文章信息

- Sun Fangli, Duan Xinfang, Mao Shengfeng, Wen Guifeng, Wang Shanshan

- 孙芳利, 段新芳, 毛胜凤, 文桂峰, 王珊珊

- Decay Resistance of Bamboo Wood Treated with Chitosan-Metal Complexes against the White-Rot Fungus Coriolous versicolor

- 壳聚糖金属配合物处理后竹材的防白腐性能

- Scientia Silvae Sinicae, 2007, 43(4): 82-87.

- 林业科学, 2007, 43(4): 82-87.

-

文章历史

Received date: 2005-09-05

-

作者相关文章

2. 浙江大学高分子科学研究所 杭州 311300;

3. 中国林业科学研究院木材工业研究所 北京 100091

2. Polymer Science Department of Zhejiang University Hangzhou 311300;

3. Research Institute of Wood Industry, CAF Beijing 100091

The diminishing wood resource and restrictions imposed on felling in natural forests, particularly in the tropics, have focused world attention on the need to identify substitute materials that should be renewable, environmentally friendly and widely available. In view of its rapid growth (exceeding most fast growing woods), a ready adaptability to most juvenile fast growing wood, bamboo emerges as a very suitable alternative. But it is ready to attack by mold fungi, decay fungi and insects. Therefore, it is important to study on the characteristics of bamboo decay and seek proper methods to preserve bamboo(Wang et al., 2004).

There are a number of methods to preserve bamboo wood, but the commonly used one is chemical process. Preservatives for bamboo wood mainly come from the successfully used wood preservatives, such as CCA(copper, chrome and arsenic complex), CCB(copper, chrome and boron complex), pentachlorophenol sodium (PCP-Na) and so on. The preservatives above face to be discarded for their toxicity to people's health and the environment(Jiang et al., 2002). Experts in wood and bamboo preservation have devoted themselves to the development of environmental and effective preservatives, and succeeded in developing new preservatives such as copper-quaternary ammonium salt compounded(ACQ). But the new preservative needs to be further studied for its high cost and low fixation in wood, and irritant ammonia(Jin et al., 2004; Fang et al., 2001). In this project, we will introduce chitosan-metal complexes(CMC), which come from reacting chitosan and metal salts. It is reported that wood or bamboo treated with CMC can successfully resist decay fungi and mold fungi(Duan et al., 2004; Sun et al., 2004; 2006; Tomonori et al., 1995). In order to develop their potential utilization in bamboo wood, we tested their resistance against white-rot fungus Coriolous versicolor.

2 Experimental 2.1 Preparation of specimens4-year-old bamboo wood, was collected from Lin'an City, Zhejiang Province on November 22nd, 2003. 2 to 4 m(from down on)portions of bamboo, with green and yellow faces planed off, are chosen and machined into specimens. The dimension of specimens were 20 by 20 by 5 mm(length by width by thickness) and free of knots.

Specimens should be sanded and got rid of burs in order to get accurate mass changes. Weigh the specimens and group them according to their weights (weight differences among all the specimens should not exceed 0.5 g) and mark the specimens, 6 specimens for each group. Then the specimens will be oven-dried at 60 ℃ for 2 h, at 80 ℃ for 2 h, then at (105±2)℃ for about 8 h until the weight of the specimens is constant. Bring the specimens into desiccator to cool them. Weigh the specimens to the nearest 0.001 g, the weight (T1)is referred to as the initial or untreated weight of the test block. After weighing, the specimens are kept in desiccator until they are to be impregnated with preservative.

2.2 Impregnation of specimensFour kinds of fungicides including chitosan-copper complex(CCC, with copperion 10.89%), chitosan-zinc complex(CZC, with zinc ion 11.86%), zinc chloride, CCB (copper, chrome and boron complexes) were chosen in this experiment. Impregnation of the specimens was the following.

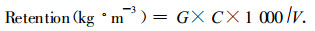

Place the specimens to be treated with a given concentration of preservative in a suitable beaker with spaces between and weigh them down to prevent eventual floating on the treating solution. Place the beaker in the vacuum desiccator, attach the apparatus to the suction pump, reduce the pressure in the vacuum desiccator to 0.1 kPa and hold this pressure for 30 min. Suck the prepared solution of preservative into the beaker slowly. After adding sufficient solution, slowly introduce the air into the desiccator to break the vacuum. Remove the beaker from the desiccator and cover it with a glass. Leave the specimens submerged in the treating solution for 2 h. Remove the specimens from the solution individually, wipe lighly to remove the surface preservative solution, and immediately weigh to the nearest 0.001 g(T2). Calculate the metal ion retention according to the following formula

|

Where:G=(T2-T1)= grams of treating solution absorbed by the block(initial weight of block before treatment substracted from the initial weight plus the treating solution absorbed); C= grams of metal ion in 100 g of treating solution; V=volume of block in cubic centimeters.

2.3 Leaching testExpose the treated specimens to leach by distilled water in a constant temperature room maintained at (28±1)℃. For each retention group, place four treated specimens in a 500 mL beaker and weigh them down with inert material, then cover the specimens with 200 mL distilled water(50 mL for each block). Place the beaker into a vacuum desiccator and evacuate to a pressure of 0.1 kPa and hold this pressure for 1.5 h. Then slowly admit air into the desiccator to break the vacuum. Remove the beaker from the desiccator and cover with a glass. Leave the specimens submerged in the water. At every 24-hour interval for a period of two weeks, remove the leach water from the beaker, measure, and save for analysis. Remove the specimens from the water onto a racks and weather them for five days, then oven-dried to constant weight and weigh them(T3).

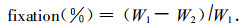

By analysing the leaching water above through AAS, the amount of leaching metal ion could be determined. Calculatie the metal ion fixation was according to the following formula

|

Where:W1=the retention of metal ion, kg·m-3; W2=the leaching amount of metal ion, kg·m-3.

2.4 Sterilization of the treated specimensPlace the specimens by retention groups into petri dishes containing a filter paper soaked with 5 mL of water and steam-sterilize at 121 ℃ and 0.1 MPa for 20 min.

2.5 Preparation of feeder stripsOne feeder strip is needed for each block in a culture bottle. The feeder strips were processed into 20 by 20 by 3 mm (length by width by thickness), and were immersed into water before using.

2.6 Preparation of test culturesFor both stock test-tube and petri dish cultures of the test fungi, use malt agar substrate. Preparation of this substrate was expatiated as follows: prepare malt solution 500 mL with the Baume density at 1.03, add 8.75 g agar into malt solution, and heat the solution until agar melted, then pour the solution evenly into three 500 mL flask, steam-sterilize the flasks with special film covered, at 121 ℃ and 0.1 MPa for 30 min.

For the inoculation of specimens in the flasks, use sand and bamboo powder substrate. The substrate was prepared by mixing brown sugar, corn flour, bamboo powder(size:0.4~0.75 mm) and clean sand(size:0.4~0.75 mm) at the proportion of 1:8.5:15:150(mass ratio). Before inoculation of the specimens into flasks, the sand and bamboo powder substrate was carefully poured into 500 mL flask through a funnel, with 180 g substrate per flask. Level the substrate and place three feeder strips directly on the substrate, then add 100 mL malt solution(with the Baume density at 1.03) slowly and carefully through a funnel, steam-sterilize the flasks with special film covered, at 121 ℃ and 0.1 MPa for 1 h.

2.7 Decay-resistance test1) Activation of the fungus:Inoculate Coriolous versicolor on to malt and agar culture, and cultivate for 9 d at the temperature of (27±2)℃ and relative humidity of (70±5)%. 2) Inoculation: After the sterilized sand culture were thoroughly cooled, cut fungus inoculum sections(with a diameter of 1 cm) from near the leading edge of mycelium in petri dish cultures. Aseptically place sections of inoculum in the center of the feeder strips of the sand culture. Cover the flasks with special films and incubate at the temperature of (27±2)℃ and relative humidity of (70±5)% until the feeder strips were covered by mycelium(approximately 3 weeks), then the culture bottles were ready to receive the specimens. 3) Incubation and duration of test: After cooling, aseptically place the sterilized specimens, with a long face centered in contact with the mycelium-covered feeder strip, in the previously prepared culture bottle. Then again cover the culture bottles with special films and incubate at the temperature of (27±2)℃ and relative humidity of (70±5)% for three months. 4) Handling specimens after exposure to test fungi: At the end of the incubation period, remove the specimens from the culture bottles. Carefully brush off the mycelium and place the specimens on racks and weathering for five days, then oven-dry them to constant weight (see section 2.1 for reference) and weigh them (T4).

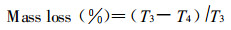

Calculation of mass losses as follows

|

For each fungus, six control specimens are used, and they put through all steps of the test.

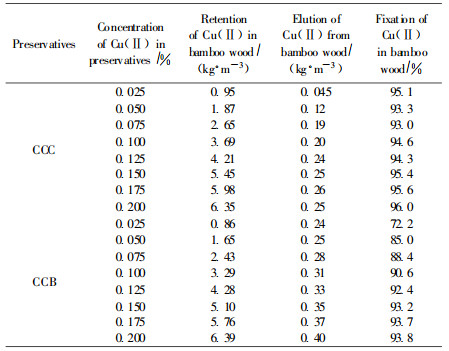

3 Results and discussion 3.1 Fixation of preservatives in bamboo wood 3.1.1 Fixation of CCC and CCBCCC had higher fixation at every concentration of the treating solution, with the percentage of Cu(Ⅱ) fixed in bamboo specimens exceeded 93.0(Tab. 1), and the percentage of Cu(Ⅱ) fixation increased with the concentration of treating solution, which was consistent with CCB preservative. CCB could fix well in bamboo wood only at higher concentrations of the treating solution, and the percentage of Cu(Ⅱ) fixed in bamboo specimens increased from 72.2 to 93.8. The main reason for the higher fixation of CCC arose from chitosan contained in CCC, which could chelated with transition metals such as copper, zinc, and could chemically link with the cell wall by H-bond and molecular interactions (He et al., 2004).

|

|

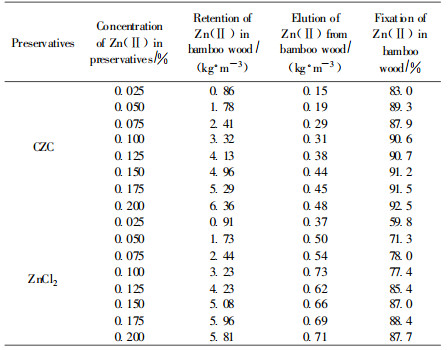

The retention of CZC in bamboo wood was lower that of ZnCl2, especially at higher concentrations of the treating solutions (Tab. 2). This phenomenon was attributed to the increased viscidity in CZC, especially at higher concentrations of the treating solutions, which could be obviously observed in the experiment. The high viscidity made it difficult for CZC solution to impregnate into bamboo wood.

|

|

The leaching test showed that CZC preservative could also fix well in bamboo specimens, and the percentage of Zn(Ⅱ) fixed in bamboo specimens increased from 83.0 to 92.5. ZnCl2 preservative had poorer fixation in bamboo specimens, and the percentage of Zn(Ⅱ) fixed in bamboo specimens increased from 59.8 to 88.4. The main reason for the higher fixation of CZC also arose from the combination of chitosan and zincion.

CCC could fixed better in bamboo wood than CZC when comparing the results of Tab. 1 with Tab. 2. Two reasons resulted in the differences mentioned above: one came from the different ability of chelation between metal ion and chitosan (Jiang, 2001), and another came from the better combination between Cu(Ⅱ) and bamboo components, especially cellulose, hemicellulose and lignin(Roger, 1984). Besides, metal ion fixed in bamboo wood increased with the increase of the retentions, regardless of fungicides, which might be explained as follows: After the specimens being impregnated with fungicides, they would be dried. And metal ions might be formed into sediment particles when the solvent evaporated. If the retentions of fungicides were higher, the particles formed in the specimens might be larger and be difficult to wash from the specimens(Qin et al., 2004; Lebow et al., 1993).

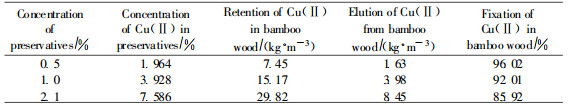

On the contrary, with the increased concentration of ACQ, fixation of copper ion in bamboo wood decreased greatly from 96.0 to 86.0(see Tab. 3).

|

|

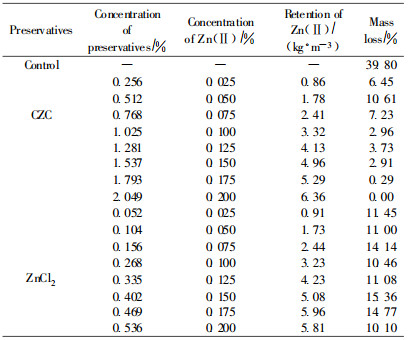

Decay-resistance of the treated bamboo wood could be evaluated by mass losses of the specimens after the decay resistance test.

3.2.1 Decay-resistance of bamboo wood treated with CCC or CCBMass losses of the specimens treated with CCC were all between 0 and 7.7 percent, obviously lower than the controls (mass loss of the control reached 39.8 percent). When the specimens were treated with CCB preservative, the mass losses were between 8.3 and 15.4 percent(Tab. 4), indicating that CCC had better resisting effects to white-rot fungi than CCB. The resisting effects of CCC and CCB mainly came from copper ion, which was proved to have resistance against white-rot fungi. The better resistance of CCC, comparing with CCB, might be contributed to the cooperation of chitosan and copper ion. Bamboo wood treated with ACQ had better resisting effects on white-rot fungi, which could be seen from Tab. 4.

|

|

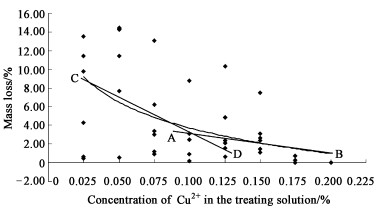

According to the American standard(AWPA E10-1), Fig. 1 could be drawn. The threshold retention of CCC(the amount of Cu(Ⅱ) retention in the specimens when mass loss is the lowest) against the test fungus obtained from Fig. 1 was 4.21 kg·m-3, and the corresponding mass loss was 4.1 percent.

|

Fig.1 Mass loss for CCC treated blocks/% AB:Operational mass loss line. CD:Operational loss plus decay loss line. Intersection of lines AB and CD indicates threshold. The same below. |

Preserving effect of CZC was slightly higher than that of CCC (Tab. 4 and Tab. 5), and evidently better than that of ZnCl2 (Tab. 5). Mass losses of the specimens treated with CZC were between 0 and 10.6 percent, that of ZnCl2 preservative between 10 and 16 percent. The probable reason came from the cooperative effects of chitosan and zinc salt. The threshold retention of CZC (the amount of Zn(Ⅱ) retention in the specimens when mass loss is the lowest) against the test fungus was 3.32 kg·m-3, and the corresponding mass loss was 3.0 percent (Fig. 2).

|

|

|

Fig.2 Mass loss for CZC treated blocks/% |

Bamboo wood treated with chitosan-zinc complex had better resistance against the white-rot fungus Coriolous versicolor than wood, mass losses of the treated bamboo wood averaged to 4.3%, while that of the treated P.tomentosa wood approached to 38.4% (Duan et al., 2004).

4 ConclusionsChitosan-metal complexes(CMC) had better fixation in bamboo wood than CCB and ZnCl2, and could successfully resist white-rot fungus Coriolous versicolor. In this experimental, mass losses of the specimens treated with CCC were all between 0 and 7.7 percent, and that of CZC between 0 and 10.6 percent, mass losses of specimens treated with CCB was between 8.3 and 15.4 percent, slightly higher than that of CCC and CZC.

The threshold retention of CCC against the test fungus was 4.21 kg·m-3, and the corresponding mass loss was 4.1 percent. The threshold retention of CZC against the test fungus was 3.32 kg·m-3, and the corresponding mass loss was 3.0 percent.

Therefore, CMC had not only good preserving effects to wood, but could preserve bamboo wood from being destroyed by white-rot fungi. With the development of CMC, it was expected that these kinds of environmental preservatives could substitute CCA in the future.

Duan Xinfang(段新芳), Sun Fangli(孙芳利), Zhu Wei(朱玮), et al. 2004. Decay-resistance of wood treated with chitosan mwtal complex. Scientia Silvae Sinicae(林业科学), 40(6): 138-143

|

Fang Guizhen(方桂珍), Ren Shixue(任世学), Jin Zhongling(金钟玲). 2001.Evolement of research on wood preservatives. Journal of Northeast Forestry University(东北林业大学学报), 29(5): 88-90

|

He Naipu, Song Pengfei, Wang Rongmin, et al. 2004. The development of study on antibacterial and antitumor activity of chitin/chitosan and their derivatives. Macromolecular Aviso, (6): 14-18. |

Jiang Tingda(蒋梃大). 2001.Chitosan. Beijing: Chemical Industry Press(北京: 化学工业出版社)

|

Jiang Mingliang(蒋明亮), Fei Benhua(费本华). 2002. Current situation of wood preservation technology and some suggestions on its research and development in China. World Forestry Research(世界林业研究), 15(3): 44-48 http://en.cnki.com.cn/Article_en/CJFDTOTAL-SJLY200203007.htm

|

Jin Zhongwei(金重为), Shi Zhenhua(施振华). 2004. Technical advances and faced problems in wood preservation industry. China Forest Products Industry(林产工业), 31(4): 3-6 http://en.cnki.com.cn/Article_en/CJFDTOTAL-LCGY200404000.htm

|

Lebow S. 1993. Leaching of wood preservative components and their mobility in the environment. USDA, Forest Products Labo-ratory, General Technical Report, FPL-GTR-93: 1-36. |

Roger M R. 1984. The chemistry of solid wood. American Chemical Society Cellulose, paper and textile Division Ⅲ. Series: 307-318. |

Sun Fangli(孙芳利), Duan Xinfang(段新芳), Mao Shengfeng(毛胜凤), et al. 2004. Anti-mold test of CMC series. China Forest Products Industry(林产工业), 31(4): 14-16 http://en.cnki.com.cn/Article_en/CJFDTOTAL-LCGY200404003.htm

|

Sun Fangli(孙芳利), Duan Xinfang(段新芳), Wen Guifeng(文桂峰), et al. 2006. Anti-mould effects of CMC wood Preservatives on bamboo wood. Scientia Silvae Sinicae(林业科学), 42(3): 40-43 http://en.cnki.com.cn/Article_en/CJFDTOTAL-LYKE200603008.htm

|

Tomonori Kobayashi, Ikuo Furukawa. 1995. Wood-preserving effectiveness of chitosan-metal salts against wood decaying fungi. The Society for Antibacterial and Antifungal Agents, Japan, 23(5): 14-20. |

Wang Yamei(王雅梅), Liu Junliang(刘君良), Wang Ximing(王喜明). 2004. Characteristics of bamboo and its preservation technology. China Wood Industry(木材工业), 18(2): 28-29 http://en.cnki.com.cn/Article_en/CJFDTOTAL-MCGY200402008.htm

|

Qin Daochun(覃道春), Wang Yamei(王雅梅), Jiang Mingliang(蒋明亮), et al.2004. Leaching characteristics of copper in copper triazole treated bmboo. China Wood Industry(木材工业), 18(1): 30-31 http://xueshu.baidu.com/s?wd=paperuri%3A%289cd812be1af05b6bac68ad454311435d%29&filter=sc_long_sign&tn=SE_xueshusource_2kduw22v&sc_vurl=http%3A%2F%2Fen.cnki.com.cn%2Farticle_en%2Fcjfdtotal-mcgy200401009.htm&ie=utf-8&sc_us=9863485171265654547&sc_as_para=sc_lib%3A

|

2007, Vol. 43

2007, Vol. 43