文章信息

- 葛超群, 汪刘应, 刘顾

- GE Chao-qun, WANG Liu-ying, LIU Gu

- 碳基/羰基铁复合吸波材料的研究进展

- Research progress in carbon-based/carbonyl iron composite microwave absorption materials

- 材料工程, 2019, 47(12): 43-54

- Journal of Materials Engineering, 2019, 47(12): 43-54.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2018.000220

-

文章历史

- 收稿日期: 2018-03-05

- 修订日期: 2019-03-25

随着电子信息技术的迅猛发展,日益强大的目标探测和跟踪能力使得武器系统受到严重的侦查威胁,电磁波辐射污染也成为人类健康的重要“杀手”。吸波材料技术能有效降低武器系统的特征信号,较大程度减轻电磁辐射污染,提高武器系统生存和突防攻击能力,已成为广泛研究的热点领域之一[1-2]。新的电磁环境对吸波材料的性能提出了更高要求,单相吸波材料难以满足“薄、轻、宽、强”的综合需求,多种材料之间的优势互补复合成为吸波材料研究和发展的重点方向[3]。

碳材料如石墨烯、碳纳米管(carbon nanotubes,CNTs)、碳纤维(carbon fibre,CF)、炭黑、石墨等是一种介电性能优异的轻质吸波材料[4-6],然而由于碳材料的介电常数较大,造成在单独使用时吸波层的阻抗匹配特性较差,存在损耗机制单一、吸收频带窄、吸收性能弱等缺点,限制了其吸波性能的提高。研究人员在碳材料中引入第二相吸波材料,如Fe/Co/Ni[7],Cu@Ni[8],Fe3O4[9-11]、铁氧体[12-14]、Co3O4[15]等磁性金属及其氧化物,通过增加新的多维结构和多重电磁损耗机制改善其吸波性能。羰基铁(carbonyl iron,CI)具有成本低、饱和磁化强度和磁导率高、吸波频带宽、吸波效果好等诸多优点[16-17],是国内外应用最为广泛的吸波材料之一,已成功应用于先进军事装备中[18]。但羰基铁的密度大、损耗机制单一,难以满足吸波涂层轻量化、宽吸收的需求[19]。因此,将碳材料与羰基铁复合,不仅能降低复合材料的密度,而且能使其兼具电、磁双重损耗,有效拓宽吸波频带,提高吸波性能,从而获得具有良好综合性能的轻质吸波材料。近年来,研究人员围绕碳基/羰基铁复合吸波材料开展了大量的研究工作。本文结合国内外学者的研究成果,综述了碳基/羰基铁复合吸波材料的最新研究进展,并探讨了当前研究亟待解决的问题及发展前景。

1 羰基铁吸波材料羰基铁是当前应用较为广泛的磁性吸波剂[20-21],其制备的吸波涂层具有吸波性能强、有效吸波频带宽、涂层厚度薄等优点。近年来围绕羰基铁吸波材料开展的研究主要可分为羰基铁的表面原位改性和增大羰基铁的形状各向异性两个方面。

1.1 羰基铁的表面改性羰基铁的表面改性主要是通过羰基铁表面原位改性、包覆无机或有机吸波材料等手段,降低介电常数,提高抗氧化性和抗腐蚀性,改善分散性,降低吸收剂密度。

羰基铁表面原位改性常用方法是通过表面原位氧化或钝化处理,改善阻抗匹配,增强抗氧化性能。Long等[22]通过机械球磨和表面氧化处理制备了Fe3O4/α-FeOOH氧化层包覆的片状羰基铁(flake carbonyl iron,FCI),经4h球磨、30min氧化处理后,羰基铁的低频吸波性能明显改善。涂层厚度为1.2mm时,反射率在2.5~8GHz时均小于-6dB,在4GHz时有最小反射率峰值-11dB。Yin等[23]将FCI采用弱氧化气体CO2钝化处理,在保持羰基铁良好吸波性能的同时,较大程度地提高了其抗氧化能力。

在无机包覆方面,通过引入包覆层的特殊性能及独特的核壳结构,拓宽吸波频带,提高抗氧化和耐腐蚀性,包覆材料主要有金属单质及其氧化物。Zhou等[24]采用化学镀制备的Co包覆FCI表现出较好的热稳定性和吸波性能。在羰基铁表面包覆SiO2可以降低其介电常数,改善阻抗匹配特性[25-26]。Li等[27]在球形羰基铁(spherical carbonyl iron,SCI)表面包覆5~10nm的SiO2壳层,其吸波性能明显改善,在11GHz时有最小反射率峰值-38.8dB,小于-10dB频带宽达6GHz。Zhang等[28]采用球磨法制备的FCI/MnO2复合材料在S波段(2~4GHz)和C波段(4~8GHz)具有较好的吸波性能。郭飞等[29]制备了海胆状SCI/ZnO核壳结构复合粒子,在不改变吸波性能的情况下显著改善其抗氧化性能。Wu等[30]采用球磨-水热配合法将SnO2包覆在FCI表面,FCI/SnO2复合材料在7~18GHz范围内均有小于-10dB的反射率,最小反射率达-57.8dB。

在羰基铁表面进行有机包覆的材料主要有聚苯胺(polyaniline,PANI)、聚吡咯(polypyrrole,PPY)等。Tang等[31-32]制备的PANI包覆SCI复合材料具有较好的耐腐蚀和吸波性能,涂层厚度为1.1mm时在27.3~39.5GHz的反射率均小于-10dB。汪晓芹等[33]采用原位聚合法制备的核壳结构SCI@PANI复合材料具有较好的防腐性能和吸波性能。Sui等[34]合成了具有三维结构的FCI@PPY复合材料,涂层厚度为2.2mm时在10~16.1GHz的反射率均小于-10dB。Song等[35]在FCI表面包覆了一层甲基丙烯酸聚苯乙烯,复合粒子介电常数降低而磁导率基本保持不变,低频吸波性能得到明显改善。

1.2 增大羰基铁的形状各向异性增大羰基铁的形状各向异性主要是通过机械球磨、调控制备工艺参数等手段,合成具有形状各向异性的片状、纤维状、壳状、树枝状羰基铁,提高其Snoek极限,从而获得较高的磁导率以及更大的磁损耗。以其为主要吸波剂制备的吸波涂层具有吸收强、有效频带宽、面密度低等特点。

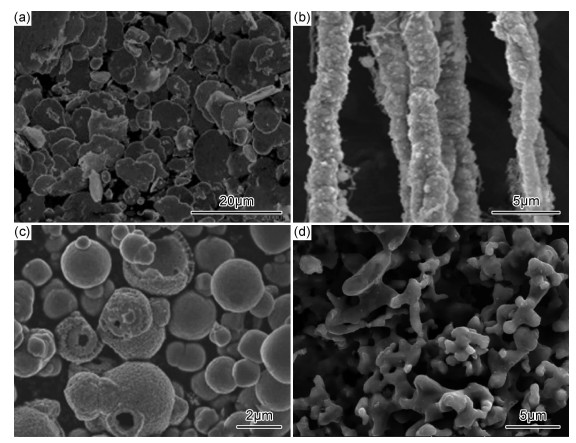

机械球磨法是制备FCI最常用的方法,研究人员围绕球磨工艺参数对羰基铁形貌及电磁性能的影响开展了深入研究。Khani等[36]发现,随着球磨时间的增加,羰基铁逐渐由球状转变为片状,磁导率虚部由1.23增大至1.88,在1~18GHz范围内呈现宽峰,这与采用有效介质理论计算的结果基本一致,制备厚度为1.75mm的双层涂层在8~18GHz的反射率均小于-10dB。Xu等[37]采用两步球磨法制备了具有较大纵横比的FCI,其磁导率相对SCI得到有效增强,采用遗传算法优化的吸波涂层在8~18GHz的反射率均小于-10dB,厚度仅为1.47mm。Qiao等[38]发现,片层状的平面各向异性羰基铁共振频率显著增大,导致其在较宽的频段内具有较大的磁导率实部与虚部。Abshinova等[39]采用机械球磨和退火处理制备的FCI磁导率显著增大,共振频率向低频转移。Wang等[40]从控制粒子微观结构入手,采用加热湿法球磨调控FCI的纵横比、晶粒尺寸和内应力(图 1(a)),优化其吸波性能,FCI体积分数仅为18%时,涂层在8~18GHz的反射率均小于-8dB。

通过控制Fe(CO)5热分解时粒子沉积方向可制备羰基铁纤维。童国秀等[41-42]通过控制Fe(CO)5的热解温度,用气流诱导法制备了化学组成与结构可控的多晶铁纤维,并分析了热解温度对多晶铁纤维的结构组成和电磁性能的影响。李小莉等[43]采用磁场引导的有机金属气相沉积法(metal organic chemical vapor deposition,MOCVD)制备了纳米晶铁纤维,并测试了其电磁参数和涂层反射率。贺君等[44]通过表面原位氧化改性制备了表面包覆铁氧化物的多晶铁纤维复合材料(图 1(b)),以20%填充量制得的1mm厚吸波涂层小于-10dB的吸收带宽可达4.5GHz,峰值达-25.38dB,涂层密度大幅降低。

在最近的研究中,出现了一些比较新颖的处理方法制备的多种形状结构羰基铁。Yin等[45]采用点腐蚀法制备了中空的球形壳状羰基铁(图 1(c)),由于趋肤效应减弱、空心结构带来的界面极化和多重反射作用增强,壳状羰基铁相对SCI具有更优异的吸波性能,涂层厚度为1mm时在6.5~18GHz频段内的反射率均小于-5dB,适合用于制备轻、薄的吸波涂层。杨芾藜等[46]研究了球状和树枝状羰基铁电磁性能(图 1(d)),由于树枝状形貌有利于形成不连续网络,增加电磁波多重散射和界面电荷极化,树枝状羰基铁比SCI具有更好的吸波性能和更低的吸收频带,其最大反射损耗增加了94%,达到-47.14dB,谐振频率也从SCI的11.88GHz变为6.44GHz。

2 碳基/羰基铁复合吸波材料目前,国内外对碳基/羰基铁复合吸波材料的研究主要集中在石墨烯/羰基铁复合吸波材料、碳纳米管/羰基铁复合吸波材料、碳纤维/羰基铁复合吸波材料、炭黑/羰基铁复合吸波材料、石墨/羰基铁复合吸波材料以及其他碳材料与羰基铁的复合吸波材料。

2.1 石墨烯/羰基铁复合吸波材料石墨烯作为一种新型碳材料,具有诸多优异性能,在吸波材料研究领域显示出了潜在的应用价值,但单独用作吸波材料时存在分散性差、吸收强度弱、阻抗匹配性差以及吸收频带窄等缺点[47]。石墨烯与羰基铁结合的形式主要有羰基铁表面负载石墨烯、石墨烯表面负载羰基铁以及两种材料的混合掺杂。

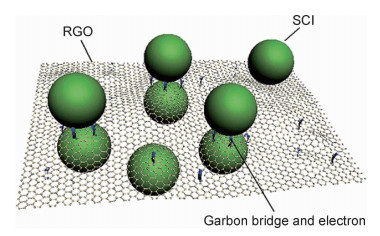

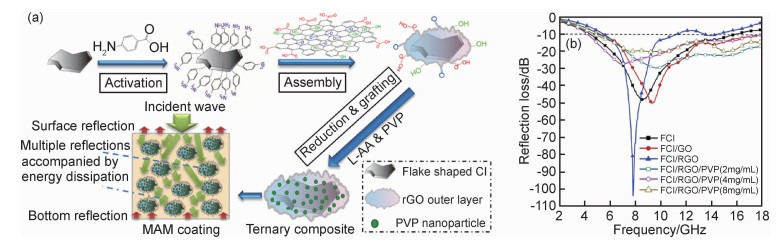

黄琪惠等[48]通过热分解Fe(CO)5在氧化石墨烯(graphene oxide,GO)片层的表面和边缘分散负载了一层尺寸小于50nm的Fe@Fe3O4纳米粒子,复合材料的饱和磁化强度可达140A·m-2·kg-1。当涂层厚度为1.5mm时,在10~16GHz范围内反射率均在-10dB以下;厚度为3mm时,反射率在4.3GHz处达到最大,约为-25dB。Xu等[49]首先采用一锅法将还原氧化石墨烯(reduced graphene oxide,RGO)负载在FCI表面,得到RGO/FCI复合粒子,然后通过原位聚合在其表面包覆PANI,得到核壳结构的RGO/FCI/PANI复合材料,制备的2mm厚的涂层在11.8GHz达到最小反射率-38.8dB。Weng等[50-51]采用一锅法制备的FCI/RGO/聚乙烯吡咯烷酮(polyvinyl pyrrolidone,PVP)核壳结构三元复合吸波材料具有优异的吸波性能(图 2(a)),涂层厚度为2.5mm时,FCI/RGO在7.8GHz处有最小反射率-103.8dB,PVP溶液浓度为4mg/mL时制备的FCI/RGO/PVP复合材料小于-10dB频带宽为13.8GHz(4.2~18GHz)(图 2(b)),厚度为4.8mm时,其小于-10dB频带覆盖2~18GHz。

|

图 2 FCI/RGO/PVP复合材料制备过程及吸波机理示意图(a),厚度为2.5mm时FCI,FCI/GO,FCI/RGO,FCI/RGO/PVP复合材料的反射率(b)[51] Fig. 2 Schematic illustration for preparation process and microwave absorbing mechanism of FCI/RGO/PVP composites(a), and reflection loss for FCI, FCI/GO, FCI/RGO, FCI/RGO/PVP composites with thickness of 2.5mm(b)[51] |

Chen等[52]采用机械球磨法制备的RGO/FCI/环氧树脂复合材料比FCI/环氧树脂复合材料具有更大的介电损耗和更低的反射率,涂层厚度为2mm时在11GHz处有最小反射率-32.3dB。Zhu等[53]通过一种简易湿化学法制备了具有交联框架结构的RGO/SCI复合材料,其阻抗匹配性和吸波性能明显改善,当涂层厚度为3mm时,在7.79~11.98GHz范围内反射率均小于-10dB,最小反射率达-52.46dB,其吸波机理可以用碳桥效应来解释,如图 3所示。王洁萱[54],李国显[55]也采用了类似的方法分别制备了GO/SCI,RGO/SCI复合材料,均展现出较好的吸波性能。Qing等[56]将石墨烯纳米片(graphene nanosheets,GNs)和FCI以不同配比均匀分散到环氧有机硅树脂中,通过改变GNs和FCI含量调整复合材料的电磁性能,涂层厚度为0.9mm时,在5.4~18GHz范围内的反射率均小于-6dB。

由于特殊的一维管状结构和良好的介电性能,CNTs表现出较好的吸波性能,同时兼具质量轻、稳定性好等优点[57]。研究人员将CNTs与羰基铁进行不同形式的复合,进一步对CNTs的吸波性能进行改善和调控。

在包覆型核壳结构复合材料方面,Liu等[58]采用MOCVD法通过热分解Fe(CO)5在CNTs表面生长羰基铁壳层,制备的CNTs/CI核壳材料吸波性能明显增强,厚度为3.6mm时小于-10dB带宽达10.6GHz(7.4~18GHz),覆盖整个X波段(8~12GHz)和Ku波段(12~18GHz)。Liu等[59]采用机械球磨法将CNTs负载在FCI表面,制备的复合材料表现出较强的宽频吸波性能,涂层在4.6~17GHz范围内的反射率均小于-4dB,而厚度仅为0.6mm。

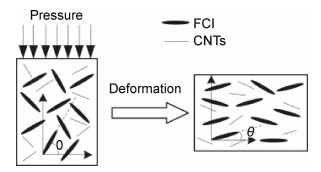

在CNTs与羰基铁的混合掺杂方面,Xu等[60]采用双辊机将CNTs和SCI, FCI分散在硅橡胶中,发现CNTs含量对复合材料吸波性能有较大影响,填充CNTs和FCI的复合材料在厚度为0.5mm时8~18GHz的反射率小于-5dB,厚度为2mm时最小反射率峰值在3.5GHz处达-35dB。该课题组还通过对填充CNTs和FCI的硅橡胶复合材料制备的同轴环施加不同压应力,实现吸波性能的可控调节[61],压缩应变示意图如图 4所示。Qing等[62-63]将CNTs和FCI均匀分散在环氧有机硅树脂中(图 5(a),(b)),通过优化设计得到涂层薄、有效吸收频带宽的吸波涂层,制备的复合材料在厚度为0.5,1,1.5mm时小于-5dB的反射率频带为10.4~18,4.4~18,2~18GHz,厚度为1.5mm时小于-10dB的反射率频带宽达14.6GHz(3.4~18GHz)(图 5(c))。Gao等[64]发现,吸收剂的交替层状分布结构能够有效降低CNTs/CI聚氯乙烯基复合材料的最小反射率,增大有效吸收带宽(反射率小于-10dB)。Tong等[65]发现,当CNTs含量为2.2%时CNTs/CI复合材料具有较好的吸波性能。Li等[66]采用超声共混将有缺陷的CNTs与羰基铁复合,制备的CNTs/羰基铁/丙烯酸树脂复合材料的吸波性能较CNTs和羰基铁的单体大幅增强。

|

图 5 CNTs和FCI颗粒填充环氧有机硅树脂复合物的断裂表面SEM图(箭头所示为CNTs)(a),CNTs,FCI和环氧有机硅树脂基体组成的三维网络结构示意图(b),填充0.5%CNTs和50%FCI的复合材料在不同厚度下的反射率(c)[63] Fig. 5 SEM images of the fracture surface of the epoxy-silicone composite filled with CNTs and FCI particles(the arrows for the CNTs)(a), schematic diagram to show the 3D network structure generated by the CNTs, FCI particles and epoxy-silicone resin matrix(b), and frequency dependent on the reflection loss of the composite filled with 0.5%CNTs and 50%FCI particles(c)[63] |

碳纤维与其他吸波材料相比,具有硬度高、高温强度大、耐腐蚀性强、质量轻、吸收频带宽等优点。通过研究碳纤维的吸波机理,对其进行改性和结构设计,研制出高性能的碳纤维复合材料是现在研究的热点[67]。目前,对碳纤维/羰基铁复合吸波材料的研究主要分为制备包覆型核壳结构复合材料和二者的混合掺杂。

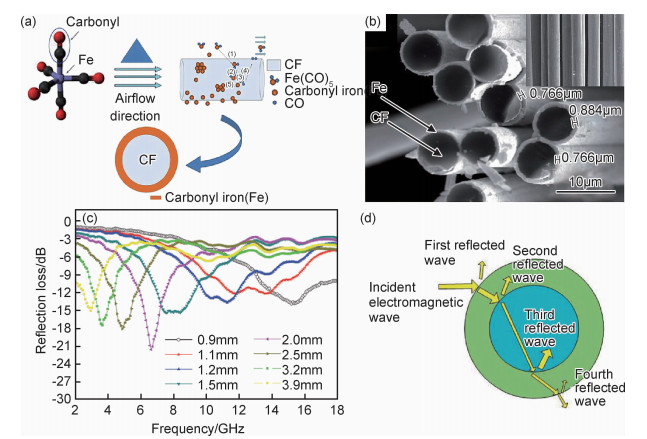

Liu等[68-69]以Fe(CO)5为前驱体,采用MOCVD工艺在CF表面沉积连续α-Fe膜,制得核壳结构的CF/CI复合材料,通过优化CF与羰基铁的质量比调控复合材料电磁性能,质量比为1:8.8时制备的复合材料具有较好的吸波性能,厚度为0.9~3.9mm时在2~18GHz频段内反射率均小于-10dB,多重散射是其衰减电磁波的重要机理,如图 6所示。Zhang等[70]采用类似方法制备了CF/CI复合材料,研究了复合材料的填充量对电磁性能的影响,并将计算反射率与实测反射率进行了对比验证,结果表明,复合材料质量分数为8%、厚度为2mm时涂层具有最优吸波性能。Salimkhani等[71]采用电沉积法将SCI成功包覆在CF表面,形成核壳结构的CF/SCI复合材料,结果表明,碘为稳定剂、沉积时间为20min、不经热处理的复合材料具有较好的吸波性能,厚度为2mm时在9.22GHz处有最小反射率-13.8dB。Youh等[72]以乙炔和氢气原料、SCI为催化剂和基体,采用化学气相沉积法在SCI表面生长CF,CF/SCI/环氧树脂复合材料的电磁性能测试结果表明,涂层厚度为2mm、CF/SCI的质量分数为45%和30%时,复合材料分别在2~18GHz和18~40GHz频段内具有较好的吸波性能。

Qing等[73]将FCI和CF在环氧有机硅树脂中复合制备复合吸波材料,发现当CF和FCI的含量分别为2%和65%时复合材料具有最优吸波性能,涂层厚度仅为1mm时,小于-10dB的吸收带宽达10GHz(8~18GHz)。Min等[74]研究了FCI的取向、CF的添加量以及取向对FCI/CF环氧树脂基复合材料吸波性能影响,制备的FCI/CF环氧树脂基双层涂层在厚度为0.8mm时小于-5dB的频带宽达12GHz。王振军等[75]研究了单掺CF和复掺SCI/CF水泥基复合材料在2~18GHz频段的吸波性能,发现SCI的添加可以有效拓宽复合材料在高频段对电磁波的吸收频宽。Afghahi等[76]将FCI, 纳米CF和镧锶锰氧化物进行多元复合,发现镧锶锰氧化物及纳米CF含量的增加不仅减小了复合材料的密度,而且有效增强了其对电磁波的衰减性能,质量分数为30%的复合材料在厚度为2mm时在8~12GHz内的平均反射率为-8.75dB,而未添加镧锶锰氧化物时仅为约-5dB。Duan等[77]将CF与SCI, 炭黑以不同比例混合,制备以SCI/CF为匹配层、炭黑/CF为吸收层的双层吸波涂层,发现CF在吸收层的适量添加更有助于增强涂层的吸波性能。

2.4 炭黑/羰基铁复合吸波材料炭黑具有质量轻、易分散、成本低、比表面积大、导电性能稳定持久等优点,在吸波材料中具有广泛的应用。炭黑/羰基铁复合吸波材料的研究主要集中在二者的掺杂共混。

Liu等[78]制备了以炭黑和SCI为吸收剂的单层吸波涂层,随着炭黑或SCI含量、厚度的增加,涂层的吸收频带向低频移动,通过调节吸收剂的比例和涂层的厚度可以在不同的频段内获得较好的吸波性能。Qing等[79]研究了炭黑含量对炭黑/SCI/环氧有机硅树脂复合材料介电性能的影响,采用幂律衰变和界面极化的概念解释了复合材料的介电常数随着炭黑含量的增加而增大、随着频率的增大在低频段快速减小、在高频段减小速度放缓的变化规律。Shen等[80]将炭黑和SCI均匀分散在线性低密度聚乙烯基体中制备复合吸波材料,通过调整炭黑、SCI的含量和涂层厚度优化复合材料的吸波性能。Li等[81]将羰基铁纳米粉、炭黑和聚亚安酯按质量比1:3.2:8混合制备复合吸波材料,在厚度为2mm时复合材料的吸波性能较未添加炭黑的复合材料有大幅的提升,在13.5GHz处有最小反射率-25.8dB,小于-10dB的反射率频带宽为3.6GHz(11.5~15.1GHz)。Pinho等[82]将炭黑/氯丁橡胶、SCI/氯丁橡胶和炭黑/SCI/氯丁橡胶复合材料的吸波性能对比后发现,炭黑和SCI复合后复合材料在8~18GHz内的反射率大幅降低,小于-10dB的反射率频带明显变宽,基本覆盖整个测试频段。Min等[83]使用剪切力制备了相互平行分散的定向FCI/炭黑复合材料,由于界面极化作用,复合材料的介电常数随着炭黑含量的增加而增大。反射率计算结果表明,FCI的排列方向对降低吸波涂层厚度、增大吸收频带宽有重要作用。厚度为0.9mm、FCI和炭黑的质量分数分别为65%和3%的涂层小于-5dB的反射率频带宽达12.5GHz(5.5~18GHz)。Wang等[84]和Chen等[85]以SCI为匹配层吸波剂、炭黑为吸收层吸波剂制备双层吸波涂层,在拓宽有效吸收频带方面取得了较好的效果,后者还将SiO2添加到匹配层。由于阻抗匹配性能的进一步改善,涂层在2~4GHz的吸波性能显著增强,反射率峰值达-17.3dB。

2.5 石墨/羰基铁复合吸波材料石墨是最早被实际应用的吸波材料,早在20世纪40年代就用来填充在飞机蒙皮的夹层中吸收雷达波。石墨常被用来与高分子材料复合,以调节高分子复合材料的导电率,提高吸波效果[86]。目前,石墨与羰基铁复合形式主要有表面包覆和掺杂共混。

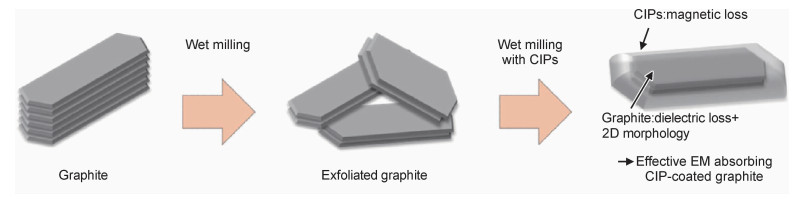

Woo等[87]采用两步湿法机械球磨,将羰基铁与石墨复合,获得羰基铁包覆的鳞片石墨复合材料,其制备过程如图 7所示,质量分数为3%的石墨复合材料在2~8GHz具有较好的吸波性能。球磨时间为1,8,16h时,分别在7,5.8,4.3GHz处有最小反射率-13,-21dB和-29dB。Xu等[88]采用MOCVD法制备了核壳结构的石墨/羰基铁复合材料。由于引入了具有高介电损耗和磁损耗的羰基铁,复合材料的介电常数和磁导率较单一石墨有明显增加,吸波性能也进一步增强,涂层厚度为6mm和8mm时分别有最小反射率-25.14,-26.52dB。

Tan等[89]将石墨和SCI分散在氯磺化聚乙烯基体中制备不同厚度的复合吸波材料,发现厚度为1.5mm时复合材料具有优异的吸波性能,在13.24GHz时有最小反射率-33.19dB,小于-10dB的频带宽达8.96GHz。Xu等[90]采用非涂装和涂装工艺分别制备了含FCI和石墨片的硅橡胶复合材料。非涂装工艺将混合的复合材料直接加入到环形模具中,片状颗粒被随机分散;涂装工艺是逐层加入混合的复合材料,每层的厚度为0.1~0.2mm,使得片状颗粒整齐定向排列。由于粒子的定向分布和两种吸收剂的相互作用,石墨/FCI复合材料具有较高的介电常数,在L波段(1~2GHz)有较强的吸波性能,厚度为1.5mm和2mm时反射率分别为-11.85~-3.60dB和-15.02~-7.30dB。Deng等[91]以SCI和石墨为吸收剂在树脂基体中制备双层结构复合吸波材料。研究发现,在阻抗匹配层含20%SCI、吸收层含35%石墨的情况下达到最佳吸波性能,反射率峰值为-20.19dB,小于-10dB的反射率频带宽为7.3GHz。

2.6 其他碳材料与羰基铁的复合Li等[92-93]通过在不同温度下分别用高纯氮气、微氧气体对聚丙烯腈(polyacrylonitrile,PAN)/SCI复合物进行炭化处理,将SCI分散在无定形碳中制备复合材料,并研究了炭化温度对复合材料物相组成和吸波性能的影响。由于同时具有电损耗和磁损耗,复合材料具有较好的吸波性能,高纯氮气条件下,750℃制备的复合材料在厚度为2~3mm时小于-10dB的吸收频带为7.5~18GHz,800℃制备的复合材料在厚度为2mm时在10GHz处有最小反射率-40dB。Wu等[94]采用胶体沉积和浸渍方法制备了SCI掺杂Ag/有序介孔碳(ordered mesoporous carbon,OMC)纳米复合材料。该复合材料比Ag/OMC和OMC/SCI具有更好的吸波性能,Ag纳米粒子、OMC纳米棒、SCI和石蜡基体之间的多重界面增强了复合材料的介电常数,而复合材料的磁损耗主要来自自然共振和涡流损耗。

3 存在的问题及展望当前,研究人员主要通过制备核壳等异质结构、共混与掺杂以及改变微观形貌等方式进行碳基/羰基铁复合吸波材料的研究,内容主要集中在不同碳材料与不同类型羰基铁之间的复合改性及其制备工艺的探索。虽然目前的研究在提高吸波性能、拓宽吸收频带上取得了一些积极的进展和突破,但是仍然存在一些问题:(1)碳材料与羰基铁在复合形式上以较为常见的包覆或掺混为主,在改进传统复合模式、构筑多维空间结构复合吸波材料以增加电磁波损耗机制、增强电磁波损耗能力方面有待进一步加强;(2)碳基/羰基铁复合吸波材料在“薄”和“宽”上取得了一些积极的突破,然而,尽管轻质碳材料的引入在一定程度上降低了复合吸波剂的填充密度,但是“轻”的问题并没有完全解决;(3)在复合材料吸波性能综合设计方面的系统理论研究不够深入,加之制备成本和工艺条件的限制,使得碳基/羰基铁复合吸波材料的研究大都处于实验室研究阶段,未获得广泛的实用和实质性的突破。

碳基/羰基铁复合吸波材料是当前吸波材料研究的重点和热点方向之一。为了满足吸波材料在“厚度薄、密度小、吸收强、频段宽”等方面的要求,碳基/羰基铁复合吸波材料的研究还应从以下方面进行努力:(1)碳基/羰基铁复合吸波材料吸波机理研究及性能调控。对碳基/羰基铁复合吸波材料与电磁波之间的作用机理进行更深入的研究,从而进一步改进制备工艺,并在此基础上通过调节复合材料的结构形貌和电磁参数增强吸波性能; (2)进一步降低碳基/羰基铁复合吸波材料密度。通过构筑中空管状、蜂窝状、多层状、团簇状等多维空间结构,改善复合材料的吸波性能,降低复合材料的密度,满足吸波材料的轻量化设计应用需求; (3)进一步拓宽碳基/羰基铁复合吸波材料的有效吸收频带。现代装备面临全方位、多模式侦查和打击威胁,实现宽频隐身是吸波材料研究的重要方向之一,需要进一步围绕拓宽有效吸收频带开展研究; (4)碳基/羰基铁复合吸波材料的工业化、可控性生产及应用。需要探索合理可行、经济实用的工艺流程,使碳基/羰基铁复合吸波材料能够走出实验室,实现工业化、可控性生产及应用。

4 结束语近年来,电子信息技术和雷达探测技术的迅猛发展对吸波材料提出了更高的要求,吸波材料的研究不断朝着“薄、轻、宽、强”的方向发展。碳基/羰基铁复合吸波材料结合了碳材料和羰基铁在吸波性能上的优势,在降低密度和匹配厚度、拓宽有效吸收频带、增强吸波性能方面取得了一些积极的进展。尽管仍然存在一些亟待解决的问题,但是随着研究的持续深入,碳基/羰基铁复合吸波材料必然会在吸波材料领域取得极大的技术突破和光明的应用前景。

| [1] |

KONG L B, LI Z W, LIU L, et al. Recent progress in some composite materials and structures for specific electromagnetic applications[J]. International Materials Reviews, 2013, 58(4): 203-259. DOI:10.1179/1743280412Y.0000000011 |

| [2] |

ZHU M, DIAO G. Review on the progress in synthesis and application of magnetic carbon nanocomposites[J]. Nanoscale, 2011, 3(7): 2748-2767. DOI:10.1039/c1nr10165j |

| [3] |

刘渊, 刘祥萱, 王煊军. 铁氧体基核壳结构复合吸波材料研究进展[J]. 材料工程, 2014(7): 98-106. LIU Y, LIU X X, WANG X J. Research progress in ferrite based core-shell structured composite microwave absorb materials[J]. Journal of Materials Engineering, 2014(7): 98-106. |

| [4] |

PATON K R, WINDLE A H. Efficient microwave energy absorption by carbon nanotubes[J]. Carbon, 2008, 46(14): 1935-1941. DOI:10.1016/j.carbon.2008.08.001 |

| [5] |

XU Y, YUAN L, ZHANG D. Enhancement mechanism of the additional absorbent on the absorption of the absorbing composite using a type-based mixing rule[J]. Journal of Physics D:Applied Physics, 2016, 49(15): 155001. DOI:10.1088/0022-3727/49/15/155001 |

| [6] |

CAO M, HAN C, WANG X, et al. Graphene nanohybrids:excellent electromagnetic properties for the absorbing and shielding of electromagnetic waves[J]. Journal of Materials Che-mistry C, 2018, 6(17): 4586-4602. DOI:10.1039/C7TC05869A |

| [7] |

WEN F, ZHANG F, LIU Z. Investigation on microwave absorption properties for multiwalled carbon nanotubes/Fe/Co/Ni nanopowders as lightweight absorbers[J]. The Journal of Physical Chemistry C, 2011, 115(29): 14025-14030. DOI:10.1021/jp202078p |

| [8] |

WANG X, ZHANG B, ZHANG W, et al. Super-light Cu@Ni nanowires/graphene oxide composites for significantly enhanced microwave absorption performance[J]. Scientific Reports, 2017, 7(1): 1584. DOI:10.1038/s41598-017-01529-2 |

| [9] |

WANG X, MA T, SHU J, et al. Confinedly tailoring Fe3O4 clusters-NG to tune electromagnetic parameters and microwave absorption with broadened bandwidth[J]. Chemical Engineering Journal, 2018, 332: 321-330. DOI:10.1016/j.cej.2017.09.101 |

| [10] |

LU M, CAO M, CHEN Y, et al. Multiscale assembly of grape-like ferroferric oxide and carbon nanotubes:a smart absorber prototype varying temperature to tune intensities[J]. ACS Applied Materials & Interfaces, 2015, 7(34): 19408-19415. |

| [11] |

MOVASSAGH-ALANAGH F, BORDBAR K A, SALIMK-HANI H. Improvement in magnetic and microwave absorption properties of nano-Fe3O4@CFs composites using a modified multi-step EPD process[J]. Applied Surface Science, 2017, 420: 726-739. DOI:10.1016/j.apsusc.2017.05.207 |

| [12] |

FENG J, HOU Y, WANG Y, et al. Synthesis of hierarchical ZnFe2O4@SiO2@RGO core-shell microspheres for enhanced electromagnetic wave absorption[J]. ACS Applied Materials & Interfaces, 2017, 9(16): 14103-14111. |

| [13] |

ZHANG K, GAO X, ZHANG Q, et al. Preparation and microwave absorption properties of asphalt carbon coated reduced graphene oxide/magnetic CoFe2O4 hollow particles modified multi-wall carbon nanotube composites[J]. Journal of Alloys and Compounds, 2017, 723: 912-921. DOI:10.1016/j.jallcom.2017.06.327 |

| [14] |

ZHANG Y, WANG X, CAO M. Confinedly implanted NiFe2O4-rGO:cluster tailoring and highly tunable electromagnetic properties for selective-frequency microwave absorption[J]. Nano Research, 2018, 11(3): 1426-1436. DOI:10.1007/s12274-017-1758-1 |

| [15] |

MA J, WANG X, CAO W, et al. A facile fabrication and highly tunable microwave absorption of 3D flower-like Co3O4-rGO hybrid-architectures[J]. Chemical Engineering Journal, 2018, 339: 487-498. DOI:10.1016/j.cej.2018.01.152 |

| [16] |

MAŁECKI P, KOLMAN K, PIGŁOWSKI J, et al. Sol-gel method as a way of carbonyl iron powder surface modification for interaction improvement[J]. Journal of Solid State Chemistry, 2015, 226: 224-230. DOI:10.1016/j.jssc.2015.03.002 |

| [17] |

REN X, CHENG Y. Electromagnetic and microwave absorbing properties of carbonyl iron/BaTiO3 composite absorber for matched load of isolator[J]. Journal of Magnetism and Magnetic Materials, 2015, 393: 293-296. DOI:10.1016/j.jmmm.2015.05.074 |

| [18] |

刘彦峰, 李磊削, 王韫宇, 等. 原子层沉积氧化铝包覆羰基铁粉的抗腐蚀性及吸波性能[J]. 无机材料学报, 2017, 32(7): 751-757. LIU Y F, LI L X, WANG Y Y, et al. Corrosion resistance and wave absorbing property of carbonyl iron powder coating with alumina by atomic layer deposition[J]. Journal of Inorganic Materials, 2017, 32(7): 751-757. |

| [19] |

景红霞, 李巧玲, 叶云, 等. 羰基铁/钛酸钡复合材料的制备及吸波性能[J]. 材料工程, 2015, 43(7): 38-42. JING H X, LI Q L, YE Y, et al. Preparation and microwave absorbing properties of Fe(CO)5/BaTiO3 composites[J]. Journal of Materials Engineering, 2015, 43(7): 38-42. |

| [20] |

QING Y, ZHOU W, LUO F, et al. Microwave-absorbing and mechanical properties of carbonyl-iron/epoxy-silicone resin coatings[J]. Journal of Magnetism and Magnetic Materials, 2009, 321(1): 25-28. |

| [21] |

WEN F, ZUO W, YI H, et al. Microwave-absorbing properties of shape-optimized carbonyl iron particles with maximum microwave permeability[J]. Physica B:Condensed Matter, 2009, 404(20): 3567-3570. DOI:10.1016/j.physb.2009.06.001 |

| [22] |

LONG C, XU B C, HAN C Z, et al. Flaky core-shell particles of iron@iron oxides for broadband microwave absorbers in S and C bands[J]. Journal of Alloys and Compounds, 2017, 709: 735-741. DOI:10.1016/j.jallcom.2017.03.197 |

| [23] |

YIN C, FAN J, BAI L, et al. Microwave absorption and antioxidation properties of flaky carbonyl iron passivated with carbon dioxide[J]. Journal of Magnetism and Magnetic Materials, 2013, 340: 65-69. DOI:10.1016/j.jmmm.2013.03.038 |

| [24] |

ZHOU Y, ZHOU W, LI R, et al. Enhanced antioxidation and electromagnetic properties of Co-coated flaky carbonyl iron particles prepared by electroless plating[J]. Journal of Alloys and Compounds, 2015, 637: 10-15. DOI:10.1016/j.jallcom.2015.03.014 |

| [25] |

KANG Y, HUANG Y, YANG R, et al. Synthesis and properties of core-shell structured Fe(CO)5/SiO2 composites[J]. Journal of Magnetism and Magnetic Materials, 2016, 399: 149-154. DOI:10.1016/j.jmmm.2015.09.061 |

| [26] |

WANG H, ZHU D, ZHOU W, et al. Electromagnetic property of SiO2-coated carbonyl iron/polyimide composites as heat resistant microwave absorbing materials[J]. Journal of Magnetism and Magnetic Materials, 2015, 375: 111-116. DOI:10.1016/j.jmmm.2014.09.061 |

| [27] |

LI J, FENG W J, WANG J S, et al. Impact of silica-coating on the microwave absorption properties of carbonyl iron powder[J]. Journal of Magnetism and Magnetic Materials, 2015, 393: 82-87. DOI:10.1016/j.jmmm.2015.05.049 |

| [28] |

ZHANG W, BIE S, CHEN H, et al. Electromagnetic and microwave absorption properties of carbonyl iron/MnO2 com-posite[J]. Journal of Magnetism and Magnetic Materials, 2014, 358/359: 1-4. DOI:10.1016/j.jmmm.2014.01.033 |

| [29] |

郭飞, 杜红亮, 屈绍波, 等. 海胆状氧化锌/羰基铁粉核壳结构复合粒子的抗氧化及吸波性能[J]. 无机化学学报, 2015, 31(4): 755-760. GUO F, DU H L, QU S B, et al. Oxidation resistance and microwave absorption property of core shell urchin-like ZnO/carbonyl iron powder composite particles[J]. Chinese Journal of Inorganic Chemistry, 2015, 31(4): 755-760. |

| [30] |

WU X, LUO H, WAN Y. Preparation of SnO2-coated carbonyl iron flaky composites with enhanced microwave absorption properties[J]. Materials Letters, 2013, 92: 139-142. DOI:10.1016/j.matlet.2012.10.093 |

| [31] |

TANG J, MA L, HUO Q, et al. The influence of PVP on the synthesis and electromagnetic properties of PANI/PVP/CIP composites[J]. Polymer Composites, 2015, 36(10): 1799-1806. DOI:10.1002/pc.23086 |

| [32] |

TANG J, MA L, TIAN N, et al. Synthesis and electromagnetic properties of PANI/PVP/CIP core-shell composites[J]. Materials Science and Engineering:B, 2014, 186: 26-32. DOI:10.1016/j.mseb.2014.02.003 |

| [33] |

汪晓芹, 徐金鑫, 黄大庆, 等. 羰基铁粉@聚苯胺防腐吸波粉体的制备与性能[J]. 材料工程, 2014(11): 90-96. WANG X Q, XU J X, HUANG D Q, et al. Synthesis and properties of CIP@PANI composite powders for anticorrosion and microwave-absorbing application[J]. Journal of Materials Engineering, 2014(11): 90-96. DOI:10.11868/j.issn.1001-4381.2014.11.016 |

| [34] |

SUI M, LÜ X, XIE A, et al. The synthesis of three-dimensional (3D) polydopamine-functioned carbonyl iron powder@polyp-yrrole (CIP@PPy) aerogel composites for excellent microwave absorption[J]. Synthetic Metals, 2015, 210: 156-164. DOI:10.1016/j.synthmet.2015.09.025 |

| [35] |

SONG Z, DENG L, XIE J, et al. Synthesis, dielectric, and microwave absorption properties of flake carbonyl iron particles coated with nanostructure polymer[J]. Surface and Interface Analysis, 2014, 46(2): 77-82. |

| [36] |

KHANI O, SHOUSHTARI M Z, ACKLAND K, et al. The structural, magnetic and microwave properties of spherical and flake shaped carbonyl iron particles as thin multilayer microwave absorbers[J]. Journal of Magnetism and Magnetic Materials, 2017, 428: 28-35. DOI:10.1016/j.jmmm.2016.12.010 |

| [37] |

XU Y, YUAN L, WANG X, et al. Two-step milling on the carbonyl iron particles and optimizing on the composite absorption[J]. Journal of Alloys and Compounds, 2016, 676: 251-259. DOI:10.1016/j.jallcom.2016.03.192 |

| [38] |

QIAO L, HAN R, WANG T, et al. Greatly enhanced microwave absorbing properties of planar anisotropy carbonyl-iron particle composites[J]. Journal of Magnetism and Magnetic Materials, 2015, 375: 100-105. DOI:10.1016/j.jmmm.2014.09.015 |

| [39] |

ABSHINOVA M A, LI Z W. Effect of milling time on dynamic permeability values of reduced carbonyl iron filled composites[J]. Journal of Magnetism and Magnetic Materials, 2014, 369: 147-154. DOI:10.1016/j.jmmm.2014.06.036 |

| [40] |

WANG W, GUO J, LONG C, et al. Flaky carbonyl iron particles with both small grain size and low internal strain for broadband microwave absorption[J]. Journal of Alloys and Compounds, 2015, 637: 106-111. DOI:10.1016/j.jallcom.2015.02.220 |

| [41] |

童国秀, 官建国, 樊希安, 等. 气流诱导多晶铁纤维的可控制备及生长机理[J]. 无机化学学报, 2008, 24(2): 270-274. TONG G X, GUAN J G, FAN X A, et al. Controllable preparation and growth mechanism of polycrystalline iron fibers induced by carrier gas flow[J]. Chinese Journal of Inorganic Chemistry, 2008, 24(2): 270-274. DOI:10.3321/j.issn:1001-4861.2008.02.018 |

| [42] |

童国秀, 官建国, 樊希安, 等. 热解温度对多晶铁纤维的静磁和微波电磁性能的影响[J]. 金属学报, 2008, 44(7): 867-870. TONG G X, GUAN J G, FAN X A, et al. Influences of pyrolysis temperature on static magnetic and microwave electro-magnetic properties of polycrystalline iron fibers[J]. Acta Metallurgica Sinica, 2008, 44(7): 867-870. DOI:10.3321/j.issn:0412-1961.2008.07.019 |

| [43] |

李小莉, 杨东方. 纳米晶铁纤维的制备及其电磁参数的测量[J]. 太原理工大学学报, 2012, 43(1): 42-46. LI X L, YANG D F. Preparation of nanocrystalline iron of their electromagnetic fibers and measurement parameters[J]. Journal of Taiyuan University of Technology, 2012, 43(1): 42-46. DOI:10.3969/j.issn.1007-9432.2012.01.011 |

| [44] |

贺君, 胡照文, 邓联文, 等. 多晶铁纤维表面原位氧化及其微波吸收性能[J]. 矿冶工程, 2016, 36(3): 98-101. HE J, HU Z W, DENG L W, et al. In-situ surface oxidation and microwave absorbing properties of polycrystalline iron fibers[J]. Mining and Metallurgical Engineering, 2016, 36(3): 98-101. DOI:10.3969/j.issn.0253-6099.2016.03.026 |

| [45] |

YIN C, CAO Y, FAN J, et al. Synthesis of hollow carbonyl iron microspheres via pitting corrosion method and their microwave absorption properties[J]. Applied Surface Science, 2013, 270: 432-438. DOI:10.1016/j.apsusc.2013.01.044 |

| [46] |

杨芾藜, 侯兴哲, 郑可, 等. 羰基铁粉形貌对吸波性能的影响[J]. 重庆大学学报, 2017, 40(10): 53-59. YANG F L, HOU X Z, ZHENG K, et al. Effect of carbonyl iron powder morphology on the absorption properties of microwave[J]. Journal of Chongqing University, 2017, 40(10): 53-59. DOI:10.11835/j.issn.1000-582X.2017.10.006 |

| [47] |

LI J, HUANG H, ZHOU Y, et al. Research progress of graphene-based microwave absorbing materials in the last decade[J]. Journal of Materials Research, 2017, 32(7): 1213-1230. DOI:10.1557/jmr.2017.80 |

| [48] |

黄琪惠, 张豹山, 唐东明, 等. 石墨烯-Fe@Fe3O4纳米复合材料的制备及其电磁性能研究[J]. 无机化学学报, 2012, 28(10): 2077-2082. HUANG Q H, ZHANG B S, TANG D M, et al. Synthesis and characteristics of graphene-Fe@Fe3O4 nano-composites materials[J]. Chinese Journal of Inorganic Chemistry, 2012, 28(10): 2077-2082. |

| [49] |

XU Y, LUO J, YAO W, et al. Preparation of reduced graphene oxide/flake carbonyl iron powders/polyaniline composites and their enhanced microwave absorption properties[J]. Journal of Alloys and Compounds, 2015, 636: 310-316. DOI:10.1016/j.jallcom.2015.02.196 |

| [50] |

WENG X, LV X, LI B, et al. One-pot preparation of reduced graphene oxide/carbonyl iron/polyvinyl pyrrolidone ternary nanocomposite and its synergistic microwave absorbing properties[J]. Materials Letters, 2017, 188: 280-283. DOI:10.1016/j.matlet.2016.10.111 |

| [51] |

WENG X, LI B, ZHANG Y, et al. Synthesis of flake shaped carbonyl iron/reduced graphene oxide/polyvinyl pyrrolidone ternary nanocomposites and their microwave absorbing properties[J]. Journal of Alloys and Compounds, 2017, 695: 508-519. DOI:10.1016/j.jallcom.2016.11.083 |

| [52] |

CHEN C, LIANG W, NIEN Y, et al. Microwave absorbing properties of flake-shaped carbonyl iron/reduced graphene oxide/epoxy composites[J]. Materials Research Bulletin, 2017, 96: 81-85. DOI:10.1016/j.materresbull.2017.01.045 |

| [53] |

ZHU Z, SUN X, XUE H, et al. Graphene-carbonyl iron cross-linked composites with excellent electromagnetic wave absorption properties[J]. Journal of Materials Chemistry C, 2014, 2(32): 6582-6591. DOI:10.1039/C4TC00757C |

| [54] |

王洁萱.石墨烯复合吸波剂的制备及电磁防护性能研究[D].北京: 北京理工大学, 2015. WANG J X. Research on synthesis of graphene composites and their electromagnetic shielding performance[D]. Beijing: Beijing Institute of Technology, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10007-1015030374.htm |

| [55] |

李国显.石墨烯/磁性纳米复合材料的制备及吸波性能[D].南京: 南京航空航天大学, 2012. LI G X. Properties of graphene/magnetic-particle nanocomposite materials[D]. Nanjing: Nanjing University of Aeronautics & Astronautics, 2012. |

| [56] |

QING Y, MIN D, ZHOU Y, et al. Graphene nanosheet and flake carbonyl iron particle-filled epoxy-silicone composites as thin-thickness and wide-bandwidth microwave absorber[J]. Carbon, 2015, 86: 98-107. DOI:10.1016/j.carbon.2015.01.002 |

| [57] |

刘顾, 汪刘应, 程建良, 等. 碳纳米管吸波材料研究进展[J]. 材料工程, 2015, 43(1): 104-112. LIU G, WANG L Y, CHENG J L, et al. Progress in research on carbon nanotubes microwave absorbers[J]. Journal of Materials Engineering, 2015, 43(1): 104-112. |

| [58] |

LIU Y, LIU X, WANG X. Preparation of multi-walled carbon nanotube-Fe composites and their application as light weight and broadband electromagnetic wave absorbers[J]. Chinese Physics B, 2014, 23(11): 117705. DOI:10.1088/1674-1056/23/11/117705 |

| [59] |

LIU T, ZHOU L, ZHENG D, et al. Absorption property of C@CIPs composites by the mechanical milling process[J]. Applied Physics A, 2017, 123(9): 565. DOI:10.1007/s00339-017-1175-z |

| [60] |

XU Y, ZHANG D, CAI J, et al. Effects of multi-walled carbon nanotubes on the electromagnetic absorbing characteristics of composites filled with carbonyl iron particles[J]. Journal of Materials Science & Technology, 2012, 28(1): 34-40. |

| [61] |

XU Y, YUAN L, CAI J, et al. Smart absorbing property of com-posites with MWCNTs and carbonyl iron as the filler[J]. Journal of Magnetism and Magnetic Materials, 2013, 343: 239-244. DOI:10.1016/j.jmmm.2013.04.051 |

| [62] |

QING Y, ZHOU W, HUANG S, et al. Evolution of double magnetic resonance behavior and electromagnetic properties of flake carbonyl iron and multi-walled carbon nanotubes filled epoxy-silicone[J]. Journal of Alloys and Compounds, 2014, 583: 471-475. DOI:10.1016/j.jallcom.2013.09.002 |

| [63] |

QING Y, ZHOU W, LUO F, et al. Epoxy-silicone filled with multi-walled carbon nanotubes and carbonyl iron particles as a microwave absorber[J]. Carbon, 2010, 48(14): 4074-4080. DOI:10.1016/j.carbon.2010.07.014 |

| [64] |

GAO Y, GAO X, LI J, et al. Improved microwave absorbing property provided by the filler's alternating lamellar distribution of carbon nanotube/carbonyl iron/poly (vinyl chloride) composites[J]. Composites Science and Technology, 2018, 158: 175-185. DOI:10.1016/j.compscitech.2017.11.029 |

| [65] |

TONG G, WU W, HUA Q, et al. Enhanced electromagnetic characteristics of carbon nanotubes/carbonyl iron powders complex absorbers in 2-18GHz ranges[J]. Journal of Alloys and Compounds, 2011, 509(2): 451-456. DOI:10.1016/j.jallcom.2010.09.055 |

| [66] |

LI Y, CHEN C, PAN X, et al. Multiband microwave absorption films based on defective multiwalled carbon nanotubes added carbonyl iron/acrylic resin[J]. Physica B:Condensed Matter, 2009, 404(8/11): 1343-1346. |

| [67] |

李斌鹏, 王成国, 王雯. 碳基吸波材料的研究进展[J]. 材料导报, 2012, 26(7): 9-14. LI B P, WANG C G, WANG W. Progress of electromagnetic wave absorbing materials based on carbon[J]. Materials Review, 2012, 26(7): 9-14. DOI:10.3969/j.issn.1005-023X.2012.07.003 |

| [68] |

LIU Y, LIU X, LI R, et al. Design and fabrication of carbon fiber/carbonyl iron core-shell structure composites as high-performance microwave absorbers[J]. RSC Advances, 2015, 5(12): 8713-8720. DOI:10.1039/C4RA15654D |

| [69] |

刘渊, 刘祥萱, 陈鑫, 等. 碳纤维表面α-Fe的MOCVD生长制备及吸波性能研究[J]. 无机材料学报, 2013, 28(12): 1328-1332. LIU Y, LIU X X, CHEN X, et al. Preparation by MOCVD and microwave absorbing properties of CF@Fe[J]. Journal of Inorganic Materials, 2013, 28(12): 1328-1332. |

| [70] |

ZHANG Z, LIU X, ZHANG H, et al. Electromagnetic and microwave absorption properties of carbon fibers coated with carbonyl iron[J]. Journal of Materials Science:Materials in Electronics, 2015, 26(9): 6518-6525. DOI:10.1007/s10854-015-3247-1 |

| [71] |

SALIMKHANI H, PALMEH P, KHIABANI A B, et al. Electrophoretic deposition of spherical carbonyl iron particles on carbon fibers as a microwave absorbent composite[J]. Surfaces and Interfaces, 2016, 5: 1-7. DOI:10.1016/j.surfin.2016.09.004 |

| [72] |

YOUH M, WU H, LIN W, et al. A carbonyl iron/carbon fiber material for electromagnetic wave absorption[J]. Journal of Nanoscience and Nanotechnology, 2011, 11(3): 2315-2320. DOI:10.1166/jnn.2011.3584 |

| [73] |

QING Y C, ZHOU W C, JIA S, et al. Electromagnetic and microwave absorption properties of carbonyl iron and carbon fiber filled epoxy/silicone resin coatings[J]. Applied Physics A, 2010, 100(4): 1177-1181. DOI:10.1007/s00339-010-5738-5 |

| [74] |

MIN D, ZHOU W, QING Y, et al. Highly oriented flake carbonyl iron/carbon fiber composite as thin-thickness and wide-bandwidth microwave absorber[J]. Journal of Alloys and Compounds, 2018, 744: 629-636. DOI:10.1016/j.jallcom.2018.02.076 |

| [75] |

王振军, 李克智, 王闯, 等. 羰基铁粉-碳纤维水泥基复合材料的吸波性能[J]. 硅酸盐学报, 2011, 39(1): 69-74. WANG Z J, LI K Z, WANG C, et al. Wave-absorbing properties of carbonyl iron powder/carbon fiber reinforced cement-based composites[J]. Journal of the Chinese Ceramic Society, 2011, 39(1): 69-74. |

| [76] |

AFGHAHI S S S, MIRZAZADEH A, JAFARIAN M, et al. A new multicomponent material based on carbonyl iron/carbon nanofiber/lanthanum-strontium-manganite as microwave absor-bers in the range of 8-12GHz[J]. Ceramics International, 2016, 42(8): 9697-9702. DOI:10.1016/j.ceramint.2016.03.058 |

| [77] |

DUAN Y P, WANG L, LIU Z, et al. Microwave properties of double layer absorber reinforced with carbon fibre powders[J]. Plastics, Rubber and Composites, 2013, 42(2): 82-87. DOI:10.1179/1743289812Y.0000000030 |

| [78] |

LIU L, DUAN Y, MA L, et al. Microwave absorption properties of a wave-absorbing coating employing carbonyl-iron powder and carbon black[J]. Applied Surface Science, 2010, 257(3): 842-846. DOI:10.1016/j.apsusc.2010.07.078 |

| [79] |

QING Y, ZHOU W, JIA S, et al. Dielectric properties of carbon black and carbonyl iron filled epoxy-silicone resin coating[J]. Journal of Materials Science, 2010, 45(7): 1885-1888. DOI:10.1007/s10853-009-4173-5 |

| [80] |

SHEN X, XIE S, GUO J, et al. Microwave absorbing properties of ternary linear low-density polyethylene/carbonyl iron powder/carbon black composites[J]. Journal of Applied Polymer Science, 2009, 114(6): 3434-3439. DOI:10.1002/app.30666 |

| [81] |

LI X, ZHANG Y, CHEN J, et al. Composite coatings reinforced with carbonyl iron nanoparticles:preparation and microwave absorbing properties[J]. Materials Technology, 2014, 29(1): 57-64. DOI:10.1179/1753555713Y.0000000096 |

| [82] |

PINHO M S, Da COSTA L R, SILVA M R D, et al. Microwave absorption of carbon black and carbonyl iron composites with polychloroprene[J]. Materials Technology, 2013, 21(1): 27-31. |

| [83] |

MIN D, ZHOU W, QING Y, et al. Enhanced microwave absorption properties of oriented carbonyl iron/carbon black composite induced by shear force[J]. Journal of Electronic Materials, 2017, 46(8): 4903-4911. DOI:10.1007/s11664-017-5493-x |

| [84] |

WANG M, DUAN Y, LIU S, et al. Absorption properties of carbonyl-iron/carbon black double-layer microwave absorbers[J]. Journal of Magnetism and Magnetic Materials, 2009, 321(20): 3442-3446. DOI:10.1016/j.jmmm.2009.06.040 |

| [85] |

CHEN L, DUAN Y, LIU L, et al. Influence of SiO2 fillers on microwave absorption properties of carbonyl iron/carbon black double-layer coatings[J]. Materials & Design, 2011, 32(2): 570-574. |

| [86] |

陈雪刚, 叶瑛, 程继鹏. 电磁波吸收材料的研究进展[J]. 无机材料学报, 2011, 26(5): 449-457. CHEN X G, YE Y, CHENG J P. Recent progress in electro-magnetic wave absorbers[J]. Journal of Inorganic Materials, 2011, 26(5): 449-457. |

| [87] |

WOO S, YOO C, KIM H, et al. Development of CIP/graphite composite additives for electromagnetic wave absorption applications[J]. Electronic Materials Letters, 2017, 13(5): 398-405. DOI:10.1007/s13391-017-7003-y |

| [88] |

XU Y, YAN Z, ZHANG D. Microwave absorbing property of a hybrid absorbent with carbonyl irons coating on the graphite[J]. Applied Surface Science, 2015, 356: 1032-1038. DOI:10.1016/j.apsusc.2015.08.162 |

| [89] |

TAN Y, TANG J, DENG A, et al. Magnetic properties and microwave absorption properties of chlorosulfonated polye-thylene matrices containing graphite and carbonyl-iron powder[J]. Journal of Magnetism and Magnetic Materials, 2013, 326: 41-44. DOI:10.1016/j.jmmm.2012.08.021 |

| [90] |

XU Y, ZHANG D, CAI J, et al. Microwave absorbing property of silicone rubber composites with added carbonyl iron particles and graphite platelet[J]. Journal of Magnetism and Magnetic Materials, 2013, 327: 82-86. DOI:10.1016/j.jmmm.2012.09.045 |

| [91] |

DENG J L, FENG B. Carbonyl iron/graphite double-layer structural absorbing composite[J]. Advanced Materials Research, 2012, 557/559: 390-393. DOI:10.4028/www.scientific.net/AMR.557-559.390 |

| [92] |

LI B P, WANG C G, WANG W, et al. Electromagnetic wave absorption properties of composites with micro-sized magnetic particles dispersed in amorphous carbon[J]. Journal of Magnetism and Magnetic Materials, 2014, 365: 40-44. DOI:10.1016/j.jmmm.2014.01.015 |

| [93] |

李斌鹏, 王成国, 王雯, 等. 无定形炭/磁性粒子复合吸波材料的制备和电磁性能研究[J]. 功能材料, 2012, 43(14): 1941-1944. LI B P, WANG C G, WANG W, et al. Electromagnetic wave absorption properties of amorphous carbon/magnetic particle composites[J]. Functional Materials, 2012, 43(14): 1941-1944. DOI:10.3969/j.issn.1001-9731.2012.14.030 |

| [94] |

WU H, WANG L, WANG Y, et al. Enhanced microwave absorbing properties of carbonyl iron-doped Ag/ordered mesoporous carbon nanocomposites[J]. Materials Science and Engineering:B, 2012, 177(6): 476-482. DOI:10.1016/j.mseb.2012.02.008 |

2019, Vol. 47

2019, Vol. 47