A review of the research on bionic flapping-wing unmanned systems

-

摘要: 仿生扑翼无人系统是模仿自然界中蝙蝠、鸟类和昆虫的飞行方式研发的一种新型无人系统,可在高度复杂和动态的环境中飞行,并对环境的干扰具有良好的鲁棒性,是机器人领域未来发展的重要研究方向之一。本文对近年来国内外扑翼无人系统方面的相关研究进行综述,分别从空气动力学、系统识别与建模、感知和控制等几个方面介绍了扑翼无人系统的最新进展,最后提炼出扑翼无人系统的各个方面的挑战,并对该领域未来的发展和研究方向做出了展望。Abstract: The bionic flapping wing unmanned system (FWUS), which can fly in a highly complex and dynamic environment, is a new type of unmanned system developed by imitating the flight mode of bats, birds and insects in nature. It has good robustness to environmental interference. It is one of the important research directions for future development in the field of robotics. This paper reviews related researches on FWUS at home and abroad in recent years, introduces the latest progress of FWUS from the aspects of aerodynamics, system recognition and modeling, perception and control, and finally summarizes the current challenges from various aspects of FWUS, and envisages the future development and research direction in this field.

-

自然界的昆虫和鸟类具备极佳的飞行技能[1]。蜜蜂可以借助高频振动的翅膀和复杂多变的扑翼运动产生前缘涡(leading edge vortex, LEV)和周期性的涡脱落[2-4],强化并合理利用LEV可以在高度动态和杂乱的环境中觅食[5]。蜻蜓敏捷、机动性强,在飞行过程中可以做加速、减速、急跃升、急转弯、俯冲等高难度动作,也是为数不多的能在空中捕获猎物的物种之一[6-7]。蜂鸟是唯一可以悬停飞行的鸟类,它可以通过对机翼攻角、翼尖轨迹模式和羽毛方向的复杂调整,以实现先进的飞行能力。蝙蝠是唯一会飞的哺乳动物,它可以通过肌肉骨骼机制的复杂交互作用来控制其身体姿态以实现敏捷飞行。

动物界展示的飞行壮举启发人们开发了固定翼、旋翼和扑翼3种类型的系统[8]。固定翼系统灵活性差,不能实现悬停飞行[9]。旋翼系统具有较高的灵活性,然而旋翼系统结构复杂[10]、边际稳定性差[11]、效率低[12]、噪声和功耗大[13]。

扑翼系统受益于C-F(clap and fling)机制[14]、旋转环流和延迟失速[15-16]、尾流捕获[17]、LEV和周期性涡脱落[18-19]等非定常空气动力学效应,具有更长的飞行包络线[20]和更高的推进效率[21-22]。不仅如此,扑翼系统还具有隐蔽性强、机动性强、适应性强、噪声低等优点[13],可帮助探索真实昆虫和鸟类敏捷飞行性能背后的机制[23],通过集群等行为在狭小空间执行更为复杂和具有挑战性的任务[24]。因此,扑翼系统将在搜索和救援、军事侦察、航空检测、边境巡逻、环境监测、生物实验等方面发挥重要作用[25-26]。

1. 研究现状

目前,仿生扑翼系统(flapping wing unmanned system, FWUS)主要有仿生蝙蝠系统、仿生鸟系统和仿生昆虫系统。

1.1 国外研究现状

1.1.1 仿生蝙蝠扑翼系统

加州大学洛杉矶分校开发了第一架手掌大小的扑翼系统MicroBat[27-29]。基于简单性和机翼扑动的对称性,MicroBat使用一种轻量化、低摩擦的曲柄推杆机构来将驱动电机的旋转运动转化为机翼的扑动运动[29]。目前MicroBat主要有超级电容驱动、镍铬电池驱动和锂电池驱动无线电控制3种原型(图1)[28-29]。原型1由超级电容供电,使用尾翼稳定器稳定飞行,最长飞行时间为9 s[27-28]。原型2使用镍铬电池供电,最长飞行时间为18~22 s[28]。原型3使用锂电池供电,并覆盖了非常薄的聚酯薄膜以减少阻力,可以通过射频模块实现偏航和俯仰控制,最长飞行时间为42 s[28-29]。

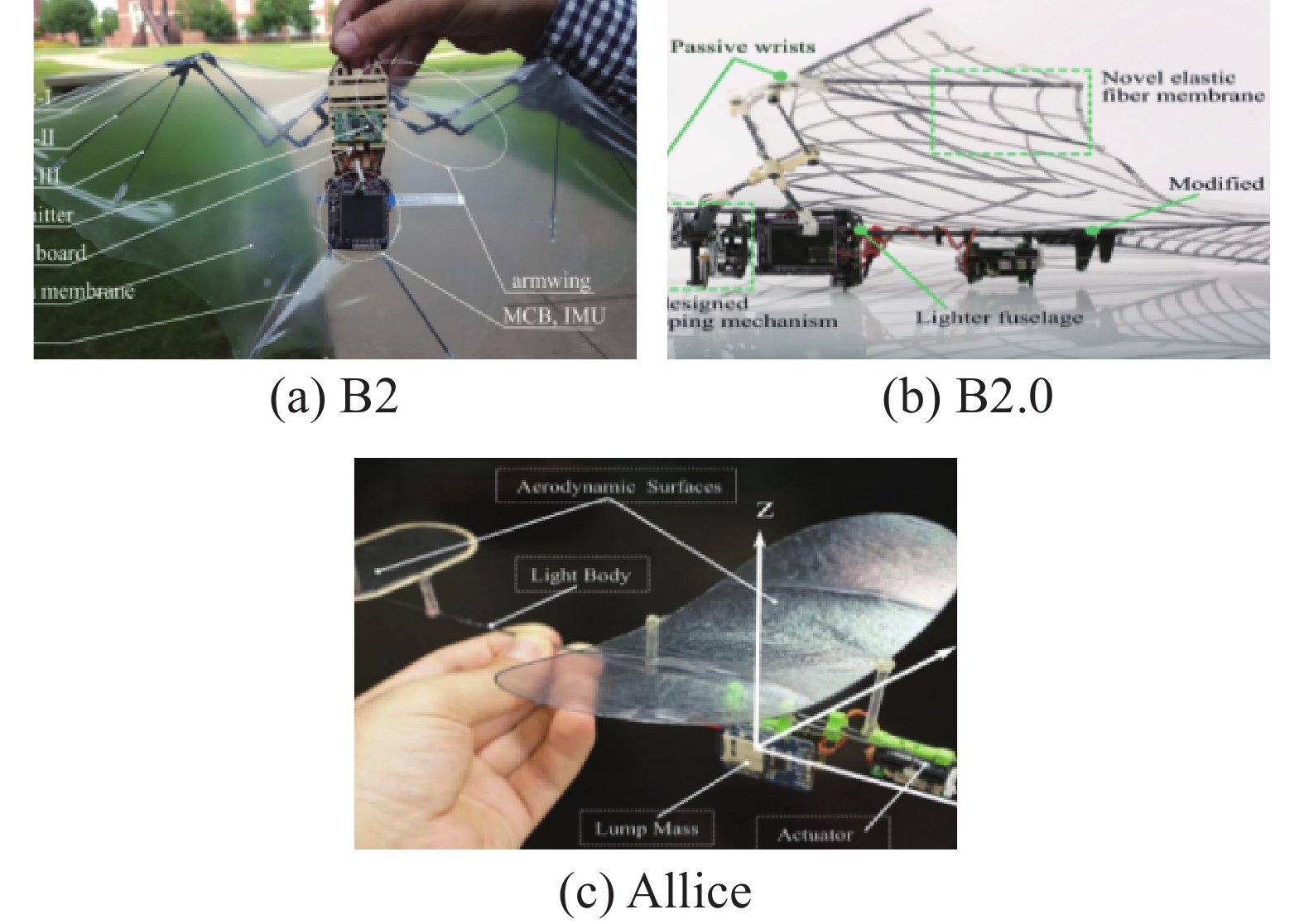

伊利诺伊大学香槟分校开发了Bat Bot(B2)[30](图2 (a))。B2通过机载惯性测量单元(inertial measurement unit,IMU)和霍尔效应编码器以及比例微分(proportional differential, PD)反馈策略来控制5个主要关节的运动,在10 Hz的扑动频率下实现了自主飞行[31]和初步无约束飞行[32]。Hoff在B2的驱动系统和翼膜上进行了改进,设计了B2.0[33] (图2 (b)),进一步模拟了蝙蝠皮肤刚度的各向异性、降低了系统的质量、提高了升力。此外,Syed开发了另一款仿蝙蝠扑翼系统Allice (图2 (c)),并通过非线性闭环反馈调整Allice重心相对于压力中心的位置,重建了埃及果蝠的着陆动作[34]。

1.1.2 仿生鸟扑翼系统

美国航空环境公司从内在不稳定性研究到推进系统评估再到控制系统优化,先后研制出Nano Hummingbird的13个原型以及首款无尾翼扑翼系统Nano Hummingbird[35](图3)。Nano Hummingbird由锂电池供电,由直流电机驱动,通过使用四连杆和弦结构以减轻扑动机构损失和冲程反转时扑动机构对机翼的强烈影响。基于陀螺仪和微控制器,Nano Hummingbird可以实现滚转、俯仰、偏航以及悬停,并可在保持6.7 m/s的飞行速度下抵抗2.5 m/s风扰。

加州大学伯克利分校研发了I-Bird[36-37] (图4 (a))。I-Bird由锂电池供电,由直流电机驱动,通过控制其尾部的磁性驱动器调节偏航。基于外部摄像机和机载微处理器,Beak等实现了对I-bird的高度控制[36]和自主飞行控制[37]。为了探索协同控制,Julian设计了H2Bird[38](图4 (b))。H2Bird机载微处理器、6轴IMU、无线模块和摄像头,可通过控制尾部螺旋桨和伺服升降舵调节偏航和俯仰。在常规飞行中,H2Bird可携带2.8 g的有效载荷飞行10 min;在协同飞行中,H2Bird实现了与轻型地面站的协同制导[39],并实现了与一个六足机器人的协同发射[40]。

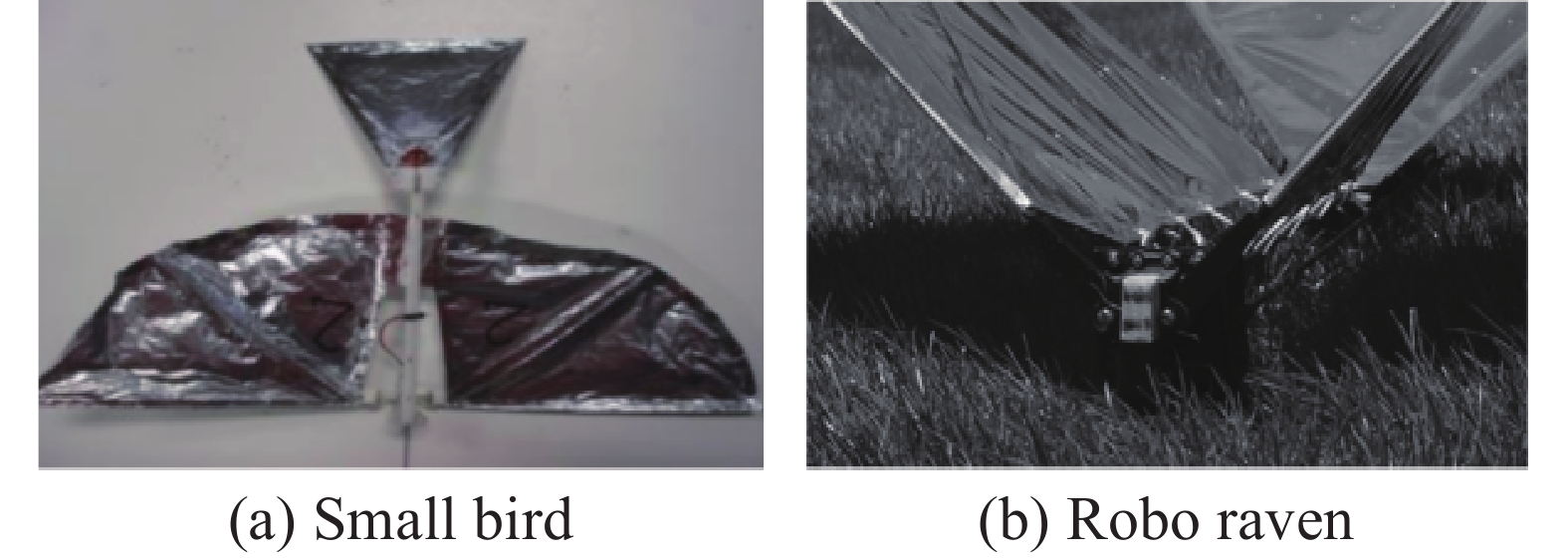

马里兰大学开发了一种具有被动折叠翼的扑翼系统,Small Bird[13,41](图5 (a))。Small Bird的机身由泡沫塑料和碳纤维杆构成,机翼由实心碳棒和聚脂薄膜组成。在5 Hz的扑动频率下,Small Bird可实现3.75 m/s 的飞行速度,并可携带多达12 g的负载飞行8 min[42]。此外,马里兰大学开发了Robo Raven (图5 (b))。Robo Raven由锂电池供电,质量为290.3 g,通过独立控制左右翼执行器和尾翼执行器可实现俯冲、准滚和转弯等机动飞行[43]。

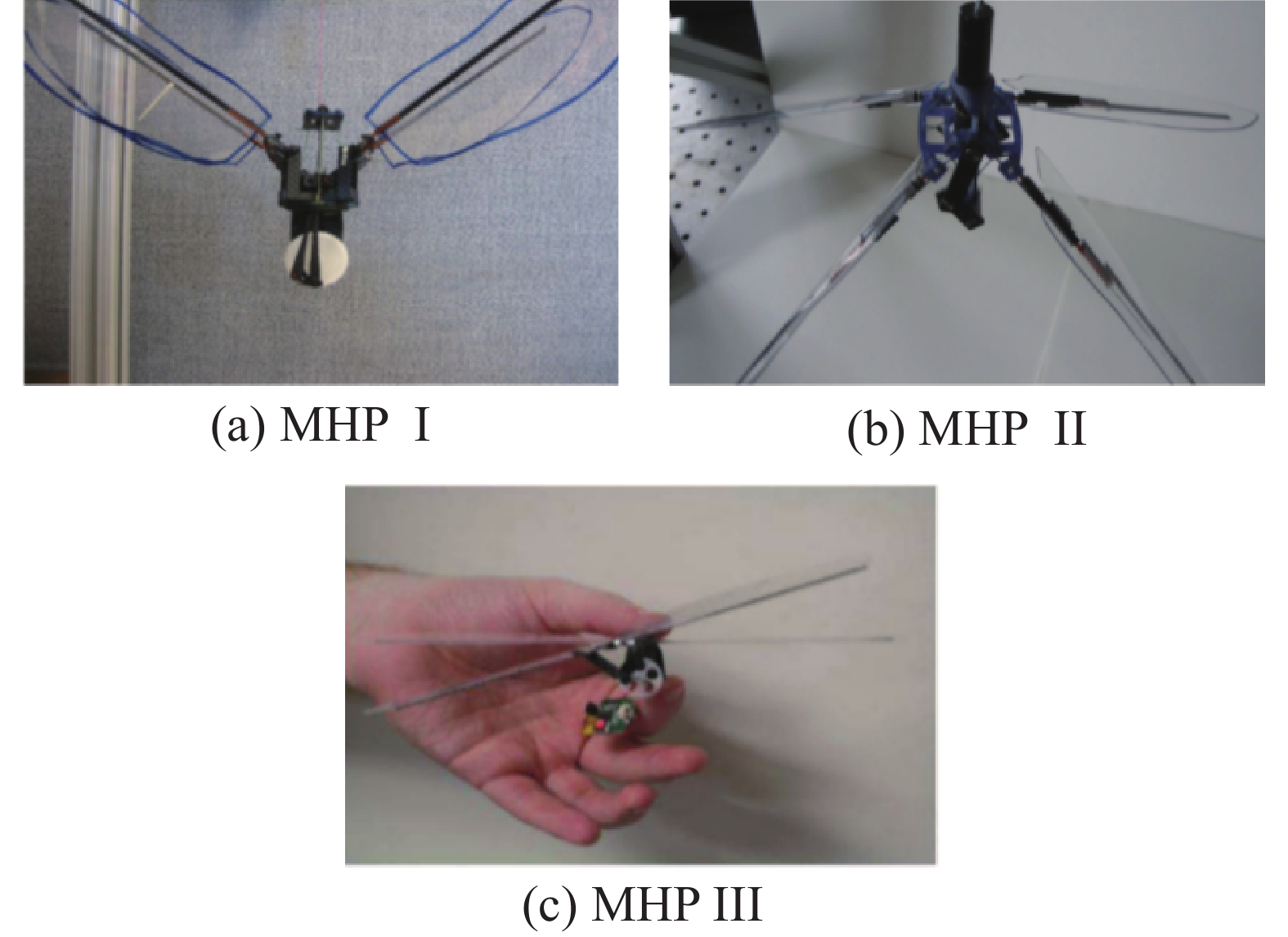

特拉华大学的Dileo等创建了MHP I、MHP II和MHP III 3种具有双轴机翼旋转功能的原型系统(图6)[44-45]。MHP I、MHP II由直流电机驱动,由双曲柄连杆滑块机构传动,通过耦合连杆改变前后翼的相位差来抑制振动,并引入被动旋转机制以产生正升力。此外,MHP I展长为60 cm,质量为40 g;MHP II展长为48 cm,质量为50 g ,翼膜为76 μm厚的聚酯薄膜;MHP III质量约4 g,扑动频率高达10 Hz。

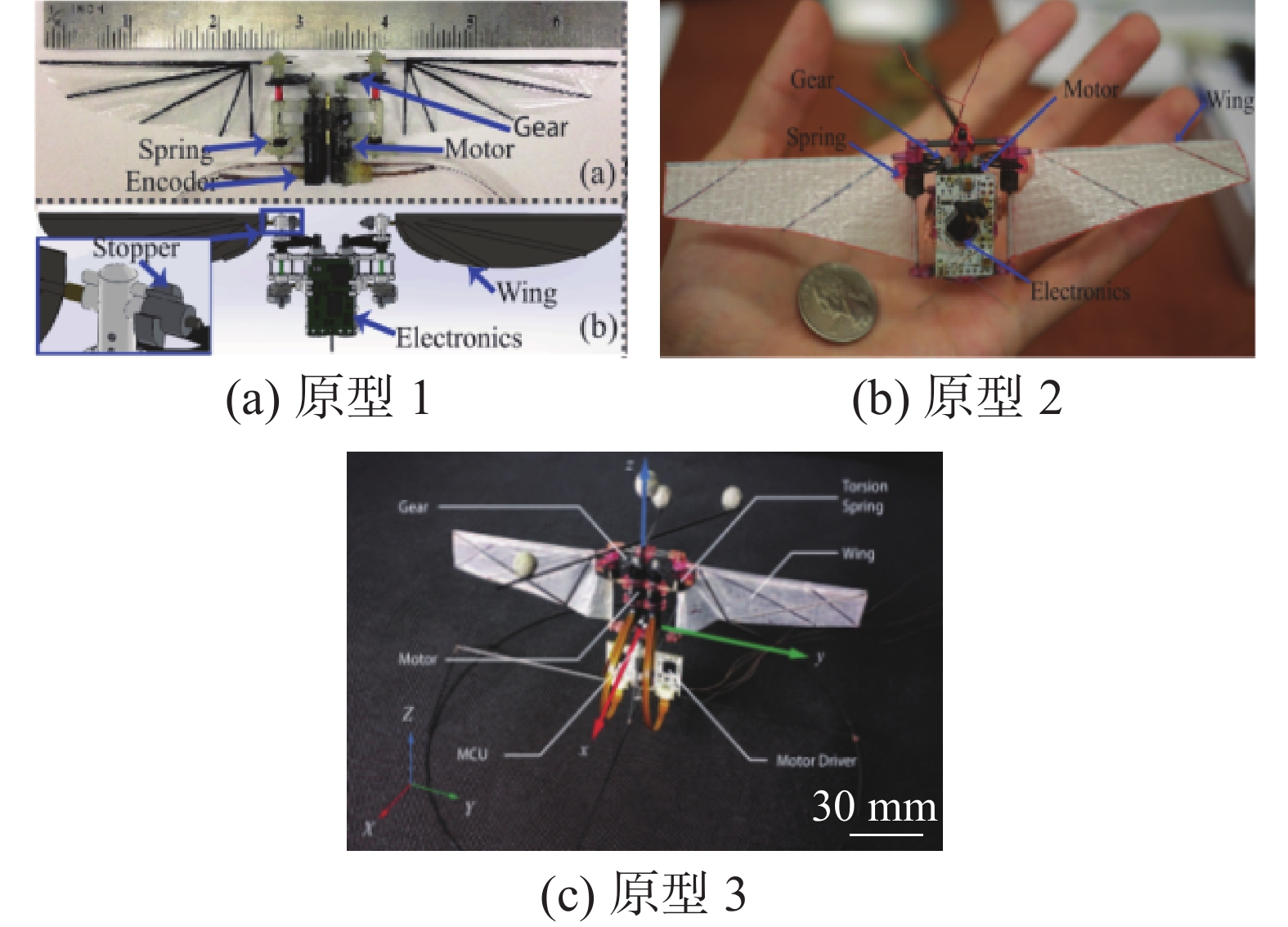

普渡大学的研究人员基于扑动共振[46-47]设计了Purdue Nano Hummingbird (PNH)的3个原型[48] (图7)。3个原型的机翼都由2个无刷直流电机直接驱动,并使用扭转弹簧在共振时恢复动能[49-50]。基于线性二次型调节器(linear quadratic regulator, LQR)控制器、比例积分微分控制器(proportion integration differentiation, PID)自适应鲁棒控制器(adaptive robust controller, ARC),实现了瞬时机翼轨迹跟踪[51];基于非线性几何控制器实现了PNH稳定的升空和悬停[52];基于自适应机载传感器融合算法,实现了对系统精确的机载姿态实时估计[53];基于驱动电机电流的变化感知室内空间地形变化[54-55],在室外环境中实现了无束缚的持续稳定飞行[56];基于非线性控制与无模型强化学习,实现了仿蜂鸟的快速躲避机动[57-58];基于自适应控制器实现了机翼破坏下的[59-60]稳定控制[61]。

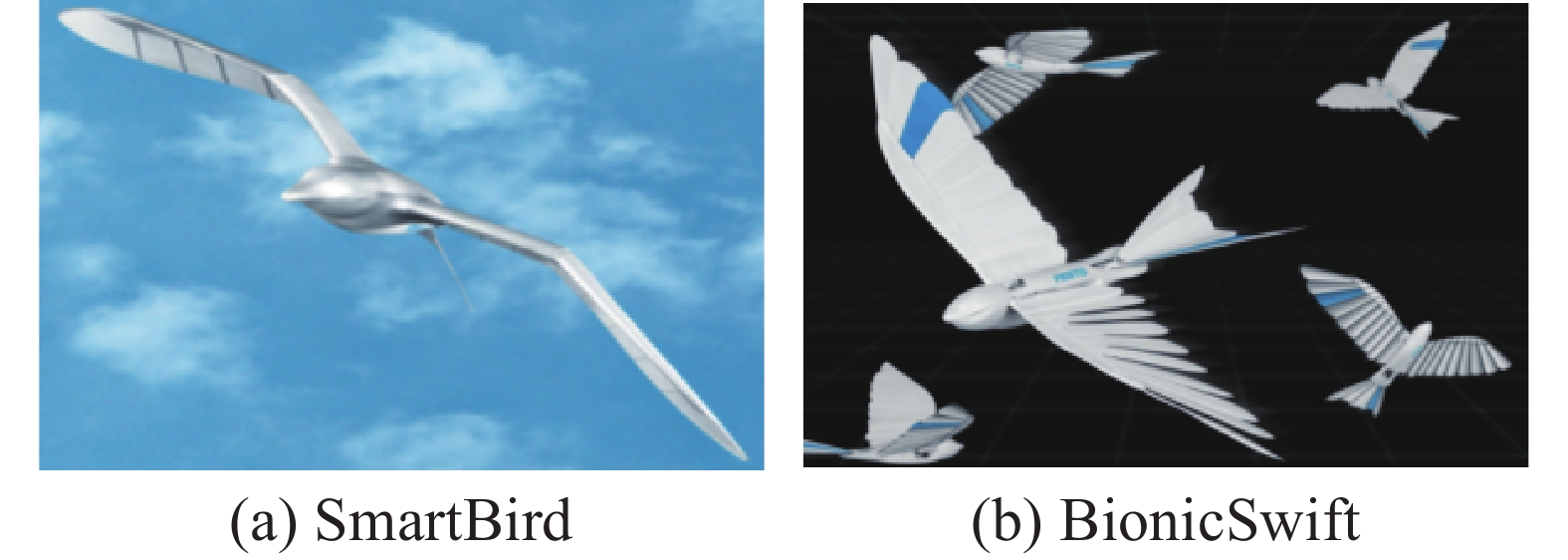

Festo公司以鲱鸥为原型,研制了可以自行起飞和降落的SmartBird[62](图8 (a))。SmartBird的内部设置有2个旋转轮,可以按照特定角度转动来为系统提供升力和推力,并通过尾翼提供紧急上升、滚动和旋转控制。此外,Festo公司以雨燕为原型,研发了BionicSwift[63](图8 (b))。BionicSwift的机翼为羽毛状的泡沫,并可基于超宽带(ultra wide band, UWB)和室内全球定位系统(global position system, GPS),实现协同和自主飞行。

布鲁塞尔自由大学的Roshanbin设计和建造一个蜂鸟大小的双翼扑动系统Colibri[64-65](图9)。Colibri质量为22 g,展长21 cm,扑动频率为22 Hz,可以实现悬停飞行和15~20 s的自由飞行。Colibri通过调制机翼扭转主动稳定俯仰和滚转[64],通过调整左右翼之间产生的差动阻力来产生偏航力矩[65]。

1.1.3 仿生昆虫扑翼系统

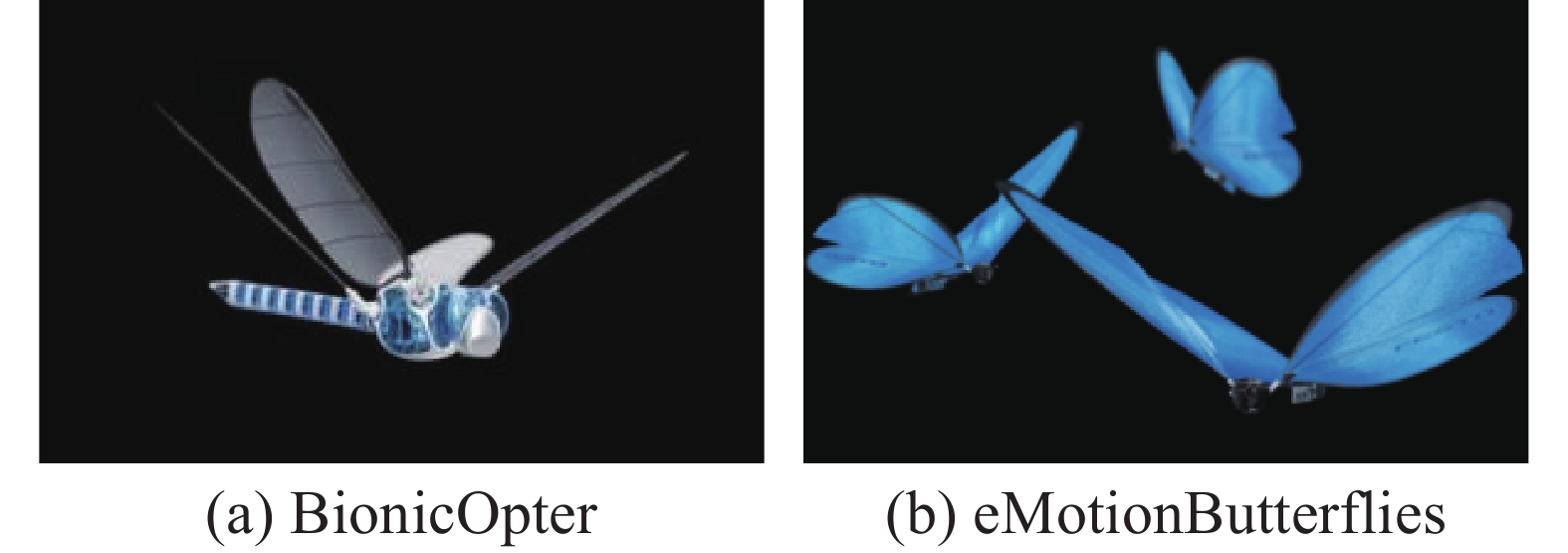

Festo公司开发了一款高度集成的仿生扑翼系统BionicOpter[66] (图10 (a))。它将传感器、制动器、控制器和机械部件集于一身,通过独立控制每个机翼的扑动频率和扭转幅度,实现了系统的机动飞行、定点悬停和滑翔。此外,Festo 开发了eMotionButterflies[67] (图10 (b)),其机翼骨架由薄碳棒弯曲而成,并覆盖着一层弹性电容薄膜。基于机载IMU、红外线技术的室内GPS定位和计算机辅助处理,可实现多扑翼系统的协调飞行。

加州大学伯克利分校设计并制作了MFI[68] (图11)。MFI通过一个二自由度共振胸腔结构[68]——一种具有2个柔性连杆的压电驱动的四连杆机构[69-70],将压电的往复振动转化为复杂的机翼运动。MFI的行程角为140°,最大被动旋转角度为90°,在压电驱动器驱动下,MFI能以高达150 Hz频率进行扑动,产生扑翼系统所需升力。

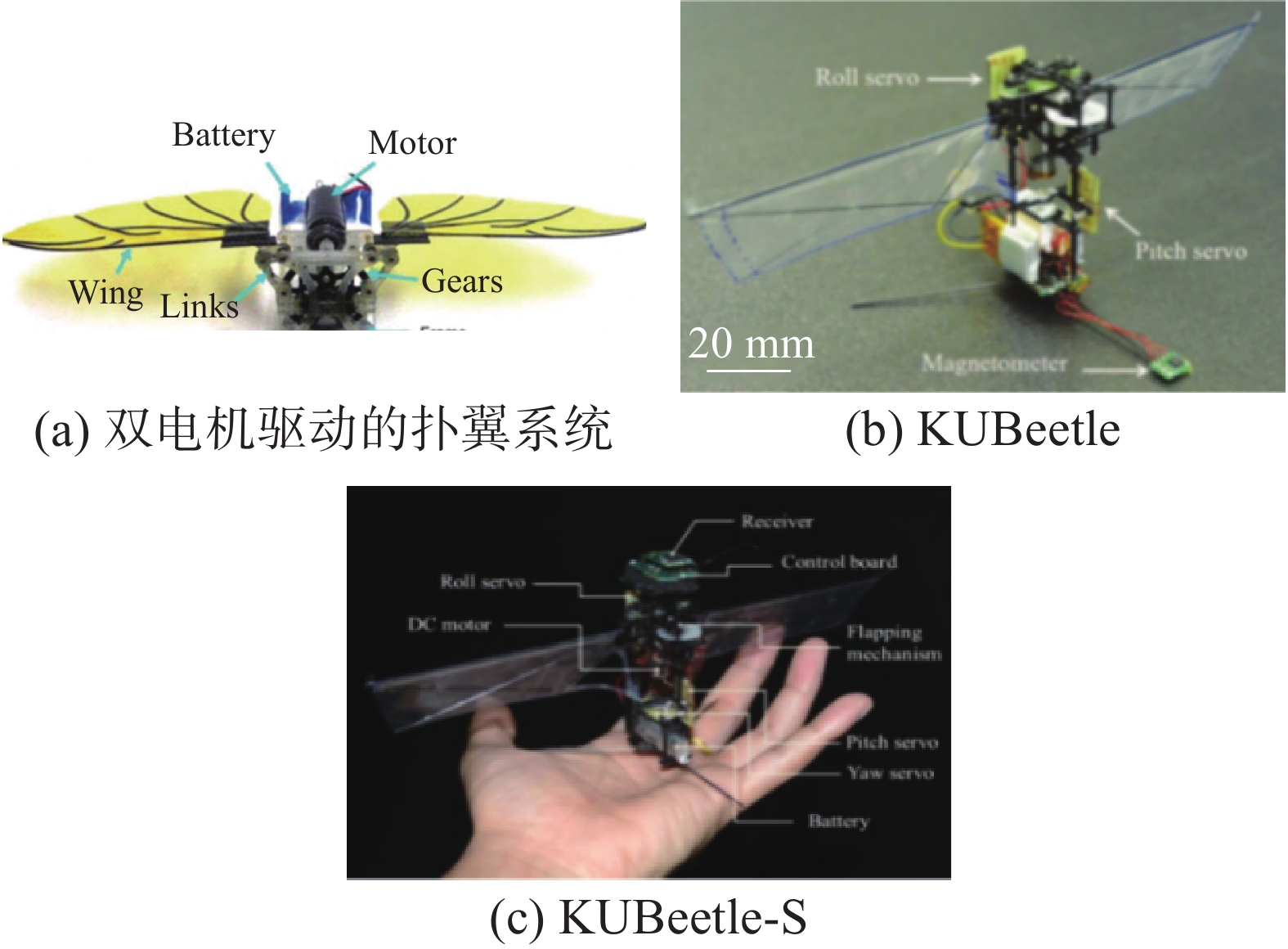

韩国建国大学的Nguyen制作了一个双电机驱动,锂电池供电的扑翼系统[71](图12 (a))。该系统的机翼可绕柔性铰链被动旋转,在扑动频率为25 Hz时,可产生3 g的平均正垂直力。Phan研发了一种仿甲虫扑翼系统KUBeetle[72] (图12 (b))。KUBeetle在扑动频率为23~26 Hz时,可以推动质量为18~22 g的物体,并可以成功执行约40 s的控制飞行[73-74]。Park还研发了一个16.4 g,具有悬停能力的双翼无尾翼扑翼系统KUBeetle-S[75] (图12 (c))。KUBeetle-S通过改变机翼行程平面和机翼扭转产生俯仰和滚转力矩,通过对左右翼根梁进行非对称调节产生偏航力矩,通过增大机翼面积提高升力/功率比[22],可以悬停8.8 min,并可以从悬停快速过渡到前进、后退和侧身飞行,还可以低风条件下实现户外飞行[22]。该系统通过使用被动可折叠机翼,实现了在碰撞后恢复飞行[71],然而增加的机制惯性动力更大[76],降低了动力效率[77]。

南洋理工大学的学者基于柔性胸腔机构制造了一款可以储存机翼反转过程中消耗的动能的Clicking样机[78-79] (图13 (a)),能够以15.8 Hz的扑动频率实现悬停。Campolo利用共振的优势开发了一款电机直接驱动样机[80-81] (图13 (b))。该样机通过改变两翼的平均行程角来产生俯仰力矩,利用螺旋弹簧和轴−弹簧−机翼联轴器恢复力矩。基于之前研究,Hines提出了能够起飞和控制的两翼扑翼系统[82] (图13 (c))。在共振频率(10 Hz)下,引入的弹性元件消除了电机转子和机翼运动的功耗,升重比达到1.4。然而在开环飞行中,该系统表现出俯仰振荡不稳定性,Hines探索了一种四翼扑翼系统减少机体振荡、改善飞行[83] (图13 (d))。

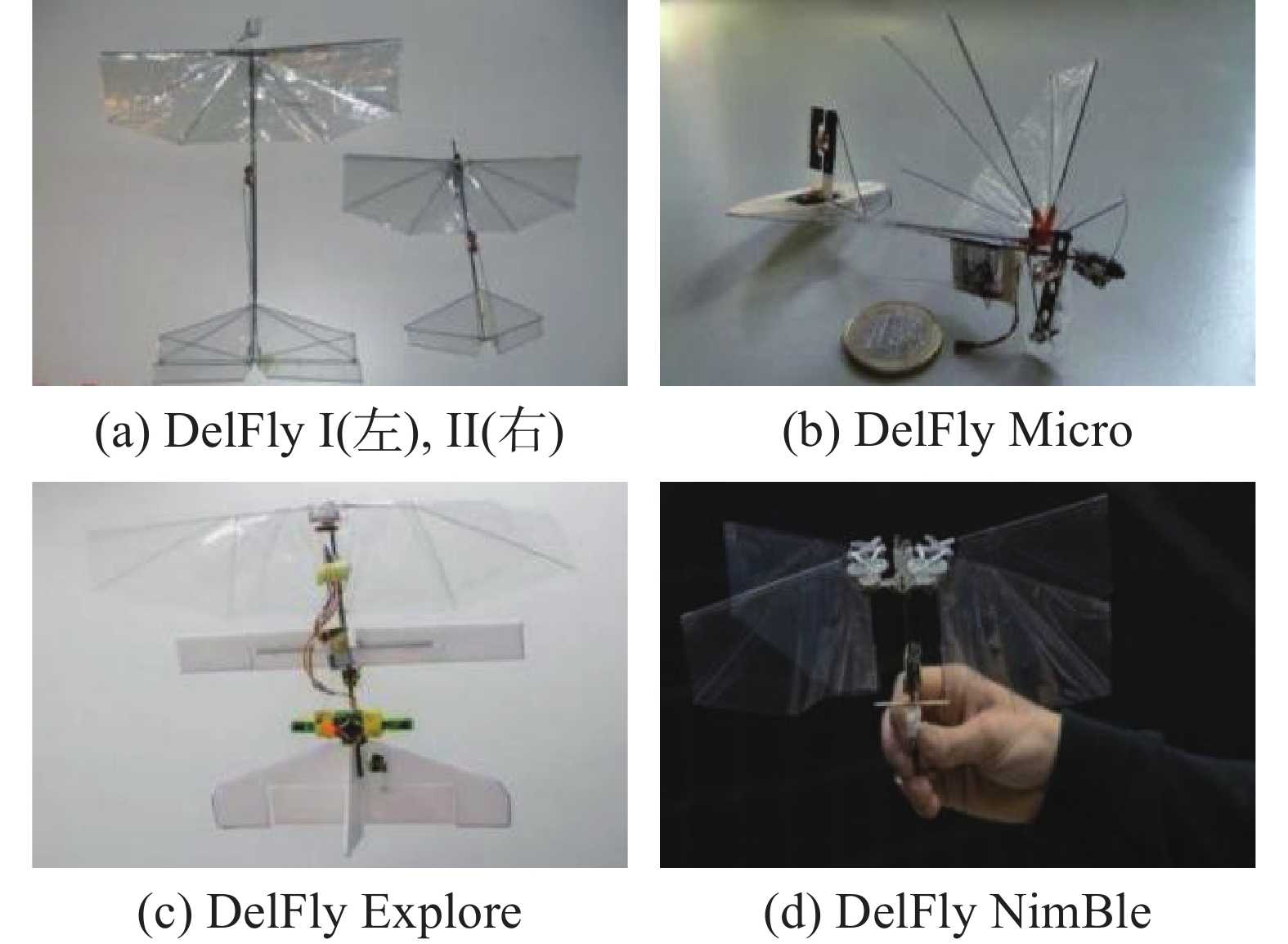

DelFly系列扑翼无人系统是荷兰代尔夫特大学研究的一系列扑翼系统。目前已经成功研制了DelFly I和DelFly II (图14 (a))、DelFly Micro (图14 (b))、DelFly Explore (图14 (c))和DelFly NimBle (图14 (d)) 5种系统[84-88]。DelFly I使用倒V型尾翼提供偏航滚转耦合,能够缓慢飞行。DelFly II在尾翼结构、传动机构上对DelFly I进行了改进,具有更小的尺寸、质量和更大的飞行包络线。DelFly Micro的机翼平面布局从DelFly II按几何比例缩小,扑动幅度从44° (DelFly II)增加到了60°。此外,它可以通过发射器将机载微型相机拍摄的照片传回地面站,在大约30 Hz的扑动频率下,最长飞行时间为3 min。DelFly Explorer是其中第一款可以实现自主飞行的系统,它在DelFly II的基础上增加了副翼、自动驾驶仪和立体视觉系统,结合路径规划控制算法可以实现无碰撞飞行。DelFly NimBle是首款无尾设计扑翼无人系统。与之前的设计不同,DelFly NimBle由独立驱动的机翼控制,非常灵活,可以悬停或飞向任何方向,并且支持远程控制和图像采集。

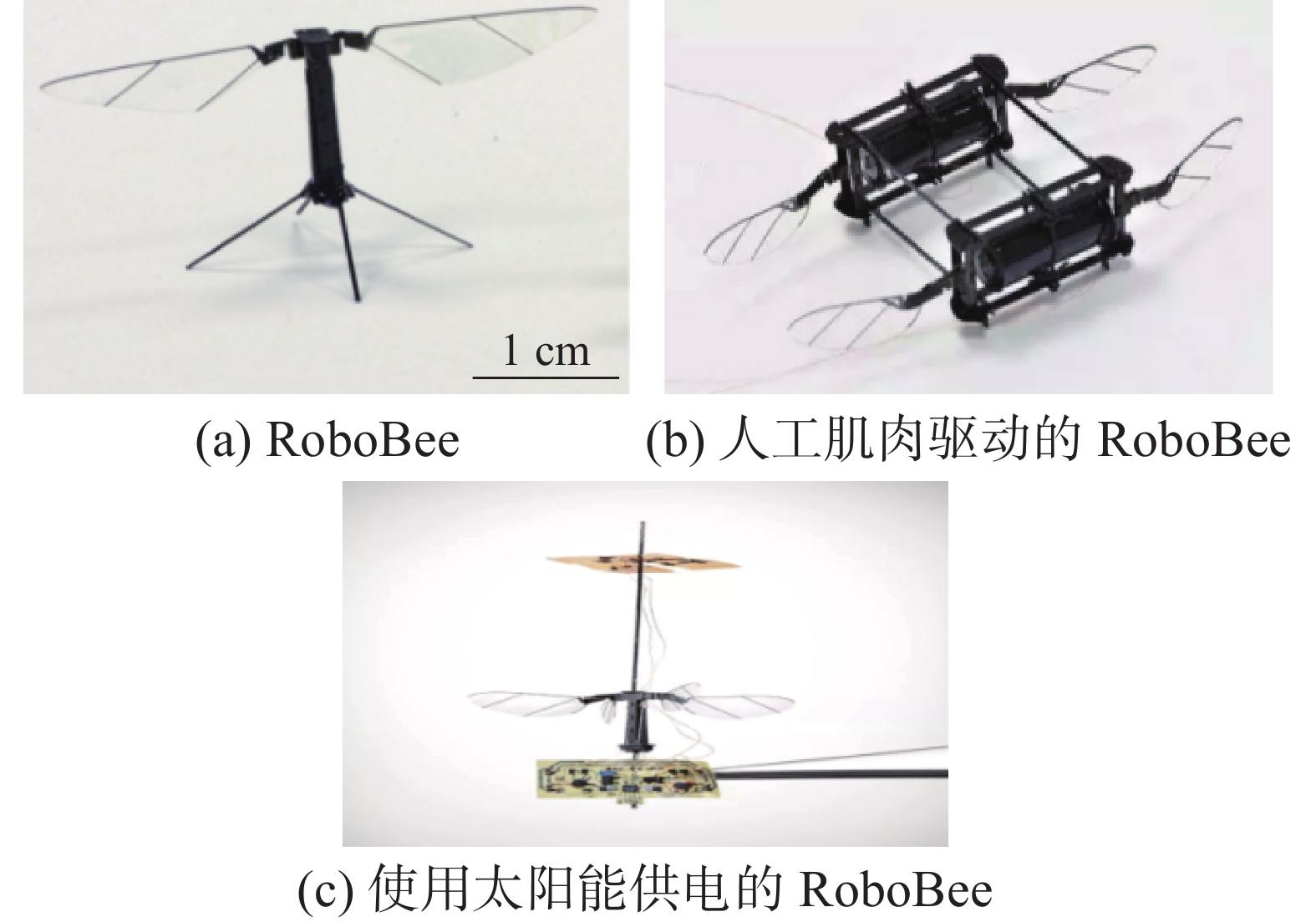

哈佛大学的Wood教授一直在从事RoboBee微型扑翼系统的研制与革新。他们使用智能复合材料微结构(smart composite microstructures, SCM)工艺[89]、在外部动力的驱动下,实现了扑翼系统在昆虫尺度上的第一次非受控垂直起飞[90]。随后,又实现了RoboBee的受控起飞[91],停靠在墙面上[92],空水混合运动[93],无缆自由飞行[94],高度控制[95]和偏航控制[96],并研制由人工肌肉驱动[97-98]和具有被动V型可变后掠机翼的微型扑翼[99]。哈佛大学开发的部分扑翼飞行器如图15所示。

1.2 国内研究现状

南京航空航天大学的昂海松团队致力于仿生扑翼系统的研发,并通过有限元分析、双重Delaunay图映射和非定常涡格法研制了天鹰和差动扑翼系统等多款无人系统[100-103] (图16 (a)、(b))。

西北工业大学的宋笔锋团队致力于“信鸽”扑翼无人系统(图16 (c))的研究[104-105]。“信鸽”的气动外形采用计算流体力学/计算结构力学(Computational Fluid Dynamics/Computational structural dynamics, CFD/CSD)方法设计,以手扔的方式起飞,以滑翔的方式着陆[10,106]。“信鸽”可以按照预先设定的航线自主飞行,也可以改变路线飞行。最近,Wang[107]提出了一个新型无尾扑翼系统NPU-Tinybird (图16 (d)),有望进一步提升扑翼无人系统的制造水平。

北京科技大学的贺威团队开发了一个手抛起飞的仿鸟扑翼系统USTBird[108] (图16 (e))。USTBird翼展为80 cm,空载质量为83.2 g,最大起飞质量为101.2 g,扑动频率约为2~4 Hz。基于2个独立可编程的伺服系统,USTBird实现了三轴解耦姿态控制;基于机载轻型相机、IMU和GPS,USTBird实现了自主起飞和低空巡逻侦察任务。

北京航空航天大学的赵龙飞团队开发了一种X型扑翼系统Beihawk[109-110] (图16 (f))。Beihawk翼展为1.5 m,质量为1.2 kg,扑动频率为0~10 Hz。它通过调节尾翼控制面来产生俯仰和滚转力矩,通过尾部螺旋桨来主动产生偏航力矩。北航的李道春团队设计了一种仿蝙蝠扑翼系统[111] (图16 (g))。该系统由电机驱动,扑动频率为3.5 Hz。该系统内外翼具有不同的行程角,内翼行程角为30°~−30°,外翼行程角为30°~−60°,在平均攻角为4.1°时飞行速度可达6.8 m/s,续航时间为5 min。部分仿生扑翼系统部分参数如表1所示。

表 1 部分仿生扑翼系统部分参数Table 1 Partial parameters of bionic flapping wing system类型 名称 制作单位 质量

/g展长

/cm有无

尾翼扑动频

率/Hz飞行速

度/(m·s−1)续航

时间MicroBat原型1[27-29] UCLA 6.5 有 >30 — 9 s 仿蝙蝠

扑翼

系统MicroBat原型2[27-29] UCLA 10.5 15 有 — — 18 s MicroBat原型3[27-29] UCLA 12.5 22.86 有 — — 42 s B2[30] UIUC 93 40 无 10 — — B2.0[33] UIUC 90 无 — — — 仿蝙蝠扑翼系统[111] 北航 289 168 无 3.5 6.8 5 min 仿鸟扑

翼系统Nano Hummingbird[35]I-Bird[36] 航空环境公司 19 16.5 无 30 6.7 11 min H2Bird[38] UC Berkeley 13 26.5 有 — 1.2 10 min Small Bird[41] 马里兰大学 35 g 57.2 有 5 3.75 8 min PNH原型1[48] 普渡大学 7.5 15 无 30 — — PNH原型3[48] 普渡大学 12.5 17 无 34 — — SmartBird[62] Festo — — 有 — — — BionicSwift[63] Festo 42 68 有 — — 7 min Colibri[64] VUB 22 21 无 22 — 15~20 s 信鸽[104-105] NWPU 245 60 有 10 10 2 min USTBird108] USTB 83.2 80 有 2~4 — — Beihawk[109-110] 北航 1200 150 有 0~10 — — BionicOpter[66] Festo 175 63 无 15~20 — — eMotionButterflies[67] Festo 32 50 无 1~2 1~2.5 3~4 min 续表 1 类型 名称 制作单位 质量

/g展长

/cm有无

尾翼扑动频

率/Hz飞行速

度/(m·s−1)续航

时间仿昆

虫扑

翼系统MFI[68] UC Berkeley 1 0.025 无 150 Hz — — KUBeetle[72-74] 建国大学 7.36 12.5 无 23~43 0.94 40 s KUBeetle-S[75] 建国大学 16.4 — 无 — 1.1~2.5 8.8 min Clicking原型[78] NTU 3.58 24 无 15.8 悬停 — 电机直驱动样机[80-81] NTU 6.8 8 无 40 — — 两翼扑翼系统[82] NTU 2.7 7 无 10 — — DelFly II[85] TUD 16 28 有 — 7 15 min DelFly Micro[86] TUD 3.07 10 有 30 — 6 min DelFly Explorer[87] TUD 20 28 有 — — 12 min DelFly NimBle[88] TUD 29 33 无 17 3 5 min Robobee[90] 哈佛大学 0.259 5 无 170 — — 2. 空气动力学

扑翼无人系统的空气动力学属于低雷诺数(Re)问题,此时存在非定常效应和复杂的流固耦合作用。了解扑翼飞行的空气动力学对指导扑翼无人系统的设计至关重要[112]。目前为止,对扑翼系统空气动力学的研究主要有数值模拟研究和实验研究。在介绍数值研究之前,首先介绍扑翼飞行的非定常气动机理和经常使用的准稳态叶片单元法。

2.1 非定常气动机理

通过对鸟类和昆虫以及相关动态模型进行流场可视化,发现扑翼飞行具有复杂的非定常气动现象[113-115]。扑翼飞行获得高升力的原因主要有延迟失速[15-16,116]、LEV和周期性涡脱落[117-122]、C-F机制[14]、尾流捕获[2,15,17]等效应。

Dickinson等[16]对放大的扑翼模型进行动力学研究,观察到了延迟失速现象,Wang等[116]通过构建和求解二维计算流体动力学模型证实了这一观察结果。

Ellington等[2]利用机械扑动模型在实验中首次可视化了扑动天蛾周围的LEV。Berg[123]、Willmot[124]、Poelma[125]等分别在真实和模型的天蛾翅膀上以及果蝇的动态比例模型证实了LEV的存在。LEV的形成、生长和脱落解释了高升力[126-128]。

C-F机制是鸟类和昆虫冲程反转时发生的翼−翼相互作用[129-130]。Lehmann等[131]对动态缩放的刚性果蝇翅膀进行了瞬时粒子图像测速(particle image velocimetry, PIV)和力测量,表明C-F机制可以提高17%的升力。

由此可见,对于真实鸟类、昆虫乃至扑翼无人系统而言,由于使用了非定常气动机制,大大提高了飞行升力。

2.2 准稳态叶片单元法

准稳态叶片单元法假设在整个扑翼冲程周期中,机翼在每个瞬时位置产生稳态力[14,132]。Weis Fogh首先使用准稳态叶片单元法解释昆虫飞行过程中的力产生机制[14];后续Desbiens[133] 、Clawson[134]等证明了准稳态方法在时间平均意义上对空气动力的精确预测,并被用于RoboBee扑动时产生的瞬时气动力和气动力矩预测[135-140]。由于经典准稳态叶片单元法不能描述附加质量力和阻尼效应,因此目前的研究多添加机翼的质量效应[109,141] 、前缘涡效应[142] 、俯仰力矩效应[143]、旋转环流效应[144] 等修正项描述非定常效应。

2.3 数值模拟

在数值模拟研究中,常使用的方法有任意拉格朗日欧拉法(arbitrary Lagrangian-Eulerian method, ALE)[145]、重叠网格法(overset mesh method, OM)[146]和浸入边界法(immersed boundary method, IBM)[147-149],研究的主要方面有机翼构型、柔性和运动学研究。

2.3.1 机翼构型研究

在机翼构型的数值模拟研究方面,Combes表明昆虫和鸟类的空气动力学性能依赖于翅翼的形态[150-151],不同的翅翼区域具有几乎相同的阻尼特性[152]。对于昆虫来说,其翅膀表面某些部分为三维波纹状,当承受不同的载荷条件时,静脉和波纹的结合使翅膀以各种规定的方式变形[153-154],这种波纹结构和翅膀柔性使得昆虫在低雷诺数下具有良好的气动性能和结构强度[155-158]。此外,机翼展弦比、俯仰偏角、翼型配置对气动性能也有重要影响[159]。

Chunlin[112]、Au[77]和Nguyen[160]等分别采用CFD和一种适用于天河II超级计算机的三维并行浸入边界−格子玻耳兹曼法(lattice Boltzmann method, LBM)研究了机翼形状对扑翼气动性能的影响。研究表明,机翼上的波纹结构有助于减轻质量,降低功耗,提高气动效率,克服行程逆转时的惯性力[77,160],其中钝翼具有最好的推力性能,其推力系数随着展弦比增大先增大后减小,随着俯仰偏角的增大而减小[112]。此外,对于小展弦比和大径向质心位置机翼,增加行程角都会增加平移升力。然而,对于大展弦比和低径向质心位置的机翼,当行程角大于160°时,由于翼尖失速效应的增加,行程角的进一步会增加导致平移升力减小[161]。

Kaya[162-163]、Tuncer[164]、Tay[165]等关注于翼型配置研究。他们的研究表明双扑动翼型或者单扑动加固定尾翼翼型比单扑动翼型产生更高的推力。具体地,Kaya采用OM和Spalart-Allmaras湍流模型,用雷诺平均Navier Stokes (N-S)求解器求解了Re=10000、翼型扑动起伏幅度为0.4、缩减频率为0.08~0.48时的单/双扑动翼型中扑动机翼上的非定常粘性流动。研究发现,在斯特劳哈尔数St范围0.17<St <0.25,双扑动翼型比单扑动翼型产生更大的推力。然而,在更高的 St下,双扑动翼型产生的推力和效率低于单扑动翼型。Tuncer使用Baldwin-Lomax湍流模型和N-S求解器,在Re=3.0×106,来流马赫数Ma=0.3时研究了串联扑动/固定翼型组合的推力增强效应。研究发现,在扑翼型尾流中增加固定翼型显著提高了推力和推进效率,且推力增加效应在相对较高的缩减频率下更为显著。此外,当两翼型对齐时,推力增加最大。Tay在Re=1000时,采用二维层流IBM N-S求解器,研究了单/双翼扑动翼型和尾翼的相对位置对气动性能的影响。研究发现,在单翼扑动翼型上增加尾翼可以提高效率和平均升力系数,分别提高了10%和25%;由于双翼扑动翼型机翼的相互作用形成了强大的动量射流,相对于单一翼型,效率提高了17%,平均推力系数提高了126%。这些研究表明,合理的翼型配置有利于提高扑翼无人系统的功效和气动性能。

2.3.2 机翼柔性研究

在机翼柔性的数值模拟研究方面,Bluman[166]首先使用二维N-S表明柔性机翼通过机翼形状的被动变形产生更多的水平速度和俯仰速度阻尼,实现稳定飞行。

Gopalakrishnan[167]、Nakata[168]、Noyon[169]、Shahzad[170]、Miller[171]、Lehmann [172]等分别通过CFD方法,研究了柔性机翼在悬停飞行中动态变形对其气动性能和功耗的影响。结果表明,机翼变形会引入外倾角[167]并增加尾流的下冲洗,导致了更快的LEV积累,增加了机翼的平均升力和推力[169-170],减小了飞行过程中产生的最大阻力[171],提高了悬停时气动性能[172]。然而,Dong等[173]通过三维数值模拟研究发现,机翼柔性虽然可以提高升力效率,但会导致净升力减小。此外,Vanella等[174]进行了机翼柔性与Re关系的研究。结果表明,Re为75、250和1000时,以升/阻力系数之比为特征的气动性能与相同运动学驱动的刚性翼的相应比别提高了28%、23%和21%。这些研究结果表明,柔性机翼对气动升力的影响似乎取决于其变形是引入阻尼还是通过变形减小阻尼效应。具体的影响需要相关研究人员进行更加全面而具体的研究。

2.3.3 机翼运动学研究

在机翼运动学的数值模拟研究方面,Nakata[168]、Yao[175]、Zheng[176]等对天蛾悬停时的运动学性能进行了数值分析,观察到有一个连续的涡流系统从机翼的前缘、内缘、后缘和翼尖发出,并在行程反转期间向下脱落,在每个翅膀下方形成尾流[175],提高升力的同时减少了功耗[176]。此外机翼的扭转可以减少飞行动力消耗,提高悬停效率[168]。Mariusz等[177]采用格子LBM模拟流场运动,用IBM处理机翼与周围的流动相互作用,使用梯度优化算法来优化平均升力和功耗,得到了扑动运动的优化和帕累托前沿,结果表明,优化扑动运动可以显著降低功耗并提高升力。

Miller[178]、Tay[179-180]等研究了机翼C-F运动对气动性能的影响。Miller采用IBM层流N-S求解器研究了8<Re<128时人工柔性机翼二维C-F运动对气动性能的影响,发现较低Re下升力增强效应大于较高Re下升力增强效应。Tay采用IBM层流N-S求解器和IBM,对Delfly Micro的C-F运动进行了三维数值模拟,捕捉了Re=1000和Re=5000时的基本流动特征。流场分析表明,复杂的涡形成和涡脱落提高了Delfly Micro的气动性能。

此外,Santhanakrishnan等[181]使用三维数值模拟量化了动态缩放旋转椭圆机翼在攻角为0~90°,Re为4~128时周围的流动结构和力,表明无量纲阻力、气动效率和展向流动都随着Re的减少而减少。Xue等[182]的研究表明,机体振动增加了气动阻力,但对升力影响较小,并且可以通过适当的机翼与机身质量比抑制振动的最大加速度。

这些研究结果表明,扑翼系统通过具体地运动学来达成前面所述非定常效应的产生条件,进而影响系统周围的空气动力。

2.4 实验分析

2.4.1 机翼构型研究

在机翼构型的实验研究方面,Lehmann等[183-184]通过实验研究表明机翼周围复杂的空气动力学与Re、机翼运动学和机翼设计高度相关[185-186]。

Rival[187]和 Boon[188]等利用PIV和力测量研究了不同机翼配置和加强筋位置对扑翼空气动力学的影响,研究结果类似于数值模拟相关的研究结果。

此外,Muniappan[189]、Deng[190-191] 、Nian[192]等通过风洞试验究了机翼构型对气动升力的影响。他们的研究结果表明,增加扑动频率将增加推力。此外,通过在根部安装一定厚度的翼型,可以抑制部分气流分离,减少气流分离造成的阻力,从而增加扑翼的净推力和爬升能力[192]。然而随着展弦比增大,推力不变[189]或增大[190],相关方面需要进行更多的研究。

2.4.2 机翼柔性研究

在机翼柔性的实验研究方面,Muniappan[189]、Deng[190]、Percin[193]、Addo[194]、Zhao[195]、Hu[196]、Ryu[197]等通过PIV、力测量、风洞实验等研究了机翼柔性对气动特性的影响。结果表明,与刚性机翼相比,柔性机翼的净力矢量的角度和压力中心都随着机翼的柔性而有系统地变化[195],显著提高了空气动力学性能[190,194,196-197];有利于升力和推力的产生[189,193]。然而柔性翼对升力的影响存在一个临界刚度值,即在临界刚度内,刚度较大的柔性翼在扑动时会产生较大的升力和推力,但同时也会消耗更多的能量[191]。具体的临界刚度取决于机翼构型和机翼运动学,需要更详细的研究。

此外,Zhao[195]和Nguyen[198]的研究表明,机翼柔性对气动性能的影响可能与攻角和飞行速度有关。对于低到中攻角,空气动力随着机翼柔性的增加而下降,但升阻比基本保持不变。另一方面,当飞行速度低于3.0 m/s时,柔性机翼有助于降低功耗并稳定横向动力学,然而在飞行速度为4.0 m/s时,柔性机翼的功耗大于刚性机翼。或许是因为在不同的流场条件下,机翼与空气动力的耦合作用不同,导致机翼发生了或大或小的形变,增加或减小了机体上的气动阻尼,使得升力表现为增加或减小[199-201]。

2.4.3 机翼运动学研究

在机翼运动学的实验研究方面,Deng[190-191]、Lin[202]、Percin[203]、Mazaheri[204]在实验中研究了扑动频率对气动性能的影响,研究表明扑动频率越高,平均升力和平均推力也越高。

Hu[196]研究了推进比和机翼柔性对所产生的气动力的影响。研究发现,当推进比小于1时,扑翼运动获得较高的气动性能,且随着推进比的增加而迅速衰减。

De Clercq[11]、Forouzi[205]通过实验研究了机翼运动方式对气动性能的影响。Clercq利用PIV和力测量研究DelFly II C-F运动阶段周围的流场和产生的气动力。PIV分析和力的测量结果显示,Fling阶段比Clap阶段对升力有显著的贡献。Forouzi设计并构建了黑头鸥扑动机构,研究了机翼弯曲挠度对扑翼系统悬停飞行空气动力学的影响。结果表明,与单纯扑动机构相比,采用弯曲偏转机构改善了系统的气动性能。

从相关实验研究中可以看到,扑翼飞行器的实验分析结果有许多相互不统一的地方,这不仅需要对扑翼飞行的内在机理和流固耦合效应进行研究,而且需要进行更加充分的实验进行对比分析。虽然如此,仍能从相关实验研究中得到一般的结论,可以用来指导扑翼飞行器的设计。比如采用更加仿生化的机翼、合理配置前后翼的间距以及机翼加强筋位置、引入一定程度的展向柔性和弦向柔性。这些措施不仅会提高仿生扑翼飞行器的气动性能,而且会显著提高扑翼飞行器的飞行稳定性。

3. 系统识别和建模

系统识别和建模技术[206-207]大致遵循3种不同的方法:白盒方法、黑盒方法和灰盒方法。

3.1 白盒方法

白盒方法基于理论考虑。首先推导运动学和动力学方程,常用的方法有虚功原理[141-142],固定翼飞机运动方程[208],牛顿−欧拉方程[209],拉格朗日能量法[210-211],凯恩方程[212],气动弹性力学[213-214];多刚体系统飞行动力学[215],扩展哈密顿原理[216-218]等。其次基于动力学方程等建立系统模型,或使用线性建模,或使用非线性建模。

在线性建模方面,Deng[219]、Khan[220]、Kajak[221]利用不同形式的平均来抵消时变的副翼周期效应以简化动力学模型,捕获了DelFly Nimble扑动周期平均纵向动力学并成功预测了质心位置变化对控制系统增益的影响[221]。Chirarattananon[222]、Fearing[223]、Caetano[224]等建立了可以描述扑翼微型系统自由飞行行为的唯象模型,预测并控制了扑翼系统的行为和动力学。Finio等[225]关注于线性二阶模型的设计,预测了Robobee系统在谐波激励下的共振行为。

在非线性建模方面,Khatait[226]、Tantanawat[227]、Madangopal[228]等关注弹性元件的设计和优化,通过弹簧等弹性元件引入非线性,以提高扑翼系统的性能。Biswal[229]和Fuller[230]等基于第一性原理建立了非线性模型,识别和描述了被动旋转扑翼系统的非线性共振行为,并通过系统参数匹配,在系统质量仅增加5%~8%的情况下,使平均升力增加了130%,使有效载荷增加了330%~470%[231],再现了当把RoboBee控制在恒定高度时,它经历的周期性姿态振荡[230]。Taha[232]以状态空间模型的形式建立了二维俯仰俯冲机翼非定常升力动力学的降阶模型,能够捕捉大攻角和高频率下的非线性流体动力学。

3.2 黑盒方法

黑盒方法表示符合实验测量的输入−输出关系,即根据飞行数据或仿真数据建立数据驱动模型[233-235]。比如Armanini[236]和Nijboer [237]等分别提出一个DelFly飞行动力学的黑盒线性状态空间模型,并采用最小二乘法和最大似然估计,对纵向和横向动力学进行模型解耦识别,以可靠精度描述了系统在前进飞行中接近特定静止点时的时间平均纵向和横向飞行动力学。此外,Armanini等[238]又针对扑翼系统的时间平均纵向动力学特性,提出了一种线性参数变化模型识别方法,可以从一组局部线性模型构造全局线性参数变化模型,其模型参数通过系统识别确定。

3.3 灰盒方法

灰盒方法是一种混合方法,其中模型结构采用第一原理和物理定律,参数从飞行实验中获得。

Wang等[107]结合准稳态气动机理和扑动机理,通过神经网络拟合和系统辨识的方法,得到NPU Tinybird线性化的纵向俯仰动态周期平均模型。Caetano采用标准的刚体固定翼飞机模型模拟机体动力,采用线性模型模拟空气动力学,采用自由飞行获取参数[239-240],并通过采用灰盒方法建模,识别了扑翼动力学中的纵向振荡模式和耦合横向振荡模式[241-242]。Armanini等[243]基于多元单形样条辨识方法,从PIV测量中估计扑翼尾迹模型各子模型的参数,结合准稳态气动理论,可以以较高的精度预测扑翼系统尾部在飞行过程中产生的时间分辨气动力。

以上各种建模方法,各有优缺点。白盒方法可以使用任意具有类似逻辑结构的扑翼系统,然而其公式推导、建模复杂,且是一种理想模型,难以与真实实验数据完全匹配。黑盒方法不具有任意性,通常仅适用于特定条件下的特定扑翼系统结构,当系统结构发生改变或者飞行条件发生改变,原有的黑盒模型将不再适用,需重新推导。灰盒方法作为一种综合方法,既考虑了理论,又结合了具体的飞行器,是一种比较良好的建模方法。

4. 感知实现

自然界的鸟类和昆虫具备良好的飞行能力,除了依赖于各种非定常机制,而且依赖于其独特的感知手段。如,果蝇是通过使用来自陀螺平衡杆的机械感觉反馈来稳定飞行[244];天蛾使用大型振动天线来感知旋转[245-246];有些昆虫通过单眼、磁接收[247]和极化[248]或仅依靠本体感觉[249-251]来进行感知。正如昆虫的感知的重要性,扑翼系统的感知实现对扑翼系统也至关重要。下面分别从机载感知实现,外部和联合感知实现介绍扑翼系统在感知方面的进展。

4.1 机载感知实现

扑翼系统的机载视觉感知传感器主要有光流传感器和立体视觉传感器。目前最为广泛的研究是受昆虫启发[252]的光流传感器[253-267]。Duhamel等[256]通过将机载光流传感器指向一个高度纹理的屏幕来感知一个101 mg微型扑翼系统的垂直位置,基于光流调节的振幅调制策略,实现了高度测量和控制垂直飞行。Fuller利用高带宽和低延迟的仿生天线和光流传感器实现了RoboBee的高度控制和俯仰控制[259],并利用来自光流传感器的角速度反馈稳定了系统的摆状动力学,结合仿生天线,可感知风速并能抑制扑翼和振动的干扰[260]。

De Wagter[87]、Clawson[268]、Tijmons[269-270]等针对扑翼系统的立体视觉问题进行了研究。Wagter首次实现在未知环境下带机载视觉处理的扑翼系统的自主飞行,并演示了稀疏避障任务,包括自主起飞和高度控制。Clawson使用4个光电晶体管组成金字塔结构的机载视觉传感器,通过测量来自固定光源的光强度变化来估计俯仰和滚转速率。Tijmons是质量为21 g的DelFly II配备立体视觉,实现了扑翼系统的鲁棒距离测量。

在机载姿态估计方面,主要使用的传感器有陀螺仪、磁力计、加速度计、气压计等。Ramezani使用机载IMU和霍尔效应编码器[30],通过IMU反馈的数据和PD反馈策略来控制关节的运动,实现了B2的自主飞行[31]和初步无约束飞行[32]。Keennon[35]首先通过陀螺仪的反馈感知旋转速率,Fuller等[271]进一步将陀螺仪用于姿态估计和相对短时间跨度的姿态控制。Fei等[51]基于机载IMU和非线性几何控制器实现了PNH稳定的升空和悬停[52],并利用驱动电机电流的变化感知室内空间地形变化[54-55],在室外环境中实现了持续稳定飞行[56]。De Croon[85]、De Wagter[87]、Verboom[272]等为DelFly II配备了机载IMU,辅以6个光流传感器和卡尔曼滤波[258],能够提取出DelFly II完整的六自由度运动和转动速率。Ma等[91]基于机载气压计实现了对系统的高度估计。Huang等[108]基于机载轻型低成本相机、IMU和GPS模块,实现了NTU-Bird的自主起飞和低空巡逻侦察。

4.2 外部感知和联合感知实现

在扑翼系统的外部感知发展进程中,最初主要使用外部激光位置传感器感知扑翼系统的垂直位置[90,273-275],其中使用最广泛的是外部运动捕捉摄像机(Vicon) [36,91,222,239,241,253,276];另外还有基于超宽带[63]和红外线[67]进行感知。

在联合感知方面,Rose等[36]通过外部摄像机和机载微处理器实现了对I-Bird稳定的高度控制。Baek等[37]为一个质量为13 g的扑翼系统配备了一个红外传感器来跟踪特定的红外目标点,并对3轴陀螺仪的反馈进行机载处理,最终可以以85%成功率飞向目标。Wood等[159]使用光流传感器感知障碍物,定位目标并向其移动,同时使用位于系统远处几何位置的2个音频传感器来跟踪音频源。Rosen等[277]同时使用Vicon系统、高速摄像机和陀螺仪捕捉飞行数据,对捕捉的数据进行滤波,成功再现了系统的身体动力学。Wagter等[278]通过3个非机载WiiMote红外追踪机载LED,结合自身陀螺仪姿态的反馈,获取三维位置信息,这些信息然后被发送到一个包含IMU的机载自动驾驶仪中,实现了DelFly II的自由飞行。

5. 控制实现

扑翼无人系统的自主飞行离不开姿态控制及位置控制,扑翼系统的控制研究是扑翼无人系统发展的重点。而扑翼无人系统是非线性非定常的复杂系统,其体型小且多采用柔性结构,易受扰动的影响,传感器和执行机构随着尺寸的减小性能急剧下降,这需要更良好的控制算法来实现系统的稳定。研究人员已经将各种方法应用于扑翼飞行器的控制当中。这部分,首先从姿态调节和稳定性研究介绍了扑翼飞行器的姿态控制相关研究进展、然后介绍了扑翼飞行器避障与导航、编队控制的相关理论研究和实验研究进展。

5.1 姿态控制

扑翼飞行的姿态控制是扑翼无人系统实现自主飞行和更复杂编队飞行的前提,而扑翼飞行的姿态控制离不开俯仰、偏航、滚转姿态的调节和飞行的稳定性。下面首先介绍目前扑翼飞行常用的姿态调节策略(主要是结构),然后介绍常用的稳定性研究方法(主要是算法)。

5.1.1 姿态调节

在俯仰姿态控制方面,有不同产生俯仰力矩的方式:Pornsin[28]、Julian[38]、Jiao[109]、Dawei[111]等通过调整尾翼相对于机体轴线的角度控制俯仰;Wood[90]利用柔性铰链和被动动力学使机翼绕机翼前缘旋转,从而产生俯仰力矩;Keennon[35]、Roshanbin[64]、Phan[75]、Campolo[81]等通过改变机翼行程平面和机翼扭转产生俯仰力矩;Finio[279]、Ma[280]、Oppenheimer和Doman[281-283]、Pérez[284]等通过机翼偏置改变其平均压力中心位置,从而产生俯仰力矩。

在滚转姿态控制控制方面,同样有不同产生滚转力矩的方式:Keennon等[35]通过差动控制左右机翼攻角进行滚转;Roshanbin等[64]通过调制机翼扭转主动稳定滚转;Hines[82]、Ma[280]等通过调制两翼平均升力产生滚转体力矩;Jiao等[109]等通过调节尾翼控制面来产生Beihawk滚转力矩;Dawei等[111]通过扭转控制面以实现滚转和偏航混合控制。

在偏航控制方面:Mueller[13]、Pornsin Sirirak[28]、Beak[36]等通过磁性驱动器或方向舵控制尾翼产生偏航力矩;Keennon等[35]通过滚转和正俯仰组合操纵调节偏航;Julian[38]、Jiao[109]等通过控制尾部螺旋桨产生偏航力矩;Finio[279]、Ma[280]等采用“分裂周期”恒周期频率调制技术,改变了上冲程和下冲程期间机翼上的阻力差异,产生偏航力矩;Fuller等[285]通过一种蠕动转向的欠驱动设计引发俯仰和滚转的耦合来产生偏航力矩;Mcgill等[286]利用机翼冲程形状与控制轴的逆映射来获得对称电压偏移,实现了系统的偏航控制。

5.1.2 稳定性研究

在扑翼飞行的稳定性研究方面,众多学者使用不同的控制策略对扑翼飞行中的振动和扰动问题进行了研究。

Roshanbin[64-65]、Ma[91]、Jiao[109]等使用PD控制器。Roshanbin通过闭环PD控制器和前馈补偿器来减小Colibri的运动耦合,使Colibri保持稳定;Ma基于运动学模型和相应的李雅普诺夫函数,开发了一个PD控制器以控制系统的高度和位置,实现了RoboBee的绳系无约束的稳定悬停和基本的受控飞行动作;Jiao针对北鹰纵向飞行控制问题,设计了具有前馈补偿的PD双环控制器,修正了北鹰的欠驱动特性,减小了悬停过程中的波动,使北鹰能够实现稳定悬停。

Yao[175]、Verboom[272]、Shen[287]、Nogar[288]等使用PID控制器。Yao使用PID控制器用于实现以天蛾为模型的类昆虫扑翼系统的准稳定悬停飞行;Verboom采用PID控制器首次实现了DelFly II姿态高度的鲁棒控制;Shen设计了2个独立的PID控制器,在平衡飞行条件附近,来稳定系统姿态;Nogar使用PID控制器,在消除机翼偏差的情况下,实现闭环稳定性,有效地稳定扑翼微型系统,在模型不确定的情况下提高了鲁棒性。

Wang[107]、Biswal[229]、Abbasi[289]等采用LQR控制器。Wang采用扑翼振动抑制观测器和LQR控制器来稳定无尾扑翼系统,减小了扑动振动对闭环反馈的影响,提高了飞行性能和控制效率;Biswal采用LQR研究了扑翼微型系统悬停时开环不稳定的稳定问题;Abbasi采用基于LQR的仿生闭环飞行控制器,减少高达50%的阵风影响,以实现在阵风中的稳定飞行。

贺威等[218]采用边界控制。采用边界控制方法抑制机翼柔性连杆弯曲和扭转中的振动。他们首先基于哈密顿原理导出了一系列偏微分方程和常微分方程,用于描述系统的控制方程和边界条件,然后通过李雅普诺夫方法,证明了机翼系统的稳定性。

Deng[265]、Shen[287]、Kamankesh[290]等使用基于周期的理论。Deng通过使用平均理论和机翼轨迹的仿生参数化的时不变模型来近似由空气动力引起的时变动力学,实现了悬停模式下的稳定飞行;Shen考虑了机翼惯性和机翼变形的影响,提出了一个新的鸟类尺度扑翼系统的飞行数学模型,通过Floquet理论和无系飞行实验,证明了该系统在无系状态下的纵向和横向稳定性;Kamankesh基于Floquet理论、动能积分和相位肖像技术研究了在非线性周期扑翼结构的稳定性特性,并通过平均理论和线性化技术,利用特征值确定与俯仰角相关的平均攻角范围,以达到动态稳定性。

Au使用刚体近似和固定翼飞机的标准运动方程研究了KUBeetle悬停时重心位置对其纵向动态飞行稳定性[291]和横向动态飞行稳定性[292]的影响。他们使用CFD获得不同重心位置的稳定性导数,采用本征值分析技术研究了系统的动态稳定性[291-292]。Bhatti等[143]提出了一种扑翼微型系统动态稳定性分析和轨迹跟踪控制器的研制方法,采用多体动力学仿真框架,结合改进的准稳态气动模型进行稳定性分析。本征模态分析表明,在纵向动力学方面,存在稳定的快沉陷模态和稳定的慢沉陷模态,纵向动力学的不稳定性随飞行速度的增加而增加。

Liang[106]、Fe[293]等使用自抗扰控制器(active disturbance rejection control, ADRC)。Liang等提出了一种ADRC架构,该控制结构由2个独立的ADRC组成,以稳定“信鸽”在自动着陆过程中的俯仰和滚转姿态。仿真和实验表明,该控制器在“信鸽”过渡模式和滑翔模式下都能获得满意的控制精度和收敛速度。Feng采用ADRC解决了惯性矩不确定性引起的非仿射控制特性,并用李雅普诺夫函数证明了闭环系统的严格稳定性。

Chirarattananon[222,276,294-295]、Pérez[273,275,296]等使用自适应控制器。Chirarattananon在建模不确定性和系统非线性特性下,基于所提出的李雅普诺夫函数设计了自适应控制器[222],以抑制扑翼系统的扰动问题[276,294]。实验结果表明,在60 cm/s[276]和80 cm/s[294]水平风的作用下,显著改善了RoboBee的飞行性能,减小了其均方根位置误差。Pérez等[273,275,296]将高度控制转化为升力控制,并把正弦激励信号作为微型扑翼系统的一个子系统来处理,通过固定其频率和改变输入的振幅来控制输出飞行高度的变化,通过外部激光位置传感器的反馈和自适应前馈控制实现了系统的稳定鲁棒性控制。

Pérez[297]、Wang[298]等使用无模型控制器。Pérez提出了一种完全实验性的和无模型的控制策略,以实现昆虫尺度扑翼系统的稳定自主飞行和悬停。Wang提出了一种基于全形式动态线性化的无模型自适应控制架构来实现被控系统的俯仰控制,该架构通过尾翼的角速度控制俯仰角,并引入抗饱和补偿器以克服由驱动器的局限性造成的控制饱和输入。

Clawson[268]、贺威[216,299]等使用神经网络技术。Clawson提出了一种基于神经形态芯片和生物大脑建模的仿生控制器,该控制器通过带泄漏积分触发(leaky integrate and fire, LIF)脉冲神经网络(spiking neural network, SNN)解决扑翼系统显著的参数变化、未建模动态和非结构化环境不确定性。贺威等研究了分布扰动下扑翼微型系统的迭代学习控制[216],设计了2种迭代学习控制方案来抑制机翼弯曲和扭转时的振动,仿真结果表明了所提出的迭代学习控制律的有效性。此外,He等[299]设计一个具有全状态和输出反馈的神经网络和干扰观测器,通过前馈回路将干扰观测器施加到系统中,以抵消干扰的不利影响。

5.2 避障与导航

在姿态调节和稳定性研究基础上,众多学者在避障与导航方面进行了研究。Wagter[87]、Tijmons[269]等基于立体视觉传感器进行避障。Wagter基于立体视觉和一种高效的立体视觉算法,实现了稀疏避障任务。Tijmons基于立体视觉传感器,实现了DelFly II的室内空间的鲁棒避障和6min以上的自主飞行。

Croon[85,253,300-302]、Zufferey[303]、Ruffier[304]、Franceschini[305]等基于光流进行避障和导航。Croon将图像外观特征作为与光流互补的信息,发送到地面站进行处理,并采用随机采样[306]、高效的计算机视觉算法[300-302],成功实现了室内避障[85,253]、导航[300]、着陆[301]和室外避障[302];Zufferey[303]、Ruffier[304]、Franceschini[305]等将旋转引起的光流通常被看作是一种扰动,并对陀螺仪反馈数据进行滤波,实现了成功的避障和速度控制。

为了考虑补偿未建模的动力学和系统误差以提高着陆精度,Chirarattananon等[92,307]采用了迭代学习控制(ILC)技术,允许RoboBee从以前的特定轨迹的飞行中学习,并通过重复相同的轨迹提高其飞行性能。此外,Chirarattananon提出了自适应跟踪控制器[308],在合理的假设条件下,该控制器使用接近传感器和机载IMU允许系统在SE(3)空间中跟踪轨迹,并具有足够的保真度。

Bhatti等[143]采用增广LQR控制器实现包括悬停、加速和减速3个阶段的过渡飞行跟踪。并采用内速度控制环和外PI位置控制环的双环控制技术进行轨迹跟踪控制。

Wissa等[144]建立了由2个控制回路组成的轨迹跟踪控制律。外环采用积分滑模控制器,产生所需的循环平均气动力和力矩,内环基于李雅普诺夫,提供闭环反馈解决方案,成功实现了轨迹跟踪。

Kan等[220]设计了一种基于差分平坦度的非线性控制器,成功地应用于时变系统的轨迹跟踪和纵向飞行动力学控制。

贺威等[309]设计了一种自适应姿态控制器来跟踪提取扑动翅膀的扑动频率和俯仰指令,利用李雅普诺夫直接法,证明了跟踪误差的有界性。此外,贺威等[310]设计了带状态反馈控制的径向基函数神经网络研究了姿态控制和位置控制,一系列的仿真显示了良好的跟踪效果。

5.3 编队控制

在自然界中,大多数生物都具有群体智能[311]。比如在大雁飞行中,后排大雁可以利用前排大雁扑动产生的涡流增加升力,并可以通过集群阵型的变换,实现整体能量消耗的最优性和均衡性,减少飞行阻力,提高续航能力[26,312]。Ghommem等[313]基于三维非定常涡格法模拟了以分组排列和相互靠近飞行的扑翼上的流场流动情况,通过仿真计算证明,由于非定常尾流效应,以适当的间距成直线飞行能够显著增加升力和推力,并降低功耗,而且在编队中增加个体的数量可以获得更好的整体性能。Tay等[314],通过数值模拟研究表明v型编队有利于提高扑翼系统续航能力。

在控制算法研究上,研究学者结合多智能体协作规划、感知卡尔曼滤波算法、滑模控制算法、状态估计算法等对传统的领导者−跟随者控制算法进行了改进,提高了该方法的鲁棒性[312]。比如,哈工大的王元鹏开发了基于领导者−跟随者的仿生扑翼编队飞行控制方法,并考虑了速度、航向、高度三方面的编队一致性,实现了三角形编队下的直线飞行、圆形轨迹飞行,以及队形变换功能[315]。北京科技大学的尹曌基于涡流理论分析、数值模拟,设计了分布式集群编队控制器,实现了仿生扑翼集群飞行的最优编队阵型分布[316]。由于编队飞行中的无人机会受阵风等干扰偏离最佳阵型分布,北航的段海滨团队基于大雁启发设计了一种PID仿雁群编队控制器,提高了仿雁群无人机编队抗干扰性和稳定性[317]。

在实际的扑翼飞行中,比较有代表的群体飞行的系统有Kim[318]团队制作的扑翼样机和Festo公司研发eMotionButterflies和BionicSwift。Kim基于外部运动捕捉系统和路径跟踪控制器,使领导者和跟随者在不发生碰撞的前提下成功完成了编队飞行。Festo公司基于红外线、室内GPS定位和计算机辅助,实现了eMotionButterflies在不发生碰撞的前提下任意调整姿态;并基于超宽带技术(UWB)和基于无线电的室内GPS,实现了BionicSwift编队飞行。

综合来看,目前国内外对于扑翼编队控制的研究匮乏,而且主要研究是基于理论分析和仿真计算,基于样机成功进行编队飞行或试飞的研究少之又少。而且在目前成功的案例(如eMotionButterflies)中,编队系统成员数量少,距离实际应用还有很大一段距离,未来需要加强扑翼编队控制相关理论研究和样机制作。

6. 困难与挑战

6.1 机翼设计

在机翼设计方面,合理的机翼设计能够促进飞行能力、降低功耗[35]。然而目前针对机翼模式和飞行动力学之间的相互作用的全面理解尚未实现;机翼设计仿生化程度低,未能模拟昆虫翅脉结构或鸟类的羽翼结构[319],人工柔性翼的设计充满了挑战[156]。此外,当前机翼的设计大多是基于实验从有限参数空间中选取“最优”参数,虽给出了气动性能随某几个参数(展弦比、加强筋位置等)的变化情况,但没有详细考究更多的参数,难以窥探机翼设计的详细细节,设计出更高效的气动机翼[320]。

将有限元建模和机器学习技术相结合可以为扑翼的多参数设计优化提供参[156]。然而,面对复杂多变的参数和流固耦合[35]作用,需要大量的数据集进行训练,这些数据集本身也是很匮乏的,通过机器学习解决扑翼的多参数设计优化问题有待进一步检验。

使用CFD等方法来设计初始径向平面和扭曲几何形状可以为机翼设计过程提供了一个起点[35]。例如,在给定扑动频率和期望推力等前提下,使用CFD寻找最佳行程角、展长、弦长分布、时变扭矩分布等。然而CFD忽略了扑动机构引起的损失,也难以构建在飞行载荷下变形为规定的时变几何形状的机翼[35]。

6.2 传动机构设计

在传动机构设计方面,合理的传动机构设计能够促进飞行能力、减少噪音、最小化驱动电机所需的峰值输入扭矩[321]。设计和制作一个高效的传动机构设计需考虑众多问题:传动机构应尽可能的轻、简单、牢固、可靠;应尽可能避免在机翼上附加应力;应尽可能使机翼的扑动运动对称[322];机翼的扑动运动应尽量接近正弦运动,以减少扑动机构损失和冲程反转时机翼行为的强烈影响。

目前传动机构主要使用的是四连杆机构。但是,曲柄摇杆机构会导致扑翼运动不完全对称;具有偏置的曲柄机构允许扑翼机构具有对称的扑翼运动,然而当摇杆位于同一垂直平面内,它们会相互交叉;曲柄滑块结构可以获得对称的扑动运动,然而其存在摩擦损失问题,运动效率低;双曲柄机构可提供对称的扑动运动,然而其复杂、占用空间较大、质量高;交替配置机构可提供相同的扑动运动,但该机构没有对称形状,不能用于双平面扑翼系统。

此外,目前传动机构的设计开发通常遵循试错法,缺乏关于机构的部件参数和扑动的物理参数对机构设计和功耗的影响的研究;也缺乏将传动机构的最佳参数与入口参数相关联的方法;同时缺乏更高效和仿生的传动机构设计。

6.3 驱动方式选择

在驱动方式方面,驱动方式的选择与扑翼系统的尺度有关。尺度越大的扑翼系统,其翼展越大,机翼扑动过程中受到的气动阻力越大,扑动频率越低,因此常选择大扭矩电机驱动,选择锂电池进行供电;对于微型尺度扑翼系统,由于非定常效应明显,需通过高频扑动克服惯性力和粘性力,一般选用压电驱动或人工肌肉驱动,常选择外接高压电源供电。

对于电机驱动方式,为了使扑翼系统尽可能轻,需要选取更轻型的电机,同时保证其扭矩可以克服气动阻力和惯性力。在满载时,电机消耗功率大,存在过热问题。对于压电驱动方式,所需电压一般在几百到上千伏。此外,扑翼系统行程角与压电的末端行程有关(一般在几百微米),压电驱动器的末端行程越大,越有利于微型传动结构的设计,然而压电驱动器末端行程受到其尺寸制约,需要更高的压电制造技术以实现更高的末端位移。此外,压电驱动方式下,需着重考虑高频振动下的机翼强度问题。对于人工肌肉驱动方式,人工肌肉提供了驱动性能、功率质量比和肌肉形态因素的内在顺应性的平衡[98,323],然而高压驱动的人工肌肉难以集成到扑翼系统中,低压驱动的人工肌肉材料响应速率慢,难以满足微型扑翼系统需要。

6.4 模型建立

在建模方面,一个完整的扑翼系统模型通常是高度非线性和时变的,这样的模型难以获得[156,243]。利用系统识别技术可以直接从实验数据中获得气动模型,然而模型是基于特定系统的特定行为的,具有一定的局限性;由于扑动飞行的高度复杂性和精确飞行数据的匮乏性,目前还没有现成的全局模型,特别是经过飞行数据验证的适合实际应用的模型[238]。因此,大多数扑翼系统采用线性化模型对机翼进行刚体简化[289],忽略机翼柔性及其与流场的耦合作用,这也导致无法识别柔性对飞行能力的影响[158,289],并可能会得到不同结果[166,324]。当考虑扑翼的惯性和柔性时,扑翼系统将成为一个柔性多体动力学系统,非定常空气动力学、结构动力学和多体动力学相互作用引起的振动使气动分析充满了挑战[182]。

此外,机翼弦向/展向柔性和尾翼可以稳定空气动力学,如何识别展向柔性或弦向柔性和非定常尾流与尾翼的相互作用非常重要,未来需要加强这方面的研究[243]。

6.5 气动性能分析

对于仿生扑翼无人系统的空气动力学研究,目前已经取得了许多的成果。非定常机理的研究、准稳态叶片单元法、数值模拟和实验分析上的研究上基本上取得了相同的研究结果,为扑翼飞行器的设计提供了重要指导,可以优化扑翼飞行器的设计,以此提高扑翼飞行器的气动性能和续航能力。

然而,也应指出,在仿生扑翼无人系统气动分析方面,目前仍存在许多困难与挑战。流体力学作为特征长度和速度的函数而变化[325]。不同Re下的流场流动情况完全不同。

采用PIV和缩放模型对扑翼运动进行气动分析,虽然可以保持流动相似性,但难以复刻真实昆虫和鸟类复杂的机翼和机体运动,而且由于激光反射,难以准确捕捉扑翼表面附近的流场。

使用数值模拟对扑翼系统进行气动分析可以得到与实验具有较高吻合度的结果[111,326]。然而由于N-S方程组不封闭,需要添加额外补充方程进行求解,而求解精度又受网格划分质量的影响,需要耗费大量时间来选取和优化求解模型和计算网格。此外,与扑翼系统有关的参数系统非常庞大(流动参数:Re、St、Ma等,运动参数:行程角、扑动频率、轨迹模式等,几何参数:前缘曲率、柔性分布等),且许多参数之间是耦合的。而目前的研究大多是关于升阻力、推力与扑动频率、翼型配置、缩减频率Re等方面的解耦研究,缺乏针对其他参数以及不同参数耦合作用的相关研究。此外,用传统的数值模拟方法难以捕捉三维复杂扑翼的流动机理和精细的涡结构[112]。而大涡模拟等方法需要算力十分强大的计算机,是一项耗时的挑战性任务。扑翼系统的空气动力学研究需要CFD相关求解技术的革新与进步。

6.6 位姿检测与导航

在位姿检测与导航方面,仿生扑翼无人系统需要低延迟的精确传感器来避免湍流、阵风或障碍物,这要求系统具有更高的机载处理能力和电源容量,而扑翼系统的质量和尺寸极大地限制了能源、传感器和机载处理。另一方面,各种传感器都存在比较明显的缺点。由于扑动运动,相机视频流帧率相对较低,导致了显著的图像失真和相机姿态变化,且图像噪声也会对测量精度产生负面影响[256,327];GPS在杂波和室内环境下,会发生信号干扰[328];加速度计的测量会受到扑翼运动会严重干扰[271];陀螺仪的信号保真度会被扑翼的振动环境严重破坏[35];磁力计虽不受机械振动的干扰,然而由于环境干扰,磁力计的测量结果可能会有偏差。

因此,在扑翼系统的位姿检测与导航中,必须将多传感器融合和适当滤波进行结合以提供更精确的位姿估计,实现更灵活的导航和避障能力。然而目前关于多传感器融合的研究比较少[277]。此外,受机载能力、续航能力和处理器运算能力的影响,扑翼系统难以搭载更多的传感器。

6.7 控制算法研究

在仿生扑翼无人系统控制算法研究方面,目前扑翼系统的自主水平和飞行特性不高,难以在复杂多变的场景和极端环境中进行导航和探索。而且受限于尺寸和质量,仿生扑翼系统难以搭载更多的传感器,为鲁棒控制带来了挑战。

此外,目前的大对数控制算法研究将扑翼系统视为线性时不变系统,采用平均法和线性控制器对扑翼系统进行控制。然而当存在强非线性效应时,线性控制器会降低性能;平均方法忽略了高频的零平均力,不适用于高振幅周期性控制系统[329];由于机翼运动和控制系统之间的强耦合作用,现有的控制器显示出跟踪性能下降,甚至闭环不稳定的现象。此外,机体对机翼相位滞后、流场流动等因素非常敏感,未来仍需要对更复杂的机翼扑动进行非线性研究[330],相应增加了控制算法的复杂性。

7. 结束语

本文首先介绍了诸如RoboBee、Nano hummingbird、Delfly Nimble、SmartBird、信鸽等优秀的仿生扑翼无人系统,然后从机翼构型、柔性和运动学,系统识别和建模,机载感知、外部感知和联合感知,姿态控制、避障与导航、编队控制等方面介绍了仿生扑翼无人系统的研究进展,为仿生扑翼系统进一步的发展提供了重要参考和借鉴意义。然而必须指出,目前的相关研究仍存在许多困难和挑战:机翼和传动机构的设计需进一步仿生化以模仿真实鸟类和昆虫的运动方式,制造技术需进一步精密化以设计更加精密和微型的零件,能源利用率和气动性能需进一步提高以最大化续航时间,实验方法需进一步改善以捕捉扑翼系统机翼表面的流场结构,传感器等硬件需进一步小型化以便能够搭载在更加微型的扑翼系统上,动力学模型需进一步简单化,CFD/CSD流固耦合作用、振动抑制和编队控制需进一步研究以揭示扑翼飞行和控制的内在机理,飞行能力需进一步自主化以提高在未知环境中的飞行能力。此外,国内在仿生扑翼无人系统的研究上起步较晚,成果较少,而且尺寸较大。未来,我们不仅要在仿生扑翼无人系统的理论研究上取得进展,更要在其小型化、自主化、编队控制方面取得突破。可以预见,在不久之后,仿生扑翼无人系统将会被广泛应用于搜索和救援、军事侦察、航空检测、边境巡逻、环境监测、娱乐等领域。

-

表 1 部分仿生扑翼系统部分参数

Table 1 Partial parameters of bionic flapping wing system

类型 名称 制作单位 质量

/g展长

/cm有无

尾翼扑动频

率/Hz飞行速

度/(m·s−1)续航

时间MicroBat原型1[27-29] UCLA 6.5 有 >30 — 9 s 仿蝙蝠

扑翼

系统MicroBat原型2[27-29] UCLA 10.5 15 有 — — 18 s MicroBat原型3[27-29] UCLA 12.5 22.86 有 — — 42 s B2[30] UIUC 93 40 无 10 — — B2.0[33] UIUC 90 无 — — — 仿蝙蝠扑翼系统[111] 北航 289 168 无 3.5 6.8 5 min 仿鸟扑

翼系统Nano Hummingbird[35]I-Bird[36] 航空环境公司 19 16.5 无 30 6.7 11 min H2Bird[38] UC Berkeley 13 26.5 有 — 1.2 10 min Small Bird[41] 马里兰大学 35 g 57.2 有 5 3.75 8 min PNH原型1[48] 普渡大学 7.5 15 无 30 — — PNH原型3[48] 普渡大学 12.5 17 无 34 — — SmartBird[62] Festo — — 有 — — — BionicSwift[63] Festo 42 68 有 — — 7 min Colibri[64] VUB 22 21 无 22 — 15~20 s 信鸽[104-105] NWPU 245 60 有 10 10 2 min USTBird108] USTB 83.2 80 有 2~4 — — Beihawk[109-110] 北航 1200 150 有 0~10 — — BionicOpter[66] Festo 175 63 无 15~20 — — eMotionButterflies[67] Festo 32 50 无 1~2 1~2.5 3~4 min 续表 1 类型 名称 制作单位 质量

/g展长

/cm有无

尾翼扑动频

率/Hz飞行速

度/(m·s−1)续航

时间仿昆

虫扑

翼系统MFI[68] UC Berkeley 1 0.025 无 150 Hz — — KUBeetle[72-74] 建国大学 7.36 12.5 无 23~43 0.94 40 s KUBeetle-S[75] 建国大学 16.4 — 无 — 1.1~2.5 8.8 min Clicking原型[78] NTU 3.58 24 无 15.8 悬停 — 电机直驱动样机[80-81] NTU 6.8 8 无 40 — — 两翼扑翼系统[82] NTU 2.7 7 无 10 — — DelFly II[85] TUD 16 28 有 — 7 15 min DelFly Micro[86] TUD 3.07 10 有 30 — 6 min DelFly Explorer[87] TUD 20 28 有 — — 12 min DelFly NimBle[88] TUD 29 33 无 17 3 5 min Robobee[90] 哈佛大学 0.259 5 无 170 — — -