The article information

- Nath Yadav Ravindra

- Development and experimental investigation of duplex turning process

- Advances in Manufacturing, 2017, 5(2): 149-157.

- http://dx.doi.org/10.1007/s40436-017-0177-6

-

Article history

- Received: 20 September, 2016

- Accepted: 25 April, 2017

- Published online: 5 June, 2017

Metal cutting is the most popular and industrialized machining process to remove the desired material from a workpiece surface in both traditional and non-traditional manufacturing industries. Many metal cutting processes like turning, drilling, boring, milling, broaching etc., are widely used in industries to achieve the desired objectives. Among the various metal cutting processes, turning is widely used for machining the rotating surfaces through application of a single point cutting tool. In this process, the cutting tool penetrates the workpiece causing removal of material in the form of chips as the result of plastic deformation, shearing and rupture [1, 2]. The main objectives of the turning process include reducing the diameter to a specified dimension and producing a desired surface finish [3]. However, turning process may be used to produce some complex and difficult profiles like gears, cams, shafts, axles etc., through application of special attachments [4].

The turning process is used for shaping both conventional and advanced engineering materials through application of the appropriate cutting tools. Generally, turned parts need further machining to achieve the desired surface quality. Many researchers have focused their work on obtaining appropriate surface finish. Dhar et al. [5] studied the effect of lubricant in turning on the surface quality. They performed experiments using an AISI 4340 steel workpiece, through which they finally developed a relationship between the quantity of lubrication used and the quality of the surface finish. Munawar et al. [6] analyzed the effects of cutting parameters on surface roughness during the internal turning of AISI 1018 steel. Das et al. [7] studied the effects of cutting parameters on surface roughness and flank wear during turning of AISI 4140 steel. Balasundaram and Ratnam [8] developed an online monitoring device to predict the surface roughness of the turned parts during turning. Jia and Zhou [9] analyzed the effect of tool wear on surface roughness during turning an optical glass with a diamond cutting tool. Krolczyk and Legutko [10] identified that surface roughness was highly influenced by feed rate, while cutting velocity significantly affected the surface quality during the turning of duplex stainless steel with a carbide cutting tool. Instead of cutting parameters, they found that tool parameters (tool angles) and the inclination of the workpiece also affected the surface quality [10, 11].

Several researchers have alternatively focused on precision and ultra-precision turning to meet the emerging demands of the miniature components with desired surface quality in the field of advanced manufacturing [12–15]. The analysis of nano-level finish in turning is a recent area of research and has been studied by Cheung and Lee [13] through a diamond cutting tool. Furthermore, the role of off-set distance between cutting tools in multi-tool turning was analyzed by Kalidasan et al. [16]. They found that the higher the off-set distance between cutting tools, the less vibration was produced, resulting in an improvement in the surface quality of the turned parts. Maruda et al. [17] analyzed the role of drop size and nozzle distance for turning duplex stainless steel. They found that droplet size (diameter) and distance of the tool-chip interference highly affected the machining performance. They also claimed that the sizes of the droplets changed up to 12% after emulsification. The surface morphology and signal power for a turned surface were analyzed by Krolczyk et al. [18]. They found that a higher wavelength of signal power for dry turning was comparable to minimum quality lubrication during turning duplex stainless steel.

Another concept of turning is multi-pass turning, where several rough cuts are followed by final finish cut turning [19]. However, this leads to an increase in the setting and machining time, which in turn leads to an overall increase in the cost of the products. With the development of high speed cutting tools, such as carbide, ceramic, cubic boron nitride (CBN) and poly-crystalline diamond (PCD), the researchers have begun to fucus on achieving the surface finish of turned parts up to grinding level at the same machine in a turning process known as hard turning [20–24]. However, the cost of high speed cutting tools is very high and high speed cutting often leads to high wear and tear of the machine tool. Therefore, to minimize the existing challenges related to turning, a novel turning process termed duplex turning is herein proposed.

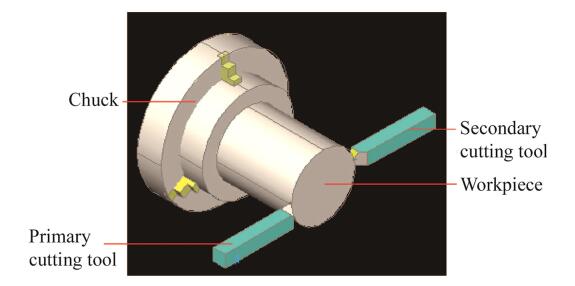

Duplex turning is an innovative idea in the field of metal cutting in which two single point cutting tools are applied to a shared surface. In this process, two cutting tools penetrate the rotating workpiece from opposite sides, as shown in Fig. 1. The basic mechanism of metal cutting is the same as that used in normal turning operation, i.e., plastic deformation, shearing and tearing. The basic purpose of the secondary cutting tool is to perform a finish cut turning operation during machining as well as provide additional support to the rotating workpiece. This process is advantageous compared to conventional turning in that it reduces the required number of passes, enhances the surface quality and, improves productivity, enhances the dynamic stability of the rotating workpiece, and provides additional support to the workpiece.

|

|

|

This paper focuses on the development and analysis of the duplex turning process, in which two single point cutting tools simultaneously penetrate a rotating workpiece surface. To do this, an additional tool post was fabricated and mounted on the carriage of a center lathe machine. The performance of the developed process was analyzed with respect to average surface roughness (Ra) produced in the turning of AISI 1040 alloy steel using cutting tools made of high speed steel (HSS). The effects of control parameters, such as cutting velocity, feed rate, primary depth of cut and secondary depth of cut, on Ra were analyzed based on the experimental results and are presented herein.

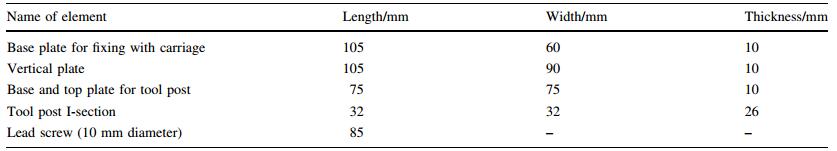

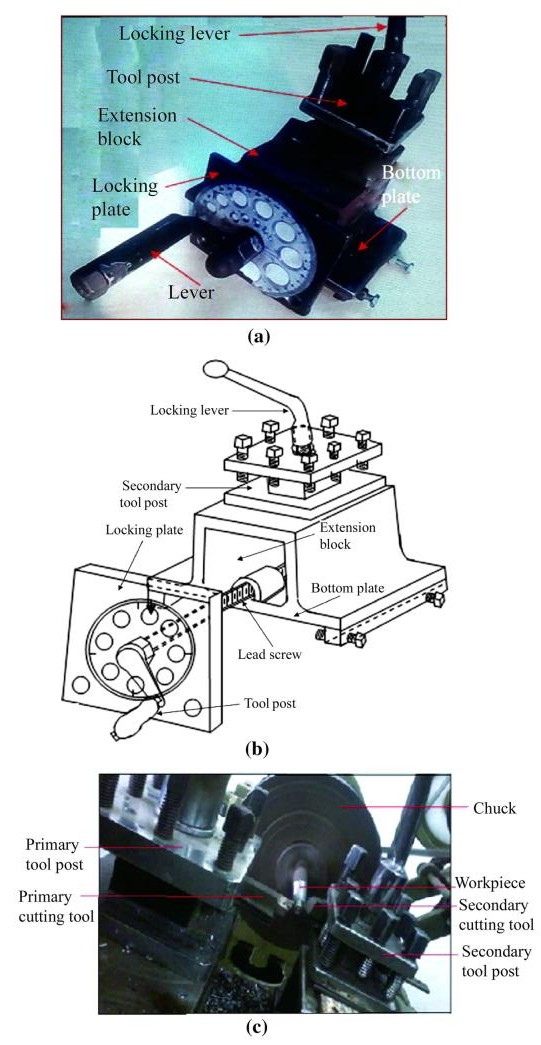

2 Development of duplex turning setupDuplex turning is an innovative concept in the field of metal cutting and accordingly, no setup has been developed for commercial use. Therefore, in this study, an indigenous and robust setup was developed to hold a secondary cutting tool, with consideration for the complexity of the process, referred to the secondary tool post. The entire unit related to the setup was comprised of a steel alloy (40Cr4Ni6Mo2), which is a suitable material for fabrication of different engineering items such as machine parts, gears, axles, nuts and bolts [25]. The dimensions of each element used in the development of the duplex turning setup are summarized in Table 1.

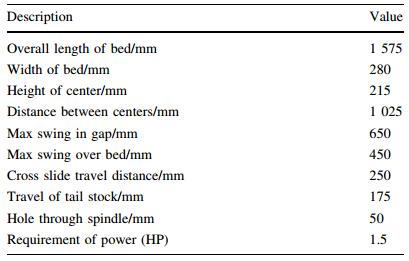

Firstly, the base of the proposed setup was fabricated using a projected V-slide at the bottom and top sides, in order to properly affix it on the cross slide with movement (to and fro) of the secondary tool post. An extension piece (a vertical plate) was welded to the top surface of the base plate to maintain the gap between the tool post and the base plate. A square threaded lead screw made of alloy steel (40Ni14) was used for the movement (to and fro) of the secondary tool post and also to control the depth of cut for the secondary cutting tool during turning. For precise control of the secondary depth of cut, a circumferentor was used and mounted on the clamping plate of the lead screw. After proper assembly of all the essential parts, a robust setup of the secondary tool post for duplex turning was obtained and mounted on the cross slide of 3-jaw centre lathe machine, as shown in Figs. 2a–c. The detailed specifications of the lathe machine are summarized in Table 2.

|

|

|

Analyses of the feasibility and machining behaviour of duplex turning process are important in understanding the capabilities of the developed setup. To this extent, the performance of duplex turning was analyzed and compared to normal turning based on their generated Ra values under constant input parameters. The turning experiments were performed using the developed setup with steel alloy (diameter = 30 mm and length = 50 mm) as AISI 1040 (w(C) = 0.435%, w(Si) = 0.20%, w(Mn) = 0.69%, w(P) = 0.035%, w(S) = 0.45%). Two cutting tools (back rake angle = 5°, side rake angle = 5°, side cutting edge angle = 7°, end cutting edge angle = 7°, side clearance angle = 15°, end clearance angle = 15° and nose radius = 0.5 mm) made of HSS were selected for turning. The reasons behind the selection of HSS as the tool material included its low cost and high availability. Generally, HSS is more suitable for rough cut machining of difficult-to-cut materials such as metal matrix composites as well as hybrid composites [26]. Therefore, an HSS tool was chosen for the preliminary studies on duplex turning process.

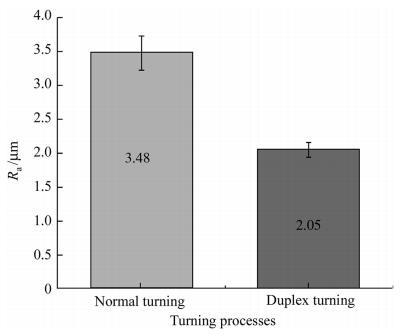

To determine the feasibility of the developed process, a comparative experimentation was conducted. For this purpose, firstly, normal turning was performed by a single cutting tool under the following constant input parameters: cutting velocity = 30 m/min, feed rate = 0.40 mm/r and depth of cut = 0.50 mm. After that, two cutting tools were used simultaneously by clamping the primary and secondary tool posts to perform the duplex turning process. The basic goal of duplex turning is to eliminate the need for a secondary finish cut turning operation. Thus, a depth of cut of 0.25 mm was assigned to each cutting tool, while keeping the other parameters constant to achieve the same diameter after turning.

Each experiment was conducted two times to account for variations in the experimental results. The response parameter, i.e., Ra of the turned surface was measured using a digital surface roughness tester (model: SJ-201) at three different locations. The average values of all measured data were used in the analysis of the experimental observations. A graphical representation with error bars of the experimental data is shown in Fig. 3.

|

|

|

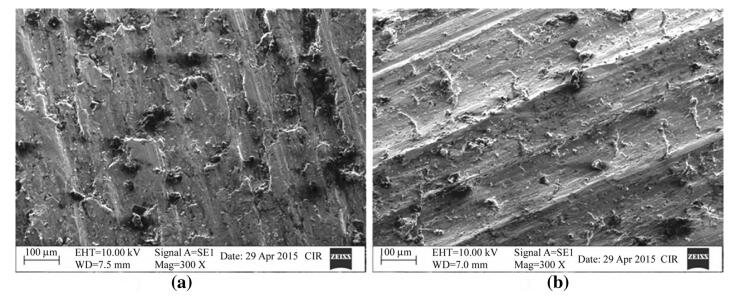

Figure 3 shows that the duplex turning process results in a better (approximately 1.7 times) surface finish compared to the normal turning process of machining steel alloy material. This is because the secondary cutting tool follows the primary cutting tool and accomplishes a finish cut turn operation with a smaller depth of cut. Consequently, the cutting forces and heat generated at tool-workpiece interface were smaller. Furthermore, the cutting tool maintains its cutting ability for a longer time. The lower variation in the error bars of the duplex turning Ra values indicates a smoother surface compared to a normally turned surface. Scanning electron microscope (SEM) images of the turned surfaces obtained by different turning processes are shown in Figs. 4a, b. These SEM images also indicate that the surface profile of the duplex turned workpiece is better than that of the normal turned surface.

|

|

|

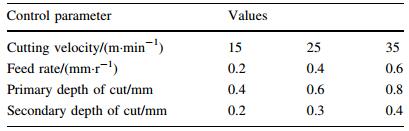

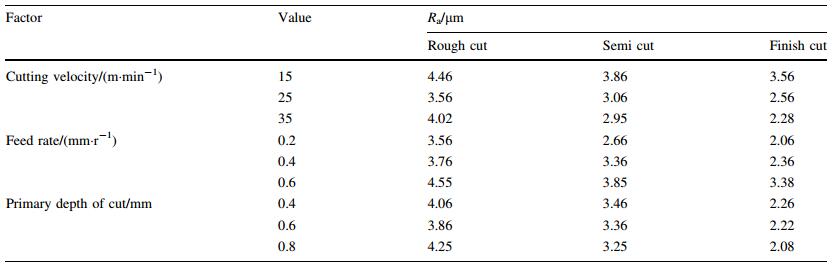

The effects of each control parameter (cutting velocity, feed rate, primary depth of cut and secondary depth of cut) on Ra of the duplex turned surface of alloy steel (AISI 1040) workpiece were analyzed. All experiments were performed according to one parameter at a time approach, which was a factorial design of experiment technique [27]. According to this technique, one parameter is varied within a range while the other parameters are kept constant. This approach is suitable for identifying the appropriate ranges of the control parameters of the newly developed setup [27, 28]. The factors and their corresponding values that were used in the experiments are summarized in Table 3. All experiments were performed using a center lathe machine and the experimental observations are summarized in Table 4. The influence of each parameter on Ra was analyzed for three different categorises of the secondary depth of cut, including rough cut (0.40 mm), semi finish cut (0.30 mm) and finish cut (0.20 mm) to identify the quality of the duplex turned surfaces.

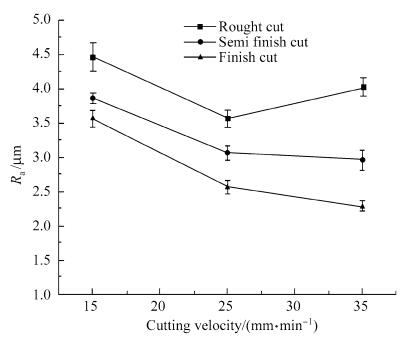

The effect of varying cutting velocity on Ra is shown in Fig. 5, for constant values of feed rate (0.20 mm/r) and primary depth of cut (0.40 mm), and different values of the secondary depth of cut (rough cut = 0.40 mm, semi finish cut = 0.30 mm and finish cut = 0.20 mm). It can be seen in Fig. 5 that the Ra value of the turned surface decreases with increasing cutting velocity during the finish cut turning, which is followed by semi finish cut turning. This is because the workpiece material becomes softer with increasing cutting velocity owing to the generation of heat and subsequent thermal softening of workpiece. As a result, there is a reduction in the required cutting force, and cutting tools retain their cutting abilities for a long time. Consequently, the turning becomes easier, and a better surface finish has been obtained.

|

|

|

Figure 5 also shows that the Ra decreases when the cutting velocity increases from 15 m/min to 25 m/min. After that, the roughness of the duplex turned surface increases with cutting velocity during rough turning, while semi finish turning and finish turning show only small improvement in surface quality. Initially, a better surface finish was obtained owing to the thermal softening of the workpiece with increased cutting velocity. During rough cut turning, the cutting resulted in a larger depth of cut. Consequently, higher cutting forces were required along with higher frictional forces at the tool-chip interface. This caused the cutting tool to lose its cutting ability and wear out rapidly, eventually resulting in blunting of the secondary cutting tool at which point the Ra increased with rough cut turning at a cutting velocity of 25 m/min.

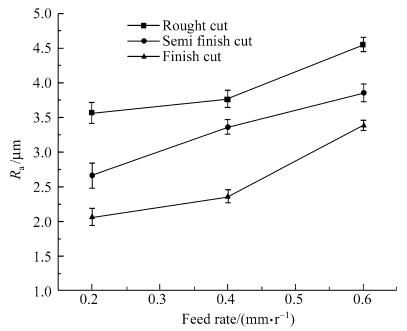

4.2 Effect of feed rateThe effect of varying the feed rate on Ra is shown in Fig. 6 with constant cutting velocity (15 m/min) and primary depth of cut (0.40 mm), and different values of the secondary depth of cut. It was observed that Ra increased with feed rate per revolution. An increase in feed rate signifiedanincrease ofthechipthickness.Asaresult, therewas an increase in the required cutting force because the cutting force was directly proportional to the cutting chip thickness. Consequently, a greater amount of heat was generated at the tool tip-workpiece interface. This caused the cutting edge of the cutting tool to become softer and lose its hot hardness strength, and therefore, its cutting ability. This phenomenon resulted in higher roughness values corresponding to higher feed rates during duplex turning.

|

|

|

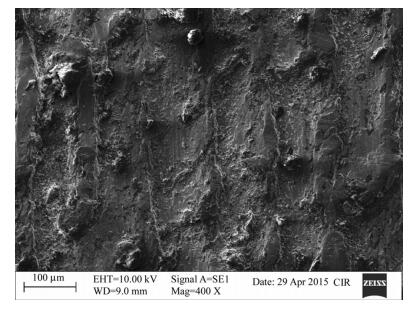

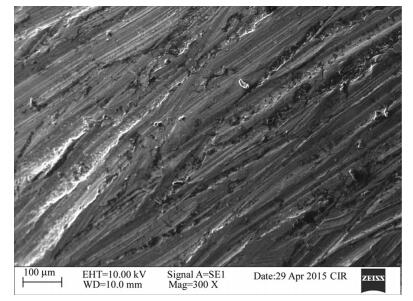

The width of the turned surface was also found to increase. Due to the wider cut marks, the over lapping of successive turning sequences became impossible. The cutting edge of the tool essentially became blunted at higher feed rate. This phenomenon also contributed to the poor surface finish corresponding with higher feed rates. An SEM image of the duplex turned surface at a high feed rate is shown in Fig. 7.

|

|

|

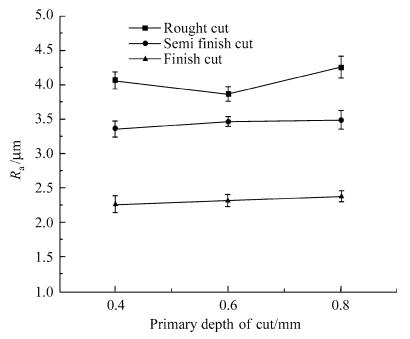

The effect of varying primary depth of cut on Ra is shown in Fig. 8 (cutting velocity = 15 m/min, feed rate = 0.20 mm/r, and different values of the secondary depth of cut). The Ra values were found to be nearly constant during the finish cut turning for different values of the primary depth of cut. It is well known that the primary depth of cut during duplex turning has a negligible impact on the surface finish, and the quality of turned parts is dependent upon the secondary depth of cut. Therefore, no changes were observed in Ra during duplex turning when varying the primary depth of cut, and the surface finishes were nearly uniform. A similar tendency was observed with semi finish cut turning of the steel alloy.

|

|

|

Figure 8 also shows that the initially Ra decreases with the increase of the primary depth of cut up to 0.60 mm, and it increases with the primary depth of cut beyond 0.60 mm during rough cut turning. Initially, the secondary cutting tool removed any hills formed by the primary cutting tool, and as a result, a smoother surface was obtained. Upon increasing the primary depth of cut beyond 0.60 mm, the secondary depth of cut became ineffective to remove the hills formed by the primary cutting tool, causing Ra to increase. It may be also possible that primary cutting tool became blunted upon increasing the primary depth of cut beyond 0.60 mm. In this situation, the secondary cutting tool was unable to remove the hill/valley formed by primary cutting tool and the surface finish was considered to be inadequate.

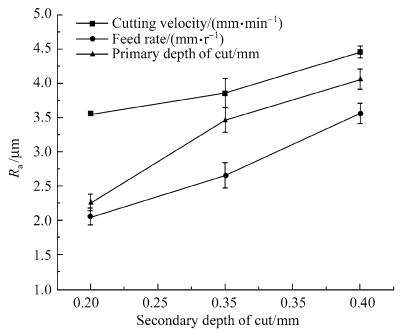

4.4 Effect of secondary depth of cutThe effect of varying the secondary depth of cut on Ra is shown in Fig. 9 with constant cutting velocity (15 m/min), feed rate (0.20 mm/r) and primary depth of cut (0.40 mm). It can be seen in Fig. 9 that Ra increases with secondary depth of cut and constant cutting velocity. This was owing to the fact that increasing the secondary depth of cut in turn increased the width of the chip thickness. Consequently, the cutting force also increased. This resulted in thermal softening of the cutting tool, a loss in cutting ability of tool, greater tool wear, and ultimately, an inadequate surface finish.

|

|

|

Figure 9 also shows that Ra increases with secondary depth of cut for a constant value of the primary depth of cut. This is because that the basic purpose of the secondary cutting tool in the duplex turning was to perform the finish operation. Despite this, it behaved like a primary cutting tool (normal) at a fixed primary depth of cut, and was responsible for the increase in Ra. A similar tendency was observed at a constant feed rate while varying the secondary depth of cut, owing to the blunting of the cutting tool at larger depth of cut. It can also be seen in Fig. 9 that the combination of a lower feed rate and a smaller secondary depth of cut are able to provide better surface finish, owing to the low cutting force and heat generated at toolworkpiece interface. This phenomenon is depicted in Fig. 10, with constant input parameters (cutting velocity = 25 m/min, feed rate = 0.20 mm/r, primary depth of cut = 0.40 mm, and secondary depth of cut = 0.20 mm). This indicates that the proper selection of the input parameters yields better surface quality of duplex turned parts.

|

|

|

In the present study, a novel setup for duplex turning process was developed, and the performance of the developed setup was tested. Several problems were identified during duplex turning, such as difficulty in controlling the chipped material generated by the secondary cutting tool and the presence of a small uncut width during duplex turning. From the results of the analysis, the following conclusions were drawn.

(ⅰ) The duplex turning process yields better (approximately 1.7 times) surface finishes compared to normal turning of the alloy steel.

(ⅱ) A higher cutting velocity is more suitable for achieving a better surface finish with a finish or semi finish cut turning, owing to the thermal softening of the workpiece material. Despite this, the combination of higher cutting velocity with rough cut turning does not produce a better surface finish.

(ⅲ) The surface finish deteriorates with a higher feed rate is used owing to the non-over lapping nature of the turning cycle during each revolution.

(ⅳ) The primary depth of cut does not affect the surface finish significantly during finish or semi finish cut turning because the surface quality depends upon the secondary depth of cut. Regardless of this, the surface finish declines during rough cut turning owing to the generation of new surfaces.

(ⅴ) The combination of a lower feed rate and a smaller secondary depth of cut results in better surface quality.

| 1. | Lal GK (1994) Introduction to machining science. New Age International Publisher, New Delhi |

| 2. | Saini M, Yadav RN, Kumar S (2015) An overview on turning process. In: Proceedings of 1st international conference on advancements and recent innovations in mechanical, production and industrial engineering (ARIMPIE-2015), vol 2. ITS Engineering College Greater Noida, India, pp, 377-386 |

| 3. | Yildiz AR(2012)A comparative study of population-based optimization algorithms for turning operations.Inf Sci 210, 81-88 doi:10.1016/j.ins.2012.03.005 |

| 4. | Grzesik W(2008)Influence of tool wear on surface roughness in hard turning using differently shaped ceramic tools.Wear 265, 327-335 doi:10.1016/j.wear.2007.11.001 |

| 5. | Dhar NR, Kamruzzaman M, Ahmed M(2006)Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel.J Mater Process Technol 172, 299-304 doi:10.1016/j.jmatprotec.2005.09.022 |

| 6. | Munawar M, Chen JC, Mufti NA(2011)Investigation of cutting parameters effect for minimization of surface roughness in internal turning.Int J Precis Eng Manuf 12, 121-127 doi:10.1007/s12541-011-0015-x |

| 7. | Das SR, Dhupal D, Kumar A(2015)Study of surface roughness and flank wear in hard turning of AISI, 2015, 4140 steel with coated ceramic inserts.J Mech Sci Technol 29, 4329-4340 doi:10.1007/s12206-015-0931-2 |

| 8. | Balasundaram MK, Ratnam MM(2014)In-process measurement of surface roughness using machine vision with sub-pixel edge detection in finish turning.Int J Precis Eng Manuf 15, 2239-2249 doi:10.1007/s12541-014-0587-3 |

| 9. | Jia P, Zhou M(2012)Tool wear and its effect on surface roughness in diamond cutting of glass soda-lime.Chin J Mech Eng 25, 1224-1230 doi:10.3901/CJME.2012.06.1224 |

| 10. | Krolczyk GM, Legutko S(2014)Experimental analysis by measurement of surface roughness variations in turning process of duplex stainless steel.Metrol Meas Syst 21, 759-770 |

| 11. | Wojciechowski S, Twardowski P, Wieczorowski M(2014)Surface texture analysis after ball end milling with various surface inclination of hardened steel. Metrol Meas Syst 21, 145-156 |

| 12. | Cheung CF, Lee WB(2000)Study of factors affecting the surface quality in ultra-precision diamond turning.Mater Manuf Process 15, 481-502 doi:10.1080/10426910008913001 |

| 13. | Cheung CF, Lee WB(2001)Characterisation of nano surface generation in single-point diamond turning.Int J Mach Tool Manuf 41, 851-875 doi:10.1016/S0890-6955(00)00102-4 |

| 14. | Duong TH, Kim CH, Lee DU(2013)Selection of machining conditions for microchannels in ultraprecision diamond turning.Proc IMechE Part B: J Eng Manuf 227, 1558-1570 doi:10.1177/0954405413490292 |

| 15. | Jung HS(2009)Environmentally conscious hard turning of cemented carbide materials on the basis of micro-cutting in SEM (2nd report): stress turning with three kinds of cutting tools.J Mech Sci Technol 23, 1959-1966 doi:10.1007/s12206-009-0512-3 |

| 16. | Kalidasan R, Ramanuj V, Sharma VK, et al(2014)Influence of cutting parameters and offset distance over cutting tool vibration in multi tool turning process.Adv Mater Res 984-985, 100-105 doi:10.4028/www.scientific.net/AMR.984-985 |

| 17. | Maruda RW, Krolczyk GM, Feldshtein E, et al(2016)A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL).Int J Mach Tools Manuf 100, 81-92 doi:10.1016/j.ijmachtools.2015.10.008 |

| 18. | Krolczyk G, Maruda R, Nieslony P, et al(2016)Surface morphology analysis of duplex stainless steel (DSS) in clean production using the power spectral density.Measurement 94, 464-470 doi:10.1016/j.measurement.2016.08.023 |

| 19. | Arif M, Stroud AI, Akten O(2014)A model to determine the optimal parameters for sustainable-energy machining in a multipass turning operation.Proc IMechE Part B: J Eng Manuf 228, 866-877 doi:10.1177/0954405413508945 |

| 20. | Hodgson T, Trendler P, Ravignani G(2001)Turning hardened tool steels with cubic boron nitride inserts.Ann CIRP 30, 63-66 |

| 21. | Aslan E(2005)Experimental investigation of cutting tool performance in high speed cutting of hardened X210 Cr12 cold-work tool steel (62 HRC).Mater Des 26, 21-27 doi:10.1016/j.matdes.2004.04.004 |

| 22. | Bouacha K, Yallese MA, Khamel S, et al(2014)Analysis and optimization of hard turning operation using cubic boron nitride tool.Int J Refract Metal Hard Mater 45, 160-178 doi:10.1016/j.ijrmhm.2014.04.014 |

| 23. | Dureja JS, Singh R, Bhatti MS(2014)Optimizing flank wear and surface roughness during hard turning of AISI D3 steel by Taguchi and RSM methods. Prod Manuf Res 2, 767-783 |

| 24. | Bartarya G, Choudhury SK(2014)Influence of machining parameters on forces and surface roughness during finish hard turning of EN, 2014, 31 steel.Proc IMechE Part B: J Eng Manuf 228, 1068-1080 doi:10.1177/0954405413500492 |

| 25. | Bhandari VB (2007) Design of machine elements. TMH Publishing Ltd. , New Delhi |

| 26. | Ahamed AR, Asokan P, Aravindan S, et al(2008)Drilling of hybrid Al-5%SiCp-5%B4Cp metal composites.Int J Adv Manuf Technol 49, 871-877 |

| 27. | Montgomery DC (2013) Design and analysis of experiments. Wiley India, New Delhi |

| 28. | Yadav RN, Yadava V(2014)A new way of electro-abrasion hybrid machining (EAHM) using slotted-diamond grinding wheel. Int J Manuf Technol Manag 28, 132-145 |

2017, Vol. 5

2017, Vol. 5