文章信息

- Song Yongming, Wang Qingwen, Gong Li, Li Chuntao

- 宋永明, 王清文, 龚丽, 李春桃

- Synergistic Effects of Expandable Graphite with Ammonium Polyphosphate on Flame Retardancy of Wood Flour/Polypropylene Composites

- 可膨胀石墨与聚磷酸铵对木粉/聚丙烯复合材料的协同阻燃作用

- Scientia Silvae Sinicae, 2011, 47(7): 145-150.

- 林业科学, 2011, 47(7): 145-150.

- DOI:

-

文章历史

- Received date: 2010-03-15

- Revised date: 2010-06-08

-

作者相关文章

Wood-plastic composites (WPCs) have been accepted by more and more people because of their good appearance, moderate mechanical properties and environmentally friendly characteristics (Klysov, 2007; Wang et al., 2007).This kind of composite materials has been applied to construction, furniture, automobile industry, and even more interesting prospect in indoor decoration field (Karnani et al., 1997).Fire resistance of WPCs is an important factor for their interior use because both wood fiber and plastics are flammable (Schartela et al., 2003; Sain et al., 2004; Li et al., 2004; Fang et al., 2008; Shao et al., 2008; Guo et al., 2007).

The conventional halogenated compounds are good flame-retardant additives for plastics.However, halogen-containing polymers generally release large amounts of corrosive and toxic smoke during combustion, thus the research and development turn towards halgen-free flame retardants in recent years because they are more environmentally friendly than the traditional halogen-containing compounds.A good approach to improve the halgen-free flame retardancy of composites is the addition of intumescent flame retardants (IFRs) to the polymer matrix (Le et al., 2005).The typical IFR system contains ammonium polyphosphate (acid source), pentaerythritol (carbonization agent) and melamine (blowing agent) (Halpern et al., 1984; Hendrickson et al., 2004). Material including such flame retardant system will form a carbonaceous polymeric layer at the surface during combustion to protect the underlying material from the action of the heat flux or flame.Recently, expandable graphite (EG), as a new type of intumescent flame retardant, has been found a lot of applications in polymeric materials (Xie et al., 2001a; 2001b).It is an environmental friendly and water insoluble flame retardant, which is very stable in normal conditions.However, when the temperature exceeds 200℃the EG will start to expand rapidly up to several hundred times in volume.Owing to the fact that the vaporization point of graphite is above 3 000℃, EG can hold its integrity in the flame zone and provide better fire protection than many other flame retardants.EG acts mainly in the condensed phase as a smoke suppressant and an insulator.Where the expanded carbon layers are too unstable, it needs to combine the EG with other flame retardants, to form stably intumescent layers.Previous studies show that phosphorus-containing compounds are the most efficient synergistic agents of the EG-based flame retardant systems in polyolefin blends, and some researches confirm that Ammonium phosphate (APP) and expandable graphite (EG) have synergistic flame retarding effective in composite materials (Han et al., 2007; Qu et al., 2003).

Even though a lot of work has been done on the flammability of polymers, very little work has been reported on the flammability of the WPC.Especially, that was barely reported in the literature on combustion behavior of EG and its interaction with APP in WPC. The object of the present work is to study the synergistic flame-retardant effects of EG with APP in wood flour/polypropylene composites by cone calorimeter test.In addition, the mechanical properties of flame retarded wood flour/polypropylene composites were also discussed.

1 Materials and methods 1.1 MaterialsPolypropylene (PP, T30 s, homopolymer, MFI:3.0 g·(10 min)-1, ASTMD 1238) used in this paper was commercial from Fushun Petroleum Company. Wood flour (WF) of poplar with average particle size of 250 μm (nominal 60 mesh), which was come from Baiquan County of Heilongjiang Province, was dried for 24 h at 105℃.Maleic anhydride grafted polypropylene copolymer (MAPP), was obtained from Ningbo Nengzhiguang New Materials Technology Co., Ltd.Expandable graphite (EG), with average particle size of 80 mesh and expandable volume 200~350 mL·g-1, was supplied by Qingdao Tianhe Graphite Co., Ltd.Ammonium polyphosphate (APP) was obtained from Chengdu Tongli auxiliary & CD., Ltd.

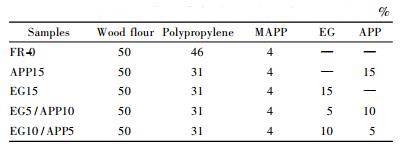

1.2 Sample preparationWood flour, polypropylene, MAPP and flame retardant additives were mixed in a high speed blender for 5 min, and then extruded by a twin-screw extruder with seven heating zones, equipped with a 100 mm×80 mm die.The extruded melts were hot-pressed under 8 MPa for 2 min at 180~190℃into a sheet, and then were cool-pressed for 3 min, at last, were cut to specimens of the size of 100 mm×100 mm×40 mm. All of the composites samples were prepared in the same processing conditions and MAPP was used as a compatibilizer between wood flour and polypropylene in the composites.The composite formulations are given in Tab. 1.

|

|

The cone calorimetric tests were performed in accordance with the standard method ISO 5660 under a heat flux 50 kW·m-2 with a standard cone calorimeter. All samples (specimen size:100 mm×100 mm×4 mm) were measured in a horizontal orientation.

1.4 Mechanical properties testIn order to analyze the effects of the flame retardants on the mechanical properties of wood flour/polypropylene composites, the flexural test and the charpy unnotched impact strength were carried out according to ASTM D790 and GB/T 1043—1993, respectively.At least five replicates were used for each measurement.

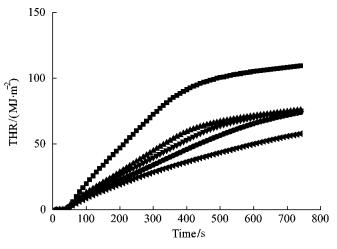

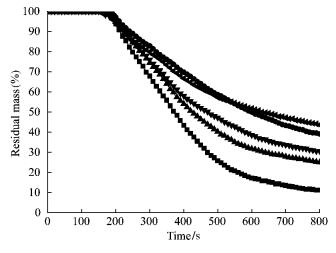

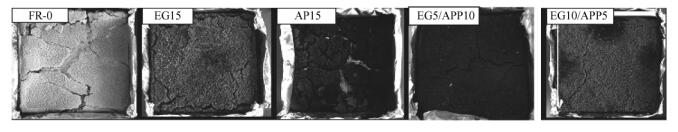

2 Results and discussionCone calorimeter provides the detailed information about flammability and smoke emission behaviors, and it has been extensively used to evaluate the flame resistance of materials (Schartel et al., 2005; Price et al., 2002).The cone calorimeter is based on the oxygen-consumption principle, which is a small scale test that provides results in good agreement with large scale flame tests (ISO 5660-1, 1993; Lefebvre et al., 2004).The curves of heat release rate (HRR) and total heat release (THR) of cone calorimeter tests using external hear flux of 50 kW·m-2 are showed in Fig. 1 and Fig. 2, respectively.The other typical values of combustion parameter in the cone calorimetric test are also summarized in Tab. 2.It can be seen from Fig. 1 that the HRR curves of investigated samples versus time show typical HRR curves for char-forming materials, with a peak of HRR (PHRR) at the beginning of the combustion and a decrease in HRR afterwards (Schartel et al., 2007).It can be seen that the untreated wood flour/polypropylene composites (FR-0) burns very fast after ignition and a sharp HRR peak appears with PHRR of 410 kW·m-2.In the case of flame retarded composites, the HRR values decreases dramatically compared to FR-0.EG15 shows a further decrease in HHR compared with APP15 material at the same additive level (15%).It was also found that the peak of HRR (PHRR), average HRR (av-HRR), average effective heat of combustion (avEHC) and average mass loss rate (av-MLR) decreased dramatically with the addition of EG. Especially, the PHRR value of EG15 sample is 54% lower than that of FR-0.EG thermally expanded and absorbed heat from the system in the temperature of 180~400℃, forming a loose expanded carbon layer on the material surface (Xie et al., 2001a).The expanded carbon layer worked as a physical protective barrier for heat transfer into the material and the process of pyrolysis was slowed down, resulting in a decreased heat release.However, EG10/APP5 sample, which is 10% EG combined with 5% APP, has the lowest the PHRR value compared with sample APP15 and sample EG15.It is also found that THR values have the similar results (as showed in Fig. 2). These indicate EG and APP has a synergistic effect in retarding WF/PP composites.The synergistic effects of EG and APP may be attributed to APP decomposes to yield polyphosphoric acid with strong dehydration function during heating, and the polyphophoric acid promotes the dehydration of wood flour and promotes the formation of char, which together with EG forms a compact carbonaceous layer with stabilized structure (as showed in Fig. 5).Fig. 3 shows the residual mass as a function of time for the different samples.The char yields of different flame retarded formulas are different.The formation of the efficient char can prevent the heat transfer between the flame zone and the burning substrate, and thus protect the underlying materials from further burning and suppressed its pyrolysis.The effective order of their char formation is as follows:EG10/APP5 > EG15 > EG5/APP10 > APP15 > FR-0.The result provides positive evidence that the incorporation of 10% EG and 5% APP can promote the formation of carbonaceous materials in the condensed phase.

|

Fig.1 HRR as a function time for the different samples |

|

Fig.2 THR as a function time for the different samples |

|

Fig.3 Residual Mass as a function of time for the different samples |

|

Fig.5 Photographs of the residue char after cone calorimeter test |

|

|

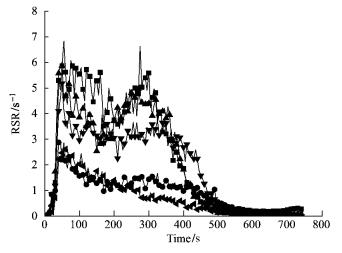

In addition, the smoke generation is an important hazard parameter in many flame situations.The effect of flame retardants on smoke formation was also measured.As can be observed in the curve of the rate of smoke released (RSR) presented in Fig. 4.The RSR curve shape of sample APP15 is similar to that of the sample FR-0, but the RSR are slight lower than that of FR-0.For the sample APP15, a second peak appeared between 250 and 350 s, which would correspond to the collapse of the charred structure leading to the liberation of trapped volatiles.However, the av-SEA of APP15 is higher than that of FR-0 (as listed in Tab. 2).This phenomenon may be attributed to the gaseous substances (e.g.NH3 and H2O) yielded from the decompositions of the APP, which diluted the volatile resulting in a deficient combustion. It can be noticed that the addition of EG in wood flour and polypropylene system leads to a remarkable decrease of the RSR and av-SEA and the second peak of smoke release was even eliminated.The results from that when exposed to fire EG creates a crosslinked carbon char and small porous holes on the surface of the char contribute to a better smoke suppressing performance.The result indicates the EG is an excellent smoke suppressant.Furthermore, the incorporation of 5% APP and 10% EG also showed good synergistic effects in smoke suppression.

|

Fig.4 RSR as a function of time for the different samples |

In order to illustrate how the formation of intumescent char affects the combustion of the flame retarded WF/PP composites, the photographs of the residues remaining after the cone calorimeter test were showed in Fig. 5.For FR-0 sample, there was almost no residue after burning; a photograph showed a spot of dash, while the flame retarded composites samples all suffered a remarkable volume expansion during the combustion.The thick char layer forms a barrier which significantly reduced heat transfer and air incursion and thus enhanced the flame retardant properties.The char from the EG10/APP5 sample seemed more compact char structures than that of EG15, APP15 and EG5/APP10.This provided the evidence that APP is an effective synergist with EG in flame retarded WF/PP system.

Tab. 3 summarized the effects of different flame retardants on flexural and impact properties of wood flour/polypropylene composites.The results of mechanical properties demonstrated that the addition of APP and EG decreased the impact and flexural strength of the composites, especially, the impact properties decreased remarkably.The addition of EG improved the flexural modulus, which was contributed to EG's high stiffness.The significant decrease of mechanical strength of the composites suggested that the compatibility between the flame retardants and wood flour/polypropylene system was poor.So even in the presence of MAPP, the flame retardant should also be treated for improving the interfacial compatibility.

|

|

Cone calorimetry showed that the flame retardancy and smoke suppression of wood flour/polypropylene composites were improved with the addition of EG and APP.EG was not only a good flame retardant in this system but also it is an excellent smoke suppressant. Incorporation of EG and APP showed good synergistic effects in smoke suppression and flame inhibition.The synergistic effects of EG and APP is attributed to APP decomposes to yield polyphosphoric acid, it promotes the char formed of wood flour, which together with EG forms a continuous and compact char layer with stabilized structure.The carbonaceous structure insulated transfer of heat and oxygen resulted in good flame retardancy.It is also noted that APP and EG have an impact on mechanical properties of wood flour/polypropylene composites, however, EG improved the flexural modulus.

Fang Yiqun(房轶群), Wang Qingwen(王清文), Song Yongming(宋永明), et al. 2008. The fire retardancy of wood flour /PS composites treated with APP-starch. Polymer Materials Science and Engineering(高分子材料与工程), 24(11), 83-86. |

Guo G, Park C B, Lee Y H, et al. 2007. Flame retarding effects of nanoclay on wood-fiber composites[J]. Polymer Engineering and Science, 47(3): 330-336. DOI:10.1002/(ISSN)1548-2634 |

Halpern Y, Mott D M, Niswarder R H. 1984. Fire retardancy of thermoplastic materials by intumescence[J]. Industrial and Engineering Chemistry Product Research and Development, 23(2): 233-238. DOI:10.1021/i300014a011 |

Han Zhidong, Dong Limin, Li Ying, et al. 2007. A comparative study on the synergistic effect of expandable graphite with APP and IFR in polyethylene[J]. Journal of Fire Sciences, 25(1): 79-91. DOI:10.1177/0734904107066308 |

Hendrickson L, Connole K B. 2004. Review of stabilization of polyolefin insulated conductors[J]. Polymer Engineering and Science, 35(2): 211-217. |

ISO 5660-1.1993.Fire tests e reaction to fire e rate of heat release from building products(cone calorimeter method.Geneva).Geneva:International Organization for Standardization.

|

Karnani R, Krishnan M, Narayan R. 1997. Biofiber-reinforced polypropylene composites[J]. Polymer Engineering and Science, 37(2): 476-483. DOI:10.1002/(ISSN)1548-2634 |

Klysov A A. 2007. Wood-plastic composites[J]. John Wiley & Sons, Inc., Hoboken, New Jersey. |

Le B M, Duquesne S, Fois M, et al. 2005. Intumescent polypropylene / flax blends:a preliminary study[J]. Polymer Degradation and Stability, 88(1): 80-84. DOI:10.1016/j.polymdegradstab.2004.04.028 |

Lefebvre J, Bastin B, Le Bras M, et al. 2004. Flame spread of flexible polyurethane foam:comprehensive study[J]. Polymer Testing, 23(3): 281-290. DOI:10.1016/j.polymertesting.2003.08.003 |

Li Bin, He Jinmei. 2004. Investigation of mechanical property, flame retardancy and thermal degradation of LLDPE-wood-fiber Composites[J]. Polymer Degradation and Stability, 83(2): 241-246. DOI:10.1016/S0141-3910(03)00268-4 |

Price D, Pyrah K, Hull T R, et al. 2002. Flame retardance of poly (methyl methacrylate)modified with phosphorus-containing Compounds[J]. Polymer Degradation and Stability, 77(2): 227-233. DOI:10.1016/S0141-3910(02)00038-1 |

Qu Baojun, Xie Rongcai. 2003. Intumescent char structures and flameretardant mechanism of expandable graphite-based halogen-free f lame-retardant linear low density polyethylene blends[J]. Polymer International, 52(9): 1415-1422. DOI:10.1002/(ISSN)1097-0126 |

Sain M, Park S H, Suhara F, et al. 2004. Flame retardant and mechanical properties of natural fibre-PP composites containing magnesium hydroxide[J]. Polymer Degradation and Stability, 83(2): 363-367. DOI:10.1016/S0141-3910(03)00280-5 |

Schartel B, Bartholmai M, Knoll U. 2005. Some comments on the use of cone calorimeter data[J]. Polymer Degradation and Stability, 88(3): 540-547. DOI:10.1016/j.polymdegradstab.2004.12.016 |

Schartela B, Brauna U, Schwarzb U, et al. 2003. Fire retardancy of polypropylene /flax blends[J]. Polymer, 44(20): 6241-6250. DOI:10.1016/S0032-3861(03)00692-X |

Schartel B, Hull T R. 2007. Development of fire-retarded materials— interpretation of cone calorimeter data[J]. Fire and Materials, 31(5): 327-354. DOI:10.1002/(ISSN)1099-1018 |

Shao Bo(邵博), Zhang Zhijun(张志军), Wang Qingwen(王清文), et al. 2008. Effects of APP on the fire-retardant and mechanical properties of wood-flour-HDPE composite. Polymer Materials Science and Engineering(高分子材料与工程), 24(4), 48-51. |

Wang Q W(王清文), Wang W H(王伟宏), Song Y M(宋永明), et al. 2007. Wood-plastic Composites and Products. Chemical Industry Press, Bei Jing(Chemical Industry Press, Bei Jing). |

Xie Rongcai, Qu Baojun. 2001a. Expandable graphite systems for halogen-free flame-retarding of polyolefins[J]. I.flammability characterization and synergistic effect.Journal of Applied Polymer Science, 80(8): 1181-1189. |

Xie Rongcai, Qu Baojun. 2001b. Synergistic effects of expandable graphite with some halogen-free flame retardants in polyolefin Blends[J]. Polymer Degradation and Stability, 71(3): 375-380. DOI:10.1016/S0141-3910(00)00188-9 |

2011, Vol. 47

2011, Vol. 47