Electrode materials are usually considered to play the most important role in the performance of capacitors. Among various electrode materials,carbonaceous materials are the most widely used ones,based on which more than 80% of the commercially available capacitors are fabricated [1, 2, 3]. Due to their relatively low cost,versatile existing forms,large surface area,good electric conductivity,and excellent chemical stability in different solutions (from strongly acidic to basic),carbon electrode materials are still considered as the most promising materials for future capacitors. Generally,the highly developed surface area,suitable pore size distribution and surface properties are necessary for carbon electrodes to achieve high specific capacitance [4, 5, 6, 7]. Hence, tailoring porous microstructure and surface chemistry of porous carbons is crucial for the optimization of electrode materials of capacitors.

To date,activated carbons produced by different activation processes from various precursors (e.g.,wood,coal,nutshell) are the most common electrode materials [8, 9]. However,the surface areas of most activated carbons are not sufficiently high and their pore size distributions are overly broad,which are not beneficial for the higher capacitance. Therefore,the methodology used for the preparation of activated carbon can be successfully applied to further control the microstructure and donate suitable pore size distribution to the frameworks of the carbons. In addition,oxygencontaining functional groups can also improve the wettability between electrode materials and electrolytes,depending on their hydrophilic nature [10]. For example,Raymundo-Pinero reported that oxygen-rich carbon material prepared through carbonization of a seaweed biopolymer exhibited good electrochemical performances [11]. Considering that the surface of carbon affords electrode/electrolyte interface for charge accommodation,high surface area oxygen-containing porous carbons should exhibit outstanding electrochemical performances for capacitors. However,to the best of our knowledge there is relatively little literature reported using the commercial activated carbon as the carbon source.

In this paper,high surface area oxygen-containing porous carbons were prepared by further KOH activation of activated carbon. The physical properties such as Brunauere-Emmette- Teller (BET) surface area,pore size distribution,total pore volume and microstructure,were analyzed as a function of the KOH/AC ratio in detail. The electrochemical characteristics of the prepared samples for electrode materials were also investigated in KOH electrolyte. 2. Experimental

Activated carbon (AC) was obtained from Aladdin (Shanghai, China). The mixtures of AC and KOH were placed into a tube furnace and heated to 750°C with a heating rate of 1.25°C/min and kept 750°C for 1 h under N2flow. After cooling down to room temperature under N2,the solid was washed with 3 mol/L HCl aqueous solution and deionized water,and then dried at 120°C overnight. The obtained samples were denoted as ACKx,in whichx denote KOH/AC mass ratios.

The products were characterized by X-ray diffraction (XRD,

Bruker D8,Cu Ka, = 0.1541874 nm),and Fourier transform

infrared spectroscopy (FTIR,EQUINOX 55). Nitrogen adsorption-

desorption was measured with a Micromeritics ASAP2020 HD88

instrument. Electrochemical performance measurements were

conducted on a CHI660B electrochemical workstation. The

measurements were carried out in a standard three-electrode cell

system. The working electrodes were prepared by pressing the

mixture of as-prepared active materials,carbon black and 5% PTFE

(85:10:5 wt%) into a foam nickel electrode,and a nickel foil

electrode as a counter electrode and an Hg/HgO as a reference

electrode.

3. Results and discussion

= 0.1541874 nm),and Fourier transform

infrared spectroscopy (FTIR,EQUINOX 55). Nitrogen adsorption-

desorption was measured with a Micromeritics ASAP2020 HD88

instrument. Electrochemical performance measurements were

conducted on a CHI660B electrochemical workstation. The

measurements were carried out in a standard three-electrode cell

system. The working electrodes were prepared by pressing the

mixture of as-prepared active materials,carbon black and 5% PTFE

(85:10:5 wt%) into a foam nickel electrode,and a nickel foil

electrode as a counter electrode and an Hg/HgO as a reference

electrode.

3. Results and discussion

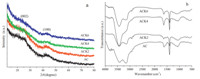

Fig. 1a shows the typical XRD patterns of the AC and ACKx samples. The XRD patterns for samples display two broad small diffraction peaks around 24° and 44°,corresponding to the (0 0 2) and (1 0 0) diffractions for carbon. Compared with the AC,the ACKxpatterns showed peaks with gradually decreased intensity, indicating that the aligned structural domains in the carbon matrix have been destroyed in the chemical etching process. Fig. 1b shows the FTIR spectra of AC and ACKx. The characteristic peaks are observed around 3400 and 1400,2900,1600,and 1000 cm-1 , which are assigned to υO-H vibrations,υC-H vibrations,yC5O vibrations andyC-Ovibrations,respectively. However,the spectra of samples give similar transmittance peaks,suggesting that they could possess similar groups on their surface. In other words,the ACKxsamples have rich oxygen-containing surface groups. The detailed characterization of scanning electron micrographs (SEM) and high-resolution transmission electron microscopy (HRTEM) were provided in the Supporting information.

|

Download:

|

| Fig. 1. XRD patterns (a) and FTIR spectra (b) of AC and ACKx. | |

Considering the surface area and pore size of carbon materials are generally believed to be critical factors for electrochemical capacitor applications,nitrogen adsorption-desorption isotherms and corresponding pore size distribution curves of AC and ACKx were studied and the results are shown in Fig. 2. The detailed BET and pore volume distribution of all the samples are listed in Table 1. It can be seen that both the BET and pore volume increase markedly with increased mixture ratios,reaching a maximum for the alkali/carbon ratio of 6. Further increase of alkali/carbon ratio reduces the micropore surface area,which may be due to the collapse of micropore that was caused by over-activation. As shown in Fig. 2a,the nitrogen adsorption-desorption isotherms are mixed type-I and -IV for all the samples,indicating the existence of many micro- and meso-porous in the samples. As a typical example of our products,the cumulative pore volume and distribution of pore volume in ACK6 are shown in Fig. 2b,which exhibited a huge pore volume of 2.01 cm3/g and above half of pore volume is contributed by the mesopores. The high BET and mesoporous property of our products make them good candidates for electrode materials for supercapacitors,especially for supercapacitors based on organic electrolytes and liquid ions that can supply high operating voltage (high energy density) but have large ion size and high viscosity [12].

|

Download:

|

| Fig. 2. (a) N2 adsorption/desorption analysis of the samples (b) cumulative pore volume and (inset) distribution of pore volume for N2. | |

| Table 1 The textural characters of AC and ACKx. |

Fig. 3a exhibits the cyclic voltammetry (CV) curves of the asprepared sample electrodes at a scan rate of 10 mV/s in 6.0 mol/L KOH. It can be observed that ACK6 electrode displays a box-like shape superimposed with one pair of broad Faradaic peaks, evidently indicating the coexistence of an electric double-layer capacitance and pseudocapacitance. The results resemble those recently reported for the activation of AC-based electrodes and may be correlated to the presence of surface oxygen-containing functionalities in ACKxas confirmed by the above FTIR data. The constant current charge-discharge at 1 A/g (Fig. 3b) is also similar. As the scan rate increases,CV curves for ACK6 electrode become slightly tilted but still maintain a rectangular-like shape even at 100 mV/s,as shown in Fig. 3c. The specific capacitance of ACK6 can still remain as typical triangle-shaped curves even at a high loading current density of 2 A/g (Fig. 3d),which reveals that the ACK6 as electrode materials is suitable for high power application in supercapacitors. The specific capacitances for all electrodes at different current densities are plotted in Fig. 3e. The maximum capacitance is always observed in the case of ACK6 at the same current density. Typically,specific capacitance of 335,314,and 291 F/g have been achieved for the ACK6 electrode at current density of 0.5 A/g,1 A/g,and 2 A/g,respectively. Furthermore, upon increasing the current density by 2 A/g,the specific capacitances of ACK6 slightly decrease to about 290 F/g (above 85% of the initial value at 0.5 A/g),highlighting the excellent rate capability of ACK6. A long cycle life for ACK6 was measured by conducting over 5000-cycle testing at a scan rate of 20 mV/s as shown in Fig. 3f. The specific capacitance for ACK6 was found to be 199 F/g in the first cycle and 168 F/g after 5000 cycles with a coloumbic efficiency of 85%,which shows that the ACK6 sample has high stability and reversibility that will be beneficial for their practical applications. The detailed characterization of electrochemical impedance spectroscopy (EIS) was provided in Supporting information.

|

Download:

|

| Fig. 3. (a) CVs at a scan rate of 10 mV/s, (b) charge–discharge curves at a current density of 1 A/g, (c) CVs at different scan rates (d) charge–discharge curves at different current densities, (e) specific capacitance versus different current densities, (f) CVs of ACK6 at a scan rate of 20 mV/s for the 1st and 5000th cycles | |

In summary,using the commercial activated carbon,high performance supercapacitor electrode materials with high BET and mainly mesoscale pores through a simple and low-cost chemical activation method were developed. The experimental results demonstrate that the methodology not only allows the efficient recovery of the electrically conductive channels within the activated carbon,but also guarantees the preservation of pseudocapacitive functional groups while endowing the material with a large specific surface area. The ACK6 shows the largest specific capacitance of 335 F/g at the current density of 0.5 A/g and 85% coloumbic efficiency for 5000 cycles at 20 mV/s. These qualities,in addition to the advantages of cheap carbon sources, simple preparation method and facile processing render these materials promising alternatives for high performance supercapacitors in practical applications. Acknowledgments

This work was supported by the National Science Foundation of China (Nos. 21371061,21031001),the Science and Technology Plan Projects of Guangdong Province (No. 2011A081301018) and the Key Academic Program of the 3rd phase "211 Project" of South China Agricultural University. Appendix A. Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://dx.doi.org/10.1016/j.cclet. 2014.05.004.

| [1] | P. Simon, Y. Gogotsi, Capacitive energy storage in nanostructured carbon-electrolyte systems, Acc. Chem. Res. 46 (2012) 1094-1103. |

| [2] | Y.P. Zhai, Y.Q. Dou, D.Y. Zhao, et al., Carbon materials for chemical capacitive energy storage, Adv. Mater. 23 (2011) 4828-4850. |

| [3] | W. Zhang, Y.H. Yao, L.J. Gao, Performance of PbO2/activated carbon hybrid supercapacitor with carbon foam substrate, Chin. Chem. Lett. 23 (2012) 623-626. |

| [4] | L. Hao, X. Li, L. Zhi, Carbonaceous electrode materials for supercapacitors, Adv. Mater. 25 (2013) 3899-3904. |

| [5] | J.C. Wang, S. Kaskel, KOH activation of carbon-based materials for energy storage, J. Mater. Chem. 22 (2012) 23710-23725. |

| [6] | M.X. Liu, L.H. Gan, W. Xiong, et al., Partially graphitic micro-and mesoporous carbon microspheres for supercapacitors, Chin. Chem. Lett. 24 (2013) 1037-1040. |

| [7] | T. Zhang, M. Zheng, N. Li, et al., Macro-microporous carbon for supercapacitors derived from rape seed shell, Mater. Lett. 105 (2013) 43-46. |

| [8] | M.M. Titirici, M. Antonietti, Chemistry and materials options of sustainable carbon materials made by hydrothermal carbonization, Chem. Soc. Rev. 39 (2010) 103-116. |

| [9] | R.J. White, V. Budarin, R. Luque, J.H. Clark, D.J. Macquarrie, Tuneable porous carbonaceous materials from renewable resources, Chem. Soc. Rev. 38 (2009) 3401-3418. |

| [10] | Z. Lin, Y. Liu, Y. Yao, et al., Superior capacitance of functionalized graphene, J. Phys. Chem. C 115 (2011) 7120-7125. |

| [11] | E. Raymundo-Piñero, F. Leroux, F. Béguin, A high-performance carbon for supercapacitors obtained by carbonization of a seaweed biopolymer, Adv. Mater. 18 (2006) 1877-1882. |

| [12] | Y. Fang, B. Luo, Y. Jia, et al., Renewing functionalized graphene as electrodes for high-performance supercapacitors, Adv. Mater. 24 (2012) 6348-6355. |