文章信息

- 乔梦吉, 姜金英, 符韵林

- Qiao Mengji, Jiang Jinying, Fu Yunlin

- 木材剩余物缓释肥料壳体的构成因素对肥料释放规律的影响

- Influence of the Wood Residues Shell's Constitution on Releasing Rules of Fertilizer

- 林业科学, 2015, 51(10): 148-153

- Scientia Silvae Sinicae, 2015, 51(10): 148-153.

- DOI: 10.11707/j.1001-7488.20151019

-

文章历史

- 收稿日期:2014-11-04

- 修回日期:2014-12-07

-

作者相关文章

2. 江山欧派门业股份有限公司 江山 324122;

3. 广西高校林业科学与工程重点实验室 南宁 530004

2. Jiangshan Oupai Door Industry Co., Ltd Jiangshan 324122;

3. Key Laboratory of Forestry Science and Engineering in Guangxi Universities and Colleges Nanning 530004

我国是一个农业和林业大国,肥料在现代农林业领域生产中具有极其重要的作用。我国的土地面积占全球的7%,但肥料的消耗量却占世界的30%,单位面积肥料的使用量达世界的4倍(齐广成等,2008)。化肥利用率低是我国肥料使用上存在的主要问题,不仅造成了资源的大量浪费和经济的巨大损失,还大大增加了农民的负担,而且对环境也产生极大的影响。提高肥料的利用率,减少因肥料而造成的环境污染,是发展高效、可持续农林业中非常关注的课题。其中一种提高农林作物肥料利用率的有效途径是控制或减缓肥料的溶解及释放速率,因而缓释肥料的研究并广泛推广的任务迫在眉睫。缓释肥料是采用各种各样的调控机制来延缓肥料养分的最初释放,使植物对肥料的有效养分吸收及利用的有效期加长,最终使养分的释放速度能按照特定的释放速率和释放期来减缓或者控制释放的一种肥料(全国肥料和土壤调理剂标准化技术委员会,2007)。缓释肥料的使用是发展趋势,其开发与应用备受重视。当前缓释肥料的研究主要集中在肥料包膜材料的选择使用、养分释放机制和肥料评价方法等方面(冯守疆等,2010),其中研究出的很多包膜肥料虽然能达到比较理想的缓释或控释效果,但却存在着使用材料难降解的问题。为了减少包膜材料对环境的负面影响,国内外对各种环保型可降解的缓释肥料进行了大量研究(Hanafi et al.,2002;Khan et al.,2008;倪博立,2012)。木材具有大量孔隙,是一种多孔性材料,具有渗透性,通过胶黏剂能将木材剩余物制备成缓释肥料壳体,供林木、花卉等植物施肥使用,壳体装载肥料施入土壤后,在雨水作用下,溶解的肥料先通过木材的纹孔等固有孔隙通道、随后又通过胶黏剂降解产生的通道等渗出供给植物养分。肥料源源不断地渗出,既保证了作物在其生长过程中可以不断获取养分,又避免了一次施肥过多而导致烧苗的发生,同时也减少了肥料的流失和施肥次数,而且木材剩余物资源丰富,符合环保型要求,对环境没有负面影响。

缓释肥料对农林作物施肥作用时,其释放受很多因素影响,如膜的材料、包膜的厚度及孔隙度等。可用于制造缓释肥料壳体的包膜材料很多,有无机物材料,如硫磺(王红飞等,2005;Grigori et al.,1990);聚合物材料,如热固性树脂(陆建刚等,1994)、水性聚氨酯(秦裕波等,2008a;2008b)、天然聚合物(Tangboriboonrat et al.,1996);高分子材料,如聚砜和淀粉(Tomaszewska et al.,2002a;2002b;2004)、瓜尔胶、海藻酸钠(倪博立,2012)等。不同材料的特性不同,作为缓释肥料包膜材料时其释放速度也有差异。同样的包膜材料,膜的厚度会影响其释放快慢,如樊小林等(2005)研究了以水溶性树脂为包膜材料的控释肥的养分释放特性受膜厚度的影响,发现N的释放速度随着膜厚度的增加而减慢。另外,膜的紧实度也影响缓释肥料的释放速度,如黄培钊等(2006)研究了不同工艺制造的紧实度不同的缓释肥料,发现其N累积溶出率不同,紧密度越好,其养分累积溶出率越低。

采用木材剩余物制作缓释肥料壳体是一种新型的缓释肥料制作方法。符韵林等(2009;2010;2013)论述了用木材剩余物制作缓释肥料壳体的构想及其制造方法;但是构成壳体的木材剩余物类型、颗粒形状及壳体密度、厚度等因素对肥料释放速度的影响以及壳体生物降解(含木材剩余物的降解、胶黏剂的降解等)形成的路径对肥料释放速度的影响等问题尚不明确。为明确木材剩余物缓释肥料壳体的肥料释放规律,本文采用人工模拟降雨方法研究构成壳体的木材剩余物类型、壳体密度和厚度等因素对肥料释放规律的影响,为制造可根据植物生长需要调控肥料释放速度的木材剩余物缓释肥料壳体提供科学指导。

1 材料与方法 1.1 材料与仪器采用马尾松(Pinus massoniana)和香椿(Toona sinensis)木材剩余物(主要为木糠、木屑)为原料,晒干后进行筛分,用于试验的规格为14~28目和≥28目2种。采用市售的脲醛树脂为胶黏剂,磷酸二氢钾做肥料。热压机压制制造壳体的板材,采用火焰光度计分析K的含量与浓度。

1.2 试验方法1)壳体的制造方法采用二次成型方法制备壳体。将脲醛胶与木材剩余物以质量比为1∶6混合,搅拌均匀后铺装在热压机模板上,采用厚度规控制厚度,热压时间7 min,热压压力1.4~2.1 MPa,热压温度130 ℃。板冷却后锯切成小块,然后用热熔胶粘成6 cm×6 cm×6 cm的立方体壳体,如图 1所示。

|

图 1 香椿木壳体 Fig. 1 T. sinensis shell |

2)人工模拟降雨方法为克服自然降雨的随机性,采用人工模拟降雨方法研究壳体特性对肥料释放规律的影响。根据南宁市平均年降雨量为1 300 mm,考虑到实际树林里的林冠节流、表径节流等因素,将水量设置为每年1 300 mm×0.6=780 mm,然后以此为基准通过降雨的表面积大小将其换算成定期的降雨量,其计算值为780 mm/365 d×15 d/10×(3.14×15×15/4 cm2)=566 mL。为操作方便,将人工降雨量设置为每次600 mL,每15天人工降雨1次。

将装载200 g磷酸二氢钾的壳体置于装满石英砂的桶中,桶底部接入导流管,导流管下面连着接收瓶,通过滴水的方法进行降雨,所滴水分通过石英砂渗入壳体中。磷酸二氢钾遇水溶解以水溶液形式向外渗透,最后流入接收瓶中,试验装置如图 2所示。每次降雨2天后收集接收瓶(2天时已回收全部液体),测定溶液中K的浓度及含量。各试验参数及因素水平设置见表 1,其中编号1-6用于研究木材剩余物类型对肥料释放规律的影响,编号7-15用于研究壳体密度对肥料释放规律的影响,编号10-12和16-21用于研究壳体厚度对肥料释放规律的影响。编号28-30为空白对比试验,不外加壳体,直接将肥料置于石英砂内。

|

图 2 试验装置 Fig. 2 Test apparatus |

|

|

由KH2PO4的分子式可知,200 g的磷酸二氢钾约有57 400 mg的K元素。

3)K测定方法 参考国家标准GB 7856—87(中国林业科学研究院林业研究所,1997)测定K的浓度。因为水样的K浓度很高,远远超出火焰光度计的测量范围,所以过滤后的待测液在测量前要进行稀释,然后根据测得的值及稀释倍数换算出K的浓度。

K含量是指所取的水样测得的K浓度与体积乘积的量,通过对比K含量变化研究壳体肥料的释放规律。采用释放率表示壳体的缓释作用,释放率表示已释放出来的K的量占总量的百分比:

| $ 释放率=\frac{a}{b}\text{ }\!\!\times\!\!\text{ }100\text{ }\!\!%\!\!\text{ }\text{.} $ |

式中: a表示某时间点之前养分的总释放量;b表示装载于壳体内养分的总含量。

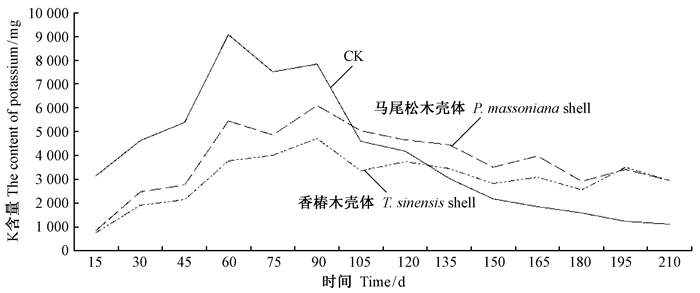

2 结果与分析 2.1 壳体的木材剩余物类型对肥料释放速度的影响木材剩余物类型对肥料释放速度的影响主要通过K的释放速度来表示,K释放速度随时间变化的规律如图 3所示。从图中可见,马尾松木及香椿木壳体的肥料释放量均呈先变大后趋于稳定或缓慢变小的趋势。木材作为一种多孔性材料,其孔隙提供了K的释放路径,前期由于木材剩余物壳体吸水后膨胀,孔隙变大,因此K的释放速度相应变快;而后期随着磷酸二氢钾总量逐渐减少,K的释放速度也相应减慢。在不同的降雨条件下,2种壳体均在90天时肥料K的释放速度达到最大值,释放率分别为39.20%和30.15%,然后逐渐变小,至210天时,释放率分别达93.01%和74.43%。从图 3还可以看出,马尾松木壳体的肥料释放速度比香椿木快,说明壳体肥料释放速度与构成壳体的木材剩余物类型有关。可能的原因有2点:首先马尾松木的密度略大于香椿木,因此由相同质量的木材剩余物压制壳体,马尾松木的组成颗粒数比香椿木少,导致压制的香椿木壳体比较密实,所以香椿木壳体内K的释放速度比马尾松木慢;其次,马尾松木和香椿木分别属于针叶材和阔叶材,2树种材性的不同也可能导致释放率的不同。空白试验中,肥料释放速度也呈现先变大后减小的变化规律,在60天时达最大值,90天时释放率达65.46%,210天时,K释放率已达99.93%,壳体中的肥料已基本被淋溶。此结果显示,木材剩余物缓释肥料壳体具有显著的缓释效果,且马尾松木壳体的肥料释放速度比香椿木快;而采用不外加壳体的直接施肥方法,其肥料约在7个月时完全淋溶。

|

图 3 木材剩余物类型对肥料释放速度的影响 Fig. 3 Variation of the potassium releasing rate with different wood residue types |

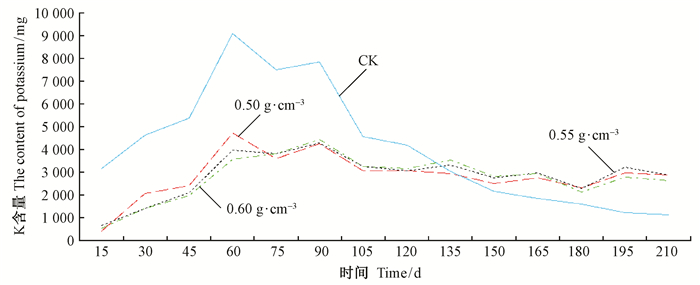

壳体密度对肥料释放速度的影响如图 4所示。从图中可见,3种不同密度的壳体中肥料释放量都呈先变大后趋于稳定或缓慢变小的趋势。在不同降雨条件下,基本在60~90天时肥料K的释放速度达到最大值,然后逐渐变小,在60天时,3种不同密度(0.50,0.55,0.60 g·cm-3)下K的释放率分别为16.77%,14.22%和13.02%;至210天时,3种不同密度下K的释放率分别达到69.70%,69.59%和67.87%。空白试验中,K释放速度呈现先变大后减小的变化规律,在60天时肥料K的释放速度达到最大,60天及210天时K的释放率分别为38.76%和99.93%。所以从本研究设置的壳体密度水平来看,肥料释放速度与壳体密度关系不显著。

|

图 4 壳体密度对肥料释放速度的影响 Fig. 4 Variation of the potassium releasing rate with different shell density |

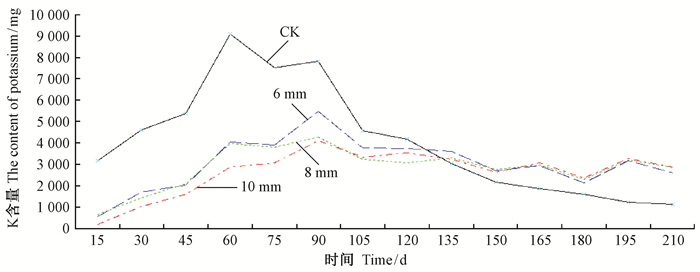

壳体厚度对壳体肥料释放速度的影响如图 5所示。从图中可见,3种不同厚度的壳体中肥料释放速度都呈现先变大后趋于稳定或缓慢变小的趋势,壳体肥料释放速度与壳体厚度有关。在设置的降雨量下,6,8及10 mm 3种不同厚度的壳体在90天时肥料K的释放速度均达到最大值,释放率分别为30.81%,28.29%和22.39%,然后逐渐变小,至210天时,释放率分别达到73.65%,69.59%和64.72%。空白试验中,K释放速度呈现先变大后减小的变化规律,在60天时达到最大,释放率为65.46%,至210天时K释放率已达99.93%,肥料已基本释放完全。因此,肥料释放速度随着壳体的厚度增加而减慢。

|

图 5 壳体厚度对肥料释放速度的影响 Fig. 5 Variation of the potassium releasing rate with different shell thickness |

木材剩余物缓释肥料壳体具有明显的缓释效果,使用壳体的肥料释放期长,释放速度较均匀,90天时,肥料释放率在39.20%以下;而没有使用壳体的肥料初期释放量很大,之后迅速减少,肥料的释放期短,90天时,肥料释放率达65.46%。

壳体的肥料释放速度与构成壳体的剩余物类型和壳体厚度有关,马尾松木壳体的肥料释放速度比香椿木快。至210天时,马尾松木、香椿木壳体的释放率分别达93.01%和74.43%。肥料释放速度随着壳体厚度的增加而减慢,至210天时,6,8及10 mm 3种不同厚度的壳体释放率分别为73.65%,69.59%和64.72%。试验设置的不同密度(0.50,0.55,0.60 g·cm-3)对壳体的肥料释放速度影响不大。

| [1] |

樊小林, 王 浩, 喻建刚. 2005. 粒径膜厚与控释肥料的氮素养分释放特性. 植物营养与肥料学报, 11(3): 327-333. (Fan X L, Wang H, Yu J G. 2005. Effect of granule size and coating thickness on nitrogen release characteristics of controlled release fertilizers (CRFs). Plant Nutrition and Fertilizer Science, 11(3): 327-333[in Chinese]).(  1) 1)

|

| [2] |

冯守疆, 龚成文, 赵欣楠, 等.2010. 包膜缓/控释肥料的研究现状及发展趋势. 安徽农业科学, 38(26): 14409-14411. (Feng S J, Gong C W, Zhao X N, et al. 2010. Research situation and developing trend of coated slow/controlled release fertilizers. Journal of Anhui Agri Sci, 38(26): 14409-14411[in Chinese]).(  1) 1)

|

| [3] |

符韵林, 莫昭展, 乔梦吉, 等. 2009. 用木材剩余物制造缓释肥料壳体的方法. 中国专利: 200710050083. (Fu Y L, Mo Z Z, Qiao M J, et al. 2009.The method of manufacturing wood residue slow release fertilizer shell. China Patent: 200710050083.[in Chinese])(  1) 1)

|

| [4] |

符韵林, 万业靖, 唐黎明. 2010. 木材剩余物制备缓/控释肥料壳体的设计. 林业实用技术, (11): 50-52. (Fu Y L, Wan Y J, Tang L M. 2010. The design of wood residue slow release fertilizer shell. Journal of Practical Forestry Technology, (11):50-52[in Chinese]).(  1) 1)

|

| [5] |

符韵林,乔梦吉,李 宁,等.2013. 一种制备缓释肥料壳体的方法. 中国专利: 201310395507.7. (Fu Y L, Qiao M J, Li N, et al. 2013.A method of manufacturing slow release fertilizer shell. China Patent: 201310395507.7.[in Chinese])(  1) 1)

|

| [6] |

黄培钊, 廖宗文, 葛仁山, 等. 2006. 不同造粒工艺的肥芯-包膜微结构特征与缓/控释性能的研究. 中国农业科学, 39(8): 1605-1610. (Huang P Z, Liao Z W, Ge R S, et al. 2006. Study on microstructures characteristics and nutrition slow/controlled-release capability of fertilizer cores with different granulating techniques and their coating CRFs. Scientia Agricultura Sinica, 39(8): 1605-1610[in Chinese]).(  1) 1)

|

| [7] |

陆建刚, 周 莺. 1994. 国内外新型肥料的开发. 化肥工业, (3): 8-10, 16. (Lu J G, Zhou Y. 1994. Development of new fertilizer all around the world. Fertilizer Industry, (3): 8-10, 16[in Chinese]).(  1) 1)

|

| [8] |

倪博立. 2012. 环境友好型多功能缓控释肥料的制备及性能研究. 兰州:兰州大学博士学位论文. (Ni B L. 2012. Preparation and properties of environmentally friendly multifunctional slow/controlled release fertilizer. Lanzhou: PhD thiesis of Lanzhou University[in Chinese]).(  2) 2)

|

| [9] |

齐广成,高翠华.2008.浅谈控释肥在农业中的应用.现代农业科学,15(11):50-51. (Qi G C, Gao C H.2008.Application of the controlled-release fertilizer in agriculture.Modern Agricultural Sciences, 15(11): 50-51[in Chinese]).(  1) 1)

|

| [10] |

秦裕波, 唐树梅, 谢佳贵, 等. 2008a. 新型缓控释肥料的研制及其缓控释性能研究. 土壤通报, 39(4): 855-857. (Qin Y B, Tang S M, Xie J G, et al. 2008a. Researches on the preparation of new type slow-release and controlled release fertilizers and their slow-release effectiveness. Chinese Journal of Soil Science, 39(4): 855-857[in Chinese]).(  1) 1)

|

| [11] |

秦裕波, 唐树梅, 黄鹤丽. 2008b. 亲水性包膜缓控释肥料的研制及其缓控释性能研究. 热带农业科学, 28(6): 29-33. (Qin Y B, Tang S M, Huang H L.2008b. Preparation of new types of controlled release fertilizers and their controlled release capability. Chinese Journal of Tropical Agriculture, 28(6): 29-33[in Chinese]).(  1) 1)

|

| [12] |

全国肥料和土壤调理剂标准化技术委员会.2007. HG/T 3931-2007, 缓控释肥料. 北京: 化学工业出版社. (The National Fertilizer and Soil Conditioner Standardization Technical Committee. 2007. HG/T 3931-2007, Slow/controlled release fertilizer. Beijing: Chemical Industry Press.[in Chinese])(  1) 1)

|

| [13] |

王红飞, 王正辉.2005. 缓/控释肥料的新进展及特性评价. 广东化工, (8): 86-90. (Wang H F, Wang Z H. 2005. Advance and evaluation methods of slow or controlled release fertilizers. Guangdong Chemical, (8): 86-90[in Chinese]).(  1) 1)

|

| [14] |

中国林业科学研究院林业研究所. 1987. GB7856-87, 森林土壤速效钾的测定. 北京: 中国标准出版社.Research Institute of Forestry, Chinese Academy of Forestry.1987. GB7856-87, the determination of forest soil rapidly available potassium. Beijing: Standards Press of China.[in Chinese])( 1) 1)

|

| [15] |

Grigori P, Shalom M, Moshe Z. 1990. Method for the manufacture of slow release fertilizers. US Patent: 4936897.( 1) 1)

|

| [16] |

Hanafi M M, Eltaib S M, Ahmad M B, et al. 2002.Evaluation of controlled-release compound fertilizers in soil. Commun Soil Sci Plant Anal, 33(7/8): 1139-1156.( 1) 1)

|

| [17] |

Khan M A, Mingzhi W, Lim B K, et al. 2008. Utilization of waste paper for an environmentally friendly slow-release fertilizer. J Wood Sci, 54(2):158 -161.( 1) 1)

|

| [18] |

Tomaszewska M, Jarosiewicz A. 2002a. Use of polysulfone in controlled release NPK fertilizer formulations. J Agric Food Chem, 50(16) : 4634-4639.( 1) 1)

|

| [19] |

Tomaszewska M, Jarosiewicz A, Karakulski K. 2002b.Physical and chemical characteristics of polymer coatings in CRF formulation. Desalination, 146(1/3): 247-252.( 1) 1)

|

| [20] |

Tangboriboonrat P, Sirichaiwat C. 1996. Urea fertilizer encapsulation using natural rubber latex. Plastics, Rubber and Composites Processing and Application, 25 (7) : 340-347.( 1) 1)

|

| [21] |

Tomaszewska M, Jarosiewicz A. 2004. Polysulfone coating with starch additzon in CRT formulation. Desalination, 163(1/3): 247-252.( 1) 1)

|

2015, Vol. 51

2015, Vol. 51