The hydrochlorination of acetylene reaction has received significant attention as an alternative route to the manufacture of vinyl chloride monomer (VCM). However, the industrially mercuric chloride (HgCl2) catalyst usually suffers from highly toxic and sublimation under the reaction conditions in spite of the high conversion. Thus, the hydrochlorination of acetylene involving the use of less hazardous mercuric-free materials as the catalysts is highly desirable.

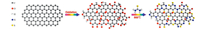

The pioneering work carried out by Hutchings and coworkers [1-6] has shown that high-valent gold(Ⅲ) catalysts can be the most promising materials of choice due to its intrinsically high activity. However, one of the current technological bottlenecks for the industrial development of acetylene hydrochlorination is the high cost and poor stability of the Au-based catalyst which severely limited their applications in catalysis. Thereafter, efforts to develop highly active and stable Au-based catalysts for the hydrochlorination of acetylene have therefore concentrated on the addition of cocatalysts to Au [7-11]. Comparing to the comprehensive study of the active components, the understanding of the substrates’ effect in reactivity promotion was scarce and not thoroughly studied. Since metal nanoparticles (NPs) play a major role to convert the reactants, the impact of appropriate substrates to promote catalytic performance shall not be ignored [6, 7, 12, 13]. Thus, the influence of the carbon support on the activity of AuCl3 catalyst for acetylene hydrochlorination is also important. In this regard, we have used activated carbon (AC) as the support for the AuCl3 catalyst to investigate the effects of nitrogen doping on the catalytic activity of the AuCl3 catalyst [14]. It is proposed that the presence of nitrogen atoms increased the electron density of Au3+ can increase the adsorption of hydrogen chloride and inhibit the reduction of Au3+ to Au0 and hence improve the catalytic stability [14, 15]. Very recently, Hutchings and co-workers reported an inspiring sulfur-containing ligands stabilized Au(Ⅰ) catalyst for acetylene hydrochlorination [16]. They also suggested that even sulfur-containing ligands dissociated, the presence of the sulfur moiety may serve to immobilize/anchor the Au and also help prevent reduction and sintering of the Au. This prompted us to investigate the use of nitrogen and sulfur dual-doped carbon materials comprising gold for acetylene hydrochlorination reaction. In this work, we have developed a simple and green approach to nitrogen and sulfur co-doped AC (NSAC) by using thiourea as nitrogen and sulfur source (Scheme 1), and investigated the gas phase hydrochlorination of acetylene over the Au/NSAC catalyst. The results showed that Au/NSAC had a higher Au dispersion and Au3+ content, giving rise to a higher catalytic activity and stability than Au/AC.

|

Download:

|

| Scheme. 1. Process depicting the formation of NSAC with the introduction of heteroatoms. | |

2. Experimental

Synthesis of NSAC: N and S codoped activated carbon was synthesized by pyrolysis of mixture of AC and thiourea (Scheme 1). The AC support was initially submitted to wash with HNO3 solution and then washed with distilled water and dried. A mixture of AC (5 g), thiourea (3 g) and distilled water (50 mL) was stirred to obtain carbon slurry. Finally, the solution was filtered and calcined at 900 ℃ under a nitrogen atmosphere for 1 h. The obtained sample was labeled as NSAC.

Catalyst preparation: Supported AuCl3 catalysts were prepared using a wetness impregnation technique. A HAuCl4 (assay: 48%) solution in HCl solution (36 wt%) was added dropwise to the NSAC or AC support with agitated stirring to obtain a catalyst with a final Au loading of 1 wt%. After the solution was homogeneously mixed with the support, the system was dried for use. The obtained catalysts were labeled as Au/NSAC and Au/AC, respectively.

Characterization: The morphology and structure of the asprepared catalysts were characterized by transition electron microscopy (TEM, JEOL JEM 2100F). The surface chemical composition of each sample was analyzed by a PHI-5600 X-ray photoelectron spectroscopy (XPS) system with Mg Ka radiation (hν=1253.6 eV).

Catalytic test: Catalysts were tested for acetylene hydrochlorination in a fixed-bed glass microreactor (i.d. 10 mm). Acetylene (10 mL/min) and hydrogen chloride (12 mL/min) were fed though a mixing vessel via calibrated mass flow controllers to a heated glass reactor containing catalyst (200 mg), with a total C2H2 GHSV of 1480 h-1. The gas phase products were passed through an absorption bottle containing NaOHsolution firstand then analysed on-line by GC equipped with a flame ionisation detector (FID).

3. Results and discussionFig. 1a shows representative Raman spectra of the NSAC and AC samples. It can be clearly seen that all spectra show two typical peaks at roughly 1342 and 1570 cm-1, which can be attributed to the well-documented D band and G band, respectively [17, 18]. The ratio of ID/IG increases from 1.46 to 1.49 indicating the presence of a largenumberofdefects in theNSAC sample[18, 19].Fig. 1b shows the survey XPS spectra of as-prepared NSAC sample, which display that besides carbon and oxygen, nitrogen and sulfur signals can be simultaneously observed. This result indicates that both N and S species have been successfully doped into carbon. To further understand the chemical state of nitrogen and sulfur in the NSAC sample, we analyzed the high resolution N 1s and S 2p peaks in details. The high-resolution N 1s peak could be further deconvoluted into three different peaks, at 398.6, 400.2 and 401.8 eV, corresponding to pyridinic-N, pyrrolic-N and graphitic-N respectively [20-22]. For S 2p peak, all the high resolution S 2p peaks of NSAC can also be resolved into three different peaks at the binding energies of 164.0, 165.2 and 169.1 eV (Fig. 1d) [23-26]. Similar to references, the three peak can be ascribed to sulfur, thiophene-S and sulphate, respectively. The doping levels of N and S indicated by XPS are 1.77 and 1.41 wt%, respectively (For AC, the overall contents of N and S are 0.29 wt% and 0.06 wt%, respectively). The element mapping images, as shown in Fig. 1e-i, clearly confirm the existence of N and S and also display the homogeneous distribution of the doped compositions. This result indicates that N and S atoms are successfully incorporated into the carbon network.

|

Download:

|

| Figure 1. (a) Raman spectra of the NSAC and AC, (b) XPS spectra of the NSAC normalized at 284.8 eV of C 1s, (c) N 1s XPS spectra of NSAC, (d) S 2p XPS spectra of NSAC, (e-i) TEM spectra of the NSAC. | |

The activity of hydrochlorination was evaluated under a fixed reaction condition over 12 h. To accelerate the deactivate process of Au-based catalysts, higher GHSV was carried out. As shown in Fig. 2a, AC and NSAC catalysts both display very poor catalytic activity ( < 7% conversion), which excludes the possible contribution of the AC and NSAC materials to the hydrochlorination activity. The catalyst evaluation data in Fig. 2a shows that Au/NSAC had best performance among the tested samples with an initial conversion of 82.3% and stabilized around 79%. As a comparison, the acetylene conversion of Au/AC catalyst decreases from 72% down to 37% after running for 12 h, indicating that Au/AC is rapidly deactivated under this reaction conditions. It should be highlighted that for all the tests carried out and reported in the current study, the selectivity to vinyl chloride was virtually 100% with trace amounts ( < 0.1%) of 1, 2-dichlorethane and chlorinated oligomers only throughout the entire run period. It is found that the acetylene hydrochlorination activity and stability for Au/NSAC is much better than Au/AC. This result demonstrates that introduction of S and N into AC greatly affects the physical and chemical properties of the carbon, and consequently, enhances the catalytic performance of Au-based catalyst. The Au/NSAC catalytic performance with different Au loadings and the relationship between them were also conducted, as showed in Fig. 2b and c. According to the results, the acetylene conversion increases with rising Au loadings. The relationship between the conversion of acetylene and Au loadings is almost linear, which suggests that although NSAC have the catalytic activity to some extent and the interfaces between Au cation-NSAC may be the active sites catalyzing the reaction, the main active sites are still Au cations in the Au/NSAC catalysts. In order to study the deactivation reasons and the effect of N and S elements on the performance of Au-based catalyst, the above Au/ AC and Au/NSAC catalysts were characterized by TEM and XPS analysis.

|

Download:

|

| Figure 2. Conversion of acetylene in acetylene hydrochlorination (a) over AC, NSAC, Au/AC and Au/NSAC catalysts, (b) over different loadings of Au/NSAC catalysts, (c) correlated with Au loadings. Reaction conditions: temperature (T)=180 ℃, GHSV(C2H2)=1480 h-1, feed volume ratio n(HCl)/n(C2H2)=1.2. | |

In view of that the structure of catalyst can be changed during the reaction, for example, by sintering of the Au NPs, thus, STEM was performed to figure out if the NPs sintered during the reaction. Fig. 3 shows STEM images of fresh and used Au/AC and Au/NSAC catalysts, the small bright dots represent the metal particles. The fresh Au/AC and Au/NSAC catalyst contains small particles ranging from 2 nm to 6 nm in diameter (Fig. 3a), indicating particles highly dispersion. The average particle size for fresh Au/AC was 4.8 nm and for fresh Au/NSAC 3.2 nm. This indicates that adding N and S atoms had caused a decrease in Au NPs particle size. Fig. 3c and d shows exemplary STEM images of used Au/AC and Au/NSAC catalysts, respectively. Au/AC catalysts are not resistant to sintering and showed that Au NPs of 6-10 nm in diameter (Fig. 3c), indicating a heterogeneous size distribution and an easy occurrence of agglomeration of Au. For Au/NSAC, the Au NPs sintering did not markedly occur and the Au NPs are well dispersed after reaction (Fig. 3d). The average particle size for used Au/AC was 8.2 nm and for used Au/NSAC 4.9 nm. For acetylene hydrochlorination, catalytic activity was correlated with Au content and the number of active sites for the adsorption of HCl and C2H2 (i.e., the dispersion of Au). That can be explained by that the activity was ascribed to Au3+ species at the perimeter of the gold NPs in contact with the support [13]. Thus, high conversions required high Au dispersion. Au/NSAC had stable conversion without significant Au agglomeration formation after 12 h test, revealing the valuable improvement of Au dispersion after the introduction of N and S in Au/NSAC.

|

Download:

|

| Figure 3. Representative STEM figures of (a) fresh Au/AC catalyst, (b) fresh Au/NSAC catalyst, (c) used Au/AC catalyst, (d) used Au/NSAC catalyst, respectively. | |

Because previous literature studies ascribed the activity of the catalyst to the presence of Au3+ species and postulated that they were the active sites, XPS was used to investigate the valence-state changes of the surface of the Au species and the relative amount of active Au3+ in Au/AC and Au/NSAC before and after the reaction. More than one gold species was evident, and thus, curve fitting was employed to determine the ratio of each species (Fig. 4). In fresh Au/ AC and Au/NSAC, the relative content of Au3+ is 23.6 and 66.8%, respectively. The higher content of Au3+ in Au/NSAC illustrated that the existence of N and S atoms inhibited the reduction of Au3+ into Au0 inthe preparationprocess. Underthe reactionconditions, Au3+is reduced into Au0, which contributes to the deactivation of the Au catalyst. In the case of the Au/AC catalyst after the reaction, only 8.7% of Au3+ species are present, which demonstrates that a reduction and/or agglomeration of Au3+ species occur. On the contrary, there is a considerable amount of Au3+ (39.4%) in the used Au/NSAC catalyst, which indicates that the presence of N and S atoms indeed inhibits the reduction of Au3+ to Au0 during the reaction.

|

Download:

|

| Figure 4. XPS spectrum and simulation for the samples: (a) fresh Au/AC catalyst, (b) fresh Au/NSAC catalyst, (c) used Au/AC catalyst, (d) used Au/NSAC catalyst. | |

4. Conclusion

In summary, we have successfully demonstrated that N and S dual-doped can efficiently enhance the catalytic performance of Au/AC. The doped Au/NSAC catalysts are quite stable and more active for the hydrochlorination of acetylene compared with Au/AC catalyst. The enhanced catalytic performance was attributed to the presence of the sulfur atoms may serve to immobilize/anchor the Au and also help prevent reduction and sintering of the Au. The excellent catalytic performance of the Au/NSAC catalyst demonstrated its potential as an alternative to mercury chloride catalysts for acetylene hydrochlorination. Furthermore, the novel idea that designs dual or multi heteroatom doped catalysts could serve as a general strategy for the synthesis of other carbon materials supported metal catalysts.

| [1] | Hutchings G.J.. Vapor phase hydrochlorination of acetylene:correlation of catalytic activity of supported metal chloride catalysts. J. Catal. 96 (1985) 292–295. DOI:10.1016/0021-9517(85)90383-5 |

| [2] | Nkosi B., Coville N.J., Hutchings G.J., Nkosi B., Hutchings G.J.. Reactivation of a supported gold catalyst for acetylene hydrochlorination. J. Chem. Soc. Chem. Commun. 1 (1988) 71–72. |

| [3] | Nkosi B., Coville N.J., Hutchings G.J.. Vapour phase hydrochlorination of acetylene with group VⅢ and IB metal chloride catalysts. Appl. Catal. 43 (1988) 33–39. DOI:10.1016/S0166-9834(00)80898-2 |

| [4] | Nkosi B., Adams M.D., Coville N.J., Hutchings G.J.. Hydrochlorination of acetylene using carbon-supported gold catalysts:a study of catalyst reactivation. J. Catal. 128 (1991) 378–386. DOI:10.1016/0021-9517(91)90296-G |

| [5] | Nkosi B., Coville N.J., Hutchings G.J., et al. Hydrochlorination of acetylene using gold catalysts:a study of catalyst deactivation. J. Catal. 128 (1991) 366–377. DOI:10.1016/0021-9517(91)90295-F |

| [6] | Conte M., Carley A.F., Heirene C., et al. Hydrochlorination of acetylene using a supported gold catalyst:a study of the reaction mechanism. J. Catal. 250 (2007) 231–239. DOI:10.1016/j.jcat.2007.06.018 |

| [7] | Conte M., Carley A.F., Attard G., et al. Hydrochlorination of acetylene using supported bimetallic Au-based catalysts. J. Catal. 257 (2008) 190–198. DOI:10.1016/j.jcat.2008.04.024 |

| [8] | Wang S.J., Shen B.X., Song Q.L.. Kinetics of acetylene hydrochlorination over bimetallic Au-Cu/C catalyst. Catal. Lett. 134 (2010) 102–109. DOI:10.1007/s10562-009-0216-4 |

| [9] | Zhang H.Y., Dai B., Wang X.G., Xu L.L., Zhu M.Y.. Hydrochlorination of acetylene to vinyl chloride monomer over bimetallic Au-La/SAC catalysts. J. Ind. Eng. Chem. 18 (2012) 49–54. DOI:10.1016/j.jiec.2011.11.075 |

| [10] | Zhang H.Y., Dai B., Wang X.Q., et al. Non-mercury catalytic acetylene hydrochlorination over bimetallic Au-Co(Ⅲ)/SAC catalysts for vinyl chloride monomer production. Green Chem. 15 (2013) 829–836. DOI:10.1039/c3gc36840h |

| [11] | J.Zhao, Xu J.T., Xu J.H., et al. Activated-carbon-supported gold-cesium(I) ashighly effective catalysts for hydrochlorination of acetylene to vinyl chloride. ChemPlusChem 80 (2015) 196–201. DOI:10.1002/cplu.201402176 |

| [12] | Conte M., Davies C.J., Morgan D.J., et al. Modifications of the metal and support during the deactivation and regeneration of Au/C catalysts for the hydrochlorination of acetylene. Catal. Sci. Technol. 3 (2013) 128–134. DOI:10.1039/C2CY20478A |

| [13] | Conte M., Davies C.J., Morgan D.J., et al. Aqua regia activated Au/C catalysts for the hydrochlorination of acetylene. J. Catal. 297 (2013) 128–136. DOI:10.1016/j.jcat.2012.10.002 |

| [14] | Zhao J., Xu J.T., Xu J.H., et al. Enhancement of Au/AC acetylene hydrochlorination catalyst activity and stability via nitrogen-modified activated carbon support. Chem. Eng. J. 262 (2015) 1152–1160. DOI:10.1016/j.cej.2014.10.071 |

| [15] | Li X.Y., Zhu M.Y., Dai B.. AuCl3 on polypyrrole-modified carbon nanotubes as acetylene hydrochlorination catalysts. Appl. Catal. B 142- 143 (2013) 234–240. |

| [16] | Johnston P., Carthey N., Hutchings G.J.. Discovery, development, and commercialization of gold catalysts for acetylene hydrochlorination. J. Am. Chem. Soc. 137 (2015) 14548–14557. DOI:10.1021/jacs.5b07752 |

| [17] | Wang S., Zhang L., Xia Z., et al. BCN graphene as efficient metal-free electrocatalyst for the oxygen reduction reaction. Angew. Chem. Intern. Ed. 51 (2012) 4209–4212. DOI:10.1002/anie.201109257 |

| [18] | Liu M.X., Gan L.H., Xiong W., et al. Partially graphitic micro-and mesoporous carbon microspheres for supercapacitors. Chin. Chem. Lett. 24 (2013) 1037–1040. DOI:10.1016/j.cclet.2013.07.013 |

| [19] | Cui Z.T., Wang S.G., Zhang Y.H., Cao M.H.. A simple and green pathway toward nitrogen and sulfur dual doped hierarchically porous carbons from ionic liquids for oxygen reduction. J. Power Sources 259 (2014) 138–144. DOI:10.1016/j.jpowsour.2014.02.084 |

| [20] | Hakoda T., Yamamoto S., Kawaguchi K., et al. Oxygen reduction activity of Ndoped carbon-based films prepared by pulsed laser deposition. Appl. Surf. Sci. 257 (2010) 1556–1561. DOI:10.1016/j.apsusc.2010.08.095 |

| [21] | Deng D.H., Pan X.L., Yu L., et al. Toward N-doped graphene via solvothermal synthesis. Chem. Mater. 23 (2011) 1188–1193. DOI:10.1021/cm102666r |

| [22] | Li X.L., Wang H.L., Robinson J.T., et al. Simultaneous nitrogen doping and reduction of graphene oxide. J. Am. Chem. Soc. 131 (2009) 15939–15944. DOI:10.1021/ja907098f |

| [23] | Wohlgemuth S.A., White R.J., Willinger M.G., Titirici M.M., Antonietti M.. A onepot hydrothermal synthesis of sulfur and nitrogen doped carbon aerogels with enhanced electrocatalytic activity in the oxygen reduction reaction. Green Chem. 14 (2012) 1515–1523. DOI:10.1039/c2gc35309a |

| [24] | Su Y.Z., Zhang Y., Zhuang X.D., et al. Low-temperature synthesis of nitrogen/sulfur co-doped three-dimensional graphene frameworks as efficient metal-free electrocatalyst for oxygen reduction reaction. Carbon 62 (2013) 296–301. DOI:10.1016/j.carbon.2013.05.067 |

| [25] | Liu M.X., Deng X.X., Zhu D.Z., et al. Magnetically separated and N, S co-doped mesoporous carbon microspheres for the removal of mercury ions. Chin. Chem. Lett. 27 (2016) 795–800. DOI:10.1016/j.cclet.2016.01.038 |

| [26] | Xing L.B., Xi K., Li Q.Y., et al. Nitrogen, sulfur-codoped graphene sponge as electroactive carbon interlayer for high-energy and -power lithium-sulfur batteries. J. Power Sources 303 (2016) 22–28. DOI:10.1016/j.jpowsour.2015.10.097 |

2016, Vol. 27

2016, Vol. 27