b Lanzhou University Second Hospital, Lanzhou 730030, China;

c Minzu University of China, Beijing 100081, China

Real-time imaging of single cells has become an essential analytical method [1, 2] for understanding cell biological phenomena [3, 4] and cell behavior [5, 6]. As an important tool for single-cell analysis [7], microfluidic chips have made significant advancements in single-cell research, such as single-cell sorting [8, 9], genome sequencing [10, 11], proteomic analysis [12], ions analysis [13], enzyme activity measurement [14], as well as facilitated the development of single-cell culture [15] and imaging [16].

Chip-based high-throughput single-cell trapping, as the premise and foundation of single-cell culture and imaging, has made significant breakthroughs in recent years [17]. The chip used for high-throughput single-cell trapping is generally combined with the external forces and array microstructures [18, 19], such as the microwells [20, 21], microchambers [22, 23], and microdams [24, 25], which have been designed to achieve batch capture of single cells. The most widely used method is the combination of hydrodynamic force and array microstructure [20-26], which used the microdam array to intercept the flowing single-cells [24, 25] or microwell array to capture the settling single-cells [20, 21]. Thereafter, the uncaptured cells are flushed out by the fluid. Although this method has a high single-cell capture rate, the cell utilization rate is low, and the pump and pressure control system increase the complexity of single-cell trapping. Other methods, such as the combination of dielectric force [27], suction force [28], or centrifugal force [29] with microwell arrays, are also commonly used for single-cell high-throughput trapping. The application of an external force shortens the time of capture, but also increases the complexity.

With the development of high-throughput single-cell trapping, improvements have been made in the application of microarrays to single-cell on-chip culture [30] and single-cell imaging [31]. To realize single-cell real-time imaging, it is necessary to realize single-cell culture without a CO2 incubator. Recently, open chips are easy to operate, but need to rely on a mature CO2 incubator to maintain a single-cell living environment [29]. Bonded or closed chips often employ perfusion flow for continuous culture of single cells [32]. This method is suitable for continuous on-chip culture of single cells without a CO2 incubator, but has operational complexity. Moreover, the closed design is challenging to be used for the subsequent single-cell operation. Although the application of microarrays for single-cell real-time imaging has been proposed [33], it has not been well applied in recent years due to the constraints of high-throughput single-cell trapping and the complexity of incubator-free on-chip culture. The chip for single-cell high-resolution imaging is mainly limited by the selection of chip substrate and chip preparation as the thickness of the chip substrate (0.13-0.17 mm) is strict. Furthermore, the thickness of the poly (dimethylsiloxane) (PDMS) substrate is difficult to control, and the ultrathin PDMS substrate is soft, which is not suitable for the chip substrate. Therefore, altogether simplifying the steps of high-throughput trapping and on-chip culture of single cells, choosing a simple and suitable chip preparation method, and improving the environment of continuous culture of open chips are the keys to realizing real-time high-resolution imaging of single cells.

In this study, an ultra-thin temperature-controllable microwell array chip (UTCMA chip) was designed to develop a living single-cell workstation that successfully realized continuous real-time high-resolution observation of single-cell behavior. One-step high-throughput single-cell patterning was achieved in the microwell array using a hydrophilic glass bottom plate and hydrophobic SU-8 photoresist wall. The cell utilization rate, single-cell capture rate, and microwell occupancy rate were close to 100% in the microwell array. Moreover, the open design of the chip provides the possibility of single-cell-related manipulation.

To achieve continuous real-time high-resolution imaging of living single cells outside the CO2 incubator, a living single-cell workstation was designed and built in this study (Fig. S1 in Supporting information). This workstation is mainly composed of imaging equipment, a UTCMA chip, a home-made temperature control device, an aseptic operating space, an atmosphere supply device, to provide conditions for high-throughput single-cell trapping, the continuous on-chip culture outside the CO2 incubator, and high-resolution imaging. At the same time, the workstation had sufficient space for the construction of the microoperation system.

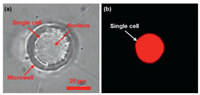

The overall design of the chip is shown in Fig. 1a. Ultra-thin ITO glass was used as the bottom plate of the chip, ensuring constant temperature for single cells in the chip culture even when the chip was absent from the CO2 incubator for an extended period. Simultaneously, the chip substrate is highly matched with a high-magnification (100× oil lens) inverted fluorescence microscope or fluorescence confocal microscope, which can be used for real-time high-resolution imaging of single cells and tracking the genetic material, protein, metabolites. The microwell array of the chip (Fig. 1b) uses hydrophilic glass as the bottom plate and hydrophobic SU-8 photoresist as the wall, which can realize one-step high-throughput single-cell patterning by controlling the number of seeding cells according to its own gravity and hydrophilicity. Compared with other single-cell trapping methods, this method does not require an additional pump and pressure control system, external force and chip modification, or the washing of excess cells on the chip. It reduces the damage to cells caused by external forces and ensures the activity of cells to the greatest extent. Moreover, this method greatly simplifies the steps of single-cell high-throughput patterning, with the added advantage of easy operation and high reproducibility. Thus, this method is very friendly to researchers without experienced operations, promoting the popularization of chips for single-cell research. Furthermore, each of the microwells is digitally encoded in the array (Figs. 1c and d) so that single cells could be accurately located. The same single cell could be quickly found in the microwell when multiple images were taken at different time points, which solves the problem that the same single cell could not be found due to cell division or migration when cells were cultured on the plane.

|

Download:

|

| Fig. 1. The design and fabrication of the UTCMA chip. (a) The overall design of the chip. (b) Schematic diagrams of 7 × 7 arrays present on the chip. (c) 10 × 10 microwells contained in each array of the chip. (d) Schematic close-up of microwells. A is the cross-section of the chip. | |

After the fabrication of the chip bottom plate with the microwell array, the surface ITO film still exists, which indicates that the chip fabrication process has little effect on the ITO layer. The double-sided conductive copper foil (Fig. S2 in Supporting information) pasted on one of the opposite edges of the chip bottom plate solved the problem of electric field inhomogeneity when the voltage was directly applied to the ITO glass in a point shape, which resulted in uneven heating of the ITO glass. A home-made temperature control device was used to apply the voltage to the copper foil (Fig. S3 in Supporting information). The voltage was applied to the chip bottom plate in a linear manner, and the chip bottom plate was heated evenly, thus successfully controlling the temperature of the chip. Finally, PDMS strips were made to create a fence on the bottom plate of the chip. The chip adopts an open design to avoid the problem that the bonded chip, which often adds complexity when single-cell operations. Also, sufficient space conditions are provided for the operation of single cells in living cell workstations, such as for electrochemical detection of single cells using electrodes, intracellular delivery of single cells by nanopipettes, and the selection of single cells.

The UTCMA chip will have broad application prospects in single-cell research. Moreover, the chip fabrication process is simple (Fig. S4 in Supporting information), increasing its likelihood for commercialization. The chip can be used as the substrate of matrix-assisted laser desorption/ionization mass spectrometry to realize rapid single-cell detection. It can also be made into a Petri dish based on the UTCMA glass substrate to achieve continuous real-time imaging of a single cell. In addition, the ITO film and copper foil of the chip can also be redesigned to produce an ultra-thin microwell array glass bottom plate for Petri dishes, which can be combined with a commercial cell workstation to observe single-cell behavior. Overall, this method is a powerful tool for research at the single-cell level.

Human lung carcinoma A549 cells (Cell line name: A549-mCherry) (Fig. S5 in Supporting information) were selected in this study as most of the single cells could express a red fluorescent protein, thereby simplifying observation based on the bright field mode, whereas the fluorescence mode was used in imaging processing under the inverted fluorescence microscope.

Cells at a certain concentration were planked and cultured on the microwell array (Figs. 2a-c) of the UTCMA chip. After 24 h of culture, single cells tended to grow in the microwells, whereas fewer cells grew outside the microwell (Fig. S6 in Supporting information). As the bottom plate of the microwell was made of glass, and the wall was made of SU-8 photoresist, single cells were more inclined to grow on glass related to their hydrophilicity. At the same time, this phenomenon was closely related to the number of planked cells. As the number of the planked cells increased, the occupancy rate of microwells and the cell utilization rate also gradually increased (Fig. S7 in Supporting information). When the volume of the cell suspension was ~20 µL (at a concentration of 106/mL), single-cell high-throughput patterning could be realized in one step on the microwell array. The cell utilization rate, single-cell capture rate, and microwell occupancy rate were all close to 100%. When the number of planked cells was far lower, single cells still grew in the microwells, but there were no single cells in some microwells, which led to a decrease in the occupancy rate of the microwells.

|

Download:

|

| Fig. 2. The schematic diagram of one-step patterning, on-chip culture, and high-resolution imaging of living single cells. (a) Culture medium added to the chip. (b) An appropriate amount of cell suspension is dropped into the medium on the chip. (c) One-step patterning of living single cells. (d) The chip is connected to a home-made temperature control device in a living cell workstation. (e) Continuous real-time high-resolution imaging of single cells. | |

When the number of planked cells far exceeded the number of microwells, the cells grew outside the microwells. Therefore, it is necessary to control the number of planked cells to ensure single-cell culture and observation. With the prolongation of culture time in the incubator, it was found that single cells in the microwells divided and formed a cell community centered on the microwells. Interestingly, there was communication between the different communities, as well as observing a phenomenon of community convergence. In addition, it was found that a small number of single cells or single-cell communities migrated short distances during the culture process relative to their initial position or function on the chip. After several days of continuous culture, the single cells were still in good condition (Fig. 3), indicating that the prepared chips could be used for long-term culture of single cells. Taken together, these findings provide technical support for on-chip culture, observation, and operation of single cells outside the incubator.

|

Download:

|

| Fig. 3. One-step patterning and on-chip culture of single cells over time in a UTCMA chip. Images are obtained under bright field mode (a, c, e) and TRITC fluorescence mode (b, d, f). All images have the same scale. | |

After single-cell patterning, the chip with a single cell was placed in the living cell workstation and connected to the temperature control device (Fig. 2d). Continuous real-time high-resolution imaging was performed for 3 h using a 100× oil lens (Fig. 2e). The results showed that the nucleus and cytoplasm of single cells in the microwell could be clearly observed in the bright field mode (Fig. 4), which enables tracking the changes in cell substances, such as genes, proteins, lipids, and metabolites at the single-cell level. After initial observation, the culture time of single cells in the microwells was extended with good overall survival (Fig. S8 in Supporting information). The single cells incubated in the chip were stained by trypan blue (Fig. S9 in Supporting information), which shows the single cells have good cell activity. Therefore, it can be shown that the microenvironment of the live single-cell workstation is suitable for the continuous culture and real-time high-resolution imaging of single cells outside the CO2 incubator.

|

Download:

|

| Fig. 4. High-resolution imaging of single cell in a microwell. Images were obtained under bright field mode (a) and TRITC fluorescence mode (b). Both images have the same scale. | |

In summary, a set of living single-cell workstation based on UTCMA chip was built in this study, to highlight the successful on-chip culture and real-time high-resolution imaging of living single cells. The microwell array on the chip used hydrophilic glass as the bottom plate and hydrophobic SU-8 photoresist as the wall. Single-cell high-throughput patterning was completed in one step. The cell utilization rate, single-cell capture rate, and microwell occupancy rate were close to 100%. This method can be used for real-time high-resolution tracking of changes in ions, DNA, proteins, and metabolites in rare living single cells. The open design of the chip provides space conditions for various single-cell operations, including in situ electrochemical detections of single cells by electrodes, and intracellular delivery of single cells by nanopipettes. Therefore, this method will have important applications in single-cell based disease diagnosis, antibody discovery, and drug screening.

Declaration of competing interestThe authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

AcknowledgmentsThis work was supported by the National Natural Science Foundation of China (Nos. 21625501, 21936001) and the Beijing Outstanding Young Scientist Program (No. BJJWZYJH01201910005017).

| [1] |

A. Maxmen, Nature 480 (2011) 139-141. DOI:10.1038/nj7375-139a |

| [2] |

S. Iwano, M. Sugiyama, H. Hama, et al., Science 359 (2018) 935-939. DOI:10.1126/science.aaq1067 |

| [3] |

H.M. Eilken, S. Nishikawa, T. Schroeder, Nature 457 (2009) 896-900. DOI:10.1038/nature07760 |

| [4] |

H. Kondo, C.D.H. Ratcliffe, S. Hooper, et al., Cell Rep. 34 (2021) 108750. DOI:10.1016/j.celrep.2021.108750 |

| [5] |

K. McDole, L. Guignard, F. Amat, et al., Cell 175 (2018) 859-876. DOI:10.1016/j.cell.2018.09.031 |

| [6] |

M. Liu, F. Wang, X. Zhang, et al., Nature Protocols 16 (2021) 383-404. DOI:10.1038/s41596-020-00420-1 |

| [7] |

J. Wu, Z. He, Q. Chen, J.M. Lin, Trends Anal. Chem. 80 (2016) 213-231. DOI:10.1016/j.trac.2016.03.013 |

| [8] |

H. Zhang, W. Ding, S. Li, et al., Talanta 220 (2020) 121351. DOI:10.1016/j.talanta.2020.121351 |

| [9] |

P. Li, Y. Ai, Anal. Chem. 93 (2021) 4108-4117. DOI:10.1021/acs.analchem.0c05352 |

| [10] |

F. Lan, B. Demaree, N. Ahmed, A.R. Abate, Nat. Biotechnol. 35 (2017) 640-646. DOI:10.1038/nbt.3880 |

| [11] |

Z. Jia, H. Yuan, X. Zhao, et al., Talanta 226 (2021) 122172. DOI:10.1016/j.talanta.2021.122172 |

| [12] |

Z.Y. Li, M. Huang, X.K. Wang, et al., Anal. Chem. 90 (2018) 5430-5438. DOI:10.1021/acs.analchem.8b00661 |

| [13] |

L. Li, Y. Fan, Q. Li, et al., Anal. Chem. 89 (2017) 4559-4565. DOI:10.1021/acs.analchem.6b05045 |

| [14] |

X.L. Guo, Y. Wei, Q. Lou, Y. Zhu, Q. Fang, Anal. Chem. 90 (2018) 5810-5817. DOI:10.1021/acs.analchem.8b00343 |

| [15] |

T. Xie, N. Li, S. Mao, Q. Zhang, J.M. Lin, ACS Omega 5 (2020) 3857-3862. DOI:10.1021/acsomega.9b03074 |

| [16] |

Q. Zhang, Y. Shao, B. Li, et al., Chem. Sci. 12 (2021) 4111-4118. DOI:10.1039/D0SC05534D |

| [17] |

Q. Luan, C. Macaraniag, J. Zhou, I. Papautsky, Biomicrofluidics 14 (2020) 031502. DOI:10.1063/5.0002866 |

| [18] |

H. Yin, D. Marshall, Curr. Opin. Biotechnol. 23 (2012) 110-119. DOI:10.1016/j.copbio.2011.11.002 |

| [19] |

C. Honrado, P. Bisegna, N.S. Swami, F. Caselli, Lab Chip 21 (2021) 22-54. DOI:10.1039/D0LC00840K |

| [20] |

S. Yamamura, H. Kishi, Y. Tokimitsu, et al., Anal. Chem. 77 (2005) 8050-8056. DOI:10.1021/ac0515632 |

| [21] |

J. Breukers, S. Horta, C. Struyfs, et al., ACS Appl Mater Interfaces 13 (2021) 2316-2326. DOI:10.1021/acsami.0c19657 |

| [22] |

S. Kobel, A. Valero, J. Latt, P. Renaud, M. Lutolf, Lab Chip 10 (2010) 857-863. DOI:10.1039/b918055a |

| [23] |

W. Zhang, R. Li, F. Jia, et al., Lab Chip 20 (2020) 4043-4051. DOI:10.1039/D0LC00847H |

| [24] |

D.D. Carlo, N. Aghdam, L.P. Lee, Anal. Chem. 78 (2006) 4925-4930. DOI:10.1021/ac060541s |

| [25] |

Y. Li, D. Motschman J, S.T. Kelly, B.B. Yellen, Anal. Chem. 92 (2020) 2794-2801. DOI:10.1021/acs.analchem.9b05099 |

| [26] |

K. Wang, L. Zhou, S. Zhao, et al., Talanta 200 (2019) 169-176. DOI:10.1016/j.talanta.2019.03.035 |

| [27] |

Y. Wu, Y. Ren, Y. Tao, L. Hou, H. Jiang, Anal. Chem. 90 (2018) 11461-11469. DOI:10.1021/acs.analchem.8b02628 |

| [28] |

Z. Dong, Y. Jiao, B. Xie, et al., Microsyst. Nanoeng. 6 (2020) 2. DOI:10.1038/s41378-019-0112-z |

| [29] |

L. Huang, Y. Chen, W. Huang, H. Wu, Lab Chip 18 (2018) 1113-1120. DOI:10.1039/C7LC01131H |

| [30] |

J. Zhai, H. Li, A.H.H. Wong, et al., Microsyst. Nanoeng. 6 (2020) 6. DOI:10.1038/s41378-019-0109-7 |

| [31] |

R.A.M. Ali, D. Mita, W. Espulgar, et al., Micromachines 11 (2020) 52. DOI:10.3390/mi11010052 |

| [32] |

I. Inoue, Y. Wakamoto, H. Moriguchi, et al., Lab Chip 1 (2001) 50-55. DOI:10.1039/b103931h |

| [33] |

C. Zheng, L. Zhao, G. Chen, Y. Zhou, Y. Pang, Anal. Chem. 84 (2012) 2088-2093. DOI:10.1021/ac2032029 |

2021, Vol. 32

2021, Vol. 32