文章信息

- 赵荻, 楼君, 庄志城, 刘圆, 喻卫武, 胡渊渊, 宋丽丽, 吴家胜.

- Zhao Di, Lou Jun, Zhuang Zhicheng, Liu Yuan, Yu Weiwu, Hu Yuanyuan, Song Lili, Wu Jiasheng

- 叔丁基对苯二酚(TBHQ)对香榧烘烤和货架品质以及抗氧化能力的影响

- Effects of Tertbutyl Hydroquinone (TBHQ) on Quality of Torreya grandis during Roasting Process and Shelf and Its Antioxidant Capacity

- 林业科学, 2018, 54(10): 39-45.

- Scientia Silvae Sinicae, 2018, 54(10): 39-45.

- DOI: 10.11707/j.1001-7488.20181005

-

文章历史

- 收稿日期:2018-04-26

- 修回日期:2018-08-13

-

作者相关文章

2. 浙江省杭州市富阳区农业技术推广中心 杭州 311300

2. Fuyang Agricultural Technology Promotion Station, Zhengjiang Province Hangzhou 311300

香榧(Torreya grandis cv.Merrillii)是红豆杉科(Taxaceae)榧树属(Torreya)经人工嫁接繁殖的优良变异树种, 营养价值高, 具有特殊风味, 具有对抗炎症、病毒、动脉硬化、钩虫病等方面药效(Chen et al., 2006; Saeed et al., 2007)。香榧籽油的含量约为42.61%~54.39%, 其中80%为不饱和脂肪酸, 以油酸和亚油酸为主(Dong et al., 2014)。有研究表明, 不饱和脂肪酸是油脂抗氧化活性的主要成分之一, 具有降低冠心病风险的功效(Giordano et al., 2014; Ramaprasad et al., 2005; Endo et al., 2006)。另外, 香榧籽油还含有其他抗氧化活性物质, 如酚类化合物、维生素E等(He et al., 2016; Shi et al., 2009)。

一般来说, 香榧籽经炒制后食用, 其炒制烘烤涉及3个工艺过程, 即第一次烘烤、浸泡盐水、第二次烘烤(汪瑶等, 2013)。烘烤可保留较多营养成分, 能改善干果的风味、口感、质地和颜色(Schlörmann et al., 2015)是较好的食品加工方式之一(Inocent et al., 2011)。贮脂细胞的结构在烘烤后容易受到损害导致氧气进入, 与水分、空气等接触发生反应, 氧化生成脂质过氧化物, 最终影响干果风味品质和货架期(Bettina et al., 2009)。葛林梅等(2011)研究认为, 浸泡炒制后香榧籽的酸价和过氧化值显著升高, 说明烘烤期间的浸泡工艺, 是影响香榧品质的重要环节。而浸泡工艺通常是添加一定量的NaCl以达到改善风味的目的。但也有学者在对鹰嘴豆(Cicer arietinum)种子的研究中发现添加过量NaCl, 会导致蛋白质流失, 赖氨酸的活性降低, 生物活性化合物减少以及抗氧化能力下降(Badshah et al., 1987; Han et al., 2008; Xu et al., 2008; Segev et al., 2012)。Thammapat等(2015)研究也发现, 糯米的总酚含量(TPC)随着NaCl含量的增加和浸泡温度的升高呈上升趋势。但在目前实际生产中, 香榧的NaCl浸泡浓度通常取决于经验, 而浸泡条件对脂质氧化和抗氧化活性的影响尚无明确研究。

为了防止脂质过氧化, 延长干果成品的保质期, 通常会使用抗氧化剂来减缓食品变质, 提高产品质量。食品生产中常用的抗氧化剂包括二叔丁基羟基甲苯(BHT)、丁基羟基茴香醚(BHA)、叔丁对苯二酚(TBHQ)和没食子酸丙酯(PG)等(Boonlam et al., 2009), 其中TBHQ能够有效提高芝麻油和花生油的氧化稳定性(Prasad et al., 2015; Banu et al., 2013)。徐超等(2013)在研究抗氧化剂对香榧油氧化稳定性的影响中发现, TBHQ与PG均能提高抗氧化能力, 且TBHQ的效果更好。而添加TBHQ是否能抑制香榧烘烤过程中脂质氧化, 进而提高成品的品质, 目前还未有研究。

本研究通过探讨不同浸盐浓度和作用时间对香榧籽烘烤过程中脂质氧化程度的影响, 同时结合TBHQ对香榧加工和常温货架期间的品质和抗氧化能力的影响, 阐明香榧籽品质劣变发生及其调控机制, 为优化香榧加工工艺和提高产品品质提供理论和实践依据。

1 材料与方法 1.1 试验材料香榧籽于2015年9月采自中国浙江省临安市板桥镇三口村。根据传统方式, 将香榧籽在太阳下晒干, 使含水量保持在8%~10%。去除有瑕疵的种籽, 筛选形状、大小、颜色一致的种籽, 混合, 确保样本一致性。晾晒后的种籽储存在4 ℃冰箱中备用。

1.2 方法处理 1.2.1 NaCl浸泡处理分别采用5%(w/w)和20%(w/w)NaCl溶液将250 ℃下高温加热7 min后香榧籽0、5、10和20 min, 然后捞出, 常温下沥干后在120 ℃下加热1.5 h。测定香榧经过烘烤加工后的过氧化值(POV)、酸价(AV)、总酚含量(TPC)、亚油酸脂质过氧化体系的抑制作用(TBA)和DPPH自由基(2, 2-diphenyl-1-picrylhydrazyl)清除活性等指标。

1.2.2 TBHQ处理将250 ℃下高温加热7 min的香榧籽, 选择20%NaCl溶液浸泡10 min, 参照徐超等(2013)研究, 外源添加0和0.02%TBHQ(w/w, Sigma Aldrich, St.Louis, USA), 浸泡10 min。浸泡前、浸泡中、浸泡后分别取样, 测定POV、AV、TBA、TPC、DPPH自由基清除活性和维生素E(VE)。

1.2.3 烘烤后货架期处理将烘烤后的香榧籽置于室温(20~25 ℃)下贮藏, 采用散装方式, 敞口放置在透明食品保鲜袋(280 mm×200 mm×0.05 mm)中, 分别对15、30、45、60天货架期的样品取样, 测定POV、AV、p-茴香胺值以及TPC和DPPH自由基清除活性。

1.3 测定方法香榧籽油的提取参考陶菲等(2008)的方法。过氧化值的测定参照叶秀娟(2011)的方法。酸价的测定参考宋丽丽等(2009)方法。p-茴香胺值的测定参考陶菲等(2008)的方法。TBA的测定参照硫代巴比妥酸法(Yuan et al., 2009)。总酚含量测定使用Folin-C(福林酚)比色法, 参考Dudonne等(2009)方法, 样品测定液提取根据Shi等(2009)的方法。DPPH自由基清除活性参考Larrauri(1998)。VE含量测定根据Wong等(1988)的比色法。

1.4 数据分析试验采用完全随机设计, 不同处理各重复3次结果, 数据使用Excel 2007和SPSS16.0统计处理。采用SPSS16.0, 用邓肯多重比较方法进行方差显著性分析。使用SigmaPlot 12.5进行绘图。

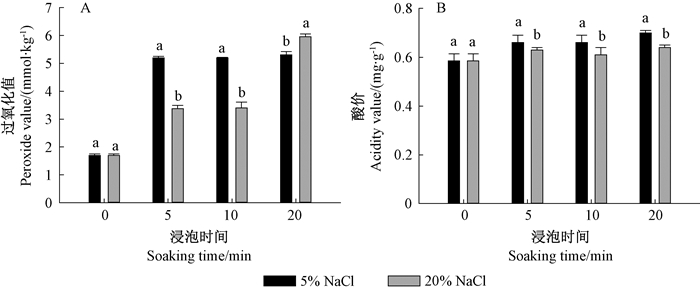

2 结果与分析 2.1 NaCl溶液浸泡对香榧烘烤过程中的脂肪氧化和抗氧化活性的影响由图 1可知, 浸泡在NaCl溶液后香榧籽的过氧化值和酸价升高。二次烘烤后, 过氧化值和酸价大幅度上升, 这表明在浸泡过程会出现脂质氧化和品质下降。不同浸泡处理中, 在20%高盐溶液浸泡10 min香榧籽的过氧化值和酸价最低。

|

图 1 浸泡条件对香榧籽烘烤过程中的过氧化值(A)和酸价(B)的影响 Figure 1 Effects of soaking condition on POV(A) and acidity value (B) in T. grandis seeds during the roasting process 图中不同字母表示不同处理之间的显著差异(P < 0.05)。下同。 The different letters means significant difference at 0.05 level.The same below. |

由图 2A可知, 与未添加NaCl溶液相比, 香榧籽浸泡在NaCl溶液后总酚含量持续长时间显著上升。浸泡时间为10 min时测得的总酚含量最高, 比空白对照组增加了31%。由图 2A、2B可知, DPPH自由基清除活性在10 min时出现最大值, 与总酚的结果一致, 进一步验证得到香榧籽中总酚含量和DPPH自由基清除活性之间呈显著正相关(R=0.95, y=0.396x-17.695)。

|

图 2 浸泡条件对香榧籽烘烤过程中总酚含量(A)、DPPH自由基清除活性(B)和脂质氧化抑制率(C)的影响 Figure 2 Effects of soaking condition on TPC(A), DPPH scavenging activity(B) and inhibityory activity of lipid oxidation (C) in T. grandis seeds during the roasting process |

图 2C中可知, 在20%高盐溶液持续浸泡10 min后观察到香榧籽对提取物中亚油酸TBA的抑制作用较强。因此结合不同浸泡条件下香榧籽的脂质氧化和抗氧化活性的变化, 在生产实际中选取最佳浸泡方式, 即在20%高盐溶液浸泡10 min来缓解香榧品质下降。

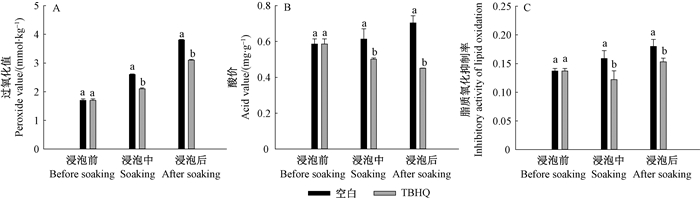

2.2 添加TBHQ对香榧烘烤过程中的脂质氧化和抗氧化活性的影响由图 3可知, 浸泡在20%高盐溶液10 min会导致过氧化值和酸价水平升高, 加剧脂质氧化。与空白对照组相比, 浸泡在具有TBHQ的20%高盐溶液中香榧籽的过氧化值和酸价上升较少, 表明在烘烤过程中添加TBHQ能够有效地缓解脂质氧化。

|

图 3 浸泡液中添加TBHQ和Vc对烘烤过程中香榧籽的过氧化值(A)、酸价(B)和脂质氧化抑制率(C)的影响 Figure 3 Effects of TBHQ and Vc in soaking medium on POV(A), acidity value(B) and inhibitory activity of lipid oxidation(C) in T. grandis seeds during the roasting process |

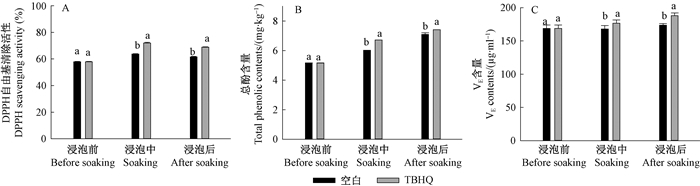

由图 4可知, 与浸泡中的香榧籽相比, 浸泡后总酚含量持续上升, 而DPPH自由基清除率下降。与浸泡前相比, 浸泡中的样品VE含量有所下降, 浸泡后略有上升。浸泡后和二次烘烤后的总酚含量、DPPH自由基清除率、VE含量, 无显著差异(P>0.05)。

|

图 4 浸泡液中添加TBHQ对香榧籽中总酚含量(A)、DPPH自由基清除活性(C)和VE含量(C)的影响 Figure 4 Effects of TBHQ in soaking medium on TPC(A), DPPH scavenging activity (B) and VE (C) in T. grandis seeds during the roasting process |

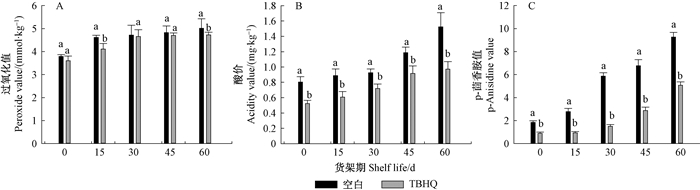

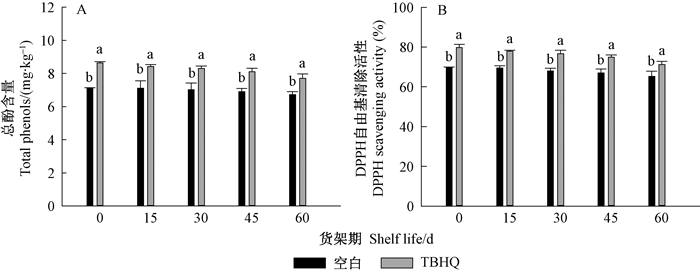

由图 5可知, 香榧籽在60天货架期内过氧化值、酸价和p-茴香胺值上升, 证明香榧籽在烘烤后脂质氧化程度加剧。由图 6可知, 总酚含量和DPPH自由基清除活性显著下降, 这可能与抗氧化能力降低有关。与空白对照组相比, 添加TBHQ的香榧籽的过氧化值和酸价水平较低, 总酚含量和DPPH自由基清除活性水平较高, 表明TBHQ可以减轻香榧烘烤后的脂质氧化程度同时提高抗氧化能力, 达到延长货架期的目的。

|

图 5 添加TBHQ对香榧烘烤产品在常温下储藏60天内的过氧化值(A)、酸价(B)、p-茴香胺值(C)的影响 Figure 5 Effects of TBHQ on vatues of POV(A), acidity(B) and p-anisidine in T. grandis roasted products during following shelf-life of 60 days at room temperature |

|

图 6 添加TBHQ对香榧烘烤产品在常温下储藏60天内的过氧化值(A)、酸价(B)、p-茴香胺值(C)的影响 Figure 6 Effects of TBHQ on POV(A) and DPPH scavenging activity(B) in T. grandis roasted products during following sheif-life of 60 days at room temperature |

过氧化物值和酸价通常用于评估干果和食物的氧化劣变程度(Chun et al., 2005), 分别测量的是初级氧化产物和次级氧化产物(Anjum et al., 2006)。Thammapat等(2015)研究表明, 高浓度盐溶液会诱导2次胁迫清除过度产生活性氧(ROS), 如氧化应激反应。葛林梅等(2011)也发现, 与第一次高温烘烤相比, 香榧籽浸泡过程中过氧化值和酸价分别增加73%和56%。另一方面, 当植物组织遭受氧化胁迫后, 自身会启动酚酶促和非酶促防御机制来清除ROS导致的氧化损伤(Ashraf et al., 2009)。本试验中, 与浸泡前相比, 香榧籽在20%高盐溶液浸泡10 min观察到总酚含量最高, 这个结果与Thammapat等(2015)在糯米中的结果一致。有研究证明, 水果和蔬菜的总酚含量与抗氧化能力呈正相关(Xu et al., 2010)。测定DPPH自由基清除活性已被广泛用于评价提取物和纯化物的抗氧化活性(Jung et al., 2008)。香榧籽中总酚含量和DPPH自由基清除活性的浓度之间的呈显著正相关, 这表明香榧籽很可能与山核桃仁(Carya cathayensis)一样, 酚类化合物是主要的抗氧化活性成分(Yang et al., 2015)。因此, 香榧籽在20%NaCl溶液浸泡10 min时抗氧化能力较强。

通常脂质过氧化被认为是缩短货架期和产生不良风味的主要原因(Ryan et al., 2008)。化合物的抗氧化活性表现为清除活性氧和自由基对抑制亚油酸的脂质过氧化。在香榧烘烤过程中添加TBHQ能够提高氧化稳定性, 这与Akhtar等(2012)研究, 葵花籽油在180 ℃下连续油炸4 h后, TBHQ展现出了较强的抗氧化活性相似。与浸泡中相比, 二次烘烤后的香榧籽总酚含量持续上升, 而DPPH自由基清除率下降, 这可能与烘烤期间脱羧形成的其他抗氧化化合物或不同化合物之间美拉德褐变反应生成酚类化合物或含有不同氨基和羰基有关(Yang et al., 2015)。添加TBHQ处理中, DPPH自由基清除活性和总酚含量都要高于未添加的空白对照, 同时过氧化值、酸价以及脂质氧化抑制率均呈较低水平。Banu等(2013)研究发现, 添加TBHQ的花生油具有更好的氧化稳定性。徐超等(2013)在对香榧籽的研究也发现采用不同溶剂对香榧籽油进行浸提时, 添加TBHQ可以有效增加氧化稳定性。因此, TBHQ可以减轻香榧烘烤后的脂质氧化程度并且提高抗氧化能力, 达到延长货架期的目的。

VE被认为是脂溶性的天然抗氧化剂, 可以避免脂质氧化, VE的作用是稳定膜脂双层内的多不饱和脂肪酸, 清除脂质自由基(Shintani et al., 2002; Warner et al., 2006)。比较香榧籽浸泡和二次烘烤工序, VE含量无显著差异, Silva等(2010)也观察到浸泡前后VE含量没有明显变化。添加TBHQ后香榧籽的VE含量显著上升, 这表明TBHQ有助于提高VE含量, 防止氧化应激, 维持细胞内的活性氧平衡(Mandhania et al., 2006)。Yasin等(2012)发现, 饲料中添加VE能降低牲畜屠宰后脂质过氧化, 提高肉质的氧化稳定性。因此, 可以通过添加TBHQ提高VE含量, 进而增强香榧的氧化稳定性。

4 结论香榧在为20%NaCl溶液中浸泡10 min, 过氧化值、酸价和脂质氧化抑制率最低, TPC含量、DPPH自由基清除率最高。在NaCl溶液中添加TBHQDPPH自由基清除活性和VE含量较高, 货架期间过氧化值和酸价较低, 表明TBHQ是一种有效的抗氧化剂, 可以减轻香榧籽在烘烤和常温货架存放过程中的脂质氧化, 并提高氧化稳定性, 从而提高香榧加工和贮藏技术, 为香榧产业的可持续发展提供理论基础。

葛林梅, 郜海燕, 陈杭君, 等. 2011. 加工工艺对香榧油脂氧化和抗氧化活性的影响. 中国粮油学报, 26(5): 42-46. (Ge L M, Gao H Y, Chen H J, et al. 2011. Effect of processing on lipid oxidation and antioxidant ability of Torreya grandis. Journal of The Chinese Cereals and Oils Association, 26(5): 42-46. [in Chinese]) |

宋丽丽, 郜海燕, 葛林梅, 等. 2009. 包装对香榧坚果贮藏中的油脂酸败和抗氧化能力的影响. 林业科学, 45(3): 49-53. (Song L L, Gao H Y, Ge L M, et al. 2009. Effect of different packaging on lipid peroxidation and antioxidant ability of Torreya grandis nuts during storage at room temperature. Scientia Silvae Sinica, 45(3): 49-53. DOI:10.3321/j.issn:1001-7488.2009.03.009 [in Chinese]) |

陶菲, 郜海燕, 陈杭君, 等. 2008. 不同包装对山核桃脂肪氧化的影响. 农业工程学报, 24(9): 303-305. (Tao F, Gao H Y, Chen H J, et al. 2008. Effect of different types of packaging on lipid oxidation of walnut (Carya cathayensis Sarg.) during storage. Transactions of the Chinese Society of Agricultural Engineering, 24(9): 303-305. DOI:10.3321/j.issn:1002-6819.2008.09.061 [in Chinese]) |

汪瑶, 余勇, 郭磊, 等. 2013. 利用正交实验和模糊评价改进香榧加工工艺. 食品与发酵工业, 39(10): 151-155. (Wang Y, Yu Y, Guo L, et al. 2013. Application of orthogonal experiment and fuzzy evaluation in development of Torreya grandis processing technology. Food and Fermentation Industries, 39(10): 151-155. [in Chinese]) |

徐超, 王鸿飞, 邵兴锋, 等. 2013. 香榧子油溶剂浸提工艺及氧化稳定性研究. 中国粮油学报, 28(9): 66-70. (Xu C, Wang H F, Shao X F, et al. 2013. Study on solvent extraction and oxidation stability of Torreya grandis seed oil. Journal of The Chinese Cereals and Oils Association, 28(9): 66-70. [in Chinese]) |

叶秀娟. 2011. 食品中酸价和过氧化值测定方法的改进. 现代食品科技, 27(10): 1285-1287. (Ye X J. 2011. Improved determination methods for acid and peroxide values in foods. Modern Food Science & Technology, 27(10): 1285-1287. [in Chinese]) |

Akhtar H, Tariq I, Mahmood S, et al. 2012. Effect of antioxidants on stability, nutritional values of refined sunflower oil during accelerated storage and thermal oxidation in frying. Bangladesh Journal of Scientific and Industrial Research, 47(2): 223-230. |

Anjum F, Anvar F, Jamil A, et al. 2006. Microwave roasting effects on the physico-chemical composition and oxidative stability of sunflower seed oil. Journal of the American Oil Chemists' Society, 83(9): 777-784. DOI:10.1007/s11746-006-5014-1 |

Ashraf M. 2009. Biotechnological approach of improving plant salt tolerance using antioxidants as markers. Biotechnology Advances, 27(1): 84-93. DOI:10.1016/j.biotechadv.2008.09.003 |

Badshah A, Ahmad Aurangzeb M, Bibi N, et al. 1988. Relationship between physicochemical characters and cooking time in chickpeas (Cicer arietinum L.). Pakistan Journal of Scientific & Industrial Research, 30: 795-798. |

Banu M, Prasad N. 2013. Stability of peanut (Arachis hypogaea) oil with TBHQ (antioxidant tertiary butyl hydroquinone) by ultrasonic studies. Kasetsart Journal:Nature Science, 47(2): 285-294. |

Bettina C, Lothar W K. 2009. Shelf life of linseeds and peanuts in relation to roasting. LWT-Food Science and Technology, 42(2): 545-549. DOI:10.1016/j.lwt.2008.08.003 |

Boonlam S, Kanjanasopa D, Pimpa B. . 2009. Effect of addition of antioxidants on the oxidative stability of refined bleached and deodorized palm olein. Kasetsart Journal:Nature Science, 43(2): 370-377. |

Chen B Q, Cui X Y, Zhao X, et al. 2006. Antioxidative and acute antiinflammatory effects of Torreya grandis. Fitoterapia, 77(4): 262-267. DOI:10.1016/j.fitote.2006.03.019 |

Chun J Y, Lee J S, Eitenmiller R R. 2005. Vitamin E and oxidative stability during storage of raw and dry roasted peanuts packaged under air and vacuum. Journal of Food Science, 70(4): 292-297. |

Dong D D, Wang H F, Xu F, et al. 2014. Supercritical carbon dioxide extraction, fatty acid composition, oxidative stability, and antioxidant effect of Torreya grandis seed oil. Journal of the American Oil Chemists' Society, 91(5): 817-825. DOI:10.1007/s11746-014-2419-0 |

Dudonne S, Vitrac X, Coutiere P, et al. 2009. Comparative study of antioxidant properties and total phenolic content of 30 plant extracts of industrial interest using DPPH, ABTS, FRAP, SOD and ORAC assays. Journal of Agricultural and Food Chemistry, 57(5): 1768-1774. DOI:10.1021/jf803011r |

Endo Y, Osada Y, Kimura F, et al. 2006. Effects of Japanese torreya (Torreya nucifera) seed oil on lipid metabolism in rats. Nutrition, 22(5): 553-558. DOI:10.1016/j.nut.2005.08.012 |

Giordano E, Visioli F. 2014. Long-chain omega 3 fatty acids:molecular bases of potential antioxidant actions. Prostaglandins, Leukotrienes & Essential Fatty Acids, 90(1): 1-4. |

Han H, Baik B K. 2008. Antioxidant activity and phenolic content of lentils (Lens culinaris), chickpeas (Cicer arietinum L.), peas (Pisum sativum L.) and soybeans (Glycine max), and their quantitative changes during processing. International Journal of Food Science and Technology, 43(11): 1971-1978. DOI:10.1111/ifs.2008.43.issue-11 |

He Z Y, Zhu H D, Li W L, et al. 2016. Chemical components of cold pressed kernel oils from different Torreya grandis cultivars. Food Chemistry, 209: 196-202. DOI:10.1016/j.foodchem.2016.04.053 |

Inocent G, Adelaide D M, Giséle E L, et al. 2011. Impact of three cooking methods (steaming, roasting on charcoal and frying) on the β-carotene and vitamin C contents of plantain and sweet potato. American Journal of Food Technology, 6(11): 994-1001. DOI:10.3923/ajft.2011.994.1001 |

Jung M J, Heo S, Wang M H. 2008. Free radical scavenging and total phenolic contents from methanolic extracts of Ulmus davidiana. Food Chemistry, 108(2): 482-487. DOI:10.1016/j.foodchem.2007.10.081 |

Larrauri J A, Sánchezmoreno A, Sauracalixto F. 1998. Effect of temperature on the free radical scavenging capacity of extracts from red and white grape pomace peels. Journal of Agricultural and Food Chemistry, 46(7): 2694-2697. DOI:10.1021/jf980017p |

Mandhania S, Mandan S, Sawhney V. 2006. Antioxidant defense mechanism under salt stress in wheat seedlings. Biologia Plantarum, 50(2): 227-231. DOI:10.1007/s10535-006-0011-7 |

Prasad N, Siddaramaiah B, Banu M. 2015. Effect of antioxidant tertiary butyl hydroquinone on the thermal and oxidative stability of sesame oil (Sesamum indicum) by ultrasonic studies. Journal of Food Science and Technology, 52(4): 2238-2246. DOI:10.1007/s13197-014-1276-z |

Ramaprasad T R, Baskaran V, Krishnakantha T P, et al. 2005. Modulation of antioxidant enzyme activities, platelet aggregation and serum prostaglandins in rats fed spray-dried milk containing n-3 fatty acid. Molecular and Cellular Biochemistry, 280(1/2): 19-26. |

Ryan L A M, Bello F D, Arendt E K. 2008. The use of sourdough fermented by antifungal LAB to reduce the amount of calcium propionate in bread. International Journal of Food Microbiology, 125(3): 274-278. DOI:10.1016/j.ijfoodmicro.2008.04.013 |

Saeed M K, Deng Y, Parveen Z, et al. 2007. Studies on the chemical constituents of Torreya grandis fort. ex lindl. Journal of Applied Sciences, 7(2): 269-273. DOI:10.3923/jas.2007.269.273 |

Schlörmann W, Birringer M, Böhm V, et al. 2015. Influence of roasting conditions on health-related compounds in different nuts. Food Chemistry, 180: 77-85. DOI:10.1016/j.foodchem.2015.02.017 |

Segev A, Badani H, Galili L, et al. 2012. Effects of baking, roasting and frying on total polyphenols and antioxidant activity in colored chickpea seeds. Food & Nutrition Science, 3(3): 369-376. |

Shi H, Wang H, Wang M, et al. 2009. Antioxidant activity and chemical composition of Torreya grandis cv. merrillii seed. Natural Product Communications, 4(4): 1565-1570. |

Shintani R, Fu G C. 2002. Highly enantioselective desymmetrization of anhydrides by carbon nucleophiles:reactions of grignard reagents in the presence of (-)-sparteine. Angewandte Cheminform:International Edition, 41(6): 1057-1059. DOI:10.1002/1521-3773(20020315)41:6<>1.0.CO;2-R |

Silva M P, Martinez M J, Casini C, et al. 2010. Tocopherol content, peroxide value and sensory attributes in roasted peanuts during storage. International Journal of Food Science and Technology, 45(7): 1499-1504. DOI:10.1111/ifs.2010.45.issue-7 |

Thammapat P, Meeso N, Siriamornpun S. 2015. Effects of NaCl and soaking temperature on the phenolic compounds, α-tocopherol, γ-oryzanol and fatty acids of glutinous rice. Food Chemistry, 175: 218-224. DOI:10.1016/j.foodchem.2014.11.146 |

Warner K, Dunlap C. 2006. Effects of expeller-pressed/physically refined soybean oil on frying oil stability and flavor of french-fried potatoes. Journal of the American Oil Chemists' Society, 83(5): 435-441. DOI:10.1007/s11746-006-1223-x |

Wong M L, Timms R E, Goh E M. 1988. Colorimetric determination of total tocopherols in palm oil, olein and stearin. Journal of the American Oil Chemists' Society, 65(2): 258-261. DOI:10.1007/BF02636412 |

Xu B J, Chang S K C. 2008. Effect of soaking, boiling, and steaming on total phenolic content and antioxidant activities of cool season food legumes. Food Chemistry, 110(1): 1-13. DOI:10.1016/j.foodchem.2008.01.045 |

Xu C, Zhang Y, Cao L, et al. 2010. Phenolic compounds and antioxidant properties of different grape cultivars grown in china. Food Chemistry, 119(4): 1557-1565. DOI:10.1016/j.foodchem.2009.09.042 |

Yang J, Zhou F, Xiong L, et al. 2015. Comparison of phenolic compounds, tocopherols, phytosterols and antioxidant potential in Zhejiang pecan[Carya cathayensis] at different stir-frying steps. LWT-Food Science and Technology, 62(1): 541-548. DOI:10.1016/j.lwt.2014.09.049 |

Yasin M, Asghar A, Anjum F M, et al. 2012. Oxidative stability enhancement of broiler bird meats with α-lipoic acid and α-tocopherol acetate supplemented feed. Food Chemistry, 131(3): 768-773. DOI:10.1016/j.foodchem.2011.09.031 |

Yuan Y V, Bone D E, Carrington M F. 2005. Antioxidant activity of dulse (Palmaria palmata) extract evaluated in vitro. Food Chemistry, 91(3): 484-494. |

2018, Vol. 54

2018, Vol. 54