b Department of Wood Science and Technology, Beijing Forestry University, Beijing 100083, China;

c Department of Chemistry, Tsinghua University, Beijing 100084, China

Wood is a complex biomass material constituted mainly of cellulose,hemicelluloses,lignin and an amount of extractives. It is widely used in buildings,furniture,and paper pulp production,etc. [1] for its advantages of high strength-weight ratio,impact resistance and high process ability. But wood is very susceptible to weathering,and the nature of hygroexpansion,easy decay and burning limit its wide application.

Steam-heat treatment of wood has been known as an effective and eco-friendly method to improve wood properties and therefore widely used. Improving dimensional stability by reducing hygroscopicity and increasing decay resistance against fungi and durability against frequent use under natural environmental conditions can be achieved through steam-heat treatment [2,3,4]. But this method can also reduce the mechanical properties of wood [5,6]. All of the modifications on the properties of steam-heat treated (SHT) wood are related to the changes of the main components of wood during treatment. Chemical modifications and degradation of wood components take place through a series of hydrolysis,oxidation,and decarboxylation reactions coupled with heat and mass transfer resulting in its structure being reformed [7].

Fourier transform infrared (FT-IR) spectroscopy is a widely used and well-established tool for structure elucidation as well as a rapid and convenient method to deduce structural information of molecules [8,9,10]. It is a useful technique to obtain rapid information about the structure of wood components,and can show chemical changes taking place in wood during steam-heat treatment. This technique has been used to study the chemical changes of the weathering of acrylic films and acrylic-coated lime wood [11],structural changes of lime wood under biodegradation [12] and to analyze extractable substances of visco-elastic thermal compression wood [13]. The second derivative IR (SD-IR) spectra are obtained on the basis of FT-IR spectra after mathematical calculation and can enhance the apparent resolution of original IR spectra. More accurate and comprehensive structural information about SHT wood can be obtained by FT-IR spectra combined with SD-IR spectra.

The correlation coefficient method can quantitatively evaluate the chemical structure modifications of SHT wood under different treatment temperatures through calculating the correlation coefficients of SHT wood spectra. This method offers an insightful way to evaluate the influence of steam-heat treatment on wood.

Two dimensional correlation infrared (2D-IR) spectroscopy was proposed by Noda in 1986 [14]. 2D-IR spectra are based on the detection of dynamic changes of a system under an external perturbation which can be thermal,compositional,optical, electrical,pressure or magnetic [11]. Furthermore,2D-IR spectra can enhance the resolution of IR spectra and provide new information about the variation of molecular structure. It has been applied in studies of traditional Chinese medicines and identification of precious tree species [15,16]. Some researchers also use the method to study the characteristics of fungal degraded and photo-degraded lime wood [17,18].

The aim of this study is to provide better insights on the chemical modifications of teak (Tectona grandis L.F.) wood during steam-heat treatment at different treatment temperatures utilizing FT-IR spectra,SD-IR spectra,correlation coefficients and 2D-IR spectra. 2. Experimental

2.1. Materials

Teak (T. grandisL.F.) wood samples are sawed into a dimension of 100 × 50 × 20 mm (length × width × height),and dried to an initial moisture content of around 8% in a high-frequency vacuum dryer. The steam-heat treatment is conducted at temperatures of 120°C,140°C,160°C,180°C,200°C and 220°C in an air-tight chamber with less than 2 percent oxygen and a duration time of 2 h. Steam is used as a heating medium and a shielding gas. The reference wood sample is kept under normal environmental conditions. KBr disks are prepared for FT-IR experiments and stored in the dryer until needed. 2.2. Methods

Wood samples are grounded into powder with a dimension between 80 and 100 mesh. Two mg of powder is then mixed with 100 mg KBr,ground and pressed into a thin disk with a diameter of 13 mm. The disk is scanned to obtain FT-IR spectra by a Spectrum GX Fourier-transform infrared spectrometer (Perkin Elmer,USA) equipped with a DTGS detector over the scan range of 4000- 400 cm-1 with a resolution of 4 cm-1 for a total accumulation of 32 scans. The second derivative IR spectra are obtained after 13-point smoothing of the original IR spectra. The correlation coefficients of SHT wood with reference are calculated through PE Spectrum Software of the Perkin-Elmer FT-IR spectrometer. The same procedure is utilized to obtain 2D-IR spectra,then the disks are put into the portable programmable temperature controller (Model 50-886,Love Control) which is connected to the spectrometer. The 2D-IR spectra are obtained by treatment of the series of temperature-dependent dynamic spectra at different temperatures from 50°C to 120°C at an interval of 10°C,with 2DIR correlation analysis software programmed by Department of Chemistry of Tsinghua University,Beijing,China. 3. Results and discussion 3.1. Analysis of Fourier-transform infrared (FT-IR) spectra and second derivative IR (SD-IR) spectra of the wood samples

The FT-IR spectra of reference and steam-heat treated teak wood and their SD-IR spectra are shown in Figs. 1 and 2. The bands in the 3800-2750 cm-1 region are assigned to the hydroxyl and methyl/methylene stretching vibrations. The main functional groups of the wood components are in the 1800-800 cm-1 region. This region is mainly analyzed because it reflects the molecular structural changes of the wood components after steam-heat treatment.

| Download: |

| Fig. 1. FT-IR spectra of reference and steam-heat treated wood in the 4000-400 cm-1 region. | |

| Download: |

| Fig. 2. SD-IR spectra of reference and steam-heat treated wood in the 1800-800 cm-1 region. | |

The spectra of wood samples in the 1800-800 cm-1 region are complicated. There are many overlapping bands contributed by different vibrations of different groups from wood components. The SD-IR spectra can separate the bands partially. The assignments of the bands are presented in Table 1 [7,16,18,19,20].

The FT-IR and SD-IR spectra of SHT wood show the molecular structural changes of the wood components after steam-heat treatment. The intensity of the band at 1659 cm-1,assigned to conjugated C-O in quinines coupled with C55O stretching of various groups,decreases with increasing treatment temperature, and is perhaps due to the degradation of the acetyl groups of hemicelluloses through the deacetylation reaction and release of acetic acid. Condensation and degradation reactions in lignin structure and depolymerisation reaction of the less ordered carbohydrates may happen under the catalysis of released acetic acid. The increase in the intensity of the band at 1508 cm-1 , assigned to the C=C stretching of the aromatic skeletal components in lignin with increasing treatment temperature,suggests the increase of the amount of lignin in the wood and degradation of amorphous carbohydrates,especially in hemicelluloses [21,22].

|

Table 1 The band assignment of wood samples in the 4000-400 cm-1 region. |

An increase in the intensity of the band at 1328 cm-1 assigned to C-H vibration in cellulose and Cl-O vibration in syringyl derivatives-condensed structures in lignin is observed,which suggests the formation of condensed structures [23]. The decrease in the intensity of the band at 1234 cm-1,assigned to C-O stretching vibration of Ph-O-C coupled with aromatic ring vibration in lignin and C-O stretching vibration in xyloglucan, indicates the loss of acetyl groups [17,24]. The increase in the intensity of the band at 1055 cm-1,assigned to C-O stretching vibrations in cellulose and hemicelluloses,suggests the formation of aliphatic alcohols during steam-heat treatment.

At the same time,the intensity in the band at 1110 cm-1 which can be seen in the SD-IR spectra (Fig. 2) is assigned to increases in the glucose ring stretching vibration,and may be due to the cleavage and dehydration of amorphous carbohydrates and/or crystallization of the paracrystalline region of cellulose. This may lead to the percentage increase of crystalline cellulose [7].

The intensity of the band at 1019 cm-1 which can be seen in the SD-IR spectra (Fig. 2),is assigned to C-O ester stretching vibrations in methoxyl and β-O-4 linkages in lignin [25] which decreases with increasing treatment temperature,indicating the cleavage of β-O-4 linkages and splitting of the methoxy groups from lignin structure [7]. The degradation reaction of the cleavage of β-O-4 linkages in lignin is catalyzed by acetic acid,which is formed and released from the degradation of acetyl groups from hemicelluloses. The acetic acid can also catalyze other degradation reactions of the wood components.

FT-IR spectra and SD-IR spectra qualitatively reveal the influence of steam-heat treatment on the main components of wood. 3.2. Quantitative evaluation of main components changes about the steam-heat treated wood

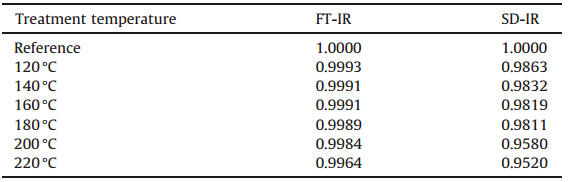

The IR spectra of wood samples show the changes of SHT wood chemical components. The correlation coefficient method can evaluate the degree of changes quantitatively. Table 2 shows the correlation coefficients of SHT wood with the reference in the 1800-800 cm-1 region of their FT-IR and SD-IR spectra.

Table 2 shows that the correlation coefficients of the SHT wood with reference decrease with the increasing of treatment temperature,indicating the change of main components of SHT wood is increasingly intense. The SD-IR spectra can enhance the apparent resolution of the original IR spectra,so the correlation coefficients of SD-IR spectra are smaller than that of FT-IR spectra and allows an evaluation of the changes of the main components of wood more accurately.

|

Table 2 The correlation coefficients of steam-heat treated wood with the reference in the 1800-800 cm-1 region. |

The correlation coefficients of the SD-IR spectra of SHT wood under 200°C and 220°C with reference are 0.9580 and 0.9520, which are much smaller than that of SHT wood below 200°C, indicating that the chemical structural changes of the SHT wood under 200°C and 220°C are greater.

The correlation coefficient method offers a more analytic way to evaluate the degree of changes about the main components of SHT wood and the influence of treatment temperature on them. 3.3. Analysis of two-dimensional infrared (2D-IR) correlation spectroscopy of the wood samples

The synchronous 2D-IR correlation spectra and auto-peaks in the 800-1800 cm-1 region of the reference and SHT teak wood are shown in Fig. 3. The auto-peaks on the diagonal line show the selfcorrelativity and sensibility of some normal vibration of functional groups with the thermal perturbation. The more sensitive the functional group,the more red the spectra becomes,and the stronger the intensity of auto-peak will be.

| Download: |

| Fig. 2. Synchronous 2D-IR spectra and auto-peaks of wood samples in the 1800-800 cm-1 region of: (a) reference,steam-heat treated wood under (b) 120°C,(c) 140°C,(d) 160°C,(e) 180°C,(f) 200°C,(g) 220°C. | |

From the 2D-IR spectra,the sensitivity of reference and wood treated under different temperatures to the thermal perturbation are different. The differences of their 2D-IR spectra in the 800- 1300 cm-1 region are obvious. The SHT wood becomes more and more sensitive to the thermal perturbation with increasing treatment temperature of 120-180°C. The SHT wood under 180°C is the most sensitive,this may occur because the pentosan content in wood appears to decrease a small amount and hemicellulose has begun to degrade. Then,subsequently,the sensitive degree of the SHT wood starts to decrease with the increasing treatment temperature from 180°C to 200°C. The SHT wood under 220°C is not very sensitive to the thermal perturbation.

The intensity of the auto-peaks of SHT wood also changed. The auto-peaks of wood samples are arranged in the order of intensity: the reference: 1651>975>950>1212>1194>1008>882> 1101>1149 cm-1; the SHT wood under 120°C: 1649>975> 953>1196>1210>1008>887>1101>1149 cm-1; the SHT wood under 140°C: 1649>975>950>1006>1199>1209> 882>1149>1098>1493 cm-1; the SHT wood under 160°C: 1649>975>948>1008>1212>1596>1196>882>1465> 1101>1498>1149>1521 cm-1; the SHT wood under 180°C: 975>950>1651>1008>1212>1199>887>1493>1149> 1101>1310 cm-1; the SHT wood under 200°C: 1651>978>1008>950>1212>885>1495>1468>1098> 1518>1149 cm-1; the SHT wood under 220°C: 1649> 1516>1463>975>953>1008>1212>1199>1166>1101> 885>1129>1149 cm-1 . The sensitivity of SHT wood to the thermal perturbation changes with different treatment temperature. The auto-peaks at around 1493 cm-1 and 1465 cm-1,which are assigned to C55C stretching of aromatic skeletal in lignin and C- H deformation in lignin and carbohydrates,respectively,becomes more and more sensitive with the increasing of treatment temperature. This may occur because the cleavage of the β-O-4 linkages and splitting of the methoxy groups of the lignin structure makes lignin unstable to the thermal perturbation. The intensity of the auto-peak at around 1651 cm-1,assigned to conjugated C-O in quinines coupled with C=O stretching of various groups,is always the strongest in the reference and SHT wood,indicating that this functional group is very sensitive to the thermal perturbation no matter whether the wood has been steam-heat treated or not.

The 2D-IR spectra show that the steam-heat treatment improves the sensitivity of wood to the thermal perturbation in the range of 800-1300 cm-1 in the spectra. The SHT wood under 180°C is the most sensitive,then the sensitivity decreases with the increasing treatment temperature. 4. Conclusion

The FT-IR spectra,correlation coefficients and 2D-IR spectra analysis of SHT teak wood under different treatment temperatures for 2 hours indicates that the chemical modifications induced by condensation,degradation and some other reactions happened to the main components of wood.

The FT-IR and SD-IR spectra proved the degradation of acetyl groups from hemicelluloses and the releasing of acetic acid through a deacetylation reaction during steam-heat treatment. The released acetic acid acted as a catalyst for condensation and degradation reactions of the lignin structure and depolymerisation reactions of carbohydrates and other degradation reactions of the wood components. With the increasing of treatment temperature, the cleavage of the β-O-4 linkages and the splitting of the aliphatic methoxyl chains from the aromatic ring in lignin are observed. Some condensed structures in lignin and aliphatic alcohols are formed during steam-heat treatment.

The correlation coefficients evaluated the changes of SHT wood quantitatively,and shows the changes become more and more intense with increasing treatment temperature. Larger changes take place at the treatment temperature of 200°C.

The 2D-IR spectra revealed the sensitivity of untreated and SHT wood to the thermal perturbation and show that the sensitivity of SHT wood initially increased with the increasing treatment temperature and then decreased. The SHT wood under 180°C was the most sensitive. The increasing intensity of auto-peaks at 1493 cm-1 and 1465 cm-1 suggested the structural degradation of lignin during steam-heat treatment.

Acknowledgments

This work was sponsored by the National Natural Science Foundation of China (No. 31270591),and Province-Academy Cooperation Project of Zhe Jiang Province and Chinese Academy of Forestry (No. 2013SY01)

| [1] | C.-M. Popescu, M.-C. Popescu, A near infrared spectroscopic study of the structural modifications of lime (Tilia cordata Mill.) wood during hydro-thermal treatment, Spectrochim. Acta A: Mol. Biomol. Spectrosc. 115 (2013) 227-233. |

| [2] | P. Navi, D. Sandberg, Thermo-hydro-mechanical Wood Processing, CRC Press, Boca Raton, 2012. |

| [3] | B.M. Esteves, H.M. Pereira, Wood modification by heat treatment: a review, Bioresources 4 (2009) 370-404. |

| [4] | B. Esteves, J. Graca, H. Pereira, Extractive composition and summative chemical analysis of thermally treated eucalypt wood, Holzforschung 62 (2008) 344-351. |

| [5] | Y.J. Cao, J.X. Lu, R.F. Huang, X. Zhao, J.L. Jiang, Effect of steam-heat treatment on mechanical properties of Chinese fir, Bioresources 7 (2012) 1123-1133. |

| [6] | B. Esteves, R. Videira, H. Pereira, Chemistry and ecotoxicity of heat-treated pine wood extractives, Wood Sci. Technol. 45 (2011) 661-676. |

| [7] | M.-C. Popescu, J. Froidevaux, P. Navi, C.-M. Popescu, Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy, J. Mol. Struct. 1033 (2013) 176-186. |

| [8] | S.Q. Sun, Q. Zhou, J.B. Chen, Infrared Spectroscopy for Complex Mixtures-Applications in Food and Traditional Chinese Medicine, Chemical Industry Press, Beijing, 2011. |

| [9] | Z. Yang, H. Lin, T. Gui, R.F. Zhou, X.S. Chen, Infrared spectroscopy of N-methylacetamide in water from high-level QM/MM calculations, Chin. Chem. Lett. 25 (2014) 107-110. |

| [10] | X.Q. Lin, Z.X. Zhang, W.Q. Hu, Concave cell design for FTIR measurements, Chin. Chem. Lett. 22 (2011) 1339-1342. |

| [11] | C.-M. Popescu, B.C. Simionescu, Structural study of photodegraded acrylic-coated lime wood using Fourier transform infrared and two-dimensional infrared correlation spectroscopy, Appl. Spectrosc. 67 (2013) 606-613. |

| [12] | C.-M. Popescu, M.-C. Popescu, C. Vasile, Structural changes in biodegraded lime wood, Carbohydr. Polym. 79 (2010) 362-372. |

| [13] | H.L. Liu, J. Shang, X.Q. Chen, F.A. Kamke, K.Q. Guo, The influence of thermal-hydromechanical processing on chemical characterization of Tsuga heterophylla, Wood Sci. Technol. 48 (2014) 373-392. |

| [14] | I. Noda, Two-dimensional infrared (2-D IR) spectroscopy of synthetic and biopolymers, Bull. Am. Phys. Soc. 31 (1986) 520. |

| [15] | Q. Zhou, J.B. Chen, S.Q. Sun, What can two-dimensional correlation infrared spectroscopy (2D-IR) tell us about the composition, origin and authenticity of herbal medicines, Biomed. Spectrosc. Imaging 2 (2013) 101-113. |

| [16] | A.M. Huang, Q. Zhou, J.L. Liu, B.H. Fei, S.Q. Sun, Distinction of three wood species by Fourier transform infrared spectroscopy and two-dimensional correlation IR spectroscopy, J. Mol. Struct. 833-834 (2008) 160-166. |

| [17] | C.-M. Popescu, M.-C. Popescu, C. Vasile, Structural analysis of photodegraded lime wood by means of FT-IR and 2D IR correlation spectroscopy, Int. J. Biol. Macromol. 48 (2011) 667-675. |

| [18] | C.-M. Popescu, M.-C. Popescu, C. Vasile, Characterization of fungal degraded lime wood by FT-IR and 2D IR correlation spectroscopy, Microchem. J. 95 (2010) 377-387. |

| [19] | T. Kondo, Polysaccharides II—structural diversity and functional versatility, in: S. Dumitriu (Ed.), Hydrogen Bonds in Cellulose and Cellulose Derivatives, Marcel Dekker, New York, 2005 (Chapter 3). |

| [20] | S. Kubo, J.F. Kadla, Hydrogen bonding in lignin: a Fourier transform infrared model compound study, Biomacromolecules 6 (2005) 2815-2821. |

| [21] | E. Windeisen, G. Wegener, Behaviour of lignin during thermal treatments of wood, Ind. Crop Prod. 27 (2008) 157-162. |

| [22] | Y. Chen, Y. Fan, J. Gao, N.M. Stark, The effect of heat treatment on the chemical and color change of black locust (Robinia pseudoacacia) wood flour, Bioresources 7 (2012) 1157-1170. |

| [23] | O. Faix, Fourier Transform Infrared Spectroscopy, Methods in Lignin Chemistry, Springer, Berlin/Heidelberg, 1992, pp. 83-109. |

| [24] | O. Faix, J.H. Bö ttcher, The influence of particle size and concentration in transmission and diffuse reflectance spectroscopy of wood, Eur. J. Wood Wood Prod. 50 (1992) 221-226. |

| [25] | M.M. Gonzá lez-Penã, M.D.C. Hale, Rapid assessment of physical properties and chemical composition of thermally modified wood by mid-infrared spectroscopy, Wood Sci. Technol. 45 (2011) 83-102. |