b Liaoning Engineering Technology Research Centre of Function Fiber and Its Composites, Dalian 116034, China

Latent heat storage based on phase change materials (PCMs) is one of the most efficient methods applied in thermal energy storage because of several advantages,such as high heat-storage efficiency,temperature stability,and easy control in the phase change process [1, 2, 3, 4, 5]. Furthermore,solid-solid phase change materials (SSPCMs),including inorganic,organic and polymerbased SSPCMs,are among the most studied phase change materials [6]. What is more,polymer-based SSPCMs are even more attractive for the advantages of lack of leakage,small volume change,no sealing receptacles,easy forming process,direct system material application and cost effective fabrication procedures [7, 8]. To summarize,there are two basic methods to prepare polymer-based SSPCMs: One is a physical method in which the PCMs composite are obtained by dispersing PCMs into polymeric matrix as supporting materials; the other is a chemical method in which the PCMs are bound onto supporting polymeric materials by chemical grafting,blocking and cross-linking copolymerization. Moreover,after being bound onto supporting polymeric materials,PCMs will keep curing at the temperature even higher than the melting point,and thus the liquid leakage problem will be solved. Therefore,several polymer-based SSPCMs such as poly(2-alkyloyloxyethylacrylate) and poly(2-alkyloyloxyethylacrylate-comethylacrylate) comb-like polymers [9],polyacrylonitrile-g-PEG [10],poly(decaglycerol-co-ethylene glycol) [11],polyacrylonitrilegraft-polyethylene glycol-maleic acid monoester [12],poly(styrene-co-allyalcohol)-graft-stearic acid [13] and cellulose-graftPEG [14, 15] have been prepared and investigated in their thermal energy storage characteristics recently.

As an important type of co-polymer,the poly(styrene-coacrylonitrile) possesses high chemical resistance and heat stability of acrylonitrile,strong rigidity and suitable processing flow ability of styrene. Therefore,the poly(styrene-co-acrylonitrile) is evidently a more ideal polymer matrix to prepare polymer-based SSPCMs using the phase-change technology,which will also expand the application of poly(styrene-co-acrylonitrile).

Thus,a kind of poly(styrene-co-acrylonitrile) was synthesized as a polymer matrix in this study. The as-synthesized poly(styreneco-acrylonitrile) was applied to react with polyethylene glycol (PEG) to prepare a series of poly(styrene-co-acrylonitrile)-graftpolyethylene glycol (SAN-g-PEG) for solid-solid thermal energy storage materials. The graft reactions were characterized by FT-IR and 1H NMR. Thermal energy storage,energy storage durability,and thermal stability of the synthesized SAN-g-PEG were investigated using DSC and TGA.

2. ExperimentalThe synthesis was carried out via a two-step polymerization procedure under nitrogen in a three-neck round-bottom flask with an overhead stirrer. 3.0 g SAN was dissolved in 40 mL of distilled dichloromethane,and 2.930 g oxalyl chloride was added under a nitrogen flow at 0 ℃. 3.376 g aluminum chloride was first dissolved in 25 mL trichloromethane,and then was added into the above solution in batches. The mixture was slowly heated up to 37 ℃ and left to stir for 4 h. After that,6.0 g dried polyethylene glycol (PEG,M = 4000) was added and the reaction lasted for 10 h at 80 ℃. After the reaction was completed,the crude product was washed four times with glacial hydrochloric acid for dissociating complex,and purified with ice ether and deionized water.

Characterization: The chemical composition and structure of SAN-g-PEG SSPCMs were qualitatively confirmed by a Spectrum One-B model FT-IR (Perkin Elmer) within the range of 4000- 400 cm-1 by averaging 32 scans,and the 1H NMR spectra were recorded on a Bruker AV 300 spectrometer in chloroform D1 (CDCl3) as solvent. The thermal energy storage of SAN-g-PEG SSPCMs was performed on a differential scanning calorimeter (DSC Q2000) within the temperature range of 0-100 ℃. Thermal cycling tests were conducted on a hot stage (STC200,Instec) within the temperature range of 0-100 ℃. Thermal stability was investigated on a thermogravimetry analysis system (TGA Q50) from 20 ℃ to 600 ℃ at a heating rate of 10 ℃/min under an argon atmosphere.

3. Results and discussionFT-IR spectra of the synthesized sample are shown in Fig. 1(a). The transmittancepeaks at2926 cm-1and 2855 cm-1are assigned to the C-H stretching vibration of -CH3 and -CH2 groups. The stretching vibration of nitrile group (-C≡N) appears at 2237 cm-1. Thestrong peak at1741 cm-1 belongstothe stretchingvibrationof C=O. The transmittance peaks at 1596,1494 and 1452 cm-1 correspond to the C=C stretching vibration of benzene skeleton. The vibration bands of C-O and -OH groups of SAN-g-PEG appear at 1106 cm-1 and 3425 cm-1,respectively. The 1H NMR spectrum of SAN-g-PEG (Fig. 1(b)) further confirms the chemical structure of the SAN-g-PEG. Compared with the 1H NMR spectrum of PEG,the chemical shift of protons from CH2 in the PEG chain move from 3.35 ppm to 3.66 ppm after the graft copolymerization,which is a critical criterion for the synthesis of SAN-g-PEG. Furthermore,these peak integration values suggest that the graft content of PEG achieved was approximately 42.3 wt%. From the above,both the FT-IR and 1H NMR spectra indicate a consistent structure of the assynthesized sample with the target.

|

Download:

|

| Fig. 1. FT-IR and 1H NMR spectra of SAN-g-PEG: (a) FT-IR spectra and (b) 1H NMR spectra. | |

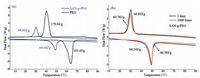

ADSC analysis was employedto investigate the latent heats and phase change temperature range of the SAN-g-PEG. In Fig. 2,the temperature of the solid-solid phase change ranges from 23 ℃ to 36 ℃,which shifts downward compared with that of PEG. It is because that the motion freedom of PEG is limited when one end of the chain is fixed,the arrangement and orientation of PEG molecule are inhibited,and the crystallization integrity of PEG is compromised,resulting in the decrease of the phase change enthalpy. Although the content of phase change unit is merely 66 wt%,the latent heat of SAN-g-PEG during the heating and cooling cycles still reaches up to high values of 66.85 J/g and 68.24 J/g,respectively. Compared with some polymeric SSPCMs in the previous work,the as-synthesized SAN-g-PEG possesses much higher latent heat storage capacity [16, 17]. The thermal properties of SAN-g-PEG almost remain the same after 1000 thermal cycles,which reveals that SAN-g-PEG keeps excellent heat storage durability after thermal cycling.

|

Download:

|

| Fig. 2.DSC curves: (a) SAN-g-PEG and (b) SAN-g-PEG after thermal cycling. | |

The thermal stability is investigated by TGA in air and the results are presented in Fig. 3. The SAN-g-PEG exhibits a one-step decomposition with an initial decomposition temperature (Td) of 350 ℃,and the temperature corresponding to the maximal decomposition rate is as high as 406 ℃,which indicates that the SAN-g-PEG has a high thermal stability for energy storage applications. Furthermore,the synthesized SAN-g-PEG has high solubility and low melting point,and can be easily processed into expected shapes,which indicates that the SAN-g-PEG is a promising material with a wide processing range and high potential for energy storage applications.

|

Download:

|

| Fig. 3.TGA curves of SAN-g-PEG. | |

A new type of novel SSPCMs was successfully synthesized via a two-step polymerization reaction,and the chemical structure and composition were confirmed by FTIR and 1H NMR spectra. The SAN-g-PEG was endowed with excellent phase change properties with a suitable solid-solid phase transition temperature range of 23-27 ℃ and a high latent enthalpy within the range of 66.8- 68.2 J/g. The SAN-g-PEG remained stable after a 1000-time thermal cycling test. SAN-g-PEG also exhibited great thermal stability with a Td of 350 ℃. Therefore,the SAN-g-PEG is a promising material with great potentials in various applications.

AcknowledgmentFinancial support of this work is provided by National Natural Science Foundation of China (No. 51373027) and Education Department of General Item of China (No. LR2012017).

| [1] | C.Z. Chen, L.G. Wang, Y. Huang, Crosslinking of the electrospun polyethylene glycol/cellulose acetate composite fibers as shape-stabilized phase change materials, Mater. Lett. 63 (2009) 569–571. |

| [2] | C. Liu, Y.P. Yuan, N. Zhang, X.L. Cao, X.J. Yang, A novel PCM of lauric–myristic– stearic acid/expanded graphite composite for thermal energy storage, Mater. Lett. 120 (2014) 43–46. |

| [3] | A. Bicçer, A. Sarı, Synthesis and thermal energy storage properties of xylitol pentastearate and xylitol pentapalmitate as novel solid–liquid PCMs, Sol. Energy Mater. Sol. Cell. 102 (2012) 125–130. |

| [4] | A. Sarı, A. Bicçer, Preparation and thermal energy storage properties of building material-based composites as novel form-stable PCMs, Energy Build. 51 (2012) 73–83. |

| [5] | C.Z. Chen, L.G. Wang, Y. Huang, Ultrafine electrospun fibers based on stearyl stearate/polyethylene terephthalate composite as form stable phase change materials, Chem. Eng. J. 150 (2009) 269–274. |

| [6] | A. Sarı, C. Alkan, A. Bicçer, Synthesis and thermal properties of polystyrene-graftPEG copolymers as new kinds of solid–solid phase change materials for thermal energy storage, Mater. Chem. Phys. 133 (2012) 87–94. |

| [7] | Y.B. Cai, X.L. Xu, C.T. Gao, et al., Structural morphology and thermal performance of composite phase change materials consisting of capric acid series fatty acid eutectics and electrospun polyamide6 nanofibers for thermal energy storage, Mater. Lett. 89 (2012) 43–46. |

| [8] | F. Kuznik, D. David, K. Johannes, J.-J. Roux, A review on phase change materials integrated in building walls, Renew. Sustain. Energy Rev. 15 (2011) 379–391. |

| [9] | C. Alkan, Ö .F. Ensari, D. Kahraman, Poly (2-alkyloyloxyethylacrylate) and poly (2-alkyloyloxyethylacrylate-co-methylacrylate) comblike polymers as novel phase-change materials for thermal energy storage, J. Appl. Polym. Sci. 126 (2012) 631–640. |

| [10] | J. Guo, H.X. Xiang, X.Y. Gong, Y.P. Zhang, Preparation and performance of the hydrolyzate of waste polyacrylonitrile fiber/poly (ethylene glycol) graft copolymerization, Energy Sour., Part A: Recov., Utilizat., Environ. Effects 33 (2011) 1067–1075. |

| [11] | J. Guo, H.X. Xiang, Q.Q. Wang, et al., Preparation of poly (decaglycerol-co-ethylene glycol) copolymer as phase change material, Energy Build. 48 (2012) 206–210. |

| [12] | J. Guo, P. Xie, X. Zhang, et al., Synthesis and characterization of graft copolymer of polyacrylonitrile-g-polyethylene glycol-maleic acid monoester macromonomer, J. Appl. Polym. Sci. 131 (2014) 40152. |

| [13] | A. Sarı, C. Alkan, Ö . Lafcçı, Synthesis and thermal properties of poly (styreneco-allyalcohol)-graft-stearic acid copolymers as novel solid–solid PCMs for thermal energy storage, Sol. Energy 86 (2012) 2282–2292. |

| [14] | Y.X. Li, R.G. Liu, Y. Huang, Synthesis and phase transition of cellulose-graft-poly (ethylene glycol) copolymers, J. Appl. Polym. Sci. 110 (2008) 1797–1803. |

| [15] | X.P. Yuan, E.Y. Ding, Synthesis and characterization of storage energy materials prepared from nano-crystalline cellulose/polyethylene glycol, Chin. Chem. Lett. 17 (2006) 1129–1132. |

| [16] | A. Sarı, C. Alkan, A. Bicçer, A. Karaipekli, Synthesis and thermal energy storage characteristics of polystyrene-graft-palmitic acid copolymers as solid–solid phase change materials, Sol. Energy Mater. Sol. Cell. 95 (2011) 3195–3201. |

| [17] | J. Hu, H. Yu, Y.M. Chen, M.F. Zhu, Study on phase-change characteristics of PET–PEG copolymers, J. Macromol. Sci., Part B: Phys. 45 (2006) 615–621. |

2015, Vol.26

2015, Vol.26