2. 高性能工具全国重点实验室, 广东 广州 510006

2. State Key Laboratory for High-Performance Tools, Guangzhou 510006, China

近三十年来,随着机床结构刚性、数控技术、刀具设计以及表面涂层技术的不断发展,针对难加工材料高速切削加工的技术优势日益凸显。切削速度的提升直接带来加工效率的大幅增加,且切削过程中大量切削热被高速排出的切屑带走,有利于减少工件的内应力与热变形;高切削速度使刀具激振频率与机床固有低阶频率错开,可以有效避免共振现象的产生,具有保证加工精度与提升表面质量等一系列优点[1-2]。但在实际切削加工过程中,存在切削力大、切削温度高、刀具磨损快等问题,高速高效切削加工刀具的性能提高很大程度上依赖于刀具涂层的发展。

为满足现代制造业对高速高效高精度切削加工的需求,世界各国对刀具涂层技术发展日益重视;我国刀具涂层技术经过多年发展,目前正处于关键时期,即国内刀具涂层装备和技术在结构外形和部分功能上已经基本赶上国外技术,但缺乏对关键核心问题和技术的理解,导致与国外先进刀具涂层技术始终保持一定差距。本文将对用于高速高效切削刀具的物理气相沉积(Physical Vapor Deposition, PVD)涂层和技术进行综述,对关键核心科学和技术问题进行阐述和总结。本文列举了氮化物、硼化物和氧化物等具有代表性的PVD硬质涂层的研究和应用近况,展望了学术界和工业界未来的关注重点和发展方向,以使其工艺和涂层更符合高速高效切削涂层刀具发展的要求。

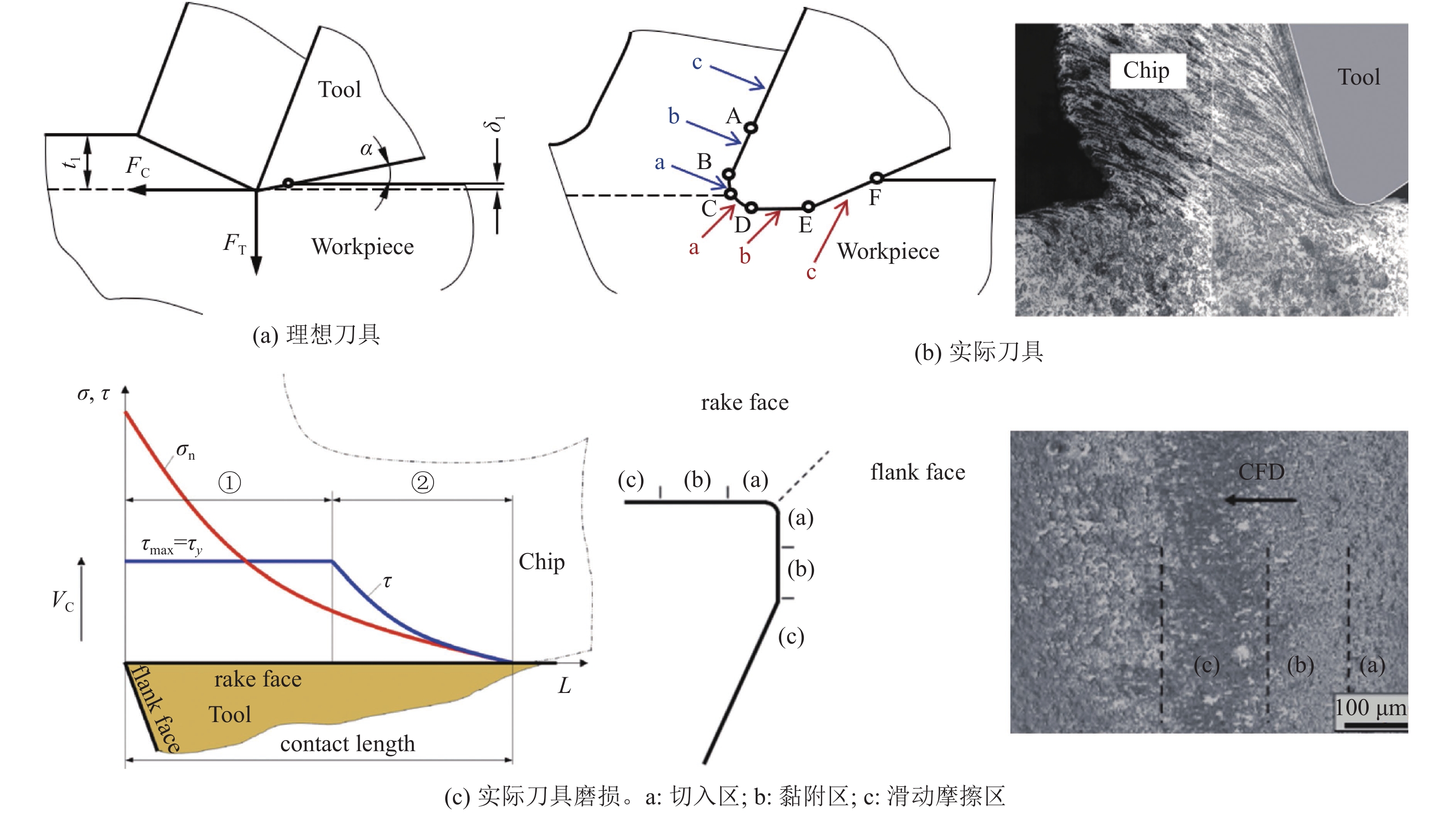

1 金属切削对刀具涂层的要求如图1,刀具在切削过程中刀尖发生强烈变形和挤压摩擦,切屑的形成过程涉及剪切区域的塑性形变,在刀具上产生切削热和接触应力,刀具受到磨粒和黏着磨损,前后刀面依次出现切入区、黏附区和滑动摩擦区,被加工材料黏附冷焊和摩擦磨损导致刀刃磨损失效[3-4]。刀具涂层切削过程中被加工材料在涂层前后刀面上黏附、磨损、氧化、破碎,导致刃口涂层的快速失效(图2);在高速精密切削中,圆弧刀尖所占厚度比例加大,高压变形和挤压摩擦加剧,断刃和涂层剥落严重;滑动摩擦速度大幅加快,温度升高,导致前后刀面快速磨损;难加工材料会进一步加速刀具磨损[5-7]。

|

图 1 实际刀具受力及摩擦示意图 Figure 1 Schematic diagram of actual tool forces and friction |

|

图 2 刀具涂层应用过程中黏结、磨损和刃口破碎图片;(a) 二次电子SEM图片,(b) 背散射SEM图片,(c) 截面背散射SEM图片[5] Figure 2 Images of bonding, wear, and edge fracture during tool coating application process, (a) Secondary electron SEM image, (b) Backscattered SEM image, and (c) Cross-section backscattered SEM Image[5] |

硬质涂层的任务是为切削刀具基体提供磨损保护和热防护,对涂层的具体要求取决于切削工艺、参数和被加工材料的选择。在连续切削过程中(如车削),刀−屑(刀刃−切屑)、刀−工(刀刃−工件)接触区域通常会达到较高温度,具有低热导率的厚涂层(5~20 μm)被认为有利于车削应用,它们为刀具基体提供热屏障,让产生的热量被转移到切屑中,从而降低刀具刃口的热负荷,阻止或延缓刀具刃口的塑性变形[8];但对于导热系数低的工件材料,接触热通过切屑转移出去的能力较弱,造成接触表面温度高和刀具表面很大的热梯度,这就需要导热系数较高的涂层来从接触区域散去热量[9],在切削难加工材料时,垂直表面导热率低、平行表面导热率高的刀具涂层是较优设计。在断续切削中,例如铣削工艺,热量不会连续产生,因此接触面温度低于连续切削,但循环的应力和热载荷会导致切削刃产生疲劳破损[9],通常具有残余压应力的薄涂层(3~5 μm)适合此类应用,如PVD涂层。在钛合金等有色合金的切削加工中,被加工材料黏附于刀具表面,是刀具涂层失效的主要原因之一。

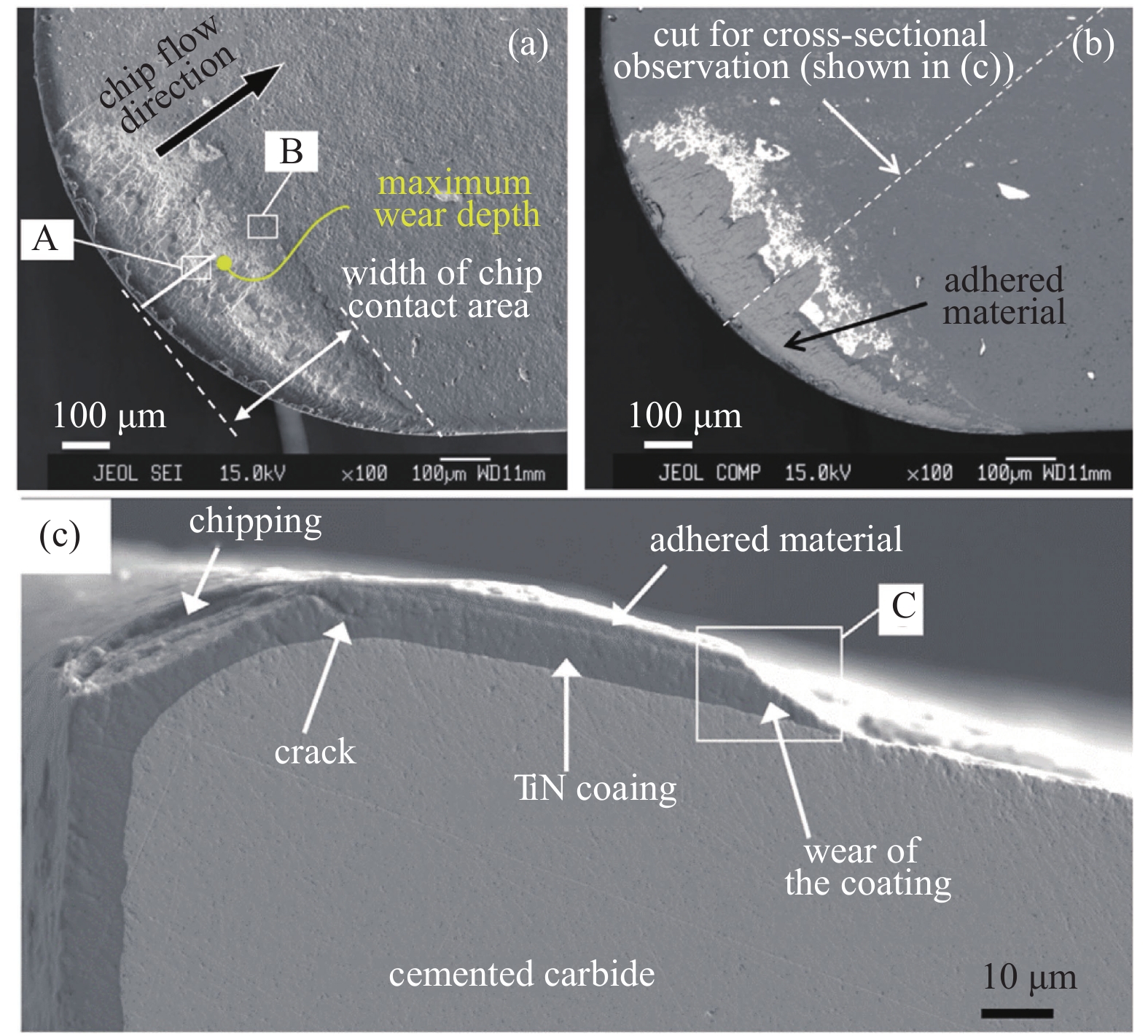

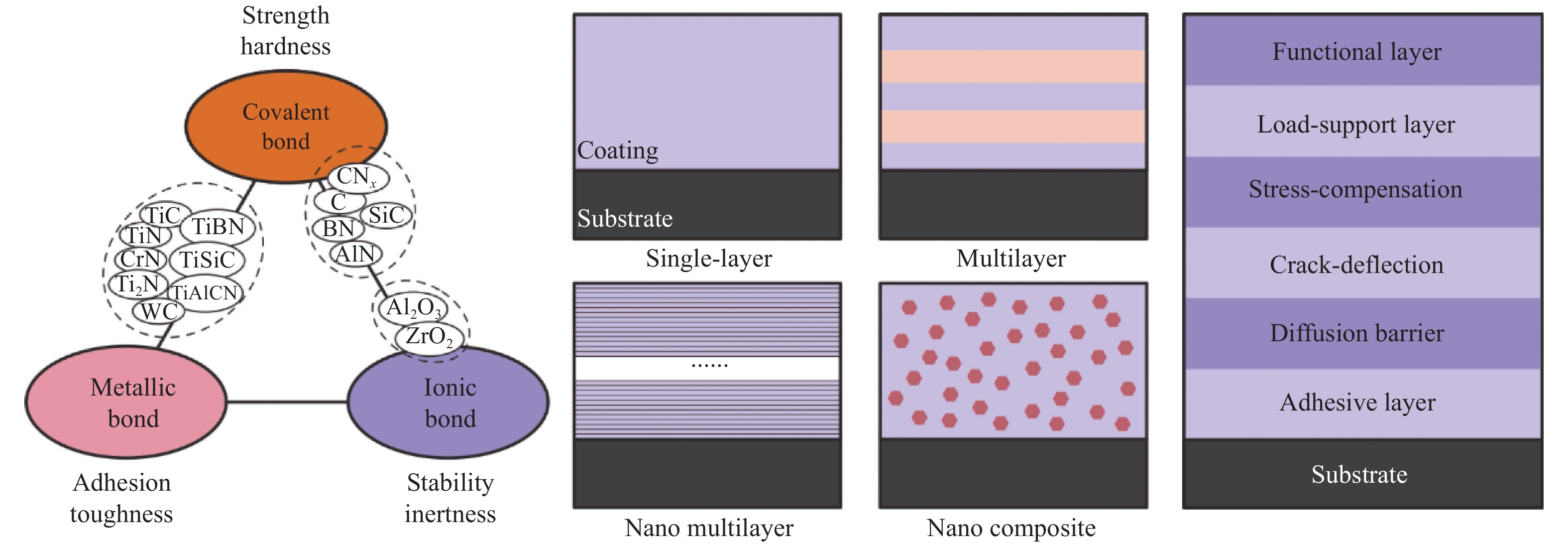

2 刀具涂层材料硬质涂层性能与其化学键成分有关(如图3[10]),分共价键为主的超硬涂层(金刚石、立方氮化硼等)、离子键为主的惰性涂层(氧化铝、氧化铬等)、金属键和共价键混合的硬韧涂层(氮化钛、硼化钛等),化学键的性质决定涂层力学、化学性能,影响涂层与基体的结合力;涂层材料以单层或者多层、纳米多层/纳米复合结构组成刀具涂层,在实际刀具涂层设计中,为改善与基体的界面结合及调控涂层的元素扩散、应力分布、承载能力和表面功能性等,会考虑多层的涂层设计。

|

图 3 刀具涂层材料化学键和常见组织结构示意图[10] Figure 3 Schematic diagram of chemical bonds and common microstructures in tool coating materials [10] |

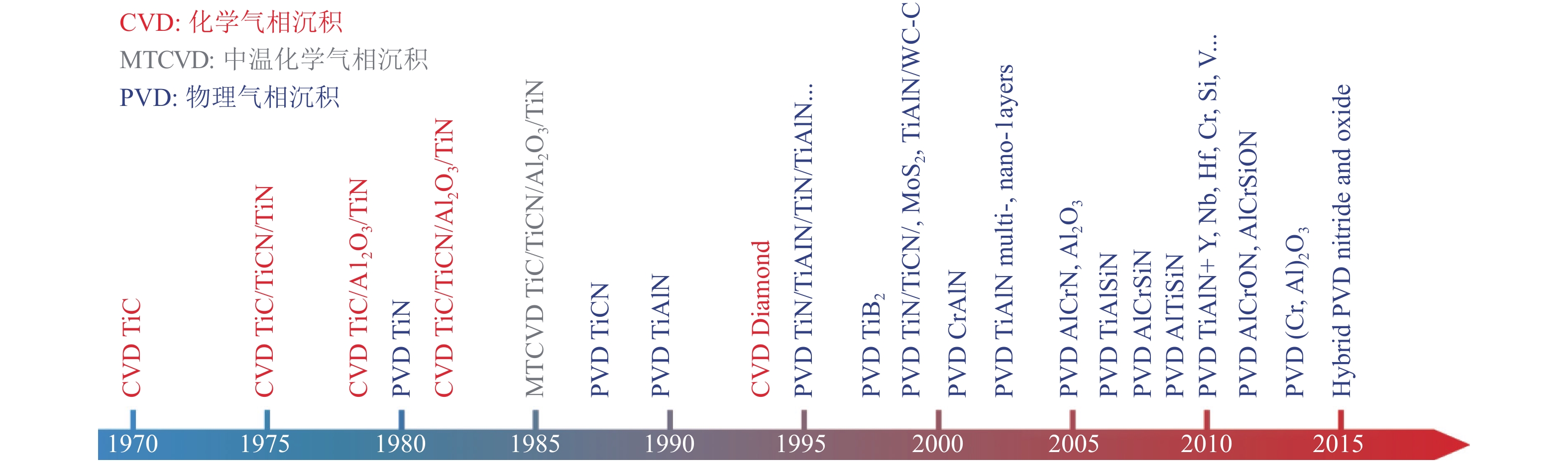

图4总结了刀具涂层材料的发展历程,刀具涂层技术分为化学气相沉积(Chemical Vapor Deposition, CVD)和物理气相沉积(PVD)。最早商用的刀具涂层为CVD-TiC涂层[11],随后TiN、TiCN和Al2O3涂层也相继投放市场[12];上世纪80年代PVD涂层(TiN、TiC)首次在高速钢钻头上成功应用[13];随着切削速度的提升和难加工材料的使用,刀具服役条件日益严苛,TiN、TiC涂层的高温性能已不能满足加工需要,1986年,Wolf-Dieter等[14]在TiN涂层中添加Al元素制备了Ti0.5Al0.5N涂层,涂层的起始氧化温度从TiN的500~550 ℃提升至700~800 ℃,钻削不锈钢时寿命较TiN增加了至少两倍,自此PVD涂层引起广泛关注,研发呈井喷趋势。相比于CVD,PVD具有显著的优点:涂层种类多,沉积温度较低,适用于大多数刀具基体材料,目前已发展出了多种元素、多种结构(多层、纳米多层、纳米复合)、多材料(氮化物、硼化物、氧化物)的PVD刀具涂层。下面将以基于PVD技术制备的氮化物、硼化物和氧化物材料分类总结和阐述刀具涂层的设计理念和研究进展。

|

图 4 刀具涂层的发展历程 Figure 4 Development history of tool coatings |

氮化物刀具涂层材料经历二元(TiN、CrN)→多元(TiAlN、CrAlN等)→纳米多层(如TiAlN/TiN)→纳米复合结构(TiSiN、TiAlSiN等)的发展[15]。在刀具涂层的发展中,多元合金化、纳米多层和纳米复合是涂层强韧化,提升高温性能、摩擦学性能的重要手段。

多元刀具涂层的典型代表是TiAlN涂层,Al的引入使涂层的硬度和抗氧化性显著提升,并具有优异的高温稳定性,目前TiAlN涂层已广泛用于切削刀具的表面防护,常见的涂层成分有:Ti0.5Al0.5N、Ti0.4Al0.6N和Ti0.33Al0.67N。CrAlN涂层作为多元涂层的另一典型代表,更适用于对韧性和抗氧化性要求较高的场景,其Al的原子分数可达到70%依然保持单相面心立方(FCC)结构[16]。目前研究者在TiAlN和CrAlN涂层的基础上加入V、Nb、Ta、Mo、W等元素开发了更多种类的多元涂层,例如,在TiAlN中引入Cr元素既能提高涂层的抗氧化性能和摩擦性能,又能减少刀具的黏附和磨损[17];V元素可在摩擦过程中生成具有润滑作用V2O5相,有利于降低涂层的摩擦系数,提高耐磨性[18];添加Ta元素可提高涂层的高温硬度和热稳定性[19];多种元素共同添加可以协同提高涂层的高温稳定性、抗氧化性和高温摩擦性能等。Lembke等[20]研究表明Cr和Y元素共同添加能明显改善TiAlN涂层的高速干式切削性能。Aninat等[21]研究发现TiAlTaYN涂层在氧化过程中能够形成独特的混合氧化物结构,表现出优异的高温抗氧化性。笔者通过Cr和Ta的共合金化添加成功实现了TiAlN涂层热稳定性和抗氧化性的协同提升[22]。

纳米多层结构基于1970年Koehler提出的材料增强理论,1978年在Al/Cu和Al/Ag等纳米多层体系得到实验验证[23]。1987年Helmersson等[24]在单晶MgO基体上构建的TiN/VN纳米多层涂层表现出5560 kg/mm2的硬度,比传统单层TiN和VN涂层高出一倍;上世纪90年代中期起纳米多层涂层已在切削刀具成功应用[25]。Li等[26]通过交替沉积TiAlN和CrAlN制备的TiAlN/CrAlN纳米多层涂层,硬度高达~38.2 GPa,且具良好的热稳定性和抗氧化性,在车削和铣削加工中表现明显优于单层涂层。而Xu等[27]通过减少TiAlN/ZrN纳米多层涂层的调制比时,实现层间界面结构从非共格到共格的转变,获得硬度提升。一般而言,纳米多层涂层由两种或者两种以上具有不同成分或结构的单层涂层交替沉积而成,纳米多层涂层存在一个最优的调制周期和调制比使涂层的力学性能达到最大值,如AlTiN/AlCrSiN涂层的调制周期为8.3 nm时具有最优的硬度和耐磨性[28];通过改变调制层的组分、调制周期和调制比,可灵活调控涂层的结构和性能以适应不同的应用场景。

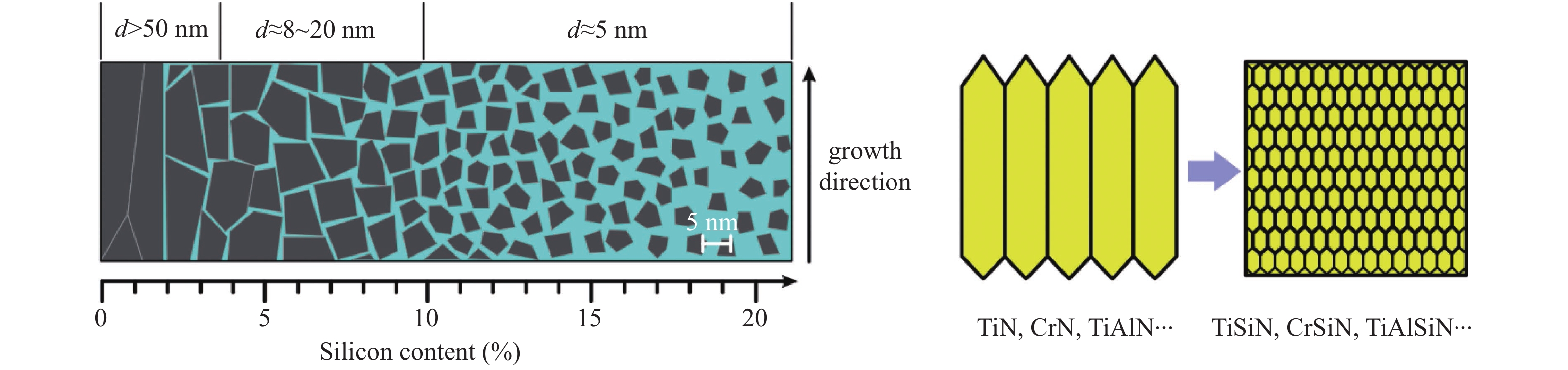

MeSiN(Me=Ti、Cr、TiAl、CrAl等)涂层基于热力学相分离产生纳米尺寸的晶粒被非晶相包裹的纳米复合结构[29](图5),硬度显著高于传统涂层且高温性能优异,Veprek报道出80~105 GPa的超高硬度,尽管后人无人能够重复如此高硬度,但纳米复合结构涂层硬度达到40 GPa已经远高于传统涂层,特别在高温下可以保持高硬度,是一类很有发展前途的刀具涂层材料[30]。学者们采用多种工艺制备MeSiN涂层,获得了性能明显优于传统涂层的纳米复合涂层,部分已在刀具涂层产业获得应用[31-34]。

|

图 5 MeSiN纳米复合涂层微观组织结构示意图[29] Figure 5 Schematic diagram of the microstructure of MeSiN nanocomposite coatings [29] |

固溶强化和调幅分解产生的共格界面强化是多元氮化物涂层常用的增强方式[22, 35],在MeSiN涂层中添加其他元素可进一步提高涂层硬度和性能,Chen[36]、Fu[37]等在TiSiN和CrSiN中加入Al和Mo金属元素,获得35.5~42.4 GPa高硬度的纳米复合涂层;Wu[38]、Gu[39]在TiAlSiN基础上加入非金属元素B和C,也获得了明显的硬度增强。但总体而言,纳米晶内固溶强化机理尚不清楚,纳米晶析出结构和共格强化也缺乏研究。纳米孪晶也是一种可能的增强方式。虽然氮化物涂层因层错能较高不易产生孪晶,但Xu[40]和Chen[41]通过等离子体参数调控制备出纳米孪晶结构的TiN涂层和CrN/AlN多层涂层,获得硬度增强。

2.2 硼化物刀具涂层过渡金属硼化物和过渡金属硼氮化物是极具潜力的刀具涂层,并被证实在钛合金、铝合金以及碳纤维增强塑料的加工场合中具有优异的切削性能,然而相对于过渡金属氮化物和碳化物在理论和实验上较多的研究,硼(氮)化物作为刀具涂层研究明显较少,限制硼(氮)化物刀具涂层广泛应用的最大难题是其力学性能不稳定、脆性大、低基体结合力和较低的氧化起始温度。硼化物M-B为本征硬质材料,其高硬度来源于B-B共价键和共价键占优的M-B混合化学键,M和B原子轨道的杂化作用影响M-B材料的本征硬度、脆性等力学性能及界面润湿性能,沉积等离子体影响的B元素含量和多元固溶掺杂可改变化学键特性,进而调控涂层性能[9, 42-43];磁控溅射的M-B涂层中,过量B偏析于晶界形成团簇柱状纳米复合结构[44-45],M-B涂层中引入N组元可生成MB、MN纳米晶,硬质h-BN或软质a-BN相,金属元素(Al、Cr、Ta等)偏析于晶界也会形成纳米复合结构,涂层硬度、韧性、残余应力和抗氧化性受显微组织结构影响[46-48]。

硼化物涂层力学性能不稳定的原因在于B元素的沉积产额和能量分布不易控制,B原子较轻,溅射粒子间的质量差异、逸散角度、离子能量分布等影响涂层性能,但相关机理尚不清晰。Neidhardt等[45]揭示溅射沉积TiBx时B+优先沿靶材法线方向运动,易出现过化学计量比;Petrov等[49]提出了外磁场牵引离子束流可对TiBx化学计量比进行调控;吴等[50]通过降低高功率脉冲磁控溅射(High Power Impulse Magnetron Sputtering, HiPIMS)的脉冲宽度提高Ti离化降低B/Ti比;但涂层性能精细调控机理尚不清晰。有关TiBx涂层的力学性能也存在争议,Mayrhofer等[44]发现过量B偏析于晶界可生成团簇柱状纳米复合结构,可提高涂层硬度,如图6,涂层表现出超高硬度和高温下的稳定性;Petrov[49]和吴等[50]认为TiBx涂层可通过降低B/Ti比降低内应力,改善涂层韧性和高温抗氧化性。

|

图 6 溅射TiB2.4涂层的平面TEM照片及涂层在室温和不同温度下退火后力学性能[44] Figure 6 Planar TEM images of sputtered TiB2.4 coating and mechanical properties after annealing at room temperature and different temperatures [44] |

通过第三元素置换固溶和生成纳米复合结构可改变涂层断裂韧性和优化高温性能。Bakhit等[51]采用HiPIMS-DCMS复合技术制备(TixHf1−x) B2涂层,发现多元涂层致密性、硬度更优,并发现在(ZrxTa1−x) By涂层中存在温度升高相分解的时效硬化现象[48];Hahn等[52]结合第一原理计算和涂层沉积实验,获得兼具超高硬度(41~45 GPa)和高韧性(3.0~3.7 MPa·m−1/2)的(WxTa1−x) B2涂层。当金属靶材和硼化物靶材共沉积时,将降低硼化物中B含量,优化涂层韧性,如TiB2-Ti涂层[53]。在TiB2中引入N元素制备TiBN纳米复合涂层可改善韧性、抗氧化性并降低残余应力,但随着N含量增加,N易与B结合,出现软质a-BN相,导致涂层力学性能急剧下降[50],TiBN纳米复合涂层的相组元调控仍有难度,受沉积等离子体影响。

2.3 氧化物刀具涂层氧化物刀具涂层以氧化铝为代表,由离子键构成,在高温下具有较高的硬度、良好的化学稳定性以及优异的抗磨损性能,是理想的刀具涂层材料。目前,用于切削加工的氧化铝涂层主要是CVD合成的刚玉型α-Al2O3。PVD制备氧化物涂层时沉积温度大多在350~650 ℃,极大地拓宽了基体材料的选择范围,涂层产生的压应力能有效抑制裂纹的产生,因此PVD氧化物涂层近来受到了广泛关注。

目前,研究人员利用PVD技术制备了多种氧化物涂层(如ZrO2、Cr2O3[54-55]、Al2O3、Al-Ti-O等)并对其结构和性能进行了深入的研究,但用于切削加工领域的氧化物仍以Al2O3基为主。电弧离子镀技术离化率高、沉积粒子能量强,更有利于Al2O3涂层的形核结晶,但涂层表面会产生大量“液滴”缺陷,通过磁过滤技术可减少涂层表面“液滴”[56]。Rosén等[57]利用磁过滤阴极弧蒸发技术在700 ℃下制备出了以α相为主的Al2O3涂层,Brill等[58]研究了沉积离子能量对涂层物相结构的影响,通过增加偏压提高沉积离子的能量可降低α相的结晶温度。Cheng等[59]利用射频技术溅射α-Al2O3靶材在550 ℃下制备了具有刚玉型结构的Al2O3涂层。靶材毒化是PVD技术沉积氧化铝涂层的重要难题[60],Bobzin等[61]通过改变O2流量制备Al2O3涂层,发现高速率沉积理想化学计量比的Al2O3涂层需将靶材控制在金属模式和中毒模式间的过渡区域工作。双极脉冲溅射技术在溅射周期内溅射靶有一半的时间被施加反向电压充当阳极,使表面累积的电荷充分释放,抑制了靶面打弧和毒化,避免阳极消失效应的产生[62]。Fietzke等[63]利用双极脉冲磁控溅射制出了刚玉结构的Al2O3涂层,硬度可达22 GPa;Zywitzki等[64]利用该方法制备了Al2O3涂层并研究沉积温度对涂层结构的影响,当沉积温度为330、480和760 ℃时,涂层分别为非晶结构、γ相为主和α相Al2O3。高功率脉冲磁控溅射(HiPIMS)利用低的占空比(0.5%~10.0%)和高的峰值功率大幅提高靶材的离化率(>50%),可制备出结构致密、性能优异的涂层[65]。Wallin等[66]发现利用HiPIMS制备Al2O3时可抑制甚至消除迟滞效应,实现对靶材溅射状态的精准调控,提高工艺的稳定性。Selinder等[67]利用HiPIMS在650 ℃的温度下成功制备了α-Al2O3涂层并展现出优异的切削性能。Bobzin等[68]对比了高功率脉冲磁控溅射(HiPIMS)和中频磁控溅射(Medium Frequency Magnetron Sputtering, MFMS)制备的γ-Al2O3涂层,发现HiPIMS的Al2O3涂层结构更加致密,在高温空气环境中具有更强的热稳定性,铣削EN-GJS-700-2钢材时寿命提升了至少1倍。然而,HiPIMS沉积涂层时,由于高的靶材电压会反向吸引靶材溅射出的离子,导致沉积速率较低,限制了其在工业中的应用。

PVD低的沉积温度(350~650 ℃)无法为α-Al2O3的形核结晶提供足够的能量,导致涂层大多由非晶或者γ相构成。氧化铝除了α相结构外还有γ、δ、η、θ、κ、χ等多种亚稳结构,这些亚稳相在服役过程中易发生相变,影响切削的稳定性;降低α-Al2O3相的沉积温度成为加快氧化铝基涂层工业化应用的关键。α-Cr2O3和α-Al2O3同属

在氧化铝涂层中引入Cr元素制备(Cr, Al) 2O3涂层也是一种获取刚玉型氧化物涂层的有效方法。(Cr, Al) 2O3涂层的结构和性能与沉积技术、涂层成分、沉积粒子能量等密切相关。Diechle等[74]通过溅射拼接靶材在500 ℃下制备了不同成分的(Cr1−xAlx) 2O3(0.1≤x≤0.27),发现所有涂层均为刚玉型结构,Cr含量减小时涂层晶粒尺寸减小,结晶度下降。200~300 ℃的沉积温度下随着涂层中Cr含量减小,涂层从刚玉型结构转变为非晶结构[75]。利用磁控溅射制备(Cr, Al) 2O3涂层时,较低的沉积速率是制约其工业化应用的重要因素。阴极弧蒸发沉积过程中,靶材表面容易生成绝缘的氧化物,影响靶材的烧蚀以及弧光放电的稳定。Ramm等[76]基于脉冲阴极弧蒸发发展了P3eTM技术,有效抑制了靶材的毒化,实现了α-(Cr, Al) 2O3涂层的稳定沉积,该项工作推动了阴极弧蒸发(Cr, Al) 2O3涂层的工业化进程。Koller等[77]利用阴极弧蒸发沉积了不同Cr含量的(Cr, Al) 2O3涂层,发现富Al的涂层由刚玉结构和立方结构两相构成,而富Cr的涂层则为单相的刚玉结构。Dalbauer等[78]发现增加O2流量时O元素优先聚集在柱状晶晶界处,涂层呈现出细小的等轴晶结构,当O2流量充足时可以获得化学计量比的(Cr, Al) 2O3,随着Cr量升高涂层由亚稳的立方相转变为刚玉结构。

涂层的微观结构和性能很大程度上取决于到达基体上的离子动能,通过提升偏压增强离子轰击可改变涂层的微观结构和应力状态。但制备(Cr, Al) 2O3等导电性较差的涂层时,为防止电荷的积累以及随着时间推移涂层质量的下降,通常使用脉冲或者射频偏压。Balazer公司推出(Cr, Al) 2O3涂层的专用P3eTM技术搭载了双极脉冲偏压[76]。Koller等[79]在−60至−160 V的范围内调控基体偏压制备了(Cr0.3Al0.7) 2O3涂层并对其结构和性能进行了系统的研究,随着基体偏压的增加涂层残余应力从拉应力转变为压应力,硬度从12.5 GPa升高到25 GPa。然而,Najafi等[80]认为沉积过程中高能沉积粒子的轰击效应会导致涂层内部产生大量空位,有利于FCC结构的形成。Koller等[81]利用第一性原理计算结果指出由空位和间隙对组成的弗兰克缺陷有利于(Cr, Al) 2O3中产生立方相。

其他元素添加对(Cr, Al) 2O3涂层的相结构和性能也有影响。Koller等[82]研究了Fe元素对阴极弧蒸发的(Cr0.3Al0.7) 2O3涂层微观结构的影响,发现Fe的合金化添加可促进(Cr0.3Al0.7) 2O3涂层中α相的产生。Paulitsch等[83]发现Si元素的掺入可抑制靶材表面岛状氧化物的产生,提高靶材烧蚀的稳定性,但Landälv等[84]发现Si元素会在“液滴”内富集,其添加导致涂层硬度下降。Liu等[85]的计算结果表明Si有利于稳定立方相,Ti、Mn、V、Y等元素固溶到(Cr, Al) 2O3中有利于形成稳定的刚玉型固溶体。B元素表现出与Si类似的作用,可细化晶粒,促进立方相的生成,抑制亚稳态立方相的相变,提高涂层的高温稳定性[86]。

采用多元多层的设计有利于调控氧化铝基涂层的结构和性能。Koller等[87]通过基体在不同成分的靶材前周期性的旋转构建了调制周期为~60 nm的(Cr, Al) 2O3/(Al, Cr, X) 2O3纳米多层涂层(X=Fe、Si、B)。如图7所示[88],单层富Al的(Al, Cr) 2O3和(Al, Cr, Fe) 2O3涂层由六方结构(α 相)和亚稳的立方结构混合而成,(Al, Cr, Si) 2O3和(Al, Cr, B) 2O3则由非晶相和立方相构成。在富Cr的(Cr0.75Al0.25) 2O3层的模板作用下,几种纳米多层均表现为结晶良好的刚玉结构。其结构和性能可以通过单层厚度和成分进行调控。

|

图 7 (a)(Al, Cr, X) 2O3基单层以及(Cr0.75Al0.25) 2O3/(Al, Cr, X) 2O3多层的涂层的XRD图谱和(b)涂层生长的结构示意图[88] Figure 7 (a) XRD patterns of (Al, Cr, X) 2O3-based single layer and (Cr0.75Al0.25) 2O3/(Al, Cr, X) 2O3 multilayer coatings, and (b) Schematic diagram of coating growth structure [88] |

现代切削加工中刀具会遭受到较大的机械载荷和温度载荷,要实现氧化物涂层的切削应用,除了对涂层的结构和性能进行优化调控外,还需要保证涂层与刀具基体具备良好的结合力。CVD Al2O3涂层主要是采用TiN或TiCN作为过渡层来提供涂层与刀具基体之间良好的附着力,PVD氧化物涂层与硬质合金刀具基体的物理性质存在巨大差异,也需引入合适的过渡层来解决涂层与刀具基体结合的问题。Åstrand等[89]利用PVD技术构建的TiN/Al2O3在车削工具钢时切削寿命明显高于PVD TiN和CVD TiCN/Al2O3涂层。Bobzin等[68]利用HiPIMS在TiAlN涂层上制备了γ-Al2O3涂层,在铣削EN-GJS-700-2钢材以及Ti-6Al-4V时均表现出优异的耐磨性。Nohava等[90]利用阴极弧蒸发技术先沉积TiN作为结合层,之后沉积AlTiN/SiNx作为过渡层,最后沉积α-(Al, Cr) 2O3层,制备出的涂层在800 ℃下经过32000圈的摩擦测试仍保持极低的磨损率,耐磨性远超同类结构的氮化物。上述结果表明,采用过渡金属氮化物作为过渡层可保证氧化物涂层与基体之间的结合,充分发挥氧化物涂层的优势。此外,通过交替沉积TiAlN和Al2O3层可制备出TiAlN/Al2O3多层涂层,该涂层在切削加工中也具有优异的性能[91]。

为进一步增强氮化物层和氧化物层之间的结合,部分研究人员在氮化物和氧化物之间引入了氧氮化物层。Bobzin等[92]利用磁控溅射制备TiAlN/Al2O3涂层时,沉积完TiAlN层后并未直接沉积Al2O3层,而是在两者之间沉积了~0.8 μm的氧氮化物过渡层。获得的TiAlN/Al2O3涂层在高温摩擦以及干式切削不锈钢时,均表现出了优异的耐磨性。Koller等[79]在沉积(Al,Cr) 2O3涂层时为保证结合力采用了FCC-AlCrN作为过渡层,并且在AlCrN和(Al, Cr) 2O3之间插入AlCrON层。

氮化物/氧化物双层或者多层涂层中,二者相互转换时形成的界面会严重影响涂层的性能。Shi等[93]在CrN/Cr2O3多层涂层中发现由于O2会优先与Cr反应,CrN向Cr2O3转换时界面清晰,过渡层厚度仅1~2 nm,而Cr2O3向CrN转换时界面处会形成40~50 nm由纳米晶和非晶组成的Cr–O–N梯度层,二者界面模糊。随着调制周期降低至440 nm时,涂层中模糊界面比例增加,CrN层或Cr2O3层纯度降低,涂层硬度下降。Raab等[94]通过改变AlCrN和(Al, Cr) 2O3层切换时的反应气体分别获取了层间界面清晰的、混合的以及模糊的AlCrN/(Al, Cr) 2O3多层涂层。所有的AlCrN/(Al, Cr) 2O3多层涂层均呈现出FCC结构,调制周期较大时,层间界面的类型会明显影响涂层的硬度,界面清晰的涂层硬度最大。当调制周期较小时AlCrN和(Al, Cr) 2O3在界面处可能会发生局部的外延生长,涂层硬度上升,界面类型对涂层硬度的影响较小。AlCrN/(Al, Cr) 2O3多层涂层的界面类型对热稳定性无明显差别,而与单层的AlCrN和(Al, Cr) 2O3相比,多层涂层展现出优异的热稳定性,温度升高到~1200 ℃后AlCrN/(Al,Cr) 2O3中的AlCrN会发生相分解[95]。在氮化物/氧化物纳米多层中通过改变调制周期或调制比等可调控二者界面结构。Li等[96]发现CrAlN/ZrO2纳米多层涂层的界面处CrAlN和ZrO2会形成共格界面,ZrO2以CrAlN为模板生长为FCC的结构。随着ZrO2子层厚度的增加涂层硬度上升,当厚度超过1.0 nm后共格界面被破坏涂层硬度下降。此外,Najafi等[80]制备(Al, Cr) 2O3时发现涂层生长初期以FCC为主,当厚度增加至2 μm涂层转变为α相,并研究了CrN和AlSiN过渡层对(Al, Cr) 2O3生长过程的影响,发现过渡层的物相结构并不会影响(Al, Cr) 2O3涂层的结构演变。

3 PVD刀具涂层沉积技术市场主流的PVD刀具涂层技术有电弧离子镀(Arc Ion Plating,AIP)和磁控溅射(Magnetron Sputtering,MS)两类,AIP刀具涂层以瑞士Oerlikon Balzers公司为代表,MS刀具涂层以德国CemeCon公司为代表。

在电弧离子镀技术中(图8(a)[97]),涂层材料通过真空室中低电压、高电流的电弧放电进入气相,以高电流密度(106~1012 A/m2) 为特征,电弧在靶材表面做无规则的运动,弧斑所到之处局部温度高达15000 ℃,靶材能够瞬间蒸发并实现高效离化,激发粒子通常具有较高的粒子能量,有助于提高涂层的结合强度和硬度,获得结构致密,力学性能优异的刀具涂层,如TiN,TiAlN,TiAlSiN和DLC等涂层[98-100]。基于电弧离子镀靶位可调性和较低沉积温度特点,可以实现较广泛材料表面防护涂层的制备,同时避免零部件的热变形及材料退火,而通过多靶组合沉积可以实现涂层成分和结构的可控调节。但是由于弧斑能量集中,靶面的不均烧蚀容易导致宏观大颗粒的蒸发并形成熔池效应[101-103],这种液滴缺陷通常会导致电弧离子镀涂层具有较高的表面粗糙度,同时在涂层生长过程中,液滴缺陷附着会打断涂层的连续生长,形成孔洞等生长缺陷,对涂层的力学性能会产生较大影响。近年来,结合电磁场和永磁场调节控制弧斑运动实现高性能涂层制备备受研究者关注[104-107]。Lang[108]等通过基于电磁线圈和永磁体配合形成轴对称磁场分布,通过径向分量和纵向分量磁场调节实现了靶材的均匀烧蚀,有效改善了沉积过程中液滴缺陷的产生。Hu[109]等通过轴对称磁场优化设计实现了ta-C涂层微观结构和表面性能的改善。笔者所在课题组近年来也针对阴极弧磁场的优化设计进行了大量研究,采用阴极弧蒸发成功制备了高性能AlCrO涂层[110]。基于磁场对弧斑运动的有效控制,国外知名涂层公司荷兰Hauzer公司通过阴极磁场分布优化推出了CARC+技术。瑞士Swiss-PVD公司推出的电弧分裂技术,及通过矩形平面电弧阴极匹配十字形磁铁实现了对弧斑的分裂,有效减少了涂层制备过程中液滴缺陷的形成[111]。此外,德国PVT公司和瑞士Balzers公司也针对磁弧约束进行了相应设备和技术研发。基于电弧离子镀技术发展的过滤电弧沉积(Filtered Arc Deposition, FAD)[112-113]和离子辅助沉积(Ion Assisted Deposition,IAD)[114-115]技术在改善电弧沉积液滴缺陷方面也有突出效果,区别于阴极电弧源磁场设计,FAD技术通过在靶材与工件间设置弧形弯管配合电磁场作用实现对大颗粒的有效过滤,而IAD技术通过辅助离化增加了沉积腔室的等离子体密度,提高了阴极弧蒸发离子碰撞和二次离化的几率,从而实现了对涂层微观结构的调控和生长缺陷的改善。

|

图 8 (a)电弧离子镀技术原理及典型涂层结构;(b)磁控溅射技术原理及典型涂层结构[97] Figure 8 (a) Arc ion plating technology principle and typical coating structures, (b) Magnetron sputtering technology principle and typical coating structures [97] |

在磁控溅射技术中(图8(b) ),通过气体放电离化形成的高能等离子在电场作用下加速轰击靶材表面,溅射出的靶材原子通过动量传递获得动能后运动到基材表面,通过吸附、形核、生长最终形成涂层。配合溅射阴极靶材磁场设计实现了靶面运动电子的控制,增加了溅射粒子的碰撞几率,提高了靶材的溅射效率。近年来非平衡磁控溅射技术得到快速发展[116-119],通过溅射阴极源非平衡磁场设计显著增加了靶前辉光放电区域,带电粒子二次碰撞几率增加,靶材离化率进一步改善[120-121]。根据工艺需要,磁控溅射技术可以实现单一金属、合金和化合物涂层的溅射制备,溅射过程中配合通入不同的反应性气体(N2、O2等)可以实现涂层成分多样化设计。磁控溅射靶面温度低,避免了溅射过程中大颗粒缺陷的产生,所以能够获得表面质量优异,结构致密的涂层。然而与电弧离子镀相比较,磁控溅射仍然存在靶材离化率低、膜基结合力差等缺点,因此实现磁控溅射的高效离化一直是研究热点方向。根据磁控溅射电源的不同可以主要分为直流磁控溅射(DC Magnetron Sputtering, DCMS),射频磁控溅射(Radio Frequency Magnetron Sputtering, RFMS)和脉冲磁控溅射,其中高功率脉冲磁控溅射(HiPIMS)在提高靶材离化率和高性能涂层制备方面表现突出。

由于普通磁控溅射技术阴极上的功率密度很低,等离子体的密度为1017 m−3,导致溅射原子离化率低[122],成膜粒子能量低。因此Kouznetsov[123]将脉冲电源引入磁控溅射,通过增加溅射靶前的等离子体密度来提高离化率,开发了一项新技术,即高功率脉冲磁控溅射(HiPIMS)[124],该技术结合了DCMS和AIP[125]的优点,且可以控制电离程度[126]。HiPIMS技术通过向靶材施加一系列的高功率密度和低占空比的周期性重复微脉冲,使靶材原子的离化率高达90%,等离子体密度达到1019 m−3 [123, 127-129]。HiPIMS制备的涂层性能优异,表面光滑无液滴、厚度均匀与基体结合良好,其致密涂层形态有利于高温稳定性及抗氧化性的提升。因为沉积过程中较高的的离化率,增强了沉积原子的迁移率,使得涂层晶粒细化、结构更致密。相比于普通磁控溅射,HiPIMS所制备的TiN[130]、CrN[124]的硬度更高。所制备的TiB2硬度高达43.4 GPa,而普通磁控制备的为29.3 GPa[131]。刘源等[132]比较了HiPIMS和电弧离子镀制备的TiAlN涂层,在硬度相当的情况下,HiPIMS制备的涂层刀具切削寿命更长。Reolon等[133]比较了电弧与HiPIMS制备的Al0.6Ti0.4N涂层切削加工镍基Inconel 718高温合金,发现HiPIMS有效降低了涂层的磨损与氧化,获得了更好的结合力与断裂韧性,使刀具的整体寿命比电弧制备的提高了约60%。HiPIMS使涂层的晶粒细化、结构致密化获得了更好的力学、摩擦磨损及高温抗氧化性能等,显著提长了刀具涂层的切削寿命,因而应用广泛。

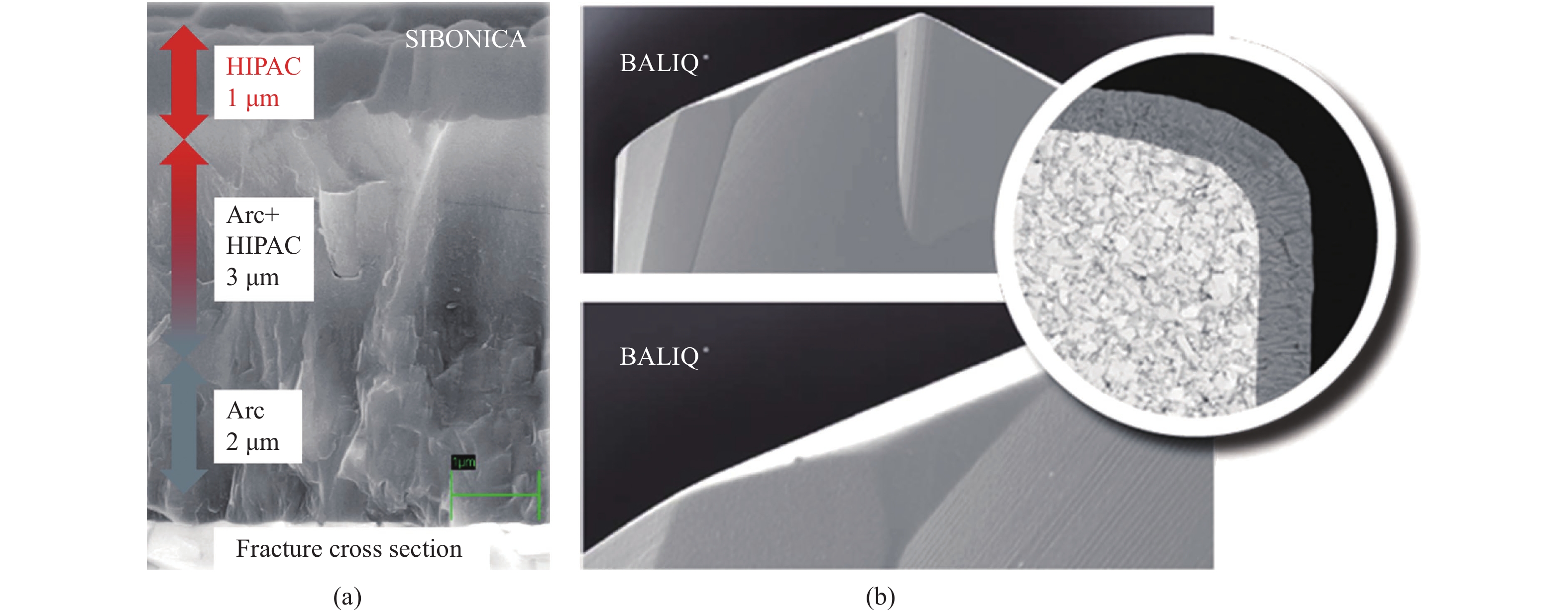

随着市场需求及要求的不断提高,以往的技术或多或少存在不足,各涂层企业也在不断加强对涂层工艺及设备的研制开发。荷兰豪泽(Hauzer)于1991年整合电弧离子镀与非平衡磁控溅射,希望结合两项技术各自的优势,因而开启了电弧/溅射复合沉积的新思路。欧瑞康巴尔查斯(Oerlikon Balzers)基于电弧与HiPIMS工艺,同时加入电弧增强辉光放电(Arc-enhanced glow discharge, AEGD)开发了High Ionization Triple(HI3)技术,用于高性能涂层的复合沉积(图9(a) )。此外,还基于HiPIMS技术发展了可扩展脉冲功率等离子体技术(S3p),能够制备出高表面质量、结构致密的高性能硬质涂层[134]。图9(b) 为Balzers公司采用S3p工艺制备的刀具,刀具涂层厚度分布均匀保证了切削刃的锋利,在使用超小直径刀具时,效果尤为显著。

|

图 9 Balzers公司采用(a)HI3和(b)S3p工艺所制备的刀具涂层 Figure 9 Tool coatings prepared by Balzers company using (a) HI3 and (b) S3p processes |

Koller等[135-136]采用电弧/溅射复合沉积TiAlN/TaAlN及TiAlTaN/TaAlN纳米多层涂层,通过改变TiAlTa电弧靶材的成分比例与TaAl溅射靶的功率调控涂层中的Ta含量,实现了共格外延生长,避免了六方相AlN的形成,使涂层获得了优异的高温力学性能。Chang等[137]使用AIP/HiPIMS混合技术降低了TiN涂层的宏观颗粒密度,提高硬度和耐磨性。笔者所在课题组优化电弧离子镀/磁控溅射复合沉积技术制备出硬度、结合力高以及内应力可控的AlTiN[138]、AlTiN/AlCrN、CrO/AlO[139]涂层。研究发现,在复合沉积过程中,衬底周期性地沉积来自电弧和溅射的粒子,形成了自组织的多层结构[140]。而将多层厚度控制在纳米范围时,相邻子层会产生外延生长,进而促进子层的结晶,稳定相结构[138, 141]。复合沉积结合各工艺的优势,成分选择更广,调控更易,且内应力可调[142],通过纳米多层以及纳米复合结构设计、工艺优化可获得性能优异的硬质涂层,显著提升刀具的切削性能。因此,复合沉积技术在生产效率、刀具涂层的定制化设计上具有明显的优势。

4 PVD刀具涂层存在问题分析及展望尽管PVD刀具涂层已有大量研究,但随着先进制造业中钛合金、高温合金、高强度钢等难加工材料应用越来越多,且对切削速度、效率和加工精度越来越高,目前刀具涂层难以满足要求。关键科学/技术问题仍未解决成为刀具涂层进一步发展的障碍。下面将对几个关键问题进行分析和阐述。

4.1 多元合金化刀具涂层的设计和性能研究刀具涂层的多元合金化是改善性能的重要途经。TiAlN是使用最广泛的刀具涂层材料之一,由于PVD是非平衡的材料制备过程,TiAlN在很大范围内不受热力学的限制,具有亚稳固溶体结构[143]。TiAlN涂层高温下的调幅分解是其具有优异切削性能的重要原因,如图10(a) ,在温度高于800 ℃时,亚稳的TiAlN分解为富Ti的FCC相和富铝的FCC相,由于不同相之间存在共格应变,会导致时效硬化,如图10(b) 所示。温度升高或保温时间变长,亚稳的FCC-AlN转变为稳定的六方纤锌矿AlN相(图10(c) )、硬度快速下降。富铝FCC相+富铝FCC相调幅结构的范围分布、起始和结束温度将极大影响涂层的高温性能。在近四十年的发展历程中,TiAlN涂层经历Ti0.75Al0.25N→Ti0.5Al0.5N→Ti0.33Al0.67N的发展。铝含量的增加有利于涂层力学性能的提高和高温氧化性能的改善,但当铝含量过高时六方AlN相的出现造成涂层力学性能下降。

|

图 10 Ti0.5Al0.5N涂层高温下微结构和硬度的演变 Figure 10 Evolution of microstructure and hardness of Ti0.5Al0.5N coating at high temperatures |

进一步改进PVD TiAlN可以通过与不同的元素合金化,如V[144]、Ta[145]、W[146]、B[147]或Si[148]。Ta的加入对合金的力学性能和摩擦学性能以及热稳定性和氧化稳定性都有有益的影响。例如在TiAlN中加入Ta会促进FCC相的形成,从而抑制高温下六方相的形成;随着Ta含量的增加,硬度最大值向更高的温度转移[19]。Ta和Cr共掺杂可以同时改善TiAlN涂层的高温硬度和抗氧化性[22]。Liu等[149]通过实验和理论方法证明了Al在FCC-TiAlN中的溶解度极限受到残余应力的显著影响,可以通过调整沉积参数来调整残余应力。Grossmann等[150]发现较高的偏压下涂层中可固溶Al含量增加,较高的压应力和缺陷密度以及较小的晶粒尺寸导致在较高的偏压下生长的高铝涂层具有较高的硬度,而且韧性及抗裂能力也较强。因此多元共掺杂和沉积参数调控可以进一步提高TiAlN涂层的高温性能,适用于高速高效切削。但是目前多元涂层中各元素对相分离的影响尚有很多未知,富钛面心立方相稳定元素、富铝面心立方相稳定元素、六方相稳定元素,对涂层中调幅分解的起始温度和完成温度、共格中间相形成有重要影响,从而影响涂层的性能,但目前对多元涂层组织结构和性能的研究尚不充分。

涂层中不出现六方相的最高铝含量,被认为是高铝涂层力学性能安全的极限值,高铝Ti1−xAlxN涂层铝原子含量最高为x = 66%~67%,Cr1−xAlxN涂层最高铝原子含量为70%左右。CVD技术制备的Ti1−xAlxN涂层近来得到广泛关注,可以沉积纯FCC-Ti1−xAlxN涂层,铝原子含量高达80%~90%,在切削试验中表现出卓越的性能[151-153],涂层中形成富Al和富Ti的Ti1−xAlxN片层交替的自组织纳米层状结构。透射电子显微图和三维原子探针层析成像可以看出,纳米片在单个颗粒内具有几纳米的周期性。PVD涂层通过调控或后处理能否可以获得类似CVD涂层中高铝含量和片层组织还未见报道。其他多元涂层中是否可以发掘出类似TiAlN系列优异性能的系列成分还缺乏深入研究。

4.2 纳米复合刀具涂层超强韧性能的调控如图11,纳米复合涂层超高硬度的关键在于非晶界面相包裹纳米晶的独特结构;纳米晶因Hall-Petch效应增加硬度;晶界相足够薄、有强内聚能无晶界滑移,且与结晶相良好结合,避免普通纳米晶的反Hall-Petch硬度下降[30]。因此,纳米复合涂层硬度增强的关键在于相分离彻底,纳米晶结晶质量好,晶界相纯度高、致密且足够薄。对于如何实现这样的结构,Veprek等认为关键在于涂层生长温度高、氮势高、杂质少[154]。

|

图 11 纳米复合涂层力学性能示意图 Figure 11 Schematic diagram of the mechanical properties of nanocomposite coatings |

研究发现,等离子沉积过程中不同元素的离子/原子比例、价态、能量分布影响涂层生长和微观结构及性能[155-157]。如表1,Hultman教授课题组[156-157]发现高离化率的Ti源(TiHIPIMS)与低离化率的Al源和Si源(AlDCMS、SiDCMS)易促进第二相h-AlN和a-SiNx析出,反之则易生成固溶体,极大影响涂层性能;工业生产中缺乏对各元素等离子体的控制而无法获得优化的纳米复合涂层结构,如何协调沉积源方便调控等离子体获得优化刀具涂层仍是一个难题。

| 表 1 不同沉积源制备TiAlN、TiSiN涂层的结构和力学性能对比 Table 1 Comparison of structural and mechanical properties of TiAlN and TiSiN coatings prepared from different deposition sources |

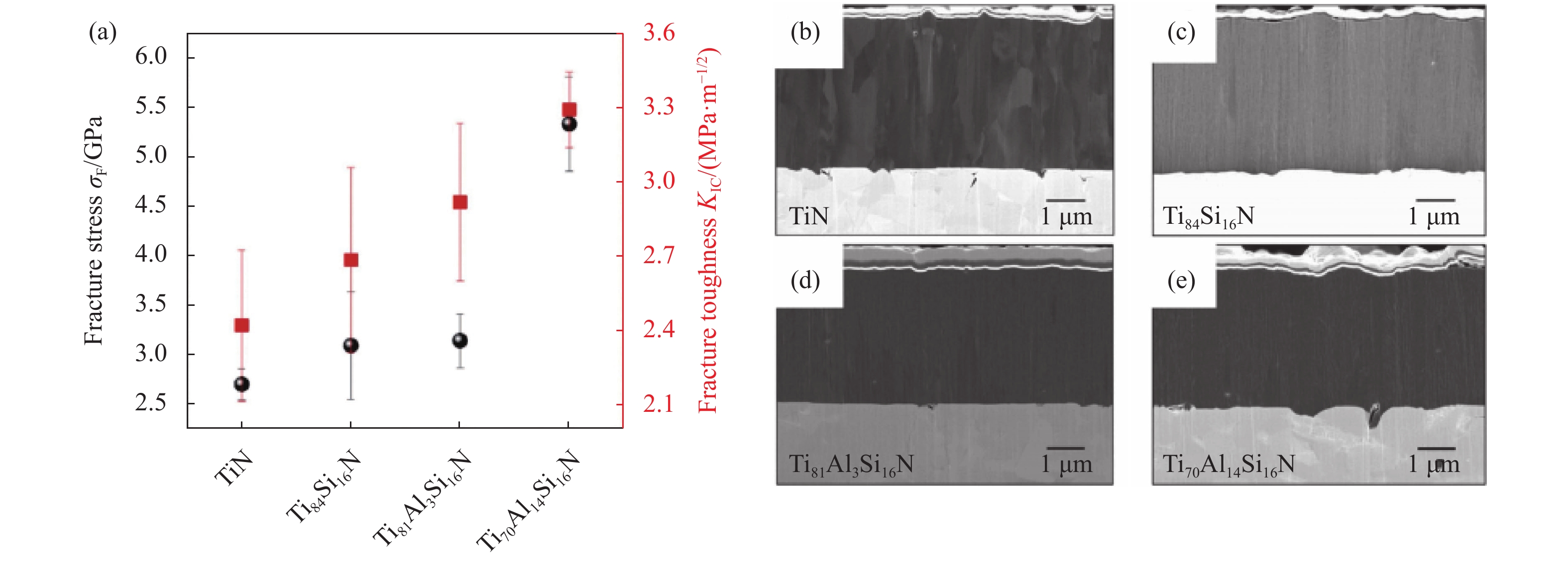

由于纳米复合结构的形成,TiAlSiN涂层可以达到40 GPa以上的极高硬度值,从而抑制晶界滑动。但是,如果Si原子含量超过7%~10%的限制,根据沉积工艺、所选参数以及Al含量的不同,涂层硬度会因非晶相变厚而降低;为了获得超硬涂层,非晶相的厚度不应超过一层或两层原子层。此外,Si的加入将促进六方TiAlN相在沉积状态下的形成,需要降低涂层中Si含量。近年来,硬质涂层断裂行为的研究引起了人们越来越多的关注,因为它对涂层的应用行为也有很大的影响。Moritz等[158]研究了两种不同铝含量的电弧蒸发TiAlSiN涂层的断裂韧性和断裂应力,并将其与TiSiN和TiN涂层进行了比较,如图12(a) 所示。微弯曲实验采用无缺口悬臂梁进行断裂应力评估,采用缺口悬臂梁进行断裂韧性评估,在TiN中加入Si后,其断裂应力和韧性分别提高到3.1±0.5 GPa和2.7±0.4 MPa·m−1/2。进一步向TiSiN中添加少量Al(Ti, Al, Si原子比为81:3:16)并没有明显改变其细晶组织(如图12(c) 和(d) 所示) ,断裂应力也基本未受影响(3.1±0.2 GPa)。然而,可以观察到断裂韧性的增加。进一步增加Al含量(Ti, Al, Si原子比为70:14:16,见图12(e) ),断裂应力为5.3±0.5 GPa,断裂韧性为3.3±0.2 MPa·m−1/2,断裂性能明显改善。尽管在Ti1-xAlxN体系中添加Si有利于形成沉积状态的六方相,但它对抗氧化性有积极影响,Pfeiler等[159]观察到Ti30.4Al68.4Si1.2N涂层的氧化层厚度低于Ti30Al70N涂层,TiAlSiN中锐钛矿向金红石转变的延迟导致金红石相粗化的时间缩短,导致金红石晶粒变小和/或氧化层厚度减小。

|

图 12 (a)电弧蒸发沉积的TiAlSiN涂层的断裂应力和断裂韧性;涂层横截面形貌图:(b)TiN、(c)Ti84Si16N、(d)Ti81Al3Si16N和(e)Ti70Al14Si16N涂层[158] Figure 12 (a) Fracture stress and fracture toughness of TiAlSiN coatings deposited by arc evaporation; Cross-sectional morphology of coatings: (b) TiN, (c) Ti84Si16N, (d) Ti81Al3Si16N, and (e) Ti70Al14Si16N Coatings[158] |

与TiAlSiN涂层多元纳米复合涂层的结构和性能调控类似,其他成分的纳米复合涂层中杂质、反应氮势和沉积等离子体对涂层结构的影响,涂层中各元素在纳米晶体相和晶界非晶相中的偏析行为,纳米晶相的相变控制等,都对涂层的硬度、韧性、高温氧化等力学和化学性能有重要影响,有效的系统研究可以进一步改善纳米复合涂层性能和发展新的纳米复合涂层体系,目前相关研究还较为缺乏。

4.3 多层梯度刀具涂层设计和切削性能研究在实际刀具涂层的设计中,除了要考虑涂层的硬度、韧性、高温抗氧化性等性能外,还要考虑其与基体的匹配、在实际切削环境中的适应性等。

涂层在刀具基体上生长时,涂层与基体界面间的形核生长和显微组织、内应力分布,将极大影响涂层结合性能;高速切削时刃口温度很高,硬质合金中Co易向外扩散导致基体力学性能下降和刃口过早崩裂破坏。需考虑刀具涂层在基体表面的形核结晶,深入研究涂层−基体界面元素分布、晶格及缺陷分布,及其在高温和使役过程中的演变,是澄清涂层界面结合的关键问题,从而优化涂层工艺,设计界面结合层和扩散阻挡层,解决刀具涂层最重要的结合问题,但目前尚缺乏深入的细节研究。

硬质涂层与刀具基体硬度相差较大,刀具涂层易发生灾难性的疲劳失效;在高速切削中,刀具刃口承受高温高压,经受严苛的热力疲劳,需要保持良好的高温硬度和韧性。功能梯度材料设计能够提高因摩擦、冲击和疲劳等所引起的接触变形和损伤的抵抗能力[160]。卢柯院士发现梯度纳米结构可以有效抑制接触载荷下材料的应变局域化,改变裂纹产生和扩散机制,呈现出与粗晶及均匀纳米晶材料截然不同的特性[161-162]。在涂层刀具中,多层和梯度涂层设计的研究主要局限于使基体与涂层热膨胀系数和力学性质均匀过渡,如何设计具有更优耐磨损性的刀具涂层,还需从内应力分布、疲劳断裂、摩擦磨损机制等方面对涂层−基体设计深入研究。

除了硬度、耐磨性、热稳定性和氧化稳定性外,硬质涂层的导热性在产生剧烈热量的切削应用中也起着至关重要的作用[163]。涂层热导率受其成分和显微结构影响很大,Samani等[164]观察到TiN的热导率约为11.9 W/(m·K),随着Al的加入,热导率可以降低到约4.6 W/(m·K)。当形成双相结构时热导率增加,这是因为AlN热导率为~30 W/(m·K),高于TiN[165, 166],合金元素的加入会导致晶格畸变和局部应变场,从而降低声子的局部平均自由程,如Ti1-xAlxN体系中加入Ta会导致导热系数进一步降低[167]。刀具涂层的热导率影响切削热分配,低热导率涂层使切屑带走更多切削热,降低刀具温升,温差可达100 ℃;但同时涂层平面内还需有足够的导热能力,使热可在刀刃表面快速扩散,不产生高温热点。目前温度测试方法较难测试到涂层内温度分布,需结合计算仿真和实验进行研究[2]。纳米复合涂层一般导热系数较低,需考虑多层涂层设计进行面内面间导热性能设计。刀具涂层设计中对热导率考虑明显不够。

切削过程中,刀具−切屑(刀−屑)和刀具−工件(刀−工)表面之间发生剧烈摩擦,金属表面层经历塑性变形和断裂,涂层刀具的作用机理需从基础接触变形研究[168]。目前涂层的力学(硬度、弹性模量、高温硬度等)和物理化学性质(热导率、高温氧化行为、表面转移膜成分等)如何影响切削摩擦行为和金属变形区的压缩行为等,以及受切削速度的影响等仍不清楚,刀具涂层在切削过程中不同切削条件和参数、冷却介质等影响下的作用和失效机理仍缺乏研究。Vereschaka等[169]从基础接触变形理论出发,利用界面接触长度、剪切角、刀−屑摩擦系数、切屑压缩比、切削力大小角度等参数,研究了过渡层、涂层成分和性能对切削行为的影响,方法可以借鉴。

5 总结及展望高速、高精、绿色切削加工的发展不仅要求刀具涂层具有优异的硬度、耐磨性,还需具备良好的韧性及精细的热管理。高性能硬质涂层的研究也不断朝着更加复杂的体系发展,多元多层多相的设计理念受到了国内外学者的广泛采纳和研究,过去十年先进表征技术的巨大进步使得多功能特性的实现成为可能,结合材料计算方法探究微观缺陷对硬质涂层性能的作用机理是目前研究的前沿领域,而涂层性能与切削表现的相关性依然是研究的难点。为实现新一代硬质涂层的落地应用,需要“沉积装备—制备技术—设计表征—切削应用”的系统性研发。国内PVD刀具涂层行业正经历从依赖进口到全面国产替代的过程,近年来国产PVD装备取得了长足进步,但在技术细节和应用稳定性上还与国际领先品牌存在一定差距,未来发展的着力点包括:涂层装备与沉积技术的一体化封装,涂层结构性能的底层设计逻辑,涂层性能与切削摩擦磨损的作用关系。

| [1] |

李忠新, 黄川, 刘延友. 高速切削加工关键技术及发展方向[J].

中国工程机械学报, 2014, 12(1): 48-51.

LI Z X, HUANG C, LIU Y Y. Enabling technologies and future directions towards high-speed cutting[J]. Chinese Journal of Construction Machinery, 2014, 12(1): 48-51. DOI: 10.3969/j.issn.1672-5581.2014.01.010. |

| [2] |

ABUKHSHIM N A, MATIVENGA P T, SHEIKH M A. Heat generation and temperature prediction in metal cutting: a review and implications for high speed machining[J].

International Journal of Machine Tools and Manufacture, 2006, 46(7-8): 782-800.

DOI: 10.1016/j.ijmachtools.2005.07.024. |

| [3] |

TRENT E M, WRIGHT P K. Metal cutting [M]. Woburn: Butterworth-Heinemann, 2000.

|

| [4] |

DAVIM J P. Tribology in manufacturing technology [M]. Berlin: Springer, 2012.

|

| [5] |

KOSEKI S, INOUE K, SEKIYA K, et al. Wear mechanisms of PVD-coated cutting tools during continuous turning of Ti-6Al-4V alloy[J].

Precision Engineering, 2017, 47: 434-444.

|

| [6] |

OKADA M, HOSOKAWA A, TANAKA R, et al. Cutting performance of PVD-coated carbide and CBN tools in hardmilling[J].

International Journal of Machine Tools and Manufacture, 2011, 51(2): 127-132.

DOI: 10.1016/j.ijmachtools.2010.10.007. |

| [7] |

NEUGEBAUER R, BOUZAKIS K-D, DENKENA B, et al. Velocity effects in metal forming and machining processes[J].

CIRP Annals, 2011, 60(2): 627-650.

DOI: 10.1016/j.cirp.2011.05.001. |

| [8] |

NEMETZ A W, DAVES W, KLüNSNER T, et al. FE temperature-and residual stress prediction in milling inserts and correlation with experimentally observed damage mechanisms[J].

Journal of Materials Processing Technology, 2018, 256: 98-108.

DOI: 10.1016/j.jmatprotec.2018.01.039. |

| [9] |

SCHALK N, TKADLETZ M, MITTERER C. Hard coatings for cutting applications: physical vs. chemical vapor deposition and future challenges for the coatings community[J].

Surface and Coatings Technology, 2022, 429: 127949.

DOI: 10.1016/j.surfcoat.2021.127949. |

| [10] |

ZHANG S, SUN D, FU Y, et al. Recent advances of superhard nanocomposite coatings: a review[J].

Surface and Coatings Technology, 2003, 167(2-3): 113-119.

DOI: 10.1016/S0257-8972(02)00903-9. |

| [11] |

REBENNE H E, BHAT D G. Review of CVD TiN coatings for wear-resistant applications: deposition processes, properties and performance[J].

Surface and Coatings Technology, 1994, 63(1): 1-13.

|

| [12] |

HAUBNER R, LESSIAK M, PITONAK R, et al. Evolution of conventional hard coatings for its use on cutting tools[J].

International Journal of Refractory Metals and Hard Materials, 2017, 62: 210-218.

DOI: 10.1016/j.ijrmhm.2016.05.009. |

| [13] |

MATTHEWS A. Titanium nitride PVD coating technology[J].

Surface Engineering, 1985, 1(2): 93-104.

DOI: 10.1179/sur.1985.1.2.93. |

| [14] |

MÜNZ W D. Titanium aluminum nitride films: A new alternative to TiN coatings[J].

Journal of Vacuum Science & Technology A:Vacuum, Surfaces, and Films, 1986, 4(6): 2717-2725.

|

| [15] |

王启民, 黄健, 王成勇, 等. 高速切削刀具物理气相沉积涂层研究进展[J].

航空制造技术, 2013(14): 78-83.

WANG Q M, HUANG J, WANG C Y, et al. Development of PVD coating for high-speed machining cutting tool[J]. Aeronautical Manufacturing Technology, 2013(14): 78-83. DOI: 10.3969/j.issn.1671-833X.2013.14.013. |

| [16] |

HE L, CHEN L, XU Y, et al. Thermal stability and oxidation resistance of Cr1−xAlxN coatings with single phase cubic structure

[J].

Journal of Vacuum Science & Technology A, 2015, 33(6): 061513.

|

| [17] |

FOX-RABINOVICH G S, YAMOMOTO K, VELDHUIS S C, et al. Tribological adaptability of TiAlCrN PVD coatings under high performance dry machining conditions[J].

Surface and Coatings Technology, 2005, 200(5): 1804-1813.

|

| [18] |

FRANZ R, MITTERER C. Vanadium containing self-adaptive low-friction hard coatings for high-temperature applications: a review[J].

Surface and Coatings Technology, 2013, 228: 1-13.

DOI: 10.1016/j.surfcoat.2013.04.034. |

| [19] |

RACHBAUER R, HOLEC D, MAYRHOFER P H. Increased thermal stability of Ti–Al–N thin films by Ta alloying[J].

Surface and Coatings Technology, 2012, 211: 98-103.

DOI: 10.1016/j.surfcoat.2011.07.009. |

| [20] |

LEMBKE M I, LEWIS D B, MüNZ W. -D, et al. Joint Second PrizeSignificance of Y and Cr in TiAlN Hard Coatings for Dry High Speed Cutting[J].

Surface Engineering, 2001, 17(2): 153-158.

DOI: 10.1179/026708401101517656. |

| [21] |

ANINAT R, VALLE N, CHEMIN J B, et al. Addition of Ta and Y in a hard Ti–Al–N PVD coating: Individual and conjugated effect on the oxidation and wear properties[J].

Corrosion Science, 2019, 156: 171-180.

DOI: 10.1016/j.corsci.2019.04.042. |

| [22] |

PENG B, LI H, ZHANG Q, et al. High-temperature thermal stability and oxidation resistance of Cr and Ta co-alloyed Ti–Al–N coatings deposited by cathodic arc evaporation[J].

Corrosion Science, 2020, 167: 108490.

DOI: 10.1016/j.corsci.2020.108490. |

| [23] |

LEHOCZKY S. Retardation of dislocation generation and motion in thin-layered metal laminates[J].

Physical Review Letters, 1978, 41(26): 1814.

DOI: 10.1103/PhysRevLett.41.1814. |

| [24] |

HELMERSSON U, TODOROVA S, BARNETT S A, et al. Growth of single‐crystal TiN/VN strained‐layer superlattices with extremely high mechanical hardness[J].

Journal of Applied Physics, 1987, 62(2): 481-484.

DOI: 10.1063/1.339770. |

| [25] |

SPROUL W D. New routes in the preparation of mechanically hard films[J].

Science, 1996, 273(5277): 889-892.

DOI: 10.1126/science.273.5277.889. |

| [26] |

LI P, CHEN L, WANG S Q, et al. Microstructure, mechanical and thermal properties of TiAlN/CrAlN multilayer coatings[J].

International Journal of Refractory Metals and Hard Materials, 2013, 40: 51-57.

DOI: 10.1016/j.ijrmhm.2013.01.020. |

| [27] |

XU Y X, CHEN L, PEI F, et al. Effect of the modulation ratio on the interface structure of TiAlN/TiN and TiAlN/ZrN multilayers: First-principles and experimental investigations[J].

Acta Materialia, 2017, 130: 281-288.

DOI: 10.1016/j.actamat.2017.03.053. |

| [28] |

ZHANG Q, XU Y, ZHANG T, et al. Tribological properties, oxidation resistance and turning performance of AlTiN/AlCrSiN multilayer coatings by arc ion plating[J].

Surface and Coatings Technology, 2018, 356: 1-10.

DOI: 10.1016/j.surfcoat.2018.09.027. |

| [29] |

PATSCHEIDER J, ZEHNDER T, DISERENS M. Structure–performance relations in nanocomposite coatings[J].

Surface and Coatings Technology, 2001, 146-147: 201-208.

DOI: 10.1016/S0257-8972(01)01389-5. |

| [30] |

VEPREK S, NIEDERHOFER A, MOTO K, et al. Composition, nanostructure and origin of the ultrahardness in nc-TiN/a-Si3N4/a- and nc-TiSi2 nanocomposites with HV= 80 to ≥ 105 GPa

[J].

Surface and Coatings Technology, 2000, 133: 152-159.

|

| [31] |

VEPREK S, VEPREK-HEIJMAN M G, KARVANKOVA P, et al. Different approaches to superhard coatings and nanocomposites[J].

Thin Solid Films, 2005, 476(1): 1-29.

DOI: 10.1016/j.tsf.2004.10.053. |

| [32] |

KIM J S, KIM G J, KANG M C, et al. Cutting performance of Ti–Al–Si–N-coated tool by a hybrid-coating system for high-hardened materials[J].

Surface and Coatings Technology, 2005, 193(1-3): 249-254.

DOI: 10.1016/j.surfcoat.2004.07.019. |

| [33] |

FLINK A, ANDERSSON J, ALLING B, et al. Structure and thermal stability of arc evaporated (Ti0.33Al0.67) 1− xSixN thin films

[J].

Thin Solid Films, 2008, 517(2): 714-721.

DOI: 10.1016/j.tsf.2008.08.126. |

| [34] |

HOLUBáŘ P, Jı́LEK M, ŠıMA M. Nanocomposite nc-TiAlSiN and nc-TiN–BN coatings: their applications on substrates made of cemented carbide and results of cutting tests[J].

Surface and Coatings Technology, 1999, 120: 184-188.

|

| [35] |

WU Z, TENGSTRAND O, BAKHIT B, et al. Growth of dense, hard yet low-stress Ti0.40Al0.27W0.33N nanocomposite films with rotating substrate and no external substrate heating

[J].

Journal of Vacuum Science & Technology A:Vacuum, Surfaces, and Films, 2020, 38(2): 023006.

|

| [36] |

CHEN L, DU Y, WANG A J, et al. Effect of Al content on microstructure and mechanical properties of Ti–Al–Si–N nanocomposite coatings[J].

International Journal of Refractory Metals and Hard Materials, 2009, 27(4): 718-721.

DOI: 10.1016/j.ijrmhm.2008.12.002. |

| [37] |

FU Y, ZHOU F, ZHANG M, et al. Structural, mechanical and tribocorrosion performances of CrMoSiN coatings with various Mo contents in artificial seawater[J].

Applied Surface Science, 2020, 525: 146629.

DOI: 10.1016/j.apsusc.2020.146629. |

| [38] |

WU Y, WANG B, XIAO L, et al. Effects of boron content on microstructure and mechanical properties of TiAlSiBxN nanocomposite films

[J].

Journal of Materials Engineering and Performance, 2020, 29(4): 2731-2736.

DOI: 10.1007/s11665-020-04795-w. |

| [39] |

GU J, LI L, MIAO H, et al. Effect of C2H2/N2 partial pressure ratio on microstructure and mechanical properties of Ti-Al-Si-CN coatings

[J].

Surface and Coatings Technology, 2019, 365: 200-207.

DOI: 10.1016/j.surfcoat.2018.06.035. |

| [40] |

XU Z, ZHANG Z, BARTOSIK M, et al. Insight into the structural evolution during TiN film growth via atomic resolution TEM[J].

Journal of Alloys and Compounds, 2018, 754: 257-267.

DOI: 10.1016/j.jallcom.2018.04.268. |

| [41] |

CHEN Z, SHAO Q, BARTOSIK M, et al. Growth-twins in CrN/AlN multilayers induced by hetero-phase interfaces[J].

Acta Materialia, 2020, 185: 157-170.

DOI: 10.1016/j.actamat.2019.11.063. |

| [42] |

黄小晓, 涂赣峰, 王术新, 等. TiB2涂层的制备及其应用研究进展

[J].

稀有金属材料与工程, 2022, 51(3): 1087-1099.

HUANG X X, TU G F, WANG S X, et al. Research progress in preparation and application of TiB2 coating [J]. Rare Metal Materials and Engineering, 2022, 51(3): 1087-1099. |

| [43] |

林海生. 面向钛合金高速切削的Hf-B和Hf-B-N涂层刀具研究 [D]. 广州: 广东工业大学, 2019.

|

| [44] |

MAYRHOFER P H, MITTERER C, WEN J G, et al. Self-organized nanocolumnar structure in superhard TiB2 thin films

[J].

Applied Physics Letters, 2005, 86(13): 131909.

DOI: 10.1063/1.1887824. |

| [45] |

NEIDHARDT J, MRáZ S, SCHNEIDER J M, et al. Experiment and simulation of the compositional evolution of Ti–B thin films deposited by sputtering of a compound target[J].

Journal of Applied Physics, 2008, 104(6): 063304.

DOI: 10.1063/1.2978211. |

| [46] |

MAYRHOFER P H, MITTERER C, CLEMENS H. Self‐organized nanostructures in hard ceramic coatings[J].

Advanced Engineering Materials, 2005, 7(12): 1071-1082.

DOI: 10.1002/adem.200500154. |

| [47] |

STüBER M, RIEDL H, WOJCIK T, et al. Microstructure of Al-containing magnetron sputtered TiB2 thin films

[J].

Thin Solid Films, 2019, 688: 137361.

DOI: 10.1016/j.tsf.2019.06.011. |

| [48] |

BAKHIT B, PALISAITIS J, WU Z, et al. Age hardening in superhard ZrB2-rich Zr1-xTaxBy thin films

[J].

Scripta Materialia, 2021, 191: 120-125.

DOI: 10.1016/j.scriptamat.2020.09.026. |

| [49] |

PETROV I, HALL A, MEI A B, et al. Controlling the boron-to-titanium ratio in magnetron-sputter-deposited TiBx thin films

[J].

Journal of Vacuum Science & Technology A, 2017, 35(5): 050601.

|

| [50] |

吴正涛, 叶榕礼, 李海庆, 等. HiPIMS 制备 TiB2, TiBN涂层及其等离子体性质

[J].

中国表面工程, 2023, 35(5): 228-235.

WU Z T, YE R L, LI H Q, et al. Fabrication and plasma properties of TiB2, TiBN films by HiPIMS [J]. China Surface Engineering, 2023, 35(5): 228-235. |

| [51] |

BAKHIT B, MRáZ S, LU J, et al. Dense Ti0.67Hf0.33B1.7 thin films grown by hybrid HfB2-HiPIMS/TiB2-DCMS co-sputtering without external heating

[J].

Vacuum, 2021, 186: 110057.

DOI: 10.1016/j.vacuum.2021.110057. |

| [52] |

FUGER C, MORAES V, HAHN R, et al. Influence of Tantalum on phase stability and mechanical properties of WB2[J].

MRS Communications, 2019, 9(1): 375-380.

DOI: 10.1557/mrc.2019.5. |

| [53] |

HELLGREN N, SREDENSCHEK A, PETRUINS A, et al. Synthesis and characterization of TiBx (1.2≤x≤2.8) thin films grown by DC magnetron co-sputtering from TiB2 and Ti targets

[J].

Surface and Coatings Technology, 2022, 433: 128110.

DOI: 10.1016/j.surfcoat.2022.128110. |

| [54] |

WANG T G, JEONG D, KIM S H, et al. Study on nanocrystalline Cr2O3 films deposited by arc ion plating: I. composition, morphology, and microstructure analysis

[J].

Surface and Coatings Technology, 2012, 206(10): 2629-2637.

DOI: 10.1016/j.surfcoat.2011.10.058. |

| [55] |

WANG T G, JEONG D, LIU Y, et al. Study on nanocrystalline Cr2O3 films deposited by arc ion plating: II. Mechanical and tribological properties

[J].

Surface and Coatings Technology, 2012, 206(10): 2638-2644.

DOI: 10.1016/j.surfcoat.2011.10.026. |

| [56] |

RANDHAWA H. High-rate deposition of Al2O3 films using modified cathodic arc plasma deposition processes

[J].

Journal of Vacuum Science & Technology A, 1989, 7(3): 2346-2349.

|

| [57] |

ROSéN J, MRáZ S, KREISSIG U, et al. Effect of ion energy on structure and composition of cathodic arc deposited alumina thin films[J].

Plasma Chemistry and Plasma Processing, 2005, 25(4): 303-317.

DOI: 10.1007/s11090-004-3130-y. |

| [58] |

BRILL R, KOCH F, MAZURELLE J, et al. Crystal structure characterisation of filtered arc deposited alumina coatings: temperature and bias voltage[J].

Surface and Coatings Technology, 2003, 174-175: 606-610.

DOI: 10.1016/S0257-8972(03)00539-5. |

| [59] |

CHENG Y, QIU W, ZHOU K, et al. Low-temperature deposition of α-Al2O3 film using Al+α-Al2O3 composite target by radio frequency magnetron sputtering

[J].

Materials Research Express, 2019, 6(8): 086412.

DOI: 10.1088/2053-1591/ab1c95. |

| [60] |

程奕天. 低温反应溅射沉积α-Al2O3薄膜的组织与性能研究 [D]. 广州: 华南理工大学; 2019.

|

| [61] |

BOBZIN K, LUGSCHEIDER E, MAES M, et al. Relation of hardness and oxygen flow of Al2O3 coatings deposited by reactive bipolar pulsed magnetron sputtering

[J].

Thin Solid Films, 2006, 494(1): 255-262.

|

| [62] |

SPROUL W D, CHRISTIE D J, CARTER D C. Control of reactive sputtering processes[J].

Thin Solid Films, 2005, 491(1): 1-17.

|

| [63] |

FIETZKE F, GOEDICKE K, HEMPEL W. The deposition of hard crystalline Al2O3 layers by means of bipolar pulsed magnetron sputtering

[J].

Surface and Coatings Technology, 1996, 86-87: 657-663.

DOI: 10.1016/S0257-8972(96)03075-7. |

| [64] |

ZYWITZKI O, HOETZSCH G, FIETZKE F, et al. Effect of the substrate temperature on the structure and properties of Al2O3 layers reactively deposited by pulsed magnetron sputtering

[J].

Surface and Coatings Technology, 1996, 82(1): 169-175.

|

| [65] |

王启民, 张小波, 张世宏, 等. 高功率脉冲磁控溅射技术沉积硬质涂层研究进展[J].

广东工业大学学报, 2013(4): 1-13.

WANG Q M, ZHANG X B, ZHANG S H, et al. Progress of high power impulse magnetron sputtering for deposition of hard coaitngs[J]. Journal of Guangdong University of Technology, 2013(4): 1-13. DOI: 10.3969/j.issn.1007-7162.2013.04.001. |

| [66] |

WALLIN E, HELMERSSON U. Hysteresis-free reactive high power impulse magnetron sputtering[J].

Thin Solid Films, 2008, 516(18): 6398-6401.

DOI: 10.1016/j.tsf.2007.08.123. |

| [67] |

SELINDER T I, CORONEL E, WALLIN E, et al. α-Alumina coatings on WC/Co substrates by physical vapor deposition[J].

International Journal of Refractory Metals and Hard Materials, 2009, 27(2): 507-512.

DOI: 10.1016/j.ijrmhm.2008.10.007. |

| [68] |

BOBZIN K, BRöGELMANN T, KRUPPE N C, et al. Development of HPPMS-Al2O3-coatings for the machining of hard-to-machine materials

[J].

Materialwissenschaft und Werkstofftechnik, 2018, 49(11): 1287-1300.

DOI: 10.1002/mawe.201800008. |

| [69] |

ANDERSSON J M, CZIGáNY Z, JIN P, et al. Microstructure of α-alumina thin films deposited at low temperatures on chromia template layers[J].

Journal of Vacuum Science & Technology A, 2003, 22(1): 117-121.

|

| [70] |

JIN P, NAKAO S, WANG S X, et al. Localized epitaxial growth of α-Al2O3 thin films on Cr2O3 template by sputter deposition at low substrate temperature

[J].

Applied Physics Letters, 2003, 82(7): 1024-1026.

DOI: 10.1063/1.1544442. |

| [71] |

ASHENFORD D E, LONG F, HAGSTON W E, et al. Experimental and theoretical studies of the low-temperature growth of chromia and alumina[J].

Surface and Coatings Technology, 1999, 116-119: 699-704.

DOI: 10.1016/S0257-8972(99)00181-4. |

| [72] |

EKLUND P, SRIDHARAN M, SILLASSEN M, et al. α-Cr2O3 template-texture effect on α-Al2O3 thin-film growth

[J].

Thin Solid Films, 2008, 516(21): 7447-7450.

DOI: 10.1016/j.tsf.2008.03.038. |

| [73] |

ANDERSSON J M, WALLIN E, HELMERSSON U, et al. Phase control of Al2O3 thin films grown at low temperatures

[J].

Thin Solid Films, 2006, 513(1): 57-59.

|

| [74] |

DIECHLE D, STUEBER M, LEISTE H, et al. Combinatorial approach to the growth of α-(Al1-x, Crx) 2O3 solid solution strengthened thin films by reactive r. f. magnetron sputtering

[J].

Surface and Coatings Technology, 2010, 204(20): 3258-3264.

DOI: 10.1016/j.surfcoat.2010.03.029. |

| [75] |

DIECHLE D. Herstellung und charakterisierung oxidbasierter PVD-hartstoffschichten in den stoffsystemen Al-Cr-O und Al-Cr-O-N [D]. Karlsruher: Karlsruher Institut für Technologie, 2012.

|

| [76] |

RAMM J, ANTE M, BACHMANN T, et al. Pulse enhanced electron emission (P3eTM) arc evaporation and the synthesis of wear resistant Al-Cr-O coatings in corundum structure

[J].

Surface and Coatings Technology, 2007, 202(4): 876-883.

|

| [77] |

KOLLER C M, DALBAUER V, SCHMELZ A, et al. Structure, mechanical properties, and thermal stability of arc evaporated (Al1-xCrx) 2O3 coatings

[J].

Surface and Coatings Technology, 2018, 342: 37-47.

DOI: 10.1016/j.surfcoat.2018.02.077. |

| [78] |

DALBAUER V, RAMM J, KOLOZSVáRI S, et al. On the phase evolution of arc evaporated Al-Cr-based intermetallics and oxides[J].

Thin Solid Films, 2017, 644: 120-128.

DOI: 10.1016/j.tsf.2017.10.055. |

| [79] |

KOLLER C M, GLATZ S A, KOLOZSVáRI S, et al. Influence of substrate bias on structure and mechanical properties of arc evaporated (Al, Cr) 2O3 and (Al, Cr, Fe) 2O3 coatings

[J].

Surface and Coatings Technology, 2017, 319: 386-393.

DOI: 10.1016/j.surfcoat.2017.04.023. |

| [80] |

NAJAFI H, KARIMI A, DESSARZIN P, et al. Formation of cubic structured (Al1-xCrx) 2+δO3 and its dynamic transition to corundum phase during cathodic arc evaporation

[J].

Surface and Coatings Technology, 2013, 214: 46-52.

DOI: 10.1016/j.surfcoat.2012.10.062. |

| [81] |

KOLLER C M, KOUTNá N, RAMM J, et al. First principles studies on the impact of point defects on the phase stability of (AlxCr1-x) 2O3 solid solutions

[J].

AIP Advances, 2016, 6(2): 025002.

DOI: 10.1063/1.4941573. |

| [82] |

KOLLER C M, RAMM J, KOLOZSVáRI S, et al. Corundum-type Fe-doped cathodic arc evaporated Al-Cr-O coatings[J].

Scripta Materialia, 2015, 97: 49-52.

DOI: 10.1016/j.scriptamat.2014.10.037. |

| [83] |

PAULITSCH J, RACHBAUER R, RAMM J, et al. Influence of Si on the target oxide poisoning during reactive arc evaporation of (Al, Cr) 2O3 coatings

[J].

Vacuum, 2014, 100: 29-32.

DOI: 10.1016/j.vacuum.2013.06.008. |

| [84] |

LANDäLV L, GöTHELID E, JENSEN J, et al. Influence of Si doping and O2 flow on arc-deposited (Al, Cr) 2O3 coatings

[J].

Journal of Vacuum Science & Technology A, 2019, 37(6): 061516.

|

| [85] |

LIU H, DU H, XIAN G, et al. Ab-initio calculations of corundum structured α-(Al0.75Cr0.22Me0.03) 2O3 compounds (Me=Si, Fe, Mn, Ti, V and Y)

[J].

Computational Materials Science, 2022, 212: 111601.

DOI: 10.1016/j.commatsci.2022.111601. |

| [86] |

KOLLER C M, DALBAUER V, KIRNBAUER A, et al. Impact of Si and B on the phase stability of cathodic arc evaporated Al0.70Cr0.30-based oxides

[J].

Scripta Materialia, 2018, 152: 107-111.

DOI: 10.1016/j.scriptamat.2018.04.018. |

| [87] |

KOLLER C M, KIRNBAUER A, KOLOZSVáRI S, et al. Impact of morphology and phase composition on mechanical properties of α-structured (Cr, Al) 2O3/(Al, Cr, X) 2O3 multilayers

[J].

Scripta Materialia, 2018, 146: 208-212.

DOI: 10.1016/j.scriptamat.2017.11.051. |

| [88] |

KOLLER C M, STUEBER M, MAYRHOFER P-H. Progress in the synthesis of Al- and Cr-based sesquioxide coatings for protective applications[J].

Journal of Vacuum Science & Technology A, 2019, 37(6): 060802.

|

| [89] |

ÅSTRAND M, SELINDER T I, FIETZKE F, et al. PVD-Al2O3-coated cemented carbide cutting tools

[J].

Surface and Coatings Technology, 2004, 188-189: 186-192.

DOI: 10.1016/j.surfcoat.2004.08.021. |

| [90] |

NOHAVA J, DESSARZIN P, KARVANKOVA P, et al. Characterization of tribological behavior and wear mechanisms of novel oxynitride PVD coatings designed for applications at high temperatures[J].

Tribology International, 2015, 81: 231-239.

DOI: 10.1016/j.triboint.2014.08.016. |

| [91] |

KLOCKE F, GERSCHWILER K, CORDES S, et al. Analyses of the performance potential of oxidic PVD wear-protection coatings on cutting tools using the example of crystalline γ-Al2O3[J].

Advanced Engineering Materials, 2008, 10(7): 622-627.

DOI: 10.1002/adem.200800064. |

| [92] |

BOBZIN K, BAGCIVAN N, EWERING M, et al. Comparison of (Ti, Al) N and (Ti, Al) N/γ-Al2O3 coatings regarding tribological behavior and machining performance

[J].

Surface and Coatings Technology, 2014, 257: 58-62.

DOI: 10.1016/j.surfcoat.2014.08.070. |

| [93] |

SHI C-M, WANG T-G, PEI Z-L, et al. Microstructure, interface, and properties of multilayered CrN/Cr2O3 coatings prepared by arc ion plating

[J].

Journal of Materials Science & Technology, 2014, 30(12): 1193-1201.

|

| [94] |

RAAB R, KOLLER C M, KOLOZSVáRI S, et al. Interfaces in arc evaporated Al-Cr-N/Al-Cr-O multilayers and their impact on hardness[J].

Surface and Coatings Technology, 2017, 324: 236-242.

DOI: 10.1016/j.surfcoat.2017.05.039. |

| [95] |

RAAB R, KOLLER C M, KOLOZSVáRI S, et al. Thermal stability of arc evaporated Al-Cr-O and Al-Cr-O/Al-Cr-N multilayer coatings[J].

Surface and Coatings Technology, 2018, 352: 213-221.

DOI: 10.1016/j.surfcoat.2018.08.002. |

| [96] |

LI W, LIU P, ZHAO Y, et al. Structure, mechanical properties and thermal stability of CrAlN/ZrO2 nanomultilayers deposited by magnetron sputtering

[J].

Journal of Alloys and Compounds, 2013, 562: 5-10.

DOI: 10.1016/j.jallcom.2013.02.020. |

| [97] |

许雨翔. TiAlN基多元和多层涂层的热稳定性和抗氧化性研究 [D]. 长沙: 中南大学, 2017.

|

| [98] |

AIHUA L, JIANXIN D, HAIBING C, et al. Friction and wear properties of TiN, TiAlN, AlTiN and CrAlN PVD nitride coatings[J].

International Journal of Refractory Metals and Hard Materials, 2012, 31: 82-88.

DOI: 10.1016/j.ijrmhm.2011.09.010. |

| [99] |

FUENTES G G, ALMANDOZ E, PIERRUGUES R, et al. High temperature tribological characterisation of TiAlSiN coatings produced by cathodic arc evaporation[J].

Surface and Coatings Technology, 2010, 205(5): 1368-1373.

DOI: 10.1016/j.surfcoat.2010.09.004. |

| [100] |

CHANG C-L, JAO J-Y, CHANG T-C, et al. Influences of bias voltage on properties of TiAl-doped DLC coatings synthesized by cathodic arc evaporation[J].

Diamond and Related Materials, 2005, 14(11): 2127-2132.

|

| [101] |

MESYATS G A, BOCHKAREV M B, PETROV A A, et al. On the mechanism of operation of a cathode spot cell in a vacuum arc[J].

Applied Physics Letters, 2014, 104(18): 1-3.

|

| [102] |

BROWN I, OKS E. Vacuum arc ion sources: recent developments and applications[J].

IEEE Transactions on Plasma Science, 2006, 33(6): 1931-1943.

|

| [103] |

BURKHARD J. Cathode spots of electric arcs[J].

Journal of Physics D:Applied Physics, 2001, 34(17): 103-123.

DOI: 10.1088/0022-3727/34/17/202. |

| [104] |

SHI Z, SONG X, WANG C, et al. Cathode spots dynamic in the initial expansion stage of high-current triggered vacuum arc and the Influence of axial magnetic field[J].

IEEE Transactions on Plasma Science, 2014, 42(8): 2124-2130.

DOI: 10.1109/TPS.2014.2336804. |

| [105] |

LI L, ZHU Y, HE F, et al. Control of cathodic arc spot motion under external magnetic field[J].

Vacuum, 2013, 91: 20-23.

DOI: 10.1016/j.vacuum.2012.10.008. |

| [106] |

STEPANOV I B, RYABCHIKOV A I, ANANIN P S, et al. Tangential cathode magnetic field and substrate bias influence on copper vacuum arc macroparticle content decreasing[J].

Surface and Coatings Technology, 2016, 306: 21-24.

DOI: 10.1016/j.surfcoat.2016.04.003. |

| [107] |

郎文昌, 肖金泉, 宫骏, 等. 轴对称磁场对电弧离子镀弧斑运动的影响[J].

金属学报, 2010, 46(3): 372-379.

LANG W C, XIAO J Q, GONG J, et al. Influence of axisymmetric magnetic field on cathode spots movement in arc ion plating[J]. Acta Metallurgica sinica, 2010, 46(3): 372-379. DOI: 10.3724/SP.J.1037.2010.00372. |

| [108] |

LANG W C, XIAO J Q, GONG J, et al. Study on cathode spot motion and macroparticles reduction in axisymmetric magnetic field-enhanced vacuum arc deposition[J].

Vacuum, 2010, 84(9): 1111-1117.

DOI: 10.1016/j.vacuum.2010.01.037. |

| [109] |

HU J, TIAN X, LIU H, et al. Enhanced discharge and microstructure of the ta-C coatings by electromagnetically enhanced cathodic arc at argon atmosphere[J].

Surface and Coatings Technology, 2019, 365: 227-236.

DOI: 10.1016/j.surfcoat.2018.08.020. |

| [110] |

GENG D, XU Y X, PENG B, et al. Comparative study on mechanical and tribological properties of Cr–Al–N and Cr–Al–O coatings deposited by cathodic arc evaporation[J].

Tribology International, 2023, 177: 107989.

DOI: 10.1016/j.triboint.2022.107989. |

| [111] |

XIAO B-J, CHEN Y, DAI W, et al. Microstructure, mechanical properties and cutting performance of AlTiN coatings prepared via arc ion plating using the arc splitting technique[J].

Surface and Coatings Technology, 2017, 311: 98-103.

DOI: 10.1016/j.surfcoat.2016.12.074. |

| [112] |

FOX-RABINOVICH G S, WEATHERLY G C, DODONOV A I, et al. Nano-crystalline filtered arc deposited (FAD) TiAlN PVD coatings for high-speed machining applications[J].

Surface and Coatings Technology, 2004, 177-178: 800-811.

DOI: 10.1016/j.surfcoat.2003.05.004. |

| [113] |

VOLKHONSKII A O, VERESHCHAKA A A, BLINKOV I V, et al. Filtered cathodic vacuum arc deposition of nano-layered composite coatings for machining hard-to-cut materials[J].

The International Journal of Advanced Manufacturing Technology, 2016, 84(5): 1647-1660.

|

| [114] |

BENDAVID A. Deposition and modification of titanium nitride by ion assisted arc deposition[J].

Journal of Vacuum Science & Technology A, 1995, 13(3): 1658-1664.

|

| [115] |

SU K, LIU D, SHAO T. Microstructure and mechanical properties of TiAlSiN nano-composite coatings deposited by ion beam assisted deposition[J].

Science China Technological Sciences, 2015, 58(10): 1682-1688.

DOI: 10.1007/s11431-015-5878-0. |

| [116] |

SAVVIDES N, WINDOW B. Unbalanced magnetron ion‐assisted deposition and property modification of thin films[J].

Journal of Vacuum Science & Technology A, 1986, 4(3): 504-508.

|

| [117] |

CONTRERAS E, GALINDEZ Y, RODAS M A, et al. CrVN/TiN nanoscale multilayer coatings deposited by DC unbalanced magnetron sputtering[J].

Surface and Coatings Technology, 2017, 332: 214-222.

DOI: 10.1016/j.surfcoat.2017.07.086. |

| [118] |

KABIR M S, MUNROE P, ZHOU Z, et al. Structure and mechanical properties of graded Cr/CrN/CrTiN coatings synthesized by close field unbalanced magnetron sputtering[J].

Surface and Coatings Technology, 2017, 309: 779-789.

DOI: 10.1016/j.surfcoat.2016.10.087. |

| [119] |

KABIR M S, MUNROE P, ZHOU Z, et al. Scratch adhesion and tribological behaviour of graded Cr/CrN/CrTiN coatings synthesized by closed-field unbalanced magnetron sputtering[J].

Wear, 2017, 380-381: 163-175.

DOI: 10.1016/j.wear.2017.03.020. |

| [120] |

HOWSON R P, J'AFER H A, SPENCER A G. Substrate effects from an unbalanced magnetron[J].

Thin Solid Films, 1990, 193-194: 127-137.

DOI: 10.1016/S0040-6090(05)80020-3. |

| [121] |

SPROUL W D. High-rate reactive DC magnetron sputtering of oxide and nitride superlattice coatings[J].

Vacuum, 1998, 51(4): 641-646.

DOI: 10.1016/S0042-207X(98)00265-6. |

| [122] |

CHRISTOU C, BARBER Z. Ionization of sputtered material in a planar magnetron discharge[J].

Journal of Vacuum Science & Technology A:Vacuum, Surfaces, and Films, 2000, 18(6): 2897-2907.

|

| [123] |

KOUZNETSOV V, MACAK K, SCHNEIDER J M, et al. A novel pulsed magnetron sputter technique utilizing very high target power densities[J].

Surface and coatings technology, 1999, 122(2-3): 290-293.

DOI: 10.1016/S0257-8972(99)00292-3. |

| [124] |

GRECZYNSKI G, JENSEN J, HULTMAN L. CrNx films prepared by DC magnetron sputtering and high-power pulsed magnetron sputtering: a comparative study

[J].

IEEE Transactions on Plasma Science, 2010, 38(11): 3046-3056.

DOI: 10.1109/TPS.2010.2071885. |

| [125] |

ANDERS A. A review comparing cathodic arcs and high power impulse magnetron sputtering (HiPIMS)[J].

Surface and Coatings Technology, 2014, 257: 308-325.

DOI: 10.1016/j.surfcoat.2014.08.043. |

| [126] |

SARAKINOS K, ALAMI J, KONSTANTINIDIS S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art[J].

Surface and Coatings Technology, 2010, 204(11): 1661-1684.

DOI: 10.1016/j.surfcoat.2009.11.013. |

| [127] |

GUDMUNDSSON J, SIGURJONSSON P, LARSSON P, et al. On the electron energy in the high power impulse magnetron sputtering discharge[J].

Journal of Applied Physics, 2009, 105(12): 123302.

DOI: 10.1063/1.3151953. |

| [128] |

OKS E, ANDERS A. Evolution of the plasma composition of a high power impulse magnetron sputtering system studied with a time-of-flight spectrometer[J].

Journal of Applied Physics, 2009, 105(9): 093304.

DOI: 10.1063/1.3125443. |

| [129] |

ALAMI J, GUDMUNDSSON J T, BOHLMARK J, et al. Plasma dynamics in a highly ionized pulsed magnetron discharge[J].

Plasma Sources Science and Technology, 2005, 14(3): 525.

DOI: 10.1088/0963-0252/14/3/015. |

| [130] |

JIANG F, ZHANG T, WU B, et al. Structure, mechanical and corrosion properties of TiN films deposited on stainless steel substrates with different inclination angles by DCMS and HPPMS[J].

Surface and Coatings Technology, 2016, 292: 54-62.

DOI: 10.1016/j.surfcoat.2016.03.007. |

| [131] |

POLYAKOV M N, MORSTEIN M, MAEDER X, et al. Microstructure-driven strengthening of TiB2 coatings deposited by pulsed magnetron sputtering

[J].

Surface and Coatings Technology, 2019, 368: 88-96.

DOI: 10.1016/j.surfcoat.2019.04.042. |

| [132] |

刘源, 丁继成, 许雨翔, 等. 电弧离子镀和高功率脉冲磁控溅射AlTiN涂层及其切削性能研究[J].

表面技术, 2022, 51(2): 57-65.

LIU Y, DING J C, XU Y X, et al. Preparation and cutting performance of AlTiN coatings by arc ion plating and high power pulsed magnetron sputtering[J]. Surface Technology, 2022, 51(2): 57-65. DOI: 10.16490/j.cnki.issn.1001-3660.2022.02.006. |

| [133] |

REOLON L W, AGUIRRE M H, YAMAMOTO K, et al. A comprehensive study of Al0.6Ti0.4N coatings deposited by cathodic arc and HiPIMS PVD methods in relation to their cutting performance during the machining of an inconel 718 alloy

[J].

Coatings, 2021, 11(6): 723.

DOI: 10.3390/coatings11060723. |

| [134] |

VETTER J. Innovative PVD processes for advanced coatings based on HiPIMS and arc: scalable pulsed power plasma and high ionization triple [C]. Functional Coatings and Surface Engineering. Montreal, Canada: [s. n. ], 2014.

|

| [135] |

KOLLER C, GLATZ S, RIEDL H, et al. Structure and mechanical properties of architecturally designed Ti-Al-N and Ti-Al-Ta-N-based multilayers[J].

Surface and Coatings Technology, 2020, 385: 125355.

DOI: 10.1016/j.surfcoat.2020.125355. |

| [136] |

KOLLER C M, GLATZ S, KOLOZSVARI S, et al. Thermal stability and oxidation resistance of architecturally designed Ti–Al–N-and Ti–Al–Ta–N-based multilayers[J].

Surface and Coatings Technology, 2020, 385: 125444.

DOI: 10.1016/j.surfcoat.2020.125444. |

| [137] |

CHANG C-L, LUO G-J, YANG F-C, et al. Effects of duty cycle on microstructure of TiN coatings prepared using CAE/HiPIMS[J].

Vacuum, 2021, 192: 110449.

DOI: 10.1016/j.vacuum.2021.110449. |

| [138] |

ZHANG Q, WU Z, XU Y X, et al. Improving the mechanical and anti-wear properties of AlTiN coatings by the hybrid arc and sputtering deposition[J].

Surface and Coatings Technology, 2019, 378: 125022.

DOI: 10.1016/j.surfcoat.2019.125022. |

| [139] |

GENG D, XU Y X, WANG Q. Hybrid deposition of Cr–O/Al–O hard coatings combining cathodic arc evaporation and high power impulse magnetron sputtering[J].

Surface and Coatings Technology, 2023, 456: 129235.

DOI: 10.1016/j.surfcoat.2023.129235. |

| [140] |

KOLLER C M, HOLLERWEGER R, RACHBAUER R, et al. Annealing studies and oxidation tests of a hybrid multilayer arrangement of cathodic arc evaporated Ti–Al–N and reactively sputtered Ta–Al–N coatings[J].

Surface and Coatings Technology, 2015, 283: 89-95.

DOI: 10.1016/j.surfcoat.2015.10.054. |

| [141] |

CHEN L, XU Y X, DU Y, et al. Effect of bilayer period on structure, mechanical and thermal properties of TiAlN/AlTiN multilayer coatings[J].

Thin Solid Films, 2015, 592: 207-214.

DOI: 10.1016/j.tsf.2015.09.029. |

| [142] |

张权, 耿东森, 许雨翔, 等. 电弧/溅射复合沉积技术的发展及其在刀具涂层中的应用[J].

表面技术, 2021, 50(5): 20-35.

ZHANG Q, GENG D S, XU Y X, et al. Development of hybrid arc/sputtering deposition techniques for tool coatings[J]. Surface Technology, 2021, 50(5): 20-35. DOI: 10.16490/j.cnki.issn.1001-3660.2021.05.002. |

| [143] |

JEHN H A, ROTHER B. Preparation and concentration distribution of multicomponent hard coatings[J].

International Journal of Refractory Metals and Hard Materials, 1996, 14(1): 87-95.

|

| [144] |

XU Y X, CHEN L, PEI F, et al. Thermal stability and oxidation resistance of V-alloyed TiAlN coatings[J].

Ceramics International, 2018, 44(2): 1705-1710.

DOI: 10.1016/j.ceramint.2017.10.100. |

| [145] |

PFEILER M, SCHEU C, HUTTER H, et al. On the effect of Ta on improved oxidation resistance of Ti–Al–Ta–N coatings[J].

Journal of Vacuum Science & Technology A, 2009, 27(3): 554-560.

|

| [146] |

GLATZ S A, BOLVARDI H, KOLOZSVáRI S, et al. Arc evaporated W-alloyed Ti-Al-N coatings for improved thermal stability, mechanical, and tribological properties[J].

Surface and Coatings Technology, 2017, 332: 275-282.

DOI: 10.1016/j.surfcoat.2017.05.097. |

| [147] |

ZHANG H, XU Y X, CHEN Y, et al. Temperature-dependent oxidation behavior of arc evaporated Al–Ti–B–N coatings[J].

Corrosion Science, 2022, 203: 110347.

DOI: 10.1016/j.corsci.2022.110347. |

| [148] |

FLINK A, ANDERSSON J M, ALLING B, et al. Structure and thermal stability of arc evaporated (Ti0.33Al0.67) 1−xSixN thin films

[J].

Thin Solid Films, 2008, 517(2): 714-721.

DOI: 10.1016/j.tsf.2008.08.126. |

| [149] |

LIU S, CHANG K, MUSIC D, et al. Stress-dependent prediction of metastable phase formation for magnetron-sputtered V1−xAlxN and Ti1−xAlxN thin films

[J].

Acta Materialia, 2020, 196: 313-324.

DOI: 10.1016/j.actamat.2020.06.044. |

| [150] |

GROSSMANN B, SCHALK N, CZETTL C, et al. Phase composition and thermal stability of arc evaporated Ti1−xAlxN hard coatings with 0.4≤x≤0.67

[J].

Surface and Coatings Technology, 2017, 309: 687-693.

DOI: 10.1016/j.surfcoat.2016.11.015. |

| [151] |

ENDLER I, HöHN M, HERRMANN M, et al. Novel aluminum-rich Ti1−xAlxN coatings by LPCVD

[J].

Surface and Coatings Technology, 2008, 203(5): 530-533.

|

| [152] |

KECKES J, DANIEL R, MITTERER C, et al. Self-organized periodic soft-hard nanolamellae in polycrystalline TiAlN thin films[J].

Thin Solid Films, 2013, 545: 29-32.

DOI: 10.1016/j.tsf.2013.08.001. |

| [153] |

TODT J, PITONAK R, KöPF A, et al. Superior oxidation resistance, mechanical properties and residual stresses of an Al-rich nanolamellar Ti0.05Al0.95N coating prepared by CVD

[J].

Surface and Coatings Technology, 2014, 258: 1119-1127.

DOI: 10.1016/j.surfcoat.2014.07.022. |

| [154] |

VEPREK S, VEPREK-HEIJMAN M. Limits to the preparation of superhard nanocomposites: impurities, deposition and annealing temperature[J].

Thin Solid Films, 2012, 522: 274-282.

DOI: 10.1016/j.tsf.2012.08.048. |

| [155] |

WU Z, WANG Q, PETROV I, et al. Cubic-structure Al-rich TiAlSiN thin films grown by hybrid high-power impulse magnetron co-sputtering with synchronized Al+ irradiation

[J].

Surface and Coatings Technology, 2020, 385: 125364.

DOI: 10.1016/j.surfcoat.2020.125364. |

| [156] |

GRECZYNSKI G, LU J, JENSEN J, et al. A review of metal-ion-flux-controlled growth of metastable TiAlN by HIPIMS/DCMS co-sputtering[J].

Surface and Coatings Technology, 2014, 257: 15-25.

DOI: 10.1016/j.surfcoat.2014.01.055. |

| [157] |

GRECZYNSKI G, PATSCHEIDER J, LU J, et al. Control of Ti1−xSixN nanostructure via tunable metal-ion momentum transfer during HIPIMS/DCMS co-deposition

[J].

Surface and Coatings Technology, 2015, 280: 174-184.

DOI: 10.1016/j.surfcoat.2015.09.001. |

| [158] |

MORITZ Y, KAINZ C, TKADLETZ M, et al. Microstructure and mechanical properties of arc evaporated Ti(Al, Si) N coatings[J].

Surface and Coatings Technology, 2021, 421: 127461.

DOI: 10.1016/j.surfcoat.2021.127461. |

| [159] |

PFEILER M, ZECHNER J, PENOY M, et al. Improved oxidation resistance of TiAlN coatings by doping with Si or B[J].

Surface and Coatings Technology, 2009, 203(20-21): 3104-3110.

DOI: 10.1016/j.surfcoat.2009.03.036. |

| [160] |

SURESH S. Graded materials for resistance to contact deformation and damage[J].

Science, 2001, 292(5526): 2447-2451.

DOI: 10.1126/science.1059716. |

| [161] |

卢柯. 梯度纳米结构材料[J].

金属学报, 2015, 51(1): 1-10.

LU K. Gradient nanostructured materials[J]. Acta metallurgica sinica, 2015, 51(1): 1-10. DOI: 10.11900/0412.1961.2014.00395. |

| [162] |

LU K. Making strong nanomaterials ductile with gradients[J].

Science, 2014, 345(6203): 1455-1456.

DOI: 10.1126/science.1255940. |

| [163] |

DöRR J, MERTENS T, ENGERING G, et al. ‘In-situ’ temperature measurement to determine the machining potential of different tool coatings[J].

Surface and Coatings Technology, 2003, 174-175: 389-392.

DOI: 10.1016/S0257-8972(03)00708-4. |

| [164] |

SAMANI M K, DING X Z, KHOSRAVIAN N, et al. Thermal conductivity of titanium nitride/titanium aluminum nitride multilayer coatings deposited by lateral rotating cathode arc[J].

Thin Solid Films, 2015, 578: 133-138.

DOI: 10.1016/j.tsf.2015.02.032. |

| [165] |

SAMANI M K, CHEN G C K, DING X Z, et al. Thermal conductivity of CrAlN and TiAlN coatings deposited by lateral rotating cathode arc[J].

Key Engineering Materials, 2010, 447-448: 705-709.

DOI: 10.4028/www.scientific.net/KEM.447-448.705. |

| [166] |

DING X-Z, SAMANI M K, CHEN G. Thermal conductivity of PVD TiAlN films using pulsed photothermal reflectance technique[J].

Applied Physics A, 2010, 101(3): 573-577.

DOI: 10.1007/s00339-010-5900-0. |

| [167] |

WALDL H, TKADLETZ M, LECHNER A, et al. Evolution of the fracture properties of arc evaporated Ti1-xAlxN coatings with increasing Al content

[J].

Surface and Coatings Technology, 2022, 444: 128690.

DOI: 10.1016/j.surfcoat.2022.128690. |

| [168] |

LIANG X, LIU Z, WANG B, et al. Modeling of plastic deformation induced by thermo-mechanical stresses considering tool flank wear in high-speed machining Ti-6Al-4V[J].

International Journal of Mechanical Sciences, 2018, 140: 1-12.

DOI: 10.1016/j.ijmecsci.2018.02.031. |

| [169] |

VERESCHAKA A, VERESCHAKA A, BATAKO A, et al. Development and research of nanostructured multilayer composite coatings for tungsten-free carbides with extended area of technological applications[J].

The International Journal of Advanced Manufacturing Technology, 2016, 87: 3449-3457.

DOI: 10.1007/s00170-016-8739-5. |

2023, Vol. 40

2023, Vol. 40