b National-Local Joint Engineering Research Center of Heavy Metals Pollutants Control and Resource Utilization, Nanchang Hangkong University, Nanchang 330063, China

Selective capture of Ag(Ⅰ) from complex industrial wastewater to achieve the recycling and utilization of resources is the common goal of modern science and enterprises [1]. Various technologies including ion exchange resin, membrane filtration and adsorption have been proposed to treat Ag(Ⅰ)-containing wastewater [2-6]. Among them, adsorption is considered the most economical and effective due to the low-budget, simple operation and satisfactory property. Although multifarious adsorption materials including porous graphene, chelating resins, metal oxides and bio-sorbents with high adsorption capacity was developed, it was still challenging to apply these adsorbents in selective removal of Ag(Ⅰ) [7-11]. Meanwhile, during the treatment of highly acidic actual Ag-containing wastewater, plenty adsorbents were suffered from the shortcomings of weak stability attributed to the inferior acid resistance [12-14]. Exploiting promising adsorbents with acid stability to achieve benign selectivity for Ag(Ⅰ) is a feasible solution to fill the gap in the field.

Polymer materials have become a class of potential adsorbents due to the high stability and task-specific endowed by grafting functional groups into the networks [15-17]. Guiding by the theory of hard and soft acids and bases, the presence of atoms with a lone pair of electrons in the groups such as S and N possessed strong affinity for some metal ions [18]. Among legion polymer adsorbents functionalized with representative S-containing groups such as thiol, thioether and thiourea, the removal of majority heavy metal ions including Pb(Ⅱ), Pd(Ⅱ), Cu(Ⅱ), Hg(Ⅱ), Cd(Ⅱ) and trace amount of Ag(Ⅰ) was fulfilled in wastewater [19-22]. However, the inferior distinguish ability of S-containing adsorbents to coordinate with different metal ions may cause the significant decrease of the selectivity of Ag(Ⅰ). Encouragingly, Nowik-Zajac research group demonstrated an array of calixpyrroles functionalized polymer inclusion membranes, which implemented efficient selective removal of Ag(Ⅰ) [23]. Yang et al. developed an adsorbent functionalized by 2-aminomethyl-pyridine to achieve selective recovery of Ag(Ⅰ) [24]. Therefore, N-rich functional groups modified polymer adsorbents with desirable integrated performance were preferred to exhibit eminent selective removal of Ag(Ⅰ).

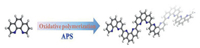

The N-rich ligand o-phenanthroline is famous for the peculiar metal ion chelating properties and extraordinary stability [25]. At present, traditional preparation methods of polymers such as thermally initiation and ring-opening polymerization usually led to low exposure active sites [26]. Herein, a novel linear o-phenanthroline-based polymer l-PRL was fabricated by the chemical oxidation polymerization method with ammonium persulfate as the oxidant (Scheme 1). Batch adsorption experiments have been conducted to evaluate the performance of l-PRL capture of Ag(Ⅰ), suggesting that l-PRL was capable of admirable selectivity of Ag(Ⅰ). Furthermore, the underlying selective adsorption mechanism of Ag(Ⅰ) on l-PRL has been disclosed based on characterizations of FT-IR and XPS as well as density functional theory (DFT) theoretical calculations. The adsorption-desorption and practical experiments were performed to content the actual application requirements of Ag-containing wastewater.

|

Download:

|

| Scheme 1. Schematic illustration for the preparation of l-PRL. | |

The detailed synthesis, characterization and experiment sections of l-PRL were provided in Support information.

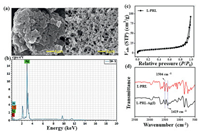

Scanning electron microscopy (SEM) was used to detect the microscopic morphology of l-PRL before and after Ag(Ⅰ) adsorption. As shown in Fig. 1a, the morphology of l-PRL showing a uniform size of granular aggregation state with large numbers of open porous structure, and the porous structure with obvious changes after adsorption illustrated that the Ag(Ⅰ) was successfully captured on the l-PRL. Meanwhile, the distribution of Ag element on the l-PRL-Ag(Ⅰ) was characterized by energy dispersive spectrometer (EDS) (Fig. 1b), the strong characteristic peak of Ag element was observed also proved the l-PRL captured of Ag(Ⅰ). The l-PRL was subjected to Brunner-Emmet-Teller (BET) experiment for detection of specific surface area and pore size distribution via N2 adsorption-desorption method (Fig. 1c). The l-PRL presented low specific surface area (27.603 m2/g) and pore size (1.424 nm) [27]. The functional groups of l-PRL were carried out by FT-IR spectrum (Fig. 1d).

|

Download:

|

| Fig. 1. (a) SEM images of l-PRL and l-PRL-Ag(Ⅰ). (b) EDS spectrum of l-PRL-Ag(Ⅰ). (c) N2 adsorption-desorption isotherms of l-PRL. (d) FT-IR of l-PRL and l-PRL-Ag(Ⅰ). | |

The spectra of l-PRL revealed the specific peak at 1504 cm−1 and 1419 cm−1 corresponding to the vibrations of C = N and C–N respectively [28, 29]. And the two peaks presented a certain decrease after Ag(Ⅰ) adsorption, which illustrated that N groups act as binding sites.

Considering the features that Ag(Ⅰ) forms metal hydroxide precipitates at alkaline conditions, the effect of pH on the Ag(Ⅰ) adsorption capacity of l-PRL was carried out in the pH range of 0 to 5. As observed in Fig. 2a, the adsorption performance of l-PRL for Ag(Ⅰ) has been slightly increased with the decreased pH values, reaching the maximum adsorption capacity at pH 0. Generally, the high concentration of H+ caused the deactivation of adsorbents, resulting in significant decreased adsorption capacity. Interestingly, the as-formed l-PRL was equipped with the unique features of superior acid resistance and acidity-enhanced adsorption, which supported that l-PRL was qualified for potential of practical application in acidic Ag(Ⅰ)-containing wastewater. The adsorption isotherms were carried out at the optimum condition of pH and collected in Fig. 2b. It can be seen that the adsorption capacity of l-PRL increased sharply with increased concentration of Ag(Ⅰ) solution, and the curve flattened out in the high concentration range until reaching the maximum capacity of 325.8 mg/g. Meanwhile, two classical isotherms adsorption models were employed to fit the experimental data to explore the adsorption behavior [30]. The correlation coefficient (R2 = 0.991) of Langmuir model for l-PRL is higher than that of Freundlich model (R2 = 0.867), which suggested that the adsorption sites of l-PRL are uniformly distributed on the surface. Furthermore, the adsorption rate was evaluated in Fig. 2c, l-PRL enabled rapid capture of aqueous Ag(Ⅰ), and the adsorption equilibrium was reached within 20 min. In order to further understand the process of Ag(Ⅰ) adsorption on l-PRL, the data of was fitted by the pseudo-first-order and pseudo-second-order kinetic model, and the pseudo-second-order kinetic model exhibited a superior correlation coefficient (R2 = 0.992), indicating that chemisorption is the key step of rate-controlling in the capture of Ag(Ⅰ) [31].

|

Download:

|

| Fig. 2. (a) The effect of pH on the adsorption of Ag (Ⅰ) by l-PRL. (b) Adsorption isotherms and (c) adsorption kinetics for Ag(Ⅰ) on l-PRL. | |

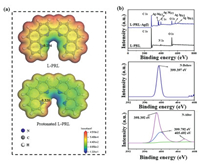

To further clarify the adsorption mechanism of Ag(Ⅰ) capture on l-PRL, the atomic charges distribution of the l-PRL and H+-protonated l-PRL were performed by Mulliken population analysis of DFT calculations. As presented in Fig. 3a, the regions of N groups possessed a more negative electrostatic formula than other regions in l-PRL, indicating N groups as the main adsorption sites of capture of Ag(Ⅰ) [32-34]. For the H+-protonated l-PRL, the electrostatic formula of N groups became more negative than l-PRL, which provided a strong theoretical support for the results of acidity-enhanced adsorption capacity of l-PRL [35]. In addition, the XPS spectra in Fig. 3b suggested that l-PRL consisted the C, O, and N elements, and the new binding energy peaks of l-PRL-Ag(Ⅰ) appeared at 366.017, 372.084, 573.299, and 602.562 eV, corresponding to electronic arrangements of 3d5/2, 3d3/2, 3p3/2 and 3p1/2 of Ag, respectively, which confirmed that the successful capture of Ag(Ⅰ) on l-PRL [36-38]. The XPS spectrum of N groups before and after adsorption of Ag(Ⅰ) was further ascertain the binding sites of l-PRL capture of Ag(Ⅰ). It can be seen that the XPS spectrum of N 1s changed significantly and new peaks of 398.392 eV and 405.692 eV were emerged after l-PRL coordinate with Ag(Ⅰ), demonstrating that peaks of the C = N bonds were evidently shifted to C–N and Ag–N, which confirmed that N groups on the l-PRL acted as the binding sites to capture of Ag(Ⅰ) [39, 40]. Considering the above evidences of DFT and XPS, N groups dominates in the capture of Ag(Ⅰ) by l-PRL attributed to more negative electrostatic formula region, which provided a strong interaction force for effective binding with Ag(Ⅰ).

|

Download:

|

| Fig. 3. (a) Atomic charges of l-PRL and protonated l-PRL by theoretical calculations. (b) XPS spectra of l-PRL before and after Ag(Ⅰ) adsorption. | |

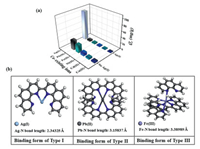

The multiple metal ions including Cd(Ⅱ), Co(Ⅱ), Ni(Ⅱ), Pb(Ⅱ) and Fe(Ⅲ) were selected as competing ions to evaluate the selectivity of l-PRL capture of Ag(Ⅰ) (Fig. 4a). It showed that the adsorption capacities of l-PRL for different metal ions displayed an apparent selectivity ranking of Pb(Ⅱ) > Fe(Ⅲ) > Ni(Ⅱ) > Cd(Ⅱ) > Co(Ⅱ) in the mixed solution without Ag(Ⅰ). However, the adsorption capacities of interfering metal ions such as Pb(Ⅱ) was dropped more than five times after adding Ag(Ⅰ) into the mixture, and all of competing ions were far below the Ag(Ⅰ), indicating that l-PRL exhibited dominance of selectivity of Ag(Ⅰ). Furthermore, the mechanism of favorable selectivity of Ag(Ⅰ) was explored by DFT calculations. Considering structural characteristics of the l-PRL and unequal coordination numbers of different metal ions, diverse metal ions coordinated with l-PRL in different manners [41]. The configurations of complexes of l-PRL coordinate with disparate metal ions were analyzed and the reasonable and most stable configurations of complexes were obtained. As presented in Fig. 4b, the calculated bond length of Ag-N (2.34325 Å) is shorter than that of Pb-N (3.15837 Å) and Fe-N (3.38989 Å). According to the stability principle of complexes, the shorter bond length of M-N demonstrated more stable combination, which indicated that the complexes coordinated by l-PRL with Ag(Ⅰ) was the most stable [42]. Moreover, different spatial localization of l-PRL with Ag(Ⅰ), Pb(Ⅱ) and Fe(Ⅲ) resulted in divergence of complexation ability of l-PRL to coordinate with various metal ions. The Ag(Ⅰ) was provided with smaller steric hindrance compared with Pb(Ⅱ) and Fe(Ⅲ), which endow the Ag(Ⅰ) with the prominent coordination preponderance to binding with l-PRL. As a result, Ag(Ⅰ) coordinate with l-PRL with higher sites utilization and form the most stable complexes, which indicated that the ascendant selectivity of l-PRL capture of Ag(Ⅰ).

|

Download:

|

| Fig. 4. (a) Selective adsorption of Ag(Ⅰ) by l-PRL in the mixture of multiple interfering ions. (b) The calculated bond length of Ag-N, Pb-N and Fe-N. | |

The recyclability and durability of l-PRL is critical to the practical application in Ag(Ⅰ) removal, which has been evaluated by the adsorption-desorption cycles regeneration experiments. Fig. 5a showed the results of four cycles of the reusability of Ag(Ⅰ) adsorption. It can be seen that only 0.6% decline of adsorption capacity for l-PRL after two cycles, and 93.5% of initial adsorption capacity of the l-PRL was reserved after four adsorption-desorption cycles. In general, the removal efficiencies of Ag(Ⅰ) after several cycles for the regeneration of the l-PRL were all above 90%, indicating that the l-PRL was equipped with astonishing reuseability in line with the concept of sustainable development and request of practical applications. It was known that the composition of the actual Ag(Ⅰ)-containing wastewater was extremely acidic and particularly complex with multiple co-exist metal ions as the main characteristics. Therefore, three different concentrations of 10, 100 and 1000 mg/L of actual Ag-containing industrial wastewater samples were collected from a smelter (Changsha, China) to determine the Ag(Ⅰ) removal performance of l-PRL in the practical process, with the corresponding Ag(Ⅰ) adsorption capacity exhibited in Fig. 5b. It was worth noting that Ag(Ⅰ) was almost completely removed from the low-concentration Ag-containing industrial wastewater. All these results indicated that l-PRL provided great application potentials in the capture of Ag(Ⅰ) from wastewater.

|

Download:

|

| Fig. 5. (a) Regeneration and recyclability of the l-PRL adsorbents. (b) Practical applications of l-PRL in the actul Ag(Ⅰ)-containing wastewater. | |

In summary, a novel linear o-phenanthroline-based polymer l-PRL was successfully synthesized by chemical oxidative polymerization. The obtained l-PRL adsorbent features a preeminent acidic resistance, desirable removal performance remarkable adsorption selectivity and in the capture of aqueous Ag(Ⅰ), achieving a maximum adsorption capacity of 325.8 mg/g at pH 0. Systematical characterizations of FT-IR, XPS and DFT calculations certified the N groups as binding sites to capture Ag(Ⅰ), and elucidated that the satisfactory selectivity of Ag(Ⅰ) was owing to the most stable complexes formed by l-PRL with Ag(Ⅰ). Furthermore, the l-PRL still retained an adsorption capacity of 93.5% after four regeneration cycles, and realized completely removal of Ag(Ⅰ) from the low-concentration Ag(Ⅰ)-containing industrial wastewater. Our study suggested that l-PRL as promising adsorbent presented great potentials to deal with the puzzles of the restoration of acidic Ag-containing wastewater.

Declaration of competing interestThe authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

AcknowledgmentsThis study was financially supported by the National Science Fund for Distinguished Young Scholars (No. 52125002), the National Science Foundation of China (No. 52100043), the National Key Research and Development Program of China (No. 2019YFC1907900), and the National Science Foundation of Jiangxi Province (No. 20202BABL213037).

Supplementary materialsSupplementary material associated with this article can be found, in the online version, at doi:10.1016/j.cclet.2022.04.083.

| [1] |

Z. Yao, P. Shao, D. Fang, et al., Chem. Eng. J. 427 (2022) 131470. DOI:10.1016/j.cej.2021.131470 |

| [2] |

M.R. Razanajatovo, W. Gao, Y. Song, et al., Chin. Chem. Lett. 32 (2021) 2637-2647. DOI:10.1016/j.cclet.2021.01.046 |

| [3] |

S.A. Ali, I.W. Kazi, N. Ullah, Ind. Eng. Chem. Res. 54 (2015) 9689-9698. DOI:10.1021/acs.iecr.5b02267 |

| [4] |

A. Almasian, M. Giahi, G. Fard, S.A. Dehdast, L. Maleknia, Chem. Eng. J. 351 (2018) 1166-1178. DOI:10.1016/j.cej.2018.06.127 |

| [5] |

Q. Huang, Y. Zhang, W. Zhou, et al., Chin. Chem. Lett. 32 (2021) 2797-2802. DOI:10.1016/j.cclet.2020.12.020 |

| [6] |

Q. Zhang, S. Bolisetty, Y. Cao, et al., Angew. Chem. Int. Ed. 131 (2019) 6073-6077. DOI:10.1002/ange.201901596 |

| [7] |

H. Ghassabzadeh, A. Mohadespour, M. Torab-Mostaedi, et al., J. Hazard. Mater. 177 (2010) 950-955. DOI:10.1016/j.jhazmat.2010.01.010 |

| [8] |

JJ. Hanzlık, J. Jehlička, O. Šebek, Z. Weishauptová, V. Machovič, Water Res. 38 (2004) 2178-2184. DOI:10.1016/j.watres.2004.01.037 |

| [9] |

X. Song, Y. Niu, Z. Qiu, et al., Fuel 206 (2017) 80-88. DOI:10.1016/j.fuel.2017.05.086 |

| [10] |

C.H. Yen, H.L. Lien, J.S. Chung, H.D. Yeh, J. Hazard. Mater. 322 (2017) 215-222. DOI:10.1016/j.jhazmat.2016.02.029 |

| [11] |

H. Musarurwa, N.T. Tavengwa, Carbohyd. Polym. 237 (2020) 116142. DOI:10.1016/j.carbpol.2020.116142 |

| [12] |

X. Song, C. Li, R. Xu, K. Wang, Ind. Eng. Chem. Res. 51 (2012) 11261-11265. DOI:10.1021/ie3010989 |

| [13] |

A.M. Donia, A.M. Yousif, A.A. Atia, M.F. Elsamalehy, Desalin. Water Treat. 52 (2014) 2537-2547. DOI:10.1080/19443994.2013.794706 |

| [14] |

P. Liu, H. Sehaqui, P. Tingaut, et al., Cellulose 21 (2013) 449-461. |

| [15] |

H. Chen, Y. Zhou, J. Wang, J. Lu, Y. Zhou, J. Hazard. Mater. 389 (2020) 121897. DOI:10.1016/j.jhazmat.2019.121897 |

| [16] |

W. Zhao, Y. Huang, R. Chen, et al., React. Funct. Polym. 163 (2021) 104899. DOI:10.1016/j.reactfunctpolym.2021.104899 |

| [17] |

X. Sheng, H. Shi, D. You, et al., Chem. Eng. J. 437 (2022) 135367. DOI:10.1016/j.cej.2022.135367 |

| [18] |

Y. He, Q. Liu, F. Liu, et al., Micropor. Mesopor. Mat. 233 (2016) 10-15. DOI:10.1016/j.micromeso.2016.06.024 |

| [19] |

G. Nie, S. Qiu, X. Wang, et al., Chin. Chem. Lett. 32 (2021) 2342-2346. DOI:10.1016/j.cclet.2020.12.014 |

| [20] |

H. Yu, P. Shao, L. Fang, et al., Chem. Eng. J. 359 (2019) 176-185. DOI:10.1016/j.cej.2018.11.149 |

| [21] |

J. Ryu, M.Y. Lee, M.G. Song, et al., Sep. Purif. Technol. 250 (2020) 117120. DOI:10.1016/j.seppur.2020.117120 |

| [22] |

Z. Yang, X. Huang, X. Yao, H. Ji, J. Appl. Polym. Sci. 135 (2018) 45568. DOI:10.1002/app.45568 |

| [23] |

A. Nowik-Zajac, I. Zawierucha, C. Kozlowski, RSC Adv. 9 (2019) 31122-31132. DOI:10.1039/C9RA04347K |

| [24] |

X. Yang, Z. Dong, M. Zhang, L. Zhao, J. Chem. Eng. Data 65 (2020) 1919-1926. DOI:10.1021/acs.jced.9b01107 |

| [25] |

A. Bencini, V. Lippolis, Coord. Chem. Rev. 254 (2010) 2096-2180. DOI:10.1016/j.ccr.2010.04.008 |

| [26] |

J.R. Nair, I. Shaji, N. Ehteshami, et al., Chem. Mater. 31 (2019) 3118-3133. DOI:10.1021/acs.chemmater.8b04172 |

| [27] |

X. Cui, H. Liu, X. Zhang, H. Liu, Chin. Chem. Lett. 32 (2021) 1135-1138. DOI:10.1016/j.cclet.2020.08.043 |

| [28] |

L. Xie, Z. Yu, S.M. Islam, et al., Adv. Funct. Mater. 28 (2018) 1800502. DOI:10.1002/adfm.201800502 |

| [29] |

M. Yuan, H. Yao, L. Xie, et al., J. Am. Chem. Soc. 142 (2020) 1574-1583. DOI:10.1021/jacs.9b12196 |

| [30] |

K.Y. Shin, J.Y. Hong, J. Jang, J. Hazard. Mater. 190 (2011) 36-44. DOI:10.1016/j.jhazmat.2010.12.102 |

| [31] |

P. Wang, M. Du, H. Zhu, et al., J. Hazard. Mater. 286 (2015) 533-544. DOI:10.1016/j.jhazmat.2014.12.034 |

| [32] |

L. Ding, P. Shao, Y. Luo, et al., Chem. Eng. J. 382 (2020) 123009. DOI:10.1016/j.cej.2019.123009 |

| [33] |

J.W. Lee, S. Jung, T.W. Lee, et al., Adv. Energy Mater. 9 (2019)1901978. |

| [34] |

M.D. Segall, R. Shah, C.J. Pickard, M.C. Payne, Phys. Rev. B 54 (1996) 16317-16320. DOI:10.1103/PhysRevB.54.16317 |

| [35] |

X. Li, S. Deng, X. Xie, J. Taiwan Inst. Chem. Eng. 45 (2014) 1865-1875. DOI:10.1016/j.jtice.2013.10.007 |

| [36] |

Y. Huang, W. Zhao, X. Zhang, H. Peng, Y. Gong, Chem. Eng. J. 375 (2019) 121935. DOI:10.1016/j.cej.2019.121935 |

| [37] |

T. Hou, L. Yan, J. Li, et al., Chem. Eng. J. 384 (2020) 123331. DOI:10.1016/j.cej.2019.123331 |

| [38] |

L. Darmayanti, G.T.M. Kadja, S. Notodarmojo, E. Damanhun, R.R. Mukti, J. Hazard. Mater. 377 (2019) 305-314. DOI:10.1016/j.jhazmat.2019.05.086 |

| [39] |

L. Ma, Q. Wang, S.M. Islam, et al., J. Am. Chem. Soc. 138 (2016) 2858-2866. DOI:10.1021/jacs.6b00110 |

| [40] |

Q. Zhang, Y. Peng, F. Deng, M. Wang, D. Chen, Sep. Purif. Technol. 246 (2020) 116890. DOI:10.1016/j.seppur.2020.116890 |

| [41] |

J. Chen, Miner. Eng. 171 (2021) 107067. DOI:10.1016/j.mineng.2021.107067 |

| [42] |

F. Allegretti, S. O'Brien, M. Polcik, D.I. Sayago, D.P. Woodruff, Phys. Rev. Lett. 95 (2005) 226104. DOI:10.1103/PhysRevLett.95.226104 |

2023, Vol. 34

2023, Vol. 34