文章信息

- 张绍群, 花军, 许威, 陈光伟, 刘阳君, 宋炜, 颜家雄

- Zhang Shaoqun, Hua Jun, Xu Wei, Chen Guangwei, Liu Yangjun, Song Wei, Yan Jiaxiong

- 木材抗剪强度与分形维数的关系及断口特征

- Fracture Features and the Relationship between Wood Shear Strength and Fractal Dimension

- 林业科学, 2015, 33(6): 127-134

- Scientia Silvae Sinicae, 2015, 33(6): 127-134.

- DOI: 10.11707/j.1001-7488.20150615

-

文章历史

- 收稿日期:2014-06-27

- 修回日期:2014-12-29

-

作者相关文章

在纤维板生产中,热磨机的电耗一般占总电耗的40%~50%,热耗占总热耗的20%~30%(庞庆海,1998),直接影响企业的生产成本与利润。热磨时,木片原料在热磨机中受到连续的机械外力,在与磨片磨齿或木片间的相互作用下发生冲击、剪切、挤压,使木片断裂,并最终被研磨解离成木纤维。这是一个极其复杂的过程,其制备的纤维质量对成品板材的物理力学性能,如板材的抗弯强度、抗拉强度等具有重要影响(关鑫,2012;Schirp et al., 2014)。因此,研究木材剪切断口的形态和分形特征及断裂时所需的力和关联因素,分析解离纤维过程能耗的变化,从而优化纤维分离设备结构的设计,使纤维板生产能耗降低、提高纤维质量,是纤维板和造纸设备生产企业急待解决的前沿性、基础性课题之一(Robertson et al..,1999)。木材是一种多孔层状生物复合材料,各项异性,其断口比金属更复杂,这使得很难定量形容木材断裂面以及断裂机制(Wu et al., 2012)。因此,科研人员把分形理论引入了木材科学领域(Mandelbrot, 1984;林鸿溢,1994;高峻等,2004;罗蓓,2010),对木材密度曲线、木材干缩的分形及木材断口的分形开展研究(江泽慧等,2000;费本华,2002;费本华等,2006),并应用CT技术研究木材断口的形态(费本华等,2007)。

近几年,又对木材抗剪切、冲击强度及其相关的计算和试验方法进行了研究(Li et al., 2013;Fakoor et al., 2013),同时,也探讨了木材抗剪切、冲击强度等与分形维数等的关系(Liang et al., 2014;Shida et al., 2010;Konas et al., 2009),用分形维数描述断裂(Zhang et al., 2012;孙建平等,2013)。但综上研究尚未形成较系统的理论。本文对木材抗剪强度与分形维数的关系及其断口形貌特征进行研究,旨在为定量形容木材断裂面和断裂机制提供依据,丰富木材断裂特征和抗剪强度的相关理论。

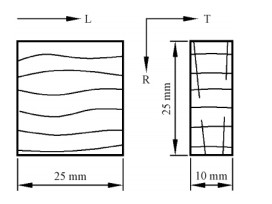

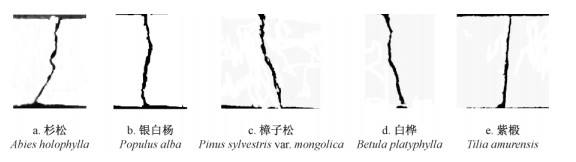

1 试件制备及试验条件与方法 1.1 木材剪切试件的制作以生长在黑龙江省35年生的杉松(Abies holophylla)、银白杨(Populus alba)、樟子松(Pinus sylvestris var.mongolica)、白桦(Betula platyphylla)和紫椴(Tilia amurensis)为试验树种,每个树种选取10个试件,其基本物理参数见表 1。纤维板生产中,热磨机系统要求木片的长度和宽度在20~30 mm,厚度5 mm左右(方普新,2013),《造纸木片》(GB/T 7909—1999)要求合格木片的长度为15~30 mm,宽度为3~5 mm。根据上述要求,按照《木材物理力学试材锯解及试样截取方法》(GB/T 1929—2009)、《木材顺纹抗剪强度试验方法》(GB/T 1937—2009)的规定,制作剪切试件如图 1所示。为了便于对比分析试件抗剪强度等,剪切试件横向(T向)、纵向(L向)截面的尺寸均为10 mm×25 mm。

|

|

|

图 1 剪切试件尺寸示意 Fig. 1 Schematic of shear specimen size |

本试验的主要目的是为了获得试件未软化和经过软化后受剪切断裂的力及其断口的剖面轮廓线,从而计算试件受剪强度和断口的分形维数。试件软化采用水热软化处理方法,将试件浸入装有水的YC3A-100压力锅中,在80 KPa下保压30 min。考虑试件纵向剪切的抗剪强度大于其横向抗剪强度,故没有做试件纵向剪切试验;但是,为了搞清木材经软化后纵向抗剪强度与其他剪切情况的关系,做了各试件软化后纵向剪切试验。因此,试验分横向剪切、软化后的横向和纵向剪切3种情况。

1.2.2 试验方法木材剪切试验的试件尺寸远小于万能材料力学试验机所要求的标准试件的尺寸规格,且万能材料力学试验机测量精度也不适合本试验,因此,本研究设计了一台操作简单、测试精度高的木材剪切力学试验台(图 2)进行剪切试验,其剪切速度为0.41 m·s-1.测量工作原理是:首先,将试件放入试件固定装置的钳口内固定,并移动试件固定装置,使其右侧与信号采集装置的拉压力传感器靠紧;然后通过载荷加载装置的气缸加载,其上的加载头与试件固定装置的钳口形成剪切,至试件断裂;信号采集装置的拉压力传感器记载了整个加载过程中剪切力的时域波形,并存储在计算机中,以便读取剪切力.

|

图 2 木材剪切力学试验台 Fig. 2 Wood shear mechanical test bench |

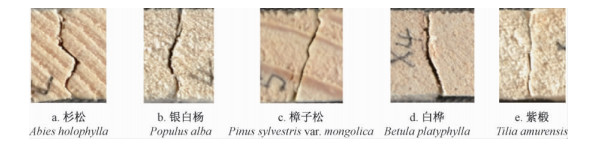

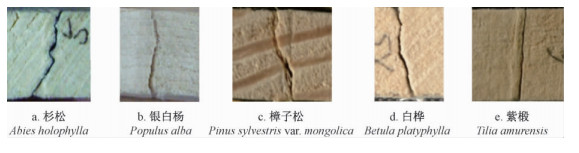

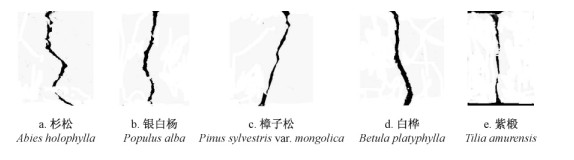

在木材剪切力学试验台上,测得各树种试件相应的剪切力,从被剪断裂的试件中找出最能反映试件断口剖面轮廓线形貌的试件,对断口进行拍照,得到各树种试件横向剪切、软化后横向和纵向剪切试件断口剖面轮廓线图像,如图 3~5所示.

|

图 3 横向剪切试件断口剖面轮廓线图像 Fig. 3 Fracture cross-sectional contour image of transverse sheared of specimen |

|

图 4 软化后横向剪切试件断口剖面轮廓线图像 Fig. 4 Cross-sectional contour image of transverse sheared fracture of specimen after softening |

|

图 5 软化后纵向剪切试件断口剖面轮廓线图像 Fig. 5 Cross-sectional contour image of longitudinal sheared fracture of specimen after softening |

1)横向剪切试件时,各树种试件沿剪切方向大多数呈曲线断裂(图 3b),在顺纤维方向基本沿直线断裂; 针叶材断裂沿剪切方向,以弯曲较大的曲线断裂,断裂面高低不平; 阔叶材断裂一般沿剪切方向,以弯曲不大、稍平直的曲线断裂,断裂表面相对平滑一点。

2)软化后横向剪切试件时,各树种试件沿剪切方向大多数呈曲线断裂(图 4b),在顺纤维方向基本沿直线断裂;针叶材断裂一般沿剪切方向,以弯曲不大的曲线断裂(图 4c),断裂面沿剪切方向高低不平;阔叶材断裂一般沿剪切方向,以弯曲稍大的曲线断裂(图 4d),断裂面沿剪切方向高低不平,个别伴有撕裂痕迹.

3)软化后纵向剪切试件时,各树种试件沿剪切方向基本呈直线断裂,在横向以弯曲较小的曲线或倾斜的接近直线的方式断裂(图 5b,e);针叶材、阔叶材的断裂特征差异不明显,杉松、紫椴断裂面相对较平,银白杨、樟子松、白桦断裂面高低不平。

从各树种试件的断裂方向和形态看:软化后和未软化横向剪切试件时,各树种试件沿剪切方向大多数呈曲线断裂,在顺纤维方向基本沿直线断裂; 软化后纵向剪切试件时,沿着剪切方向,各树种试件基本呈直线断裂,在横向以弯曲较小的曲线或倾斜的接近直线的方式断裂。

3 剪切断口分形曲线分析及分形维数计算 3.1 剪切断口分形曲线的获得采用Photoshop CS5软件对横向剪切、软化后横向和纵向剪切试件断口的剖面轮廓线图像进行灰度、除噪处理,得到3种剪切试验试件断口剖面轮廓线的分形曲线如图 6~8所示。

|

图 6 横向剪切试件断口剖面轮廓线的分形曲线 Fig. 6 Fractal curves of cross-sectional contour of transverse sheared fracture of specimen |

|

图 7 软化后横向剪切试件断口剖面轮廓线的分形曲线 Fig. 7 Fractal curves of cross-sectional contour of transverse sheared fracture of specimen after softening |

|

图 8 软化后纵向剪切试件断口剖面轮廓线分形曲线 Fig. 8 Fractal curves of cross-sectional contour of longitudinal sheared fracture of specimen after softening |

1)从图 6,7中的横向和软化后横向剪切试件的断口分形曲线可以看出:软化后试件的横向剪切断口分形曲线比未软化的试件横向剪切断口分形曲线略显复杂,而且分形曲线不是光滑曲线,而是呈细小的锯齿状或“Z字状”。

2)对比图 6,7,8剪切试件断口分形曲线可以看出:图 8所示的软化后试件纵向剪切断口的分形曲线没有软化前、后横向剪切断口分形曲线复杂,软化后试件纵向剪切断口分形曲线也是不光滑曲线,且呈细小的锯齿状或“Z字状”。

3)试件断口剖面轮廓线的分形曲线形状较复杂,分布具有随机性,其结构具有不规则的自相似性。

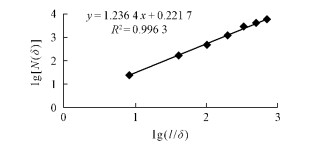

3.3 剪切断口分形维数的计算应用数盒子法(任宁等,2007; Sarker et al., 1992; Chaudhuri et al., 1995)计算试件剪切断口剖面轮廓线的分形维数。试件剪切断裂后,首先,仔细观察断口的剖面轮廓线和断裂表面,找出最能体现断裂表面形貌特征的剖面轮廓线并取样; 然后,用Photoshop CS5软件对所取样进行灰度处理,并利用Photoshop CS5软件的网格功能使网格覆盖整个曲线,调节网格线的间距并确定线元码尺δ,如图 9a所示;最后,通过增加网格中子网格的数量来改变线元码尺δi,如图 9b所示。由于含有曲线的格子的数量N(δ)随着码尺δ的变化而变化,从而得到一组变化的数据[δi,N(δi)]。分别对该组数据δi的倒数和N(δi)取对数,得到相应新数据[lg(1/δi),lg(N(δ ))],对新数据进行线性回归,可得回归图,如图 10所示为软化后纵向剪切桦木的线性回归图。图 10反映出,lg(N(δ))和lg(1/δ)之间存在非常明显的线性关系,拟合优度R2为0.996 3,这表明断口剖面轮廓线的整体与局部之间存在明显的相似性(相关性),即断口剖面轮廓线具有分形特征,线性回归方程的斜率1.236 4就是断口剖面轮廓线的分形维数DL。根据断口剖面轮廓线分形维数DL与断口表面分形维数DA之间的关系式(1)求出断口表面分形维数DA=2.147(季坤等,2009; 杨国伟,1998; Underwood,1994; 褚武扬等,2004):

|

图 9 试件断口剖面轮廓线的盒子覆盖法 Fig. 9 Box covering method for cross-sectional contour of longitudinal sheared fracture of specimen |

|

图 10 软化后纵向剪切桦木线性回归 Fig. 10 Longitudinal shear birch linear regression chart of Betula platyphylla after softening |

| $ {D_A} = \frac{{\ln \left[ {\frac{{\pi {\delta ^4}}}{{4\left( {{\delta ^{1 - {D_L}}} - 1} \right) + \pi }}} \right]}}{{2\ln \delta }}。 $ | (1) |

式中:δ为线元码尺; DL为试件断口剖面轮廓线分形维数,取值范围在1~2之间; DA为试件断口表面分形维数,取值范围在2~3之间。

用上述方法,分别求出各树种试件剪切断口表面分形维数,并取平均值列于表 2中。从表 2可以看出:

|

1)各树种试件横向剪切断口表面的分形维数在2.047~2.105之间,紫椴最大,白桦最小,二者相差0.058。分形维数量化了断口表面的不规则性和复杂程度,0.058从数量上表示了各树种横向剪切断口复杂程度的最大差异。 2)各树种试件软化后横向剪切断口表面的分形维数在2.081~2.133之间,樟子松最大,紫椴最小,二者相差0.052,表示了各树种软化后横向剪切断口复杂程度的最大差异,与横向剪切相比这种差异二者比较接近。 3)各树种试件软化后纵向剪切断口表面的分形维数在2.047~2.080之间,银白杨最大,白桦最小,二者相差0.033。由于剪切方向沿着纤维方向,细胞之间沿纤维方向滑移,断口表面相对简单,断口复杂程度的最大差异也相对较小。 4 抗剪强度与断口分形维数的关系 4.1 试验试件抗剪强度的计算抗剪强度是木材抵抗剪应力的最大能力,一般按GB/T 1937—2009中的抗剪强度公式计算。本研究中试验试件是非标准试件,考虑到试件受剪切力方向与受剪面平行,因此将GB/T 1937—2009抗剪强度计算公式修正为:

式中:τw为试件含水率为W%时的强度(MPa);Pmax为破坏载荷(N);b为试样受剪面宽度(mm);l为试样受剪面长度(mm)。 通过剪切试验获得试件的横、纵向剪切力,根据式(2)计算各树种试件的抗剪强度,并取平均值列于表 3中。

表 3 各树种试件的抗剪强度

Tab.3 Shear strength

for specimens of various species

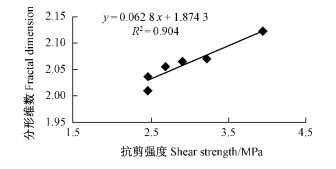

如图 11所示(方法、曲线形式一样,只列出银白杨),将各树种试件横向抗剪强度与其断口分形维数进行线性回归分析。结果反映:各树种试件的横向抗剪强度和其断口分形维数之间存在着正相关关系。银白杨的横向抗剪强度与其断口分形维数正相关性最为显著,其拟合优度为0.904; 紫椴正相关性也较为显著,其拟合优度为0.689; 而杉松、樟子松和白桦的正相关性稍差,显著性较为相近,拟合优度分别为0.438,0.469和0.464。

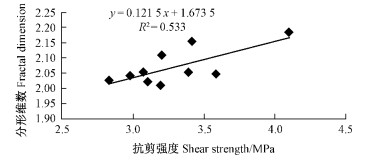

如图 12所示(方法、曲线形式一样,只列出紫椴),将各树种试件软化后纵向抗剪强度与其断口分形维数进行线性回归分析。结果反映:各树种试件软化后纵向抗剪强度与其断口分形维数之间存在着正相关关系,相关性并不显著。其中紫椴的相关性最显著,拟合优度为0.533;杉松、樟子松、银白杨、白桦的拟合优度分别为0.104,0.357,0.248和0.309。

1)横向和软化后横向剪切试件时,各树种试件沿剪切方向大多数呈曲线断裂,在顺纤维方向基本沿直线断裂; 软化后纵向剪切试件时,沿着剪切方向,各树种试件基本呈直线断裂,在横向以弯曲较小的曲线或倾斜的接近直线的方式断裂。 2)横向和软化后横向、纵向剪切试件断口的分形曲线总体上形状较复杂,都不是光滑曲线,而是呈细小的锯齿状或“Z字状”,分布具有随机性,其结构具有不规则的自相似性。软化后的横向剪切试件断口分形曲线比未软化的横向剪切试件断口分形曲线略显复杂; 软化后纵向剪切试件断口的分形曲线要比软化前、后横向剪切试件断口分形曲线简单一些。 3)各树种试件软化及未软化的横向和软化后纵向剪切断口表面的分形维数在2.047~2.133之间,樟子松软化后横向剪切断口表面的分形维数最大,白桦横向和其软化后纵向剪切断口表面的分形维数最小,二者相差0.086。各树种试件纵向抗剪强度与其断口分形维数之间存在正相关关系,但是相关性并不显著。 4)各树种试件,软化后横向抗剪强度最低,最易断裂; 其次是未软化的横向抗剪强度,软化后的纵向抗剪强度仍然大于未软化的横向抗剪强度许多,其最不易断裂。因此,在研磨解离木片时,应使原料软化,沿着横向剪切,这样消耗能量较小。试件的横向抗剪强度和其断口分形维数之间存在着正相关的关系。

参考文献(References)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2015, Vol. 33

2015, Vol. 33

1)

1)