2. 中国石化西南石油工程有限公司井下作业分公司, 四川 德阳 618000;

3. 中国石油天然气股份有限公司西南管道分公司, 四川 成都 610041

2. Downhole Operation Company, Xinan Oilfield Service Corporation, SINOPEC, Deyang, Sichuan 618000, China;

3. Southwest Pipeline Company, CNPC, Chengdu, Sichuan 610041, China

中国的成品油管道采用“水联运”的方式投产,管道内不可避免地存在水,从而导致管道的内腐蚀[1]。由于油水密度差较大,在地势复杂、起伏较大的大落差地带,可能出现油品已越过高点而水仍沉积在管道低洼处形成积水的情况。若利用上游来油将管道低洼处积水携出,既可减轻管道的内腐蚀,又能减少阻塞事故。而管内油水两相流流型对于混油量和管内积水形态具有极大影响[2-3]。因此,研究油水两相流流型对保障成品油管道的安全运营具有重要的工程应用价值[4]。

很多学者对油水两相流在管道中的流动特性进行了实验研究。徐广丽等在50 mm内径起伏管道中实验研究了不同含水率、不同倾角、不同油相表观流速下倾斜管道内的流型,但该实验架管径较小、倾角变化范围较小,故而无法广泛说明倾角对流型变化规律的影响[5]。Pedram等用内径20 mm,长6 m,倾角分别为0°,

因此,本文对内径100 mm上倾管道中油水两相流系统的积水形态、临界携水参数等进行了实验研究。

1 实验系统 1.1 实验装置实验装置为大型流动环道。油流由油罐供应,水由注入阀注入,油流经离心泵后将水推入实验管线,流经实验段后在油罐中利用两相密度差实现重力沉降分离后油循环使用。

油罐直径323.9 mm,高1.2 m。油罐下方为倒锥形并连有一排水阀以排出底部积水。油罐上方开有70 mm孔洞与橡胶软管相连,以循环实验介质。实验段为不同倾角(

|

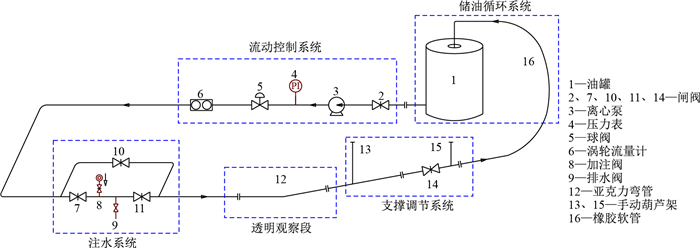

| 图1 实验装置示意图 Fig. 1 Schematic of experimental setup |

实验介质为柴油和去离子水,20 ℃、101 kPa下实验流体物理性质见表 1。为便于流型观察,在水中加入了高锰酸钾(颜色剂)以区别油水两相。

| 表1 实验流体物理性质 Tab. 1 Physical properties of the liquids used |

实验介质温度控制在19~21 ℃,出口压力为101 kPa。关闭阀门(7,9,11),打开阀门(10),油流从旁通管流过后,由阀门(8)加入8 L水,然后打开阀门(7,11),关闭阀门(10),利用低流速油流将水带至亚克力弯管处。然后以0.180 m/s为初始油流表观流速,以0.020 m/s为梯度开始增加,直至水平段积水被完全携出上倾段。实验现象通过透明实验段进行观察,由高清摄像仪进行拍摄。

2 实验结果与讨论采用Song等和Izwan等的研究结果进行流型划分[24-25]。实验工况下,共观察到波状分层流(Stratified-Wavy flow, STW)、有液滴的波状分层流(Stratified-Wavy flow with Water Droplets, SW & WD)、分散流(Despersion of Water in Oil, DW/O)3种流型。

2.1 倾角10°油相表观流速为0.168~0.308 m/s,管道倾角为10°时,流型均为如图 2所示的油水两相整体分层但界面有波动的波状分层流。上倾段水层厚度随油相表观流速的增大而减小。油流对水层的剪切作用力随油相表观流速的增大而增大,水相流动阻力随爬坡距离增加而增大,因此,在上倾段管道内形成了波状分层流。

|

|

图2

|

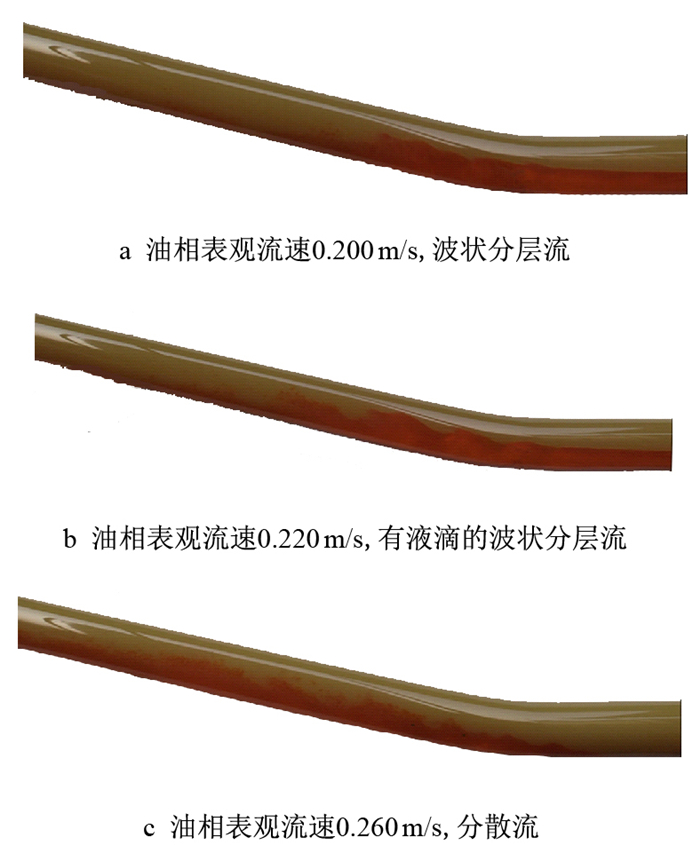

管道倾角为15°时,不同油相表观流速的流型如图 3所示。油相表观流速为0.198~0.218 m/s时,流型为波状分层流;油相表观流速为0.220~0.237 m/s时,流型为有液滴的波状分层流;油相表观流速为0.248~0.308 m/s时,流型为水在油中的分散流。重力沿管道轴向的分力随倾角增大而增大,由油水密度差形成的浮力沿管道轴向的分量减小,相同表观流速下,油流对水相的携带能力下降,因此,管道倾角为15°时,油流能将水相携入上倾段的临界表观流速比管道倾角为10°时大。在相对较高的流速下,部分水相被剪切为水滴,从油水界面处分离,流型转化为有液滴的波状分层流。随油相表观流速继续增加,上倾段几乎所有水相均被剪切为液滴分散在油中,流型转化为水在油中的分散流。在上倾管道顶端,部分液滴在重力作用下重新在管道下壁面处汇聚成较大的水团。水团比表面积较分散的水珠减小,导致水团所受黏性力与重力的比值减小,因此水团向下流动形成回流,导致水相无法被完全携出上倾段直至油相表观流速增加至能为水团提供足够黏性力。

|

|

图3

|

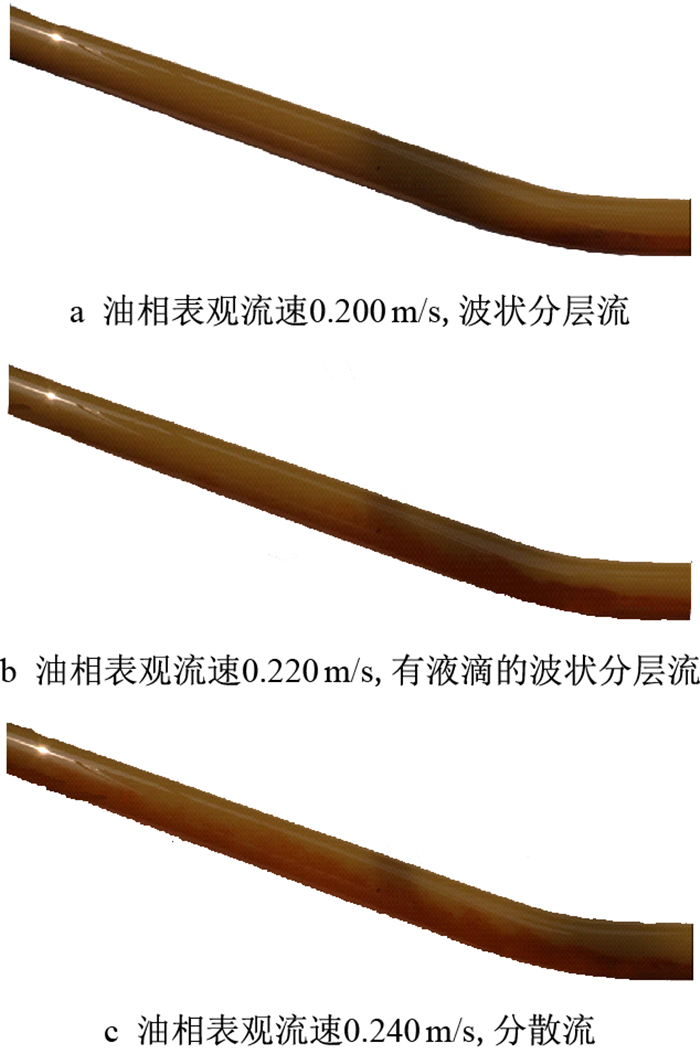

管道倾角为20°时,不同油相表观流速的流型如图 4所示。油相表观流速为0.200~0.211 m/s时,流型为波状分层流;油相表观流速0.220~0.223 m/s时,流型为有液滴的波状分层流;油相表观流速为0.230~0.308 m/s时,流型为水在油中的分散流。管道倾角为20°时,重力沿管道轴向的分量比管道倾角为15°时大,湍流程度加剧,因此,在较低流速时,流型即从有液滴的波状分层流转化为水在油中的分散流。对比倾角为10°、15°、20°工况可知,流型相同时,油流能将水相携入上倾段的临界表观流速与倾角正相关。

|

|

图4

|

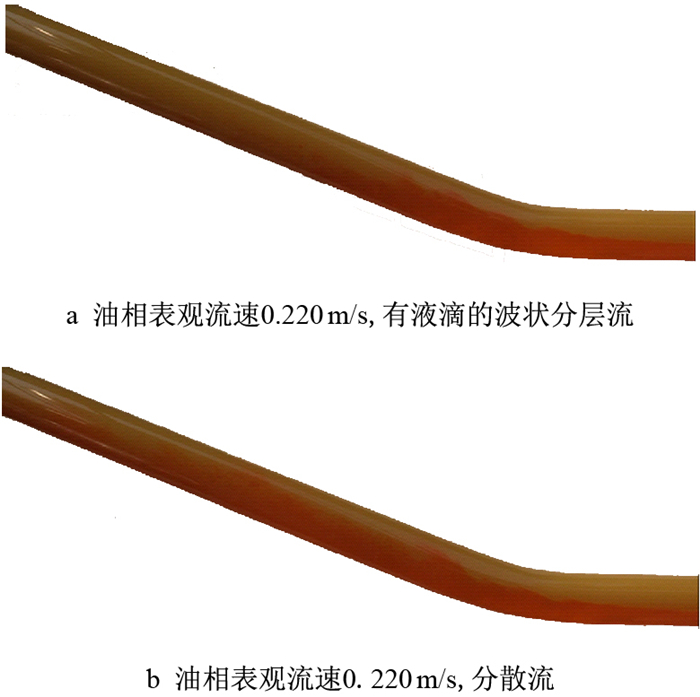

管道倾角25°时,不同油相表观流速的流型如图 5所示。油相表观流速为0.187~0.198 m/s时,流型为有液滴的波状分层流;油相表观流速为0.211~0.312 m/s时,流型为水在油中的分散流。因为湍流程度随倾角增大而加剧,当倾角为25°时,在较低流速下进入上倾段的水相前端即被剪切为水珠,呈现出有液滴的波状分层流流型,而无单纯的波状分层流流型出现。水珠与油相的接触面积比波状分层流中相同体积的连续水相与油相接触面积大,受到的油相黏性力更大,因此,管道倾角为25°时,在有液滴的波状分层流流型下,油相能将水相携入爬坡管道上倾段的临界表观流速较管道倾角为20°时小。

|

|

图5

|

管道倾角为30°时,不同油相表观流速的流型如图 6所示。油相表观流速为0.205~0.211 m/s时,流型为有液滴的波状分层流;油相表观流速为0.212~0.312 m/s时,流型为水在油中的分散流。管道倾角为30°时各表观流速下流型变化规律与管道倾角为25°时相似。油相能将水相携带入上倾段的最低表观流速比倾角为25°时稍大。对比倾角为25°、30°工况可知,流型均为有液滴的波状分层流时,油相能将水相携入倾斜段的临界表观流速随倾角增大而增大。

|

|

图6

|

管道倾角为35°时,不同油相表观流速的流型如图 7所示。油相表观流速为0.194~0.314 m/s时,流型均为水在油中的分散流。由于管道倾角增大,重力沿管道轴向分力增大,油相无法将连续水相携入管道上倾段,所以在管道上倾段不会出现有液滴的波状分层流流型。在较低流速下,水相在重力、黏性力的共同作用下形成小水滴而被油相携带入管道上倾段,形成水在油中的分散流流型。随油相表观流速增大,湍流程度加剧,越来越多水珠被携入管道上倾段且爬坡距离增加,又在重力作用下在管壁处汇聚成大水团向下流动形成回流。直至油相表观流速上升至黏性力足以克服重力后,水相被完全携出管道上倾段。

|

|

图7

|

管道倾角为40°时,不同油相表观流速的流型如图 8所示。油相表观流速为0.198~0.315 m/s时,流型均为水在油中的分散流。管道倾角为40°时,流型随表观流速的变化规律与管道倾角为35°时相似。在分散流流型下,由于倾角增加,油相能将水相携入上倾段和将水相完全携出上倾段的临界表观流速均有所增大。

|

|

图8

|

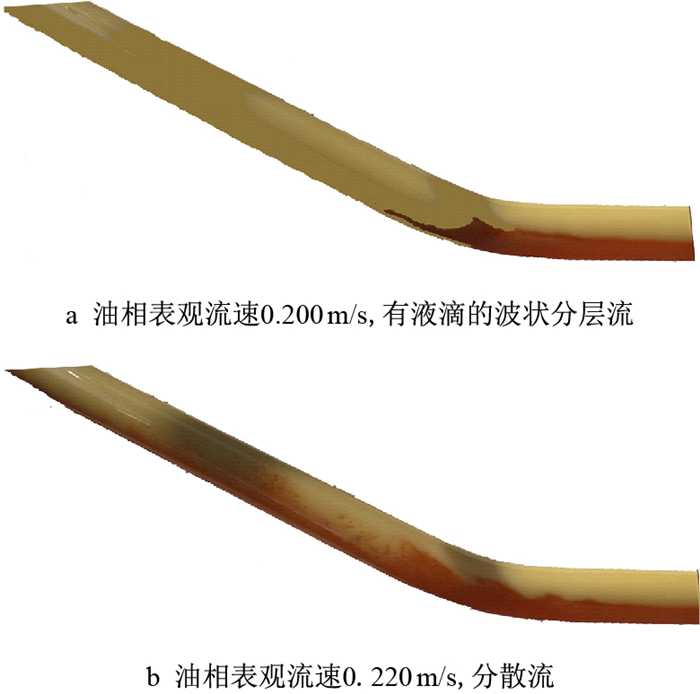

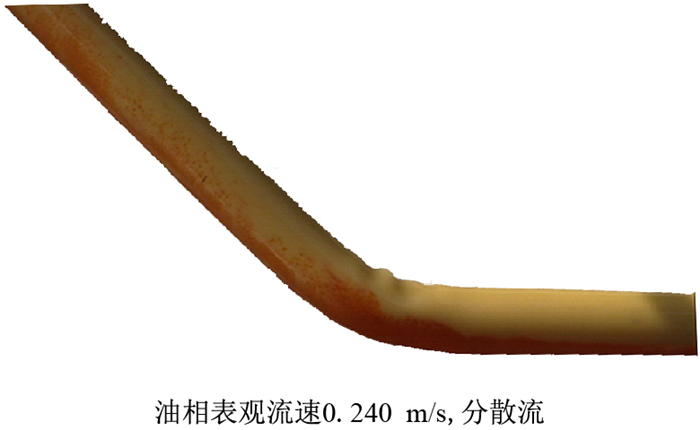

管道倾角为45°时,油相表观流速为0.240 m/s对应的流型如图 9所示。管道倾角为45°时,流型随表观流速的变化规律与管道倾角为35°、40°时均相似,且油相将水相携入管道上倾段和将水相完全携出上倾段的临界流速均在倾角为40°的基础上略微增大。

|

|

图9

|

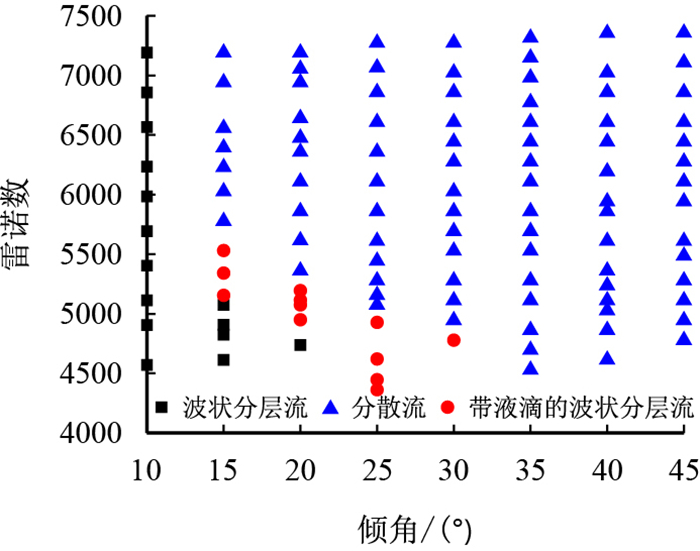

根据各工况流型,得到实验工况对应流型图谱如图 10所示。由图 10可知,波状分层流只在倾角小于20°时出现;当管道倾角在15°~30°时,低流速下管道上倾段为有液滴的波状分层流流型,随流速增大,流型从有液滴的波状分层流逐渐转化为水在油中的分散流流型;当管道倾角在35°~45°时,一旦水相被携入上倾段,即呈现水在油中的分散流流型。

|

| 图10 实验工况流型图谱 Fig. 10 Flow pattern map in experimental conditions |

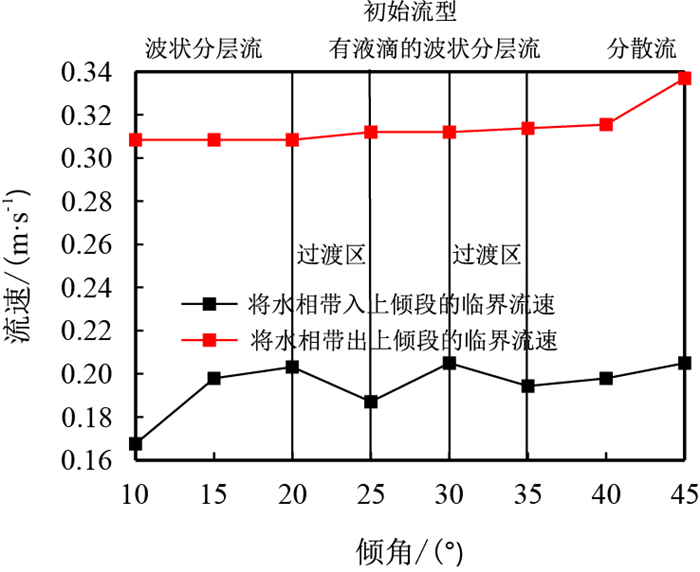

各工况下柴油将水相携入管道上倾段的临界流速和将水相携出管道的临界流速如表 2所示。油相能将水相携入管道上倾段和完全携出管道上倾段的临界流速随倾角的变化规律如图 11所示。

| 表2 临界流速 Tab. 2 Critical velocity |

|

| 图11 临界流速随倾角的变化规律 Fig. 11 Variation of critical velocity with inclination angle |

由图 11可知,随倾角增大,水相进入上倾段的初始流型从波状分层流转化为有液滴的波状分层流,最终转化为水在油中的分散流。初始流型相同时,油相能将水相携入上倾段的临界流速随倾角增大而增大。倾角从20°增大至25°时,流型从波状分层流转化为有液滴的波状分层流,由于湍流程度加剧,油相能将水相携入管道上倾段的临界流速略有减小,流型从有液滴的波状分层流转化为水在油中的分散流时油相能将水相携入管道上倾段的临界流速略有减小。油相能将水相完全携出管道上倾段的临界流速随倾角增大总体呈缓慢上升趋势。

4 结论(1) 在油流剪切作用下,水相刚被携入上倾段的初始流型随管道倾角增大由波状分层流转化为有液滴的波状分层流,最终转化为分散流。

(2) 倾角从20°增大到25°使初始流型从波状分层流转化为有液滴的波状分层流时,油相能将水相携入上倾段的临界流速从0.203 m/s减小为0.187 m/s;倾角从30°增大至35°使初始流型从有液滴的波状分层流转换为分散流时,油相能将水相携入上倾段的临界流速从0.205 m/s减小为0.194 m/s。

(3) 初始流型相同时,油相能将水相携入管道上倾段的临界流速随倾角增大而增大。

(4) 上倾管段内湍流程度从波状分层流、有液滴的波状分层流到分散流依次增大。流型转化流速随倾角增大而降低。

| [1] |

王剑波, 陈振友, 窦志宽. 成品油管内腐蚀的危害分析及对策[J]. 石油规划设计, 2008, 19(2): 39-41. WANG Jianbo, CHEN Zhenyou, DOU Zhikuan. Analysis and countermeasures of the hazard caused by internal corrosion in product oil pipeline[J]. Petroleum Planning & Engineering, 2008, 19(2): 39-41. doi: 10.3969/j.issn.1004-2970.2008.02.015 |

| [2] |

GHOSH S, DAS G, DAS P K. Pressure drop analysis for liquid-liquid downflow through vertical pipe[J]. Journal of Fluids Engineering, 2011, 133(1): 011202. doi: 10.1115/1.4003354 |

| [3] |

PEDDU A, CHAKRABORTY S, DAS P K. Visualization and flow regime identification of downward air-water flow through a 12 mm diameter vertical tube using image analysis[J]. International Journal of Multiphase Flow, 2018, 100: 1-15. doi: 10.1016/j.ijmultiphaseflow.2017.11.016 |

| [4] |

SONG Xiaoqin, YANG Yuexin, YU Dongliang, et al. Studies on the impact of fluid flow on the microbial corrosion behavior of product oil pipelines[J]. Journal of Petroleum Science and Engineering, 2016, 146: 803-812. doi: 10.1016/j.petrol.2016.07.035 |

| [5] |

徐广丽, 张鑫, 蔡亮学, 等. 起伏管内局部油水两相流流动特性实验研究[J]. 西南石油大学学报(自然科学版), 2015, 37(5): 85-90. XU Guangli, ZHANG Xin, CAI Liangxue, et al. Experimental investigation on the flow characteristics of the local oil-water two phases flow system in hilly-terrain tube[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2015, 37(5): 85-90. doi: 10.11885/j.issn.1674-5086.2013.07.09.12 |

| [6] |

PEDRAM H, AMIR K, ALIREZA T, et al. Experimental investigation of two-phase water-oil flow pressure drop in inclined pipes[J]. Journal of Petroleum Science and Engineering, 2016, 74: 169-180. doi: 10.1016/j.expthermflusci.2015.11.024 |

| [7] |

CHAKRABARTI D P, DAS G, DAS P K. Identification of stratified liquid-liquid flow through horizontal pipes by a non-intrusive optical probe[J]. Chemical Engineering Science, 2007, 62(7): 1861-1876. doi: 10.1016/j.ces.2006.11.056 |

| [8] |

PEDRAM H, ALIREZA H, AMIR K. Experimental investigation of oil-water two phase flow regime in an inclined pipe[J]. Journal of Petroleum Science and Engineering, 2015, 136: 12-22. doi: 10.1016/j.petrol.2015.10.031 |

| [9] |

LOVICK J, ANGELI P. Experimental studies on the dual continuous flow pattern in oil-water flows[J]. International Journal of Multiphase Flow, 2004, 30(2): 139-157. doi: 10.1016/j.ijmultiphaseflow.2003.11.011 |

| [10] |

LUM J Y L, AL-WAHAIBI T, ANGELI P. Upward and downward inclination oil-water flows[J]. International Journal of Multiphase Flow, 2006, 32(4): 413-435. doi: 10.1016/j.ijmultiphaseflow.2006.01.001 |

| [11] |

FLORES J G, CHEN X T, BRILL J P. Characterization of oil-water flow patterns in vertical and deviated wells[J]. SPE Production & Facilities, 1999, 14(2): 94-101. doi: 10.2118/38810-MS |

| [12] |

VIELMA M A, ATMACA S, SARICA C, et al. Characterization of oil/water flows in horizontal pipes[C]. SPE 109591-MS, 2007. doi: 10.2118/109591-MS

|

| [13] |

WANG Wei, GONG Jing, ANGELI P. Investigation on heavy crude-water two phase flow and related flow characteristics[J]. International Journal of Multiphase Flow, 2011, 37(9): 1156-1164. doi: 10.1016/j.ijmultiphaseflow.2011.05.011 |

| [14] |

GRASSI B, STRAZZA D, POESIO P. Experimental validation of theoretical models in two-phase high-viscosity ratio liquid-liquid flows in horizontal and slightly inclined pipes[J]. International Journal of Multiphase Flow, 2008, 34(10): 950-965. doi: 10.1016/j.ijmultiphaseflow.2008.03.006 |

| [15] |

SOTGIA G, TARTARINI P, STALIO E. Experimental analysis of flow regimes and pressure drop reduction in oil-water mixtures[J]. International Journal of Multiphase Flow, 2008, 34(12): 1161-1174. doi: 10.1016/j.ijmultiphaseflow.2008.06.001 |

| [16] |

RODRIGUEZ O M H, OLIEMANS R V A. Experimental study on oil-water flow in horizontal and slightly inclined pipes[J]. International Journal of Multiphase Flow, 2006, 32(3): 323-343. doi: 10.1016/j.ijmultiphaseflow.2005.11.001 |

| [17] |

ZONG Yanbo, JIN Ningde, WANG Zhenya, et al. Nonlinear dynamic analysis of large diameter inclined oil-water two phase flow pattern[J]. International Journal of Multiphase Flow, 2010, 36(3): 166-183. doi: 10.1016/j.ijmultiphaseflow.2009.11.006 |

| [18] |

AL-WAHAIBI T, YUSUF N, AL-WAHAIBI Y, et al. Experimental study on the transition between stratified and non-stratified horizontal oil-water flow[J]. International Journal of Multiphase Flow, 2012, 38(1): 126-135. doi: 10.1016/j.ijmultiphaseflow.2011.08.007 |

| [19] |

KUMARA W A S, HALVORSEN B M, MELAAEN M C. Particle image velocimetry for characterizing the flow structure of oil-water flow in horizontal and slightly inclined pipes[J]. Chemical Engineering Science, 2010, 65(15): 4332-4349. doi: 10.1016/j.ces.2010.03.045 |

| [20] |

DU Meng, JIN Ningde, GAO Zhongke, et al. Flow pattern and water holdup measurements of vertical upward oil-water two-phase flow in small diameter pipes[J]. International Journal of Multiphase Flow, 2012, 41: 91-105. doi: 10.1016/j.ijmultiphaseflow.2012.01.007 |

| [21] |

JANA A K, DAS G, DAS P K. Flow regime identification of two-phase liquid-liquid upflow through vertical pipe[J]. Chemical Engineering Science, 2006, 61(5): 1500-1515. doi: 10.1016/j.ces.2005.09.001 |

| [22] |

JIN N D, NIE X B, WANG J, et al. Flow pattern identification of oil/water two-phase flow based on kinematic wave theory[J]. Flow Measurement and Instrumentation, 2003, 14(4-5): 177-182. doi: 10.1016/S0955-5986(03)00023-2 |

| [23] |

JIN N D, NIE X B, REN Y Y, et al. Characterization of oil/water two-phase flow patterns based on nonlinear time series analysis[J]. Flow Measurement and Instrumentation, 2003, 14(4-5): 169-175. doi: 10.1016/S0955-5986(03)00022-0 |

| [24] |

SONG Xiaoqin, YANG Yuexin, ZHANG Tao, et al. Studies on water carrying of diesel oil in upward inclined pipes with different inclination angle[J]. Journal of Petroleum Science and Engineering, 2017, 157: 780-792. doi: 10.1016/j.petrol.2017.07.076 |

| [25] |

IZWAN Ismail A S, ISMAIL I, ZOVEIDAVIANPOOR M, et al. Experimental investigation of oil-water twophase flow in horizontal pipes:Pressure losses, liquid holdup and flow patterns[J]. Journal of Petroleum Science and Engineering, 2015, 127: 409-420. doi: 10.1016/j.petrol.2015.01.038 |

2019, Vol. 41

2019, Vol. 41