文章信息

- Li Yudong

- 李玉栋

- STUDY ON PREVENTION OF RUBBERWOOD AGAINST SAPSTAIN AND MOLD INFECTION

- 预防橡胶木蓝变和霉变的研究

- Scientia Silvae Sinicae, 2003, 39(4): 98-103.

- 林业科学, 2003, 39(4): 98-103.

-

文章历史

Received date: 2002-03-01

-

作者相关文章

Rubberwood is very susceptible to sapstain and mold fungal attack (Xing, 2001; Hong et al., 1994). Hence, it must be properly treated to prevent deterioration of wood, which would result in much wastage of useful material and financial loss (Li, 2002; Chen, 1997; Shi, 2001).

Air drying has been using in China rubberwood industry, which can reduce both kiln drying time and drying cost of timber. However, boron preservatives do not prevent rubberwood from mold and/or sapstain fungal growth. Therefore, if the boron compounds treated rubberwood can not be dried in few days after treatment, short term prevention (also called temporary treatment), such as dipping with anti sapstain chemicals should be used. Temporary prevention involves the momentary dipping of the timber into a preservative solution containing fungicide (sometime also containing insecticide). The preservatives are deposited only on the surfaces, and therefore it will be removed during further processing of the boards.

In the selection of temporary preservatives, not only the effectiveness of the chemical but also the safety of the chemical, both to the human being and to the environment, have to be considered(Li, 2002). Until the 1970s, salts of pentachlorophenol dominated the antisapstain industry, providing generally excellent performance at low costs. The chemical been using in China rubberwood industry for last 20 years was sodium pentachlorophenol (NaPCP) (Jiang, 2001). NaPCP contains dioxin which can cause a number of hazard: carcinogenic, ecotoxic, central nervous system damage, blood disorder, liver and kidney damage, stomach pain, vomiting, nausea, fever, eyes/skin/respiratory irritation. The research showed the acute toxicity of pentachlorophenol as below (FAO, 1997): Oral LD50: 27~205 mg·kg-1 (tests with a variety of species); Inhalation Rabbit (35.2%) LD50 201 mg·kg-1; Dermal LD50:80~350 mg·kg-1(tests with a variety of species); and Irritating to skin, eyes and mucous membranes. PCP is also highly toxic to aquatic organisms, invertebrates and fish.

This was why NaPCP was banned in a lot of countries (Li, 2001; Morrell, 1999), such as Sweden, Germany, Spain, Chile, Denmark, Switzerland, Italy, Greece, Indonesia, Malaysia, Japan, New Zealand, Australia and USA (restricted used). The moves away from pentachlorophenol formulations accelerated during the 1980s (Preston, 1999).As the environmental and health concerns about, the old generation of preservatives cast doubt on their future (Nicholas et al., 1994). Since that time, a number of low toxic biocides have been evaluated for possible use as wood preservatives to control wood sapstain and mold. The anti-sapstain chemicals includes 2-(thiocyanomethylthio) bezathiazole (TCMTB), Methylene-bis-thiocyanate (MBT), Cu-8-quinolinolate, didecyldimethyl-ammonium chloride (DDAC), 3-iodo-2-propynylbutyl carbamate (IPBC), carbendazim, triazoles, and chlorothalonil etc (Habicht et al., 1999). Antiblu 20EC is a commercial product used as fungicide for control of sapstain and mold of wood. Its major active components are Methylene-bis-thiocyanate (MBT) and 2-(thiocyanomethylthio) bezathiazole (TCMTB). The LD50 data indicated that the acute oral toxicity of TCMTB and MBT was 1 590 and 79 mg·kg-1 respectively. And the laboratory study showed that TCMTB and MBT were effective against sapstain and mold infection on timber (Cserjesi et al., 1982).

To reach the quality level of China rubberwood products internationally, it is necessary to replace NaPCP with environmental-friendly chemicals (Li, 2000). In order for developing appropriate technology to replace NaPCP, Antiblu 20EC was used in this study to evaluate the short term protection performance for rubberwood in Hainan Xilian Woodworking Factory in the summer of 1998.

2 Materials and methods 2.1 Timber650 pieces of fresh sawn rubberwood sample with no stain, insect damage and bark were selected. The timber size was 50~100 cm long, 8 cm wide and 3 cm thick. The 650 timber samples were divided into 13 groups, 50 pieces of sample for each group.

2.2 ChemicalsAntiblu 20EC and Antiborer 10EC were in concentrated liquid form. Antiblu 20EC treatment solution was prepared by putting water (49 litres for 1%, 48.5 litres for 1.5%, and 48 litres for 2%) into the dip tank, then adding Antiblu 20EC (1 litre for 1%, 1.5 litres for 1.5%, and 2 litres for 2%) while stirring.

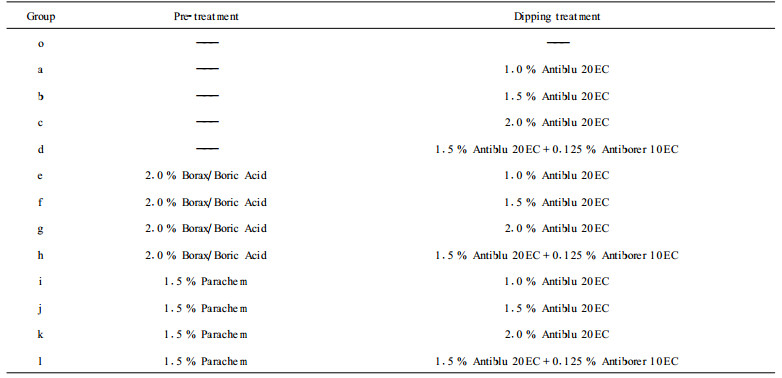

2.3 TreatmentOne group (Group o) was no any treatment (no pressure treatment and no dipping treatment) as control. The 4 groups (Group a, b, c, and d) were no pre-treatment, no pressure treatment. The 4 groups (Group e, f, g, and h) were pressure treated with boric acid and borax at the ratio of 1:1 and at the concentration of 2.0% for 60 minutes without vacuum period. The other 4 groups (Group i, j, k, and l) were pressure treated with Parachem at the concentration of 1.5% for 60 minutes without vacuum period. The details of pre-treatment of each group were listed in Tab. 1.

|

|

The dip treatment was carried out one day after the pressure treatment of boron chemicals. Each pieces of timber sample of the 14 groups (except of Group o) were individually immersed in 1.0%, 1.5% and 2.0% Antiblu solution, and 1.5% Antiblu+0.125% Antiborer solution, respectively for at least 30 seconds. After dipping treatment, the treated samples were stacked with sticker and with space between each piece.

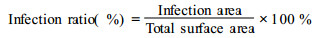

2.4 InspectionThe inspection was carried out at 1st week 2nd weeks, 4th weeks and 12th weeks for sapstain and mold fungal growth for all of the trial timber boards. The infection area was measured for mold and blue stain at every surface except the 2 ends. The total area of the sample was measured by Length ×Width×2+Length×Thickness×2+Width×Thickness×2. And the infection ratio (in percentage) was calculated by:

|

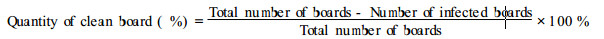

The quantity of clean board was calculated by (Tony, 1992):

|

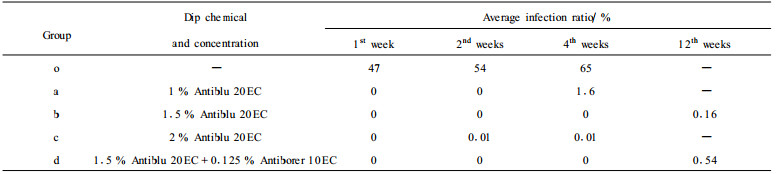

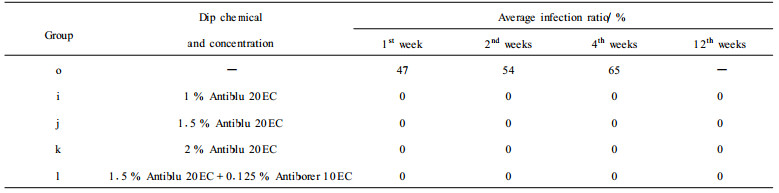

The control group of rubberwood was no any pressure treatment and no any anti sapstain (dipping) treatment. Tab. 2 showed that the average infection ratio of the control was increased when the storage time increased. The quantity ratio of clean board was already 0% at the 1st week (Tab. 3). This indicated that rubberwood without any treatment was very susceptible to mold and sapstain fungal attack. The trial samples of the control group were lost after 4 weeks storage.

|

|

|

|

The fresh rubberwood samples used in the trial were no any pressure treatment with boron preservative, only dipping treated with Antiblu.

Tab. 2 and 3 showed the infection result of Antiblu 20EC treated rubberwood sawn timber. In the 200 trial samples of rubberwood, there were no sample infected by sapstain or mold fungi during 1 week's storage. And 1 and 3 samples were infected respectively after 2 and 4 weeks' storage, and the average infection ratios were less than 2%. After 4 weeks, Group a and Group c were lost during storage. In the 100 samples treated with Antiblu (Group b and d), 9 boards of trial samples were infected by sapstain or mold fungi from the 4th week to the 12th week, in which the infection ratio of 8 boards was less than 5%. It indicated that the anti mould and antisapstain efficacy of Antiblu was rather good for fresh rubberwood sawn timber.

If less than 5% of the infection ratio on timber was considered as acceptable, the acceptable rubberwood were 100% for 1.5% Antiblu treatment and 98% for 1.5% Antiblu+0.125% Antiborer treatment after 3-month storage.

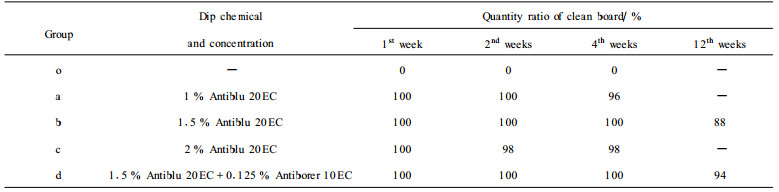

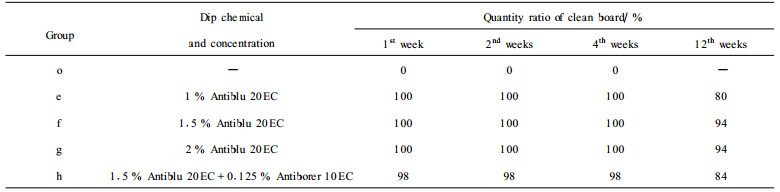

3.3 Antisapstain efficacy on rubberwood pressure treated with borax and boric acidTab. 4 and 5 showed the infection result of Antiblu 20EC dipping treated rubberwood which was pre-treated with borax and boric acid by pressure. It can be seen that all 3 concentrations of Antiblu 20EC-treated rubberwood were no any mold and sapstain after 1, 2 and 4 weeks' storage, and all of the quantity ratios of clean board were 100%. After storage of 1, 2 and 4 weeks, the result showed that 1 sample of 1.5% Antiblu 20EC+0.125% Antiborer 10EC-treated rubberwood (Group h) was fungal attacked, and its infection ratio were 0.5%.

|

|

|

|

After storage of 12 weeks, 10 samples of 1% Antiblu 20EC treated rubberwood (Group e) were stained, in which the infection ratio of 1 sample were 6% and that of others was less than 5%. For 1.5% and 2% Antiblu 20EC treated rubberwood (Group f and Group g), 4 timber samples each group was fungal attacked. Of which, the infection ratios were all less than 3%. For 1.5% Antiblu 20EC + 0.125% Antiborer 10EC treated rubberwood (Group h), 8 timber samples were fungal attacked. Of which, the infection ratios of 2 samples were 5.5% and 15.47% respectively, and the other 6 samples were less than 3%.

The result showed that only 1 board of totally 200 trial samples was fungal attacked after 1-month storage. After 3-month storage, 26 boards of totally 200 trial samples were stained, in which the infection ratios of 23 boards were less than 5%. It indicated that the anti mold and anti sapstain efficacy of Antiblu was also good for borax and boric acid treated rubberwood sawn timber. If less than 5% of the infection ratio on timber was considered as acceptable, the acceptable rubberwood were 98% for 1% Antiblu treatment, 100% for 1.5% and 2% Antiblu treatment, and 96% for 1.5% Antiblu+0.125% Antiborer treatment respectively, after 3-month storage.

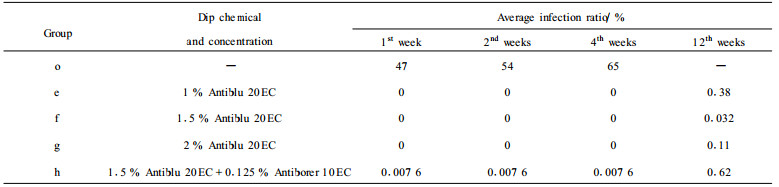

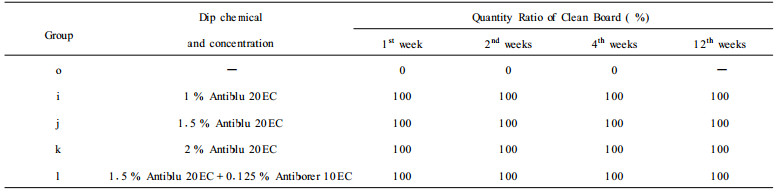

3.4 Antisapstain efficacy on rubberwood pressure treated with ParachemTab. 6 and 7 showed the infection result of Antiblu 20EC dipping treated rubberwood which was pre-treated with Parachem by pressure. It can be seen that all 3 concentrations of Antiblu 20EC and Antiblu + Antiborer treated rubberwood were no any mold and sapstain after 1, 2, 4 and 12 weeks' storage. All of the quantity ratios of clean boards were 100%. This indicated that Antiblu treatment was mostly effective for controlling mould and sapstain fungal attack on Parachem pressure treated rubberwood.

|

|

|

|

It can be drawn from the result that the protection of fresh sawn rubberwood and borax and boric acid treated sawn rubberwood from deterioration (mold and sapstain) can be achieved for 4 weeks by dipping treatment with Antiblu 20EC. For Parachem preservative treated rubberwood, dipping treatment with Antiblu 20EC can provide 12 weeks' protection against mold and sapstain fungal infection.

In order to replace sodium pentachlorophenol (NaPCP) which is toxic to both human being and environment, the preservation of rubberwood may be divided into 2 treatments. One is pressure treatment with boron chemicals; the other is dipping treatment with anti sapstain and anti mold chemical, such as Antiblu 20EC.

If pressure treated rubberwood with boron preservative can not be kiln dried in few days, or air drying is taken to reduce the drying cost, short term protection of rubberwood against mold and sapstain fungal infection during air-dry period can be achieved by dipping treatment with Antiblu 20EC.

Chen Y S(陈允适). Wood preservation is one of the important measures to save wood and solve the problem of insufficient wood resource. Seminar on "Can Chinese people solve the problem of wood demand by themselves", 1997: 129-132

|

Cserjesi A J, Johnson E L. 1982. Mold and sapstain control: laboratory and field tests of 44 fungicidal formulations. Forest Products journal, 32(10): 59-68. |

Food and Agriculture Organization of the United Nations(FAO). Prior Informed Consent Decision Guidance Document, 1997: 49-61

|

Habicht J, Wormuth E W. 1999. Antisapstain treatments in Europe—a comparison with overseas markets, Proceedings of The 2nd New Zealand Sapstain Symposium, Rotorua. New Zealand: 51-60. |

Hong L T, Sim H C. Rubberwood processing and utilization. Kuala lumpur, Forest Research Institute Malaysia, 1994

|

Jiang M L. 2001. Recent trends of chemical studies of fungicide in China. Proceedings of the International Symposium on Development of Natural Pesticide from Forest Resources, Seoul Korea: 71-84. |

Li Y D. Sustainable development of rubberwood in China. Forests and Society: The role of Research, POSTER ABSTRACTS. XXI IUFRO World Congress 2000, Kuala Lumpur, Malaysia, 2000, (3): 291

|

Li Y D(李玉栋). Wood preservation—an effective measure of extending the service life of wood. Newsletter of Wood-based Panels, 2001, 11: 3-5 http://en.cnki.com.cn/Article_en/CJFDTotal-CWBP200111000.htm

|

Li Y D(李玉栋). Wood stain and its prevention and control. Newsletter of Wood-based Panels, 2002, 3: 10-13

|

Morrell J. 1999. Global perspective on future opportunities for alternatives to conventional antisapstain treatments. Proceedings of The 2nd New Zealand Sapstain Symposium, Rotorua, New Zealand: 7-12. |

Nicholas D D, Schultz T P. 1994. Biocides that have potential as wood preservatives-an overview, wood preservation in the 90's and beyond. Proceedings No. 7308, Forest Products Society: 169-173. |

Preston A F. 1999. Global perspective on future trends for the antisapstain industry. Proceedings of The 2nd New Zealand Sapstain Symposium, Rotorua, New Zealand: 3-5. |

Shi Z H(施振华). Developing wood preservation with great strength for the economical use of wood. China Wood Industry, 2001, 15(4): 6-8 http://en.cnki.com.cn/Article_en/CJFDTOTAL-MCGY200104001.htm

|

Tony B. Lumber protection in the 90's. Compiled Proceedings, Forintek Canada Corp. Western Laboratory, Vancouver, Canada, Special Publication No. SP 33, 1992

|

Xing J Q(邢嘉琪). The fungi and insects which attack rubberwood. Forest Research, 2001, 14(2): 230-235 http://en.cnki.com.cn/article_en/cjfdtotal-lykx200102017.htm

|

2003, Vol. 39

2003, Vol. 39