Light olefins (C2= and C3=) are vital building-block chemicals [1].At present, the methanol-to-hydrocarbons (MTH) process has become one of the most prominent routes for the production of light olefins, as it allows the conversion of renewable methanol, made from nonoil resources such as coal, natural gas, or biomass, to a range of hydrocarbons [2]. Specifically, the rapidly changing market demand for light olefins [3] stimulates the enthusiasm to vigorously develop MTH process with highly adjustable C3=/C2= (P/E) ratio.

SAPO-34 and high-silica ZSM-5 as catalysts have been successfully used in industrial MTH process [1a, 3, 4]. The MTH process using SAPO-34 mainly produces C2= and C3=, eventually becoming the methanol-to-olefins (MTO) process. Unfortunately, the P/E ratios can only be adjusted in the very narrow range of 0.8-1.3 in commercial DMTO units [3]. In contrast, the methanol-topropene (MTP) process using high-silica ZSM-5 predominantly generates C3=, in which the P/E ratios are within the range of 1.7-6.3 with a C2= + C3= selectivity of around 60% at complete CH3OH/ DME conversion [4]. That means C2= selectivity does not exceed 20.8% [4b] or C3= selectivity is limited to 55.6% [4a]. Consequently, flexible regulation towards the P/E ratio from MTH on the same zeolite topology has not yet been achieved.

Based on literature reports [4, 5], we roughly divide the complex reaction network for MTH process over ZSM-5 into three major types of reactions (Fig. 1), including: 1) Dual-cycle reactions, wherein C2= is formed exclusively from the arene-based cycle related to lower methylbenzenes (MBs), while the alkene-based cycle favors C3= formation by methylation/cracking reactions of C3+ olefins [4, 5]; 2) Conversion reactions from the alkene-based to arene-based cycle through higher alkenes, which undergo dehydrogenation or hydrogen transfer, along with cyclization reactions to form MBs [4, 5c]; 3) Side reactions including hydrogen transfer and dehydrogenation, producing alkanes with the same carbon number, aromatics, H2 as well as coke resulting in light olefin consumption and catalyst deactivation [4, 6].

|

Download:

|

| Fig. 1. Possible reaction network for MTH over ZSM-5. (Methy/Crack, methylation/cracking; Dehy, dehydrogenation; Htf, hydrogen transfer; Cyclis, cyclization). | |

Firstly, in order to obtain a high total selectivity of C2= + C3=, we must suppress the side reactions 3). Also it must be noted that the conversion reactions 2) are always changing in the same direction as they have the similar reaction type. Secondly, making C2= or C3= the favored product arbitrarily, depends on the good control of the propagation of the arene-based and alkene-based cycles. Clearly, if it were possible to inhibit the conversion reactions 2), the formation of MBs might be avoided and then the arene-based cycle would not be carried out smoothly. As a result, C2= decreases and C3= accordingly increases, thereby leading to a high P/E ratio.Conversely, a low P/E ratio may be obtained by promoting the conversion reactions 2). It implies that the heart of achieving different product targets is the control on the conversion reactions 2).

Herein we propose a principle of controllable regulation of the P/E ratio in MTH process by a large margin from 0.72 to 7.56 with a C2= + C3= selectivity as high as 66%, by precise control of acidity of ZSM-5 catalyst.

2. Results and discussionConcerning the suppression of side reactions 3) for higher C2= + C3= selectivity, Brønsted acid density of ZSM-5 zeolites may be a key factor [4, 6, 7]. Generally, different Si/Al2 ratios or steamed ZSM-5 are used to consider the effect of Brønsted acid density on MTH reaction, yet ignoring the clear distinction of acid strength [4, 6, 7], which may also play an important role in the MTH product control [8]. Our previous studies have proved that the SCS (selective cracking of a silane) is an excellent method to obtain zeolitic materials with highly adjustable acid density and strength, causing no undesirable structural changes [9]. Hence, by means of the SCS method at fixed 450 ℃, we prepared a series of ZSM-5 with gradually decreasing acid density from 0.646 to 0.251 mmol/g, no obvious change in acid strength distribution was found (Figs. S1-S3 and Table S1 in Supporting information).

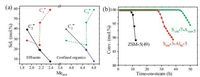

The results show that the increase of Brønsted acid density of ZSM-5 catalysts, not only greatly promotes the side reactions (Table S2 in Supporting information), but also accelerates the conversion reactions from the alkene-based to arene-based cycle, since both parts contain a series of bimolecular reactions which require a high density of acid sites [6, 10]. With increasing the conversion reactions, C3= decreases gradually via suppressing the alkene-based cycle while arene-based cycle species increase significantly. However, the increase of C2= depends on the effective cracking of the aromatic species. As shown in Fig. 2a and Table S2, ZSM-5 zeolites with Brønsted acid density above 0.4 mmol/g generate a large number of aromatics in a short time, which are directly involved in the subsequent reaction to the formation of byproducts, rather than cracked effectively into C2=. Consequently, C2= decreases instead of increasing and C2= + C3= reduces obviously. Yet, when Brønsted acid density of ZSM-5 is lower than 0.4 mmol/g, C2= + C3= selectivity reaches as high as 62-66% and the P/E ratio can be flexibly adjusted from 1.32 to 3.70. It demonstrates that Brønsted acid density of catalysts is really a determinant of a high selectivity of C2= + C3=.

|

Download:

|

| Fig. 2. Effect of Brønsted acidity of ZSM-5 on the MTH reaction. (a) Brønsted acid density and (b) Brønsted acid strength represented by the SA/WA ratio. Reaction conditions: cat., 0.8 g; 450 ℃; 0.1 MPa; WHSV, 4.0 h-1; TOS, 2.5 h. | |

With respect to gaining an adjustable P/E ratio from MTH, acid strength of catalysts may have very powerful effects [8]. These papers indicate that catalysts with a lower acid strength favor an alkene-based cycle compared with the isostructural materials with a higher acid strength, such as AFI (SAPO-5 versus SSZ-24). Unfortunately, the conclusion may be not a strong evidence to illustrate the effect of Brønsted acid strength of the catalysts, owing to the absence of the control towards density and type. On the other hand, SAPO-5 gives a predominant product to C4= rather than the desired C2= and C3= [8b, c, d], SSZ-24 inevitably generating large amounts of aromatics, due to the increased available internal space [8b, d]. More importantly, Brønsted acid strength of zeolite catalysts with the same topology cannot be arbitrarily adjusted, resulting in the difficulty of adapting to the requirements of highly adjustable P/E ratio. It impels us to further explore the important role of Brønsted acid strength in the adjusting P/E ratio over ZSM-5 with suitable pore for C2= and C3= production.

Herein, ZSM-5 zeolites with a large variation range of acid strength were prepared using the SCS method simply changing treatment temperatures as well as duration times [9]. However, it cannot be excluded that some extra-framework aluminum (Alex), serving as Lewis acid sites (LASs) [11], may be produced under high temperature (Fig. S4a in Supporting information). Fortunately, these Alex species can be removed by simple acid leaching [12], with 1mol/L HNO3 at 70 ℃ for 5h (Fig. S4b in Supporting information). Eventually, ZSM-5 zeolites with identical Brønsted acid density of about 0.33mmol/g but different Brønsted acid strength represented by the ratio of the strong to weak acid sites (SA/WA ratio), which ranged from 0.203 to 0.784 (Figs. S5-S7 and Table S3 in Supporting information), serve to elucidate the effect of Brønsted acid strength on MTH reaction. With the increase of the SA/WA ratio, the arene-based cycle is enhanced to promote C2= while the alkene-based cycle is weakened to gradually reduce C3= (Fig. 2b). Meanwhile, an upward ethene/2MB, that is C2=/(2-methylbutane+2-methylbutene) [5e], provides additional evidence that the relative rates of the arene-based cycle are increased relative to the alkene-based cycle with increasing acid strength (Table S4 in Supporting information). Clearly, ZSM-5(49) parent has a lower P/E ratio of 1.24 and C2=+C3= selectivity of 43.4% due to high Brønsted acid density up to 0.646mmol/g and high Brønsted acid strength at a SA/WA ratio of 0.804 (Fig. 2b, Tables S3 and S4). Thus a wider range of the P/E ratio from 7.56 to 2.43 with C2=+C3= selectivity of around 66% can be easily obtained (Fig. 2b and Table S4). Strikingly, a C2=-C5= selectivity as high as 94.8%, especially C3= selectivity of 59.0% beyond the maximum (55.6%) of the current literatures [4a], is obtained over the ZSM-5(46) -S150-7-A1M-5 sample with the lowest Brønsted acid strength at a SA/WA ratio of 0.203 (Fig. 2b and Table S4). The selectivity to C2=+C3= can be further increased by additional recycling process of C4= and C5= [4c, 12]. Methylation is a major reaction of dual-cycle process [5a, d]. Results combined computational techniques and co-reaction experiments of methanol with alkenes or arenes [5a, d, 8c, d] strongly suggest that the methylation rate of arenes is usually higher than or close to the methylation rate of alkenes, implying that both cycles can be successfully catalyzed by relatively weak Brønsted acid sites (BASs). This means that the conversion reaction from olefins to aromatics requires strong BASs.The stronger BASs result in more aromatics induced by faster conversion reaction to involve in the arene-based cycle, and thereby increase C2= production.

The above results (Fig. 2a and Table S2) and the results of the literatures [4b, 13] suggest that the selectivity to C2= is limited to 26.5% and the P/E ratio cannot be further reduced at a relative high C2=+C3= selectivity over ZSM-5.

Prior literatures state that C2= selectivity is governed by the number of methyl groups on MBs, which are the reaction intermediates in the arene-based cycle. The lower MBs favor C2=, whereas the higher MBs produce C3= [5b, 14]. The number of methyl groups of MBs is determined by the zeolite topology [14]. Moreover, higher MBs are essentially unreactive on ZSM-5 and unable to diffuse out of the pore [5b], probably staying in the channel andthen causingthe rapiddeactivation.Thereforein order to further promote C2= selectivity, we try to lower the internal space of ZSM-5 for generating smaller MB intermediates. Gounder et al. propose an approach to reduce the effective void size in FAU via introducing space-occluding Alex species in supercages [15].

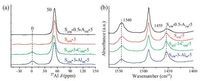

Alex species usually act as LASs [11]. It is generally accepted that the MTH reaction is catalyzed by BASs [8d], without considering the important role of LASs. To the best of our knowledge, we first clarify the effect of LASs and obtain exceptionally high C2= selectivity of 39.6% in the MTH process (Table 1). The four samples in Table 1 first experienced SCS treatment [9] at high temperature of 450 ℃ to reduce Brønsted acid density to the appropriate level and retain relatively high Brønsted acid strength (Figs. S1, S2 and Table S1). On this basis, a series of ZSM-5 zeolites with different Lewis acid density were prepared by the method of acid leaching (A) [12], high temperature calcination (C) [11] or Al exchange (Al) [16] (Fig. S8 and Table S5 in Supporting information). Details on the preparation procedure can be found in the Supporting information. From the 27Al MAS NMR results (Fig. 3a), it can be seen that the peak at 0ppm attributed to sixcoordinate Alex species [11, 12] gradually increases. FTIR of adsorbed pyridine data show that the total density of BASs and LASs (B+L), calculated by the adsorption amount of 1540 and 1455 cm-1 at 150 ℃ [9, 11, 12b], is approximately the same (around 0.73mmol/g), but different in the ratio between the amounts of LASs and BASs (L/B ratio) from 0.41 to 2.24 (Fig. 3b and Table S5 in Supporting information), which represents the variation of acid type.

|

|

Table 1 Influence of the acid type of ZSM-5 on the MTH reaction.a |

|

Download:

|

| Fig. 3. (a) 27Al MAS NMR spectra and (b) FTIR spectra of adsorbed pyridine at 150 ℃ of a series of ZSM-5 samples with different acid-type modified from ZSM-5(49) parent. | |

An evident increasing trend of C2= is observed with increasing L/B ratio, while the opposite is observed for C3= (Table 1). And with respective to C2= growth, C0+H2+aromatics (Arom) related to the weight of side reactions is not obviously increased. According to the above theory about Brønsted acid density and strength, C2= should be decreased and C3= increased with the decrease of Brønsted acid density of the samples, since Brønsted acid strength of these four samples are controlled at the same level. However, the result is just the opposite (Table 1). The possible explanation is that Lewis acid density of catalysts plays a decisive role for high C2= selectivity. That is to say, LASs favor the conversion reactions from the alkene-based to arene-based cycle to form more aromatics, and then more C2= through arene methylation/cracking cycle.

The above results show that C2= selectivity increases as the SA/WA ratio of BASs or the L/B ratio increases, but the increments are different. C2= selectivity is limited to 20% only by adjusting the SA/WA ratio, whereas C2= selectivitycan approach40% afteradding appropriate amounts of LASs.

In fact there are striking differences in pathways for forming MBs species betweenthe changeof acid strength and the change of acid type (Fig. S9 in Supporting information). As mentioned previously, the conversion reactions 2) from higher alkenes to MBs can occur via the hydrogen transfer or dehydrogenation reaction, accompanied by C30-C50 alkanes and H2, respectively [4, 5c]. Our reaction results in Fig. S9a indicate that with increasing the SA/WA ratio of BASs, the increase of C30-C50 selectivity is much more significant than that of H2. Rather, as the L/B ratio increases, C30-C50 selectivity shows a downward trend and H2 selectivity is observably increased (Fig. S9b). It means that strong BASs improve the hydrogen transfer, while the dehydrogenation can only be obviously strengthened by LASs. Related literatures suggest that LASs are beneficial toalkane dehydrogenation [11] and strong BASs contribute to alkene hydrogen transfer [17].

Interestingly, Fig. 4a confirms the correlation between C2= selectivity and the average number of methyl groups per benzene ring (Meave). TetraMB is the largest MB speice detectable in the effluents by GC-FID after CH3OH feed for 30min at 450 ℃ (Table S6 in Supporting inforamtion), and pentaMB and hexaMB are too large to leave the channel only analyzed by GC-MS after the HF dissolution (Table S7 in Supporting information). C2= selectivity is higher as the Meave both in the effluents and confined organics within the ZSM-5 catalyst decreases (Fig. 4a). The ZSM-5(49) -S450-3-Al80-5 sample with the highest L/B ratio at 2.24 displays the lowest Meave, thereby obtaining the highest C2= selectivity (Tables 1, S6 and S7). One reasonable explanation is that the ZSM-5 pore is slightly blocked by Alex, so the smaller micropore volume (Table S5) contributes to lower MBs and subsequent C2= formation due to steric constraints.

|

Download:

|

| Fig. 4. (a) Correlation between the C2=/C3= selectivity and the average number of methyl groups per benzene ring (Meave) in the effluents and confined organics within the ZSM-5 catalyst over modified ZSM-5(49). Reaction conditions: cat., 0.8 g; 450 ℃; 0.1 MPa; WHSV, 4.0 h-1; TOS, 0.5 h and (b) conversion versus time-on-stream in MTH reaction over modified ZSM-5(49). Reaction conditions: cat., 0.8 g; 450 ℃; 0.1 MPa; WHSV, 4.0 h-1. | |

Stability evaluation of MTH catalysts confirms that both ZSM-5 (49) -S150-7-A1M-5 sample with the highest P/E ratio (7.56) (Fig. 2b and Table S4) and ZSM-5(49) -S450-3-Al80-5 sample with the lowest P/E ratio (0.72) (Table 1) exhibit a fairly stable performance, compared with ZSM-5(49) parent at 450 ℃, 0.1 MPa, and a high mass space velocity of 4.0 h-1 (Fig. 4b). Especially, the lifetime of ZSM-5(49) -S150-7-A1M-5 up to 50 h is closely linked to the quite low level of Brønsted acid density, Brønsted acid strength and Lewis acid density, which suppresses the by-products formation.

3. ConclusionIn conclusion, we have demonstrated that the control on the conversion reactions from the alkene-based to arene-based cycle in the MTH is crucial to obtaining high C2= + C3= selectivity as well as highly adjustable P/E ratio. And the acidity control of MTH catalyst plays a key role in controlling the conversion reactions. A single factor experiment with only one acidity variable at a time is firstly achieved by adopting the same modification method of SCS from the identical parent zeolites to separately clarify the effect of acid density, strength and type on MTH reaction network. MTH catalysts with Brønsted acid density, Brønsted acid strength and Lewis acid density as low as possible, on the premise of the complete conversion of methanol, contribute to high C3= selectivity due to the suppression of the conversion reactions. Yet, MTH catalysts with medium Brønsted acid density typically below 0.4 mmol g-1, higher Brønsted acid strength and in particular a certain amount of Lewis acid density conduce to high C2= selectivity due to the promotion of the conversion reactions generating more MBs species. More importantly, owing to steric constraints of Alex, MBs can be cracked more efficiently to C2=. As a result, a wider range of the P/E ratio from 0.72 to 7.56 with high C2= + C3= selectivity of around 66% can be realized, wherein the maximum selectivity of C2= is 39.6% or C3= is 59.0%, using ZSM-5 catalysts with highly adjustable acidity in a fixed-bed reactor. These findings open up a new avenue for development of MTH process, which may allow the optimal utilization of sustainable methanol for diverse olefin products in accordance with market demand.

4. Experimental 4.1. Catalyst preparationSynthesis of HZSM-5(49) : Typically, high aluminum content ZSM-5 was synthesized via a hydrothermal route. Firstly, seeding gel was prepared by thoroughly mixing deionized water, NaOH (>96.0 wt%, Sinopharm Chemical Reagent Co., Ltd.), TPAOH (tetrapropylammonium hydroxide, 25 wt%, Sinopec Co., Ltd.) and TEOS (tetraethyl orthosilicate, TEOS, 28.4 wt% SiO2, Sinopharm Chemical Reagent Co., Ltd.) together in the molar ratio of 1SiO2:0.32NaOH:0.2TPAOH:20H2O, accordingly. Stirring of the resulting mixture for 1 h at ambient temperature, followed by aging at 100 ℃ for 20 h, were performed. A mixture consisting of H2O, NaOH, aluminum isopropoxide (24.7 wt% Al2O3, Sinopharm Chemical Reagent Co., Ltd.), TEOS and seeding gel with the respective molar ratio of 35H2O:0.16NaOH:0.023Al2O3:1SiO2:0.10-seeding was stirred at ambient temperature for 2 h. Then the resulting gel was placed into an autoclave and aged at 175 ℃ for 48 h. The products were recovered by filtration, washing and drying at 80 ℃ for 24 h. Finally, the as-synthesized samples were calcined at 550 ℃ (5 ℃/min) for 6 h. Obtained Na-ZSM-5 was exchanged with 0.1 mol/L NH4NO3 aqueous solution. The mixture was stirred at 80 ℃ for 2 h. Subsequently, this solution was filtered and washed with deionized water. Then the obtained product was dried at 80 ℃. After repeating the above mentioned processed for 3 times, NH4-ZSM-5 was obtained. Finally, NH4-ZSM-5 was calcined at 550 ℃ (5 ℃/min) for 6 h. The Si/Al2 mole ratio of obtained H-ZSM-5 was 49, as determined by ICP-AES. Thus, we denoted the zeolite as HZSM-5(49).

SCS treatment: The SCS treatments over dehydrated ZSM-5 zeolite with Si/Al2 of 49 were performed by altering the temperature (x = 150-450 ℃) and duration time (y = 0.5-6 h), denoted as ZSM-5(49) -Sx-y. Say concretely, the ZSM-5(49) sample was carried out in a quartz glass tube steel, with a thermocouple in the center of the catalyst bed. Typically, 4.0 g of ZSM-5(49) sample was pre-treated in nitrogen stream (30 mL/min) at 550 ℃ for 2 h.Then, at the predetermined temperature, methyldiethoxy-silane (MDES) vapor was carried by nitrogen stream (5 mL/min) into catalyst bed. All modified samples were swept with nitrogen at elevated temperature 450 ℃ for 3 h and then calcined at 550 ℃ (5 ℃/min) for 6 h prior to further modification, characterization and catalytic evaluation.

Acid leaching treatment: Symbol A1M-5 represents that one sample was leached with 1 mol/L HNO3 at 70 ℃ for 5 h under continuous stirring, followed by washing with deionized water, dried, and then calcined at 550 ℃ (5 ℃/min) for 6 h. For example, ZSM-5(49) -S150-4-A1M-5 sample was prepared as follows: HZSM-5 zeolite with Si/Al2 of 49 was treated by SCS method at low temperature of 150 ℃ for 4 h. Then, ZSM-5(49) -S150-4 sample was leached according to the above mentioned leaching conditions.After all these procedures, ZSM-5(49) -S150-4-A1M-5 was successfully obtained.

High temperature calcination: Symbol C600-5 represents that one sample was packed in a shallow bed on a quartz crucible and then heated from room temperature to 600 ℃ in air at a rate of 5 ℃/min and kept there for 5 h, before it was allowed to cool to room temperature. For example, ZSM-5(49) -S150-7-C600-5 sample was prepared as follows: HZSM-5 zeolite with Si/Al2 of 49 was treated by SCS method at low temperature of 150 ℃ for 7 h. Then, ZSM-5(49) -S150-7 sample was calcined according to the above mentioned calcination conditions. After all these procedures, ZSM-5(49) -S150-7-C600-5 was successfully obtained.

Al exchange: Symbol Al80-5 represents that one sample was treated with 1 mol/L Al (NO3) 3 aqueous solution at 80 ℃ for 5 h under continuous stirring. The obtained products were washed by deionized water and then dried at 80 ℃. Finally, dried sample was calcined at 550 ℃ (5 ℃/min) for 6 h. For example, ZSM-5(49) -S150-7-Al80-5 sample was prepared as follows: HZSM-5 zeolite with Si/Al2 of 49 was treated by SCS method at low temperature of 150 ℃ for 7 h. Then, ZSM-5(49) -S150-7 sample was exchanged according to the above mentioned Al exchange conditions. After all these procedures, ZSM-5(49) -S150-7-Al80-5 was successfully obtained.

4.2. Catalyst characterizationX-ray diffraction (XRD) patterns were recorded on a Rigaku Ultima Ⅳ X-ray diffractometer (35 kV and 25 mA) using Cu Ka radiation (λ = 1.5405 Å). N2 physisorption was carried out at 77 K on a BELSORP-MAX instrument after outgassing the samples under vacuum at 573 K for 10 h. The specific surface area was calculated with Brunauer-Emmett-Teller method. The crystal morphology and size were measured by scanning electron microscopy (SEM) on a Hitachi S-4800 microscope. The amounts of Si and Al in the catalysts were quantified by inductively coupled plasma (ICP) on a Thermo IRIS Intrepid Ⅱ XSP atomic emission spectrometer after dissolving the samples in HF solution.

27Al solid-state MAS NMR spectra were recorded on a VARIAN VNMRS-400WB spectrometer under one pulse condition. 27Al NMR spectra were recorded with a frequency of 104.18 MHz, a spinning rate of 10.0 kHz, and a recycling delay of 4 s. KAl (SO4) 2·12H2O was used as the reference for chemical shift.

Acidity was measured by temperature-programmed desorption of ammonia (NH3-TPD) with a Micromeritics tp-5080 equipment equipped with a thermal conductivity detector (TCD). Typically, 100 mg of sample was pre-treated in helium stream (30 mL/min) at 550 ℃ for 2 h. The adsorption of NH3 was carried out at 50 ℃ for 0.5 h. The catalyst was flushed with helium at 100 ℃ for 2 h to remove physisorbed NH3 from the catalyst surface. The TPD profile was recorded at a heating rate of 5 ℃/min from 100 ℃ to 550 ℃.

The Brønsted and Lewis acid sites of the catalysts were investigated by FTIR of adsorbed pyridine in an in situ cell with CaF2 windows. Wafers with a weight of about 25 mg and radius of 6.5 mm were degassed for 1 h under vacuum at 550 ℃. Then pyridine was admitted, and, after equilibration, the samples were outgassed for 0.5 h at increasing temperatures (150, 200, 250, 350 and 450 ℃). The spectra were recorded on a Nicolet iS50 FT-IR spectrometer.

4.3. Catalytic testingThe methanol-to-hydrocarbons (MTH) reactions over the ZSM-5 zeolites were carried out in a stainless steel continuousflow reactor (10 mm i.d.), with a thermocouple in the center of the catalyst bed. Catalyst (0.8 g) was pressed, crushed, and sorted into grains by 40-60 meshes, and then was activated at 550 ℃ for 3 h under a nitrogen flow before it was allowed to cool to reaction temperature of 450 ℃. Then liquid methanol (99.9%) was fed into the preheating zone of the reactor using a high performance liquid chromatography (HPLC) pump, where it was subsequently vaporized in a nitrogen flow (N2/CH3OH = 8.99, mole ratio, analyzed by GC) to achieve a desired weight hourly space velocity. The output products were analyzed online by Agilent 7890A gas chromatograph equipped with an HP-PLOT Q capillary column (30 m × 0.53 mm × 40mm), a Dikma 2 m × 1/8 5A column, a Dikma 2 m × 1/8 Porapak Q column, two Dikma 1 m × 1/8 Porapak Q columns, a flame ionization detector (FID) which was used to detect hydrocarbons and two TCD detectors which were used to detect hydrogen and nitrogen. Both methanol and dimethylether were considered as reactant species in calculating the conversion.

The effluents of MTH reaction at 450 ℃ for 0.5 h were analyzed quantitatively by online GC (Linghua GC-9890A) equipped with a FID and a DW-WAX capillary column (60 m × 0.25 mm × 0.25mm) and GS-Alumina PLOT column (50 m × 0.53 mm × 15μm). The catalysts after MTH reaction were dissolved in 20% HF, and the liberated organics were extracted from the aqueous phase with CCl4. The confined organics were analyzed by GC-MS (Agilent GC-7890B and Agilent MS-5977A) with a HP-5 capillary column (30 m × 0.32 mm × 0.50μm).

AcknowledgmentsWe gratefully acknowledge the National Natural Science Foundation of China (Nos. U1462106 and 21673076) and the National Key Research and Development Program of China (No.2016YFB0701100).

Appendix A. Supplementary dataSupplementary data associated with this article can be found, in the online version, at http://dx.doi.org/10.1016/j.cclet.2017.03.023.

| [1] |

(a) H.M. Torres Galvis, K.P. de Jong, Catalysts for production of lower olefins from synthesis gas:a review, ACS Catal. 3(2013) 2130-2149; (b) K. Cheng, B. Gu, X. Liu, et al., Direct and highly selective conversion of synthesis gas into lower olefins:design of a bifunctional catalyst combining methanol synthesis and carbon-carbon coupling, Angew. Chem. Int. Ed. 55(2016) 4725-4728. |

| [2] |

(a) S. Xu, A. Zheng, Y. Wei, et al., Direct observation of cyclic carbenium ions and their role in the catalytic cycle of the methanol-to-olefin reaction over chabazite zeolites, Angew. Chem. 52(2013) 11564-11568; (b) U. Olsbye, S. Svelle, K.P. Lillerud, et al., The formation and degradation of active species during methanol conversion over protonated zeotype catalysts, Chem. Soc. Rev. 44(2015) 7155-7176. |

| [3] | P. Tian, Y. Wei, M. Ye, Z. Liu. Methanol to olefins (MTO):from fundamentals to commercialization. ACS Catal. 5(2015)1922–1938. DOI:10.1021/acscatal.5b00007 |

| [4] |

(a) J. Liu, C.X. Zhang, Z.H. Shen, et al., Methanol to propylene:effect of phosphorus on a high silica HZSM-5 catalyst, Catal. Commun. 10(2009) 1506-1509; (b) Y.J. Lee, Y.W. Kim, N. Viswanadham, K.W. Jun, J.W. Bae, Novel aluminophosphate (AlPO) bound ZSM-5 extrudates with improved catalytic properties for methanol to propylene (MTP) reaction, Appl. Catal. A:Gen. 374(2010) 18-25; (c) U. Olsbye, S. Svelle, M. Bjørgen, et al., Conversion of methanol to hydrocarbons:how zeolite cavity and pore size controls product selectivity, Angew. Chem. Int. Ed. 51(2012) 5810-5831. |

| [5] |

(a) S. Svelle, S. Kolboe, O. Swang, U. Olsbye, Methylation of alkenes and methylbenzenes by dimethyl ether or methanol on acidic zeolites, J. Phys. Chem. B 109(2005) 12874-12878; (b) S. Svelle, F. Joensen, J. Nerlov, et al., Conversion of methanol into hydrocarbons over zeolite H-ZSM-5:ethene formation is mechanistically separated from the formation of higher alkenes, J. Am. Chem. Soc. 128(2006) 14770-14771; (c) M. Bjørgen, S. Svelle, F. Joensen, et al., Conversion of methanol to hydrocarbons over zeolite H-ZSM-5:on the origin of the olefinic species, J. Catal. 249(2007) 195-207; (d) V. Van Speybroeck, J. Van der Mynsbrugge, M. Vandichel, et al., First principle kinetic studies of zeolite-catalyzed methylation reactions, J. Am. Chem. Soc. 133(2011) 888-899; (e) S. Ilias, R. Khare, A. Malek, A. Bhan, A descriptor for the relative propagation of the aromatic-and olefin-based cycles in methanol-to-hydrocarbons conversion on H-ZSM-5, J. Catal. 303(2013) 135-140. |

| [6] |

(a) D. Mores, J. Kornatowski, U. Olsbye, B.M. Weckhuysen, Coke formation during the methanol-to-olefin conversion:in situ microspectroscopy on individual H-ZSM-5 crystals with different Brønsted acidity, Chem. Eur. J. 17(2011) 2874-2884; (b) S.M. Almutairi, B. Mezari, E.A. Pidko, P.C. Magusin, E.J. Hensen, Influence of steaming on the acidity and the methanol conversion reaction of HZSM-5 zeolite, J. Catal. 307(2013) 194-203. |

| [7] | C. Wang, J. Xu, G. Qi, et al., Methylbenzene hydrocarbon pool in methanol-toolefins conversion over zeolite H-ZSM-5. J. Catal. 332(2015)127–137. DOI:10.1016/j.jcat.2015.10.001 |

| [8] |

(a) F. Bleken, M. Bjørgen, L. Palumbo, et al., The effect of acid strength on the conversion of methanol to olefins over acidic microporous catalysts with the CHA topology, Top. Catal. 52(2009) 218-228; (b) M.W. Erichsen, S. Svelle, U. Olsbye, The influence of catalyst acid strength on the methanol to hydrocarbons (MTH) reaction, Catal. Today 215(2013) 216-223; (c) M.W. Erichsen, S. Svelle, U. Olsbye, H-SAPO-5 as methanol-to-olefins (MTO) model catalyst:Towards elucidating the effects of acid strength, J. Catal. 298(2013) 94-101; (d) M.W. Erichsen, K. De Wispelaere, K. Hemelsoet, et al., How zeolitic acid strength and composition alter the reactivity of alkenes and aromatics towards methanol, J. Catal. 328(2015) 186-196. |

| [9] | S.F. Zhao, D. Yang, X.W. Zhang, et al., ZSM-5 with controllable acidity as an efficient catalyst for a highly adjustable propene/ethene ratio in the 1-butene cracking. Chem. Commun. 52(2016)11191–11194. DOI:10.1039/C6CC04680K |

| [10] | S. Borghèse, M. Haouas, J. Sommer, F. Taulelle. Activation energy of hydride transfer between isobutane molecules on USY zeolite. First direct experimental measurement by in situ MAS NMR using mixtures of isotopomers. J. Catal. 305(2013)130–134. DOI:10.1016/j.jcat.2013.05.004 |

| [11] | S. Schallmoser, T. Ikuno, M.F. Wagenhofer, et al., Impact of the local environment of Brønsted acid sites in ZSM-5 on the catalytic activity in npentane cracking. J. Catal. 316(2014)93–102. DOI:10.1016/j.jcat.2014.05.004 |

| [12] |

(a) L.F. Lin, C.F. Qiu, Z.X. Zhuo, et al., Acid strength controlled reaction pathways for the catalytic cracking of 1-butene to propene over ZSM-5, J. Catal. 309(2014) 136-145; (b) L.F. Lin, S.F. Zhao, D.W. Zhang, et al., Acid strength controlled reaction pathways for the catalytic cracking of 1-pentene to propene over ZSM-5, ACS Catal. 5(2015) 4048-4059. |

| [13] | W. Guo, W. Wu, M. Luo, W. Xiao. Modeling of diffusion and reaction in monolithic catalysts for the methanol-to-propylene process. Fuel Process. Technol. 108(2013)133–138. DOI:10.1016/j.fuproc.2012.06.005 |

| [14] | S. Svelle, U. Olsbye, F. Joensen, M. Bjørgen. Conversion of methanol to alkenes over medium-and large-pore acidic zeolites:steric manipulation of the reaction intermediates governs the ethene/propene product selectivity. J. Phys. Chem. C 111(2007)17981–17984. DOI:10.1021/jp077331j |

| [15] | R. Gounder, A.J. Jones, R.T. Carr, E. Iglesia. Solvation and acid strength effects on catalysis by faujasite zeolites. J. Catal. 286(2012)214–223. DOI:10.1016/j.jcat.2011.11.002 |

| [16] | J. Huang, Y. Jiang, V.R. Marthala, et al., Characterization and acidic properties of aluminum-exchanged zeolites X and Y. J. Phys. Chem. C 112(2008)3811–3818. DOI:10.1021/jp7103616 |

| [17] | P. Arudra, T.I. Bhuiyan, M.N. Akhtar, et al., Silicalite-1 as efficient catalyst for production of propene from 1-butene. ACS Catal. 4(2014)4205–4214. DOI:10.1021/cs5009255 |

2017, Vol. 28

2017, Vol. 28