2. Ontario Forest Research Institute, 1235 Queen Street E, Sault Ste. Marie, ON P6A 2E5, Canada

Biochar is a highly porous and stable carbon-rich co-product of pyrolysis that has many uses including soil amendments and long term carbon sequestration (Lehmann et al. 2006). Pyrolysis is defined as a thermochemical decomposition process occurring in the absence of oxygen (Spokas et al. 2012). Although chemically similar, Biochar differs from charcoal in the sense that it is not used as fuel (Lehmann and Joseph 2009). In this paper we deal with biochar produced from woody biomass in a bioenergy plant using the slow pyrolysis technique, a process that maximizes production, at 300–500 ℃ with a vapour residence time of 5–30 min (Boateng et al. 2010; Bruun et al. 2012; Sohi et al. 2010). Co-production of bioenergy with biochar, with the latter's subsequent application to the soil, has been suggested as one possible method to reduce atmospheric carbon-dioxide (CO2) concentration (Lehmann et al. 2006; Fowles 2007; Laird 2008; Lehmann 2007), thereby mitigating the problem of global warming in the long term (Campbell et al. 2008). However, very few studies have been conducted to assess the comprehensive environmental impacts of biochar-based bioenergy production (IBI 2013). A comparison of a pyrolysis biochar system (PBS) with other bioenergy production systems for carbon abatement found that PBS is 33 % more efficient than direct combustion, even if the soil amendment benefits of biochar are ignored (Hammond et al. 2011). There are also many environmental, economic and legal concerns about the production of biochar and the incorporation of this manufactured material into soils on farms, in forests and elsewhere in the environment (Kookana et al. 2011). Although PBS can be a net GHG emitter (Roberts et al. 2010), biochar produced from forest residue can significantly reduce GHG emissions if biochar is used in land application (Dutta and Raghavan 2014).

Power generation is one of the significant contributors to current GHG emissions (IEA 2013). As of 2009, the electricity and heat generation sectors alone contributed about 9 % of total GHG emissions in the province of Ontario (OPG 2012). Ontario enacted its green energy act (MOE 2010) in 2009 with a major milestone of achieving significant reduction of GHG emissions related to power production. The province has banned the use of coal in electricity production by replacing its coal-generating plants with biomass as feedstock by the end of 2014 (MOE 2010). Accordingly, Ontario Power Generation's (OPG) two coal-fired generating stations (Thunder Bay and Atikokan) are being converted to use wood pellets, from Ontario-sourced forest biomass, as feedstock. The Atikokan station (AGS), with an installed capacity of 230 megawatts (OPG 2012), is now one of the largest 100 % biomass fuelled power plant in North America (Basso et al. 2013). If wood pellets used for power production are locally produced, these will have much less impact on ecosystem quality, climate change, and human health as compared to fossil fuels, whereas transporting wood pellets over long distances adds to the GHG emissions, as transportation is estimated to consume about 35 % of total energy (Dwivedi et al. 2011; Pa et al. 2012). However, conversion from traditional power generation using fossil fuel to wood pellets may have both short and long term unknown (positive or negative) environmental impacts.

Ontario has a large forestland base including 26.2 million hectares of boreal forest. A significant proportion of this (about 18.8 million hectares) is available for intensive forest management activities (MNR 2014). However, concerns have been raised about sustainable supply of woody biomass to produce wood pellets for power generating stations. As the new operations will require more than a million metric tonnes of wood pellets annually, the harvesting of biomass for wood pellets production could possibly have negative environmental impacts. Studies on forest based fibre availability suggest that Ontario has enough surplus biomass available (Wood and Layzell 2003) to meet the demand. There are 18 actively operating forest management units in Northwestern Ontario, which can supply about 2.1 million green tonnes (Finnveden et al. 2009) of forest harvest residue and 7.6 million green tonnes of underutilized woody biomass for bio-energy production, assuming an average annual forest depletion rate 0.6 % of the total productive forest area (Alam et al. 2012).

Use of woody biomass in producing biofuel is becoming a popular practice elsewhere in the world as agriculture grain based biofuel is facing food security critics (Elbehri et al. 2013). Production of biofuel as a stand-alone product from woody biomass is technically viable but financially may not be sustainable (Stephen 2013). A trade of between different co-products of biofuel and biochar is widely considered as one of the GHG emission reduction strategy as land application of biochar sequesters the carbon relatively in a very long time. Han et al. (2013) conducted a life cycle (well-to-wheel) assessment of fast pyrolysis woody biomass based biofuel and found that biofules can reduce the GHG emission when co-produced biochar is applied to the soil.

An effective implementation of biochar as a climatemitigating tool would require an application of vast quantities of biochar into the environment (Biederman and Harpole 2013), which may result in its exposure to nontarget terrestrial and aquatic systems, as wind and water can erode up to 50 % of applied biochar material during application (Major et al. 2010). Therefore, a comprehensive study of biochar-based bioenergy production and its subsequent application to land is required to assess its potential impacts on environmental and economic parameters of the region. Ideally, such a study should include every stage of production and utilization of the product in its life cycle. Woody biomass can be converted into bioenergy (heat or electricity) or energy carriers (char, oil or gas) by different thermochemical and biochemical conversion technologies (Van-Loo and Koppejan 2008). Life cycle assessment (LCA, also known as life-cycle analysis or ecobalance) is a standard technique (ISO 14040: 2006 series) to assess environmental impacts associated with all stages of a product's life from cradle-tograve (i.e., from raw material extraction through materials processing, manufacturing, distribution, use, repair and maintenance, and disposal or recycling) (Afrane and Ntiamoah 2011). LCA techniques have been widely applied to study the impacts of biofuel and bioenergy systems (Roberts et al. 2010; Steele et al. 2012; Rehl and Mueller 2011; Fantozzi and Buratti 2010; Kilpelainen et al. 2011; Zhang et al. 2010) in different regions including Northwestern Ontario. A few studies have also used LCA to compare GHG mitigation and direct carbon sequestration potential of biochar produced from different feedstocks (Hammond et al. 2011; Roberts et al. 2010; Gaunt and Lehmann 2008; Woolf et al. 2010). Although these studies conclude that all biochar systems have GHG mitigation and direct carbon sequestration potential, there exists an inherent trade-off between bioenergy and biochar production (Fowles 2007). A recent review (Homagain et al. 2014) also suggested a thorough life cycle study of biochar-based bioenergy production.

Therefore, the general purpose of this paper is to collect and analyse background information using standard methods, and establish the context within which LCA of biochar and bioenergy co-production in Northwestern Ontario could be carried out. The specific objectives are: (1) to conduct a thorough life cycle inventory of biochar-based bioenergy production with the use of standard local and related global databases; (2) to calculate net energy and GHGs emission of the biochar-based bioenergy production system; (3) to conduct a life cycle environmental impact assessment for potential damage in different impact categories; and (4) to compare the potential environmental impact assessment results for conventional energy production with those for biochar based bioenergy production and its land application in Northwestern Ontario.

Materials and methodsIn this paper, we use International Standards Organisation's (ISO) 14040 series standard LCA methodology consisting of four major steps—goal and scope definition, inventory analysis, impact assessment, and interpretation (SAIC 2006).

Goal and scope definitionThe goal and scope of LCA for this study is to assess the net energy balance, greenhouse gas emissions and associated environmental impact s of a biochar-based bioenergy system and its utilization as a soil amendment to sequester carbon.

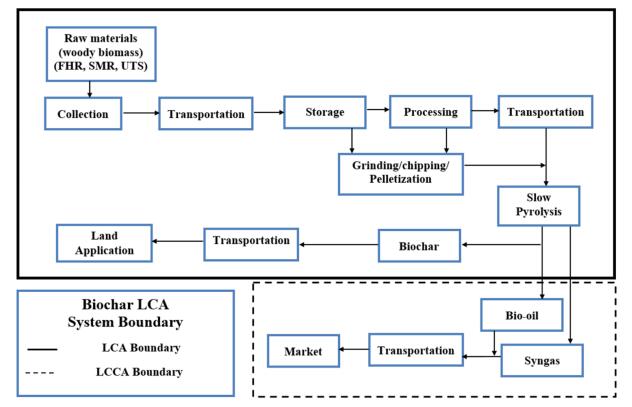

LCA system boundary and functional unitFigure 1 illustrates the life cycle study system boundary within the solid lines. The dotted lines represent the life cycle cost analysis (LCCA) boundary which is not covered in this paper. The unit of analysis is one tonne of biochar (and one megawatt of equivalent electricity that is generated) produced from woody biomass processed into wood pellets. The System boundary, depicted by the solid line in Fig. 1, extends from raw material collection to the application of biochar to the forest, and includes different interdependent phases including collection, transportation, storage, processing and pyrolysis with and without land application. The extended system boundary, depicted by both solid and dotted lines, is used in the life cycle cost estimation phase and is not part of this paper.

|

Fig. 1 System boundary for LCA of biochar-based bioenergy production |

The study area lies in Northwestern Ontario Canada, where the Atikokan Generating Station (AGS) has been converted from coal to biomass (wood pellet) feedstock. Although AGS plans to use the combustion process for energy generation, our study uses a scenario where biomass feedstock will be converted to biochar using the best available pyrolysis process in order to illustrate the benefits of biochar-based bioenergy production. The input–output data for the system boundary and unit processes were obtained directly from the regional forest management unit, forest management plan, and personal communication with harvesters, transporters and other professionals.

Inventory analysisAn ISO standard inventory analysis was performed on material and energy inputs, air emissions (GHGs), and other environmental factors using SimaPro 8.1 LCA software. Inventory data of the built-in database (Ecoinvent and USLCI) of SimaPro 8.1 LCA software for input materials, equipment, processes and emissions was used in this paper (Table 1).

|

|

Table 1 Inventory data and general assumptions of study |

Forest harvest residue (FHR), sawmill residue (SMR) and underutilized trees (UTS) are used as feedstock raw materials, with each source contributing equally in the feedstock mix. FHR and SMR are mostly composed of boreal softwoods (especially SPF-Spruce, Pine, Fir), whereas UTS consists of hardwoods (e.g. Poplars and Birch) and some Tamarack.

Transportation at different stagesNorthern Ontario forest industry standards for transporting biomass feedstock from the forest management unit to storage (average 200 km one-way distance), processed feedstock from storage to the pyrolysis unit (20 km), biochar from the pyrolysis unit to land application (100 km one-way), and biofuels from the pyrolysis unit to markets (100 km) are used in the study. The average truck size is 40 tonnes (60 m3) (Hammond et al. 2011) with a load factor of 75 %. Regular gasoline is used as standard fuel type.

Biochar productionThe standard biochar production process or ''slow pyrolysis'' occurs at 450 ℃ with a 5–30 min vapour residence time (Brown 2009). The process of slow pyrolysis using standard wood pellets (moisture content less than 12 %) is simulated within SimaPro 8.1 LCA software environment with the help of Ecoinvent and USLCI databases. A product yield of bio-oil 35 %, syngas 30 % and biochar 35 % by weight of dry feedstock was used for this study (Brownsort 2009; Ronsee et al. 2013).

StorageTwo different storage stages are considered in the LCA: (ⅰ) storage of biomass feedstock before processing and pelletizing, and (ⅱ) storage of pellets. Storage of biochar is not considered in this study, assuming that it will be applied to land immediately after production.

Land applicationLand application of biochar is used to sequester carbon, and a weight loss of 10 % is assumed during transportation and application. Application loss in could be as high as 30 % depending on the type of biochar (Major 2010).

Impact assessmentEco indicator 99 model of SimaPro 8.1 LCA software, one of the most widely used impact assessment methods in LCA (Cavalett et al. 2013), is used to assess endpoint damage for each scenario in this study based on its scope (system boundary) and available life cycle inventory database (Goedkoop and Spriensma 2001). Impact categories analyzed in this study include damages to human health, damages to ecosystem quality, damages to resources and climate change in global warming potential terms (Afrane and Ntiamoah 2011). Damages to human health are caused by emissions of carcinogens, respiratory effects caused by the emission of organic and inorganic substances, climate change, ionising radiation and ozone layer depletion. Impact assessment unit for this category is disability-adjusted-life-years (DALY). According to Jolliet et al. (2003) DALY characterizes the disease severity, accounting for both mortality (years of life lost due to premature death) and morbidity (the time of life with lower quality due to an illness, e.g., at hospital). Default DALY values of 13 and 1.3 (years/incidence) are adopted for most carcinogenic and non-carcinogenic effects, respectively. For example, a product having a human health score of 3 DALYs implies the loss of 3 years of life over the overall population not the person (Humbert et al. 2012). Damages to ecosystem quality are caused by ecotoxic emissions, combined effects of acidification and eutrophication, and land occupation and conversion. LCA unit for ecosystem quality damage assessment is Potentially Disappeared Fraction (PDF) of species over an area during a certain amount of time (PDF.m2.yr) (Humbert et al. 2012). This represents the fraction of species disappeared on 1 m2 of earth's surface during 1 year. For example, a product having an ecosystem quality score of 0.2 PDF.m2.yr implies the loss of 20 % of species on 1 m2 of earth surface during 1 year (Jolliet et al. 2003). Damages to resources are caused by extraction of minerals and fossil fuels. Climate change impact in this study was assessed by the global-warming potential (Afrane and Ntiamoah 2011) which is a relative measure of how much heat a greenhouse gas traps in the atmosphere. GWP compares the amount of heat trapped by a certain mass of the gas in question to the amount of heat trapped by a similar mass of CO2. It is calculated over a specific time interval, e.g. 20, 100 or 500 years. GWP is expressed as a factor of carbon dioxide (whose GWP is standardized to 1).

InterpretationThe results from SimaPro 8.1 LCA software were normalized, weighted and interpreted in terms of defined impact categories within production stages of the System boundary. In order to understand the effect of changes in the availability of biomass raw material in future, a sensitivity analysis was carried out. It is likely that biomass feedstock for wood pellets will experience competition from other conventional uses. Therefore, the sensitivity analysis is designed to assess the overall impacts of low, medium and high availability of biomass feedstock.

Life cycle net energy analysisNet energy of the system was calculated by deducting the energy output from the total energy input. Similar previous studies indifferent areas ofbiomass and bioenergy production (Hammond et al. 2011; Zhang et al. 2010; Papong and Malakul 2010)were followed tocal culate the net energy of the system in each stages of production within system boundary.

Results Life-cycle inventorySelected key environmental flows for the production stages of biochar, including land application, are presented in Table 2. Processing, pyrolysis and transportation, in that order, utilize the highest total amounts of primary fossil fuel inputs. Storage and land application account for less than half these amounts with collection at about 5 % of processing. With respect to emissions, the order of the largest contributor changes to pyrolysis, transportation and processing with the other three stages accounting for less than 10 % of the amount associated with pyrolysis. Of these emissions, nearly 100 % are accounted for by CO2, SO2, SOx, NMVOC, COD and phosphate for all stages but pyrolysis. Pyrolysis, which consists of several internal thermochemical processes converting biomass to char, gas and bio-oil, also results in the highest levels of CH4, N2O, NOx and nitrate emissions. Net energy and GHG emissions.

|

|

Table 2 Life-cycle inventory for production of 1 tonne biochar from forest biomass feedstock |

Values for net energy and GHG missions for the production stages of biochar do not differ based on the addition of land application. Net energy and GHG emissions per tonne dry feedstock with and without land application of biochar are therefore presented in Table 3 for comparison. Energy balance results show that about 1 GJ more energy is consumed when biochar is applied to the land however, emissions change from a source (-215 kg CO2e) to a sink (68 kg CO2e) when land application is included.

|

|

Table 3 Net energy and GHG emissions per tonne dry feedstock with and without land application of biochar as compared to coal based energy production system |

Transportation and pyrolysis are the largest consumers of energy while pyrolysis and collection are the largest generators of energy.

Environmental impactsSimaPro results for biochar-based bioenergy production using pyrolysis with and without land application for potential environmental impacts and impact reduction by each impact category are compared with a conventional coal-based system and presented in Table 4. Negative percent variations indicate reductions from the reference scenario which means that there is a positive environmental impact. With or without land application, the biochar production scenario adversely impacts respiratory organics and inorganics, ionizing radiations, and aquatic acidification. However, the impact on aquatic acidification with land application scenario is less severe than in the pyrolysis alone scenario. Similarly, aquatic eutrophication changes with land application improving the situation substantially. The pyrolysis scenario alone leads to reductions in the impacts of 9 categories; inclusion of land application actually reduces this number to 8 with terrestrial ecotoxicity and acidification increasing while aquatic eutrophication declines. The negative impacts of global warming and non-renewable energy, respectively, are reduced from 18 to 21 % and from 4 to 7 % with land application.

|

|

Table 4 Comparative environmental impact potential per tonne of biochar produced as compared to coal based energy production system |

Damage assessment and total impact single scores per tonne of biochar production within the system boundary are presented in Table 5. Both scenarios resulted in reduced impacts on all scores except DALY. Land application nearly doubles the positive impacts on ecosystem quality and climate change while improving resource use by approximately 30 %. DALY increases by 1.69 and 3.39 % with and without land application, respectively.

|

|

Table 5 Life cycle impact points of biochar-based bioenergy per tonne of biochar produced |

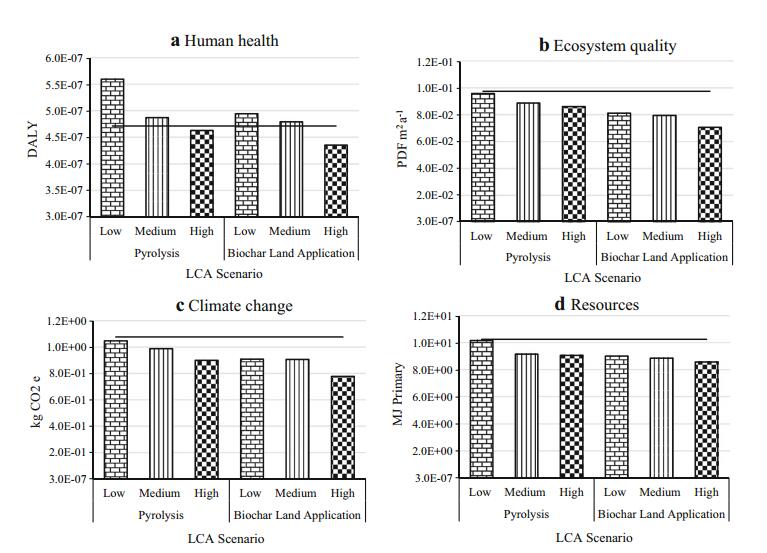

Sensitivity analysis based on biomass availability was done to assess the damage for each impact category (Fig. 2). Impacts decline as biomass availability increases and land application improves all impacts over pyrolysis alone.

|

Fig. 2 Sensitivity analysis of biomass feedstock availability for different impact categories. (Horizontal line is the reference case) |

Use of woody biomass for biochar-based bioenergy production is a relatively new initiative in Northwestern Ontario. Life cycle assessment inventory and impact assessment results presented in this paper are based on system boundary and the model assumptions made during the run. Production of biochar-based bioenergy and replacing it with conventional (Faaij et al.1998)energyproduction system adds several activities that may not have been accounted for in our analysis. We have only accounted for collection of raw materials (woody biomass), transportation in different stages, storage, processing (drying, grinding and pelletization), pyrolysis and land application of biochar in the system boundary defined for our analysis.

Our assumption of biochar-based bioenergy production is based on conventional forest biomass transportation, storage, processing and burning in a modern pyrolysis plant. Each of these operations requires major consumption of fossil fuel and has related GHG emissions (Pa et al. 2011; Magelli et al. 2009). The additional GHG emissions may be reduced by land application of biochar, which is stable for many years, and also by using bio-oil and syngas produced in the pyrolysis process to replace fossil fuel in power generation.

Net energy consumption warrants that the biochar-based bioenergy system is a net energy consumer, which uses more energy than it generates. But it will reduce GHG emissions significantly within the life cycle if biochar is applied to the land. Xu et al. (2011) also concluded that the thermal self-sustainability of lab based biochar production by pyrolysis can be energy negative but with the alternation in the system and use of advanced technology these losses can be reduced in the future. Our results of consumption of 3.7 GJ of more energy to sequester 214 kg of equivalent CO2 is consistent with other studies (Hammond et al. 2011; Zhang et al. 2010).

Both positive and adverse environmental impacts of biomass burning are eminent. Among the different kind of biomass available for burning, forest based woody biomass are considered environmentally cleaner as they claim that they are being burned for the power generation instead of letting them decompose in the nature and they use less energy input in production. In our results, we found that most of the impact categories are positively impacted by biochar production and land application. The most notable advantage is reduction of global warming potential by 18 and 21 % with either scenario. Some notable adverse effects are mostly related to human health by exposing to carcinogenic emissions, respiratory organics and land pollution but which are pretty low in scale as compared to similar other disadvantages of burning coal. This adverse impact is mainly due to the new wood burning scenario and added biomass transportation in the system boundary which in the future might be reduced by proper personal protection instruments and improving pyrolysis plant and improving transportation efficiency. The damage assessment of the unit process as indicated by LCA and inventory is mostly positive for each impact category except in human health. With the improvement of ecosystem quality by 18 % reducing climate impact by up to 15 % and reducing non-renewable resource dependency by 15 % in the life cycle of biochar can easily contribute to compensate this human health impact of 2–3 % DALY. Similar increase of DALY was also reported by Huang et al. (2013). Our sensitivity analysis of availability of biomass also resulted in best performance when availability of biomass is high in the close area to the pyrolysis plant. It reflects directly with the reduced transportation and low loss of energy. It also supports the local use of biomass resource.

ConclusionsLife cycle assessment of biochar-based bioenergy production system with land application of biochar is conducted within a defined system boundary in Northwestern Ontario. It is found that (ⅰ) biomass collection, transportation and pyrolysis processes are most energy intensive and account for about 75 % of the total GHG emissions of the system; (ⅱ) the net energy of the biochar-based bioenergy system is negative but it can reduce and GHG emissions with land application of biochar; (ⅲ) biochar-based bioenergy can have some adverse impact on human health but it significantly reduces the impact of climate change by improving ecosystem quality and reduction of dependence on nonrenewable resources; and (ⅳ) pyrolysis and land application of biochar have most promising positive environmental impacts as compared with conventional coal based power generation system, if biomass availability is high. In this paper, we have only accounted for the environmental impact side of biochar-based bioenergy production, and did not consider the cost of production and GHG emissions reduction. Further research should focus on life cycle cost analysis of the biochar-based bioenergy system, as its economics are fundamental to the financial sustainability of the system.

AcknowledgmentsFinancial contributions from (1) Natural Sciences and Engineering Research Council of Canada through Industrial Postgraduate Scholarships (NSERC-IPS), (2) Ontario Graduate Scholarship (OGS) and (3) Ontario Power Generation (OPG) for this study is highly acknowledged.

Afrane G, Ntiamoah A (2011) Comparative life cycle assessment of charcoal, biogas, and liquefied petroleum gas as cooking fuels in Ghana. J Ind Ecol 15: 539-549. DOI:10.1111/j.1530-9290.2011.00350.x |

Alam MB, Pulkki R, Shahi C (2012) Woody biomass availability for bioenergy production using forest depletion spatial data in Northwestern Ontario. Can J For Res 42: 506-516. DOI:10.1139/x2012-011 |

Basso AS, Miguez FE, Laird DA, Horton R, Westgate M (2013) Assessing potential of biochar for increasing water-holding capacity of sandy soils. GCB Bioenergy 5: 132-143. DOI:10.1111/gcbb.12026 |

Biederman LA, Harpole WS (2013) Biochar and its effects on plant productivity and nutrient cycling: a meta-analysis. GCB Bioenergy 5: 202-214. DOI:10.1111/gcbb.12037 |

Boateng AA, Mullen CA, Goldberg NM, Hicks KB, Devine TE, Lima IM, McMurtrey JE (2010) Sustainable production of bioenergy and biochar from the straw of high-biomass soybean lines via fast pyrolysis. Environ Prog Sustain Energy 29: 175-183. DOI:10.1002/ep.v29:2 |

Brown R (2009) Biochar production technology. In: Lehmann J, Joseph S (eds) Biochar for environmental management: science and technology. Routledge, London, pp 127-146

|

Brownsort P (2009) Biomass pyrolysis processes: performance parameters and their influence on biochar system benefits. M. Sc. Dissertation, University of Edinburgh, Edinburgh

|

Bruun EW, Ambus P, Egsgaard H, Hauggaard-Nielsen H (2012) Effects of slow and fast pyrolysis biochar on soil C and N turnover dynamics. Soil Biol Biochem 46: 73-79. DOI:10.1016/j.soilbio.2011.11.019 |

Campbell JE, Lobell DB, Genova RC, Field CB (2008) The global potential of bioenergy on abandoned agriculture lands. Environ Sci Technol 42: 5791-5794. DOI:10.1021/es800052w |

Cavalett O, Chagas MF, Seabra JEA, Bonomi A (2013) Comparative LCA of ethanol versus gasoline in Brazil using different LCIA methods. Int J Life Cycle Assess 18: 647-658. DOI:10.1007/s11367-012-0465-0 |

Department for Environment, Food and Rural Affairs (DEFRA) (2009) Guidance on how to measure and report your greenhouse gas emissions. Department for Environment, Food and Rural Affairs UK. https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/69282/pb13309-ghg-guidance-0909011.pdf. Accessed 10 May 2013

|

Dutta B, Raghavan V (2014) A life cycle assessment of environmental and economic balance of biochar systems in Quebec. Int J Energy Environ Eng 5: 1-11. DOI:10.1186/2251-6832-5-1 |

Dwivedi P, Bailis R, Bush TG, Marinescu M (2011) Quantifying GWI of wood pellet production in the Southern United States and its subsequent utilization for electricity production in the Netherlands/Florida. Bioenergy Res 4: 180-192. DOI:10.1007/s12155-010-9111-5 |

Elbehri A, Segerstedt A, Liu P (2013) Biofuels and the sustainability challenge: a global assessment of sustainability issues, trends and policies for biofuels and related feedstocks. Food and agriculture organization of the United Nations (FAO), Rome

|

Elsayed MA, Mortimer ND (2001) Carbon and energy modelling of biomass systems: conversion plant and data updates. DTI http://www.pfpi.net/wp-content/uploads/2011/04/PFPI-biomass-carbon-accounting-overview_April.pdf. Accessed 27 May 2014

|

Faaij A, Meuleman B, Turkenburg W, van Wijk A, Bauen A, Rosillo-Calle F, Hall D (1998) Externalities of biomass based electricity production compared with power generation from coal in the Netherlands. Biomass Bioenergy 14: 125-147. DOI:10.1016/S0961-9534(97)10005-8 |

Fantozzi F, Buratti C (2010) Life cycle assessment of biomass chains: wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 34: 1796-1804. DOI:10.1016/j.biombioe.2010.07.011 |

Finnveden G, Hauschild MZ, Ekvall T, Guinee J, Heijungs R, Hellweg S, Koehler A, Pennington D, Suh S (2009) Recent developments in life cycle assessment. J Environ Manag 91: 1-21. DOI:10.1016/j.jenvman.2009.06.018 |

Fowles M (2007) Black carbon sequestration as an alternative to bioenergy. Biomass Bioenergy 31: 426-432. DOI:10.1016/j.biombioe.2007.01.012 |

Gaunt JL, Lehmann J (2008) Energy balance and emissions associated with biochar sequestration and pyrolysis bioenergy production. Environ Sci Technol 42: 4152-4158. DOI:10.1021/es071361i |

Goedkoop M, Spriensma R (2001) The Eco-indicator 99: a damage oriented method for life cycle impact assessment—methodology report. PRe Consultants, Amersfoort

|

Hammond J, Shackley S, Sohi S, Brownsort P (2011) Prospective life cycle carbon abatement for pyrolysis biochar systems in the UK. Energy Policy 39: 2646-2655. DOI:10.1016/j.enpol.2011.02.033 |

Han J, Elgowainy A, Dunn JB, Wang MQ (2013) Life cycle analysis of fuel production from fast pyrolysis of biomass. Bioresour Technol 133: 421-428. DOI:10.1016/j.biortech.2013.01.141 |

Homagain K, Shahi C, Luckai N, Sharma M (2014) Biochar-based bioenergy and its environmental impact in northwestern Ontario Canada: a review. J For Res 25(4): 737-748. DOI:10.1007/s11676-014-0522-6 |

Huang YF, Syu FS, Chiueh PT, Lo SL (2013) Life cycle assessment of biochar cofiring with coal. Bioresour Technol 131: 166-171. DOI:10.1016/j.biortech.2012.12.123 |

Humbert S, Schryver AD, Bengoa X, Margni M, Jolliet O (2012) Life cycle assessment IMPACT 2002+ User Guide. http://www.quantis-intl.com/files/8814/1198/3664/IMPACT2002_UserGuide_for_vQ2.21_30April2014a.pdf. Accessed 17 May 2014

|

Intergovernmental Panel on Climate Change (IPCC) (2007) Climate change 2007: the physical science basis. Contribution of Working Group Ⅰ to the Fourth Assessment Report of the IPCC. http://www.ipcc.ch/pdf/assessment-report/ar4/wg1/ar4_wg1_full_report.pdf. Accessed 11 Dec 2012

|

International Biochar Initiative (IBI) (2013) Biochar research and educational resources. http://www.biochar-international.org/research/education. Accessed 10 Dec 2013

|

International Energy Agency (IEA) (2013) World Energy outlook 2013: executive summary. Paris

|

Jolliet O, Margni M, Charles RL, Humbert S, Payet J, Rebitzer G, Rosenbaum R (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8: 324-330. DOI:10.1007/BF02978505 |

Kilpelainen A, Alam A, Strandman H, Kellomaki S (2011) Life cycle assessment tool for estimating net CO2 exchange of forest production. Glob Chang Biol Bioenergy 3: 461-471. DOI:10.1111/gcbb.2011.3.issue-6 |

Kookana RS, Sarmah AK, Van Zwieten L, Krull E, Singh B (2011)Biochar application to soil: agronomic and environmental benefits and unintended consequences. In: Donald LS (ed)Advances in agronomy. Academic Press, San Diego, pp 103-143

|

Laird DA (2008) The charcoal vision: a win-win-win scenario for simultaneously producing bioenergy, permanently sequestering carbon, while improving soil and water quality. Agron J 100: 178-181. DOI:10.2134/agronj2007.0161 |

Lehmann J (2007) A handful of carbon. Nature 447: 143-144. DOI:10.1038/447143a |

Lehmann J, Joseph S (2009) Biochar for environmental management: an introduction. In: Lehmann J, Joseph S (eds) Biochar for environmental management science and technology. Earthscan, London, Washington D. C., pp 1-12

|

Lehmann J, Gaunt J, Rondon M (2006) Bio-char sequestration in terrestrial ecosystems: a review. Mitig Adapt Strateg Glob Chang 11: 395-419. |

Magelli F, Boucher K, Bi HT, Melin S, Bonoli A (2009) An environmental impact assessment of exported wood pellets from Canada to Europe. Biomass Bioenergy 33: 434-441. DOI:10.1016/j.biombioe.2008.08.016 |

Major J (2010) Guidelines on practical aspects of biochar application to field soil in various soil management systems. Int Biochar Initiat, IBI p20

|

Major J, Lehmann J, Rondon M, Goodale C (2010) Fate of soilapplied black carbon: downward migration, leaching and soil respiration. Glob Chang Biol 16: 1366-1379. DOI:10.1111/gcb.2010.16.issue-4 |

Ministry of Environment Ontario (MOE) (2010) Ontario's coal phase out plan 2010. http://news.ontario.ca/mei/en/2009/09/ontarioscoal-phase-out-plan.html. Accessed 13 July 2014

|

Ministry of Natural Resources (MNR) (2014) Forest resources of Ontario 2011. Ministry of Natural Resources Ontario. https://www.ontario.ca/environment-and-energy/forest-resourcesontario-2011. Accessed 15 July 2014

|

Mortimer ND, Evans A, Shaw VL, Hunter AJ (2009) Life cycle and techno-economic assessment of the North East biomass to liquids project. North Energy Associates Limited, New York

|

Ontario Power Generation (OPG) (2012) Atikokan Generating Station bio-mass fuel suppliers announced: meeting the needs of a growing economy in Northwestern Ontario. http://www.opg.com/news/releases/121122Atikokan%20Fuel%20Contracts_FINAL.pdf. Accessed 13 July 2014 Pa A, Bi XTT, Sokhansanj S (2011) A life cycle evaluation of wood pellet gasification for district heating in British Columbia. Bioresour Technol 102: 6167-6177

|

Pa A, Craven JS, Bi XTT, Melin S, Sokhansanj S (2012) Environmental footprints of British Columbia wood pellets from a simplified life cycle analysis. Int J Life Cycle Assess 17: 220-231. DOI:10.1007/s11367-011-0358-7 |

Papong S, Malakul P (2010) Life-cycle energy and environmental analysis of bioethanol production from cassava in Thailand. Bioresour Technol 101: S112-S118. DOI:10.1016/j.biortech.2009.09.006 |

Rehl T, Mueller J (2011) Life cycle assessment of biogas digestate processing technologies. Resour Conserv Recycl 56: 92-104. DOI:10.1016/j.resconrec.2011.08.007 |

Roberts KG, Gloy BA, Joseph S, Scott NR, Lehmann J (2010) Life cycle assessment of biochar systems: estimating the energetic, economic, and climate change potential. Environ Sci Technol 44(2): 827-833. DOI:10.1021/es902266r |

Ronsse F, Van Hecke S, Dickinson D, Prins W (2013) Production and characterization of slow pyrolysis biochar: influence of feedstock type and pyrolysis conditions. GCB Bioenergy 5: 104-115. DOI:10.1111/gcbb.12018 |

Scientific Applications International Corporation (SAIC) (2006) Life cycle assessment: principles and practice. 11251 Roger Bacon Drive, Reston, VA 20190 USA, p 14

|

Sohi SP, Krull E, Lopez-Capel E, Bol R (2010) A review of biochar and its use and function in soil. In: Donald LS (ed) Advances in agronomy. Academic Press, San Deigo, pp 47-82

|

Spokas KA, Cantrell KB, Novak JM, Archer DW, Ippolito JA, CollinsHP, Boateng AA, Lima IM, Lamb MC, McAloon AJ, Lentz RD, Nichols KA (2012) Biochar: a synthesis of its agronomic impact beyond carbon sequestration. J Environ Qual 41: 973-989. DOI:10.2134/jeq2011.0069 |

Statistics Canada (StatsCan) (2012) The energy statistics handbook first quarter 2012 (2012). http://www.statcan.gc.ca/pub/57-601-x/57-601-x2012001-eng.pdf. Accessed 10 Feb 2014

|

Steele P, Puettmann ME, Penmetsa VK, Cooper JE (2012) Life-cycle assessment of pyrolysis bio-oil production. For Prod J 62: 326-334. |

Stephen JD (2013) The viability of lignocellulosic ethanol production as a business endeavour in Canada. PhD Thesis, Faculty of Forestry, University of British Columbia, Canada. P225+xiv

|

Van-Loo S, Koppejan J (2008) The handbook of biomass combustion and cofiring. Earthscan, London, Washington, DC, p 442+xii

|

Wood SM, Layzell DB (2003) A Canadian biomass inventory: feedstocks for a bio-based economy. Canada, BIOCAP Canada Foundation, Queen's University Ontario

|

Woolf D, Amonette JE, Street-Perrott FA, Lehmann J, Joseph S (2010) Sustainable biochar to mitigate global climate change. Nat Commun 1: 56. |

Xu R, Ferrante L, Hall K, Briens C, Berruti F (2011) Thermal selfsustainability of biochar production by pyrolysis. J Anal Appl Pyrol 91: 55-66. DOI:10.1016/j.jaap.2011.01.001 |

Zhang Y, McKechnie J, Cormier D, Lyng R, Mabee W, Ogino A, MacLean HL (2010) Life cycle emissions and cost of producing electricity from coal, natural gas, and wood pellets in Ontario, Canada. Environ Sci Technol 44: 538-544. DOI:10.1021/es902555a |

2015, Vol. 26

2015, Vol. 26