b School of Horticulture and Plant Protection, Yangzhou University, Yangzhou 225009, China;

c State Key Laboratory Breeding Base of Green Pesticide and Agricultural Bioengineering, Key Laboratory of Green Pesticide and Agricultural Bioengineering, Ministry of Education, Research and Development Center for Fine Chemicals, Guizhou University, Guiyang 550025, China;

d Sichuan Selewood Technology Company Limited, Chengdu 610218, China;

e Department of Applied Chemistry, Faculty of Engineering, Kyushu Institute of Technology, Kitakyushu 804-8550, Japan

Chalcogen element-containing compounds and materials have very wide application scopes [1-3]. In the field, the selenium chemistry attracts comprehensive attention for the unique chemical- and bio-activities of the element. Selenium-containing compounds and materials are comprehensively employed as bioactive reagents in medicinal chemistry [4], as building blocks in organic synthesis [5-8], as catalysts in fine chemical production [9-14] and as the distinctive components in materials science [15-19]. Selenium is a necessary trace element for human beings and can be metabolized by organisms [20]. Moreover, China is rich in selenium resources, endowing a relatively low cost for the largescale applications of selenium-containing compounds and materials (e.g., the price of 99.99% pure Se powder is only ca. $26/kg at present).

On the other hand, nano materials have been focused on for years owing to their advanced performances over traditional materials [21, 22]. In comparison with the noble metal nanoparticles [23-31], carbon-based nano-materials may be more practical for their easily available starting materials resulting in very low cost, as well as their bio-compatible features, which is an important key factor in industry for the environment-protection concern of people since the new century [32-34]. During our continuous investigations on selenium chemistry including the organoselenium-catalyzed reactions, we started our project on the recyclable heterogeneous selenium catalysts for industrial application purposes and the carbon-supported nano selenium (Se/C) catalyst was invented in 2018 [35, 36]. Interestingly, recent investigations showed that, besides its catalytic activity, the Se/C material was bio-active for restraining Xanthomonas campestris pv. campestris (Xcc) and might be used as the key component in related new biocide development for cabbage black rot disease prevention and cure. Herein, we wish to report our findings.

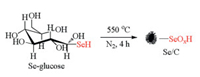

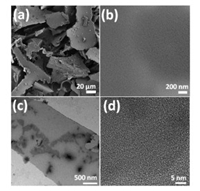

The Se/C material was prepared by calcining the selenized glucose at 550 ℃ under nitrogen atmosphere protection (Scheme 1), while the starting selenized glucose could be synthesized from glucose as the cheap and abundant carbon source via the selenization reaction using in-situ generated NaHSe as the selenization reagent (for experimental details, please see Supporing information). The material was a black powder and the inductively coupled plasma-mass spectrometry (ICP-MS) analysis demonstrated that it contained ca. 1.14% of selenium (weight content). X-ray photoelectron spectroscopy (XPS) analysis showed that Se was in Se4+ and Se0 form in the mateiral (Fig. S2 in Supporting information). The Se4+ attributed to the SeOxH moeties anchored onto the mateirals via C—Se bond, other than SeO2 because the later easily lost during the calcination procosses via sublimation and the subsequent blowing away by the N2 flow. Field emission-scanning electron microscope (SEM) analysis indicated that it was formed by a variety of curled fragments in micro-scale (Fig. 1a). In further magnified image in nano-scale, the surface of the fragments appealed to be very smooth (Fig. 1b). Transmission electron microscope (TEM) image of the material demonstrated that it was in an amorphous state (Fig. 1c), in accordance with the result being reflected by the high resolution TEM image with 5 nm scale bar, in which no crystal of selenium was detected (Fig. 1d).

|

Download:

|

| Scheme 1. Synthesis of Se/C. | |

|

Download:

|

| Fig. 1. Morphologies of Se/C in micro- and nano-scales: (a, b) SEM images, (c) TEM image, (d) HR-TEM image. | |

Energy dispersive X-ray spectroscopy (EDX) analysis attested the successful loading of selenium into the carbon materials (for details, please see Supporting information). Composition of the material was further analyzed by high-angle annular dark field scanning transmission electron microscope (HAADF-STEM) and elemental mapping (Fig. 2). HAADF-STEM images are highly sensitive to variations in the atomic number of atoms in the sample (Z-contrast images). Specifically, the Z-contrast intensity is proportional to the square of the atomic number [37]. Thus, the almost equal brightness of the material in selected zone in HAADFSTEM image indicated the uniform disperse of the elements (Fig. 2a). In elemental mapping images, the dispersion of selenium was in good agreement with that of carbon (Fig. 2c vs . Fig. 2b), indicating that the selenium element was anchored into the material via C—Se bond other than physical adsorption, and this could be well explained by the principle of the selenization reaction in material fabrication process, in which nucleophilic attack of HSe- anion to the carbon positive sites of glucose formed the C—Se bond (Scheme 2, as the bond being marked in blue color). The Se/C material also involved oxygen element (Fig. 2d), which came from the starting glucose or was introduced from the air via the oxidation of the selenium-containing groups in the material.

|

Download:

|

| Fig. 2. Composition analysis of Se/C: (a) HAADF-STEM image, and (b–d) elemental mapping images. | |

|

Download:

|

| Scheme 2. Principle for the formation of C—Se bond in the materials. | |

Selenium-containing compounds and materials are usually bioactive and have been widely used as biocides for both animals and plants [4]. Thus, we wondered whether the Se/C material might be used as biocide and it was expected to be better than traditional organoselenium compounds because the insoluble material might well adhered onto the leaves of the plants to allow a slow and sustained release of its efficacy. In addition, the carbon-based materials are expected to be more bio-compatible than normal chemical biocides. Xcc was chosen as the model object of study because it is a typical and very harmful germ causing the devastating cabbage black rot and resulting in huge economic losses (Fig. 3), and developing new bacteriostat against Xcc is also a highly demanded issue for the continuously increasing drug resistances of the germ [38].

|

Download:

|

| Fig. 3. Disease symptoms of cabbage caused by Xcc: (a) photo of the infected cabbage, (b) photo of the leaves of the infected cabbage. | |

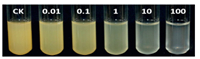

The experiments in vitro were initially performed in laboratory for the conveniences of operation and high efficiency in biocide screenings. As shown in Fig. 4, Se/C well restrained the Xcc samples when reaching a certain concentration. The material with its concentration less than 0.1 mg/L poorly restrained the Xcc (< 12.96%). The bioactivity of the material rose with the increased concentration. The restrain rate could be enhanced to 68.39% by using Se/C with its concentration being increased to 10 mg/L. The regressive analysis of the data (for details, please see Supporting information) demonstrated that the EC50 value of Se/C against Xcc was 4.7403 mg/L, attesting that it was an efficient material for the cabbage black rot disease prevention and cure. The activity mechanism of Se/C in restraining Xcc was probably via interruption of bacteria cell membrane and increased generation of bacterial intracellular reactive oxygen species (ROS) [39, 40].

|

Download:

|

| Fig. 4. Inhibitory effect of 10% Se/C at different concentrations (mg/L) on the growth of Xcc in the experiments in vitro. | |

In conclusion, we found that, by doping with very small amount of selenium into carbon, the resulted Se/C material was bioactive and could restrain Xcc. In comparison with traditional biocides, this material was prepared by using glucose as the abundant and cheap starting material. It was majorly composed by carbon, which was bio-compatible. As an insoluble material, it could adhere onto the leaves of the plants to allow a slow and sustained release of its efficacy, affording an efficient method for the cabbage black rot disease prevention and cure. This work as the first report on the bioactivity of Se/C is novel and may attract comprehensive attention in the fields of both materials science and biochemistry. The related field experiments and continuous investigations on the applications of selenium-containing materials are ongoing in our laboratory.

Declaration of competing interestThere is no interest statement to declare.

AcknowledgmentsWe thank National Key Research and Development Program of China (No. 2018YFD0200100), the Fund of Science and Technology Project of Jiangsu Province (No. BE2018359), Natural Science Foundation of Jiangsu Province (No. BK20181449), Jiangsu Provincial Six Talent Peaks Project (No. XCL-090) and Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Appendix A. Supplementary dataSupplementary material related to this article can be found, in the online version, at doi: https://doi.org/10.1016/j.cclet.2020.01.027 .

| [1] |

X. Deng, H.E. Cao, C. Chen, et al., Sci. Bull. 64 (2019) 1280-1284. DOI:10.1016/j.scib.2019.07.007 |

| [2] |

W.H. Bao, M. He, J.T. Wang, et al., J. Org. Chem. 84 (2019) 6065-6071. DOI:10.1021/acs.joc.9b00178 |

| [3] |

M.X. Liu, Y.M. Li, L. Yu, et al., Sci. China Chem. 61 (2018) 294-299. DOI:10.1007/s11426-017-9158-y |

| [4] |

G.M. Fang, X.X. Chen, Q.Q. Yang, et al., Chin. Chem. Lett. 29 (2018) 1033-1042. DOI:10.1016/j.cclet.2018.02.002 |

| [5] |

S. Kodama, T. Saeki, K. Mihara, A. Ogawa, et al., J. Org. Chem. 82 (2017) 12477-12484. DOI:10.1021/acs.joc.7b02276 |

| [6] |

L.H. Lu, Z. Wang, W. Xia, et al., Chin. Chem. Lett. 30 (2019) 1237-1240. DOI:10.1016/j.cclet.2019.04.033 |

| [7] |

L.H. Lu, S.J. Zhou, W.B. He, et al., Org. Biomol. Chem. 16 (2018) 9064-9068. DOI:10.1039/C8OB02368A |

| [8] |

M. Wang, Q.L. Fan, X.F. Jiang, Org. Lett. 18 (2016) 5756-5759. DOI:10.1021/acs.orglett.6b03078 |

| [9] |

Y.H. Zheng, A.Q. Wu, Y.Y. Ke, et al., Chin. Chem. Lett. 30 (2019) 937-941. DOI:10.1016/j.cclet.2019.01.012 |

| [10] |

H.E. Cao, M.X. Liu, R.R. Qian, et al., Appl. Organomet. Chem. 33 (2019) e4599. |

| [11] |

X. Liu, Y.Y. Liang, J.Y. Ji, et al., J. Am. Chem. Soc. 140 (2018) 4782-4786. DOI:10.1021/jacs.8b01513 |

| [12] |

T.T. Wang, X.B. Jing, C. Chen, et al., J. Org. Chem. 82 (2017) 9342-9349. DOI:10.1021/acs.joc.7b01245 |

| [13] |

F. Wang, L. Xu, C. Sun, et al., Chin. J. Org. Chem. 37 (2017) 2115-2118. DOI:10.6023/cjoc201701026 |

| [14] |

X.B. Jing, T.T. Wang, Y.H. Ding, et al., Appl. Catal. A-Gen. 541 (2017) 107-111. DOI:10.1016/j.apcata.2017.05.007 |

| [15] |

L. Yu, H.E. Cao, X. Zhang, et al., Sustain. Energ. Fuels 4 (2020) 730-736. DOI:10.1039/C9SE00850K |

| [16] |

C. Liu, J.F. Mao, X. Zhang, et al., Catal. Commun. 33 (2020) 105828. |

| [17] |

K.H. Cao, X. Deng, T. Chen, et al., J. Mater. Chem. A:Mater. Energy Sustain. 7 (2019) 10918-10923. DOI:10.1039/C9TA00846B |

| [18] |

X.B. Jing, C.Z. Chen, X. Deng, et al., Appl. Organomet. Chem. 32 (2018) e4332. |

| [19] |

Y. Wang, L. Yu, B. Zhu, et al., J. Mater. Chem. A:Mater. Energy Sustain. 4 (2016) 10828-10833. DOI:10.1039/C6TA02566H |

| [20] |

M.P. Rayman, Lancet 379 (2012) 1256-1268. DOI:10.1016/S0140-6736(11)61452-9 |

| [21] |

H. Yang, B. Xu, S. Yuan, et al., Appl. Catal. B:Environ. 243 (2019) 513-521. DOI:10.1016/j.apcatb.2018.10.057 |

| [22] |

C. Chen, K.H. Cao, Z. Wei, et al., Mater. Lett. 226 (2018) 63-66. DOI:10.1016/j.matlet.2018.05.021 |

| [23] |

Y.H. Yang, B.L. Xu, J. He, et al., Appl. Organomet. Chem.33 (2019) e5204. |

| [24] |

Y.F. Yang, M.X. Li, H.E. Cao, et al., Mol. Catal. 74 (2019) 110450. |

| [25] |

F. Wang, L. Xu, C. Sun, et al., Appl. Organomet. Chem. 32 (2018) e4505. |

| [26] |

S. Zhao, B. Xu, L. Yu, et al., Chin. Chem. Lett. 29 (2018) 475-478. DOI:10.1016/j.cclet.2017.09.020 |

| [27] |

D.L. Zhang, Z. Wei, L. Yu, Sci. Bull. 62 (2017) 1325-1330. DOI:10.1016/j.scib.2017.09.016 |

| [28] |

S. Zhao, B. Xu, L. Yu, et al., Chin. Chem. Lett. 29 (2018) 884-886. DOI:10.1016/j.cclet.2017.11.016 |

| [29] |

L. Yu, Z. Han, Y. Ding, Org. Process Res. Dev. 20 (2016) 2124-2129. DOI:10.1021/acs.oprd.6b00322 |

| [30] |

L. Yu, Z. Han, Mater. Lett. 184 (2016) 312-314. DOI:10.1016/j.matlet.2016.08.056 |

| [31] |

L. Fan, R. Yi, L. Yu, et al., Catal. Sci. Technol. 2 (2012) 1136-1139. DOI:10.1039/c2cy20132a |

| [32] |

H. Zhang, M.T. Han, C.G. Yang, et al., Chin. Chem. Lett. 30 (2019) 263-265. DOI:10.1016/j.cclet.2018.01.035 |

| [33] |

L. Yu, R.R. Qian, X. Deng, et al., Sci. Bull. 63 (2018) 1010-1016. DOI:10.1016/j.scib.2018.06.002 |

| [34] |

L. Yu, M.T. Han, J. Luan, et al., Sci. Rep. (2016) 30432. |

| [35] |

S.N. Chu, H.E. Cao, T. Chen, et al., Catal. Commun. 29 (2019) 105730. |

| [36] |

Y.F. Yang, X. Fan, H.E. Cao, et al., Catal. Sci. Technol. 8 (2018) 5017-5023. DOI:10.1039/C8CY01413B |

| [37] |

K. Sohlberg, T.J. Pennycook, W. Zhou, et al., Phys. Chem. Chem. Phys. 17 (2015) 3982-4006. DOI:10.1039/C4CP04232H |

| [38] |

V.R. Marin, J.H. Ferrarezi, G. Vieira, et al., World J. Microb. Biot. 5 (2019) 72. |

| [39] |

X. Huang, X. Chen, Q. Chen, et al., Acta Biomater. 30 (2016) 397-407. DOI:10.1016/j.actbio.2015.10.041 |

| [40] |

T. Huang, J.A. Holden, D.E. Heath, et al., Nanoscale2019 11 (2019) 14937-14951. DOI:10.1039/C9NR04424H |

2020, Vol. 31

2020, Vol. 31