b University of Chinese Academy of Sciences, Beijing 100049, China;

c State Key Joint Laboratory of Environment Simulation and Pollution Control, Research Center for Eco-Environmental Sciences, Chinese Academy of Sciences, Beijing 100085, China

Volatile organic compounds (VOCs) are a major contributor to air pollution [1]. Emissions of VOCs from industrial processes and transportation activities pose considerable harm to both the atmospheric environment and human health [2, 3]. Therefore, VOCs abatement is an important pollutant control issue.

Catalytic oxidation isoneof the most effective means for reducing VOCs emissions due to its high destruction efficiency, low NOx emissions, and minimal operation and energy costs [4], and has thus gained increasing interest [5-7]. Noble-metal-based catalysts, such as platinum (Pt) [8-11], gold (Au) [12], and palladium (Pd) catalysts [13, 14], are considered the most desirable candidates. Among them, Pd-based catalysts offer several advantages, including high activity, thermal stability, and low cost [13, 15]. As such, Pd-based catalysts have gained growing attention. For instance, Wang et al. [16] established a highly active and anti-coking Pd-Pt/SiO2 catalyst for the elimination of toluene at low temperature. Zhu et al. [17] studied Al-doped TiO2 mesoporous material supported by Pd for the complete oxidation of ethanol. Tang et al. [18] reported on the promotion effect of acid treatment on Pd-Ni/SBA-15 catalysts for complete oxidation of benzene vapor.

Pd-based catalyst supports are highly important, with performance tightly related to support type [4]. Al2O3, a porous support, is a desirable choice to load Pd, and has been investigated extensively for the catalytic oxidation of VOCs [13, 15, 19]. Huang et al. [15] studied the complete oxidation of o-xylene over Pd/Al2O3 catalysts at low temperature and found Pd/Al2O3 to be the most active among Pt and Au noble metal catalysts. Kim and Shim [13] investigated the catalytic oxidation of benzene, toluene, and o-xylene VOCs over a 1 wt% Pd/γ-Al2O3 catalyst and reported an activity order of o-xylene > toluene > benzene. Jiang et al. [19] prepared a monolithic Pt-Pd bimetallic catalyst supported on γ-Al2O3 for catalytic combustion of benzene series, which achieved good catalytic combustion for benzene and other aromatic hydrocarbons. While the above research has obtained credible achievements, the influence of water vapor on the activity of catalysts has not been emphasized, which is inevitable in practical application. More importantly, the presence of water vapor may severely inhibit the operation of catalysts.

The alkali metal Na can serve as electronic or textural promoters for catalysts in various catalytic processes [20]. Haneda et al. [21] have demonstrated good reactivity for NO decomposition over Co3O4 with the addition of alkali metal Na. Li et al. [20] reported that Na addition had a remarkable promotion effect on Pd/TiO2 catalysts for HCHO oxidation. As for Soot abatement, Rao et al. [22] have confirmed that Na addition is favorable for soot degradation over SnO2 catalysts. Recently, we found the alkali metal Na is affirmative in enhancing water resistance and low temperature activity of Pd/Al2O3 catalysts in the elimination of VOCs.

Herein, a series of Na-Pd/Al2O3 catalysts with different Na to Pd mole ratios were prepared via wet impregnation. Benzene, a major and difficult-to-decompose VOC in the environment [13], was chosen as the model compound to test the effect of Na addition on the water resistance of Pd/Al2O3. The catalysts were characterized by means of X-ray diffraction (XRD), Brunauer Emmett Teller (BET), transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), O2-temperature-programmed desorption (O2-TPD), and in situ DRIFTS. Results showed that Na addition had a remarkable promotion effect on water resistance and improved low temperature activity. The well-dispersed Pd particles, abundant liable surface oxygen species, and enhanced mobility of lattice oxygen species derived from Na addition contributed to the good performance in the elimination of VOCs.

We prepared 1 wt% Pd/Al2O3 and Na-doped 1 wt% Pd/Al2O3 catalysts, with different Na to Pd mole ratios of 1:1, 5:1, and 10:1, using wet impregnation. Four beakers filled with the same amount of deionized water were prepared. The same amount of γ-Al2O3 (5 g, SASOL, SBa-200) and 15% Pd(NO3)2 solution (0.3325 g, Shanghai Jiu Ling Chemical Co., Ltd.) were then dissolved in the four beakers, respectively. Next, 0.025, 0.125, and 0.25 g of Na2CO3 (Sinopharm Chemical Reagent Co., Ltd.) were added into the three solutions separately. After stirring for 3 h, the excess water of the aforementioned mixed solution was removed in a rotary evaporator at 60 ℃. To decompose the metal salt adsorbed on the Al2O3 supports, the samples were dried at 100 ℃ overnight, then calcined in air at 500 ℃ for 3 h. After the prepared samples cooled to room temperature, they were crushed and sieved through 40–60 mesh. Prior to activity testing and characterization, the catalysts were pre-reduced at 300 ℃ for 1 h in mixed gas of 5 vol% H2 and balanced N2 at a total flow rate of 300 mL/min. Finally, we denoted 1 wt% Pd/Al2O3 and Na-doped 1 wt% Pd/Al2O3 catalysts with Na to Pd mole ratios of 1:1, 5:1, and 10:1 as Pd/Al2O3, Na1Pd1/Al2O3, Na5Pd1/Al2O3, and Na10Pd1/Al2O3, respectively.

To verify the credibility of this study, Na-doped Pd/Al2O3 catalysts with Na and Pd mole ratios of 0.5:1, 20:1, and 40:1 were prepared, as per above, and named Na0.5Pd1/Al2O3, Na20Pd1/Al2O3, and Na40Pd1/Al2O3, respectively.

The activity tests for the catalytic oxidation of benzene over Pd/ Al2O3 and Na-doped Pd/Al2O3 catalysts were performed in a continuous flow fixed bed reactor. The catalyst (40–60 mesh) was supported on a small plug of glass wool in the middle of a straighttube quartz reactor. Before the activity tests, the catalysts were pretreated in mixed gas of 5 vol% H2 and balanced N2 at a total flow rate of 300 mL/min. The 1500 ppm benzene gas and 2 vol% water vapor were produced by a N2 stream bubbling through a saturator filled with liquid benzene and water. The concentrations of benzene and water vapor were controlled by the flow rate of nitrogen or temperature of the water bath, which was kept at 36 ℃. The reaction feed under dry conditions consisted of 1500 ppm benzene and 20 vol% O2 in N2. We introduced 2 vol% water vapor into the mixed gas under wet conditions. The flow rate of the gas mixture through the reactor was 300 mL/min, corresponding to a gas hourly space velocity (GHSV) of 45, 000 h-1. The benzene concentration was analyzed online by a gas chromatograph (GC; Agilent 7890B, HP-5 capillary column) with a flame ionization detector. CO2 and O2 concentrations were analyzed by the same GC equipped with a thermal conductivity detector (Porapak Q and HayeSep Q column).

Powder XRD measurements were performed on an X'pert Pro instrument equipped with an X-ray source of Cu-Kα at a 2θ angle ranging from 5° to 90°. Brunauer-Emmett-Teller (BET) surface area measurement was performed with N2 adsorption/desorption isotherms on a Quantachrome QuadraSorb-evo system. TEM Images were obtained using a JEOL JEM-ARM2100 F with 200 kV acceleration voltage. XPS measurements were carried out with an ESCALAB250 spectrometer using a monochromatic Al Kα X-ray source (1486.6 eV). The binding energy was calibrated using the adventitious C 1s peak at 284.6 eV. The continuum spectra were fitted according to Gaussian-Lorentzian line shapes. The O2-TPD tests were carried out on a Micromeritics Autochem Ⅱ 2920. The signals were monitored using an Ametek LC-D200 M PRO Mass Spectrometer. In situ DRIFTS spectra were recorded on a Thermo Fisher 50 Fourier transform infrared (FT-IR) spectrometer equipped with an in situ diffuse reflectance chamber (Harrick) and high sensitivity MCT/A detector.

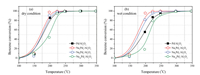

The Na loading effect on 1 wt% Pd/Al2O3 was examined in terms of benzene oxidation, with results shown in Fig. 1. The conversion of benzene under dry conditions over different Na-doped Pd/Al2O3 catalysts as a function of temperature is displayed in Fig. 1a. The complete conversion temperature of Pd/Al2O3 was about 210 ℃. When an appropriate amount of Na was doped, the conversion of benzene over the whole range was improved slightly, and Na1Pd1/ Al2O3 exhibited the best performance. The conversion of benzene under wet conditions over different Na-doped Pd/Al2O3 catalysts is shown in Fig. 1b. Increasing the mole ratio from 0 to 5 significantly enhanced benzene conversion. Among them, Na1Pd1/Al2O3 exhibited the highest benzene conversion, and the reaction temperature for >90% conversion (T90) was 196 ℃. Increasing the mole ratio to 10 significantly decreased benzene conversion, indicating that there is an optimal amount of Na that can improve catalytic performance.

|

Download:

|

| Fig. 1. (a) Benzene conversion over Pd/Al2O3 catalysts under dry conditions. Reaction conditions: 1500 ppm benzene, 20 vol% O2, N2 balance, total flow rate = 300 mL/min, GHSV = 45, 000 h-1. (b) Benzene conversion over Pd/Al2O3 catalysts under wet conditions. Reaction conditions: 1500 ppm benzene, 20 vol% O2, 2 vol% water vapor, N2 balance, total flow rate = 300 mL/min, GHSV = 45, 000 h-1. | |

Comparison of benzene oxidation over the Pd-based catalysts is listed in Table S1 (Supporting information). Our catalysts exhibited outstanding combined performance. The CO2 selectivity curves over different Na-doped Pd/Al2O3 catalysts are plotted in Fig. S1 (Supporting information), which demonstrated the same trend as the conversion of benzene. As shown in Fig. S2 (Supporting information), suitable Na addition had a promotion effect on the Pd/Al2O3 catalysts for benzene catalytic oxidation under both dry and wet conditions, and the optimal mole ratio between Na and Pd was 1:1.

To demonstrate the promotion effect of Na addition on water resistance of the Pd/Al2O3 catalyst, durability tests for Pd/Al2O3 and Na1Pd1/Al2O3 were carried out at 215 ℃, as shown in Fig. S3 (Supporting information). It is clear that benzene conversion by Pd/Al2O3 decreased from 96% to 90% when 2 vol% water vapor was introduced into the feed gas, however, benzene conversion by Na1Pd1/Al2O3 was maintained at 97% at 215 ℃, even after the introduction of water vapor. Comparison of the catalytic performances of Pd/Al2O3 and Na1Pd1/Al2O3 in dry and wet conditions is shown in Fig. S4 (Supporting information). Thus, the introduction of water vapor significantly reduced the activity of Pd/Al2O3 but demonstrated little impact on the Na1Pd1/Al2O3 catalyst.

The result of XRD shown in Fig. S5 (Supporting information) suggests that the Pd species were dispersed better on the surface of the Na-doped γ-Al2O3 support than the undoped one.

The specific surface areas (SBET) and pore volumes (Vpore) of the catalysts listed in Table S2 (Supporting information) together with the STEM images shown in Fig. S6 (Supporting information) indicate that excess Na addition may block some pore openings and then inhibit reactants in gaining access to the active sites in the pores, thus leading to the decrease in catalytic activity and water resistance over the Na10Pd1/Al2O3 catalyst.

SEM-EDS of the as-prepared catalysts was shown in Fig. S7 (Supporting information). It can be clearly seen that the percentages of weight for Pd of all the samples are around 1%, and the actual values of the Na to Pd mole ratios are close to the theoretical values.

The chemical states of the supported Pd and O species were characterized by XPS, with results shown in Fig. 2 and Table S3 (Supporting information). As shown in Fig. 2a, the Pd 3d5/2 peaks could be divided into two peaks with binding energies of 335.1 eV [23] and 336.4 eV [24], assigned to metallic Pd (Pd0) and oxidized Pd (Pd2+), respectively. It is worth noting that the binding energy of Pd0 derived from the sample with Na addition slightly shifted to lower binding energy compared to Pd/Al2O3, revealing that electrons are donated from the Na species to metallic Pd due to promoter-metal interaction [25]. Metallic Pd is more active than Pd oxide for total VOC oxidation [13, 15]. As shown in Table S3, the relative content of Pd0 was higher than that of Pd2+ in all Na-related catalysts, except Na10Pd1/Al2O3, with Na1Pd1/Al2O3 exhibiting the highest amount of Pd0. Thus, the performance of Na10Pd1/Al2O3 was the weakest and the performance of Na1Pd1/Al2O3 was the strongest.

|

Download:

|

| Fig. 2. XPS spectra of Pd/Al2O3 and Na-doped Pd/Al2O3 catalysts: (a) Pd 3d, (b) O 1s. | |

Oxygen chemisorption can be enhanced by negatively charged metallic Pd species [26]. Thus, the O 1s XPS spectra of the catalysts were investigated, as shown in Fig. 2b. The O 1s spectra could be fit with three peaks at 529.9, 531.4, and 532.8 eV, which were assigned to lattice oxygen species (denoted as Olatt), surface adsorbed oxygen species (named as Osur), and chemisorbed water and/or dissociated oxygen and/or hydroxyl species (labeled as Oads), respectively [27, 28]. Due to the higher mobility, the adsorbed oxygen (Osur) was deemed to be more reactive during oxidation [29], thus the high relative contents of adsorbed oxygen (Osur) on the catalyst surface could be favorable for benzene removal. The specific peak positions and relative contents of different oxygen species are listed in Table S3. The relative contents of Olatt and Oads were decreased, whereas active Osur increased for both Na1Pd1/ Al2O3 and Na5Pd1/Al2O3. This is consistent with the excellent water resistance of the Na1Pd1/Al2O3 and Na5Pd1/Al2O3 catalysts. Conversely, the relative content of Oads was remarkably increased, whereas active Osur was decreased for Na10Pd1/Al2O3. This may be one of the most important reasons why Na loading cannot be doped redundantly. In brief, the addition of Na plays a crucial role in tuning the relative content of different oxygen species, which eventually influences the activity to a great degree. The Na 1s XPS was shown in Fig. S8 (Supporting information). On increasing the initial Na loading, the surface sodium content was observed to increase substantially.

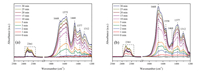

The O2-TPD experiments were performed over the samples to identify and confirm the activity and mobility of different oxygen species, with results shown in Fig. 3. The desorption peaks between 50–150 ℃ were ascribed to physical absorbed oxygen [30], the peaks obtained at 150–300 ℃ were attributed to the desorption of surface oxygen species such as O2- and O- [31], and the peaks above 300 ℃ were attributed to the evolution of lattice oxygen [32]. Compared with pure Al2O3, the Pd/Al2O3 catalyst displayed an obvious lattice oxygen desorption peak, indicating that Pd doping promoted lattice oxygen mobility. When Na was introduced to Na1Pd1/Al2O3, the amount of physical absorbed oxygen was decreased, but the mobility of the lattice oxygen was enhanced, because the desorption regions for the lattice oxygen moved toward lower temperatures and the amount was dramatically increased. This result indicates that surface oxygen species are facilitated from bulk oxygen species [33]. Therefore, the oxidative property of the catalyst is reasonably improved, which is consistent with the catalytic performance. After water vapor was introduced to interact with the surface of the catalysts, the main desorption peak of lattice oxygen decreased for both Pd/Al2O3 and Na1Pd1/Al2O3, indicating that the presence of water vapor deactivated the lattice oxygen species. However, a desorbed peak of surface oxygen species appeared from the Na1Pd1/Al2O3 catalyst, indicating that the absorbed water can be transformed into liable surface oxygen, which is favorable for oxidation reaction activity [34]. These findings are consistent with the XPS-O1 s characterization and catalytic activity measurement results.

|

Download:

|

| Fig. 3. O2-TPD profiles of Al2O3, Pd/Al2O3, and Na1Pd1/Al2O3 samples. | |

Based on these observations, the addition of Na not only improved the mobility of lattice oxygen, which helped facilitate redox reactions and enhance catalytic activity for benzene combustion, but also motivated the absorbed water to form liable surface oxygen species and promoted water resistance of the catalyst.

To elucidate the role of Na addition in the surface mechanism, in situ DRIFTS spectra were collected as a function of time in a mixture gas of benzene, O2, and water vapor at a fixed temperature of 200 ℃, with the results illustrated in Fig. 4. Exposure of the Pd/Al2O3 and Na1Pd1/Al2O3 catalysts to the feed gas resulted in the appearance of several peaks within the range of 1200–2500 cm-1. In accordance with other reports, the board peak around 2361 cm-1 was attributed to the asymmetric stretch of carbonate species [35]. The band at 1668 cm-1 was assigned to the C=O stretching vibration of surface o-benzoquinone-type species [36]. The bands at 1575 cm-1 and 1468 cm-1 were assigned to the C=C stretching vibrations of surface phenolate species [36]. Bands corresponding to carboxylate species such as formate and acetate were detected at 1558, 1450 and 1377 (CH2 stretching vibration) cm-1 [15, 37]. The band at 1312 cm-1 was assigned to a surfacemaleate species [38]. As shown in Fig. 4a, as the reaction proceeded, the surface o-benzoquinone-type species (1668 cm-1), phenolate species (1575 cm-1 and 1468 cm-1), acetate species (1377 cm-1), maleate species (1312 cm-1) and CO2 (2361 cm-1) were gradually produced. Thus, it can be concluded that benzene was oxidized into o-benzoquinone, phenolate, maleate, acetate species and CO2 on the Pd/Al2O3 catalyst at 200 ℃ in the presence of benzene, O2, andwater vapor mixture.

|

Download:

|

| Fig. 4. In situ DRIFTS of benzene oxidation over Pd1/Al2O3 (a) and Na1Pd1/Al2O3 (b) catalysts at different times. Reaction conditions: 1500 ppm benzene, 20 vol% O2, 2 vol% water vapor, N2 balance, total flow rate = 100 mL/min, T = 200 ℃. | |

In comparison to Fig. 4a, similar bands at 1688, 1377, and 1312 cm-1 can be observed in Fig. 4b as the reaction proceeded. A new band at 1558 cm-1 corresponding to acetate species emerged. It is quite different to Pd1/Al2O3 the surface phenolates species (1468 cm-1) cannot be observed until 10 min later. Since phenolate species are very active and can be easily oxidized into benzoquinone [37], the presence of phenolate species indicated the exhaustion of the original liable surface oxygen species on the catalysts. The replenishment of gaseous oxygen to oxygen vacancies clearly decelerated the rate of oxidation. This finding indicates that Na1Pd1/Al2O3 is more active than Pd/Al2O3. Moreover, the band intensities of surface organic species on Na1Pd1/Al2O3 were relatively higher than that on Pd1/Al2O3, confirming that Na addition indeed promotes activity. The in situ DRIFTS spectra under both dry and wet conditions were compared and displayed in Fig. S9 (Supporting information). Based on these results, a reaction mechanism was proposed and is displayed in Fig. S10 (Supporting information).

The water resistance of the 1 wt% Pd/Al2O3 catalyst during benzene oxidation was significantly promoted by the suitable addition of Na, with the Na and Pd mole ratio of 1:1 found to be optimal. The appropriate addition of Na led to the formation of well-dispersed and negatively charged metallic Pd particles, which facilitated oxygen adsorption. Proper Na addition promoted the transformation of absorbed water into liable surface oxygen species. In addition, the mobility of the lattice oxygen species was also significantly improved, which contributed to the enhanced catalytic activity and water resistance.

AcknowledgmentsThis work was supported by the National Natural Science Foundation of China (No. 51608504), Youth Innovation Promotion Association, and Chinese Academy of Sciences (No. 2017064).

Appendix A. Supplementary dataSupplementary material related to this article canbefound, in the online version, at doi:https://doi.org/10.1016/j.cclet.2019.03.023.

| [1] |

Y. Shu, J. Ji, Y. Xu, et al., Appl. Catal. B-Environ. 220 (2018) 78-87. DOI:10.1016/j.apcatb.2017.08.019 |

| [2] |

J.J. Li, E.Q. Yu, S.C. Cai, et al., Appl. Catal. B-Environ. 240 (2019) 141-152. DOI:10.1016/j.apcatb.2018.08.069 |

| [3] |

J. Yang, Y. Guo, Chin. Chem. Lett. 29 (2018) 252-260. DOI:10.1016/j.cclet.2017.09.013 |

| [4] |

H. Deng, S. Kang, C. Wang, H. He, C. Zhang, Chem. Eng. J. 348 (2018) 361-369. DOI:10.1016/j.cej.2018.04.184 |

| [5] |

C.J. Liang, J.W. Fang, Chem. Eng. Sci. 144 (2016) 101-107. DOI:10.1016/j.ces.2016.01.038 |

| [6] |

W. Tang, J. Li, X. Wu, Y. Chen, Catal. Today 258 (2015) 148-155. DOI:10.1016/j.cattod.2015.04.023 |

| [7] |

P. Yang, S. Yang, Z. Shi, Z. Meng, R. Zhou, Appl. Catal. B-Environ. 162 (2015) 227-235. DOI:10.1016/j.apcatb.2014.06.048 |

| [8] |

H.J. Joung, J.H. Kim, J.S. Oh, et al., Appl. Surf. Sci. 290 (2014) 267-273. DOI:10.1016/j.apsusc.2013.11.066 |

| [9] |

Z. Zhang, Y. Zhu, H. Asakura, et al., Nat. Commun. 8 (2018) 16100. |

| [10] |

S. Zhao, B. Xu, L. Yu, Y. Fan, Chin. Chem. Lett. 29 (2018) 884-886. DOI:10.1016/j.cclet.2017.11.016 |

| [11] |

S. Zhao, B. Xu, L. Yu, Y. Fan, Chin. Chem. Lett. 29 (2018) 475-478. DOI:10.1016/j.cclet.2017.09.020 |

| [12] |

A.M. Ali, M.A. Daous, A.A.M. Khamis, et al., Appl. Catal. A-Gene 489 (2015) 24-31. DOI:10.1016/j.apcata.2014.10.006 |

| [13] |

S.C. Kim, W.G. Shim, Appl. Catal. B-Environ. 92 (2009) 429-436. DOI:10.1016/j.apcatb.2009.09.001 |

| [14] |

W.W. Liu, Y.S. Feng, G.Y. Wang, W.W. Jiang, H.J. Xu, Chin. Chem. Lett. 27 (2016) 905-909. DOI:10.1016/j.cclet.2016.02.026 |

| [15] |

S. Huang, C. Zhang, H. He, Catal. Today 139 (2008) 15-23. DOI:10.1016/j.cattod.2008.08.020 |

| [16] |

H. Wang, W. Yang, P. Tian, et al., Appl. Catal. A-Gene 529 (2017) 60-67. DOI:10.1016/j.apcata.2016.10.016 |

| [17] |

J. Zhu, W. Mu, L. Su, et al., J. Solid State Chem. 248 (2017) 142-149. DOI:10.1016/j.jssc.2017.01.028 |

| [18] |

W. Tang, Y. Deng, Y. Chen, Catal. Commun. 89 (2017) 86-90. DOI:10.1016/j.catcom.2016.10.032 |

| [19] |

L. Jiang, N. Yang, J. Zhu, C. Song, Catal. Today 216 (2013) 71-75. DOI:10.1016/j.cattod.2013.05.026 |

| [20] |

Y. Li, C. Zhang, H. He, Catal. Today 281 (2017) 412-417. DOI:10.1016/j.cattod.2016.05.037 |

| [21] |

M. Haneda, Y. Kintaichi, N. Bion, H. Hamada, Appl. Catal. B-Environ. 46 (2003) 473-482. DOI:10.1016/S0926-3373(03)00287-X |

| [22] |

C. Rao, J. Shen, F. Wang, et al., Appl. Surf. Sci. 435 (2018) 406-414. DOI:10.1016/j.apsusc.2017.11.109 |

| [23] |

Q. Lin, Y. Ji, A.Z.D. Jiang, W.D. Xiao, Ind. Eng. Chem. Res. 46 (2007) 7950-7954. DOI:10.1021/ie070640b |

| [24] |

K. Otto, L.P. Haack, J.E. Devries, Appl. Catal. B-Environ. 1 (1992) 1-12. DOI:10.1016/0926-3373(92)80003-I |

| [25] |

L.F. Liotta, G. Deganello, P. Delichere, C. Leclercq, G.A. Martin, J. Catal. 164 (1996) 334-340. DOI:10.1006/jcat.1996.0389 |

| [26] |

H. Huang, D.Y.C. Leung, ACS Catal. 1 (2011) 348-354. DOI:10.1021/cs200023p |

| [27] |

H. Li, G. Lu, Q. Dai, Y. Wang, G. Yun, et al., Appl. Catal. B-Environ. 102 (2011) 475-483. DOI:10.1016/j.apcatb.2010.12.029 |

| [28] |

H. Cao, X. Li, Y. Chen, M. Gong, J. Wang, J. Rare Earths 30 (2012) 871-877. DOI:10.1016/S1002-0721(12)60148-3 |

| [29] |

F. Liu, H. He, Y. Ding, C. Zhang, Appl. Catal. B-Environ. 93 (2009) 3760-3769. |

| [30] |

M. Sun, L. Yu, X.H. Na, G.Q. Diao, F. Ye, J. Fuel Chem. Technol. 41 (2013) 1115-1121. DOI:10.1016/S1872-5813(13)60047-X |

| [31] |

Y. Wang, C. Zhang, Y. Yu, R. Yue, H. He, Catal. Today 242 (2015) 294-299. DOI:10.1016/j.cattod.2014.06.032 |

| [32] |

L. Xue, H. He, C. Liu, C. Zhang, B. Zhang, Environ. Sci. Technol. 43 (2009) 890-895. DOI:10.1021/es801867y |

| [33] |

P. Yang, J. Li, Z. Cheng, S. Zuo, Appl. Catal. A-Gene 542 (2017) 38-46. DOI:10.1016/j.apcata.2017.05.016 |

| [34] |

B.K. Min, C.M. Friend, Chem. Rev. 107 (2007) 2709-2724. DOI:10.1021/cr050954d |

| [35] |

L. Ren, M. Mao, Y. Li, et al., Appl. Catal. B-Environ. 198 (2016) 303-310. DOI:10.1016/j.apcatb.2016.05.073 |

| [36] |

J. Lichtenberger, M.D. Amiridis, J. Catal. 223 (2004) 296-308. DOI:10.1016/j.jcat.2004.01.032 |

| [37] |

J. Zeng, X. Liu, J. Wang, H. Lv, T. Zhu, J. Mol. Catal. A-Chem. 408 (2015) 221-227. DOI:10.1016/j.molcata.2015.07.024 |

| [38] |

C.E. Hetrick, J. Lichtenberger, M.D. Amiridis, Appl. Catal. B-Environ. 77 (2008) 255-263. DOI:10.1016/j.apcatb.2007.07.022 |

2019, Vol. 30

2019, Vol. 30