文章信息

- 伊力达尔·伊力亚斯, 朱思洪, Do.MinhCuong, 聂信天, 徐刚

- Yilidaer YILIYASI, ZHU Sihong, Do. Minh Cuong, NIE Xintian, XU Gang

- 湿软水田土壤行驶工况下拖拉机振动特性研究

- Study on vibration characteristics of tractor travel at the condition of marshy paddy soil

- 南京农业大学学报, 2016, 39(6): 1062-1068

- Journal of Nanjing Agricultural University, 2016, 39(6): 1062-1068.

- http://dx.doi.org/10.7685/jnau.201512001

-

文章历史

- 收稿日期: 2015-12-03

2. 新疆农业大学机械交通学院, 新疆 乌鲁木齐 830052 ;

3. Faculty of Engineering and Post Harvesting, Hue University of Agriculture and Forestry, Thua Thien Hue 47000, Vietnam

2. College of Mechanical and Transportation, Xinjiang Agricultural University, Urumqi 830052, China ;

3. Faculty of Engineering and Post Harvesting, Hue University of Agriculture and Forestry, Thua Thien Hue 47000, Vietnam

拖拉机在湿软水田土壤中行驶时的振动特性与在农村未覆盖土路上行驶时是不同的, 揭示拖拉机在两种不同行驶工况下的振动特性对水、旱田两用拖拉机减振系统设计和悬架智能控制具有重要的参考价值和实际意义。

揭示轮胎与土壤相互作用规律是研究拖拉机在软黏性土壤中行驶时行驶安全性和乘坐舒适性的基础。当拖拉机行驶在软黏性土壤中时, 土壤硬底层不平度是影响其振动的主要因素, 而振动能量主要靠轮胎和土壤变形产生的阻尼吸收[1]。在国外, 对拖拉机在不同土壤上行驶时振动问题的研究最早可以追溯到20世纪50年代, 研究的重点大多集中在土壤变形、土壤与轮胎的相互作用以及松软土壤对拖拉机振动的影响[2]。Yong等[3]研究了轮胎-土壤间的相互关系, 并研究了拖拉机行驶工况下轮胎与土壤的弹性变形。Mao等[4]建立了轮胎-土壤的非线性振动模型。Hildebrand等[5]建立了一种拖拉机与土壤的振动模型, 并发现拖拉机的部分振动可以被土壤吸收。大量的研究表明, 土壤是一种具有阻尼性质的材料, 黏软性土壤具有降低拖拉机振动的作用[6-7]。

在国内, 有关轮胎与土壤相互作用规律的研究涉及不多。樊慧文等[8]建立了轮胎与沙漠土壤相互作用的数学模型, 但拖拉机在湿软水田土壤中行驶时的振动特性研究鲜见报道。本论文以江苏常发集团CF700型拖拉机为研究对象, 用理论分析的方法研究拖拉机在湿软水田土壤中行驶时的振动特性, 揭示其与拖拉机在硬质路面上行驶时振动特性的差异, 为水、旱田作业拖拉机减振系统的方案设计和参数优化提供理论依据。

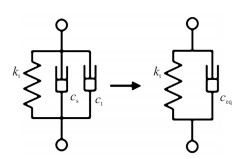

1 理论计算模型的建立 1.1 轮胎-湿软水田土壤系统模型的建立拖拉机在水田中行驶时, 其轮胎深陷在湿软土壤中。在进行振动特性研究时除了轮胎的刚度和阻尼外, 还要考虑湿软水田土壤对拖拉机振动特性的影响。本实验室根据湿软水田土壤阻尼系数的测定结果, 提出了图 1所示的轮胎-湿软水田土壤系统模型。其中:kt为轮胎刚度系数; ct为轮胎阻尼系数; cs为湿软水田土壤阻尼系数; ceq为轮胎-湿软水田土壤系统等效阻尼系数。在该模型中, 湿软水田土壤的弹性忽略不计, 轮胎-湿软水田土壤系统的垂向等效阻尼系数ceq等于轮胎阻尼系数ct和土壤阻尼系数cs之和, 即ceq=ct+cs[9]。

|

图 1 轮胎-湿软水田土壤系统模型 Figure 1 Tire-marshy paddy soil system model |

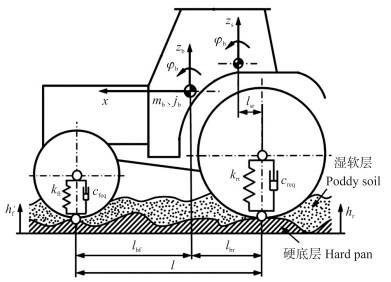

基于上述轮胎-湿软水田土壤系统模型建立拖拉机在湿软水田土壤行驶工况下的二自由度振动模型, 如图 2所示。图中:mb为拖拉机质量; jb为拖拉机绕其质心的转动惯量; kft为拖拉机前轮刚度; krt为拖拉机后轮刚度; cfeq为拖拉机前轮-土壤等效阻尼系数; creq为拖拉机后轮-土壤等效阻尼系数; zb为拖拉机质心垂向位移; φb为拖拉机机身俯仰角位移; zs为拖拉机座椅安装处垂向位移; lbf为质心到前桥轴心的水平距离; lbr为质心到后桥轴心的水平距离; lsr为座椅安装处质心到后桥轴心的水平距离; hf为前轮与水田土壤硬底层接触点高度; hr为后轮与水田土壤硬底层接触点高度。

|

图 2 拖拉机二自由度振动模型 Figure 2 Tractor two degree-of-freedom (2DOF) vibration model |

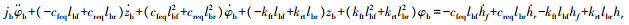

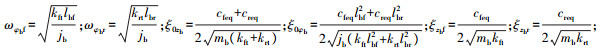

基于图 2拖拉机二自由度振动模型, 建立系统振动微分方程如下:

|

(1) |

|

(2) |

将其转换成矩阵形式:

|

(3) |

式中:

|

|

|

为了研究拖拉机在湿软水田土壤行驶工况下的振动特性, 选取机身振动位移对前、后轮激励的幅频特性、机身振动加速度、座椅安装处加速度以及前、后轮动载荷作为评价指标, 由方程(3)得到各评价指标的理论计算模型如下。

机身振动位移对前、后轮激励的幅频特性:

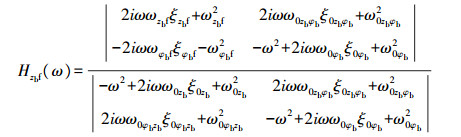

|

(4) |

|

(5) |

|

(6) |

|

(7) |

式中:Hzbf(ω)、Hzbr(ω)分别为机身垂向振动相对于前、后轮激励的幅频特性; Hφbf(ω)、Hφbr(ω)分别为机身俯仰振动相对于前、后轮的幅频特性。

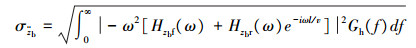

机身垂向振动加速度和俯仰振动角加速度:

|

(8) |

|

(9) |

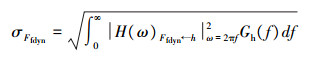

拖拉机前、后轮动载荷:

|

(10) |

|

(11) |

式中:H(ω)Ffdyn←h、H(ω)Frdyn←h分别为拖拉机前、后轮动载荷的频率响应函数; Gh(f)为水田土壤硬底层时间频率功率谱密度, 其值等于Gh(n)/v; Gh(n)为水田土壤硬底层空间频率功率谱密度; v为拖拉机行驶速度。

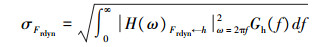

座椅安装处垂向振动加速度:

|

(12) |

以江苏常发集团CF700型拖拉机为研究对象, 其主要参数在自行研制的试验台上测得, 结果如表 1所示。

| 参数名称Parameter name | 数值Values |

| 拖拉机机身质量(mb)/kg Tractor body mass | 2 694 |

| 机身俯仰转动惯量(jb)/(kg·m2) Body pitch moment of inertia | 3 547 |

| 前轮刚度系数(kft)/(N·m-1) Front wheel stiffness | 714 354 |

| 后轮刚度系数(krt)/(N·m-1) Rear wheel stiffness | 718 608 |

| 前轮阻尼系数(cft)/(N·s·m-1) Front wheel damping | 3 578 |

| 后轮阻尼系数(crt)/(N·s·m-1) Rear wheel damping | 5 034 |

| 拖拉机轴距(l)/m Tractor wheelbase | 2.188 |

| 机身质心距前桥水平距离(lbf)/m Body centroid of the horizontal distance from the front axle | 1.347 |

| 机身质心距后桥水平距离(lbr)/m Body centroid of the horizontal distance from the rear axle | 0.841 |

| 座椅质心距后桥水平距离(lsr)/m Seat centroid of the horizontal distance from the rear axle | 0.311 |

| 注:驾驶员质量按75 kg计算。Driver mass is equal to 75 kg. | |

湿软水田土壤样本取自南京农业大学江浦农场水稻试验田, 土壤含水率为48.8%, 在自行研制的试验台上测得土壤阻尼系数cs=849 N · s · m-1[12]。

2.3 路面功率谱密度根据1984年国际标准化组织在ISO/TC108/SC2N67文件中提出的“路面不平度表示方法草案”和中国长春汽车研究所1986年起草制定的《GB 7031-1986车辆振动输入-路面平度表示》标准的建议, 路面功率谱密度Gh(n)用下式表达[13]:

|

(13) |

式中:Gh(n0)为路面不平度系数(m3); n为空间频率(m-1); n0为参考空间频率(n0=0.1 m-1); w为频率指数。

用自行研制的测试装置, 在南京农业大学江浦农场水稻试验田测得典型湿软水田土壤硬底层的不平度系数Gh(n0)=645×10-6 m3, 频率指数w=1.24[9]。

为了将拖拉机在水田作业工况下的振动特性与类似工况下的振动特性进行比较, 选取农村未覆盖土路作为参照路面。根据国际路面不平度分类标准 ISO8608[14], 农村未覆盖土路一般为国标D级路面, 其路面不平度系数Gh(n0)=1 024×10-6 m3, 频率指数w=2。

3 计算结果及分析根据拖拉机在水田作业时的常见行驶速度, 拖拉机行驶速度变化范围取为3~18 km · h-1, 以3 km为间隔取6个离散点。利用理论计算模型式(4)~(12), 在数值分析软件MATLAB环境下, 计算得到拖拉机在水田作业工况和在农村未覆盖土路行驶工况下的振动特性。

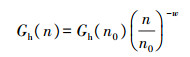

3.1 幅频特性从图 3可以看出, 机身垂向振动和俯仰振动对前轮激励响应的最大峰值都出现在俯仰振动固有频率3.91 Hz处, 而对后轮激励响应的最大峰值则出现在垂向振动固有频率3.11 Hz处。与未覆盖土路行驶工况(国标D级路面)相比拖拉机在湿软水田土壤中行驶时垂向振动固有频率和俯仰振动固有频率没有变化, 机身垂向振动幅值相对于前、后轮的位移传递率分别下降31.4%和23.5%, 俯仰振动幅值分别下降29.5%和24.6%。

|

图 3 机身振动位移对前、后轮的激励幅频特性曲线 Figure 3 Body vibration displacement for front and rear excitation amplitude-frequency characteristics curve |

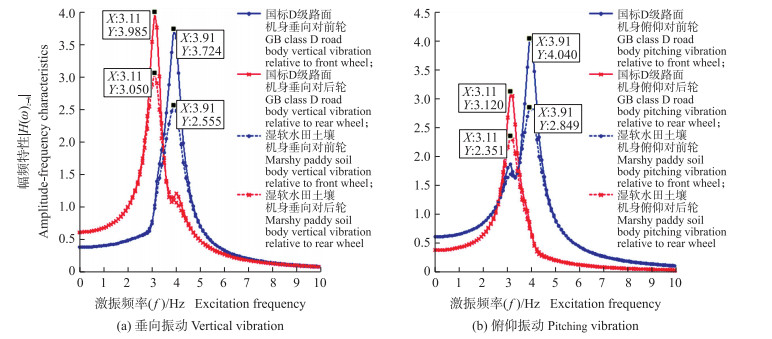

从图 4可以看出, 当拖拉机以3~18 km · h-1速度在湿软水田土壤中行驶时, 其机身垂向振动加速度和俯仰振动角加速度较在农村未覆盖土路(国标D级路面)上行驶时平均降低33.0%和32.6%。

|

图 4 机身振动加速度随拖拉机行驶速度的变化规律 Figure 4 Body vibration acceleration variation with tractor driving speed |

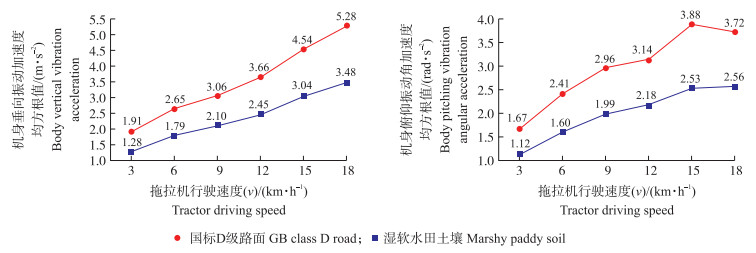

从图 5可以看出, 当拖拉机以3~18 km · h-1速度在湿软水田土壤中行驶时, 其前、后轮动载荷较在农村未覆盖土路(国标D级路面)上行驶时平均降低34.0%和31.2%。

|

图 5 前、后轮动载荷随拖拉机行驶速度的变化规律 Figure 5 Front and rear wheel dynamic load variation with tractor driving speed |

从图 6可以看出, 当拖拉机以3~18 km · h-1速度在湿软水田土壤中行驶时, 其座椅安装处垂向振动加速度较在农村未覆盖土路(国标D级路面)上行驶时平均降低32.9%。

|

图 6 座椅安装处垂向振动加速度随拖拉机行驶速度的变化规律 Figure 6 Tractor seat vertical vibration acceleration variation with tractor driving speed |

用理论分析和数值计算相结合的方法, 研究了拖拉机在湿软水田土壤行驶工况下的振动特性。与农村未覆盖土路行驶工况(国标D级路面)相比, 拖拉机在湿软水田土壤中行驶时, 其垂向振动相对前、后轮的位移传递率分别下降31.4%和23.5%, 俯仰振动分别下降29.5%和24.6%;机身垂向振动加速度和机身俯仰振动角加速度平均降低33.0%和32.6%;前、后轮动载荷平均降低34.0%和31.2%;座椅安装处垂向振动加速度平均降低32.9%。研究结果可以作为水、旱田两用拖拉机减振系统设计与悬架智能控制的重要依据。

| [1] | Laib L. Measurement and mathematical analysis of agricultural terrain and road profiles[J]. Journal of Terramechanics, 1977,14(2): 83–97. DOI: 10.1016/0022-4898(77)90003-9 |

| [2] | Bekker M G. Introduction to Terrain-Vehicle Systems[M]. Beijing: China Machine Press, 1978 : 122 -235. |

| [3] | Yong R N, Boonsinsuk P, Fattah E A. Tyre load capacity and energy loss with respect to varying soil support stiffness[J]. Journal of Terramechanics, 1980,17(3): 131–147. DOI: 10.1016/0022-4898(80)90023-3 |

| [4] | Mao S G, Ray P S. Nonlinear complementarity equations for modeling tire-soil interaction:an incremental Bekker approach[J]. Journal of Sound and Vibration, 2008,312: 380–398. DOI: 10.1016/j.jsv.2007.07.090 |

| [5] | Hildebrand R, Keskinen E, Navarrete J A R. Vehicle vibrating on a soft compacting soil half-space:ground vibrations, terrain damage, and vehicle vibrations[J]. Journal of Terramechanics, 2008,45(4): 121–136. DOI: 10.1016/j.jterra.2008.09.003 |

| [6] | Okhitin A A, Lipiec J, Tarkiewicz S, et al. Deformation of silty loam soil under the tractor tire[J]. Soil and Tillage Research, 1991,19: 187–195. DOI: 10.1016/0167-1987(91)90086-D |

| [7] | Park S, Popov A A, Cole D J. Influence of soil deformation on off-road heavy vehicle suspension vibration[J]. Journal of Terramechanics, 2004,41(1): 41–68. DOI: 10.1016/j.jterra.2004.02.010 |

| [8] | 樊慧文, 赵六奇. 轮胎与土壤相互作用的数学模型和实验研究[J]. 清华大学学报(自然科学版), 1997, 37(11): 110–114. Fan H W, Zhao L Q. Mathematical models and experimental study of interaction between tire and soil[J]. Journal of Tsinghua University (Science and Technology Edition), 1997,37(11): 110–114. (in Chinese) |

| [9] | 杜明强.拖拉机在水田土壤条件下的振动特性研究[D].南京:南京农业大学, 2013:57-75. Do M C. Study on characteristics of tractor vibration works on the paddy field[D]. Nanjing:Nanjing Agricultural University, 2013:57-75(in Chinese with English abstract). |

| [10] | 聂信天, 史立新, 朱思洪, 等. 农用轮胎径向刚度和阻尼系数试验研究[J]. 南京农业大学学报, 2011, 34(5): 139–143. Nie X T, Shi L X, Zhu S H, et al. Research on the radial stiffness and damping of tractor coefficient tires through test[J]. Journal of Nanjing Agricultural University, 2011,34(5): 139–143. DOI: 10.7685/j.issn.1000-2030.2011.05.025 (in Chinese) |

| [11] | 聂信天, 史庆春, 朱思洪, 等. 拖拉机转动惯量测量及误差分析[J]. 机械科学与技术, 2012(8): 1325–1326. Nie X T, Shi Q C, Zhu S H, et al. Method of measuring the moment of inertia of tractors and the error analysis[J]. Mechanical Science and Technology for Aerospace Engineering, 2012(8): 1325–1326. (in Chinese) |

| [12] | Do M C, Zhu S H. Study on the variation characteristics of vertical equivalent damping ratio of tire-soil system using semi-empirical model[J]. Journal of Terramechanics, 2014,51: 67–80. DOI: 10.1016/j.jterra.2013.10.002 |

| [13] | 余志生. 汽车理论[M]. 5版. 北京: 机械工业出版社, 2009 : 206 -208. Yu Z S. Automotive Theory[M]. 5th ed. Beijing: China Machine Press, 2009 : 206 -208. (in Chinese) |

| [14] | ISO-8608 International Standard. Mechanical vibration-road surface profiles-reporting of measured data[S]. International Organization for Standardization, Printed in Switzerland.1995:17-20. |