Insoluble acid salts of metals with the general formula M(HPO4)2·H2O where M is a tetravalent cation (e.g., Zr, Ti, Hf, Ge, Sn, Ce) have been synthesized since 1956 due to their ionexchange behavior and good resistance to radiation [1-3]. These compounds exist in both gelatinous and crystalline forms, exhibiting different thermal stability and ion exchange properties [4-7]. The gelatinous amorphous metal phosphates are readily obtained via precipitation of aqueous metal salt solutions by phosphoric acid. However, the amorphous phase is less resistant to high temperature, oxidizing environment and radiation. It has poor mechanical and hydrodynamic properties which prevents their use in column. In addition, there is a strong dependency between ion-exchange performance and moisture content, resulting in deterioration of its performance over time as loss of water occurs during storage. In 1964, Clearfield et al. reported the first crystalline zirconium phosphate, α-zirconium phosphate (Zr (HPO4)2·H2O, abbreviated as α-ZrP) [4]. This compound was synthesized by refluxing the amorphous zirconium phosphate with concentrated phosphoric acid [4, 8]. Since then, many other crystalline ZrP has been synthesized, e.g., β-Zr(PO4)(H2PO4) and γ-Zr(PO4)(H2PO4)·2H2O [9-12], θ-Zr(HPO4)2·6H2O [13-17], and τ and τ-Zr(HPO4)2 with three-dimensional frameworks [18, 19]. Of the crystalline zirconium phosphates, α-ZrP has been the one most studied. Hence, it is the focus of this short review.

The structure of α-ZrP was obtained from single crystal X-ray diffraction measurements [20]. α-Zirconium phosphate was found to consist of layers where zirconium atoms are alternately above and below the central planes (Fig. 1). Each zirconium atom is bonded to six HPO42- groups. Three of the oxygen atoms in the HPO42- bind to three different zirconium atoms, forming a twodimensional structure while the fourth negatively charged oxygen atom carries a proton. This proton which points toward the interlayer region can be exchanged by other cations. The stacking of layers forms zeolitic (microporous) cavities where the one molecule of water resides. The interlayer distance is 7.56 Å.

|

Download:

|

| Fig. 1. Structure of Zr(HPO4)2·H2O. All hydrogen atoms are omitted for clarity. | |

Using neutron powder diffraction, Albertsson et al. showed that the layers are held together by van der Waals forces only [21]. There are three intralayer hydrogen bonds (Fig. 2). Each water oxygen accepts two hydrogen bonds from nearby P—OH groups in the same layer, O(4)—H(1)· · ·O(W) and O(8)—H(2)· · ·O(W). Of the water hydrogens, only one is involved in the formation of hydrogen bonding, O(W)—H(3)· · ·O(4) [21].

|

Download:

|

| Fig. 2. Illustration of hydrogen bonding in α-ZrP. | |

2. Synthesis methods

Refluxing in concentrated H3PO4 for extended periods of time can yield crystalline zirconium phosphates. However, it was difficult to obtain a linear correlation between reflux time and crystal size even when the concentration of H3PO4 was as high as 12 mol/L [22]. Alberti and Torraca reported another method to synthesize crystalline zirconium phosphate, using direct precipitation [23]. In this method, hydrofluoric acid is added into an aqueous solution of zirconium salt, followed by concentrated phosphoric acid. As fluoride is a good complexing agent for zirconium, the formation of fluorocomplex of zirconium (possibly ZrF62-) inhibits the precipitation of Zr(IV) and HPO42- which leads to the amorphous compound. The removal of HF under a low flow of nitrogen or water lowers the fluoride ion concentration resulting in gradual dissociation of the fluorozirconium complex and α-ZrP is slowly precipitated at room temperature. By heating to 80 ℃, the precipitation of ZrP can be accelerated [24, 25]. The degree of crystallinity depends on the removal rate of HF. α-Zirconium phosphates obtained by this HF method have a larger size which is suitable for column application. Besides HF, oxalic acid is another complexing agent that is employed in the synthesis of α-ZrP. It was first reported in 1973 by Horsley and Nowell but the yield was low, ~18% [26]. Further investigations by Capitani et al. led to a much improved yield of 90% using molar ratios of H3PO4/Zr and H2C2O4/Zr of 6 and 10, respectively [27].

Instead of reflux, hydrothermal method has been adopted to allow for high synthesis temperatures [28, 29]. Sun et al. reported an increase in the lateral length of α-ZrP crystallites from 300 nm to 1200 nm when the temperature was maintained at 200 ℃. The particles obtained have a narrow size distribution but its size was in between that of the reflux method and the HF method. By substituting aqueous solution of zirconium salts with zirconium propoxide, nanocrystalline α-ZrP could be synthesized quickly under mild conditions without adding complexing agents [30, 31].

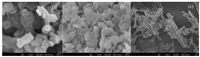

Recently, our group reported a new route to the synthesis of α-ZrP with a range of crystallinity [32]. In this minimalistic route, solid zirconium salt (ZrOCl2·8H2O) is simply mixed with a slight excess of 85% H3PO4 and heated in a polypropylene container for a few hours to no more than 1 day. Depending on the length of heating and temperature (≤120 ℃), α-ZrP with various crystallinity could be obtained. As the only source of water comes from the reactants, we called it a "minimal solvent" synthesis. The α-ZrP synthesized from this minimalistic method formed hexagonal platelets (Fig. 3a), which is similar to that obtained using conventional reflux method (Fig. 3b). Interestingly, highly crystalline α-ZrP with a novel shape is obtained by adding a small amount NH4F or NaF as mineralizer (Fig. 3c). It was found that the crystallinity and uniformity of particles are optimum for F to Zr molar ratio of 0.3. The use of NaF was more effective than NH4F in accelerating the crystal growth. Such rod-shaped crystals have not been previously reported. From selected-area electron diffraction, it was found that the crystals grew along the a direction. The crystals grown in this way could be as long as 10 μm. Compared to the conventional synthesis methods, this minimalistic protocol is green, easy and fast. It embodies the principles of green synthesis in high atom efficiency and waste minimization.

|

Download:

|

| Fig. 3. SEM image of α-ZrP prepared by (a) reflux in 6 mol/L H3PO4 for 48 h, (b) minimalistic protocol using H3PO4 /Zr = 3, 120 ℃ for 24 h and (c) minimalistic protocol with NH4F/Zr = 0.3, H3PO4/Zr = 3, 100 ℃ for 24 h. | |

3. Applications

The applications of α-ZrP are mainly based on two aspects of its structural properties, namely, the acidic group (—HPO42-) and its layered structure. Making use of the first structural property is the application of α-ZrP as a cation exchanger. It has been widely studied in the treatment of wastewater contaminated by heavy metals or radioactive isotopes [25, 33-39]. Highly crystalline zirconium phosphate is less susceptible to hydrolysis than the amorphous gel, enabling the material to be used in strongly acidic as well as fairly alkaline solutions. However, access of incoming cations to the exchangeable protons is limited by its narrow interlayer space [2, 20, 40]. Therefore, semi-crystalline phase was found to be a better choice [25, 33, 41]. In a series of sorption experiments conducted by Ahrland et al. [33], very nearly complete uptake of transition metals (Cu2+, Co2+, Mn2+, Ni2+, Zn2+) was easily achieved in a media of pH > 4 by semi-crystalline ZrP prepared by refluxing in 6 mol/L H3PO4 for 6 h. Unlike the amorphous phase, the semi-crystalline ZrP hardly suffered from hydrolysis if the pH was below 10. For the crystalline α-ZrP, it is generally necessary to increase the interlayer spacing by reaction with Brønsted bases so that the protons can be replaced by bigger cations [21, 37, 42, 43]. However for Pb2+, even without any such modification, a high sorption amount of about 140 mg/g was reported for polymersupported crystalline α-ZrP [36]. The selectivity to Pb2+ was not significantly affected by competing cations such as Ca2+, Mg2+, and Na+. This behavior can be attributed to the strong affinity between PO43-and Pb2+ [44].

Arising from the mobile protons in —O3POH, α-ZrP has been studied as proton conductors in fuel cells and sensors [45-49]. Porous phosphates heterostructures were prepared by introducing mesoporous silica into the interlayer region of ZrP [49]. The material showed increased proton conductivity in the presence of ammonia which was attributed to a larger number of available Brønsted sites after expansion. This phenomenon provides the basis for the design of ammonia sensor.

α-ZrP has been used as acid catalysts and catalyst supports [50-60]. Syntheses of cyclic ethers from 6-methylhept-5-en-2-ol and 1, 3-diols were efficiently performed by using zirconium phosphate as catalyst [61]. Both α-and γ-ZrP have been used for the selective transformation of carbohydrates into 5-hydroxymethyl-2-furaldehyde, an important renewable platform chemical [62]. α-Zirconium phosphate serves as a Friedel-Crafts catalyst for the liquid and gas-phase alkylation of anisole in both liquid and gas phase [63]. A novel photocatalyst was synthesized by reaction of HCl with Ag+-exchanged α-ZrP [53]. The ZrP/AgCl composite had smaller AgCl particles, compared to pure AgCl. The ZrP/AgCl composites exhibited better photocatalytic activity for the degradation of Rhodamine B which was attributed to the chemisorption of RhB on the ZrP support and the acidic environment it provided.

A functionalized material was synthesized by intercalation of aggregation-induced emission (AIE) luminogen, quaternary tetraphenylethene cation, and the anti-cancer drug, doxorubicin, into α-ZrP. The material exhibits a strong blue emission at 476 nm with a pH-dependent release of doxorubicin. Hence, the hybrid material has potential as an image-guided pH-responsive delivery system for targeted therapy [64]. Diaz et al. studied the encapsulation of insulin into α-ZrP nanoparticles [65]. The sequestered insulin was structurally and chemically stable for up to six months at room temperature. The acid-resistant nature of ZrP protects the insulin from digestive enzymes and opens up possibility for it to be administrated orally rather than by injections. In another study, cisplatin was intercalated into ZrP by direct ion-exchange and tested for cytotoxicity in the human breast cancer (MCF-7) cell line [16]. The cisPt@ZrP was found to reduce the cell viability by up to 40%. Furthermore, the pH dependence of the Pt-complex release profile suggests that only tumour cells will be exposed to cisplatin while healthy tissues will not.

The use of α-ZrP as a flame retardant material is drawing increasing attention [66]. It can act as a physical barrier to prevent the escape of decomposed gases. Studies into the composites of α-ZrP in polyamide 6 showed that it could reduce the total heat release as well as the heat release rate during combustion [67]. In addition, α-ZrP reduced the flammability of polyethylene terephthalate and ethylene vinyl acetate copolymer acting in synergistic effect with phosphorous based flame retardants. The dispersion of α-ZrP affects the flammability of the composites. Li et al. reported that polyacrylate/α-ZrP nanocomposites with 0.5 wt% α-ZrP had better flame retardancy than polyacrylate itself [68]. This was deduced from the lower peak heat release rate and higher limiting oxygen index. In contrast, when α-ZrP was increased to 3.0 wt%, the flame retardancy was reduced due to poor dispersion.

Lamellar ZrP composing of single sheets or several sheets can be obtained by exfoliating or delaminating α-ZrP with suitable molecules. This is achieved through Brønsted acid-base reactions as α-ZrP is easily intercalated by organic molecules such as alkanols [69], glycol [69] and various amines [70-73]. Alberti et al. found that the pellicular α-ZrP exhibits higher specific conductivity than anhydrous microcrystalline powder [74]. They have been used as nanofillers in polymer matrices to enhance physico-chemical properties such as decreased gas permeability, better mechanical strength and improved thermostability [75-80]. Instead of prior exfoliation, Mosby et al. directly incorporated α-ZrP nanoplatelets into the polymer matrix [81]. The surface of ZrP was functionalized with epoxides leaving the sites in the interlayer structure available for intercalation or ion-exchange.

The application of ZrP in tribology is an emergent subject in the last decade. It was reported that compared to graphite and MoS2, ZrP and its derivatives exhibited betterlubrication enhancement such as reduced wear, scar size and friction [82-85]. Intercalation of α-ZrP nanosheets with amines were tested as lubricant additives [84]. When added as lubricant additives, the coefficient of friction of the mineral oil was significantly reduced. The interlayer spacing could be adjustedbychoice of the amine. α-Zirconium phosphatewith the smallest interlayer spacing gave a greater friction reduction.

4. Conclusionsα-Zirconium phosphate with varying crystallinity and particle sizes can be synthesized by refluxing, direct precipitation, sol-gel, and minimal-solvent method. Compared to the conventional methods, the newly reported minimal-solvent synthesis offers a minimalistic approach where the reactants are used with close to stoichiometric amounts to give excellent yields of highly crystalline α-ZrP. Although α-ZrP is well known as an inorganic ionexchanger and an acidic catalyst, more recent investigations have focused on the applications as intercalation hosts for drug delivery systems, lubricant additives, sensors, polymer fillers and flame retardant additives.

AcknowledgmentsFinancial support from the Academic Research Grant (Tier 1), Faculty of Science, National University of Singapore (No. R-143-000-667-114) is gratefully acknowledged. Y. Cheng thanks NUS-IPP program for award of a research scholarship.

| [1] |

C. Amphlett, L. McDonald, M. Redman, J. Inorg. Nucl. Chem. 6 (1958) 220-235. DOI:10.1016/0022-1902(58)80152-9 |

| [2] |

G. Alberti, Acc. Chem. Res. 11 (1978) 163-170. DOI:10.1021/ar50124a007 |

| [3] |

G. Alberti, U. Constantino, J. Chromatogr. 102 (1974) 5-29. DOI:10.1016/S0021-9673(01)85423-6 |

| [4] |

A. Clearfield, J. Stynes, J. Inorg. Nucl. Chem. 26 (1964) 117-129. DOI:10.1016/0022-1902(64)80238-4 |

| [5] |

S. Allulli, C. Ferragina, A. La Ginestra, M. Massucci, N. Tomassini, J. Inorg. Nucl. Chem. 39 (1977) 1043-1048. DOI:10.1016/0022-1902(77)80261-3 |

| [6] |

G. Alberti, P. Cardini-Galli, U. Costantino, E. Torracca, J. Inorg. Nucl. Chem. 29 (1967) 571-578. DOI:10.1016/0022-1902(67)80063-0 |

| [7] |

A. Clearfield, D.S. Thakur, Appl. Catal. 26 (1986) 1-26. DOI:10.1016/S0166-9834(00)82538-5 |

| [8] |

A. Clearfield, A. Oskarsson, C. Oskarsson, Ion Exch. Membr. 1 (1972) 91-107. |

| [9] |

A. Clearfield, R.H. Blessing, J.A. Stynes, J. Inorg. Nucl. Chem. 30 (1968) 2249-2258. DOI:10.1016/0022-1902(68)80224-6 |

| [10] |

D.M. Poojary, B. Shpeizer, A. Clearfield, J. Chem. Soc. Dalton Trans. (1995) 111-113. |

| [11] |

M. Salvado, P. Pertierra, S. Garcia-Granda, et al., Z. Kristallogr.-Cryst. Mater. 216 (2001) 326-330. |

| [12] |

Y. Cheng, X.D. Wang, S. Jaenicke, G.K. Chuah, Inorg. Chem. 57 (2018) 4370-4378. DOI:10.1021/acs.inorgchem.7b03202 |

| [13] |

A. Clearfield, A. Landis, A. Medina, J. Troup, J. Inorg. Nucl. Chem. 35 (1973) 1099-1108. DOI:10.1016/0022-1902(73)80182-4 |

| [14] |

G. Alberti, U. Costantino, J. Gill, J. Inorg. Nucl. Chem. 38 (1976) 1733-1738. DOI:10.1016/0022-1902(76)80670-7 |

| [15] |

T. Kijima, Bull. Chem. Soc. Jpn. 55 (1982) 3031-3032. DOI:10.1246/bcsj.55.3031 |

| [16] |

V. Saxena, A. Diaz, A. Clearfield, J.D. Batteas, M.D. Hussain, Nanoscale 5 (2013) 2328-2336. DOI:10.1039/c3nr34242e |

| [17] |

A. Díaz, V. Saxena, J. González, et al., Chem. Commun. 48 (2012) 1754-1756. DOI:10.1039/c2cc16218k |

| [18] |

A.M.K. Andersen, P. Norby, J.C. Hanson, T. Vogt, Inorg. Chem. 37 (1998) 876-881. DOI:10.1021/ic971060h |

| [19] |

M. Pica, R. Vivani, A. Donnadio, et al., Inorg. Chem. 54 (2015) 9146-9153. DOI:10.1021/acs.inorgchem.5b01573 |

| [20] |

A. Clearfield, G.D. Smith, Inorg. Chem. 8 (1969) 431-436. DOI:10.1021/ic50073a005 |

| [21] |

J. Albertsson, A. Oskarsson, R. Tellgren, J.O. Thomas, J. Phys. Chem. 81 (1977) 1574-1578. DOI:10.1021/j100531a011 |

| [22] |

A. Clearfield, L. Kullberg, A. Oskarsson, J. Phys. Chem. 78 (1974) 1150-1153. DOI:10.1021/j100605a004 |

| [23] |

G. Alberti, E. Torracca, J. Inorg. Nucl. Chem. 30 (1968) 317-318. DOI:10.1016/0022-1902(68)80096-X |

| [24] |

G. Alberti, U. Costantino, S. Allulli, M. Massucci, M. Pelliccioni, J. Inorg. Nucl. Chem. 35 (1973) 1347-1357. DOI:10.1016/0022-1902(73)80209-X |

| [25] |

G. Alberti, U. Costantino, S. Allulli, M. Massucci, J. Inorg. Nucl. Chem. 37 (1975) 1779-1786. DOI:10.1016/0022-1902(75)80316-2 |

| [26] |

S.E. Horsley, D.V. Nowell, J. Appl. Chem. Biotechn. 23 (1973) 215-224. |

| [27] |

D. Capitani, M. Casciola, A. Donnadio, R. Vivani, Inorg. Chem. 49 (2010) 9409-9415. DOI:10.1021/ic101200f |

| [28] |

L. Sun, W.J. Boo, H.J. Sue, A. Clearfield, New J. Chem. 31 (2007) 39-43. DOI:10.1039/B604054C |

| [29] |

M. Shuai, A.F. Mejia, Y.W. Chang, Z. Cheng, CrystEngComm 15 (2013) 1970-1977. DOI:10.1039/c2ce26402a |

| [30] |

H. Benhamza, P. Barboux, A. Bouhaouss, F.A. Josien, J. Livage, J. Mater. Chem. 1 (1991) 681-684. DOI:10.1039/JM9910100681 |

| [31] |

M. Pica, A. Donnadio, D. Capitani, et al., Inorg. Chem. 50 (2011) 11623-11630. DOI:10.1021/ic2015594 |

| [32] |

Y. Cheng, X. Wang, S. Jaenicke, G.K. Chuah, ChemSusChem 10 (2017) 3235-3242. DOI:10.1002/cssc.201700885 |

| [33] |

S. Ahrland, N.O. Björk, R. Blessing, R. Herman, J. Inorg. Nucl. Chem. 36 (1974) 2377-2383. DOI:10.1016/0022-1902(74)80287-3 |

| [34] |

S. Allulli, A. La Ginestra, M. Massucci, M. Pelliccioni, N. Tomassini, Inorg. Nucl. Chem. Lett. 10 (1974) 337-341. DOI:10.1016/0020-1650(74)80193-5 |

| [35] |

A. Clearfield, J.M. Kalnins, J. Inorg. Nucl. Chem. 38 (1976) 849-852. DOI:10.1016/0022-1902(76)80369-7 |

| [36] |

B. Pan, B. Pan, X. Chen, et al., Water Res. 40 (2006) 2938-2946. DOI:10.1016/j.watres.2006.05.028 |

| [37] |

J.P. Gupta, D.V. Nowell, J. Chem. Soc. Dalton Trans. (1981) 385-389. |

| [38] |

A. Clearfield, Solvent Extr. Ion Exch. 18 (2000) 655-678. DOI:10.1080/07366290008934702 |

| [39] |

A. Clearfield, L. Kullberg, J. Phys. Chem. 78 (1974) 1812-1817. DOI:10.1021/j100611a008 |

| [40] |

A. Clearfield, W. Duax, A. Medina, G.D. Smith, J. Thomas, J. Phys. Chem. 73 (1969) 3424-3430. DOI:10.1021/j100844a047 |

| [41] |

S. Ahrland, J. Albertsson, Å. Oskarsson, A. Niklasson, J. Inorg. Nucl. Chem. 32 (1970) 2069-2078. DOI:10.1016/0022-1902(70)80615-7 |

| [42] |

C. Wang, Q. Cheng, Y. Wang, Inorg. Chem. 57 (2018) 3753-3760. DOI:10.1021/acs.inorgchem.7b03030 |

| [43] |

A. Clearfield, H. Hagiwara, J. Inorg. Nucl. Chem. 40 (1978) 907-914. DOI:10.1016/0022-1902(78)80173-0 |

| [44] |

C. Gunathilake, M.S. Kadanapitiye, O. Dudarko, S.D. Huang, M. Jaroniec, Appl. Mater. Interface 7 (2015) 23144-23152. DOI:10.1021/acsami.5b06951 |

| [45] |

P. Armento, M. Casciola, M. Pica, et al., Solid State Ion. 166 (2004) 19-25. DOI:10.1016/j.ssi.2003.10.016 |

| [46] |

G. Alberti, M. Casciola, D. Capitani, et al., Electrochim. Acta 52 (2007) 8125-8132. DOI:10.1016/j.electacta.2007.07.019 |

| [47] |

A. Clearfield, Chem. Rev. 88 (1988) 125-148. DOI:10.1021/cr00083a007 |

| [48] |

A. Clearfield, Annu. Rev. Mater. Sci. 14 (1984) 205-229. DOI:10.1146/annurev.ms.14.080184.001225 |

| [49] |

T. Simons, J.F.B. Villalba, J. Jiménez-Jiménez, E. Rodríguez-Castellón, U. Simon, Sensor. Actuat. B-Chem. 217 (2015) 175-180. DOI:10.1016/j.snb.2014.09.030 |

| [50] |

K. Segawa, Y. Kurusu, Y. Nakajima, M. Kinoshita, J. Catal. 94 (1985) 491-500. DOI:10.1016/0021-9517(85)90213-1 |

| [51] |

A. Sinhamahapatra, N. Sutradhar, B. Roy, et al., Appl. Catal. A: Gen. 385 (2010) 22-30. DOI:10.1016/j.apcata.2010.06.016 |

| [52] |

C. Petrucci, M. Cappelletti, O. Piermatti, et al., J. Mol. Catal. A: Chem. 401 (2015) 27-34. DOI:10.1016/j.molcata.2015.02.012 |

| [53] |

M. Pica, M. Nocchetti, B. Ridolfi, et al., J. Mater. Chem. A: Mater. Energy Sustain. 3 (2015) 5525-5534. DOI:10.1039/C5TA00274E |

| [54] |

Y. Kamiya, S. Sakata, Y. Yoshinaga, R. Ohnishi, T. Okuhara, Catal. Lett. 94 (2004) 45-47. DOI:10.1023/B:CATL.0000019329.82828.e4 |

| [55] |

D. Li, W. Ni, Z. Hou, Chin. J. Catal. 38 (2017) 1784-1793. DOI:10.1016/S1872-2067(17)62908-5 |

| [56] |

R. Weingarten, Y.T. Kim, G.A. Tompsett, et al., J. Catal. 304 (2013) 123-134. DOI:10.1016/j.jcat.2013.03.023 |

| [57] |

D. Cao, B. Yu, S. Zhang, et al., Appl. Catal. A: Gen. 528 (2016) 59-66. DOI:10.1016/j.apcata.2016.09.017 |

| [58] |

Z. Ye, L. Chen, H. Chen, et al., Chem. Phys. Lett. 709 (2018) 96-102. DOI:10.1016/j.cplett.2018.08.046 |

| [59] |

J. Xiao, J. Xu, Y. Wu, Z. Gao, Appl. Catal. A: Gen. 181 (1999) 313-322. DOI:10.1016/S0926-860X(98)00392-5 |

| [60] |

M. Curini, O. Rosati, U. Costantino, Curr. Org. Chem. 8 (2004) 591-606. DOI:10.2174/1385272043370735 |

| [61] |

F.A. Al-Qallaf, L.F. Hodson, R.A. Johnstone, et al., J. Mol. Catal. A: Chem. 152 (2000) 187-200. DOI:10.1016/S1381-1169(99)00296-4 |

| [62] |

F. Benvenuti, C. Carlini, P. Patrono, et al., Appl. Catal. A: Gen. 193 (2000) 147-153. DOI:10.1016/S0926-860X(99)00424-X |

| [63] |

M.C.C. Costa, R.A. Johnstone, D. Whittaker, J. Mol. Catal. A: Chem. 103 (1995) 155-162. DOI:10.1016/1381-1169(95)00123-9 |

| [64] |

D. Li, Y. Zhang, B. Zhou, J. Solid State Chem. 225 (2015) 427-430. DOI:10.1016/j.jssc.2015.01.025 |

| [65] |

A. Díaz, A. David, R. Pérez, et al., Biomacromolecules 11 (2010) 2465-2470. DOI:10.1021/bm100659p |

| [66] |

T. Jiang, C. Liu, L. Liu, et al., RSC Adv. 6 (2016) 91720-91727. DOI:10.1039/C6RA15542A |

| [67] |

J. Alongi, A. Frache, Polym. Degrad. Stab. 95 (2010) 1928-1933. DOI:10.1016/j.polymdegradstab.2010.04.007 |

| [68] |

K. Li, H. Lei, X. Zeng, et al., RSC Adv. 7 (2017) 49290-49298. DOI:10.1039/C7RA07131K |

| [69] |

U. Costantino, J. Chem. Soc. Dalton Trans. (1979) 402-405. |

| [70] |

A. Clearfield, R.M. Tindwa, J. Inorg. Nucl. Chem. 41 (1979) 871-878. DOI:10.1016/0022-1902(79)80283-3 |

| [71] |

L. Li, X. Liu, Y. Ge, L. Li, J. Klinowski, J. Phys. Chem. 95 (1991) 5910-5914. DOI:10.1021/j100168a037 |

| [72] |

R.A. Bermudez, Y. Colon, G.A. Tejada, J.L. Colon, Langmuir 21 (2005) 890-895. DOI:10.1021/la048783f |

| [73] |

D. MacLachlan, K. Morgan, J. Phys. Chem. 94 (1990) 7656-7661. DOI:10.1021/j100382a062 |

| [74] |

G. Alberti, M. Casciola, U. Costantino, J.ColloidInterfaceSci. 107 (1985) 256-263. |

| [75] |

H.J. Sue, K. Gam, N. Bestaoui, N. Spurr, A. Clearfield, Chem. Mater. 16 (2004) 242-249. DOI:10.1021/cm030441s |

| [76] |

M. Casciola, G. Alberti, A. Donnadio, et al., J. Mater. Chem. 15 (2005) 4262-4267. DOI:10.1039/b506768e |

| [77] |

W.J. Boo, L. Sun, G. Warren, et al., Polymer 48 (2007) 1075-1082. DOI:10.1016/j.polymer.2006.12.042 |

| [78] |

M. Casciola, G. Bagnasco, A. Donnadio, et al., Fuel Cells 9 (2009) 394-400. DOI:10.1002/fuce.200800135 |

| [79] |

L. Sun, W.J. Boo, D. Sun, A. Clearfield, H.J. Sue, Chem. Mater. 19 (2007) 1749-1754. DOI:10.1021/cm062993r |

| [80] |

M. Wong, R. Ishige, K.L. White, et al., Nat. Commun. 5 (2014) 3589. DOI:10.1038/ncomms4589 |

| [81] |

B.M. Mosby, A. Díaz, V. Bakhmutov, A. Clearfield, Appl. Mater. Interface 6 (2013) 585-592. |

| [82] |

Y. Dai, H. Xu, J. Dong, Lubricants 6 (2018) 63. DOI:10.3390/lubricants6030063 |

| [83] |

W. Niu, L. Liu, H. Xu, J. Dong, Lubr. Sci. 31 (2019) 51-60. DOI:10.1002/ls.1445 |

| [84] |

H. Xiao, W. Dai, Y. Kan, A. Clearfield, H. Liang, Appl. Surf. Sci. 329 (2015) 384-389. DOI:10.1016/j.apsusc.2014.12.061 |

| [85] |

X. He, H. Xiao, H. Choi, et al., Colloids Surf. Physicochem. Eng. Aspects 452 (2014) 32-38. DOI:10.1016/j.colsurfa.2014.03.041 |

2020, Vol. 31

2020, Vol. 31