2. 中海油田服务股份有限公司油田生产事业部, 天津 塘沽 300452;

3. University of Oklahoma, 660 Parrington Oval, Norman, OK 73019, USA

2. Production Optimization Division, China Oilfield Services Limited, Tanggu, Tianjin 300452, China;

3. University of Oklahoma, 660 Parrington Oval, Norman, OK 73019, USA

随着非常规资源的开发以及天然气技术的推广和改善,致密油/页岩油的开发也越来越引人瞩目。以美国巴肯页岩油为例,虽然巴肯组储层物性差,渗透率极低(0.001~0.100 mD),但仍然能够获得非常可观并且长期稳定的产量[1, 2]。由于长段水平井多段(10~20段以上)压裂技术的突飞猛进,使得泄油面积成倍增加成为可能,并且由于地层中存在微裂缝,储层整体有效渗透率能够提高十倍左右,为稳定的产量供应提供了物质基础。此外,这类储层有效厚度薄(1.83~4.57 m),压力系数高(1.2~1.4),这些因素都促成了巴肯组高压油区开采初期并不需要能量补充[3-6]。中国鄂尔多斯盆地致密油储层与巴肯组高压产区存在很大的不同[7-10],除储层物性较差外,压力系数低使得该类储层只能获得工业化的初产,储层流体的运移速度太小,其补充速度赶不上需求,造成单井体积压裂改造后有较高初产而不能稳产的局面。因此,本文立足于致密油储层改造后注水能量补充方式,综合考虑直井体积压裂复杂缝网特征及渗流特点,运用数值模拟方法对缝网与井网的匹配方式进行了探索,并结合典型致密油区块对体积压裂井开发的注采井网进行了优化设计。

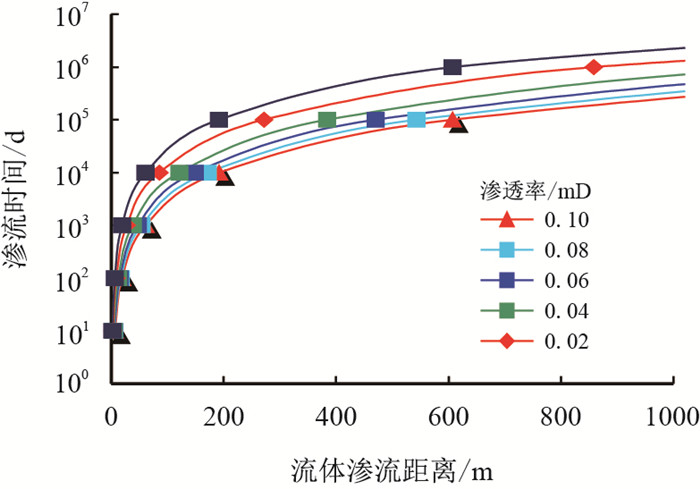

1 体积压裂复杂缝网渗流特征分析 1.1 体积压裂缝网内质点渗流时间与距离的关系体积压裂是以在井筒附近致密储层中形成主次裂缝相互交错的复杂裂缝网络为目的,从而增大储层泄油体积和缝网内部向裂缝的压力传播速度,大幅度缩短储层内部流体流向裂缝的距离,实现提高单井产能和提高采收率的压裂改造技术。改造过程使储层形成具有一定导流能力的复杂裂缝网络,相当于提高了改造区域内储层渗透率,储集层渗流特征发生了改变[11-14]。根据式(1),在注采压差相同的条件下,可计算得到不同基质渗透率下流体渗流时间与质点的渗流距离的关系。

| $ L = \sqrt {\frac{{1.2 \times {{10}^{ - 4}}{K_{\rm{m}}}\Delta pt}}{{{\phi _{\rm{m}}}\mu }}} $ | (1) |

式中:

L-质点渗流距离,m;

Km-基质渗透率,mD;

∆p-生产压差,MPa;

t-质点渗流时间,min;

ϕm-基质孔隙度,%;

µ-流体黏度,mPa·s。

从不同基质渗透率流体渗流时间与渗流距离关系(图 1)看出,随着缝网改造区域逐渐变大,流体渗流距离的缩小,其有效渗流时间也在急剧减小。同时,当基质渗透率越小时,相同生产压差下缝网内流动相同距离所需要时间也越长。因此,体积改造后,缝网系统“最短渗流距离”的特点会使得油井见水后含水上升较常规单一裂缝井快得多。

|

| 图1 不同基质渗透率流体渗流时间与渗流距离关系 Fig. 1 The relationship between flowing time and flowing distance in matrix with different permeability |

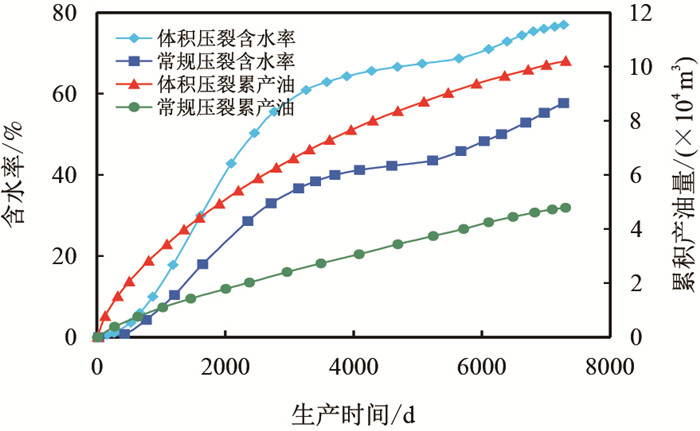

根据致密油储层地质特征,基于典型直井体积压裂缝网形态,运用EQ-LGR方法建立了相应数值模拟模型[15],对直井单一裂缝及体积压裂矩形井网的开发效果进行了对比。文中选取相应的计算单元,两种压裂方式主裂缝半长均为150 m,导流能力40.0 D·cm,体积压裂直井裂缝网络导流能力为0.7 D·cm,油藏改造体积(SRV)为168×104 m3(主裂缝长度300 m、次裂缝长度200 m),模型定流压控制方式进行生产。研究结果表明,矩形井网形式下,直井体积压裂较单一裂缝改造方式累积产油量有较大幅度提高(图 2);缝网内由于压力传递速度快,体积压裂直井改造后见水时间提前,并且见水后含水上升较快。

|

| 图2 注采井网形式下的直井常规压裂与体积压裂开发指标对比 Fig. 2 Development index comparison between vertical well network fracturing and conventional fracturing in water flooding well pattern |

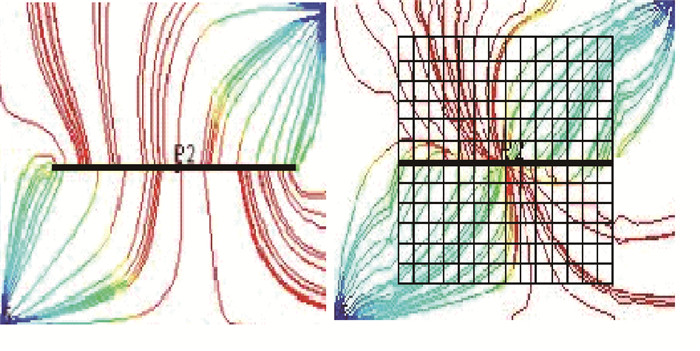

图 3给出了两种压裂方式十年末的流线分布图。流线分布区域表明了水驱波及范围的大小,流线密度则反映了水驱波及均匀程度[16, 17]。直井常规压裂注采井间流线分布非均匀程度较高,沿裂缝垂向的水驱程度较低,流线主要在注水井与压裂裂缝尖端较为密集;而体积压裂改造后形成的缝网分布于主裂缝两侧,注采井间裂缝网络改造区域流线数量明显增多,缝网系统内部流线发生扭曲、呈现簇状均匀分布,提高了注入水的利用效率,有效地增大了水驱波及体积,裂缝两侧的剩余油饱和度大大降低。

|

| 图3 注采井网形式下的直井常规压裂与体积压裂流线分布特征 Fig. 3 Streamline distribution of vertical well conventional fracturing and network fracturing in water flooding well pattern |

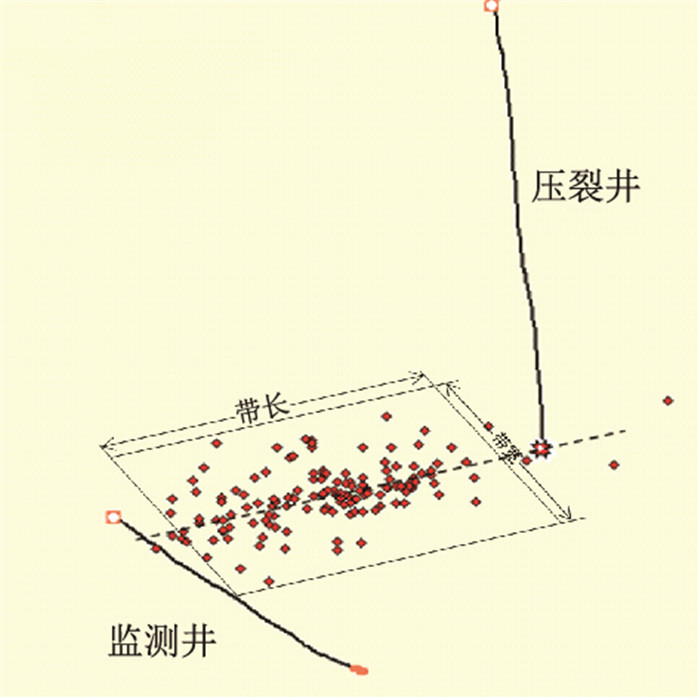

鄂尔多斯盆地长7致密油储层开展了体积压裂先导试验,试验井试油产量较常规压裂有了大幅度提高,平均试油产量19.4 t/d。井下微地震监测结果表明,直井体积压裂缝网以主裂缝为主、分支裂缝为辅的缝网系统。监测到的微地震事件显示(图 4),裂缝方位为NE 74°,裂缝带长400 m,裂缝带宽170 m。

|

| 图4 直井体积压裂井下微地震监测成果图 Fig. 4 The microseismic monitoring figure of vertical network fractured well |

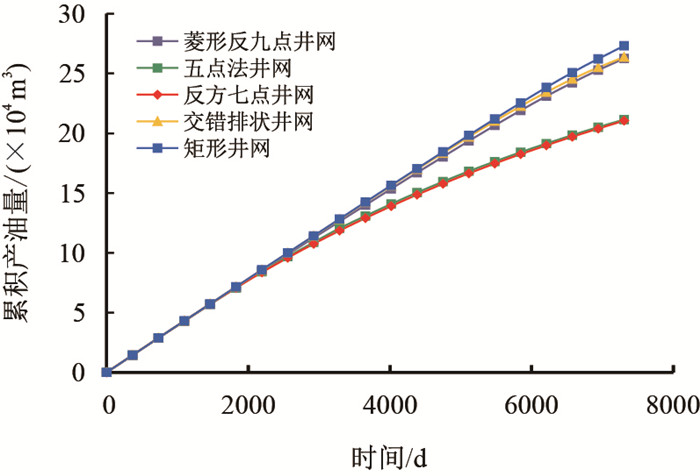

根据目标试验单井体积压裂改造微地震监测结果,建立直井体积压裂缝网改造模型,分别对矩形井网、交错排状井网、菱形反九点井网、反方七点井网、五点法井网进行了研究,不同井网形式下仅生产井压裂注水井不压裂。从不同井网形式开发效果对比(图 5)可以看出,矩形井网形式下采出程度最高,开发效果最好,其余依次是交错排状井网、菱形反九点井网。五点法井网和反方七点井网油井控制程度高,但注入水利用效率较低,油井水窜明显,含水率上升较快。

|

| 图5 不同井网形式累积产油量对比 Fig. 5 Comparison on cumulative oil production of different well patterns |

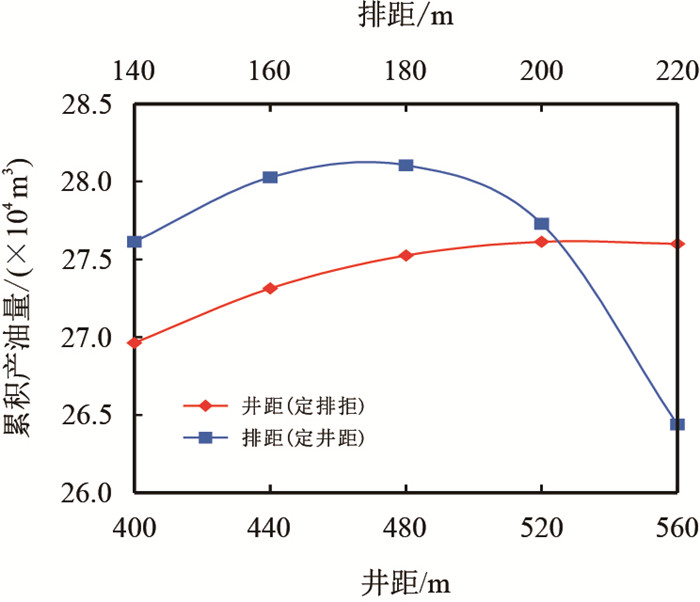

在矩形井网的基础上,保持排距140 m不变,对比研究了当井距为400,440,480,520和560 m时直井体积压裂注水开发的效果(图 6)。

|

| 图6 不同井网参数累积产油量对比 Fig. 6 Comparison on cumulative oil production of different well pattern parameters |

从不同井网参数累积产油量可以看出,相同排距时随着井距的增加累积产油量逐渐增大,当井距为520 m时,累积产油量达到最大值。保持井距520 m不变,当排距为140,160,180,200和220 m时直井体积压裂注水开发的效果如图 6所示。由图 6可见,当井距一定(520 m),累积产油量随着排距的增加呈现出先增大后减小的趋势,这是因为当排距小于180 m时,在垂直于主应力方向的缝网见水后,含水率急剧上升,累积产油量水平较低;而排距继续增加会造成注采井间波及体积低,水驱效果变差,因此采用180 m的排距开发时较为合适。

3 结语(1)鄂尔多斯盆地致密油储层物性差,压力系数低,必须立足补充能量的开发方式。直井体积压裂采用注水井网补充能量进行开发能够大幅度提高水驱波及体积。

(2)体积改造后缝网系统“最短渗流距离”使得相同生产压差下,体积压裂直井见水时间有所提前,并且见水后含水上升较快。

(3)基于鄂尔多斯盆地直井体积压裂微地震监测结果,对注采井网条件下的体积压裂开发方式进行了优化。由于直井体积压裂改造后单井控制体积增大,井距、排距应适当增大。在压裂规模SRV为272×104 m3时,井排距为520 m×180 m的矩形井网形式为最优开发井网。

| [1] | Tan T, Pahala S, Wattenbarger R A. Production characteristics of the Bakken shale oil[C]. SPE 145684, 2011. https://www.researchgate.net/publication/254534847_Production_Characteristics_of_the_Bakken_Shale_Oil |

| [2] |

陈作, 薛承瑾, 蒋廷学, 等. 页岩气井体积压裂技术在我国的应用建议[J].

天然气工业, 2010, 30 (10) : 30 –32.

Chen Zuo, Xue Chengjin, Jiang Tingxue, et al. The Application proposal of network fracturing technology in shale gas well[J]. Natural Gas Industry, 2010, 30 (10) : 30 –32. |

| [3] |

董丙响, 程远方, 刘钰川, 等. 页岩气储层岩石物理性质[J].

西安石油大学学报:自然科学版, 2013, 28 (1) : 25 –36.

Dong Bingxiang, Cheng Yuanfang, Liu Yuchuan, et al. Research of the petrophysical property of shale gas reservoirs[J]. Journal of Xi'an Shiyou University:National Science Edition, 2013, 28 (1) : 25 –36. |

| [4] | Anish S C, Christine E E, Robert W. Shale oil production performance from a stimulated reservoir volume[C]. SPE 147596, 2011. https://www.researchgate.net/publication/241790122_Shale_Oil_Production_Performance_from_a_Stimulated_Reservoir_Volume |

| [5] |

李勇明, 彭瑀, 王中泽. 页岩气压裂增产机理与施工技术分析[J].

西南石油大学学报:自然科学版, 2013, 35 (2) : 90 –95.

Li Yongming, Peng Yu, Wang Zhongze. Analysis of shale gas fracture stimulation mechanism and operating techniques[J]. Journal of Southwest Petroleum University:Science & Technology Edition, 2013, 35 (2) : 90 –95. |

| [6] |

赵金洲, 任岚, 胡永全. 页岩储层压裂缝成网延伸的受控因素分析[J].

西南石油大学学报:自然科学版, 2013, 35 (1) : 1 –9.

Zhao Jinzhou, Ren Lan, Hu Yongquan. Controlling factors of hydraulic fractures extending into network in shale formations[J]. Journal of Southwest Petroleum University:Science & Technology Edition, 2013, 35 (1) : 1 –9. |

| [7] |

许建红, 程林松, 鲍朋, 等. 鄂尔多斯盆地三叠系延长组油藏地质特征[J].

西南石油大学学报:自然科学版, 2007, 29 (5) : 13 –17.

Xu Jianhong, Cheng Linsong, Bao Peng, et al. Reservoir characteristics of Yanchang Formation, in Triassic, Ordos Basin[J]. Journal of Southwest Petroleum University:Science & Technology Edition, 2007, 29 (5) : 13 –17. |

| [8] |

贾承造, 邹才能, 李建忠, 等. 中国致密油评价标准、主要类型、基本特征及资源前景[J].

石油学报, 2012, 33 (3) : 343 –350.

Jia Chengzao, Zou Caineng, Li Jianzhong, et al. Assessment criteria, main types, basic features and resource prospects of the tight oil in China[J]. Acta Petrolei Sinica, 2012, 33 (3) : 343 –350. |

| [9] |

张伟, 刘建朝, 高志亮, 等. 鄂尔多斯盆地吴堡地区长6段浊积特征及其石油地质意义[J].

地球科学与环境学报, 2012, 34 (2) : 64 –70.

Zhang Wei, Liu Jianchao, Gao Zhiliang, et al. Turbidity characteristics and petroleum geological significance of Chang-6 Section in Wubu area of Ordos Basin[J]. Journal of Earth Sciences and Environment, 2012, 34 (2) : 64 –70. |

| [10] |

刘小平, 潘继平, 刘东鹰, 等. 苏北地区下寒武统幕府山组页岩气勘探前景[J].

成都理工大学学报:自然科学版, 2012, 39 (2) : 198 –204.

Liu Xiaoping, Pan Jiping, Liu Dongying, et al. Shale gas exploration prospect of Lower Cambrian Mufushan Formation in the northern Jiangsu, China[J]. Journal of Chengdu University of Technology:Science & Technology Editon, 2012, 39 (2) : 198 –204. |

| [11] | Rick R, Mike M, Erik P, et al. A practical use of shale petrophysics for stimulation design optimization:all shale plays are not clones of the Barnett shale[C]. SPE 115258, 2008. http://www.nexoncn.com/read/60a62b315f19d6fa1a4ea9a7.html |

| [12] | Loyd E J, Soliman M Y, Jody A. Methods of enhancing far-field complexity in fracturing operation[C]. SPE 133380, 2010. |

| [13] | Cipolla C L, Warpinski N R, Mayerhofer M J, et al. The relationship between fracture complexity, reservoir properties, and fracture-treatment design[C]. SPE 115769, 2010. |

| [14] | Meng C F, Pater C J. Hydraulic fracture propagation in per-fracture natural rocks[C]. SPE 140429, 2011. |

| [15] |

王文东, 苏玉亮, 慕立俊, 等. 致密油藏直井体积压裂储层改造体积的影响因素[J].

中国石油大学学报:自然科学版, 2013, 37 (3) : 1 –5.

Wang Wendong, Su Yuliang, Mu Lijun, et al. Influencing factors of stimulated reservoir volume vertical wells in tight oil reservoirs[J]. Journal of China University of Petroleum:Edition of Natural Science, 2013, 37 (3) : 1 –5. |

| [16] |

曾保全, 程林松, 罗鹏. 基于流线模拟的压裂水平井渗流场及产能特征[J].

西南石油大学学报:自然科学版, 2010, 32 (5) : 109 –113.

Zeng Baoquan, Cheng Linsong, Luo Peng. Flow characteristics and productivity of fractured horizontal wells based on streamline simulation[J]. Journal of Southwest Petroleum University:Science & Technology Edition, 2010, 32 (5) : 109 –113. |

| [17] |

汪全林, 廖新武, 赵秀娟, 等. 低渗油藏水平井注水合理井距研究[J].

新疆石油地质, 2012, 33 (6) : 727 –729.

Wang Quanlin, Liao Xinwu, Zhao Xiujuan, et al. Study on reasonable well spacing of horizontal well in low permeability reservoir by water drive process[J]. Xinjiang Petroleum Geology, 2012, 33 (6) : 727 –729. |

2015, Vol. 37

2015, Vol. 37