文章信息

- 谢力生, 刘佳权, 乔鹭婷, 李贤军, 周先雁

- Xie Lisheng, Liu Jiaquan, Qiao Luting, Li Xianjun, Zhou Xianyan

- 结构用集成材落叶松层板指接工艺

- Finger-Jointing Technique of Larch Structural Glued Laminated Timber

- 林业科学, 2016, 52(9): 107-112

- Scientia Silvae Sinicae, 2016, 52(9): 107-112.

- DOI: 10.11707/j.1001-7488.20160913

-

文章历史

- 收稿日期:2015-07-31

- 修回日期:2015-10-13

-

作者相关文章

结构用集成材也称结构用胶合木、层板胶合木或胶合木(GB/T 26899—2011; GB/T 50708—2012)。《胶合木结构技术规范》(GB/T 50708—2012)和《木结构设计规范》(GB/T 50005—2003)都规定:制作胶合木构件的木板接长应采用指接,其指接边坡度η不宜大于1/10,指长不应小于15 mm(GB/T 50708—2012)和20 mm(GB/T 50005—2003); 但都没有对指榫嵌合度(指榫齿顶宽-指榫槽底宽)和指榫胶接时的端向压力等进行规定。层板指接胶合性能对结构用集成材的力学性能具有重要影响(Francois et al.,1993),其影响因素主要有层板的材质、含水率、指榫的齿型与尺寸、指榫嵌合度和指接压力等(Ayarkwa et al.,2000)。国内外不少学者对其进行了研究(Ozcifci et al.,2008; 何盛等,2012),主要针对指接压力的确定(Hideo et al.,1986)及其对指接质量的影响(刘进等,2013)和指接工艺参数对力学性能的影响(黄仲华等,2012;李海栋等,2014;Marra,1992;Bustos et al.,2003)等,而综合考虑对于某树种的层板应采用的指接工艺(包括应采用的铣刀型号、嵌合度和指接压力等)的研究还未见报道。为此,笔者以兴安落叶松(Larix gmelinii)层板为对象,以目前国内最常使用的5种胶合木指榫铣刀片分别加工不同嵌合度的榫齿,研究榫型参数、嵌合度和指接压力对榫齿胶接性能的影响及较佳的指接工艺。该研究对其他树种层板的指接工艺研究具有参考价值。

1 材料与方法 1.1 试验材料兴安落叶松板材:含水率为16%,密度约为0.55 g·cm-3,宽×厚×长为150 mm×35 mm×4 020 mm,年轮宽度为0.5~2 mm,树龄为60~80年。

双组分聚氨酯:南京某胶黏剂公司生产,型号为SR-100,主剂固体含量为58%,黏度100 mPa·s(25℃),pH 7.0; 交联剂固含量99%,黏度2 mPa·s(25℃); 配胶时主剂:交联剂=100:(15~20)。

1.2 仪器设备木工圆锯机、木工刨床、电子天平等。

梳齿榫开榫机,型号MH1540,佛山吉祥木工机械厂生产;10 t万能力学试验机,型号E43.104,美特斯工业系统(中国)有限公司(MTS)生产; 30 t电液伺服万能力学试验机,型号SHT 4305-W,MTS公司生产; 指榫加工用铣刀片由河北石家庄先锋工具有限公司制造,型号规格如表 1所示。

|

|

选择无节落叶松锯材,通过圆锯机和刨床加工成长×宽×厚为200 mm×65 mm×30 mm的木板。采用指榫铣刀片在梳齿榫开榫机上将木板的一端加工成具有一定嵌合度(指榫齿顶宽-指榫槽底宽)的垂直型指榫(层板正面可见到指榫形状,各种榫型和嵌合度时的齿形参数见表 2),然后将两指榫对接并在力学试验机上加压至齿顶和槽底紧密接触,读取其压力,各种榫型和嵌合度的试件各10对,取压力的平均值作为指榫胶接时的端向压力。

选择无节落叶松锯材,通过圆锯机和刨床加工成长×宽×厚为 400 mm×65 mm×25 mm的木板。用指榫铣刀片在梳齿榫开榫机上将木板的一端加工成具有一定嵌合度的垂直型指榫(齿形参数值见表 2),对指榫进行手工涂胶(双面施胶,施胶量为180 g·m-2),根据前述测试得到的指接压力对各种榫型和嵌合度的开榫木板进行对接加压胶合,试件放置24 h后按照GB/T 26899—2011《结构用集成材》中5.3.3抗弯试验方法C和5.4抗拉强度试验测试指接部位的弹性模量、静曲强度和抗拉强度。各种榫型和嵌合度的试件各10个,一半用于测试静曲强度和弹性模量,另一半用于测试抗拉强度,其值取平均值。

根据测试所得数据,考察榫型、嵌合度、指接压力与指接力学性能的关系,探讨落叶松的最佳指接工艺。

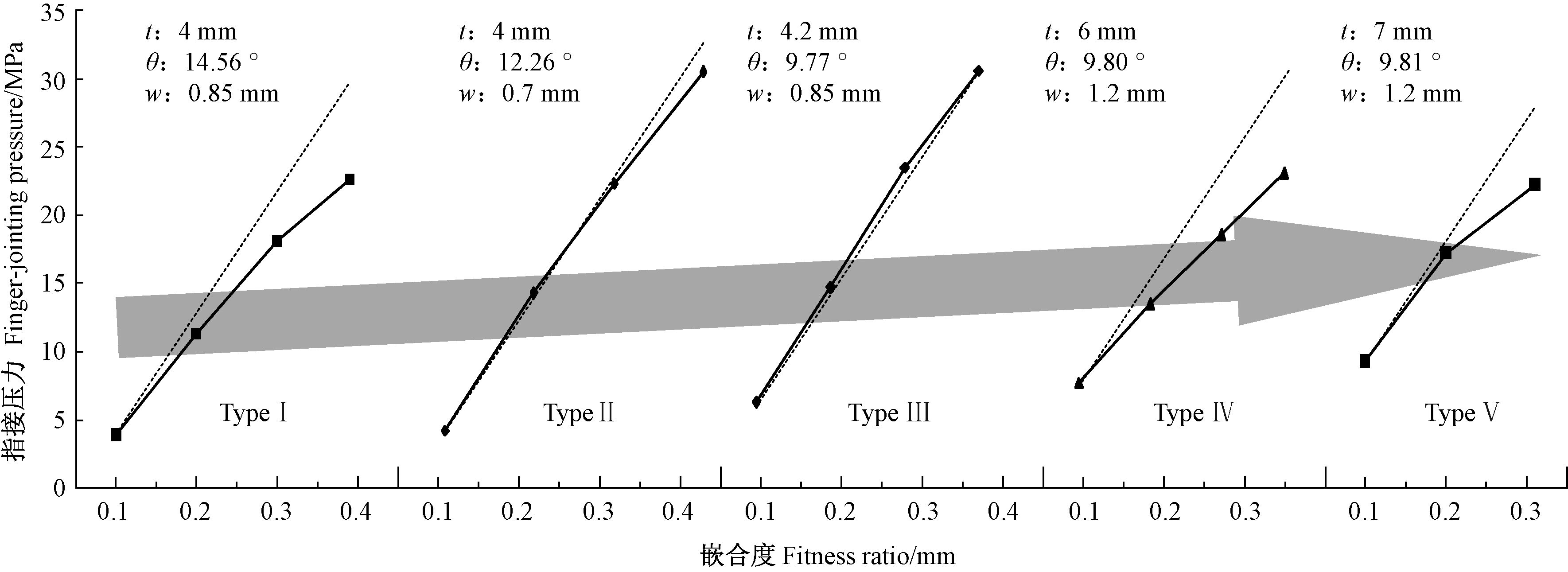

2 结果与分析 2.1 指接压力与榫型和嵌合度的关系各种指榫齿型和嵌合度下的指接压力测试值如表 2和图 1所示。图中箭头表示在相同嵌合度条件下榫型Ⅰ至榫型Ⅴ所需指接压力的趋势。

|

|

|

图 1 落叶松指榫接合嵌合度与指接压力的关系 Fig.1 The curve between finger-joint tenon fitness ratio and finger-jointing pressure of larch |

由表 2和图 1可知,指接压力受嵌合度的影响十分显著,随嵌合度的增大而显著增大,但各榫型下嵌合度与指接压力的关系不尽相同,同时受榫齿长、榫齿角、齿距和槽底宽等影响。

图 1中为比较各榫型下嵌合度与指接压力的关系,以榫型Ⅲ为基准各作了一条平行的斜虚线。比较榫型Ⅰ和榫型Ⅲ可以看出,榫齿角较小时嵌合度对指接压力的影响更加显著; 比较榫型Ⅳ和榫型Ⅴ可以看出,指接压力随榫齿长度(由表 2可知榫型Ⅴ的齿长比榫型Ⅳ约长6 mm)的增加而增大。

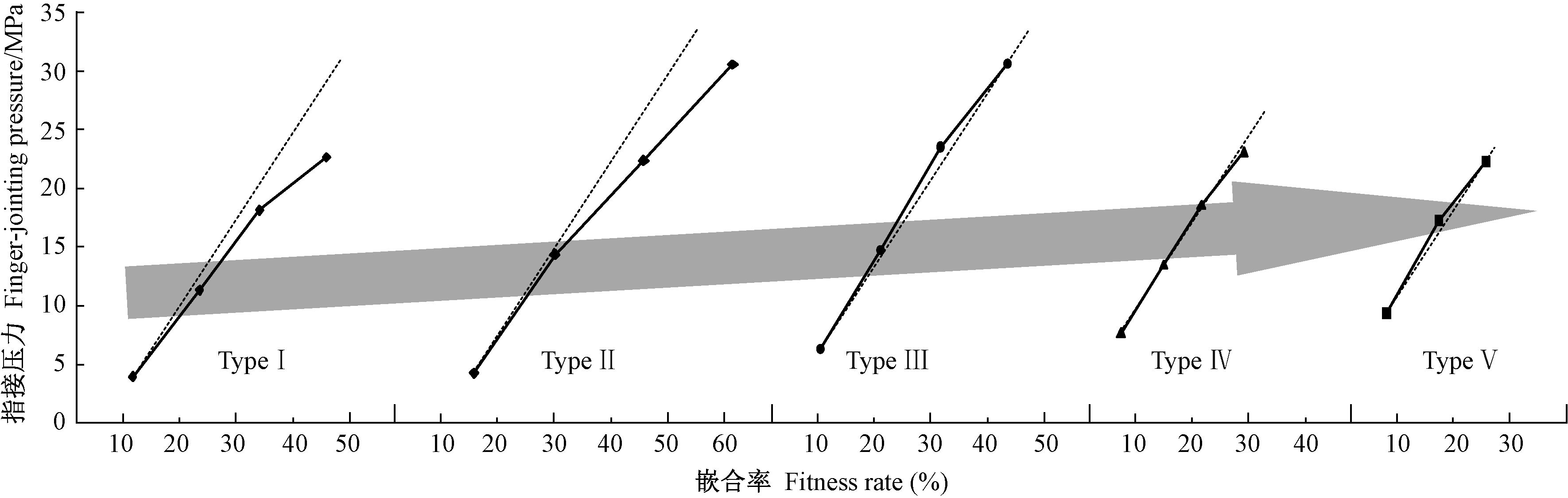

嵌合度相同时,槽底宽不同则指榫受挤压的程度不同,槽底宽越大指榫受挤压的程度越小,所需要的指接压力越小。为了消除槽底宽和嵌合度的交互影响,引入“相对嵌合度”即“嵌合率”的概念,定义嵌合率为单位槽底宽度的嵌合度,用百分数表示。各榫型在各嵌合度下的嵌合率经过计算已在表 2中给出。根据表 2中嵌合率和指接压力测试值的平均值,各种指榫齿型的嵌合率与指接压力的关系如图 2所示。图中斜虚线为以榫型Ⅲ为基准作的一组平行线,以便比较各榫型曲线的斜率; 灰色箭头表示在相同嵌合率条件下榫型Ⅰ至榫型Ⅴ所需指接压力的趋势。

|

图 2 落叶松指榫接合嵌合率与指接压力的关系 Fig.2 The curve between finger-joint tenon fitness rate and finger-jointing pressure of larch |

由图 2可知,指接压力与嵌合率基本呈正比,其斜率(变化速度)与榫齿角相关。当榫齿角不变时(比较榫型Ⅲ、Ⅳ和Ⅴ,榫齿角均约为9.8°),指接压力随嵌合率的变化速率不变; 榫齿角增大时(比较榫型Ⅲ、Ⅱ和Ⅰ,榫齿角从9.77°增大至14.56°),指接压力随嵌合率的变化速率减小。

2.2 嵌合度、指接压力与指接力学性能的关系各种指榫齿型和嵌合度下的指接力学性能测试值如表 3和图 3所示。

|

|

|

图 3 落叶松指榫接合嵌合度和指接压力与指榫力学性能的关系 Fig.3 The relationship between finger-jointing fitness ratio,pressure and mechanical properties |

由表 3和图 3可知,各种榫型下嵌合度对指接力学性能(抗拉强度、静曲强度和弹性模量)的影响有很大差别,但仔细比较各榫型嵌合度下的指接压力与抗拉强度、静曲强度和弹性模量的关系可以发现,当指接压力在8~15 MPa时各榫型都有较大的力学强度,且该值随榫齿长度的增加(由表 3可知,榫型Ⅰ至榫型Ⅴ其榫齿最大长度由9 mm逐渐增加至27 mm)而基本上呈比例地增大(如图中灰色剪头所示)。再比较指接压力在8~15 MPa时各榫型下的嵌合度可以看出,随着榫齿长度的增加(由榫型Ⅰ至榫型Ⅴ),相同指接压力的嵌合度减小,指接压力8~15 MPa时榫型Ⅰ至榫型Ⅴ的嵌合度从0.2 mm左右减小到0.1 mm左右。即各榫型产生最大力学强度的嵌合度各不相同,随榫齿长度的增加而减小,榫长9 mm的榫型Ⅰ产生最大力学强度的嵌合度为0.2 mm左右,而榫长27 mm的榫型Ⅴ产生最大力学强度的嵌合度为0.1 mm左右。

由图 3可知,当指接压力大于8~15 MPa时,指接力学性能呈下降趋势。这是由于当指接压力太大时,指接榫齿之间挤压力太大,胶黏剂被过多地挤出而难以形成有效的胶层,从而导致指接力学强度下降。理论上讲,当嵌合度为0时,指接压力应该为0,由于没有压力其胶合强度也应该很低;或者说,当指接压力太小时,指接榫齿之间由于没有足够的胶合压力,不能形成良好的胶合界面,因而指接力学强度会降低。这一点在榫型Ⅰ,Ⅱ和Ⅲ中已得到验证。对于榫型Ⅳ和Ⅴ也应该如此,即当嵌合度为0或很小时,因指接压力太小而影响指接力学强度。因此,为保证良好的指接力学性能,指接压力不能太小也不能过大。

GB/T 26899—2011《结构用集成材》4.2.6.2机械分等层板力学性能要求规定,最高等级ME18的抗弯和抗拉强度的平均值为72 MPa和42.5 MPa。由表 3和图 3可知,除榫型Ⅰ不能满足要求外,其余榫型均能满足要求。从安全和经济2方面综合考虑,采用榫型Ⅲ或榫型Ⅳ为佳,所对应的齿长为15~20 mm、榫齿角9.8°。因此,兴安落叶松的较佳指接工艺可以确定为:榫型Ⅲ或榫型Ⅳ(榫齿角9.8°、榫齿长15~20 mm、齿槽底宽0.8~1.2 mm)、指接压力10~15 MPa、嵌合度0.12~0.20 mm(榫齿较长时嵌合度取较小值)。

3 结论通过对兴安落叶松层板垂直型指榫胶接试验研究,探明了指榫胶接所需端向压力(指接压力)与榫型参数和嵌合度(或嵌合率)的关系,也明确了榫型、嵌合度、指接压力对指榫胶接力学性能的影响规律,获得了较佳的指榫胶接工艺。结论如下:

1) 指榫胶接所需指接压力随嵌合度的增大而显著增大,且榫齿角和槽底宽度较小时更加显著; 指接压力随榫齿长度的增加而增大; 指接压力与嵌合率基本上呈正比,其斜率随榫齿角的增大而减小。

2) 各榫型的指接强度随榫齿长度的增加而增大;指接压力过小或过大其指接强度均下降,指接压力在8~15 MPa时各榫型都呈现较大的力学强度。

3) 短齿榫型产生最大指接强度的嵌合度比长齿榫型的大,榫长9 mm和27 mm的榫型产生最大指接强度的嵌合度分别约为0.2 mm和0.1 mm。

4) 从安全和经济2方面综合考虑,兴安落叶松的较佳指接工艺为:榫齿角9.8°、榫齿长15~20 mm、齿槽底宽0.8~1.2 mm、指接压力10 ~15 MPa、嵌合度0.12~0.20 mm(榫齿较长时嵌合度取较小值)。

| [1] |

GB/T 26899-2011.2011.结构用集成材.北京:中国标准出版社,1-3. ( GB/T 26899-2011.2011.Structural glued laminated timber.Beijing:China Standard Press,1-3.[in Chinese][in Chinese]) |

| [2] |

GB/T 50708-2012.2012.胶合木结构技术规范.北京:中国建筑工业出版社,2-65. ( GB/T 50708-2012.2012.Technical code of glued laminated timber structures.Beijing:China Building Industry Press,2-65.[in Chinese][in Chinese]) |

| [3] |

GB/T 50005-2003.2006.木结构设计规范(2005年版).北京:中国建筑工业出版社,50-51. ( GB/T 50005-2003.2006.Code for design of timber structures (2005).Beijing:China Building Industry Press,50-51.[in Chinese][in Chinese]) |

| [4] |

何盛, 林兰英, 傅峰, 等. 2012. 樟子松指接材抗弯强度有限元模拟分析. 林业科学 , 48 (11) : 63–68.

( He S, Lin L Y, Fu F, et al.2012. Finite element analysis of bending strength for Pinus sylvestris var. mongolica finger-jointed lumber.Scientia Silvae Sinicae , 48 (11) : 63–68. [in Chinese] ) (  0) 0)

|

| [5] |

黄仲华, 王朝晖, 李海栋. 2012. 结构用落叶松材指接工艺试验研究. 木材加工机械 , 13 (2) : 21–25.

( Huang Z H, Wang Z H, Li H D.2012. Research of manufacture process for Larix gmelinii finger-joint structural timber. Wood Processing Machinery , 13 (2) : 21–25. [in Chinese] ) (  0) 0)

|

| [6] |

李海栋, 王朝晖, 黄仲华, 等. 2012. 落叶松结构用胶合木层板指接工艺参数对力学性能的影响. 林产工业 , 41 (1) : 13–18.

( Li H D, Wang Z H, Huang Z H, et al.2012. Effects of finger-jointing parameters on mechanical properties of dahurian larch laminate for structural glulam. China Forest Products Industry , 41 (1) : 13–18. [in Chinese] ) (  0) 0)

|

| [7] |

刘进, 罗海, 王乃雯, 等. 2013. 不同端压下杨木指接质量的分析. 南京林业大学学报:自然科学版 , 37 (3) : 92–96.

( Liu J, Luo H, Wang N W, et al.2013. Effects of end pressures on the finger-joint quality of poplar wood. Journal of Nanjing Forestry University:Natural Science Edition , 37 (3) : 92–96. [in Chinese] ) (  0) 0)

|

| [8] |

Ayarkwa J, Hirashima Y, Sasaki Y.2000. Effect of finger geometry and end pressure on the flexural properties of finger jointed tropical African hardwoods. Forest Prod J , 50 (11/12) : 53–63.

( 0) 0)

|

| [9] |

Bustos C, Mohammad M, Hernandez R E, et al.2003. Effects of curing time and end-pressure on the tensile strength of finger-jointed black spruce lumber. Forest Product Journal , 53 (12) : 85–89.

( 0) 0)

|

| [10] |

Francois C, Robert H F.1993. Investigation of laminating effects in glued-laminated timber. Products Laboratory (8) : 1–13.

( 0) 0)

|

| [11] |

Hideo H, Kurata Y.1986. Properties of finger-jointed lumber. Report of Forest Product Research (75) : 45–47.

( 0) 0)

|

| [12] | Marra A A. 1992. Technology of wood bonding:principles in practice. New York: Van Nostrand Reinhold Co : 3 -45. |

| [13] |

Ozcifci A, Yapici F.2008. Structural performance of the finger-jointed strength of some wood species with different joint configurations. Constr Build Mater , 22 (7) : 1543–1550.

DOI:10.1016/j.conbuildmat.2007.03.020 ( 0) 0)

|

2016, Vol. 52

2016, Vol. 52