b College of Chemistry, Beijing University of Chemical Technology, Beijing 100029, China;

c School of Civil and Environmental Engineering, Georgia Institute of Technology, Atlanta, GA 30332, United States;

d College of Engineering and Applied Sciences, and School of Energy Resources, University of Wyoming, Laramie, WY 82071, United States;

e Key Laboratory for Green Chemical Technology of the Ministry of Education, School of Chemical Engineering and Technology, Tianjin University, Tianjin 300072, China;

f Collaborative Innovative Center of Chemical Science and Engineering(Tianjin), Tianjin 300072, China;

g Institute for Superconducting and Electronic Materials, Australian Institute for Innovative Materials, University of Wollongong, Wollongong, NSW 2522, Australia;

h Laboratory of Advanced Materials, Department of Chemistry, Fudan University, Shanghai 200438, China;

i Institute of Fundamental and Frontier Sciences, University of Electronic Science and Technology of China, Chengdu 610054, China;

j Chemical Synthesis and Pollution Control Key Laboratory of Sichuan Province, College of Chemistry and Chemical Engineering, China West Normal University, Nanchong 637002, China;

k Institute of Chemistry, St. Petersburg State University, 7/9 Universitetskaya emb., St. Petersburg 199034, Russian Federation;

l Department of Chemical Engineering, University of Patras, Patras 26500, Greece;

m School of Environmental Science and Engineering, Guangdong Provincial Key Laboratory of Environmental Pollution Control and Remediation Technology, Sun Yat-sen University, Guangzhou 510275, China;

n School of Materials Science and Engineering, Nankai University, Tianjin 300350, China;

o Department of Chemistry, Chinese University of Hong Kong, Hong Kong, China;

p Institute of Nanoscience and Nanotechnology, NCSR "Demokritos", Athens 15341, Greece;

q State Key Laboratory of School of Radiation Medicine and Protection and School for Radiological and interdisciplinary Sciences(RAD-X), Soochow University, Suzhou 215123, China;

r State Key Laboratory of High Performance Ceramics and Superfine Microstructure, Shanghai Institute of Ceramics, Chinese Academy of Sciences, Shanghai 200050, China;

s Center of Materials Science and Optoelectronics Engineering, University of Chinese Academy of Sciences, Beijing 100049, China;

t Key Laboratory of Materials Processing and Mold(Zhengzhou University), Ministry of Education, Zhengzhou University, Zhengzhou 450002, China

Yang Tang, Haomin Jiang, Yongmei Chen*, Pingyu Wan, Maohong Fan*

1.1. StatusThe depletion of fossil fuels and pollution of environment have motivated us to develop clean and efficient energy storage and conversion devices. H2-O2 fuel cell, methanol-O2 fuel cell, N2H4-O2 fuel cell and metal-O2 batteries are a series of promising candidates [1, 2]. Electro- catalyzed oxygen reduction reaction (ORR) is the key to those devices. However, the slow kinetics of ORR resulting from the strong bonds of oxygen molecules has greatly hindered the power density and energy efficiency of those ORRrelated electrochemical devices. For example, the overpotential of ORR is as high as 300~500 mV, which is much higher than that (< 50 mV) of hydrogen oxidation reaction in the current H2-O2 fuel cells, making the practical output voltage of single cell 0.6-0.8 V higher than theoretical values. Furthermore, three possible pathways via acceptance of 1, 2 or 4 electrons from cathode for ORR: correspondingly generate superoxide radical (·O2-) and hydrogen peroxide anion/hydrogen peroxide (OOH-/H2O2) as well as hydroxyl anion/water (OH-/H2O), which causes great concern on the selectivity of ORR pathways.

1.2. ORR related applications with different 1e, 2e or 4e pathwaysOwing to the enhanced stability of superoxide radicals (·O2-) in an aprotic ionic liquid (AIL), 1e-ORR could steadily occurs, which is the key cathodic reaction in metal-O2 batteries [3-5]. It was found that 1e-ORR pathway (Fig. 1) in an AIL shifts a 2e or 4e pathway to produce OOH-/H2O2 or OH- when some protic additives [6], water [7-9] or metal ions (such as Mg2+) [10] were present in AIL, or a protic ionic liquid (PIL) was used as the supporting electrolyte [11]. These so called "reactive oxygen species (ROS)", including ·O2-, OOH- or H2O2 formed on site through ORR process, are utilized to electrochemically degrade p-benzyloxyl phenol, a lignin model compound, where ROS attacks C4 atom on the opposite site of the phenolic hydroxyl, resulting in the cleavage of alkyl-O-aryl bond [12].

|

Download:

|

| Fig. 1. Illustration of ORR-related devices. | |

The 2e-ORR pathway is favorable to the electrochemical production of H2O2 aqueous solution, which is an important chemical as oxidant/reductant in industry, medicine manufacturing, and environmental treatment [13]. As compared with anthraquinone process, electrochemical production of high concentration of H2O2 with high selectivity, activity and longterm durability is still a great challenge.

ORR mainly proceeds via 4e pathway when appropriate catalysts are loaded on cathodes in aqueous solution or polymer electrolytes (proton/alkaline ion exchange membrane). In the case of fuel cell, 4e pathway is an ideal reaction in which 2e pathway is considered as a side-reaction. H2O2 and its generated ROSs can attack the electrocatalyst or carbon substrate or membrane, resulting in the deterioration of these devices.

1.3. Advances in 4e-ORR catalyst and its challengesIn order to decrease the overpotential and improve the 4e pathway selectivity of ORR in fuel cell and metal air batteries, numerous works are focused on preparing high-performance ORR electrocatalyst with high activity, durability and low yield of H2O2. The precious Pt, PtRu, and PtPd alloys are regard as the most efficient 4e-ORR electrocatalysts, but their large-scale applications are greatly hindered due to their high costs. Non-precious metals, such as Co, Ni, Fe or Mo are used to interact with Pt to decrease consumption of Pt. Also, adjusting their compositions will also improve activity and durability. Moreover, the nanostructure engineering of Pt based electrocatalyst in forms of hollow, branch, polyhedron or core-shell can introduce more preferential crystal facet, corner, step or defect, further improve the activity. Huang and the coworkers [14] prepared a series of ternary octahedral MPt3Ni (M = V, Cr, Mg, Fe, Co, Mo, W or Re). Mo-Pt3Ni/C demonstrated the outstanding 4e-ORR performance, with a specific activity of 10.3 mA/cm2 and mass activity of 6.98 A/mg Pt, and improved stability for 8000 cycles. Theoretical calculations suggest that the surface Mo-oxide near the particle vertex/edge sites can be improved from the perspectives of performance and the stability of the Pt3Ni catalyst.

In order to be less dependent on expensive and scarce Pt based materials, nonprecious ones, including spinel oxides, perovskite, MnO2, metal-free heteroatom (N, P, S and B) doped carbon, and nonprecious metal (Fe, Co, Ni and Cu) and heteroatom co-doped carbon (MNC) (Fig. 2), have been extensively investigated [15-18]. Ten years ago, Dai's group [19] reported that metal-free nitrogen doped carbon nanotubes (NCNTs) had lower overpotential, longer operation stability than Pt for ORR in alkaline fuel cells. The relatively high positive charge density on carbon atoms induced by adjacent nitrogen atoms contributes to a 4e pathway for the ORR on NCNTs with excellent performance. Zelenay's group [17] prepared a family of MNC (M = Fe or Co) materials and the highperformance PANI-Fe-C catalyst exhibits a H2O2 yield of less than 1% over the potential range of 0.1-0.8 V (vs. RHE), signaling virtually complete reduction of O2 to H2O via 4e pathway. With respect to MNC electrocatalysts, not only pyridinic-N and graphitic-N, but also MNx and MCx as well as MNxCy have been disclosed as the active sites for ORR by different authors. Recently, in-situ XANES, EXAFS spectroscopy characterization and DFT calculation are used to further understand the ORR mechanism on MNC, which is beneficial to confirmation of the exact active sites in MNC.

|

Download:

|

| Fig. 2. (a) Synthesis summary for typical MNC ORR catalysts. Produced with permission [15]. Copyright 2018, American Chemical Society. (b) Schematic illustration of the formation of the FeN-HPC using NaCl as templates. Produced with permission [16], Copyright 2019, New York, Pergamon Press. (c) Schematic illustration of the synthesis PANI-M-C catalysts. Produced with permission [17]. Copyright 2011, American Association for the Advancement of Science. (d) Schematic illustration of the synthesis of FeISAs/CN. Produced with permission [18]. Copyright 2011, John Wiley and Sons Ltd. | |

As shown in Fig. 2, pyrolysis of nitrogen-containing organics, transition metal precursors with or without use of template is widely used as a universal method for fabricating MNC. Typical steps include: (1) mixing or coordinating the nitrogen containing organic compounds with transition-metal salt, (2) heat treatment in N2, Ar or NH3 atmosphere, (3) acid washing, and (4) second heat treatment. Numerous MNCs are prepared by this method or the modified methods in the past decade. Metal-organic frameworks (MOFs), which are constituted by organic ligand and metals and characterized with structural diversity, easily functionalized and high specific surface area, have been widely adopted for preparing MNC by pyrolysis recently [20]. By tuning the metal species, organic ligands and pyrolysis procedure, the MOF derived MNC not only possesses uniform active sites and large specific surface area, but also maintains the ordered structure of original MOF. Li's group [18] introduced a MOF derived single-atom FeNC catalyst by using ZIF-8 as molecular-scale cages to trap and separate iron(Ⅲ) in precursor. After pyrolysis, Fe atom was surrounded with four nitrogen atoms to assemble FeN4 coordination site, a key to the excellent ORR performance of the single-atom FeNC with its one half-wave potential (E1/2) being as high as 0.900 V, which outperformed commercial Pt/C and most non-precious-metal catalysts. In the past several years, lots of reported MNCs especially single-atom electrocatalysts have exhibited comparable or even better activities than Pt for ORR in basic media. However, most of them are still inferior to Pt in the acidic electrolyte within the practical pH environment in commercial PEMFC. Currently, larger numbers of researchers are devoted to designing and preparing high performance ORR catalysts in acidic electrolyte with tireless efforts.

1.4. Concluding remarks and prospectsIn summary, the species on active sites determine the intrinsic activity of the electrocatalyst, reflected by the onset potential, half wave potential, tafel slope and H2O2 selectivity. The nano/micro structure of electrocatalyst greatly influences the apparent activity, such as the diffusion limiting current. Those factors will synergistically determine the energy efficiency, power density, long-term durability of the fuel cells. With the tremendous efforts of scientists and the development of in-situ instruments, it is very possible to clearly reveal the complicated mechanism of ORR, design and prepare ORR electrocatalysts with low cost, high activity, long durability for preparation of future fuel cells, metal air batteries and other ORR-related devices.

1.5. AcknowledgmentThe authors greatly appreciate the support from the Beijing Municipal Natural Science Foundation (Nos. 2182046, 2182050).

2. Electrocatalytic oxygen evolution reactionRongrong Zhang, Sana Ullah, Lun Pan, Jijun Zou*

2.1. StatusElectrocatalytic oxygen evolution reaction (OER), an important reaction involved in water splitting and rechargeable metal-air batteries, has been researched since 1830s when Faraday's law of electrolytic equivalent was proposed. The kinetically favorable OER process occurs through multi-step reactions with four electrons transfer as reported by Hoar at 1933. The thermodynamic potential required for OER at 25 ℃ is 1.23 V in acidic solutions (2H2O (l) ↔ 4H+ + O2 (g) + 4e-) and 0.404 V in alkaline solutions (4OH- ↔ 2H2O (l) + O2 (g) + 4e-) [21]. However, the accumulation of energy at each step makes OER kinetics sluggish and results in large overpotential. Therefore, an electrocatalyst is needed to overcome the energy barrier. Generally, a good electrocatalyst should have high quality and quantity of active sites as well as good electronic conductivity, also corrosion resistance and good durability are necessary. Noblemetal-based materials like IrO2 and RuO2 are regarded as most promising for OER in terms of their good activity and stability in both acid and alkaline electrolytes [22]. However, the high price and scarcity are the major bottlenecks in practical applications, which urge developments of strategies and new materials to decrease usage of noble metals and further enhance activities. Transition metal-based (Co, Ni, Mn, Fe, etc.) materials like oxides, (oxy-) hydroxides, sulfides, phosphides, alloys, and carbon-based materials are promising alternative despite the high overpotential and unsatisfied stability. Therefore, recent research mainly focuses on developing catalysts with superior activities by strategies like defect engineering, coordination control, synergy effects, etc. to modulate electron structures of catalysts to reach appropriate adsorption of intermediates. Studies to understand OER mechanisms and real active sites by experiments and theory calculations are also vital for catalysts design. Besides, self-supporting electrodes demonstrate more satisfied activities and stability than powder catalyst electrodes attributed to its 3D structure and high three-phase contact area, which has more potential in industry.

2.2. Current and future challengesCurrently, a great progress has been made in mechanism understanding and catalyst designing. Since 1930s, several OER mechanisms were proposed, from which the metal peroxide path, also named adsorbate evolution mechanism (AEM), has been widely used for metal-based materials. This mechanism involves multiple adsorbed intermediates (*OH, *O, *OOH, *O2) that exhibit highly correlated adsorption strength. Moreover, kinetics of those mechanisms was studied since 1950s by assuming various rate controlling steps (RCS) first and then equilibrium equations were used to calculate the reaction rate, from which tafel slop was found as a constant varying with different RCS. A recently identified mechanism for perovskite oxides, namely the lattice oxygen oxidation mechanism (LOM) involving direct O-O coupling of intermediates and lattice oxygen, shows lower energy barrier for RCS [23]. It is mandatory to understand mechanisms and find out its kinetic pathway on different catalysts. However, the attention of mechanism research on specific catalysts is still insufficient.

Current OER catalysts can be classified into two categories. Noble metal catalysts (e.g., IrO2 and RuO2) are among the most active catalysts reported to date (with overpotentials of ~330 mV and ~270 mV at current density of 10 mA/cm2, respectively). Due to their high cost and low elemental abundance, IrO2 and RuO2- based materials with high surface area-to-mass ratios have been studied. The activities of these oxides depended on particle sizes, crystal structures (rutile or amorphous), surface terminations, and degrees of hydration (IrO2·xH2O or RuO2·xH2O). As reported, rutile IrO2 and RuO2 nanoparticles and thin films with (100) crystal face show better performance than other structures [24]. In addition, some researches focus on using non-noble metal atoms like Co to substitute noble metals to decrease their usage and also to modify their properties further via doping, building complex and so on. Non-noble metal catalysts - transition metal compounds including metal oxides, hydroxides, oxy-hydroxides, sulfides, phosphides, alloys, etc., show promising activities in OER (with overpotentials of ~190-460 mV at current density of 10 mA/cm2) attributed to their adjustable electronic structures [25]. Among these, the perovskite oxides and lanthanide nickel oxides with eg occupancy close to 1.2 and high covalency of transition metal-oxygen bonds demonstrate excellent activities. Besides, coordination unsaturated metal organic frameworks (MOFs) and heteroatom (N, S, P, O) doped carbon materials with intrinsic defects also show considerable activities. The real active sites of most metal compounds are regarded as MOOH (M = Co, Ni, Fe, etc.) in-situ formed under the high potential oxidization process, which is also more active than pre-formed MOOH crystals probably due to crystal defects and multi-substances synergistic effect.

There are some factors influencing the performance of catalysts, such as morphology, crystal phase and facets, eg electronic configuration, strain, magnetism, which are actually electronic structure regulations to make appropriate adsorption energies of each oxygen intermediates to decrease overpotentials. Some regulation strategies like defect engineering, coordination control and multi-atoms synergistic effects are efficient to modulate the electronic structures to enhance conductivity and optimize intermediates adsorption energies. Especially metal vacancy defects can not only induce electron delocalization to increase electronic conductivity but also modulate coordination and electron structure of lattice oxygen to improve H2O activation and optimize adsorption of intermediates [26, 27]. Besides, recent reports show the magnetic enhancement of electrocatalysis by applying moderate magnetic field to anode, on account of electron spin polarization modulation of active sites and intermediate radicals for optimal adsorption [28].

Although great progress has been made in decreasing overpotential of OER by trying a mass of related catalysts, the bottleneck still exists in current catalyst systems for further improving performance. Hence, more open mind should be used to develop new OER pathways beside catalysts design to bypass high energy barrier steps and substantially reduce energy consumption. For example, it will be imaginative to couple OER with analogous mechanism reactions such as Fenton like reactions. Moreover, under conditions with high oxidation potential and alkali solution, many catalysts will transform to real active sites rapidly, but become relatively stable compound after removing the voltage. As a result, the real active sites are still unclear, which is another challenge to understand the mechanism and catalyst design. In addition, stability studies are far from meeting the requirements of industrialization (>1584 h, one quarter) at high current density (500 mA/cm2).

2.3. Advances in science and technology to meet challengesMore high-end instruments and technologies can be used to characterize the structure of catalyst, so that the structurefunction relationship and OER mechanisms can be better understood. Especially in-situ characterizations like XAFS, Raman, FTIR, etc. are good probes to detect reaction intermediates, as well as the in-situ change of catalysts and real active sites. Combined with electrochemical testing techniques, the reaction kinetics of each step can be measured, so that the catalyst can be modified in a targeted manner. DFT is another powerful tool widely used in simulating of material properties, such as conductivity, electron structures, and adsorption/desorption energies.

2.4. Concluding remarks and prospectsOER as an essential but sluggish reaction of hydrogen production and energy storage is widely studied from aspects of mechanism and catalysts design. With the help of in-situ characterizations and theory calculations, structure-function relationship of catalysts and OER mechanisms have been illustrated to some degree, and thereby many promising catalysts have been developed. In terms of application in industry, more attention should be paid to catalysts in acid electrolyte to fit current proton exchange membrane (PEM) in water splitting, and bifunctional catalysts (OER/ORR) in alkaline electrolyte for rechargeable metal-air batteries. Moreover the stability at high current density should be a focus to satisfy requirements of industrialization.

2.5. AcknowledgmentThe authors appreciate the support from the National Natural Science Foundation of China (Nos. 21676193, 51661145026).

3. Electrocatalytic hydrogen evolution reactionMengmeng Lao, Wenping Sun*

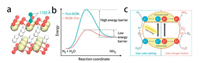

3.1. StatusHydrogen generated from electrochemical water splitting, particularly driven by renewable energy resources, will play an important role in the future clean and sustainable energy society. Basically, the water electrolysis process consists of two half elemental reactions: oxygen evolution reaction (OER) and hydrogen evolution reaction (HER). The development of costeffective and efficient electrocatalysts is critical for realizing the large-scale application of water electrolysis for hydrogen production. The electrocatalytic reaction is a heterogeneous process that occurs on the catalyst surface. According to Sabatier principle, an optimized catalyst surface for a given reaction should have a moderate adsorption strength for the reaction intermediates [29]. Volcano plots, where the exchange current densities (i0) obtained from experimental results plotted as a function of the calculated free energy of hydrogen adsorption (ΔGH*), were developed to elucidate the intrinsic activity of various metal catalysts for HER in acidic medium. As shown in Fig. 3a, it is clear that platinum group metals (PGMs) sit at the top of the volcano plot under acidic conditions, demonstrating the highest HER activity [30]. Although descriptors for alkaline HER activity have not been unified, Markovic et al. also built a simple "volcano" to study the alkaline HER activity trend by plotting overpotential as a function of metal-hydrogen binding energy, which also implies that PGMs exhibit the highest activity (Fig. 3b) [31]. The scarcity and high cost of PGM-based catalysts significantly hinders the substantial large-scale application of water electrolysis plants. In order to address this concern, a varieties of catalyst design strategies and catalyst systems have been developed, including but not limited to, single atom-catalysts (SACs) with ultralow metal loading and long-term durability [32], transition metal-based catalysts such as transition metal dichalcogenides (TMDs) [33], and metal-free catalysts such as heteroatom-doped carbon [34]. Although significant research progresses have been achieved, the activity of those new catalyst systems is still inferior to those of PGMs under both acidic and alkaline conditions. Particularly, the development of alkaline HER catalysts is a bigger challenge. The reaction pathways under alkaline conditions are more complicated (Fig. 3c). It is generally proposed that an additional energy barrier for water dissociation needs to be overcome to proceed the subsequent hydrogen production process [35], and it was found that the alkaline HER kinetics could be greatly accelerated by developing hybrid catalysts with the incorporation of a co-catalyst for water dissociation like Ni (OH)2 (Fig. 3d) [36].

|

Download:

|

| Fig. 3. (a) Volcano plot of i0 as a function of ΔGH* for various metal-based catalysts in acidic conditions. Produced with permission [30]. Copyright 2010, American Chemical Society. (b) A volcano plot, measured in 0.1 mol/L KOH (pH 13), of several metals denoting their HER activity, overpotential at 5 mA/cm2 as a function of their calculated M–H binding energy. Produced with permission [31]. Copyright 2013, Serbian Chemical Society. (c) Schematic pathways for hydrogen evolution reaction under acidic and alkaline conditions. Produced with permission [35]. Copyright 2018, Springer Nature. (d) Comparison between activities for the HER, expressed as overpotential required for a 5 mA/cm2 current density in 0.1 mol/L HClO4 and 0.1mol/L KOH for both bare metal surfaces and Ni (OH)2 modified surfaces. Produced with permission [36]. Copyright 2012, John Wiley & Sons, Inc. | |

3.2. Current and future challenges

Considering the scarcity of PGMs, one challenge is developing efficient catalyst design strategies to substantially reduce PGMs loadings without deteriorating the performance of the catalysts. Secondly, exploiting PGM-free catalysts with comparable activity to that of PGMs is much tougher. For example, the active centers of MoS2 have been verified to be the edge sites. Triggering the activity of basal planes to enhance the catalytic activity is very challenging. Thirdly, it is of great significance to design either PGM- or PGM-free-based heterostructures to address the sluggish kinetics of water dissociation for alkaline HER, and the descriptors for illustrating the alkaline HER activities have not been unified as well. Further, it is also challenging to seek effective approaches that can precisely control and determine the active sites of the catalysts. Moreover, although a large number of electrocatalysts with promising catalytic performances have been reported, the inherent reasons for the enhanced catalytic activity and quantitative structure-property relationships still require indepth understanding.

3.3. Advances in science and technology to meet challengesEngineering PGM-based heterostructures with low PGM loading is no doubt one of the most promising approaches. It has been extensively reported that the unique heterostructures with well-defined interfaces could improve the intrinsic activity, the density of active sites, and performance durability simultaneously. Specifically, designing heterostructures combined decent water adsorption/dissociation capability with favourable hydrogen affinity has been proved to be an appealing way to accelerate the sluggish alkaline HER kinetics [36, 37]. For example, Sun et al. reported a new Pt/Ni(HCO3)2 heterostructure, where Pt nanoparticles (NPs) were uniformly anchored on Ni (HCO3)2 nanoplates, towards efficient alkaline HER [37]. The promoted alkaline HER activity could be attribute to the following reasons: ⅰ) the electron redistribution at the interface of the heterostructure, which optimizes the hydrogen affinity of the Pt surface and thus enhances its intrinsic HER activity; ⅱ) the welldispersed Pt NPs with high exposure of active sites, and the strong interaction between Pt NPs and Ni(HCO3)2 which prevents the aggregation of Pt NPs during long-term operation; ⅲ) the accelerated Volmer step of alkaline HER process due to the strong water adsorption/dissociation capability of Ni (HCO3)2. Furthermore, developing TMD-based heterostructures is supposed to be another profound strategy, where the catalytically inert basal planes of TMDs can be triggered by the electron interaction and synergistic effect, thus promoting the HER activity [38]. The combination of advanced characterization protocols such as scanning transmission electronic microscopy (STEM), X-ray absorption fine structure (XAFS) and density function theory (DFT) computation methodologies could provide detailed information on the atomic coordination and electronic structure modulation at the interface of the heterostructured catalysts, which is of critical importance for acquire deep understanding of the interface chemistry and the underlying structure-property relationships of the catalysts.

3.4. Concluding remarks and prospectsSignificant progress on rational design and development of HER electrocatalysts has been achieved recently. Nevertheless, there still exist many scientific concerns for HER, such as how to construct single/multiple descriptors for elucidating the origin of alkaline HER activity, and how to illustrate the so-called "synergistic effect" regarding the enhanced catalytic activity of heterostructures in a more convincing way. Researchers should pay more attention to taking the advantages of computational chemistry for investigating the energetics and kinetics of this reaction particularly alkaline HER, and to finally establishing reliable principles for guiding alkaline HER catalysts design. The alkaline HER mechanism remains to be comprehensively understood by the development of advanced in-situ characterization techniques along with theoretical calculations. With regard to catalyst design, surface and interface engineering by designing heterostructures would be the forefront. Controlling and understanding the interface chemistry at atomic level of the heterostructures would be vital to unravelling the related performance enhancement mechanism and achieving rational design of efficient electrocatalysts.

3.5. AcknowledgmentWe acknowledge the support from Australian Research Council (ARC) DECRA Grant (No. DE160100596).

4. Electrocatalytic CO2 reduction toward specific productsChao Yang, Gengfeng Zheng*

4.1. statusThe emission of anthropogenic CO2 gas has been increasing, especially in the combustion of fossil fuels. About 880 ± 35 Gt CO2 of the emissions are still in the atmosphere except for those stored on land (plants and soil) and in the ocean [39]. The accumulated CO2 greenhouse gas is important factor that causes the global temperature to rise in recent years. The electrocatalytic CO2 reduction (ECR) reaction has been suggested as a viable alternative that may help to close the anthropogenic carbon cycle and convert electricity to chemical energy in the form of fuels and feedstocks.

4.2. Current and future challengesCompared to the traditional thermo-catalytic transformations of CO2, the ECR uses protons from the water instead of H2 produced by methane reforming in traditional catalysis. Although there are extensive researches focused on the ECR process by experiments and theories, many significant challenges still remain. Electrochemical reduction of CO2 is a multi-step reaction process, leading to complicated products. Among them, CO and formate are the two simplest products of ECR, which only need two proton-electron pairs. These two C1 products possess different critical intermediates, known as *COOH and *HCOO (where * indicates the atom bound to the catalyst), respectively [40]. Multi-carbon products, such as ethylene and ethanol, represent a more attractive feature for ECR due to their higher energy storage capacity and reactive capability. However, the selective formation and subsequent separation of different products, as well as the elucidation of the molecular-level reaction mechanisms place a critical challenge in these processes. As a consequent, the rational design of electrocatalysts toward specific products should be a key principle for high-efficiency catalysts, especially for the multi-carbon products. Moreover, these electrocatalysts generally present a lower product yield, which limits their further application in the industry. Thus, enhancing both the selectivity and activity is the central part of further research.

4.3. Advances in science and technology to meet these challengesCO, as a significant intermediate, is not only evolved by the twoelectron transfer, but also plays an important role in the C-C coupling to form multi-carbon products. For the CO formation, physisorbed CO2 transforms to chemisorbed CO2 (*CO2δ-) by a single electron reaction, subsequent *CO2δ- protonation to form *COOH, and the dissociation of *COOH to form *CO, by the electroncoupled hydrogenation [41]. The first step for the formation of *CO2δ- is always recognized as the rate-determination step (RDS), with a free energy barrier of 0.43 eV (Fig. 4a) [41].

|

Download:

|

| Fig. 4. (a) Reaction pathway of CO2 to C1 products. (b) Edge site weight percentage for a 2 nm wide Au NW and an Au NP as a function of the number of Au atoms. (c) Idealized ratios of edge/corner for the Au NW and Au NP. (b, c) Produced with permission [42]. Copyright 2014, American Chemical Society. (d) Free-energy diagrams for HCOO-, CO and H2 formation on Bi (001) plane. (e) Projected p-orbital density of states (DOS) of the Bi site with OCHO*, COOH*, or H* adsorbates. The Fermi level (EF) was at 0 eV. Ep in OCHO*, and COOH* and H* were highlighted with yellow, blue, and green dashed lines, respectively. (d, e) Produced with permission [43]. Copyright 2018, Nature Publishing Group. (f) Reaction pathway of *CO to C2+ products in different pH scale. Produced with permission [44]. Copyright 2016, American Chemical Society. (g) Schematic illustration of the graphite/carbon nanoparticles/Cu/PTFE electrode. (h) Cross-sectional SEM image of a fabricated graphite/carbon nanoparticles/Cu/PTFE electrode. (g, h) Produced with permission [46]. Copyright 2018, American Association for the Advancement of Science. (i) Selectivity of Cu2O, Ag-Cu2OPS, Ag-Cu2OPB. Produced with permission [47]. Copyright 2017, American Chemical Society. (j) Reaction pathways for ethanol on a Cu (111) surface. Produced with permission [48]. Copyright 2019, American Chemical Society. | |

Many metal catalysts have been demonstrated to have a good performance for CO2 to CO, such as Au, Ag, Zn, Pd. Au and Ag are noble metal catalysts with high intrinsic selectivity of CO2 to CO. Besides, as these two elements are on the weak bonding side of Cu from the ECR volcano plot, they are easy for *CO desorption to obtain CO product [40]. Based on this, the morphology, grain boundaries and the size effect of Au and Ag have attracted the attention of researchers. For instance, Sun et al. synthesized ultrathin 2 nm Au nanowires supported by carbon, reaching a 94% CO faradaic efficiency (FE) at –0.35 V versus reversible hydrogen electrode (RHE), duo to a high edge-to-corner ratio (Figs. 4b and c) [42]. Considering the expense of the noble metal, carbon- based materials by modulating the electronic properties of adjacent carbons, and single atom materials with tunable coordination environments, have also shown promising CO performances [40]. On the other hand, formate has a high production value per mole electron (16.1×10-3 $/mol electron), with various industrial applications such as a promising chemical for hydrogen storage. In an ECR process, formate is produced through the *HCOO intermediate, bounded to the surface via both oxygen atoms. The P-block metals (e.g., Sn, Bi, In and Pb) are generally the main section for selectivity to formate. For instance, Li and coworkers reported that ultrathin bismuth (Bi) nanosheets prepared by the in-situ topotactic transformation of bismuth oxyiodide nanosheets showed an optimal performance of >90% formate FE over a broad potential (Figs. 4d and e) [43]. Besides, the Pd-based catalyst in ECR is also a research hotspot, which can reduce CO2 to different C1 products, highly dependent on the applied potential, pH, electrolyte concentration, and electrolysis time.

Compared with C1 products, the formation of high-efficiency multi-carbon products are confronting more complicated reaction pathways and more electrons and proton transfer. To date, Cu is the only pure metal that can reduce CO2 to products with >2e transfers. Considering the whole process, the C - C coupling plays a significant role, which involves pathways with *CO intermediates. For instance, Goddard and coworkers proposed a whole pH scale for multi-carbon products by density functional theory (DFT). At an acidic pH, the C2 (or C3) pathways are kinetically blocked. At a neutral pH, *COH (i.e., the protonated *CO) is the common intermediate, followed by a CO - COH pathway to achieve the C-C coupling. At a high pH, the early C - C coupling through adsorbed CO dimerization suppresses the C1 pathways by kinetics, thereby boosting selectivity for multi-carbon products (Fig. 4f) [44]. The effect of the applied potential and *CO coverage have also been studied. At potentials greater than -0.6 V (vs. RHE), CO was dimerized at the lowest activation energy barrier (0.69 eV), and then *OC - CO intermediate is immediately reduced to *OC - COH and *HOC - COH. At this low potential, the hydrogenation steps take place in the ethylene pathway through the Eley–Rideal mechanism with the protons provided by water molecules. With the increasing of potential, the competition of the *H and *CO occurred due to the higher surface protons binding energy. Thus, the mechanism for ethylene production was altered to the *CHO and *CO coupling at potential less than -0.85 V (vs. RHE). At more negative potentials, the much more *H active sites block the CO adsorption, which slows down the *CO dimerization [45].

Based on the perplexing roadmap of the ECR to C2+ products, we must explicitly design our catalysts in more specific product orientation. Ethylene is a strongly demanding precursor for plastics and ethylene glycol production process, which is normally obtained by processes involving repeated cycles of steam cracking at 750 - 950 ℃ followed by a series of quenching, distillation, and recompression. Sargent and coworkers reported that a copper electrocatalyst at an abrupt reaction interface in an alkaline electrolyte can reduce CO2 to ethylene with 70% Faradaic efficiency at -0.55 V (vs. RHE). In such a system with adaptability to abrupt environment, constant ethylene selectivity was achieved for 150 h. Meanwhile, the electrolyzer engineering can help to eliminate the mass transport limitation of CO2 dissolved in the liquid electrolyte (Figs. 4g and h) [46].

Ethanol (C2H5OH) is a fuel with high volumetric energy density nowadays and thus represents a market with high growth potential and profit compared with the common fossil fuels in the transport industry. Lee et al. incorporated Ag into the phaseblended Cu2O-Cu catalyst to get a 34.15% FE for ethanol at –1.2 V vs. RHE. The remarkable effect derived from the geometric characteristics of phase-blended Ag-Cu2O, which inferred that Ag and Cu are closer to each other within an appropriate distance for efficient CO insertion, leads to an enhancement in the product selectivity toward ethanol (Fig. 4i) [47]. Recently, Sargent and coworkers introduced Ag to a Cu catalyst, producing diverse binding sites confirmed by in-situ Raman spectroscopy. Such a Cu-Ag catalyst achieved an FE of 41% for ethanol at –0.67 V (vs. RHE) and provided a new physical picture to design multi-metallic catalysts to control reaction paths in CO2 reductions toward desired products (Fig. 4j) [48].

4.4. Concluding remarksFromwhat have been discussed above, we can realize the ECR is a promising direction for reducing the CO2 level and obtaining many value-added products. Based on different ECR products, extensive research efforts have been invested to design catalysts for different product specificity. In order to bring the technology closer to the industrial level, the key performance index (such as FE, current and stability) of most economically compelling products, such as CO, formate, ethylene and ethanol should be achieved a higher standard. There are several promising strategies to design catalysts oriented to specific products. Combined with the mechanism of a specific product path with the reaction condition, such as applied electric potential, surface coverage, pH, a vast variety of opportunities can be further revealed in this highly promising and important direction.

4.5. AcknowledgmentWethank the National NaturalScience Foundation of China(No. 21773036) for supporting this work.

5. Earth-abundant catalysts for electrochemical N2 reductionQiling Peng, Ting Wang, Yonglan Luo, Xuping Sun*

5.1. StatusNH3 plays a key role in the Earth's ecosystem and is widely used as an activated N2 building block to manufacture fertilizers and other products. Due to its large hydrogen capacity (17.6 wt%) and high energy density (4.3 kWh/h), NH3 is also regarded as an attractive energy carrier to establish a low-carbon society. The ever-increasing NH3 demand has stimulated significant research interest in artificial N2 fixation. Converting N2 to NH3, however, is difficult because N2 is quite unreactive due to its strong N≡N bond (with bond energy of 941kJ/mol), low polarizability, and lack of dipole moment. Currently, industrial-scale NH3 production mainly relies on the Haber–Bosch process operating at high temperature andpressure.This process consumes a large amount of energy with heavy CO2 emission. In this regard, searching an environmentallybenign and sustainable alternative for artifical N2-to-NH3 fixation is of great importance.

Biologically, N2 fixation occurs at ambient conditions enabled by natural nitrogenases in specific bacteria through multiple proton and electron transfer steps with a significant energy input delivered by ATP. Electrochemical N2 reduction has emerged as an environmentally-benignprocess for sustainable NH3 production at ambient conditions, but it is severely challenged by N2 activation and its efficiency strongly depends on the identification of electrocatalysts with high activity for the N2 reduction reaction (NRR) [49, 50].

5.2. Current and future challengesPrecious-metal catalysts perform efficiently to catalyze the NRR, their scarcity and high cost however hinder the widespread uses. Although organometallic catalysts show high selectivity, they not only suffer from limited stability under rigorously reducing conditions, but face difficulty of effective immobilization onto electrode surfaces because of synthesis issues of such complexes. Another big issue lies in the competitive hydrogen evolution reaction which limits the current efficiency for NH3 formation. It still remains a key challenge to design and develop earthabundant heterogeneous NRR electrocatalysts with a high Faradic efficiency (FE) and a large NH3 yield rate for ambient N2-to-NH3 conversion.

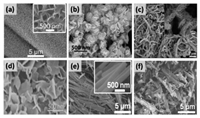

5.3. Advances in science and technology to meet challengesMo is not only involved in nitrogenases to catalyze the natural N2 fixation underambient reactionconditions [51], but also proven as the most successful metal for homogeneous N2 functionalization reactions and many Mo-based molecular complexes have been designed for N2 reduction [52]. Although achieving high selectivity, these homogenous catalysts suffer from limited stability under rigorously reducing conditions, and they also face another difficulty in effective grafting onto electrode materials because of synthesis issues of such complexes. These issues have been solved by developing heterogenous nanoelectrocatalysts. Inspired by that Mo and S elements play significant roles in nitrogenases, we first performed theroetical calculations to study the electronic structures of MoS2 and mapped out the energy profile of NRR on MoS2, with a conclusion that the positively charged Mo-edge played the key role to polarize and activate the N2 molecules [53]. To verify the electrocatalytic activity of MoS2, a proof-of-concept experiment was designed by using MoS2 array on carbon cloth as the cathode, although this catalyst only achieves a low FE of 1.17%. Subsequently, we developed defect-rich MoS2 nanoflower through improvement of preparation technology to boost the NRR activity [54]. This catalyst attains a much higher FE of 8.34% with a large NH3 yield of 29.28 mg h–1 mgcat–1 at -0.40 V vs. reversible hydrogen electrode (RHE), outperforming defect-free MoS2 counterpart (2.18% and 13.41 mg h–1 mgcat–1), with strong electrochemical stability. In another study, Zhao and co-workers demonstrated in-operando created strong Li-S interactions empower the S-rich MoS2 nanosheets with superior NRR catalytic activity [55]. These interactions effectively suppress the HER by reducing H* adsorption free energy from 0.03 eV to 0.47 eV, facilitate N2 adsorption by increasing N2 adsorption free energy from -0.32 eV to -0.70 eV and improve the NRR activity by decreasing the activation energy barrier of the reaction control step (*N2 → *N2H) from 0.84 eV to 0.42 eV. Very interestingly, our results also confirm that other Mo compounds are also active to catalyze the electrochemical N2 reduction, including MoO3 [56], Mo2N [57] and Mo2C [58]. Fig. 5 shows the scanning electron microscopy images for these Mobased NRR nanoelectroatalysts.

|

Download:

|

| Fig. 5. Scanning electron microscopy images for Mo-based NRR nanoelectroatalysts: (a) MoS2 nanosheets/carbon cloth. Produced with permission [53]. Copyright 2018, Wiley-Blackwell. (b) defect-rich MoS2 nanoflowers. Produced with permission [54]. Copyright 2018, Wiley-VCH Verlag. (c) S-rich MoS2 nanosheets. Produced with permission [55]. Copyright 2019, Wiley-VCH Verlag. (d) MoO3 nanosheets. Produced with permission [56]. Copyright 2018, Royal Society of Chemistry. (e) Mo2N nanorods. Produced with permission [57]. Copyright 2018, Royal Society of Chemistry. (f) Mo2C nanorods. Produced with permission [58]. Copyright 2019, American Chemical Society. | |

As one of the cheapest and most abundant metals on the earth, Fe also exists in biological nitrogenases in the form of Fe-protein and MoFe- protein for reduction of N2 to NH3. The Haber–Bosch process uses Fe catalysts to make NH3 from N2 and H2. Fe is also emerged as an interesting metal with catalytic power for electrochemical N2-to-NH3 fixation. Licht et al. reported using Fe2O3 for efficient N2 reduction electrocatalysis in a molten hydroxide electrolyte cell at temperatures ≥200 ℃ [59]. Under ambient conditions, however, carbon nanotube- supported Fe2O3 nanoparticles as a NRR catalyst only achieves a low FE of 0.15% [60]. Fe3O4 is also capable of catalyzing the NRR with a FE of 2.6% [61]. Our recent studies suggests that β-FeOOH nanorod acts as a highperformance NRR catalyst with a FE of 6.7% [62] and its current efficiency for NH3 formation can be further increased to 9.02% by F doping [63]. Besides, Fe3S4 attains a FE of 6.45% for the NRR [64]. V has been found in some organisms such as algae and fungi, and it is directly relevant to the active center or cofactor of nitrogenase. Theoretical [65] and experimental [66] studies suggest that VN is active for electrocatalytic N2 reduction. Both V2O3/C [67] and VO2 hollow microsphere [68] are also proven effectively for the NRR.

Although Mn2+ is not involved in nitrogenases, previous studies suggest that Mn2+ can greatly enhance the catalytic activity of nitrogenases in extracts from the photosynthetic bacterium rhodospirillum rubrum. Although playing an important role in vitro activate nitrogenases for N2 fixation, Mn2+ is not required for the catalysis. In this regard, it is quite interesting to examine the electrochemical NRR behavior of Mn compounds. Our experimental results suggest that MnO particles on Ti mesh behaves as a robust NRR catalyst for high-performance electrohydrogenation of N2 to NH3 with excellent selectivity at ambient conditions, capable of attaining a high FE of 8.02% and a large NH3 yield of 1.11×10–10 mol s–1 cm-2 at –0.39 V vs. RHE [69]. Of note, metal oxides of other metals without any implications for nitrogenases are also able to perform efficiently for N2 reduction electrocatalysis, including Ti [70], Cr [71], Nb [72], W [73], Co [74], Sn [75], etc.

Some progress has also been achieved in metal-free NRR catalysts. We adopted boron carbide (B4C) nanosheets as a catalyst for high-performance electrochemical NRR process at ambient conditions [76]. S has been utilized as an effective dopant to increase the NRR performances of carbon sphere [77] and graphene [78]. Effective N2 reduction electrocatalysis is also enabled by sulfur dots-graphene nanohybrid [79]. B [80] and O [81] are also effective as dopants to boost the NRR performances of graphene. All these carbon nanocatalysts, however, suffer from the involvement of energy-intensive high-temperature thermal annealing processes for material preparation. We also reported a proof-of-concept demonstration of using a chemically oxidized carbon nanotube as a superior NRR electrocatalyst with a high FE of 12.50% and a large NH3 yield of 32.33 mg h-1 mgcat–1 and at -0.4 V vs. RHE [82]. Our recent work further suggests that surface modification of reduced graphene oxide (rGO) by oxygen-rich tannic acid (TA) is also a mild and effective strategy to boost the NRR activity [83]. It is believed that the strong π–π stacking interactions between π-rich TA and rGO brings the TA into very close proximity to rGO, leading to intimate contact of the oxygen groups of TA and rGO, which favors the effective manipulation of the electronic property of rGO. Of note, other non-metal materials like B [84], black P [85], BP [86], BN [87] and carbon nitride [88] are also active for the NRR.

5.4. Concluding remarks and prospectsAlthough tremendous studies have been carried out in electrochemical N2 reduction, this process is still challenged by N2 activation and its efficiency. Such issues can be fixed by introducing heteroatoms or defects to tune the electronic structures, exposing more active sites, and enhancing the adsorption and activation of N2 molecules. Surface/interface engineering would be another effective strategy. Considerable recent attention has focused on screening non-noble-metal catalysts by theoretical calculations, but more detailed experimental evidences still lack. The perfect combination of theoretical and experimental studies is needed to drive continuous progress in this emerging field of electrochemical N2-to-NH3 conversion for applications.

5.5. AcknowledgementThis work was supported by the National Natural Science Foundation of China (No. 21575137).

6. Photoelectrocatalytic O2 reductionAlexander S. Konev, Oleg V. Levin*

6.1. StatusOxygen reduction reaction (ORR) is a key process in fuel cells technology and it also has a strong prospective for waste water treatment through in situ generation of a green and strong oxidant, H2O2. In energy converting systems, such as fuel cells, oxygen reduction reaction occurs at the cathode, either as a four-electron reduction to H2O or as a two-electron reduction to H2O2. Sluggish ORR kinetics fosters the development of cathode materials capable of catalyzing this process. Additionally, ORR may be enhanced by irradiation of the cell with visible light. An impressive number of photocatalytic systems with internal electron transfer has been reported for production of H2O2 via photoinduced ORR (Fig. 6a), with H2O2 concentration approaching 3 mmol/L [89]. Probing of the photoredox reactions in electrochemical cells [90] created a novel concept of photocatalytic fuel cells [91]. Anodic process was proven to account for the observed photoresponse in most of such systems, while cathodic ORR was shown to be independent on illumination [92]. In accord with this, most common architecture of photoelectrochemical cell contains water splitting photoanode, with oxygen reduction occurring as a dark process at catalytic cathode (Fig. 6b). Application of dual-compartment architecture for such cells allowed to raise the H2O2 concentration limit to impressive 61 mmol/L [93].

|

Download:

|

| Fig. 6. Implementation of photoinduced ORR. (a) Photoredox catalysis: O2 is photocatalytically reduced by the catalyst, which is recovered by using a sacrificial electron donor. (b) Photoanodic cell: electrocatalytic reduction of oxygen by dark cathodic process, driven by photoelectrochemical water oxidation at photoanode. (c) photocathodic cell: photoelectrocatalytic oxygen reduction at photocathode, coupled with a sacrificial electron donor oxidation at anode. | |

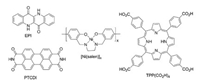

Cells with photoactive cathode (Fig. 6c) are less usual, which is caused by presumed instability of most p-type semiconductors in contact with an electrolyte [91]. To date, true photoelectrocatalytic O2 reduction is reported mostly on organic semiconductors with quinone-like electrochemistry [94], porphyrins [95] and metal salen-type complexes as active redox centers [96] (Fig. 7). The most recent example of organic photoelectrocatalysts reports photocurrent density of ca. 600 μA/cm2 (1 sun illumination, 0.22 V vs. RHE), faradaic efficiency of 60% and H2O2 concentrations of millimolar level [97].

|

Download:

|

| Fig. 7. Examples of compounds used as catalysts for photocathodic ORR: EPIepindolidione, PTCDI- N, N'-dimethyl perylenetetracarboxylic acid diimide, [Ni(salen)]x-polymerized Ni complex with salen ligands, TPP(CO2H)4-5, 15, 20, 25-tetrakis(4-carboxyphenyl)porphyrin. | |

6.2. Current and future challenges

The efficiency of H2O2 production is governed by the faradaic yield of two-electron ORR vs. four- electron ORR and by the rate of this process measured as photocurrent at photocathode. The reported values of faradaic efficiency in one-compartment cells range typically from 15% to 80%. At least in some cases, the observed non-quantitative faradaic efficiency was shown to be caused by re-oxidation of the produced H2O2 at the anode [98].

Typical photocathodic currents for hydrogen evolution are two orders of magnitude higher than the observed values for H2O2 production (e.g., 22 mA/cm2 vs. 0.1 mA/cm2, 1 sun irradiation, 0 V vs. Ag|AgCl). Taking into consideration concentration and diffusion rate for dissolved O2, theoretical photocathodic current for ORR was predicted by Gryszel et al. to be limited by several mA/cm2, which shows the prospect for the increase of the present values of photocathodic current [94].

In terms of practical applicability, achievement of stable photocurrent response is the important challenge due to the known problem of photocurrent decline during the cell operation [94, 96, 98]. The origin of this problem might be either degradation of the photocathode material [96] or detrimental morphological changes in the photoactive layer [94, 98].

An interesting approach of in situ utilization of superoxide radical-anions generated by photocathodic ORR was suggest by Wu et al., who report on mA/cm2 photocurrent densities for transformation of benzoyl chloride to benzoate by using a PTCD-Ipolythiophentriphenylamine dye as a photoelectrocatalyst of ORR in non-protic medium [97].

6.3. Advances in science and technology to meet challengesPerformance of the photocathodes for H2O2 production was shown to be limited by charge carriers recombination [94]. However, control of the recombination rate by deposition of the electron collecting Au layer on the photoelectroactive material/solution interface, though gave 20-fold increase in photocurrent (to 800 μA), declined the faradaic efficiency to 18%-30%, which is caused by catalyzing of both four-electron and two-electron ORR on Au surface. To favor two-electron ORR, Au layer was covered with organic dyes EPI or PTCDI, that recovered the faradaic efficiency to 60%-80% without loss in photocurrent [94]. Further improvement in faradaic efficiency could be achieved by separating the anodic and cathodic space with a porous membrane to suppress re-oxidation of H2O2 at the anode [98]. Gryszel et al. suggest that utilization of a bulk heterojunction instead of layered architecture should allow for further improvement in the cell performance [94].

A mirror solution to the problem of the simultaneous increase of faradaic efficiency and photocurrent might be implication of dye-sensitized NiO as the photoactive cathode material, where NiO acts as a hole-collecting layer on the pigment/current collector interface and decreases the recombination rate of charge carriers. This allowed to obtain photocurrent of up to 400 μA/cm2 and close to 100% faradaic efficiency in a two-compartment cell [95].

Though significant success has been achieved in affording high faradaic efficiency and photocurrent, securing stability of the photoresponse remains to be mentioned as an issue to be solved, typical reported periods of stable operation of photoelectrosynthetic cells being tens of hours. It should be stressed, however, that the observed decline in cell performance may be caused not only by chemical instability of the material [96], but also by morphological changes of the photoactive layer [94]. Utilization of non-covalent intermolecular interactions like hydrogen bonding can be mentioned as an interesting approach to fix the layer morphology [98], while structural modifications of the photocatalyst to impart hydrophobicity to the material could help to overcome the chemical instability problem [97].

6.4. Concluding remarks and prospectsAt first glance, O2 reduction in photo (electro)chemical cells is a process known for quite a long time. However, most examples involve oxygen reduction as a dark process coupled with photoinduced water oxidation either at anode or at the semiconductor surface. Though true photocathodic oxygen reduction has been known since early 80 s, formulation of the concept of photoelectrocatalytic fuel cells and positioning of H2O2 as a cheap and "green" oxidant catalyzed the recent interest to this topic. To date, organic dyes based photocathode materials showed attractive performance producing H2O2 in millimolar concentrations and giving photocurrent density of up to 800 μA/cm2, which is still below the few milliampere limit based on O2 concentration and diffusion rate. To achieve this goal, suitable photoredox catalysts, including those applicable for solution processing, and favorable architecture of the photoelectrochemical cell are searched. As prospective catalysts, π-extended organics with carbonyl or phenol fragments capable of demonstrating quinone-like redox behavior and showing high light absorption in visible range can be envisioned. Implementation of device architectures developed for photovoltaic devices like bulk heterojunction, p-n junction and dual band gap configurations is expected to constitute future trend.

6.5. AcknowledgmentThis work was supported by the Russian Foundation for Basic Research (No. 18-03-00864).

7. Photoelectrocatalytic H2 productionPanagiotis Lianos*

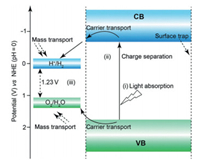

7.1. StatusPhotoelectrocatalytic hydrogen production involves the use of a photoelectrochemical cell where hydrogen is produced by reduction of protons or reduction of water at the cathode electrode. For this reason, the term "photoelectrolysis" or "photoelectrocatalysis" cell may also apply to the same procedure. In its most common configuration, the photoelectrocatalysis cell comprises two electrodes, one photoanode where oxidation reactions take place and one cathode electrode where reduction reactions take place [91]. In some cases, a photocathode may be used alone or in combination with a photoanode [91, 99]. In the standard configuration, the photoanode carries an n-type photocatalyst, which absorbs photons generating electron-hole pairs. Photogenerated holes are consumed in oxidation reactions while photogenerated electrons move through an external circuit to the cathode electrode where they assist hydrogen production. The efficiency of electron-hole separation depends on many factors, two of them being the most important. Thus the presence of a sacrificial electron donor helps consumption of holes while the existence of sufficient bias drives electrons away and thus prevents recombination. In the case of a photocathode, the photogenerated electrons are consumed in situ to carry out reductions while the holes are transferred through an external circuit to the anode. So far no photocathode has been found which is stable or efficient enough to substitute for the standard photoanode-dark-cathode configuration.

The sacrificial electron donor may derive from a broad choice of organic and inorganic materials. The most celebrated is water itself. Water can be photocatalytically oxidized at the photoanode producing oxygen and be reduced at the cathode producing hydrogen. This challenging project (water splitting) has enjoyed high popularity. However, water oxidation is a 4-electron low probability process thus demanding the presence of oxygen evolution catalysts [91, 99]. On the contrary, oxidation of organic substances is a 2-electron process [91]; therefore, it is easier to oxidize an organic substance than to oxidize water. In addition, oxidation of organics is facilitated in the presence of hydroxyl radicals who may be easily produced by simple one- electron processes OH- + h+ → ·OH. Despite of the tremendous popularity of water splitting, it is more interesting to photocatalytically produce hydrogen by oxidizing an organic sacrificial agent, a process that does notnecessitate anycatalyst other than the photocatalyst itself [100-103]. In addition, the organic substance may be a waste or a pollutant. In that case, a double environmental benefit is gained by degrading a harmful substance and producing renewable hydrogen though photoelectrocatalysis.

7.2. Current and future challengesThe most important factors ensuring cell function is hole scavenging and sufficient bias to drive electrons away from the photocatalyst. If water remains the target, it is necessary to search for oxygen evolution catalysts. However, the matter of hole scavenging is pretty well solved in the presence of organic donors, which offer the above discussed advantages. In this respect, the main challenge remains the complete mapping of the degradation products and the achievement of mineralization [104, 105].

The question of forward bias for electrons is equally important for water splitting as it is for the degradation of organic substances. This is an intrinsic propertyof the cell independentof what the fuel is. In fact no efficient photocatalysts have so far being found which may provide enough potential to drive electrons for hydrogen production. To make it more clear, hydrogen production is obtained at 0 V vs. SHE. The most popular (and most efficient) photocatalysts have a conduction band located either at slightly negative or at 0 V (TiO2 and BiVO4) or even below it at positive potentials (WO3 and Fe2O3). Photogenerated electrons in these photocatalysts cannot drive reduction reactions since they do not have enough electronegativity. Other n-type photocatalysts, like CdS, are better positioned but theyare vulnerable to self-oxidation. This is the reason that researchers have studied p-type semiconductors to make photocathodes. p-type semiconductors do provide electrons with sufficient electronegativity. However, photocathodes alone are no use in organics photodegradation and may only be used in combination with a photoanode. In a standard cell, an external bias is then necessary in order to produce hydrogen. To this end, researchers have examined several approaches. For example, to combine the photoelectrocatalysis cell with a photovoltaic cell or to use tandem cells, one generating the necessary bias and the other producing hydrogen [99]. In this respect, it is attractive to use a photocatalyst that necessitates the lowest possible bias, for example, TiO2 or BiVO4. Anyhow, photoelectrocatalysis is more interesting than electrolysis, which necessitates high voltages and powerful electrocatalysts while photoelectrolysis needs only photocatalysts and small bias ranging below 1 V [91, 99].

Another issue is the efficiency and the light-spectrum span of the photocatalyst. The best photocatalysts in terms of charge carrier mobility are TiO2 and WO3. However, titania absorbs only UV light while WO3 can absorb only a tiny portion of the Visible. This limits their capacity to absorb photons and to produce photocurrent. Visible light absorbing photocatalysts like BiVO4 and Fe2O3 have smaller charge carrier mobility, in particular hematite, and for this reason it must be deposited in very thin films, otherwise it is transformed into an insulator, again becoming weak charge generator. High charge mobility organometallic semiconductors like organometal halide perovskites cannot function in liquid environments, therefore, they are excluded. One solution is to sensitize titania with CdS quantum dots (Fig. 8). We have carried out a systematic study on CdS/TiO2 combined photocatalyst. It functions very well in alkaline electrolytes strictly in the presence of organic fuel. It may also be used in electrolytes containing sulfide salts. It seems then a good choice to spend more effort on improving titania sensitization than waste time on inefficient or exotic photocatalysts. In this respect, I believe that a lot of efforts have been wasted on the search for producing titania in various exotic forms. Nanoparticulate titania can do all the job while titania nanorodes, nanostars or nanoflowers are mere curiosities and offer only a small deal. Visible light absorbing BiVO4 also attracts a lot of interest and for this reason it is very frequently the subject of intensive research [91, 99, 103].

|

Download:

|

| Fig. 8. (a) Light absorption range and (b) photocurrent production by a CdS/TiO2 photoanode in the presence of ethanol in an alkaline electrolyte. | |

No mention has so far been made to the nature and the materials used for the construction of the (dark) cathode. The cathode electrode must carry an electrocatalyst which facilitates electron transfer from the electrode to the liquid phase. Any electrocatalyst must be characterized by the basic quality triad: large active surface, high conductivity and presence of active sites. These necessary properties are not simultaneously present in untreated materials, hence a great effort is made to develop efficient electrocatalysts. The benchmark choice is, of course, nanostructured noble metals, but they are expensive, limited in quantities and not without problems. This matter concerns not only photoelectrocatalytic hydrogen production but is more important in water electrolysis and fuel cells. Hydrogen production by proton or water reduction is a 2-electron process, therefore, not as difficult to realize as water oxidation. In fact, there are works which describe hydrogen production simply by nanoparticulate carbon electrocatalyst (carbon black) [102]. Such simple electrocatalysts are acceptable because photoelectrocatalysis is a slow process running at small current densities dictated by the light conversion limitations of the photocatalyst. Small current densities result into small hydrogen production rates, therefore, the research on powerful electrocatalysts is welcome but not of prime concern in photoelectrocatalytic hydrogen production.

7.3. Advances in science and technology to meet challengesThe above discussion lets a few issues to emerge as possible targets for the future. Mapping of photocatalytic degradation should be extended to cover all possible organic fuels and conditions for complete mineralization should be ensured. This effort will establish organic substances as first-choice fuel for photoelectrocatalytic hydrogen production. Of course, the ultimate target is the use of wastes or pollutants as fuel. Concerning the choice of photocatalyst, increased effort must be spent on titania sensitization in the Visible while further elaboration on visiblelight absorbing BiVO4 is also realistic. The search for efficient noble-metal-free electrocatalysts will continue, even though, as already said this is not of prime concern to photoelectrocatalytic hydrogen production at the present stage.

It is also necessary to design up-scaled devices. This has already been done in solar cells. In photoelectrocatalysis there exists no experience with up-scaling. Devices remain in laboratory scale so that issues such as charge collection and mass transfer remain at an infant age.

Finally, many researchers recently use photoelectrocatalysis to produce hydrogen peroxide instead of hydrogen, due to the several advantages H2O2 offers as a fuel [106]. In addition, formation of H2O2 does not necessitate a bias since it is formed by oxygen reduction at positive potential thus creating sufficient intrinsic bias. Researchers may then seriously consider this alternative instead of or parallel to hydrogen.

7.4. Concluding remarks and prospectsEnhancement of research on photoelectrocatalysis using organic fuels, search for efficient nanoparticulate titania sensitizers, elaboration on photocatalysts of certified efficiency and upscaling measures together with the study of alternative production of hydrogen peroxide instead of hydrogen may mark the future trends in photoelectrocatalysis.

8. How to improve the efficiency for photoelectrochemical water oxidationZhuofeng Hu*, Zhurui Shen*

8.1. StatusPhotoelectrochemical cells (PECs) are promising technology to convert solar energy into electrical energy or chemical fuel [107]. One important application of PECs is water splitting. Usually, a typical photoelectrochemical cell consists of a semiconductor photoanode, a Pt or graphite cathode, and a reference electrode (applicable). Under illumination, photoexcited electrons and holes are generated in the photoanode. Then, the photoelectrons will migrate to the cathode because the Fermi level of the Pt or graphite is often lower than the conduction band (CB) of the photoanode. As a result, with electrons accumulated, hydrogen could be produced on the cathode. On the photoanode, band bending induces an internal electric field toward the electrolyte. The remaining holes in the photoanode will be driven by the electric field to the interface between the photoanode and the electrolyte. As a result, the hole could oxidize water to produce oxygen. Currently, the most widely-used photoanode materials are metal oxides and sulfide. The photocurrent density is in the range of 1.0 - 8.0 mA/cm2 under AM 1.5 G illumination.

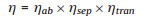

8.2. Current and future challengesThe efficiency of a photoelectrochemical cell is determined by the light absorption efficiency, charge carrier separation efficiency and charge transfer efficiency.

|

(1) |

Where ηab, ηsep and ηsep is the absorption efficiency, separation efficiency and transfer efficiency, respectively.

Nowadays, the promotion of three kinds of efficiencies of PEC above is the main challenge. Absorption is of great significance to the photoelectrochemical cell, which will determine the utilization rate of the solar spectrum. The solar spectrum is mainly composed of ultraviolet light, visible light and infrared light. TiO2, the firstlydiscovered photocatalyst, has been widely used for photoelectrochemical water splitting [108]. It has very high utilization rate of ultraviolet light. However, the ultraviolet light only account for about 5% in the solar spectrum. Besides, charge carrier separation efficiency is another important challenge for the photoelectrochemical cells. When the charges are separated and reach the interface between the photoanode and the electrolyte. Their transfer efficiency determines the efficiency of chemical reaction rate at the interface. For water splitting, the charge transfer efficiency mainly reflects the efficiency of water oxidation rate. However, the kinetic of water oxidation is much slower than that of hydrogen evolution. The water oxidation rate is often considered to be the reaction rate limiting step. It will determine the efficiency of a photoelectrochemical cell.

8.3. Advances in science and technology to meet challenges 8.3.1. Absorption efficiencyIn the past decades, many strategies have been devoted to enhance its solar absorption. Doping is an effective strategy to extend its absorption spectrum [109, 110]. The dopant atoms will cause structure disturbance of the TiO2 and the bandgap of TiO2 become narrow. Also, the dopant will cause dopant level in the middle of the bandgap. These will greatly beneficial to extend the light absorption of TiO2. For example, Horst Kisch and coworkers reports a nitrogen doped TiO2 photoanode with an absorption edge up to 520 nm. This is much wider than pristine TiO2 (320 nm), The efficiency of the photoelectrochemical cell is greatly enhanced [109].

Coupling with other materials with wider absorption spectrum is another effective strategy to enhance the absorption efficiency. Yu and coworkers use a nitrogen-doped carbon layer to extend the photoresponse of TiO2 nanorod array from UV to NIR region. The nitrogen-doped carbon layer could absorb the majority of the solar spectrum. Importantly, the nitrogen-doped carbon layer contact with the TiO2 nanorod array closely, which ensure charge transfer between them. With wider solar spectrum absorption, the photocurrent is superior to that of pristine TiO2 nanorod arrays, and the on-set potential shifted negatively by 0.1 V [111].

8.3.2. Charge carrier separation efficiencyUsually, construction of hetero-structure is a promising method to enhance the separation efficiency, such as CaFe2O4/TaON [112], WO3/BiVO4 [113], Fe2O3/MgFe2O4 [114] and Cr2O3/WO3 [115]. In a hetero-structure, the band diagram of two components of the hetero-structure is different. When they are in contact with each other, internal electric field could be formed and it could promote the charge separation efficiency. Zheng's group construct a WO3/BiVO4 core/shell structure for photoelectrochemical water oxidation. BiVO4 is the primary light-absorber and WO3 acts as an electron conductor. This will dramatically promote the charge separation efficiency. The hetero-structure produces a photocurrent of 3.1 mA/cm2 under simulated sunlight and an incident photon-to-current conversion efficiency of 60% at 300-450 nm, both at a potential of 1.23 V versus RHE [113].

In 2015, Hu and coworkers propose a p-n junction heterostructure to promote charge separation. The Fermi level of p-type semiconductor is close to the valance band, while that of n-type semiconductor is close to the conduction band. When they are in contact with each other, a strong internal electric band could be built, and could remarkably promote charge separation. They build a nanostructured chromium(Ⅲ) oxide/tungsten(Ⅵ) oxide (Cr2O3/WO3) p–n junction photoanode prepared by depositing Cr2O3 nanoparticles onto WO3 nanosheet arrays. Electrochemical and spectroscopic methods indicate that the recombination rate of photogenerated charges becomes lower in this photoanode. Consequently, its onset potential shifts negatively by about 0.1 V and photocurrent density increases from 0.7 mA/cm2 to 1.8 mA/cm2 at 1.8 V vs. RHE. The incident photonto- current efficiency (IPCE) also shows a one-fold improvement. In addition, the construction of the p–n junction leads to an increase of faradaic efficiency (holes to oxygen) from 73.9% to 92.0%, which is attributed to the suppression of side reactions in water oxidation [115].

Besides heterojunction, homojunction is another strategy for charge separation. Homojunction is the junction constructed by the same semiconductors with different band structures [116, 117]. Compared with heterojunction, they are greatly beneficial to charge transfer due to little lattice mismatching and continuity of the chemical bonding. Their morphology, size and defect type determine their efficiency. In 2017, Yu's group diminishes one component of the homojunction to as small as 5 nm by in-situ constructing a QDs- backbone hematite (Fe2O3) homojunction [117]. This novel QDs-based homojunction is formed via intrinsic defects (mainly oxygen vacancies), which is totally different from most reported homojunctions based on extrinsic defects like external doping. With ultrahigh specific surface area, QDs contain sufficient high density of oxygen vacancies to generate "intrinsic" impurity energy levels and form a homojunction. Therefore, the effective hole diffusion length in the QDs-Fe2O3 (0.5–5.0 nm) becomes larger than that of Fe2O3 (0.2–1.0 nm). Consequently, this homojunction shows pronounced enhancement in photoelectrochemical (PEC) performance.

8.3.3. Charge transfer efficiencyDeposition of water oxidation cocatalysts is a generallyaccepted method [118, 119]. Gamelin and coworkers discover a cobalt-phosphate water oxidation catalyst ("Co-Pi") [119]. The cocatalysts can be electrodeposited onto mesostructured Fe2O3 photoanodes. A kinetic bottleneck of water oxidation limiting the activity can be largely overcome by more sparse deposition of Co-Pi onto the Fe2O3. Compared with pure Fe2O3 photoanodes, the sample with Co-Pi loaded exhibit a sustained 5-fold enhancement in the photocurrent density and O2 evolution rate at 1.0 V vs. RHE. It shows that integration of water oxidation cocatalyst with a photon-absorbing substrate can reduce the external power needed to drive the catalyst's electrolysis chemistry.

Besides the kinetic limitation, surface states are another important factor influencing the charge transfer efficiency [120, 121]. The surface of Fe2O3 often contains unwanted surface states. They are mainly attributed to Fe3+/Fe2+ redox couples in oxygen deficient regions (surface oxygen vacancies). They will trap holes or electrons on the surface and cause serious recombination problem during charge/discharge process, thereby inhibiting the increasing of photocurrent density. One method to overcome the surface state is to deposit a passivation overlayers against surface states. Traditional passivation overlayers are metal oxide. However, oxygen vacancies are prevalent for most metal oxides. This is because their formation in metal oxides is often thermodynamically favorable. In contrast, the formation of oxygen vacancies is more energy-consuming when oxygen atoms are covalently bonded. On the basis of this understanding, Shen and coworkers propose a new strategy to transform the surface of Fe2O3 into amorphous iron phosphate (denoted "Fe-Pi"), where the oxygen atoms are "covalently fixed" in phosphate (PO43-). As a result, the oxygen vacancies are decreased and the surface states are effectively suppressed. The onset potential of corresponding photoanode shifts negatively by 0.15 V, and the photocurrent density increases by 4.2 (simulated sunlight) and 4.1 (visible light) times. The suppression of surface states by amorphous Fe-Pi overlayer is then confirmed by series of electrochemical analysis [121].

8.4. Concluding remarks and prospectsOverall, much endeavor has been devoted to develop high efficiency photoelectrochemical cell for water oxidation. Currently, light absorption of photoanode has been extended to near infrared light. Charge separation and transfer efficiency have not yet been reached a satisfactory value. In the future, developing more effective structure and promising materials are the main challenge for photoelectrochemical cells. With the developing of nanoscience and material design, we believe the next generation of photoelectrode could be more and more effective.

8.5. AcknowledgmentThis work is supported by the National Natural Science Foundation of China (Nos. 21872101 and 51902357) and the Start-up Funds for High-Level Talents of Sun Yat-sen University (No. 38000-18841209).

9. Towards artificial photosynthesis: photoelectrocatalytic reduction of carbon dioxideQinglan Zhao, Ying Wang*