文章信息

- Lu Baowang, Du Guanhua, Matsui Takanao, Matsushita Yoh-ichi, Sugamoto Kazuhiro

- 鲁保旺, 杜冠华, 松井隆尚, 松下洋一, 菅本和宽

- Effect of Pretreatment with Freezhing on Carbonization of Sugi (Cryptomeria japonica) Sapwood

- 冷冻处理对日本柳杉边材炭化的影响

- Scientia Silvae Sinicae, 2005, 41(1): 131-135.

- 林业科学, 2005, 41(1): 131-135.

-

文章历史

Received date: 2002-12-17

-

作者相关文章

2. 河南省农业厅 郑州 450000

2. Agriculture Agency, Henan Province Zhengzhou 450000

Water in organic polymers such as celluloses, pulps, consists of free water and bound water, which were measured by low-temperature differential scanning calorimetric (DSC). Nakamura and his coworkers reported that water absorbed into celluloses, was classified into three types by DSC: nonfreezing water, freezing bound water and free water. From DSC measurements at 0 to -50 ℃ of water in Pinus densiflora wood meal, three kinds of water, such as nonfreezing water, freezing bound water and free water were estimated, and freezing temperature was about -43 ℃ in the case of 25.4% or 29.2% of moisture content, -30 ℃ in 33.5% and -20 ℃ in 37.8%(Kabeya, 1993).

There was a large amount of water in cell of Sugi sapwood, and many of that were froze blow freezing point. Freezing of water in Sugi sapwood was firstly occurred in outside (free water) of cell, and then in inside (bound water) of cell. The second freezing can physically destroy internal structure of cell, and the chemical change maybe generated in this process.

We are studying carbonization of Sugi sapwood and utilization of carbonization products. However the effect of moisture on the pyrolysis of wood has received very little attention in the past(Matsui et al., 2002; Murry et al., 1985), and there is not report on influence of freezing on carbonization of wood. From measurements of moisture content in Sugi sapwood, moisture content of raw state was about 52.0%, 32.0% of fiber saturation and 11.8% of drying state. After the Sugi sapwood samples at different moisture content were frozen at low temperature, tissue structure of their cell may be destroyed to cause physical and chemical change. In the present paper, freezing at low temperature was used to treat the Sugi sapwood samples at 11.8%, 32.0% and 52.0% of moisture content, to investigate the effect of pretreatment on carbonization of Sugi sapwood by analyzing 11 components(Matsui et al., 2002)in Sugi wood-vinegar.

1 Materials and methods 1.1 Materials and pretreatmentSugi sapwood samples used in this report were produced in Miyazaki prefecture of Japan. Wood samples were powdered in a mill, passed through 60 mesh and trapped in 115 mesh. Its moisture content was ca. 11.8%.

The powdered wood samples were immersed in distilled water, and treated for about 2 min at room temperature with sonication apparatus (Sndto). Subsequently, they were filtered through a fused glass funnel, and then adjusted to 32.0% and 52.0% of moisture content by air-drying in room at ca. 20 ℃. The Sugi sapwood samples at different moisture contents were frozen at -20 and -75 ℃ for 12 h or 24 h.

1.2 Preparation of carbonization productsTreated and untreated Sugi sapwood samples were carbonized separately in a carbonization apparatus as shown in Fig. 1. About 20 g of Sugi woods sample in the carbonization apparatus was streamed about 15 min with nitrogen gas at ca. 100 mL·min-1, then heated at the rate of 200 ℃·h-1 from room temperature to 400 ℃ under nitrogen gas at 20 mL·min-1, held at 400 ℃ for 1 h, then cooled to room temperature. Crude Sugi wood-vinegar and charcoal were obtained and wood-tar was gathered with acetone. After crude Sugi wood-vinegar was centrifuged, the upper layer was separated by pipette as wood-vinegar. The gathered wood-tar was evaporated in a vacuum rotary evaporator to eliminate acetone. Wood-tar obtained from crude wood-vinegar and the gathered wood-tar were put together.

|

Fig.1 Apparatus for carbonization of Sugi sapwood |

Capillary GC was carried out with a GC-14B model (Shimadzu, Japan) coupled with hydrogen flame ionization detector and data management apparatus (Chromatopac C-4A), in a capillary column BP-21 (0.25 mm I.D.×25 m, SGE Japan). The carrier gas was helium at 1.61 mL·min-1. The column temperature programming for methanol, acetic acid and propionic acid was 3 min at 45 ℃, 45~109 ℃ at 4 ℃·min-1, injection temperature was 150 ℃ and detector temperature was 300 ℃. The column temperature programming for 2-furaldehyde, 5-hydroxymethyl-2-furaldehyde, maltol, phenol, o-cresol, pyrocatechol, guaiacol and 4-methylguaiacol was 3 min at 45 ℃, 45~209 ℃ at 4 ℃·min-1, holding at 209 ℃ for 6 min, injection and detector temperature were both 300 ℃.

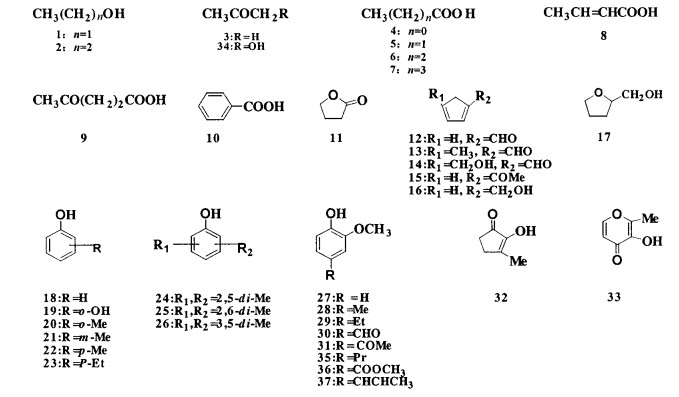

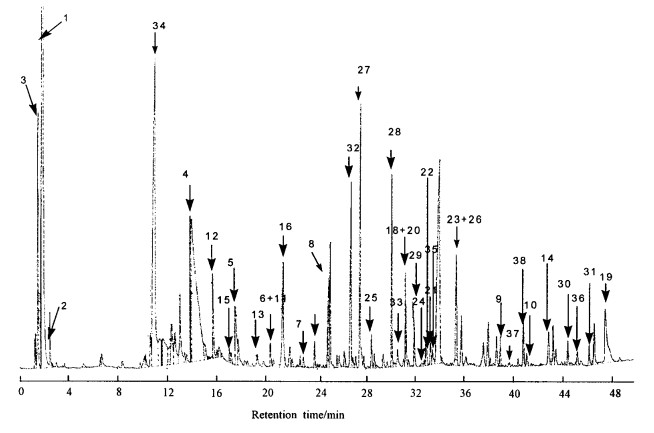

Wood-vinegar was filtered with a 0.45 μm filter, then analyzed at 0.1 μL injection. Wood-vinegar had been found to contain 37 components(Matsui et al., 2002) by capillary GC. Chemical structures of 37 components in wood-vinegar from sugi sapwood were shown in Fig. 2. Quantitative analysis were performed using additional method(Kojima et al., 2002)with authentic samples. Here methanol (1), acetic acid (4), propionic acid (5), 2-furaldehyde (12), 5-hydroxymethyl-2-furaldehyde (16), maltol (33), phenol (18)+o-cresol (20), pyrocatechol (19), guaiacol (27) and 4-methylguaiacol (28) in wood-vinegar of Sugi sapwoods were selected for capillary GC. The GC chart of wood-vinegar of Sugi sapwood at 11.8% of moisture content before treatment was shown in Fig. 3.

|

Fig.2 Chemical structure of components in Sugi wood-vinegar |

|

Fig.3 Capillary GC chromatogram of wood-vinegar of untreated Sugi sapwood at 11.8 of moisture content |

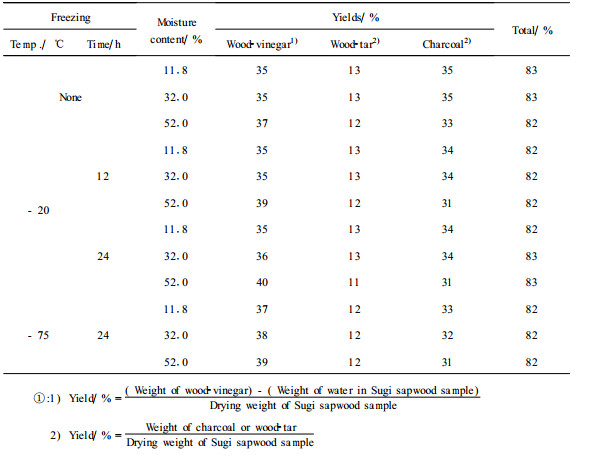

Tab. 1 lists yields of carbonization products. Though yield of wood-tar was almost constant, yield of wood-vinegar tended to increase with moisture content, and yield of charcoal indicated decreasing tendency. It is suggested that moisture could lower the viscosity of the polymer melt at reaction temperatures, which facilitate the formation and evolution of bubbles of vapor (tar + aqueous product) and gas. Moisture would also increase the volume of volatile escaping from the wood. Both effects would reduce the residence time of tar inside the particles, reducing the extent of secondary reactions, and giving greater yields of volatile products and less charcoal(Murry et al., 1985).

|

|

Yields of carbonization products of the treated Sugi sapwood at-20 ℃ were almost constant with the increase of freezing time. Change in yields of carbonization products from Sugi sapwood at 52.0% of moisture content after freezing treatment could not be observed, but yield of wood-vinegar indicated increasing tendency and yield of charcoal did opposite tendency at 11.8% and 32.0% with decrease of freezing temperature from -20 ℃ to -75 ℃. These results suggest that parts or all of bound water in Sugi sapwood could be dewatered to become to free water after freezing treatment, when the treated Sugi sapwood was carbonized, vaporization of water in Sugi sapwood became easily, more water vapor could be occurred to give greater yield of wood-vinegar and less charcoal. On the other hand, bound water in Sugi sapwood at low moisture content could be frozen with decrease of freezing temperature to become to free water.

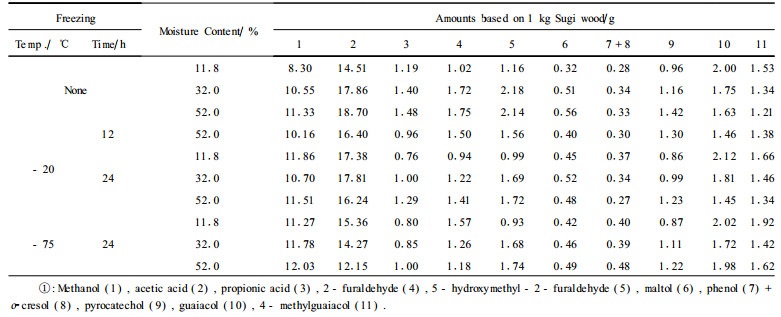

2.2 Comparison of components in sugi wood-vinegarCarboxylic acids, furans and maltol in wood-vinegar were produced over 258 ℃ through thermal decomposition of hemicelluloses and cellulose in Sugi wood, and phenols, pyrocatechol and guaiacols over 300 ℃ through that of lignin. Methanol and acetic acid in wood-vinegar were produced through O-methyl groups and acetyl groups in Sugi sapwood, respectively (Matsui et al., 2002). Amounts of 11 components in wood-vinegar from the treated Sugi sapwoods are shown in Tab. 2. Amounts of methanol, acetic acid, propionic acid, 2-furaldehyde, 5-hydromethyl-2-furaldehyde in wood-vinegar were increased with increase of moisture content before freezing because moisture could facilitate the elimination of O-methyl groups and acetyl groups in Sugi sapwood and hydration of molecular fragments to form furans, but amounts of maltol, phenols, pyrocatechol and guaiacols were unaffected by moisture content.

|

|

Amounts of 5-hydromethyl-2-furaldehyde, maltol, phenols, pyrocatechol and guaiacols in wood-vinegar from the treated Sugi sapwood at same moisture content were unaffected by the freezing treatment.

Amounts of methanol and acetic acid in wood-vinegar from Sugi sapwood at 11.8% of moisture content were increased after freezing treatment at -20 ℃, equal each other at 32.0% and 52.0%. However amount of propionic acid from Sugi sapwood at 32.0% or 52.0% of moisture content was decreased after freezing treatment at -20 ℃, almost constant at 11.8% and equal each other, and amounts of 11 components in wood-vinegar were almost constant as freezing time was increase from 12 h to 24 h at -20 ℃. These results indicate that 11 components in wood-vinegar from Sugi sapwood were little affected by moisture content after freezing treatment, parts of bound water in Sugi sapwood at 11.8% of moisture content could be froze to become to free water and give greater methanol and acetic acid from carbonization.

Amount of acetic acid in wood-vinegar from Sugi sapwood was decrease with the decrease of freezing temperature from -20 ℃ to -75 ℃, amounts of methanol and propionic acid were almost constant. However amount of 2-furaldehyde from Sugi sapwood at 11.8% of moisture content was increased and almost constant at 32.0%, but decreased at 52.0% with the decrease of freezing temperature, and amount of acetic acid was decrease with the decrease of freezing temperature. It is suggested that all of bound water in Sugi wood could be froze, were removed to become to free water and electrolytes such as amino acid and inorganic minerals in Sugi sapwood were leaked after freezing treatment at more low temperature, these components in wood-vinegar were affected by moisture content and electrolytes such as amino acid and inorganic minerals.

3 ConclusionsYield of wood-vinegar tended to increase, yield of charcoal did opposite tendency, though yield of wood-tar was unaffected by moisture and freezing.

Though amounts of maltol, phenols, pyrocatechol, and guaiacols were unchanged, amounts of methanol, carboxylic acids and 2-furaldehyde in wood-vinegar from the treated sapwood were affected by moisture and freezing. Amount of 5-hydroxymethyl-2-furaldehyde was unaffected by freezing, but changed with moisture. It is assumed that Sugi sapwood at high moisture content was little affected by freezing at -20 ℃ comparing with low moisture content, but Sugi sapwood at different moisture content was differently affected by freezing at -75 ℃.

Kabeya H. 1993. Effect of grinding on bound water in cellulosic materials. Mokuzai Gakkaishi, 39(11): 1291-1297. |

Kojima T, Ooi N. 1985. Kikibunseki System Gasukuromatogurafuhou. Japan, Kyouritusyutubann, 120-121

|

Matsui T, Matsushita Y, Sugamoto K, et al. 2002. Analysis of wood-vinegars prepared from Sugi (Cryptomeria japonica D. Don) sapwood and its components. Nippon Kagaku Gakkaishi, 3(3): 385-392. |

Matsui T, Matsushita Y, Sugamoto K, et al. 2002. Influence of moisture content of Sugi (Cryptomeria japonica D. Don) wood on yields of carbonization products and constituents of wood-vinegar. Miyazakidaigaku Kougakubukenkyuukiyou, 31: 69-74. |

Murry R G, WIIIIam H C, George R G. 1985. Pyrolysis of a wood-derived material. Effect of moisture and ash content. Ind Eng Chem Des Dev, 24: 646-651. DOI:10.1021/i200030a020 |

2005, Vol. 41

2005, Vol. 41