文章信息

- 鲁浩, 李楠, 王海波, 廖帮全, 姜亚明, 荆妙蕾, 徐志伟, 陈莉, 张兴祥

- LU Hao, LI Nan, WANG Hai-bo, LIAO Bang-quan, JIANG Ya-ming, JING Miao-lei, XU Zhi-wei, CHEN Li, ZHANG Xing-xiang

- 碳纳米管复合材料的3D打印技术研究进展

- Research progress in 3D printing technology for carbon nanotubes composites

- 材料工程, 2019, 47(11): 19-31

- Journal of Materials Engineering, 2019, 47(11): 19-31.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2018.001239

-

文章历史

- 收稿日期: 2018-10-19

- 修订日期: 2019-03-25

2. 天津工业大学 纺织学院 先进纺织复合材料教育部重点实验室, 天津 300387

2. Key Laboratory of Advanced Braided Composites, School of Textiles, Tianjin Polytechnic University, Tianjin 300387, China

现代高科技的发展离不开材料,而复合材料的发展带动了现代材料应用领域的革命。复合材料是指由两种以上材料通过一定的工艺加工而成的新型材料,它与金属、高聚物、陶瓷并称为四大材料[1-2]。复合材料的成型工艺是复合材料发展的基础和条件,经过半个多世纪的发展,其传统成型工艺日渐成熟。当前,在工业生产中较为常见的成型工艺包括模压成型工艺、以树脂传递模塑成型工艺为代表的渗透成型技术、缠绕成型工艺和拉挤成型工艺等。虽然这些传统工艺成熟度较高、适用性广泛,但其生产成本高昂,效率较低,而且制造模具难度较大。因而,近些年来产生了许多新型的成型制备工艺,例如激光固化成型、电子束固化成型和3D打印(3DP)成型工艺等[3-5],其中尤其以3DP工艺发展最为引人注目。

3DP技术是一种重要的快速制造复杂组件的增材制造技术。该技术通过计算机软件辅助设计,然后通过材料成型设备一层一层逐渐叠加的方式制造出与所导入模型形状和结构一致的实体,是非常具有吸引力,并且被广泛认为是一次制造业的技术革命[6-9]。3DP技术以其成本低、材料利用率高、无需传统的刀具、夹具、机床或任何模具、能快速精准的将三维模型转化为实体等优势,广泛应用在生物组织工程[10]、航空航天[11]、储能[12]、电子与器件[13]、车辆制造业[14]、工程复合材料[15]等领域(如图 1所示)。3DP技术根据制造塑型工艺核心的不同,主要分为熔融沉积造型/液体沉积造型、选择性激光烧结、光固化立体成型、数字光处理成型、溶剂浇铸成型以及紫外辅助3D打印等类型[16-18]。虽然不同类型的3DP成型工艺有着不同的技术核心,但它们适配的材料都以金属、陶瓷、聚合物及其复合材料为主[8, 19]。其中聚合物复合材料以种类多样、可加工性强、成本低、导电和高强度等功能性卓越尤为受人青睐[9, 20-21]。

|

图 1 3D打印的应用领域 (a)异构组织工程的三维打印厚结构胶膜[10];(b)3D打印风洞模型[11];(c)交错电极体系结构的扫描电镜图[12];(d)电子电路[13];(e)休闲车辆太阳能光伏安装系统的支架结构[14];(f)蜂窝夹层板[15] Fig. 1 Application fields of 3D printing (a)3D printing thick structure film in heterogeneous tissue engineering[10]; (b)3D printing wind-tunnel model[11]; (c)SEM images of printed and interdigitated electrode architectures[12]; (d)electronic circuit[13]; (e)mounting bracket of recreational vehicle solar photovoltaic mounting systems[14]; (f)honeycomb sandwich panel[15] |

在聚合物基复合材料中,碳材料增强体主要有碳纤维、炭黑、石墨烯、碳纳米管等。其中碳纤维增强树脂基复合材料的研究已经非常多,由于文章篇幅的限制,在此不再赘述。而在炭黑、石墨烯、碳纳米管等纳米尺度的增强体中,碳纳米管(carbon nanotubes, CNTs)具有优越的导热和导电性[21-23],是一种具有高纵横比的长而薄的碳柱,并且CNTs具有诱导高阶间相聚合物层形成的能力,可通过纳米管和聚合物之间的界面应力传递促进机械强化[24-27]。所以,随着CNTs制备方法的成熟[28-35],采用3DP技术制备CNTs复合材料已逐渐成为研究热点。然而,采用3DP技术制备CNTs复合材料在充分体现传统方法所不具备的优势同时,不同类型的3DP制备工艺也暴露出一些各自的问题,比如,熔融沉积塑型技术在制备CNTs复合材料时容易发生喷嘴堵塞的问题;激光选择性烧结技术制备的工件表面会有毛孔和缺陷等。基于此,本文以CNTs增强聚合物复合材料为媒介,综述和分析了不同类型3DP工艺在制备复合材料时的研究进展,并对3DP技术在该领域的发展前景进行了分析和展望。

1 熔融沉积塑型熔融沉积塑型(fused deposition modeling, FDM)是一种新兴3DP技术,但它是应用最广泛的增材制造技术之一。该类型打印机的加热喷头受计算机控制,根据水平切片数据作x-y平面运动。其打印原材料是丝状的热塑性聚合物。原材料被一个牵引轮的装置送至喷头,经过加热、软化或熔化,从喷头挤出黏结到工作台面,然后快速冷却并凝固。每一层截面完成后,工作台下降一层的高度,再继续进行下一层的造型。如此重复,直至完成整个实体的造型,每层的厚度根据喷头挤丝的直径大小确定[36-37],其原理如图 2所示。目前这种3DP技术主要的热塑性材料有丙烯酸-丁二烯-苯乙烯三元共聚物(ABS)、聚乳酸(PLA)和聚己内酯等[38]。

但FDM技术打印复合材料时存在着很多限制性因素,其中由纳米填充粒子的团聚和机器工作参量的不合适而导致的喷嘴堵塞问题依然是一个瓶颈。为了解决喷嘴堵塞的问题,Gnanasekaran等[9]使用商业台式打印机制备非常规聚酯纳米复合材料(CNTs、石墨烯基聚对苯二甲酸丁二醇酯),通过对导电填料的尺寸和粒径分布,以及打印温度、打印速率、打印底板温度等参数和条件进行优化,克服了FDM技术打印纳米复合材料时通常会出现的喷嘴堵塞问题。另外,在FDM技术制备的聚对苯二甲酸丁二醇酯/石墨烯和聚对苯二甲酸丁二醇酯/CNTs的对比中发现,FDM技术在制备聚对苯二甲酸丁二醇酯/CNTs时更加具有优势,打印结构除了出色的导电性能外,还具有更好的表面强度特性。Dul课题组[39]也做了相似的工作,他们将ABS作为基质,探索了CNTs/ABS复合材料的制备。他们一方面在打印过程中对机器控制参数进行优化,另一方面在原材料的制备上采用完全无溶剂化的工艺,制备了适合FDM技术使用的原料细丝。结果显示,打印组件的拉伸模量、强度以及热稳定性均获得了显著提升。另外通过FDM技术构建的有效导电网络使得打印组件的导电性也得到了显著的改善。更重要的是,在碳纳米管浓度为8%(质量分数,下同)时,FDM技术依然是可行的,不会出现喷嘴堵塞问题。虽然对于更高浓度的情况,Dul等没有进行说明,但通过FDM技术制备ABS/CNTs复合材料的相似实验,Dorigato等[40]证明,当CNTs的浓度达到更高的15%时,虽然打印组件的弹性模量会有着一定的增加,但是打印组件已经严重脆化,以至于在未达到屈服点之前就已经失效了。另外,作者在进行熔融指数的测试时也指出,15%的CNTs浓度已经使得复合材料的黏度太大以至于不能进行既定条件下的测试。因此,通过以上两项测试侧面说明了15%及以上的CNTs浓度会使得FDM打印机更加容易堵塞,喷丝时容易断断续续。当然,除了控制复合材料中填充粒子的浓度可以一定程度上解决喷嘴堵塞的问题外,打印机参数的设定与匹配也是不能忽视的。一种具有更高存储模量的材料需要以较慢的速率进行3D打印,或者使用更高的喷嘴温度。然而,如果打印温度过高,或者在热端辅以较慢的打印速率,聚合物的停留时间太长,可能会发生聚合物降解,通常会破坏掉打印结构。

采用FDM技术制备复合材料时,虽然容易发生喷嘴堵塞的问题,但其具有的优势也是非常独特的。由于FDM技术的打印过程是喷嘴挤出的细丝层层叠加累积最终形成实体,这样的方式通过融化再固化的过程使得制备的复合材料组件的强度更加优越,同时层层之间形成的均匀交错的导电网络有效地拓展了电子迁移路径,从而使得复合材料组件的导电性可以获得显著提升。Tsiakatouras等[41]在ABS树脂中加入一定量的CNTs作为耗材,进行了包括注塑成型在内的传统制造方法和3DP技术的力学性能对比研究。结果显示,3DP技术可以提升目标物的力学性能,更为值得注意的是,注塑成型的方式产生了更刚性的结构,而3DP方式却表现出了更好的制造灵活性。采用同样的耗材(CNTs和ABS),有更多的研究学者们对其进行了电气性能的研究。Thomas课题组[42]将不同浓度石墨化的多壁碳纳米管(multiwalled carbon nanotubes, MWCNTs)分散到丙烯腈丁二烯苯乙烯聚合物基体中,制备3DP组件。结果显示:由于碳纳米管的高渗透阈值,复合材料的可打印性没有明显的降低。0.75%的CNTs比例就可以使得打印组件的导电性能有显著的提升,其中以1%时的提升最为显著。相同耗材以及相同CNTs浓度配比下,Dorigato等[40]可以将电导率提升9个数量级,并且进一步可以通过提升填充物浓度提升至13个数量级。除此之外,打印组件的热扩散率和热导率也有着显著的提升。在非磁性复合材料的电磁屏蔽研究中,电导率是一项非常重要的指标,导电性的高低一定程度上直接决定了电磁屏蔽性能的好坏。Schmitz课题组[43]将碳材料(碳纳米管和炭黑)作为填充物混合到ABS中,3D打印制备了具有电磁屏蔽性能的复合材料组件。结果显示电磁屏蔽性能可以达到16dB,这基本上达到了有效电磁衰减的标准。另外作者对不同成型方向对电磁屏蔽性能的影响也进行了对比研究。垂直同心的成型方向可以在不影响打印组件力学性能实质性变化的基础上,通过微孔和腔隙来降低组件的电导率,从而实现电磁屏蔽的目的。

采用FDM制备的聚合物纳米复合材料中,Prashantha等[44]证明了采用FDM工艺制备石墨烯/PLA复合材料的可行性。10%的石墨烯含量在打印研究中是可行的,并且制备的轻质石墨烯/PLA组件可以用于电磁屏蔽研究。同时,Zhang等[45]报道称制备了电导率可以媲美铜导线的氧化石墨烯/PLA组件。总之,经过多年的发展,FDM制备纳米复合材料组件的应用已经非常广泛,例如工业上零件、夹具、电子器件以及复杂形状产品的制造[46],生物医学上人体局部组织或器官模型以及细胞载体支架结构的制造[47]等都已较为成熟。但是它依然主要存在以下两个限制因素。其一是打印精度低。打印精度和打印速率是相互制约的,高的打印速率会大幅降低打印精度,而一味地追求高精度又会降低打印速率,这并不是工业生产中所希望看到的[48]。其二便是材料的限制性较大。一方面塑性材料存在一些缺陷,功能性不强,需要填充物的增强,然而填充物的添加又容易造成喷嘴的堵塞等问题[49-50];另一方面FDM型打印机的打印材料需要丝状,这一定程度上对材料的复合或再加工产生了限制与不便。所以FDM类型打印机虽已广泛应用,但其改进和发展的空间还比较大,尤其是在多功能复合材料的3D打印制备方面。

2 选择性激光烧结成型选择性激光烧结(selective laser sintering, SLS)是增材制造技术中一个重要分支,并且是一种比较成熟的3DP技术。它可以通过使用二氧化碳激光束将金属、陶瓷或聚合物粉末进行选择性的烧结,其中粉末材料通过铺粉滚筒均匀地铺在粉末床上。这样,通过粉床在z轴方向的移动从而使零件的制造成为可能[51],其原理如图 3所示[52]。与传统的处理方法不同,SLS技术在打印过程中是无剪切和自由流动的。此外,使用SLS工艺制备聚合物复合材料的另一个特点是,只有粉末形式的聚合物才能被使用,并且材料、填充剂和聚合物需要在成为3DP耗材之前充分混合。SLS技术所用的材料主要为金属、陶瓷和高分子材料[53]。其中高分子材料有着优良的成型条件和较高的成型精度,更为关键的是它没有金属烧结时较难克服的“球化”效应[54-55],因而成为目前使用最广泛也是使用最成功的SLS打印材料。其中应用最为广泛的主要有聚碳酸酯、聚苯乙烯、尼龙、聚丙烯、聚醚醚酮等热塑性高分子及其复合材料[54]。

由于SLS技术不是通过施加压力来成型的,仅仅是通过熔融后高分子粉末的流动性来进行熔结。而这种熔结并不能使得粉末充分融合,所以在高分子SLS加工制品中都会存在一定程度的缺陷与空隙,从而导致了SLS制备的成型品力学性能远不如传统的成型品[56]。但是在SLS打印高分子材料粉末中加入无机填料可以较大程度地提升SLS成型品的性能,而且还可以实现成型品的功能化(例如高导电、构建介电网络等),并且SLS成型技术具有低渗透阈值的特性。所以关于SLS成型工艺制备高分子无机粉末复合材料的电气性能研究一直是一个热点。

SLS成型技术作为一种无剪切和自由流动的无压加工技术,提供了一种独特的方法来构造聚合物矩阵中CNTs的导电隔离网络,具有渗透阈值非常低的特点,是制备高导电材料的一种重要方法。Li课题组[57]采用自制的CNTs包裹热塑性聚氨酯粉末来制备柔性热塑性聚氨酯导体。在本研究中,用超声波对CNTs在乙醇中进行了分散。然后将热塑性聚氨酯粉末添加到CNTs的悬浮液中,在过滤和干燥前机械搅拌以获得CNTs包裹的热塑性聚氨酯粉末用以SLS成型材料,通过SLS处理的热塑性聚氨酯/CNTs复合材料的导电率有较低的渗透阈值,仅为0.2%。此时CNTs复合材料的导电率获得了显著的提升,对不同的成型方法所得样品的电导率也进行了比较,在CNTs的浓度不超过1%的情况下,SLS的成型方法比传统的成型方法有着更低的渗透阈值以及更高的导电性。例如当CNTs浓度为0.2%时,SLS方法比传统的注塑成型的热塑性聚氨酯/CNTs复合材料高出7个数量级。并且SLS成型方式制备的热塑性聚氨酯/CNTs复合材料组件可以保持良好的灵活性和耐用性,即使在重复了上千次的弯曲测试之后,电阻也可以保持近乎恒定的值。因此通过这种方法可以很容易地获得柔性的具有复杂结构和形状的导电热塑性聚氨酯/CNTs复合材料。Yuan研究小组[52]通过超声引导和胆盐钠的表面改性,将MWCNTs均匀分散到去离子水中,得到功能化的CNTs。然后将聚酰胺-12和聚氨酯粉末分散到去离子水中,加热软化和活化聚合物粉末表面。最后将加热过的功能化CNTs水悬液加到聚合物乳状悬液中,经过混合、冷却、过滤和干燥制得功能化CNTs/聚酰胺-12和功能化CNTs/聚氨酯粉末用于SLS技术的成型材料。SLS成型方式加工时诱发的隔离微观结构更加有利于复合材料的导电性能。0.5%的低渗透阈值行为可以将制备的功能化CNTs/聚酰胺-12和功能化CNTs/聚氨酯的电导率均提升7个数量级。虽然同时产生的不可避免的毛孔会影响热导性能。但是,这种高导电的复合材料零件(功能化CNTs/聚酰胺-12)和多孔混合的复合材料零件(功能化CNTs/聚氨酯)在航空航天、电子器件和汽车领域都有着非常巨大的应用潜力。

由于SLS成型工艺具有无剪切、低渗透阈值、能构建三维隔离网络的优势,采用该工艺在储能方面的工作已经被报道。Qi等[58]提出了一种适用于压电装置的聚酰胺/碳酸钡/碳纳米管三元纳米复合材料。在该研究中,由于SLS技术的无剪切和自由流动特点,三维隔离的渗透网络在聚酰胺/碳酸钡/碳纳米管中被构建。结果表明:涂覆CNTs的聚酰胺/碳酸钡纳米复合粉末比传统的聚酰胺/碳酸钡/碳纳米管三元复合粉末具有更高的激光吸收特性和更广泛的烧结窗,其结构是将CNTs随机分布在粉末颗粒中,使复合粉末具有更好的烧结性。在聚酰胺/碳酸钡/碳纳米管组件中,有效地构造了三维隔离传导通路,其渗透阈值仅为0.3%。三维隔离的渗流网络极大地增强了聚酰胺/碳酸钡/碳纳米管三元纳米复合材料的介电常数,覆盖了整个频率范围,这是因为在聚酰胺/碳酸钡/碳纳米管组件中形成了大量的微电容器。更重要的是,聚酰胺/碳酸钡/碳纳米管的压电应变系数d33的值提升为2.1 pC/N。因此采用SLS技术在压电材料中构建三维隔离渗流网络能有效提升压电聚合物的性能,这将是提高能量收集和能量存储设备性能的有效手段。

虽然由于毛孔和缺陷的存在,SLS技术制备的3DP组件力学性能存在一定劣势,但在加入增强体后,SLS技术制备的复合材料在力学性能方面的特色也一样值得关注。Li等[57]制备的CNTs/聚氨酯复合材料组件性能研究中表明,SLS成型工艺制备的聚氨酯/CNTs样品可以保持良好的灵活性和耐用性,即使在重复了上千次的弯曲测试之后,电阻也可以保持近乎恒定的值,是一种非常好的制备优良柔韧性复合材料的方法。而在通过SLS成型工艺增强复合材料强度方面,Zhang课题组[59]以新型的木塑复合材料(CNTs、木纤维、聚醚砜)作为SLS成型材料,CNTs可以作为激光束与聚合物粉末之间的良好热导体,有效地使木材/聚合物粉末从激光束中获得更多的热量。通过激光烧结将聚合物部分熔解,使复合粉末颗粒表面的CNTs嵌入到聚合物中,实现了木粉颗粒与聚醚砜颗粒之间较好的黏结,进而增强了复合材料的机械强度。

SLS技术在储能方面具有非常大的应用潜力,不仅仅是针对碳纳米管复合材料,据Sha课题组[60]报道,通过SLS技术原位制备的石墨烯泡沫塑料具有非常高的孔隙率,储能模量可以达到11 kPa,在储能领域具有潜在的应用价值。除此之外,SLS技术在制造领域同样占有不可忽视的地位。在金属零件制造方面,航空航天、桥梁建筑、航海领域、车辆制造以及模具等都是其应用范围。在生物医学领域,由于传统加工方法难以制备类似于骨骼、生物组织支架等一些复杂的结构,而应用SLS技术快速获得个性化的复杂结构也是一项热门的研究应用领域[61-62]。另外,由于SLS技术的无剪切和自由流动的加工特点,可以有效构建隔离导电网络,大幅度提升高分子复合材料的导电性能。因而其在导电器件的制备、柔性电路、传感器以及可穿戴设备方面有着巨大的优势与潜力。当然也正是SLS技术无剪切、自由流动的特点,使材料在加工时产生的毛孔和缺陷,以及由于聚合物和纳米填料密度差而产生的“沉析”现象都将使得未来更多的科研工作致力于此。

3 光固化立体成型和数字光处理成型3DP根据成型方式的不同,可细分为黏结材料3D打印、熔融材料3D打印和光固化3D打印,其中光固化3DP技术是集光固化成型与喷射成型的优点为一体的最早实用化的一种打印速率快、成型精度高、采用液态光敏树脂作为原材料的3DP技术。光固化立体成型(stereolithography, SLA)和数字光处理成型(digital light processing, DLP)的原理都是光固化成型,其中SLA是用紫外光照射液态光聚物来成型的,而DLP是用数字光处理器来照射光聚合物成型的。由于前者是点到线、线到面的成型方式,而后者是以面叠加的方式,故而DLP的成型速率要比SLA快,但他们所用的树脂均为光敏树脂[63],其主要成分是光敏树脂预聚物、小分子活性单体、光引发剂等。挥发性小、可以在紫外光源的辐照下迅速固化、黏度较低并且不会产生絮凝物堵塞喷头是液态光敏树脂的必要条件。目前用到的光敏树脂主要有3类:第一类是主要以环氧树脂和含乙烯基醚基团的阳离子型光敏树脂,其中以环氧树脂应用最为广泛;第二类是以含不饱和双键树脂为主的自由基型光敏树脂,比如环氧丙烯酸树脂和聚氨酯丙烯酸酯就是比较常用的两种自由基型光敏树脂;第三类是自由基-阳离子混合型光敏树脂,这是集自由基光固化和阳离子光固化的优点为一体的一种光敏树脂,仍属于目前的一个研究热点[64]。

光固化3DP技术虽然是最早实用化的,然而其依然存在着一些不足之处。比如相比于传统的制备方法,光固化3DP组件的力学性能就不如注塑、压模等一些传统的制备方法。据此,大量关于提升3DP组件的力学性能和电气性能的工作已经被进行。Eng等[65]对由可见光固化的丙烯酸酯和基于环氧树脂的寡聚物而研发的光敏树脂进行了CNTs提升光固化3DP组件力学性能的研究。该研究中,通过同时结合改进的CNTs分散过程和热固化后处理方法,显著提升了光固化组件的力学性能,实现了力学性能的整体增强,拉伸强度和杨氏模量分别约为48MPa和885 MPa。这样的力学性能基本可以达到注塑组件的基准性能。虽然伸长率仍低于注塑零件的值,但这种增强对于不以力学性能见长的光固化成型工艺来说已是难得,而且对于热固性材料来说是可以接受的,因为热固性材料往往比热塑性材料更脆。Sandoval课题组[66]依次通过剪切、超声以及机械搅拌等方法将MWCNTs均匀分散到环氧树脂中,采用光固化立体成型技术制备了复杂的三维组件,通过力学性能测试,对光固化3DP组件进行了评估。结果显示,少量的MWCNTs对聚合树脂的物理性质产生了显著的影响。与不含有MWCNTs的对照组相比,MWCNTs浓度即使为0.05%时,纳米复合材料的极限拉伸应力和断裂应力也分别提高了17%和37%。当MWCNTs的浓度增加到0.5%时,可以在更宽的操作温度下增强纳米复合材料样品的完整性。在提升基体力学性能的研究上,Lin等[67]证实不仅仅是碳纳米管可以有效提升复合材料的力学性能,0.2%含量的氧化石墨烯同样可以将复合材料的拉伸强度提升62.2%,伸长率提升12.8%。

由于光固化3DP技术的成形精度高、固化快、成形质量高、对喷嘴的要求低等一些优势,制备具有智能与功能性材料的研究也越来越多。Mu等[49]采用DLP类型的打印机制备和研究了导电的聚合物纳米复合材料。打印墨水由基于丙烯酸的光固化树脂和MWCNTs混合而成,二甲基甲酰胺和聚乙二醇辛基苯基醚作为MWCNTs的分散溶剂。结果显示,导电渗透阈值仅为0.1%,并且在同时考虑导电性和可打印性两个因素时,可以将最优打印参数中的层厚控制到19.05μm,而固化时间仅为40s。除此之外,基于其导电性,制备的MWCNTs纳米复合材料可作为具有应变敏感性和形状记忆效应的智能材料和结构。并且力学性能实验表明,MWCNTs的加入能使模量和极限拉伸应力略微增加,同时伴有极限断裂伸长率的小幅度降低,这表明制备的MWCNTs纳米复合材料新功能的产生不是以牺牲力学性能为代价获得的。在生物医学与生物组织工程方面,Lee等[68]在通过采用光固化3DP技术在神经治疗领域获得了巨大成就,聚乙二醇二丙烯酸酯和胺功能化的多壁碳纳米管作为光固化3D打印原材料来制备具有可控空隙复杂结构的神经支架,研究了其对电学性能和支架表面的纳米特性的增强。主要研究结果表明,与没有加入MWCNTs的支架相比,含有MWCNTs的支架可以促进神经干细胞的增殖和早期神经元分化。另外,MWCNTs的加入,使神经支架具有了导电性,据此作者辅以实验证实,通过配合相应的电刺激会对神经再生治疗应用领域中的促进神经再生有协同作用。

光固化3DP技术作为实用化最早的一种3DP方式,以成型过程自动化程度高、制备组件表面质量好、尺寸精度较高、能够制备复杂和精细化的结构等优势在航空航天、汽车、电子设备和医疗领域获得了广泛的应用[69]。然而也存在着一些不足之处,光固化3DP设备的造价较为昂贵,而且所打印的模型需要有支撑结构的存在来减小组件的弯曲和变形。力学性能相比较于其他3DP成型技术要差。不仅如此,由于支撑材料的存在,在后期处理时要依次经过拆卸、清洗、去除支撑以及表面打磨等过程,所以光固化3DP技术的后期处理也较为繁琐。另外材料研发也不可忽视,光敏树脂除了要具有黏度低、固化快等一些基本条件外,导电、耐高温、耐腐蚀以及好的力学性能等一些特性也是亟须解决的一大难题,所以光固化3DP技术在制备复合材料领域上还有很长的路要走。

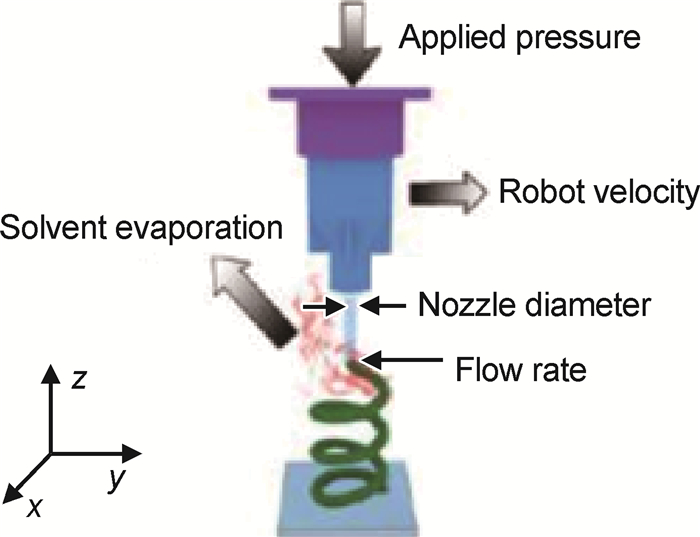

4 溶剂浇铸成型溶剂浇铸成型3D打印(solvent cast 3DP, SC-3DP)技术是基于聚合物溶剂凝固成型的一种增材制造方式。其在移动平台上由机器人控制将聚合物溶剂按程序模型沉积到平台上,通过蒸发溶剂使沉积样凝固成型, 其原理图如图 4所示[70]。这种基于溶液的打印技术是一种最具有发展潜力的3DP技术,它简单易操作、价格低廉、精度较高、易于制备复杂的结构网络、材料的选择灵活性强并且易于调节,无须考虑由于填充物的存在而导致的复合材料熔点变化[70-71]。

FDM类型3DP广泛应用以后,研究人员对该种技术的局限性的体会也越来越深,打印材料的不易制备、不灵活、不便于材料改性等一些因素限制着该技术的发展。因而在研究者们纷纷对材料进行改性的同时,Postiglione等[72]将FDM打印机改装成基于液体沉积的打印机,并将其称作液体沉积成型(liquid depo- sition modeling, LDM)。该研究中,用一个注射器代替原FDM类型打印机的标准打印头并进行相应压力驱动的改装。通过改装后,液体将直接被作为打印原料。在用于导电聚酯纳米复合材料的研究中,PLA和MWCNTs溶于二氯甲烷中作为打印墨水。结果显示,当MWCNTs的浓度为5%~10%时,打印试样MWCNTs/PLA纳米复合材料的导电性可以达到10~100S/m,相比于基于打印丝沉积的方法有了较大的提升。

SC-3DP目前只是处于实验室实验阶段,尚未应用于工业级生产和市场上的广泛推广,但是其应用于实验研究的成效还是非常显著的,尤其在制备高填充粒子含量的复合材料时更加具有优势。Chizari等[73]采用溶剂浇铸的3DP方法,以CNTs和PLA的混合溶液作为打印墨水制备了用于液体传感器的支架结构。打印墨水的制备是将PLA溶解到二氯甲烷中得到PLA-二氯甲烷溶液,然后通过球磨的方法将MWCNTs均匀分散到PLA-二氯甲烷溶液中,得到的CNTs/PLA-二氯甲烷溶液在室温下干燥24h,最后将干燥后的CNTs/二氯甲烷复合材料溶解于一定量的二氯甲烷中制得打印墨水。通过测试研究表明,虽然CNTs的浓度为2%时,导电性可以达到45S/m(大于10S/m[74], 1S/m[75]),足够用于液体传感器灵敏度的研究。然而低压状态的实际应用中要求高导电性的复合材料,这要求复合材料中CNTs的含量要比较高,相对于其他几种3DP技术来说,SC-3DP技术更容易获得高填充粒子含量的复合材料。Chizari等通过采用球磨的方法将PLA/CNTs中CNTs的含量提升到40%(力学性能较低,但可以顺利制备)。在同时考虑可打印性、力学性能以及导电性的情况下,30%的CNTs浓度是最佳效果,导电性能可以达到2350S/m, 远高于Postiglione等的100S/m,这可以完全适用于不同种类的电子组件的应用。在后续的工作中,Chizari课题组[76]采用相同的混合方法制备了CNTs/PLA的打印墨水,打印制备了高导电的纳米复合材料用于电磁屏蔽研究。作者得出了相同的结论,30%的CNTs浓度依然是最优效果,同时通过打印制备不同结构的复合材料组件可以将导电性进一步提升至5000S/m。遗憾的是作者没有解释说明为什么相同的工作,材料的导电性会是之前所涉及材料的两倍多。但该现象也充分体现了SC-3DP技术制备高含量填充粒子、高导电性的聚酯复合材料具有绝对优势,表 1所示为采用不同3DP工艺制备导电复合材料时的一些研究比较[6, 9, 39-40, 43, 49, 52, 57, 72-73, 76-79]。

| Technique | Polymer | Mass fraction of CNT/% | Conductivity/(S·m-1) | Ref. |

| FDM | TPU | 5 | 10 | [6] |

| ABS | 8 | < 102 | [40] | |

| ABS | 3 | 1 | [43] | |

| PBT | 4 | 30 | [9] | |

| ABS | 8 | 50 | [39] | |

| PVDF | 1.7 | 10-3 | [77] | |

| PLA | 12 | 4.5 | [78] | |

| SLS | PU | 1 | 1 | [57] |

| PA12 | 1 | 10-2 | [57] | |

| TPU | 1 | 0.1 | [52] | |

| SLA, DLP | Methacrylate | 0.5 | 2×10-3 | [79] |

| Photopolymer based on acrylic acid | 0.3 | 2.7×10-2 | [49] | |

| SC-3DP | PLA | 10 | 102 | [72] |

| PLA | 30 | 5.1×103 | [76] | |

| PLA | 30 | 2.35×103 | [73] |

由于SC-3DP技术对打印墨水的要求较低,材料灵活性更强,所以该技术不仅仅是适用于制备CNTs复合材料。Ma等[80]通过将氧化石墨烯流体油墨作为墨水制备了可应用于能源和电子领域的低密度、高导电性能的材料,验证了SC-3DP技术在纳米复合材料制备中的可行性。

5 结论和展望3DP技术是一项具有划时代意义的材料制造工艺,相比于传统工艺具有无需模具、材料利用率高、成型简单、成本低等独特的优势。而且不同类型的3DP工艺有着各自的特点和优势,呈现出百花齐放、百家争鸣的现状,表 2所示为相应的几种打印技术的主要工艺参数和特点[67, 81-93]。当然3DP技术也依然存在着一些难点和瓶颈亟待解决,因此吸引了一大批学者的关注。本文通过综述不同类型3DP工艺制备CNTs复合材料的研究状况,进一步分析了各成型工艺的特点。下面对3DP技术进行进一步的总结,并对3DP技术在未来的发展趋势和前景进行探讨和展望。

| Technique | Compatible materials | Resolution | Printing speed | Characteristic | Ref. |

| FDM | Filament thermoplastic | 40-500μm | 0.1-6mm·s-1 | High print strength; nozzle clogging | [81-84] |

| SLS | Powder thermoplastic | < 80μm | ≈60mm·s-1 | High strength;easy to removal of supporting materials; pore like surface | [85-87] |

| SLA | Photopolymers | 100nm | 2mm·s-1 | High resolution; good surface quality; limited materials | [67, 88-89] |

| DLP | Photopolymers | Up to 2μm | Print 100 layers within 10s | Higher speed; high cost; limited materials | [90] |

| SC-3DP | Polymer solution | 80μm | 0.3-1mm·s-1 | Little limitation of materials; suitable for flexible parts; poor mechanical properties | [91-93] |

通过综述和分析FDM, SLS, SLA/DLP和SC-3DP 4种类型3DP技术制备CNTs复合材料的研究,发现4种类型的3DP技术在电气性能方面都有着一定的优势,其中由于FDM技术采用融化再固化的成型方式,在保证力学性能强度的情况下,层层堆叠时形成的均匀交错导电网络能在较低浓度下获得相对较好的导电性能。但是FDM技术最显著的问题则是喷嘴堵塞,高CNTs浓度的复合材料制备较为困难,一般浓度不会超过10%,当超过10%时材料表面较脆、易碎,力学性能急剧下降。与此相对应,SC-3DP技术是最适合制备高CNTs含量复合材料的成型方式,其在保证力学性能的前提下,可以将CNTs的含量提升到30%,更为值得关注的是,相比于其他成型方式,导电性可以提升102~106个数量级,在制备高导电性能的复合材料上具有显著的优势。SLS工艺是一种无剪切和自由流动的无压成型工艺,其具有低渗透阈值的特性,其导电渗透阈值可以低至0.2%,其机械渗透阈值甚至可以低至0.1%。因此SLS工艺在制备一些具有特定功能的复合材料组件时具有独特的优势。例如在储能方面,通过SLS技术可以有效提升能量的收集和存储;采用SLS技术制备的含微孔和瑕疵的多孔复合材料在电子器件、汽车领域都有着巨大的应用潜力。相比于其他几种类型的3DP工艺,光固化成型方式制备复合材料时力学性能较差,通过添加CNTs依然无法获得显著提升,甚至无法和注塑成型的方式相比。但光固化3DP技术精度高、成型速率快、表面质量好,在生物医学和生物组织工程方面有着不可忽视的作用。

5.2 3DP技术的发展趋势和前景虽然3DP技术从诞生到现在获得了飞速的发展,3D打印产品遍及各个领域,然而3DP工艺依然不够成熟,还存在很大的发展空间,尤其在制备复合材料方面。结合3DP技术的特点以及限制给出以下一些未来3DP技术发展的趋势:

(1) 高精度。虽然在原则上,只要通过软件设计出打印模型,将STL格式的模型导入打印机系统,打印机就可根据切片数据将模型还原成实体,然而打印机的精度却限制了这一情况。对于精度比较高、结构比较复杂的模型,3DP技术依然无法实现,所以提升3DP技术的精度不仅是现在学者们的研究热点,在将来,高精度的3D打印机也依然会是研究者们致力的目标。

(2) 3DP技术应用的产业化和大众化。3DP技术主要以研究应用为主,很少有投入实际的生产应用,尤其是诸如复合材料此类具有特定性能的3D产品。因此在未来的发展中,3DP技术应该形成自己的生产系统,使3DP技术及产品产业化,向人们的平常生活中推广。

(3) 3DP技术的智能化和集成化。未来的3DP技术会更加智能化和多功能化。例如上述提到的SLS技术在制备复合材料时,材料表面会出现毛孔和缺陷,通过在3DP技术中嵌入智能检测模块,对每一层出现的缺陷进行修复,从而弥补SLS技术的这一缺陷。除此之外,集原材料配置、3D打印、打印组件检测、打印组件后处理等一体化的3DP生产系统也有望实现。

(4) 3DP原材料的研发。3DP技术的发展离不开材料的研制,例如本文综述的CNTs复合材料,进一步的研究将不仅仅是对复合材料的填充物或者基质材料的研发,研发与打印机相匹配的、可打印性更强、更具功能化的材料,解决3DP打印时喷嘴堵塞的情况,提升打印产品的性能也是3DP技术发展至关重要的方面。除此之外,基于“智能材料+3DP技术”的4D打印技术也具有非常大的发展潜力[94]。

总之,近年来3DP技术获得了快速发展,尤其在制备CNTs复合材料方面取得了不俗的成就。虽然3DP技术依然存在着一些瓶颈和难点,但其发展潜力和前景却依然是巨大的。3DP技术将会在理论研究、基础研究以及商业化的新型材料等方面引领革新与发展的新征程。

| [1] |

何亚飞, 矫维成, 杨帆, 等. 树脂基复合材料成型工艺的发展[J].

纤维复合材料, 2011 (2): 7–13.

HE Y F, JIAO W C, YANG F, et al. The development of polymer composites forming process[J]. Fiber Composites, 2011 (2): 7–13. DOI: 10.3969/j.issn.1003-6423.2011.02.002 |

| [2] |

诸爱士, 郑传祥, 成忠. 复合材料基体固化成型工艺综述[J].

浙江科技学院学报, 2008, 20 (4): 269–273.

ZHU A S, ZHENG C X, CHENG Z. Review of matrix solidif-ication and forming processes of composite materials[J]. Journal of Zhejiang University of Science and Technology, 2008, 20 (4): 269–273. DOI: 10.3969/j.issn.1671-8798.2008.04.007 |

| [3] |

张明煜, 郑世勋, 张丽琴, 等. 复合材料基体固化成型工艺研究[J].

西部皮革, 2016 (2): 9.

ZHANG M Y, ZHENG S X, ZHANG L Q, et al. Study on curing and forming technology of composite matrix[J]. West Leather, 2016 (2): 9. DOI: 10.3969/j.issn.1671-1602.2016.02.008 |

| [4] |

杨其, 李光宪. 聚合物及其复合材料的微成型加工研究进展[J].

高分子通报, 2013 (9): 107–115.

YANG Q, LI G X. Advances in microforming of polymers and their composites[J]. Polymer Bulletin, 2013 (9): 107–115. |

| [5] |

于天淼, 高华兵, 王宝铭, 等. 碳纤维增强热塑性复合材料成型工艺的研究进展[J].

工程塑料应用, 2018, 46 (4): 139–144.

YU T M, GAO H B, WANG B M, et al. Research progress of molding process of carbon fiber reinforced thermoplastic composites[J]. Engineering Plastics Application, 2018, 46 (4): 139–144. DOI: 10.3969/j.issn.1001-3539.2018.04.027 |

| [6] | CHRIST J S, ALIHEIDARI N, AMELI A, et al. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermopla-stic polyurethane nanocomposites[J]. Materials & Design, 2017, 131 : 394–401. |

| [7] | CAMPBELL T A, IVANOVA O S. 3D printing of multifunctional nanocomposites[J]. Nano Today, 2013, 8 (2): 119–120. DOI: 10.1016/j.nantod.2012.12.002 |

| [8] |

杜宇雷, 孙菲菲, 原光孙, 等. 3D打印材料的发展现状[J].

徐州工程学院学报(自然科学版), 2014, 29 (1): 20–24.

DU Y L, SUN F F, YUAN G S, et al. Development status of 3D printing materials[J]. Journal of Xuzhou Institute of Technology(Natural Sciences Edition), 2014, 29 (1): 20–24. DOI: 10.3969/j.issn.1674-358X.2014.01.004 |

| [9] | GNANASEKARAN K, HEIJMANS T, BENNEKOM S V, et al. 3D printing of CNT- and graphene-based conductive polymer nan-ocomposites by fused deposition modeling[J]. Applied Materials Today, 2017, 9 : 21–28. DOI: 10.1016/j.apmt.2017.04.003 |

| [10] | TAYEBI L, UI Z, YE H, et al. 3D-printed thick structured gelatin membrane for engineering of heterogeneous tissues[J]. Materials Letters, 2018, 217 : 39–43. DOI: 10.1016/j.matlet.2018.01.032 |

| [11] | KROLL E, ARTZI D. Enhancing aerospace engineering students' learning with 3D printing wind-tunnel models[J]. Rapid Prototyping Journal, 2011, 17 (5): 393–402. DOI: 10.1108/13552541111156522 |

| [12] | FU K, YAO Y, DAI J, et al. Progress in 3D printing of carbon materials for energy-related applications[J]. Adv Mater, 2017, 29 (9): 1603486. DOI: 10.1002/adma.201603486 |

| [13] | LOPES A J, ERIC M, RYAN B W. Integrating stereo lithogr-aphy and direct print technologies for 3D structural electronics fabrication[J]. Rapid Prototyping Journal, 2012, 18 (2): 129–143. |

| [14] | WITTBRODT B, LAURETO J, TYMRAK B, et al.Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems[J/OL].Journal of Frugal Innovation, 2015, 1(1): doi10.1186/s40669-014-0001-z. |

| [15] | LLEWELLYN-JONES T, ALLEN R, TRASK R. Curved layer fused filament fabrication using automated toolpath generation[J]. 3D Printing and Additive Manufacturing, 2016, 3 (4): 236–243. DOI: 10.1089/3dp.2016.0033 |

| [16] |

李梦倩, 王成成, 包玉衡, 等. 3D打印复合材料的研究进展[J].

高分子通报, 2016 (10): 41–46.

LI M Q, WANG C C, BAO Y H, et al. Research progress of 3D printing composites[J]. Polymer Bulletin, 2016 (10): 41–46. |

| [17] |

王强华, 孙阿良. 3D打印技术在复合材料制造中的应用和发展[J].

玻璃钢, 2015 (4): 9–14.

WANG Q H, SUN A L. Application and development of 3D printing technology in composite material manufacturing[J]. Fiber Reinforced Plastics, 2015 (4): 9–14. |

| [18] |

王成成, 李梦倩, 雷文, 等. 3D打印用聚乳酸及其复合材料的研究进展[J].

塑料科技, 2016 (6): 89–91.

WANG C C, LI M Q, LEI W, et al. Research progress on 3D printing polylactic acid and its composites[J]. Plastic Science and Technology, 2016 (6): 89–91. |

| [19] | FARAHANI R D, DUBE M, THERRIAULT D. Three-dimen-sional printing of multifunctional nanocomposites:manufacturing techniques and applications[J]. Adv Mater, 2016, 28 (28): 5794–5821. DOI: 10.1002/adma.201506215 |

| [20] | RANEY J R, COMPTON B G, MUELLER J. Rotational 3D pri-nting of damage-tolerant composites with programmable mechanics[J]. Proc Natl Acad Sci USA, 2018, 115 (6): 1198–1203. DOI: 10.1073/pnas.1715157115 |

| [21] | SAMANI M K, KHOSRAVIAN N, SHAKERZADEH M, et al. Thermal conductivity of individual multiwalled carbon nanotubes[J]. International Journal of Thermal Sciences, 2012, 62 : 40–43. DOI: 10.1016/j.ijthermalsci.2012.03.003 |

| [22] | SCHLAGENHAUF L, NUESCH F, WANG J. Release of carbon nanotubes from polymer nanocomposites[J]. Fibers, 2014, 2 : 108–127. DOI: 10.3390/fib2020108 |

| [23] | HU Z, HUANG Y D, WANG F, et al. Synthesis of novel single-walled carbon nanotubes/poly (p-phenylene benzobisoxazole)nanocomposite[J]. Polymer Bulletin, 2011, 67 (9): 1731–1739. DOI: 10.1007/s00289-011-0476-1 |

| [24] | WANG P H, GHOSHAL S, GULGUNJE P, et al. Polypropylene nanocomposites with polymer coated multiwall carbon nanotubes[J]. Polymer, 2016, 100 : 244–258. DOI: 10.1016/j.polymer.2016.07.070 |

| [25] | ZHANG Y, SONG K, MENG J, et al. Tailoring polyacrylonitrile interfacial morphological structure by crystallization in the presence of single-wall carbon nanotubes[J]. ACS Appl Mater Interfaces, 2013, 5 (3): 807–814. DOI: 10.1021/am302382m |

| [26] | DOWNES R D, HAO A, PARK J G, et al. Geometrically constrained self-assembly and crystal packing of flattened and aligned carbon nanotubes[J]. Carbon, 2015, 93 : 953–966. DOI: 10.1016/j.carbon.2015.06.012 |

| [27] |

林天津, 朱燕娟, 张伟, 等. 多壁碳纳米管的CVD法制备[J].

广东工业大学学报, 2007, 24 (4): 1–5.

LIN T J, ZHU Y J, ZHANG W, et al. CVD preparation method of multiwalled carbon nanotubes[J]. Journal of Guangdong University of Technology, 2007, 24 (4): 1–5. |

| [28] | ZHENG N, HUANG Y D, LIU H Y, et al. Improvement of interlaminar fracture toughness in carbon fiber/epoxy composites with carbon nanotubes/polysulfone interleaves[J]. Composites Science and Technology, 2017, 140 : 8–15. DOI: 10.1016/j.compscitech.2016.12.017 |

| [29] |

常保和, 解思深, 李文治, 等. 用电弧放电法大面积地制备离散的碳纳米管[J].

中国科学(A辑), 1998, 28 : 151–156.

CHANG B H, XIE S S, LI W Z, et al. Preparation of discrete carbon nanotubes in abundance by arc discharge[J]. Science in China (Series A), 1998, 28 : 151–156. |

| [30] |

赵建国, 史建华, 邢宝岩, 等. 以生物质为催化剂化学气相沉积制备碳纳米管[J].

新型炭材料, 2012, 27 (3): 175–180.

ZHAO J G, SHI J H, XING B Y, et al. Preparation of carbon nanotubes by chemical vapor deposition using biomass as catalyst[J]. New Carbon Materials, 2012, 27 (3): 175–180. |

| [31] |

王必本, 王万录, 刘高斌, 等. 定向生长碳纳米管的研究进展[J].

重庆大学学报(自然科学版), 2002, 25 (8): 134–136.

WANG B B, WANG W L, LIU G B, et al. Research progress of oriented growth of carbon nanotubes[J]. Journal of Chongqing University (Natural Science Edition), 2002, 25 (8): 134–136. |

| [32] |

周小康, 周明, 吴春霞, 等. 定向生长碳纳米管阵列的制备及其应用研究进展[J].

材料导报, 2007, 21 : 95–98.

ZHOU X K, ZHOU M, WU C X, et al. Progress in preparation and applications of aligned carbon nanotubes arrays[J]. Materials Review, 2007, 21 : 95–98. |

| [33] |

周鹏, 苏言杰, 赵江, 等. 低压空气中直流电弧法制备单壁碳纳米管[J].

功能材料与器件学报, 2012, 18 (3): 192–196.

ZHOU P, SU Y J, ZHAO J, et al. Synthesis of single-walled carbon nanotubes in reduced air atmosphere by DC arc discharge[J]. Journal of Functional Materials and Devices, 2012, 18 (3): 192–196. DOI: 10.3969/j.issn.1007-4252.2012.03.003 |

| [34] |

黄瑶, 李里, 修姝, 等. 二次电弧放电法调控单壁碳纳米管的直径分布[J].

黑龙江大学自然科学学报, 2015, 32 (5): 641–644.

HUANG Y, LI L, XIU S, et al. Adjusting the diameter distr-ibution of single-walled carbon nanotubes by secondary arc discharge[J]. Journal of Natural Science of Heilongjiang University, 2015, 32 (5): 641–644. |

| [35] | YANG W, CHU W, JIANG C, et al. Cerium oxide promoted Ni/MgO catalyst for the synthesis of multi-walled carbon nanotubes[J]. Chinese Journal of Catalysis, 2011, 32 (6/8): 1323–1328. |

| [36] |

唐通鸣, 张政, 邓佳文, 等. 基于FDM的3D打印技术研究现状与发展趋势[J].

化工新型材料, 2015, 43 (6): 228–230.

TANG T M, ZHANG Z, DENG J W, et al. Research status and trend of 3D printing technology based on FDM[J]. New Chemical Materials, 2015, 43 (6): 228–230. |

| [37] |

龚运息. 基于SLA和FDM的3D打印发动机风扇工艺与性能分析[J].

工艺与检测, 2015 (11): 111–115.

GONG U X. Performance analysis and process of 3D printing engine fan based on the SLA and FDM[J]. Technology and Test, 2015 (11): 111–115. |

| [38] |

李新, 孙良双, 杨亮, 等. FDM 3D打印高分子材料改性及应用进展[J].

胶体与聚合物, 2017, 35 (3): 139–141.

LI X, SUN L S, YANG L, et al. Modification and application of FDM 3D printing polymer materials[J]. Chinese Journal of Colloid & Polymer, 2017, 35 (3): 139–141. |

| [39] | DUL S, FAMBRI L, PEGORETTI A. Filaments production and fused deposition modelling of ABS/carbon nanotubes composites[J]. Nanomaterials (Basel), 2018, 8 (1): 49. |

| [40] | DORIGATO A, MORETTI V, DUL S, et al. Electrically cond-uctive nanocomposites for fused deposition modelling[J]. Synthetic Metals, 2017, 226 : 7–14. DOI: 10.1016/j.synthmet.2017.01.009 |

| [41] | TSIAKATOURAS G, TSELLOU E, STERGIOU C. Compara-tive study on nanotubes reinforced with carbon filaments for the 3D printing of mechanical parts[J]. World Transactions on Engineering and Technology Education, 2014, 12 : 392–296. |

| [42] | THOMAS D J. Developing nanocomposite 3D printing filaments for enhanced integrated device fabrication[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95 (9/12): 4191–4198. |

| [43] | SCHMITZ D P, ECCO L G, DUL S, et al. Electromagnetic interf-erence shielding effectiveness of ABS carbon-based composites manufactured via fused deposition modelling[J]. Materials Today Communications, 2018, 15 : 70–80. DOI: 10.1016/j.mtcomm.2018.02.034 |

| [44] | PRASHANTHA K, ROGER F. Multifunctional properties of 3D printed poly(lactic acid)/graphene nanocomposites by fused deposition modeling[J]. Journal of Macromolecular Science:Part A, 2017, 54 (1): 24–29. DOI: 10.1080/10601325.2017.1250311 |

| [45] | ZHANG D, CHI B H, LI B W., et al. Fabrication of highly conductive graphene flexible circuits by 3D printing[J]. Syn-thetic Metals, 2016, 217 : 79–86. DOI: 10.1016/j.synthmet.2016.03.014 |

| [46] |

田小永, 刘腾飞, 杨春成, 等. 高性能纤维增强树脂基复合材料3D打印及其应用探索[J].

航空制造技术, 2016 (15): 26–31.

TIAN X Y, LIU T F, YANG C C, et al. 3D printing of high performance fiber reinforced resin matrix composites and its application exploration[J]. Aeronautical Manufacturing Techn-ology, 2016 (15): 26–31. |

| [47] | RAHMAN M H, YUSOF M S, OSMAN S A, et al. Feasibility study:Investigation of polymer nano-composites (PNC) material for biomedical application via fused deposition modelling (FDM) routes[J]. Applied Mechanics and Materials, 2015, 773/774 : 267–271. DOI: 10.4028/www.scientific.net/AMM.773-774.267 |

| [48] | CHUNG M, RADACSI N, ROBERT C, et al.On the optimiz-ation of low-cost FDM 3D printers for accurate replication of patient-specific abdominal aortic aneurysm geometry[J/OL].3D Print Med, 2018, 4(1): doi10.1186/s41205-017-0023-2. |

| [49] | MU Q, WANG L, DUNN C K, et al. Digital light processing 3D printing of conductive complex structures[J]. Additive Manufacturing, 2017, 18 : 74–83. DOI: 10.1016/j.addma.2017.08.011 |

| [50] |

王利, 李自良, 王靖, 等. 熔融沉积成型过程喷头的传热模拟及实验研究[J].

机械与电子, 2016, 34 (1): 27–30.

WANG L, LI Z L, WANG J, et al. Numerical simulation and experimental study on heat transfer of nozzle in Fused Deposition Molding process[J]. Machinery & Electronics, 2016, 34 (1): 27–30. DOI: 10.3969/j.issn.1001-2257.2016.01.007 |

| [51] |

蒲以松, 王宝奇, 张连贵. 金属3D打印技术的研究[J].

表面技术, 2018, 47 (3): 78–83.

PU Y S, WANG B Q, ZHANG L G. Research on metal 3D printing technology[J]. Surface Technology, 2018, 47 (3): 78–83. |

| [52] | YUAN S, ZHENG Y, CHUA C K, et al. Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering[J]. Composites:Part A, 2018, 105 : 203–213. DOI: 10.1016/j.compositesa.2017.11.007 |

| [53] |

张正义, 陈英红, 戚方伟, 等. 固相剪切碾磨制备尼龙12/多壁碳纳米管复合粉体及选择性激光烧结3D打印[J].

高分子材料科学与工程, 2017, 33 (3): 122–127.

ZHANG Z Y, CEHN Y H, QI F W, et al. Preparation of nylon 12/MWNT composite powder by solid-state shear milling and selective laser sintering 3D printing[J]. Polymer Materials Science and Engineering, 2017, 33 (3): 122–127. |

| [54] |

史玉升, 闫春泽, 魏青松, 等. 选择性激光烧结3D打印用高分子复合材料[J].

中国科学:信息科学, 2015, 45 (2): 204–211.

SHI Y S, YAN C Z, WEI Q S, et al. Polymer composites for selective laser sintering 3D printing[J]. Science China:Infor-mation Science, 2015, 45 (2): 204–211. |

| [55] |

吴琼, 陈惠, 巫静, 等. 选择性激光烧结用原材料的研究进展[J].

材料导报, 2015, 29 (26): 78–83.

WU Q, CEHN H, WU J, et al. Research development of the material used for selective laser sintering[J]. Materials Review, 2015, 29 (26): 78–83. |

| [56] |

李志超, 甘鑫鹏, 费国霞, 等. 选择性激光烧结3D打印聚合物及其复合材料的研究进展[J].

高分子材料科学与工程, 2017, 33 (10): 170–174.

LI Z C, GAN X P, FEI G X, et al. Advances in the study of selective laser sintering of 3D printed polymers and their comp-osites[J]. Polymer Materials Science and Engineering, 2017, 33 (10): 170–174. |

| [57] | LI Z, WANG Z, GAN X, et al. Selective laser sintering 3D prin-ting:a way to construct 3D electrically conductive segregated network in polymer matrix[J]. Macromolecular Materials and Engineering, 2017, 302 (11): 1700211. DOI: 10.1002/mame.201700211 |

| [58] | QI F, CHEN N, WANG Q. Dielectric and piezoelectric properties in selective laser sintered polyamide11/BaTiO3/CNT ternary nanocomposites[J]. Materials & Design, 2018, 143 : 72–80. |

| [59] | ZHANG Y, FANG J, LI J, et al. The effect of carbon nanotubes on the mechanical properties of wood plastic composites by selective laser sintering[J]. Polymers, 2017, 9 (12): 728. DOI: 10.3390/polym9120728 |

| [60] | SHA J W, LI Y L, SALVATIERRA R V, et al. Three-dime-nsional printed graphene foams[J]. ACS Nano, 2017, 11 (7): 6860–6867. DOI: 10.1021/acsnano.7b01987 |

| [61] | SASKA S, PIRES L C, COMINOTTE M A, et al. Three-dim-ensional printing and in vitro evaluation of poly(3-hydroxy-butyrate) scaffolds functionalized with osteogenic growth peptide for tissue engineering[J]. Mater Sci Eng C Mater Biol Appl, 2018, 89 : 265–273. DOI: 10.1016/j.msec.2018.04.016 |

| [62] | SHIRAZI S F, GHAREHKHANI S, MEHRALI M, et al. A rev-iew on powder-based additive manufacturing for tissue engin-eering:selective laser sintering and inkjet 3D printing[J]. Sci Technol Adv Mater, 2015, 16 (3): 033502. DOI: 10.1088/1468-6996/16/3/033502 |

| [63] |

张超, 马文茂. DLP光固化3D打印关键技术研究[J].

航空科学技术, 2018, 29 (4): 47–51.

ZHANG C, MA W M. Research on key technologies of DLP photocuring 3D printing[J]. Aeronautical Science & Technolo-gy, 2018, 29 (4): 47–51. |

| [64] |

闫梦霞, 陈晓婷, 康婷, 等. 适用于光固化3D打印的光敏树脂的研究进展[J].

浙江化工, 2018, 49 (2): 8–11.

YAN M X, CHEN X T, KANG T, et al. Research progress of photosensitive resin for photocurable 3D printing[J]. Zhejiang Chemical Industry, 2018, 49 (2): 8–11. DOI: 10.3969/j.issn.1006-4184.2018.02.002 |

| [65] | ENG H, MALEKSAEEDI S, YU S, et al. Development of CNTs-filled photopolymer for projection stereolithography[J]. Rapid Prototyping Journal, 2017, 23 (1): 129–136. |

| [66] | SANDOVAL J H, SOTO K F, MURR L E, et al. Nanotailoring photocrosslinkable epoxy resins with multi-walled carbon nano-tubes for stereolithography layered manufacturing[J]. Journal of Materials Science, 2006, 42 (1): 156–165. |

| [67] | LIN D, JIN S, ZHANG F, et al. 3D stereolithography printing of graphene oxide reinforced complex architectures[J]. Nanotec-hnology, 2015, 26 (43): 434003. DOI: 10.1088/0957-4484/26/43/434003 |

| [68] | LEE S J, ZHU W, NOWICKI M, et al. 3D printing nano conduc-tive multi-walled carbon nanotube scaffolds for nerve regen-eration[J]. J Neural Eng, 2018, 15 (1): 016018. DOI: 10.1088/1741-2552/aa95a5 |

| [69] |

王广春, 袁圆, 刘东旭. 光固化快速成型技术的应用及其进展[J].

航空制造技术, 2011 (6): 26–29.

WANG G C, YUAN Y, LIU D X. Application and progress of SLA rapid prototyping technology[J]. Aeronautical Manu-facturing technology, 2011 (6): 26–29. DOI: 10.3969/j.issn.1671-833X.2011.06.001 |

| [70] | GUO S Z, HEUZEY M C, THERRIAULT D. Properties of polylactide inks for solvent-cast printing of three-dimensional freeform microstructures[J]. Langmuir, 2014, 30 (4): 1142–1150. DOI: 10.1021/la4036425 |

| [71] | GUO S Z, GOSSELIN F, GUERIN N, et al. Solvent-cast three-dimensional printing of multifunctional microsystems[J]. Small, 2013, 9 (24): 4118–4122. DOI: 10.1002/smll.201300975 |

| [72] | POSTIGLIONE G, NATALE G, GRIFFINI G, et al. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling[J]. Composites:Part A, 2015, 76 : 110–114. DOI: 10.1016/j.compositesa.2015.05.014 |

| [73] | CHIZARI K, DAOUD M A, RAVINDRAN A R, et al. 3D printing of highly conductive nanocomposites for the functional optimization of liquid sensors[J]. Small, 2016, 12 (44): 6076–6082. DOI: 10.1002/smll.201601695 |

| [74] | LEIGH S J, BRADLEY R J, PURSSELL C P, et al. A simple, low-cost conductive composite material for 3D printing of electronic sensors[J]. Plos One, 2012, 7 (11): 49365. DOI: 10.1371/journal.pone.0049365 |

| [75] | CZYZEWSKI J, BURZYNSKI P, GAWET K, et al. Rapid prototyping of electrically conductive components using 3D printing technology[J]. Journal of Materials Processing Tech-nology, 2009, 209 (12/13): 5281–5285. |

| [76] | CHIZARI K, ARJMAND M, LIU Z, et al. Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications[J]. Materials Today Communications, 2017, 11 : 112–118. DOI: 10.1016/j.mtcomm.2017.02.006 |

| [77] | KIM H, OHNSON J, CHAVEZ L A, et al. Enhanced dielectric properties of three phase dielectric MWCNTs/BaTiO3/PVDF nanocomposites for energy storage using fused deposition mod-eling 3D printing[J]. Ceramics International, 2018 (44): 9037–9044. |

| [78] | LAMBERTI P, SPINELLI G, KUZHIR P P, et al.Evaluation of thermal and electrical conductivity of carbon-based PLA nano-composites for 3D printing[C]//9th International Conference on "Times of Polymers and Composites". NY: AIP Publishing and AIP Member Societies, 2018: 020158. |

| [79] | GONZALEZ G, CHIAPPONE A, ROPPOLO I, et al. Devel-opment of 3D printable formulations containing CNT with enhanced electrical properties[J]. Polymer, 2017, 109 : 246–253. DOI: 10.1016/j.polymer.2016.12.051 |

| [80] | MA J H, WANG P, DONG L, et al. Highly conductive, mech-anically strong graphene monolith assembled by three-dimen-sional printing of large graphene oxide[J]. Journal of Colloid and Interface Science, 2019, 534 : 12–19. DOI: 10.1016/j.jcis.2018.08.096 |

| [81] | DUL S, FAMBRI L, PEGORETTI A. Fused deposition mode-lling with ABS-graphene nanocomposites[J]. Composites:Part A, 2016, 85 : 181–191. DOI: 10.1016/j.compositesa.2016.03.013 |

| [82] | SHOFNER M L, LOZANO K, BARRERA E V, et al. Nanofiber-reinforced polymers prepared by fused deposition modeling[J]. Journal of Applied Polymer Science, 2003, 89 : 3081–3090. DOI: 10.1002/app.12496 |

| [83] | WENG Z X, WANG J L, SENTHIL T, et al. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing[J]. Materials and Design, 2016, 102 : 276–283. DOI: 10.1016/j.matdes.2016.04.045 |

| [84] |

许婧, 邢悦, 郝思嘉, 等. 石墨烯/聚合物基复合材料3D打印成型研究进展[J].

材料工程, 2018, 46 (7): 1–11.

XU J, XING Y, HAO S J, et al. Research progress in graphene/polymer processing using 3D printing technology[J]. Journal of Materials Engineering, 2018, 46 (7): 1–11. |

| [85] | DUAN B, WANG M, ZHOU W Y, et al. Three-dimensional nanocomposite scaffolds fabricated via selective laser sintering for bone tissue engineering[J]. Acta Biomaterialia, 2010, 6 : 4495–4505. DOI: 10.1016/j.actbio.2010.06.024 |

| [86] | CHUNG H, DAS S. Functionally graded nylon-11/silica nano-composites produced by selective laser sintering[J]. Materials Scie-nce and Engineering A, 2008, 487 : 251–257. DOI: 10.1016/j.msea.2007.10.082 |

| [87] | SALMORIA G V, PAGGI R A, LAGO A, et al. Microstr-uctural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering[J]. Polymer Testing, 2011, 30 : 611–615. DOI: 10.1016/j.polymertesting.2011.04.007 |

| [88] | MANAPAT J Z, MANGADLAO J D, TIU B D B., et al. High-strength stereolithographic 3D printed nanocomposites:grap-hene oxide metastability[J]. ACS Appl Mater Interfaces, 2017, 9 : 10085–10093. DOI: 10.1021/acsami.6b16174 |

| [89] | ZHOU X, CASTRO N J, ZHU W, et al. Improved human bone marrow mesenchymal stem cell osteogenesis in 3D bioprinted tissue scaffolds with low intensity pulsed ultrasound stimulation[J]. Scientific Reports, 2016, 6 : 32876. DOI: 10.1038/srep32876 |

| [90] | DÍEZ-PASCUAL A M, NAFFAKH M, MARCO C, et al. High-performance nanocomposites based on polyetherketones[J]. Progress in Materials Science, 2012, 57 : 1106–1190. DOI: 10.1016/j.pmatsci.2012.03.003 |

| [91] | GUO S Z, YANG X L, HEUZEY M C, et al. 3D printing of a multifunctional nanocomposite helical liquid sensor[J]. Nano-scale, 2015, 7 : 6451–6456. |

| [92] | GUO S Z, GOSSELIN F, GUERIN N, et al. Solvent-Cast Three-Dimensional Printing of Multifunctional Microsystems[J]. Small, 2013, 9 (24): 4118–4122. DOI: 10.1002/smll.201300975 |

| [93] | GUO S Z, HEUZEY M C, THERRIAULT D. Properties of polylactide inks for solvent-cast printing of three-dimensional freeform microstructure[J]. Langmuir, 2014, 30 : 1142–1150. DOI: 10.1021/la4036425 |

| [94] |

王亚男, 王芳辉, 汪中明, 等. 4D打印的研究进展及应用展望[J].

航空材料学报, 2018, 38 (2): 70–76.

WANG Y N, WANG F H, WANG Z M, et al. Research progress and application prospect of 4D printing[J]. Journal of Aeronautical Materials, 2018, 38 (2): 70–76. |

2019, Vol. 47

2019, Vol. 47