmmm.2017.09.059. |

| [14] |

NIITSU K, SATO A, SASAKI T T, et al. Magnetization measurements for grain boundary phases in Ga-doped Nd-Fe-B sintered magnet[J].

Journal of Alloy and Compounds, 2018, 752: 220–230. DOI: 10.1016/j.jallcom.2018.04.055. |

| [15] |

DEREWNICKA, FERRARI S, BILOVOL V, et al. Influence of Nb, Mo, and Ti as doping metals on structure and magnetic response in NdFeB based melt spun ribbons[J].

Journal of Magnetism and Magnetic Materials, 2018, 462: 83–95. DOI: 10.1016/j.jmmm.2018.05.004. |

| [16] |

MA Y G, LI R S, YANG Z, et al. Effect of additive elements (Cu, Zr, Al) on morphological and magnetic properties of NdFeB thin films with perpendicular magnetic anisotropy[J].

Materials Science and Engineering:B, 2005, 117: 287–291. DOI: 10.1016/j.mseb.2004.12.009. |

| [17] |

GAO J R, SONG X P, WANG X T, et al. Effects of Co and Zr additions on microstructure and anisotropy of HDDR-treated NdFeB alloy powders[J].

Journal of Alloy and Compounds, 1997, 248: 176–179. DOI: 10.1016/S0925-8388(96)02670-9. |

| [18] |

CUI X G, WANG X H, YIN G C, et al. Magnetic properties and microstructure of sintered NdFeB magnets with intergranular addition of Ni powders[J].

Journal of Alloys and Compounds, 2017, 726: 846–851. DOI: 10.1016/j.jallcom.2017.08.061. |

| [19] |

ZHANG X F, GUO S, YAN C J, et al. Improvement of the thermal stability of sintered Nd-Fe-B magnets by intergranular addition of Dy82.3Co17.7[J].

Journal of Applied Physics, 2014, 115: 17–21. |

| [20] |

MATSUURA Y, HIROSAWA S, YAMAMOTO, et al. Phase diagram of the NdFeB ternary system[J].

Journal of Applied Physics, 1985, 24: 635–638. DOI: 10.1143/JJAP.24.L635. |

| [21] |

WANG X L, ZHAO L, DING K H, et al. Influence of dysprosium distribution on properties of sintered and aged Dy-doped NdFeB permanent magnets[J].

Rare Metal Materials and Engineering, 2016, 45: 309–314. DOI: 10.1016/S1875-5372(16)30060-1. |

| [22] |

WANG Y, DONG P B, ZHANG B C, et al. Stability and estimate for flux irreversible loss of Nd-Fe-B magnets[J].

Metallic Functional Materials, 2006, 13: 5–9. |

| [23] |

ZHOU S Z, DONG Q F.

Supermagnets:rare-earth & iron system permanent magnet[M]. Beijing: Metallurgical Industry Press, 2004.

|

| [24] |

RAO G J, PRASAD T, SHAMEER S, et al. Soapnut extract mediated synthesis of nanoscale cobalt substituted NdFeB ferromagnetic materials and their characterization[J].

Journal of Magnetism and Magnetic Materials, 2018, 451: 159–166. DOI: 10.1016/j.jmmm.2017.11.009. |

2019, Vol. 10

2019, Vol. 10