Nitrogen-containing compounds are widely existed in many natural products, pharmaceutics, and functional materials [1, 2]. So far, the main methods for the construction of the C-N bond have been represented by Ullmann and Buchwald-Hartwig amination, using copper or palladium as catalyst [3-6]. Despite the fact that these means are well developed and widely applied, aryl halides or complex ligands are required in most cases. Recently, the direct C-H amination of the aromatic ring and the redox amine source has been developed. The common redox amine sources [7-9], include imidoiodine [10, 11], organic azide [12-21], hydroxamate [22-24], heterocyclic amines [25-33]. Among which, dioxazolones are used as effective amidation reagents to construct C-N bonds due to their high efficiency, safety, and ease of preparation [28, 33, 34].

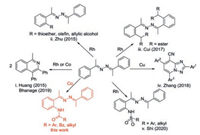

Azine is an important nitrogen-containing compound, which is widely used in pesticides, medicine, functional materials and other fields [35-40]. Nowadays, direct C-H bond functionalization has been established to build various azine derivatives. Rh(Ⅲ)-catalyzed ortho-alkenylation [41], ortho-thioetherification and ortho-allylation [42, 43], ortho-alkylation [44] of azines have been respectively developed by Huang, Zhu and our group (Scheme 1, i-v). Bhanage's group [45] utilized a relatively inexpensive cobalt as a catalyst to achieve the cyclization reaction of azines with two molecules of alkyne through N-N bond cleavage, to synthesize a series of polysubstituted isoquinolines (Scheme 1, i). Subsequently, Shi [46] first developed rhodium-catalyzed ortho-C-H sulfamidation of azines and obtained the corresponding sulfamidated products with high regioselectivity. Nevertheless, equivalent oxidant was required (Scheme 1, v). Based on the relevant reports [47-52] and the importance of azines, cobalt-catalyzed directed C-H amidation of azines should be attractive and feasible. In continuation of our ongoing exploration of redox C-H amidation [26, 30, 53], herein, we report Co-catalyzed amidation of azines with dioxazolones via direct C-H activation. This transformation could be carried out smoothly without additional oxidant, acid or base. And, CO2 is released as the sole byproduct, thus providing an environmentally benign amidation process.

|

Download:

|

| Scheme 1. Direct functionalization of azines by transition metal catalysis. | |

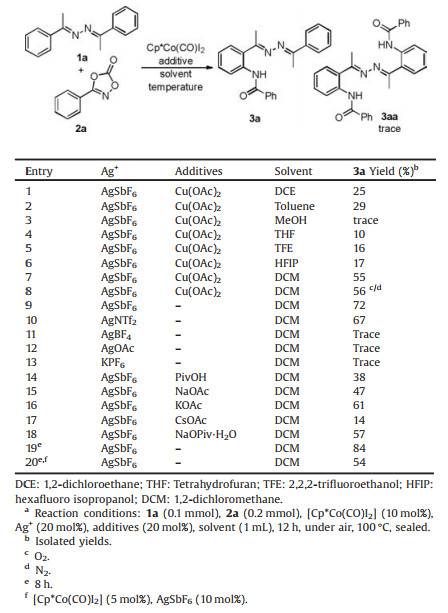

First, we investigated the direct C-H amination with acetophenazine 1a and dioxazolone 2a as the model substrates (Table 1). Inaninitial setofexperiment, the expected ortho-amided product 3a was obtained in 25% isolated yield in the presence of [Cp*Co(CO)I2] (10 mol%), AgSbF6 (20 mol%), and Cu(OAc)2 (20 mol%) in DCE at 80 ℃ for 12 h (entry 1). Due to the solubility of the substrates, we initiated our studies by examining the effects of the solvent. And DCM was found to be optimal (entries 1-7). The yield was almost unaffected under air, N2, O2, respectively. So we decided to conduct the reaction at air atmosphere (entry 8). Considering the redox property of dioxazolone, we tried to avoid the use of Cu(OAc)2 as oxidant.Surprisingly, theyieldwasincreasedfrom55% to72% (entry 9). Afterward, the effect of silver salt was investigated (such as AgSbF6, AgNTf2, AgBF4, AgOAc) (entries 9-12), and AgSbF6 gave the better result. However, the corresponding product was not obtained when the silver saltwas replaced with KPF6 (entry 13).Subsequently, some additives were screened (entries 14-18), and yield was slightly reduced compared to the yield in the absence of any additives. It was noting that the desired product 3a could be obtained in 84% yield when the reaction time was decreased to 8 h because the formation of di-substituted amination as by-product 3aa was reduced (entry 19). Reducing the amount of catalyst to 5 mol%, only 54% of product 3a was obtained (entry 20). Finally, the optimal reaction conditions were determined as follows: [Cp*Co(CO)I2] (10 mol%), AgSbF6 (20 mol%), in 1 mL DCM under air atmosphere at 100 ℃ for 8 h.

|

|

Table 1 Optimization of direct amidation conditions.a |

With the optimized conditions in hand, the scope of azines was next examined (Scheme 2). The coupling of dioxazolone (2a) and para-substituted azines 1b-1c with electron-donating groups (-Me and -OMe) was found to react smoothly more than para-substituted azines 1h with electron withdrawing groups (COOMe). The 4-halo azines (1d-1g) reacted with the dioxazolone to give the target products in moderate to good yields, significantly better than 3-halo azines (1i-1k). For the same substituent, the overall yields of 4-substituted products (3b-3f, 58%-81%) were significantly higher than that of 3-substituted products (3i-3m, 48%- 62%). The reaction of 1p was sluggish and only 18% product 3p was obtained. Surprisingly, 3n was afforded in 76% yield with good regioselectivity. In a similar fashion, 1, 2-bis((E)-3, 4-dihydronaphthalen-1(2H)-ylidene) hydrazine 1o and bis(ferrocenyl acetone) hydrazine 1p were also tolerated. Moreover, dibenzaldehyde hydrazine provided the amidated product 3q in 56% yield.

|

Download:

|

| Scheme 2. Scope of azines. Reaction conditions: 1a (0.1 mmol), 2a (0.2 mmol), [Cp*Co(CO)I2] (10 mol%), AgSbF6 (20 mol%), DCM (1 mL), 8 h, 100 ℃, sealed. Isolated yields. | |

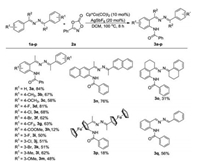

To further examine the substrate scope of this procedure, a series of dioxazolones (2a-2t) were screened for coupling with acetophenazine 1a (Scheme 3). Both electron-donating (e.g., Me, MeO) and electron-withdrawing groups (e.g., F, Cl, Br, CF3, 3, 5-diCl) in benzene were compatible with this reaction protocol. Dioxazolones bearing electron-withdrawing substituents on the aromatic ring were generally more efficient, giving the desired amidated product in relatively higher yields. Importantly, halides, such as chloride (4d, 4h, 4m and 4n), bromide (4i), could survive under the optimized conditions, giving the desired products in 58%-85% yields. Furthermore, thiophene- and naphthalenefunctionalized dioxazolones also reacted smoothly to afford products 4o and 4p in 70% and 75% yields, respectively. Nevertheless, aliphatic dioxazolone, such as 2r, was not amenable to this protocol. The yield of the corresponding products (4t, 62%; 4q, 41%; 4s, 28%) decreased along with increasing the steric hindrance for aliphatic-dioxazolone (2t, 2q, 2s).

|

Download:

|

| Scheme 3. Scope of dioxazolones. Reaction conditions: 1a (0.1 mmol), 2a (0.2 mmol), [Cp*Co(CO)I2] (10 mol%), AgSbF6 (20 mol%), DCM (1 mL), 8 h, under air, 100 ℃, sealed. Isolated yields. | |

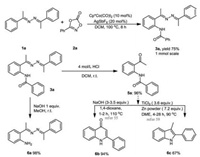

To demonstrate the practical application of the amidation reaction, a scaling up experiment was carried out with 1 mmol scale of acetophenazine 1a, which successfully afforded the aminated product 3a in 75% under the optimal reaction conditions (Scheme 4). The product 3a could be hydrolyzed, treated by 1 equiv. of sodium hydroxide in methanol, to obtain 6a in 98% yield. Similarly, 3a was stirred in 4 mol/L hydrochloric acid solution in DCM at room temperature to give the hydrolysis product 5a in 96% yield. According to the literature, 5a could be easily transformed to the corresponding biologically active 2-phenyl-4-quinolinone (6b) [54-57] and 3-methyl-2-phenylindole (6c) [58-60].

|

Download:

|

| Scheme 4. Scale-up experiment and transformations of the amidated product. | |

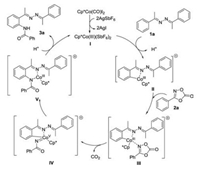

Based on the above results and previous reports [61, 62], a plausible reaction mechanism was proposed (Scheme 5). Firstly, the reactive cationic Cp*CoⅢ species I was generated with the assistance of AgSbF6. Subsequently, Cp*CoⅢ species I coordinated to nitrogen atom of the substrate 1a, and formed cobaltacycle Ⅱ through C-H bond cleavage. Cobaltacycle Ⅱ subsequently coordinated with nitrogen atom of 2a to form intermediate Ⅲ. Next, nitrogen carbine intermediate Ⅳ was afforded by extrusion of CO2 as a single byproduct. Subsequently, migratory insertion of intermediate Ⅳ provided the intermediate Ⅴ. Finally, protondemetallization of intermediate Ⅴ liberated the desired product 3a along with the regeneration of the active catalyst into the next cycle.

|

Download:

|

| Scheme 5. Proposed reaction mechanism. | |

In summary, we have developed an efficient and convenient cobalt(Ⅲ)-catalyzed C-H amidation of azines with dioxazolones. The method could be scalable and compatible with a broad range of functional groups. The results have paved the way toward construction of 2-phenyl-4-quinolinone and 3-methyl-2-phenylindole derivatives, which exist in drug molecule with broad anti-infection, anti-tumor, anti-inflammatory and other biological activities.

Declaration of competing interestNo conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors.

AcknowledgmentsThis work was financially supported by the Ministry of Science and Technology of China (No. 2016YFE0132600), Henan Center for Outstanding Overseas Scientists (No. GZS2020001).

Appendix A. Supplementary dataSupplementary material related to this article can be found, in the online version, at doi:https://doi.org/10.1016/j.cclet.2020.08.046.

| [1] |

T. Naito, Chem. Pharm. Bull. 56 (2008) 1367-1383. DOI:10.1248/cpb.56.1367 |

| [2] |

Y. Wu, B. Tian, C. Hu, et al., Org. Biomol. Chem. 17 (2019) 5505-5508. DOI:10.1039/C9OB00740G |

| [3] |

C. Sambiagio, S.P. Marsden, A.J. Blacker, P.C. McGowan, Chem. Soc. Rev. 43 (2014) 3525-3550. DOI:10.1039/C3CS60289C |

| [4] |

S. Bhunia, G.G. Pawar, S.V. Kumar, Y. Jiang, D. Ma, Angew. Chem. Int. Ed. 56 (2017) 16136-16179. DOI:10.1002/anie.201701690 |

| [5] |

C. Torborg, M. Beller, Adv. Synth. Catal. 351 (2009) 3027-3043. DOI:10.1002/adsc.200900587 |

| [6] |

F. Monnier, M. Taillefer, Angew. Chem. Int. Ed. 48 (2009) 6954-6971. DOI:10.1002/anie.200804497 |

| [7] |

Y. Park, Y. Kim, S. Chang, Chem. Rev. 117 (2017) 9247-9301. DOI:10.1021/acs.chemrev.6b00644 |

| [8] |

Y. Park, K.T. Park, J.G. Kim, S. Chang, J. Am. Chem. Soc. 137 (2015) 4534-4542. DOI:10.1021/jacs.5b01324 |

| [9] |

Y. Park, S. Jee, J.G. Kim, S. Chang, Org. Process Res. Dev. 19 (2015) 1024-1029. DOI:10.1021/acs.oprd.5b00164 |

| [10] |

J.A. Souto, P. Becker, Á. Iglesias, K. Muñiz, J. Am. Chem. Soc. 134 (2012) 15505-15511. DOI:10.1021/ja306211q |

| [11] |

C. You, T. Yuan, Y. Huang, et al., Org. Biomol. Chem. 16 (2018) 4728-4733. DOI:10.1039/C8OB01108G |

| [12] |

K. Shin, H. Kim, S. Chang, Acc. Chem. Res. 48 (2015) 1040-1052. DOI:10.1021/acs.accounts.5b00020 |

| [13] |

C. Pi, X. Cui, Y. Wu, J. Org. Chem. 80 (2015) 7333-7339. DOI:10.1021/acs.joc.5b01377 |

| [14] |

J.Y. Kim, S.H. Park, J. Ryu, et al., J. Am. Chem. Soc. 134 (2012) 9110-9113. DOI:10.1021/ja303527m |

| [15] |

S.H. Park, J. Kwak, K. Shin, et al., J. Am. Chem. Soc. 136 (2014) 2492-2502. DOI:10.1021/ja411072a |

| [16] |

L. Jie, L. Wang, D. Xiong, et al., J. Org. Chem. 83 (2018) 10974-10984. DOI:10.1021/acs.joc.8b01618 |

| [17] |

Y. Feng, Y. Li, Y. Yu, L. Wang, X. Cui, RSC Adv. 8 (2018) 8450-8454. DOI:10.1039/C8RA00524A |

| [18] |

L. Xu, L. Wang, Y. Feng, et al., Org. Lett. 19 (2017) 4343-4346. DOI:10.1021/acs.orglett.7b02028 |

| [19] |

Y. Li, Y. Feng, L. Xu, L. Wang, X. Cui, Org. Lett. 18 (2016) 4924-4927. DOI:10.1021/acs.orglett.6b02406 |

| [20] |

B. Zhu, X. Cui, C. Pi, D. Chen, Y. Wu, Adv. Synth. Catal. 358 (2016) 326-332. DOI:10.1002/adsc.201501036 |

| [21] |

Y. Feng, Z. Zhang, Q. Fu, et al., Chin. Chem. Lett. 31 (2020) 58-60. DOI:10.1016/j.cclet.2019.05.013 |

| [22] |

H. Jung, H. Keum, J. Kweon, S. Chang, J. Am. Chem. Soc. 142 (2020) 5811-5818. DOI:10.1021/jacs.0c00868 |

| [23] |

D. Dev, N.B. Palakurthy, K. Thalluri, J. Chandra, B. Mandal, J. Org. Chem. 79 (2014) 5420-5431. DOI:10.1021/jo500292m |

| [24] |

J. Senger, J. Melesina, M. Marek, et al., J. Med. Chem. 59 (2016) 1545-1555. DOI:10.1021/acs.jmedchem.5b01493 |

| [25] |

S. Huang, H. Li, X. Sun, L. Xu, L. Wang, X. Cui, Org. Lett. 21 (2019) 5570-5574. DOI:10.1021/acs.orglett.9b01902 |

| [26] |

L. Xu, T. Li, L. Wang, X. Cui, J. Org. Chem. 84 (2019) 560-567. DOI:10.1021/acs.joc.8b02396 |

| [27] |

X.H. Hu, X.F. Yang, T.P. Loh, ACS Catal. 6 (2016) 5930-5934. DOI:10.1021/acscatal.6b02015 |

| [28] |

J. Park, S. Chang, Angew. Chem. Int. Ed. 54 (2015) 14103-14107. DOI:10.1002/anie.201505820 |

| [29] |

Y. Park, K.T. Park, J.G. Kim, S. Chang, J. Am. Chem. Soc. 137 (2015) 4534-4542. DOI:10.1021/jacs.5b01324 |

| [30] |

X. Mi, W. Feng, C. Pi, X. Cui, J. Org. Chem. 84 (2019) 5305-5312. DOI:10.1021/acs.joc.9b00300 |

| [31] |

Y. He, C. Pi, Y. Wu, X. Cui, Chin. Chem. Lett. 31 (2020) 396-400. DOI:10.1016/j.cclet.2019.09.025 |

| [32] |

J. Ren, C. Pi, Y. Wu, X. Cui, Org. Lett. 21 (2019) 4067-4071. DOI:10.1021/acs.orglett.9b01246 |

| [33] |

N.K. Mishra, Y. Oh, M. Jeon, et al., Eur. J. Org. Chem. 2016 (2016) 4976-4980. DOI:10.1002/ejoc.201601096 |

| [34] |

K.M. van Vliet, B. de Bruin, ACS Catal. 10 (2020) 4751-4769. DOI:10.1021/acscatal.0c00961 |

| [35] |

G. Le Goff, J. Ouazzani, Bioorg. Med. Chem. 22 (2014) 6529-6544. DOI:10.1016/j.bmc.2014.10.011 |

| [36] |

L.M. Blair, J. Sperry, J. Nat. Prod. 76 (2013) 794-812. DOI:10.1021/np400124n |

| [37] |

Y. Zhu, H. Jin, Y. Huang, Chem. Commun. (Camb.) 55 (2019) 10135-10137. DOI:10.1039/C9CC05276C |

| [38] |

W. Tang, Y. Xiang, A. Tong, J. Org. Chem. 74 (2009) 2163-2166. DOI:10.1021/jo802631m |

| [39] |

C. Chakravarty, B. Mandal, P. Sarkar, J. Phys. Chem. C 122 (2018) 3245-3255. DOI:10.1021/acs.jpcc.7b11609 |

| [40] |

M.X. Wu, Y.W. Yang, Chin. Chem. Lett. 28 (2017) 1135-1143. DOI:10.1016/j.cclet.2017.03.026 |

| [41] |

W. Han, G. Zhang, G. Li, H. Huang, Org. Lett. 16 (2014) 3532-3535. DOI:10.1021/ol501483k |

| [42] |

J. Wen, A. Wu, M. Wang, J. Zhu, J. Org, Chem. 80 (2015) 10457-10463. |

| [43] |

J. Wen, A. Wu, Y. Miao, J. Zhu, Tetrahedron Lett. 56 (2015) 5512-5516. DOI:10.1016/j.tetlet.2015.08.025 |

| [44] |

Y. Yu, C. Kuai, R. Chauvin, et al., J. Org. Chem. 82 (2017) 8611-8616. DOI:10.1021/acs.joc.7b01472 |

| [45] |

D.S. Deshmukh, P.A. Yadav, B.M. Bhanage, Org. Biomol. Chem. 17 (2019) 3489-3496. DOI:10.1039/C9OB00174C |

| [46] |

H.M. Vu, J.Y. Yong, F.W. Chen, X.Q. Li, G.Q. Shi, J. Org. Chem. 85 (2020) 4963-4972. DOI:10.1021/acs.joc.0c00138 |

| [47] |

P.W. Tan, A.M. Mak, M.B. Sullivan, D.J. Dixon, J. Seayad, Angew. Chem. Int. Ed. 56 (2017) 16550-16554. DOI:10.1002/anie.201709273 |

| [48] |

J.S. Sun, M. Liu, J. Zhang, L. Dong, J. Org. Chem. 83 (2018) 10555-10563. DOI:10.1021/acs.joc.8b01354 |

| [49] |

J. Park, S. Chang, Angew. Chem. Int. Ed. 54 (2015) 14103-14107. DOI:10.1002/anie.201505820 |

| [50] |

Y. Liu, F. Xie, A.Q. Jia, X. Li, Chem. Commun. (Camb.) 54 (2018) 4345-4348. DOI:10.1039/C8CC01447G |

| [51] |

B. Khan, V. Dwivedi, B. Sundararaju, Adv. Synth. Catal. 362 (2020) 1195-1200. DOI:10.1002/adsc.201901267 |

| [52] |

J. Huang, J. Ding, T.M. Ding, et al., Org. Lett. 21 (2019) 7342-7345. DOI:10.1021/acs.orglett.9b02632 |

| [53] |

D.-G. Yu, M. Suri, F. Glorius, J. Am. Chem. Soc. 135 (2013) 8802-8805. DOI:10.1021/ja4033555 |

| [54] |

C. Brouwer, K. Jenko, S.S. Zoghbi, R.B. Innis, V.W. Pike, J. Med. Chem. 57 (2014) 6240-6251. DOI:10.1021/jm5007947 |

| [55] |

C.P. Jones, K.W. Anderson, S.L. Buchwald, J. Org. Chem. 72 (2007) 7968-7973. DOI:10.1021/jo701384n |

| [56] |

J. Huang, Y. Chen, A.O. King, et al., Org. Lett. 10 (2008) 2609-2612. DOI:10.1021/ol800837z |

| [57] |

C. Eidamshaus, T. Triemer, H.U. Reissig, Synthesis 2011 (2011) 3261-3266. DOI:10.1055/s-0030-1260198 |

| [58] |

A. Fuerstner, A. Hupperts, A. Ptock, E. Janssen, J. Org. Chem. 59 (1994) 5215-5229. DOI:10.1021/jo00097a024 |

| [59] |

A. Fuerstner, A. Hupperts, J. Am. Chem. Soc. 117 (1995) 4468-4475. DOI:10.1021/ja00121a004 |

| [60] |

A. Fürstner, D.N. Jumbam, Tetrahedron 48 (1992) 5991-6010. DOI:10.1016/S0040-4020(01)89848-3 |

| [61] |

Y. Liang, Y.F. Liang, C. Tang, Y. Yuan, N. Jiao, Chem. Eur. J. 21 (2015) 16395-16399. DOI:10.1002/chem.201503533 |

| [62] |

P. Shi, L. Wang, K. Chen, J. Wang, J. Zhu, Org. Lett. 19 (2017) 2418-2421. DOI:10.1021/acs.orglett.7b00968 |

2020, Vol. 31

2020, Vol. 31