b School of Chemistry, Beihang University, Beijing 100191, China

As an important class of energy-storage devices, supercapacitors are attracting wide attention due to their fast charge and discharge rates, high power density, and long cycle lifetimes [1-10]. Beside these remarkable advantages, supercapacitors also exhibit many other favorable attributes. It can be easily processed to construct flexible, stretchable or miniaturized configurations, for ease of applications in portable and wearable electronics [11-19]. Moreover, these unique configurations facilitate their greater compatibility with various other functional devices.

The traditional single-function supercapacitor always appearing in a rigid bulky or planar format with large volume and structure limitation can no longer satisfy the development of next-generation electronics [20-30]. And most of the state-of-the-art electronic devices rely on the connection to external power supply through long wires, which often impede their mobile applications. Consequently, there is an urgent need to develop the unconventional multifunctional integrated supercapacitor. The integration strategy can endow the supercapacitors with multifunction as well as minimize the size of the electronic equipment [31-38]. For example, people may come across the inconvenience of sudden power cut when using indoor electric appliances, and be bothered by carrying heavy batteries and power cords during a trip. Out of this consideration, some researchers come up with the ideal of constructing a wire-shaped device with an integrated current transmitting module and an incorporated supercapacitor. With such advanced "electric wire", when people are using their electric appliances, the cable can store the energy for later usage and provide the insurance for some delicate equipments by preventing them from being damaged during a sudden power cut.Some researchers introduced an ethanol-detecting function to a supercapacitor, and the resultant ethanol sensor can achieve self-powering and detectingthe concentration of ethanol in real time. The whole device is integrated tightly on one piece of flexible substrate, soit has enormous potential to be used as a wearable multifuntional device.

In this review, we summary the latest works in the field of integrated multifunctional supercapacitors. We describe the integration of the electrochemical energy storage with distinct functionalities such as photodectecting, electrochromism, activity monitoring, chemicals sensing, etc. The fabrication, characterization and performance of these diverse multifunctional supercapacitors are systemically discussed. Finally, we propose the outlook of the future development of the multifunctional integrated supercapacitors.

2. Multifunctional integrated supercapacitors 2.1. Photodetector/supercapacitor integrated devicesLow-cost and fast response photodetectors are in great demand for various applications, such as security monitoring, environmental monitoring and space-to-space communication technologies, etc. [39-42]. The conventional photodetector must work with external power supply, resulting in waste of additional space and energy. Integrating the photodetecting and energy storage function into one simplified and compact configuration can make the device portable to meet the demand of lightweight electronics [43-52].

To incorporate the photodetecting function into supercapacitor, most researchers used the metallic oxide as the photosensitive material, while Zhang [53] used the Si nanowire (NW) to afford the electrode and the photocollector of a quick-chargingand endurable integrated device. The device can run more than 10h with once single charge in less than 100s. Firstly, they grew the Si NW arrays on the silicon substrate vertically and orderly (Fig. 1a) and coated part of the Si NWs with carbon, with another carbon-coated Si NW arrays to build the positive and negative electrodes (Figs. 1b–d). The Si NWs without carbon coating served as the UV detector. Upon UV illumination, the photo-generated carriers would diffuse into the micro-supercapacitor, resulting in the increase of current in the circuitand the potential betweenthe two electrodes(Figs. 1e and f). Because of the UV detector consuming extremely low power and high specific surface area of Si NW array favorable to fast UV detection and high energy storage capacity as well, the device still showed excellent endurance, even though the capacitance density was 13.6F/cm3.

|

Download:

|

| Fig. 1. Schematic of fabrication process and structure of the CNT/V2O5 NW based micro-supercapacitor integrated with a SnO2 nanowires UV sensor. The illustration of Si NWarray grow on the silicon substrate (a), selective coated carbonwall (b), the as-prepared multifunction supercapacitor (c), the charging circuit (d), the photodetecting process (e), and working mechanism (f). Copied with permission [53]. Copyright 2015, Elsevier Ltd. | |

By a facile solvothermal method, Shen's group fabricated a fiber-shaped asymmetric supercapacitor which was integrated with photodetecting function [54]. They wrapped the graphenecoated carbon fibers around the Co3O4-coated titanium fibers which were immersedin thePVA-KOH gelsolution before. Because of the overpotential of reversible hydrogen electrosorption in a nanoporous carbon-based negative electrode, the operating potential window of the supercapacitor could be extended, which led to the enhancement of the as-assembled integrated system's energy storage and power density. When the light was spread on the device, electron-hole pairs generated in graphene. Under the external field which was coming from the charged supercapacitor, electron-hole pairs separated and the current was generated.

Ha's group assembled a flexible all-solid-state planar-type micro-supercapacitor which can power the SnO2 NW UV sensor that was integrated on the same flexible PET substrate [55]. By a simple sol-gel method, they synthesized multi-walled carbon nanotube (MWCNT)/V2O5 NW composites as the electrodes. With PVA-LiCl electrolyte, the patterned micro-supercapacitor exhibited excellent electrochemical performance with a high volume capacitance of 80F/cm3 at a scan rate of 10mV/s and excellent energy density of 6.8mWh/cm3. After the irradiation of UV light, photocurrent through the SnO2 NW sensor sharply increased, resulting in the enhancement of discharge rate of the microsupercapacitor. With the increase of the UV intensity from 0 to 1.4mW/cm2, the voltage drop rose from 6mV/s to 18mV/s, which showed its potential application in the photodetecting area.

Xu used a conventional photolithography method to create the patterned graphene oxide (GO) film [56]. Then the GO film was reduced to reduced graphene oxide (rGO) pattern and Au film was sprayed on the square electrodes to reinforce the conductivity. After several simple steps, the all-solid-state flexible rGO microsupercapacitor was obtained. By a chemical vapor deposition method, CdS NWs were synthesized. The CdS NWs were placed in gaps between the square electrodes to afford the photodetector part. The integrated device showed excellent photosensitivity that the photoelectric response time and recover time are 0.83s and 2.90s, which was even quicker than that driven by external power source.

Watanabe assembled an all-solid-state carbon micro-supercapacitor bylaser writing directlyonpolyimide (PI) films in Ar [57]. Then they integrated this micro-supercapacitor with a UV photodetector based on ZnO nanoparticles with a small commercial solar panel on the same PI film to build an on-chip selfpowered photodetection system. The micro-supercapacitor could be fully charged within 1min and voltage remained above 0.55V after 2h. This on-chip integrated photodetection system exhibited a stable, distinct and fast response tothe UV light illuminationwith a current on/off ratio of about 31.2 and the rise and decay times of 9.9s and 15.9s.

Niu's team fabricated the foldable all-solid-state paper-like bifunctional integrated device with supercapacitor and photodetector functions based on single-walled carbon nanotube (SWCNT) films and TiO2 nanoparticles [58]. What the device was quiet unique about was that it remained almost unchanged even folded by 180°. The sheet resistance of TiO2 nanoparticles-coated SWCNT film exhibited excellent stability at different folding levels. The specific capacitance and maximum power density can reach 28F/g and 66.7kW/kg. When the integrated device was exposed to the UV light with an intensity of 40mW/cm2, the photocurrent reached 2.77μA and sensitivity of 38.5 was achieved.

Zhi et al. synthesized h-WO3 through a microwave-assisted hydrothermal process and they found that h-WO3 based supercapacitors surprisingly show 17% enhanced performance under solar light [59]. The wavelength dependence, capacitive mechanism, energy storage dynamics, and impedance analyses were put forward to investigate the enhancement mechanism. As an application of this finding, they built a self-powered photodetector-supercapacitor system based on h-WO3. The device's voltagedrop rate was different between dark and illuminated conditions. The photoresponsivity increased from 0.11 to 0.16 as the light intensity increased from 40mW/cm2 to 100mW/cm2 and increased rapidly when the wavelength was less than 450nm. Their work built the basis of later research on the h-WO3's photosensitivity and opened a new gate to this field.

Chen made a hierarchically structured carbon microfiber composed of an interconnected network of aligned SWCNTs and intercalated nitrogen-doped rGO sheets [60]. The mesoporous construction endowed the material with a large specific surface area of 396 m2/g and excellent electrical conductivity of 102 S/cm. The composite fibers showed an ultrahigh specific volumetric capacity of 305 F/cm3. The micro-supercapacitor was composed of PVA/H3PO4 gel electrolyte, without current collector, binder, separator or any other packaging materials, had a volumetric energy density of 6.3 mWh/cm3 while maintaining the 93% power density after 10000 cycles life (Fig. 2a) and it retained more than 97% of its initial capacitance after bending 1000 times at 90° (Fig. 2b). They assembled micro-supercapacitors in series and integrated the supercapacitor with a TiO2-based UV photodetector on a fluorine doped tin oxide (FTO) glass substrate (Fig. 2c). The test showed the photodetector had a steady response to ultraviolet light irradiation (Fig. 2d).

|

Download:

|

| Fig. 2. (a) The cycling stability of the micro-supercapacitor. The inset is the galvanostatic charge/discharge curve near 10, 000 cycles. (b) Capacitance retention during 1, 000 cycles at 90° bending angle. The inset is digital photo of a bent micro-supercapacitor. (c) Schematic of a self-powered photodetecting nanosystem. The inset is the SEM image of TiO2 nanorods array, and the scale bar is 1 mm. (d) Current response of the UV light. Copied with permission [60]. Copyright 2014, Macmillan Publishers Limited. | |

The works mentioned above unify the photodetector and supercapacitor by the subtle design of architecture of electrode the hybridization of active materials. Although the devices showed excellent stability and fast response to the light, there are some improvement can be made in the later research, due to the limitation of photosensitive and the capacity short of the device.

2.2. Electrochromic supercapacitorsElectrochromic supercapacitor can be used not only for energystorage smart windows, which can adjust the lighting and heating of the building by charging the windows and changing its own color [19, 61-65], but also for sensing variations of stored energy and being able to respond to the variations in a noticeable and predictable manner [66, 67]. Most of the planar electrochromic supercapacitors were built on the indium tin oxide (ITO) substrate just like Lee and Wright did [68], to meet the demand of wearable electronics, Lee [69], Mai [70] and Han [71] used the Ag NWs to made the flexible device. And the fiber construction was also put forward by Lin [72].

Wright reported new nanostructured Er-containing titania materials (Er@TiO2) which was made of a novel heterometallic Er (Ⅲ)-doped polyoxotitanate cage [Ti8O7(OEt)21Er] [73]. Utilizing the Li+ storage capacity and electrochromic properties of Er@TiO2, they sprayed the Er@TiO2 on the ITO glass to fabricate a bifunctional integrated electrochromic supercapacitor, which exhibited excellent electrochromic performances. At its rest state, the device was in yellow. The color turned dark gray when the device was charged above 1.3 V and bleached when it was discharged below 0.3 V. And the switching response time of coloring was 16.3 s and bleaching was 17.7 s.

In 2014, Lee designed a electrochromo-supercapacitor with the electrode that was composed of NiO nanoparticles uniformly grown on the ITO substrate by a simple and low-cost solvothermal method [69]. The NiO turned out to be appropriate electrode materials as chromo-supercapacitor. When the device was charged to 0.5 V, the color of the NiO film turned dark brown (Fig. 3a). After the electrical charge was completely consumed, the film returned to transparent. The device remained a transmittance modulation of 56.4% after 5000 cycles (Fig. 3b) which may be due to the uniform nanoparticles morphology and stable chemical bonding of the NiO nanoparticle that benefited the charge transferring between the contact surfaces and within the electrode materials during the electrochemical process.

|

Download:

|

| Fig. 3. (a) Transmittance spectra of the NiO nanoparticles film on ITO glass with seed layer under different voltage conditions, and the insets are the corresponding digital photos of the film. (b) Cycle performance of the NiO nanoparticles film measured in 1 mol/L KOH. Copied with permission [70]. Copyright 2014, Elsevier Ltd. (c) Schematic description of the structure of the silver grid/PEDOT:PSS hybrid film. (d) Transmittance spectra of WO3 deposited on the pristine silver grid and the silver grid/PEDOT:PSS hybrid films under different voltage condition. Insets: The corresponding digital images of the electrodes. Copied with permission [71]. Copyright 2015, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. | |

For the reason that ITO and FTO are fragile and expensive to produce and the sheet resistance is in the range of tens to hundreds of ohms per square which could cause the color change lagging behind the change of the stored energy under high current density. After several years of research, Lei's group replace the ITO for the silver grids as the flexible transparent conductors, aiming to improve the electrochemical stability and flexibility of silver-based transparent electrode [74]. They coated a layer of WO3 nanoparticles on the silver grid/PEDOT:PSS hybrid film to compose the flexible electrochromic device (Fig. 3c). The advantages of using silver grid as substrate were improving the conductivity of the electrode and reducing the blooming effect distinctly. And the silver grid/PEDOT:PSS sheet showed an outstanding performance with sheet resistance of 0.62V/sq at over 70% transparency. This hybrid device presented optical modulation of 81.9% at 633 nm, fast switching, and high coloration efficiency (124.5 cm2/C) and an excellent electrochemical cycling stability (Fig. 3d).

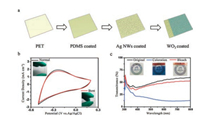

Mai invented a flexible electrochromic supercapacitor electrode based on the flexible transparent conducting silver nanowire (Ag NW) substrates as well and active material WO3 film [70] (Fig. 4a). The device was stable under different bending conditions (Fig. 4b). The color changed between dark blue and transparent as the pseudocapacitive reactions happened: WO3 + xe- + xH+ ↔ HxWO3. When -0.5 V was applied on the Ag NW/WO3 electrode, the supercapacitor changed to dark blue with an optical transparency of 11.8% (Fig. 4c). This electrode exhibited high coloration efficiency up to 80.2 cm2/C, fast response speed (coloring in 1.7 s and bleaching in 1.0 s) and outstanding stability (remained 72.6% of the initial capacitance at a scan rate of 100 mV/s after 5000 cycles).

|

Download:

|

| Fig. 4. (a) Schematic illustration of the fabrication of a flexible electrochromic supercapacitor electrode. (b) CV curves under normal and bent conditions at the scan rate of 100 mV/s, inset is digital photos of the supercapactor under the corresponding condition. (c) Transmittance spectra of the Ag NW/WO3 electrode measured under different voltage conditions, inset is corresponding digital images of the electrode. Copied with permission [72]. Copyright 2016, The Royal Society of Chemistry. | |

Unlike conventional electrochromic systems making use of multilayer coatings on a glass substrate to adjust the light transmittance and control the temperature which cannot adapt its color according to the sunlight automatically. Han integrated the supercapacitor with a solar sensor to build a smart flexible electrochromic supercapacitor system [71]. They sprayed the Ag NWs network on top of cellulose nanofiber based on paper substrate and deposited a thin layer of rGO layer on top of the Ag NWs serving as the supercapacitor active material and preventing from the air corrosion. Finally, they deposited WO3 nanoparticles uniformly on the electrode surface. Using ultrathin cellulose nanofiber paper as a substrate made the system showing exceptionally high transmittance of 99.1%. The as-prepared device exhibited a high coloration efficiency of 64.8 cm2/C, specific capacitance of 406.0 F/g, energy density of 40.6–47.8 Wh/kg and power density of 6.8–16.9 kW/kg. The coloration efficiency of the device remained 75.0% after 10000 charge discharge cycles.

Different with previous works on the development of fibershaped devices focusing on either core-shell fibers or thread-like electronic devices, Lin prepared two parallel coil electrodes on a single fiber by a template method, using the poly(3, 4-ethyl-enedioxythiophene) (PEDOT) deposited on the electrode surface as the active material [72]. When the potential of 0.6 V was applied, the PEDOT coated on the cathode turned dark blue, while the anode showed no change in color. When the bias potential was applied to an opposite direction, the PEDOT in dark blue returned to the natural gold color, while anther electrode turned to dark blue. The device reaction was so fast that coloring/bleaching time was less than 5 s. The single fiber device showed several advantages over yarn and fabric, such as high integration ability. But its original gold color, compared to the mainstream transparent state, may limited its application.

Most flexible planar electrochromic supercapacitors are built on the silver grid or NWs coated PET substrates as the current collector, which can better suits the demands of wearable devices than the counterpart built on the ITO or FTO. And the flexible fiber electrochromic supercapacitors are also brought out to meet the weavability.

2.3. Physiological and mechanical activity monitor/supercapacitor integrated devicesThe supercapacitor can also be integrated with the function to sense the physiological and mechanical activity. Since wearable electronics have attracted increasing attention along with the development of flexible and stretchable devices as well as the rapid spread of mobile equipment [43, 75-79]. Extended efforts on wearable electronics make it a promising platform to collect physiological and mechanical information from the human body [80-86]. Integrating the supercapacitor with the activity-monitoring function can ensure its application in medical diagnosis and treatment, wellness preventive care and sports game.

Kim presented a wearable energy storage device, composed of triboelectric generators (TEGs) integrated with supercapacitors, which can be applied either as an activity monitor or as power source for wearable sensors [87]. Since all parts were fabricated on a conductive carbon fabric, they could be woven onto any location people desired of the conventional cloth, and interconnected with each other by conductive threads. The structure and working, mechanism of the wearable energy storage system are exhibited schematically in Figs. 5a and b. The TEGs were placed in the armpit area to collect friction, whereas the supercapacitor was located on the chest section that is free from friction and other external force, and still close to the TEGs. The current generated during walking and storage was also shown in Fig. 5c. The design of the TEGs was based on four parallel TEGS, which allowed them to utilize both the vertical and horizontal friction generated between the arm and the torso. The most novel design of this device was that unlike TEGs developed before, it allowed TEGs to generate electricity without the need for air gaps. And it can generated electricity through both horizontal and vertical friction, with an average output power density of 0.18 μW/cm2 at 1.5 Hz under typical activity of running.

|

Download:

|

| Fig. 5. (a) Schematic description of arm swings with TEG and supercapacitor equipped. (b) Circuit diagram of the integrated TEG and supercapacitor. (c) Illustration of the human activity sensor. The generated electricity was recorded during the stretching, walk, running, sprint, and walk again. Copied with permission [87]. Copyright 2014, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. | |

Fan et al. introduced a flexible, lightweight, hierarchical porous Mn3O4/graphite foams electrode [88]. Hierarchical porous structure offered the flexible supercapacitors outstanding properties, including high specific surface area, low areal mass density and high electric conductivity. The Mn3O4/graphite foams could be facilely integrated as both liquid-state and solid-state supercapacitor electrodes without additives or bindings. The specific capacitance of 538 F/g and an optimal overall capacitance of 260 F/g based on the pure Mn3O4 have been achieved. The multilevel porous graphite foam showed excellent electrical stability with the capacitance retention of 90% after 10000 cycles at 10 A/g. They integrated the supercapacitor with a wearable ultrasensitive strain sensor (Fig. 6a), and the integrated flexible device could power itself, fit into human skins, and accurately detect both coarse and steady motions. For example, when attached to a finger (Fig. 6b), the device showed unstable electric signals as the finger bent. When attached to skins where the carotid artery is (Fig. 6c), periodic electric signals are collected, giving the information that the heart beating rate was 96 per minute.

|

Download:

|

| Fig. 6. (a) Schematic description of the flexible all-solid-state supercapacitor integrated with a strain sensor. (b) Real-time detection of finger bending. (c) Realtime detection of carotid artery pulses in real time, inset: digital image of the integrated device (left) and the application in pulse test (right). Copied with permission [88]. Copyright 2017, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. | |

Pan's team presented an electrospun ionic fabric utilizing nanofibrous structures with an extraordinarily high pressure-tocapacitance sensitivity of 114 nF/kPa with resolution of 2.4 Pa and mechanical response time of 4.2 ms, which was at least 1, 000 times higher than any existing capacitive sensors [89]. Under the external pressure, the nanofibrous layer and the conductive fabric was compressed and charged ionic was increasing. And the change of the contact area would lead to a variation in interfacial capacitance. In this way, the pressure applied on the device can be detected. And the device was noise proof and exhibited excellent signal stability for wearable applications.

The supercapacitor mentioned above can detect various kinds of physiological or mechanical movement such as pressure, friction and stretch which is merely on one dimension direction. For this reason, we hoped the supercapacitor which can detect combination of complex move patterns can be brought out.

2.4. Other multifunctional integrated supercapacitors 2.4.1. Chemical sensor/supercapacitor integrated devicesInstead of the photodetecting and physiological mechanical activity detecting function, the supercapacitor can also be integrated with the chemical sensor. The pollution of air and water has become a major problem that all people are concerned about. The detection of the chemical plays a vital role in preventing people from chemical pollutions. And the chemical sensors can be applied to detect the concentration of certain kind of chemcial and help people to control the taking in of this chemical [90, 91]. The supercapacitor integrated with chemical sensor can work continuously without external power, which suits the development direction of future chemical sensor.

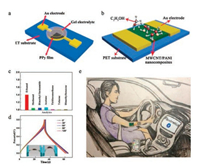

Zhen's group connected micro-supercapacitor arrays to afford the power resource for a wearable ethanol sensor on the same PET substrate [92] (Fig. 7a). The voltage of the micro-supercapacitor arrays was calibrated by voltage regulate device, making the output voltage stable at 0.8 V. When the sensor was exposed to the C2H5OH gas, the C2H5OH and O2 reacted and produced CO2, H2O and a large number of electronics on the MWCNTs/PANI composite layer (Fig. 7b). The electron-hole connection and the reduction of PANI caused the resistance of the active layers increasing, leading to the decrease of current and the increase of tandem resistor. The device built accurate selectivity to the ethanol among the other gas such as methanol, dimethyl formamide, acetone, etc. (Fig. 7c). And the as-prepared system was quite stable under different bending station (Fig. 7d). The signal was further collected and settled by the CPU and alarmed the user (Fig. 7e).

|

Download:

|

| Fig. 7. (a) Schematic of the micro-supercapacitor based on PPy film. (b) Schematic of the as-fabricated ethanol gas sensor part. (c) Sensitivity test towards different gas of the device. (d) The potential under different bent level. (e) Drawing of a user using the alcohol detecting integrated system while driving. Copied with permission [92]. Copyright 2017, Elsevier Ltd. | |

2.4.2. Integrated electrical cable/supecapacitors

Other than the detecting function mentioned above, the supercapacitors can achieve the energy storage and transmission meantime. Cable-shaped supercapacitors are welcome for its attractive properties such as small size, lightweight, and bendability [93]. Combining the supercapacitor's intrinsic capability to store energy with the electricity transmittance function can alleviate energy distribution and guarantee the electricity supply after cutting off the power, liberating people from the heavy energy supply system [94]. Therefore the integrated electrical cable/supercapacitors could provide potential applications in energy storage and electronics.

Thomas grow Fe2O3@C nanorods uniformly on strand of carbon fiber and coated the cooper wire with CuO nanowhiskers to afford the anode and cathode of the coil-type asymmetric supercapacitor electrical cable [95]. Compared to symmetric supercapacitor, the as-prepared device has broader cell operation voltage. And the device showed extraordinary mechanical and electrochemical stability, extraordinary rate capability (95.4%), high energy density (0.85 mWh/cm3), remarkable flexibility and bendability, and superior bending cycle stability (Capacitance retention remained 94% after 4000 cycles at different bending states). The superb electrical performance can be attributed to the novel nanostructure design in both anodes and cathodes.

Wang fabricated a juglone/PPy composite-based fiber electrode by a facile galvanostatic polymerization method [96]. They then connected these wire-shaped electrodes with the metal cores on the two side of a conventional electrical wire to form an integrated electrical cable/supercapacitor. When this integrated electrical cable/supercapacitor was used in practical application, it constituted a classical parallel resistor–capacitor circuit along with the external electric appliance. With this integrated electrical cable/supercapacitor, the bulk can be lighted with the power supply and stay bright even after the power was cut off (Figs. 8a–d). Compared to the traditional cable's voltage suddenly dropping after cutting out the power, the counterpart of integrated cable could significantly retain a high voltage for a long time (Figs. 8e and f). Both circuit analysis and display demonstration testified that the integrated electrical cable/supercapacitor acted as a conductive wire to conduct the electricity and a supercapacitor to store the energy simultaneously. Using this integrated cable/supercapacitor to replace conventional electrical wires, the energy distribution and supply applications might be revolutionized, because energy generated by various physical or chemical sources can be distributed to users directly with no need of additional energy storage equipment.

|

Download:

|

| Fig. 8. Schematic of the bulbs powered by (a) a conventional electric wire and (b) an as-fabricated flexible integrated electrical cable. (c, d) Demonstration of the bifunctional integrated cable can light the LED after removing the power. Variations of the voltage across the bulbs after cutting off the power with conventional electric wires (e) and this integrated electrical cables (f) used as connections, respectively. Insets in e and f are the corresponding circuit schematics. Copied with permission [96]. Copyright 2016, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. | |

And there are some other function integrated with the capacitor, such as Liu integrated the SnO2-based memristor with supercapacitor to stabilize the voltage of supercapacitor [97]. Fan integrated solar hydrogen generation function with supercapacitor [98].

3. Conclusions and outlookWith the rapid development of portable, wearable and smart electronics, there is an urgent need for a breaking through development of the traditional single-function supercapacitor with sole energy supply ability. Integration approaches can endow the supercapacitor with multiple functionalities, e.g., photodetecting, electrochromism, activity monitoring, chemicals sensing, etc. In this review, we conclude the recent progress in the field of integrated multifunctional supercapacitor. We highlight the delicate design which brought several distinct functions into one device. And these kinds of devices make it possible for the development of flexible, wearable, portable, lightweight electronics.

Due to the urgent need for the unconventional multifunction supercapacitors, various kinds of integrated systems are emerging rapidly. Despite the success in proof-of-concept demonstrations, further improvement needs to be carried out before practical applications of these lab-scale integrated devices. In particular, the capacitance of these integrated supercapacitors is mostly low, and still cannot support durable usage of electronics. And the accuracy and detection limitation of these sensors or detectors still have some room to enhance. In order to meet the demand of the practical application, the method to produce the multifunctional supercapacitors facilely on large scale should be brought out.

Besides these unconventional integrated multifunctional supercapacitors discussed in the review, more integration device which can detect the mechanical activity, humidity, sound and chemical compound could be figured out. Detecting mechanical activity could be applied on the man-machine interaction. Detecting humidity can facilitate supervising the condition and environment of manufacture process. Detecting sound can be used to monitor the noise level. Detecting chemical compound could play a vital role in the petrochemical engineering and prevent people from the chemical poison. Additionally, more than two kinds of function can be integrated into one device to minimize the volume and promote the development of portable and wearable electronics.

AcknowledgmentsThe authors acknowledge the financial support of the National Natural Science Foundation of China (No. 51502009) and the Key Laboratory of Jiangxi Province for Persistent Pollutants Control and Resources Recycle (No. ST201522008).

| [1] |

Z. Zhu, F. Cheng, Z. Hu, Z. Niu, J. Chen, J. Power Sources 293 (2015) 626-634. DOI:10.1016/j.jpowsour.2015.05.116 |

| [2] |

X. Wang, X. Lu, B. Liu, et al., Adv. Mater. 26 (2014) 4763-4782. DOI:10.1002/adma.v26.28 |

| [3] |

D. Yu, W. Hua, Y. Jie, et al., ACS Appl. Mater. Interface 9 (2017) 21298-21306. DOI:10.1021/acsami.7b05318 |

| [4] |

H. Wang, H. Feng, J. Li, Small 10 (2014) 2165-2181. DOI:10.1002/smll.201303711 |

| [5] |

L.F. Chen, X.D. Zhang, H.W. Liang, et al., ACS Nano 6 (2012) 7092-7102. DOI:10.1021/nn302147s |

| [6] |

S. Luo, M. Yao, S. Lei, et al., Nanoscale 9 (2017) 4646-4651. DOI:10.1039/C7NR00999B |

| [7] |

Z.S. Wu, X. Feng, H.M. Cheng, Natl. Sci. Rev. 1 (2014) 277-292. DOI:10.1093/nsr/nwt003 |

| [8] |

Z. Niu, W. Zhou, X. Chen, J. Chen, S. Xie, Adv. Mater. 27 (2015) 6002-6008. DOI:10.1002/adma.201502263 |

| [9] |

P. Luan, N. Zhang, W. Zhou, et al., Adv. Funct. Mater. 26 (2016) 8178-8184. DOI:10.1002/adfm.201603480 |

| [10] |

B. Liu, D. Tan, X. Wang, D. Chen, G. Shen, Small 9 (2013) 1998-2004. DOI:10.1002/smll.v9.11 |

| [11] |

D. Qi, Z. Liu, Y. Liu, et al., Adv. Mater. 27 (2015) 5559-5566. DOI:10.1002/adma.201502549 |

| [12] |

P. Hu, T. Chen, Y. Yang, et al., Nanoscale 9 (2017) 1423-1427. DOI:10.1039/C6NR09190C |

| [13] |

W. Zeng, L. Shu, Q. Li, et al., Adv. Mater. 26 (2014) 5310-5336. DOI:10.1002/adma.201400633 |

| [14] |

Z. Niu, J. Du, X. Cao, et al., Small 8 (2012) 3201-3208. DOI:10.1002/smll.v8.20 |

| [15] |

L. Peng, P. Xu, B. Liu, et al., Nano Lett. 13 (2013) 2151-2157. DOI:10.1021/nl400600x |

| [16] |

L. Liu, Z. Niu, J. Chen, Nano Res. 10 (2017) 1524-1544. DOI:10.1007/s12274-017-1448-z |

| [17] |

X. Wang, C. Yan, A. Sumboja, J. Yan, P.S. Lee, Adv. Energy Mater. 4 (2014) 1301240. DOI:10.1002/aenm.201301240 |

| [18] |

X. Lu, M. Yu, G. Wang, et al., Adv. Mater. 25 (2013) 267-272. DOI:10.1002/adma.201203410 |

| [19] |

Z. Niu, L. Liu, L. Zhang, et al., Adv. Energy Mater. 5 (2015) 1500677. DOI:10.1002/aenm.201500677 |

| [20] |

C. Chen, J. Cao, Q. Lu, et al., Adv. Funct. Mater. 27 (2017) 1604639. DOI:10.1002/adfm.v27.3 |

| [21] |

T. Miyasaka, T.N. Murakami, Appl. Phys. Lett. 85 (2004) 3932-3934. DOI:10.1063/1.1810630 |

| [22] |

M.F. Elkady, M. Ihns, M. Li, et al., Proc. Nalt. Acad. Sci. U. S. A. 112 (2015) 4233-4238. DOI:10.1073/pnas.1420398112 |

| [23] |

C.T. Chien, P. Hiralal, D.Y. Wang, et al., Small 11 (2015) 2929-2937. DOI:10.1002/smll.201403383 |

| [24] |

X. Wang, B. Liu, Q. Wang, et al., Adv. Mater. 25 (2013) 1479-1486. DOI:10.1002/adma.v25.10 |

| [25] |

P. Lin, L. Hu, X. Fang, Adv. Funct. Mater. 24 (2014) 2591-2610. DOI:10.1002/adfm.v24.18 |

| [26] |

Y. Yang, H. Wang, R. Hao, L. Guo, Small 12 (2016) 4683-4689. DOI:10.1002/smll.v12.34 |

| [27] |

H. Wang, B. Zhu, W. Jiang, et al., Adv. Mater. 26 (2014) 3638-3643. DOI:10.1002/adma.v26.22 |

| [28] |

H. Wang, Y. Yang, L. Guo, Adv. Energy Mater. 7 (2017) 1601709. DOI:10.1002/aenm.201601709 |

| [29] |

Z. Niu, P. Luan, Q. Shao, et al., Energy Environ. Sci. 5 (2012) 8726-8733. DOI:10.1039/c2ee22042c |

| [30] |

J. Chang, S. Adhikari, T.H. Lee, et al., Adv. Energy Mater. 5 (2015) 1500003. DOI:10.1002/aenm.201500003 |

| [31] |

U.N. Maiti, J. Lim, K.E. Lee, W.J. Lee, S.O. Kim, Adv. Mater. 26 (2014) 615-619. DOI:10.1002/adma.201303503 |

| [32] |

L. Nyholm, G. Nyström, A. Mihranyan, M. Strømme, Adv. Mater. 23 (2011) 3751-3769. |

| [33] |

P. Du, X. Hu, C. Yi, et al., Adv. Funct. Mater. 25 (2015) 2420-2427. DOI:10.1002/adfm.201500335 |

| [34] |

J. Wang, L. Zhang, L. Yu, et al., Nat. Commun. 5 (2014) 4921-4927. DOI:10.1038/ncomms5921 |

| [35] |

Y. Chen, J. Au, P. Kazlas, et al., Nature 423 (2003) 136. |

| [36] |

M. Kaempgen, C.K. Chan, J. Ma, Y. Cui, G. Gruner, Nano Lett. 9 (2009) 1872-1876. DOI:10.1021/nl8038579 |

| [37] |

G. Nyström, A. Marais, E. Karabulut, et al., Nat. Commun. 6 (2015) 7259-7266. DOI:10.1038/ncomms8259 |

| [38] |

B.Y. Lim, J. Yoon, J. Yun, et al., ACS Nano 8 (2014) 11639-11650. DOI:10.1021/nn504925s |

| [39] |

J. Xu, H. Wu, L. Lu, et al., Adv. Funct. Mater. 24 (2014) 1814. DOI:10.1002/adfm.v24.13 |

| [40] |

D. Spanos, L. Baussá, C.P. Baron, M.A. Tørngren, Angew. Chem. Int. Ed. 53 (2014) 1849-1853. DOI:10.1002/anie.201307581 |

| [41] |

N. Kaur, M. Singh, D. Pathak, T. Wagner, J.M. Nunzi, Synth. Met. 190 (2014) 20-26. DOI:10.1016/j.synthmet.2014.01.022 |

| [42] |

L.G.H. Staaf, P. Lundgren, P. Enoksson, Nano Energy 9 (2014) 128-141. DOI:10.1016/j.nanoen.2014.06.028 |

| [43] |

J. Ren, W. Bai, G. Guan, Y. Zhang, H. Peng, Adv. Mater. 25 (2013) 5965-5970. DOI:10.1002/adma.201302498 |

| [44] |

H. Sun, X. You, J. Deng, et al., Angew. Chem. Int. Ed. 53 (2014) 6664. DOI:10.1002/anie.201403168 |

| [45] |

S. Pan, Z. Zhang, W. Weng, et al., Mater. Today 17 (2014) 276-284. DOI:10.1016/j.mattod.2014.04.024 |

| [46] |

C.Y. Hsu, H.W. Chen, K.M. Lee, C.W. Hu, K.C. Ho, J. Power Sources 195 (2010) 6232-6238. DOI:10.1016/j.jpowsour.2009.12.099 |

| [47] |

Z. Huang, Z. Zhang, X. Qi, et al., Nanoscale 8 (2016) 13273. DOI:10.1039/C6NR04020A |

| [48] |

H.W. Chen, C.Y. Hsu, J.G. Chen, et al., J. Power Sources 195 (2010) 6225-6231. DOI:10.1016/j.jpowsour.2010.01.009 |

| [49] |

J. Cao, C. Chen, Q. Zhao, et al., Adv. Mater. 28 (2016) 9629-9636. DOI:10.1002/adma.201602262 |

| [50] |

W. Guo, X. Xue, S. Wang, C. Lin, Z.L. Wang, Nano Lett. 12 (2012) 2520-2523. DOI:10.1021/nl3007159 |

| [51] |

M. Peng, S. Hou, H. Wu, et al., J. Mater. Chem. A 2 (2013) 926-932. |

| [52] |

S. Pan, Z. Yang, H. Li, et al., J. Am. Chem. Soc. 135 (2013) 10622-10625. DOI:10.1021/ja405012w |

| [53] |

L. Sun, X. Wang, K. Zhang, et al., Nano Energy 15 (2015) 445-452. DOI:10.1016/j.nanoen.2015.05.008 |

| [54] |

X. Wang, B. Liu, R. Liu, et al., Angew. Chem. Int. Ed. 126 (2014) 1880-1884. DOI:10.1002/ange.201307581 |

| [55] |

D. Kim, J. Yun, G. Lee, J.S. Ha, Nanoscale 6 (2014) 12034-12041. DOI:10.1039/C4NR04138K |

| [56] |

J. Xu, G. Shen, Nano Energy 13 (2015) 131-139. DOI:10.1016/j.nanoen.2015.02.027 |

| [57] |

J. Cai, C. Lv, A. Watanabe, Nano Energy 30 (2016) 790-800. DOI:10.1016/j.nanoen.2016.09.017 |

| [58] |

C. Chen, J. Cao, Q. Lu, et al., Adv. Funct. Mater. 27 (2017) 1604639. DOI:10.1002/adfm.v27.3 |

| [59] |

M. Zhu, Y. Huang, Y. Huang, et al., Adv. Funct. Mater. 26 (2016) 4481-4490. DOI:10.1002/adfm.201601260 |

| [60] |

D. Yu, K. Goh, H. Wang, et al., Nat. Nanotechnol. 9 (2014) 555-562. DOI:10.1038/nnano.2014.93 |

| [61] |

X. Chen, H. Lin, J. Deng, et al., Adv. Mater. 26 (2014) 8126-8132. DOI:10.1002/adma.201403243 |

| [62] |

M. Yu, Y. Han, X. Cheng, et al., Adv. Mater. 27 (2015) 3085-3091. DOI:10.1002/adma.201500493 |

| [63] |

Y. Yang, D. Yu, H. Wang, L. Guo, Adv. Mater. 29 (2017) 1703040. DOI:10.1002/adma.201703040 |

| [64] |

Z. Niu, L. Zhang, L. Liu, et al., Adv. Mater. 25 (2013) 4035-4042. DOI:10.1002/adma.v25.29 |

| [65] |

Y. He, W. Chen, C. Gao, et al., Nanoscale 5 (2013) 8799-8820. DOI:10.1039/c3nr02157b |

| [66] |

P. Yang, W. Mai, Nano Energy 8 (2014) 274-290. DOI:10.1016/j.nanoen.2014.05.022 |

| [67] |

Q. Meng, H. Wu, Y. Meng, et al., Adv. Mater. 26 (2014) 4100-4106. DOI:10.1002/adma.v26.24 |

| [68] |

P. Qiang, Z. Chen, P. Yang, et al., Nanotechnology 24 (2013) 435403. DOI:10.1088/0957-4484/24/43/435403 |

| [69] |

G.F. Cai, X. Wang, M.Q. Cui, et al., Nano Energy 12 (2014) 258-267. |

| [70] |

L. Shen, L. Du, S. Tan, et al., Chem. Commun. 52 (2016) 6296-6299. DOI:10.1039/C6CC01139J |

| [71] |

T.G. Yun, D. Kim, Y.H. Kim, et al., Adv. Mater. 29 (2017) 1606728. DOI:10.1002/adma.201606728 |

| [72] |

Y. Zhou, Y. Zhao, J. Fang, T. Lin, RSC Adv. 6 (2016) 110164-110170. DOI:10.1039/C6RA20729D |

| [73] |

Y. Lv, W. Du, Y. Ren, et al., Inorg. Chem. Front. 3 (2016) 1119-1123. DOI:10.1039/C6QI00114A |

| [74] |

G. Cai, P. Darmawan, M. Cui, et al., Adv. Energy Mater. 6 (2016) 1501882. DOI:10.1002/aenm.201501882 |

| [75] |

J. Yang, H. Wang, Y. Yang, et al., Nanoscale 9 (2017) 9879-9885. DOI:10.1039/C7NR03385K |

| [76] |

H. Guo, M.H. Yeh, Y.C. Lai, et al., ACS Nano 10 (2016) 10580-10588. DOI:10.1021/acsnano.6b06621 |

| [77] |

Z. Cai, L. Li, J. Ren, et al., J. Mater. Chem. 1 (2013) 258-261. DOI:10.1039/C2TA00274D |

| [78] |

C. Meng, C. Liu, L. Chen, C. Hu, S. Fan, Nano Lett. 10 (2010) 4025-4031. DOI:10.1021/nl1019672 |

| [79] |

S. Liu, J. Xie, H. Li, et al., J. Mater. Chem. A 2 (2014) 18125-18131. DOI:10.1039/C4TA03192J |

| [80] |

F.R. Fan, L. Lin, G. Zhu, et al., Nano Lett. 12 (2012) 3109-3114. DOI:10.1021/nl300988z |

| [81] |

Y. Yang, H. Zhang, Z.H. Lin, et al., ACS Nano 7 (2013) 9213-9222. DOI:10.1021/nn403838y |

| [82] |

G. Zhu, Z.H. Lin, Q. Jing, et al., Nano Lett. 13 (2013) 847-853. DOI:10.1021/nl4001053 |

| [83] |

X. Wang, J. Zhou, J. Song, et al., Nano Lett. 6 (2006) 2768-2772. DOI:10.1021/nl061802g |

| [84] |

S. Niu, Y. Liu, S. Wang, et al., Adv. Funct. Mater. 24 (2014) 3332-3340. DOI:10.1002/adfm.201303799 |

| [85] |

K. Wang, Q. Meng, Y. Zhang, Z. Wei, M. Miao, Adv. Mater. 25 (2013) 1494-1498. DOI:10.1002/adma.v25.10 |

| [86] |

X. Li, X. Zang, Z. Li, et al., Adv. Funct. Mater. 23 (2013) 4862-4869. |

| [87] |

S. Jung, J. Lee, T. Hyeon, M. Lee, D.H. Kim, Adv. Mater. 26 (2014) 6329-6334. DOI:10.1002/adma.201402439 |

| [88] |

W. Li, X. Xu, C. Liu, et al., Adv. Funct. Mater. 27 (2017) 1702738. DOI:10.1002/adfm.v27.39 |

| [89] |

R. Li, Y. Si, Z. Zhu, et al., Adv. Mater. 29 (2017) 1700253. DOI:10.1002/adma.201700253 |

| [90] |

H. Yan, M. Zhong, Z. Lv, P. Wan, Small 13 (2017) 1701697. DOI:10.1002/smll.v13.41 |

| [91] |

L. Xue, W. Wang, Y. Guo, G. Liu, P. Wan, Sens. Actuators B-Chem. 244 (2017) 47-53. DOI:10.1016/j.snb.2016.12.064 |

| [92] |

L. Li, C. Fu, Z. Lou, et al., Nano Energy (2017) 41 (2017) 261-268. DOI:10.1016/j.nanoen.2017.08.060 |

| [93] |

X. Chen, L. Qiu, J. Ren, et al., Adv. Mater. 25 (2013) 6436-6441. DOI:10.1002/adma.v25.44 |

| [94] |

J. Han, Y. Lin, L. Chen, et al., Adv. Sci. 2 (2015) 1500067. DOI:10.1002/advs.201500067 |

| [95] |

Z. Yu, J. Moore, J. Calderon, L. Zhai, J. Thomas, Small 11 (2015) 5289-5295. DOI:10.1002/smll.201501802 |

| [96] |

H. Wang, F. Li, B. Zhu, et al., Adv. Funct. Mater. 26 (2016) 3472-3479. DOI:10.1002/adfm.v26.20 |

| [97] |

B. Liu, B. Liu, X. Wang, et al., Adv. Mater. 26 (2014) 4999-5004. DOI:10.1002/adma.201401017 |

| [98] |

X. Xia, J. Luo, Z. Zeng, et al., Sci. Rep. 2 (2012) 981. DOI:10.1038/srep00981 |

2018, Vol. 29

2018, Vol. 29