文章信息

- Sui Yaping, Bao Binfu, Sun Fangli, Duan Xinfang, Yang Zhongping

- 眭亚萍, 鲍滨福, 孙芳利, 段新芳, 杨中平

- Termite Resistance of Pinus massoniana Treated with Chitosan-Copper Complexes

- 壳聚糖铜复合物处理后马尾松的防白蚁效果

- Scientia Silvae Sinicae, 2008, 44(8): 152-154.

- 林业科学, 2008, 44(8): 152-154.

-

文章历史

- 收稿日期:2007-04-24

-

作者相关文章

2. 浙江林学院工程学院 临安 311300;

3. 中国林业科学研究院木材工业研究所 北京 100091

2. School of Engineering, Zhejiang Forestry University Lin'an 311300;

3. Research Institute of Wood Industry, CAF Beijing 100091

Wood is easy to destroy by termites in tropical or subtropical area. The conventional and effective methods to preserve wood are treating wood with wood preservatives. Wood preservatives used presently are chlordane, deltametthrin, CCA (copper, chrome and arsenic complex), CCB (copper, chrome and boron complex), pentachlorophenol sodium (PCP-Na) and so on. Because of their toxicity to people's health and the environment, some preservatives such as CCA, PCP-Na are discarded or only permitted in special environments in many countries (Jiang et al., 2002). Therefore, it is important and necessary to develop novel effective and environmentally friendly wood preservatives in termite's control. Chitosan is a non-toxic natural biopolymer and derived from chitin which is the second most abundant natural polymer after cellulose in the world, and easily chelates with metal salts to form chitosan metal complexes(CMC). It is reported that chitosan or its derivatives are good preservatives in many areas, such as food, medicine, textile and wood(Duan et al., 2004; Sun et al., 2006; Hong et al., 2002; Tomonori et al., 1995; Roller et al., 1999). In order to develop novel environmentally friendly wood preservatives, the termite resistance properties of wood treated with CCC and modified CCC respectively are investigated in comparison with CCB treated products.

1 Experimental 1.1 MaterialsChitosan copper complex (CCC) was prepared by reacting chitosan with copper chloride under laboratory condition. Modified chitosan copper complex (M-CCC) was prepared by reacting chitosan with copper chloride and sodium perborate. The concentrations of Cu(Ⅱ) in CCC and M-CCC were respectively 10.5%and 12.5%. The molecular weight of CCC and M-CCC were determined by Ubbelohde viscometer, and the viscosity average molecular weight were respectively 6.01×105 and 1.26×105.The structures of CCC and M-CCC were determined by FTIR.CCB preservative was prepared by dissolving potassium dichromate, copper sulfate and boric acid into water in the proportion of CrO3:CuO:B2O5=51.4:21.5:27.1.

Clear treated wood blocks with 6.4 mm × 25.4 mm × 25.4 mm (L × W × T) were collected from sapwood of Pinus massoniana. Coptotermes formosanus, collected from Pingshang village, Lin'an City, Zhejiang Province, were used in termite resistance test. Sand, screened, washed, and heat-sterilized.

1.2 MethodsImpregnation of test blocks and termite resistance test was conducted in accordance with AWPA E1-97(AWPA 1999) and GB/T 18260-2000.

1) Impregnation of test blocks The treating solutions of the preservatives were prepared by controlling the percentage of Cu(Ⅱ) in the test preservative solutions as 0.05, 0.1 and 0.2 respectively. For each given concentration of each preservative, five replicate blocks were needed. Before impregnation, the blocks should be dried at (40±2)℃ to constant weight (T1), which was the initial or untreated weight of the test block. Then the preservatives will be vacuum absorbed into the test blocks. Remove the blocks from the solution individually, wiped lightly to remove the surface preservative solution, and immediately weighed to the nearest 0.001 g(T2). Calculation of the metal ion retention was obtained from the following formula: Retention(kg·m-3)=(T2-T1)×C×1 000/V. Where, T2:weight of blocks after treatment, g; T1:initial weight of blocks before treatment, g; C: weight of metal ion in 100 g of treating solution; V:volume of block in cubic centimeters.

Five control blocks were needed to employ in the following test. The blocks were oven-dried at 60 ℃ for 2 h, then dried at 80 ℃ for 2 h and finally the temperature was increased to (105±2)℃ for about 8 h until the weight of the blocks was constant. Weighed the blocks to the nearest 0.001 g(T3), T3 was referred to as the weight before termites attacking.

2) Termite resistance test Termite resistance test was conducted in accordance with AWPA E1-97(AWPA 1999).

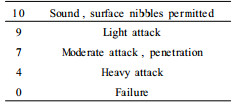

3) Evaluation on the degree of damage Damage evaluation was undertaken by synthetically calculating four parameters as follows. Firstly, examine and visually rate each block according to the rating system provided in AWPA E1-97(AWPA 1999) (Tab. 1). Secondly, evaluate each block by the mass loss of each block (ML): ML=100×(T3-T4)/T3. Where, ML:percentage of mass loss, %; T3:weight of each block before attacking by termite, g; T4:weight of each block after attacking by termite, g.

|

|

Thirdly, evaluated each block by the percentage of dead termites in the container (D): D=(1-W1/1.0)×100. Where, D:percentage of termite mortality in the container, %; W1:weight of the termites alive after termite-resistance test, g; 1.0:weight of the termites alive before termite-resistance test, g.

Finally, the damage degree of blocks was synthetically evaluated as the follows: G=V+ D-ML.

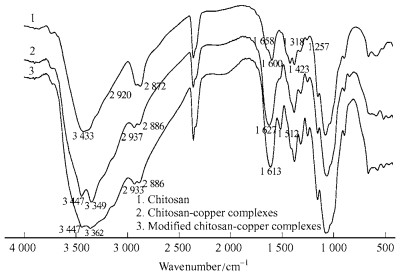

2 Results and discussion 2.1 FTIR spectra of chitosan and modified chitosan-copper complexesThe wide peak at 3 433 cm-1 corresponding to the stretching vibration of —NH2 group and —OH group split into two peaks in the CCC and M-CCC, and the stretching vibration of —NH2 group shifted to lower frequency in the complexes, indicating —NH2 groups take part in complexation. Absorption bands at 1 658 cm-1 assigned to acetamide group disappeared in the complexes. Instead, a new absorption band at 1 512 cm-1 in M-CCC appeared, that was considered as characteristic peak of the association of chitosan and metal, and maybe perborate ion. It suggested that the amine or the acetamide group at C2 interacted with metal. The peak at 1 420 cm-1 attribute to bending vibration of —OH gradually disappeared in the complexes, indicating —OH take part in chelation (Fig. 1).

|

Fig.1 FTIR spectra of chitosan(curve 1), modified chitosan-copper complexes(curve 2) and chitosan-copper complexes(curve 3) |

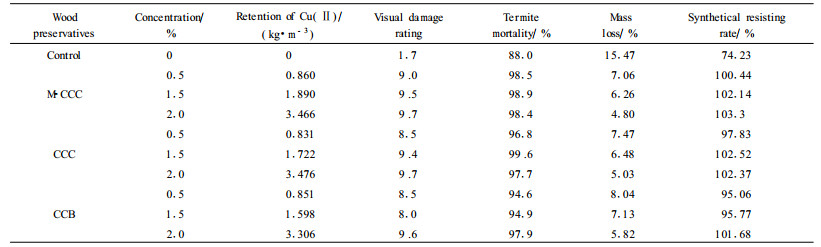

For each preservative, the Cu(Ⅱ) retention in the blocks closely relates to the concentration of preservative, that is, the higher concentration, the more Cu(Ⅱ) retention in the blocks(Tab. 2). When evaluating the termite-resistance effect from the visual rating, the controls were only 1.7, indicating that the controls were seriously destroyed by termites, while the treated ones had better resistance, The visual rating of CCB treated ones exceeded 8.0, while that of the CCC and M-CCC treated ones exceeded 8.5.According to the mass loss results, the final mass losses of the treated blocks were lower than 8.0 percent, while the controls reached 15.5 percent. Comparing the three kinds of preservatives at the same concentration level, the M-CCC treated ones had the minimum mass losses, then the CCC treated ones, and finally the CCB treated ones. For each preservative, with the increase of concentration, the mass losses of blocks decreased. Although the termites could eat the treated wood blocks, over 95 percent died during four weeks, while the controls had lower termite mortality, only 88 percent. Comparing with the CCC and CCB preservatives, M-CCC had the highest termite mortality, exceeded 98 percent. Based on the above rating results, the synthetical rating of the treated blocks exceeds 95, while that of the controls was only 74.2.Of which, M-CCC beheld the best, the synthetical rating of which exceeded 100, then the CCC, the synthetical rating exceeded 97, and the synthetical rating of CCB exceeded 95.With the increased concentrations of the preservatives, termite-resistance effects increased a little. From the results, we can conclude that the three test preservatives had the ability to drive the termites, keeping them far away from the treated blocks.

|

|

A modified chitosan-copper complex was prepared to improve the termite-resistance of CCC. Masson pine treated with M-CCC had better resisting results on Coptotermes formosanus than with CCC and CCB, the synthetical resisting rates of M-CCC, CCC and CCB to termites were respectively 100.44 to 103.3, 97.83 to 102.37 and 95.06 to 101.68, indicating that modified CCC had excellent termite-resistance activity against Coptotermes formosanus compared to CCC.

Duan Xinfang(段新芳), Sun Fangli(孙芳利), Zhu Wei(朱玮), et al. 2004. Decay-resistance of wood treated with chitosan metal complex. Scientia Silvae Sinicae (林业科学), 40(6): 138-143. http://www.linyekexue.net/EN/Y2004/V40/I6/138

|

Hong K N, Na Y P, Shin H L, et al. 2002. Antibacterial activity of chitosans and citosan oligomers with different molecular weights. Intern ational Journal of Food Microbiology, 74: 65-72. DOI:10.1016/S0168-1605(01)00717-6 |

Jiang Mingliang(蒋明亮), Fei Benhua(费本华). 2002. Current situation of wood preservation technology and some suggestions on its research and development in China. World Forestry Research(世界林业研究), 15(3): 44-48. http://en.cnki.com.cn/Article_en/CJFDTOTAL-SJLY200203007.htm

|

Roller S, Covill N. 1999. The antifungal properties of chitosan in laboratory media and apple juice. International Journal of Food Microbiology, 47: 67-77. DOI:10.1016/S0168-1605(99)00006-9 |

Sun Fangli(孙芳利), Duan Xinfang(段新芳), Wen Guifeng(文桂峰), et al. 2006. Anti-mold effects of CMC wood preservatives on bamboo wood. Scientia Silvae Sinicae(林业科学), 42(3): 40-43. http://www.linyekexue.net/EN/abstract/abstract5850.shtml

|

Tomonori Ikuo. 1995. Wood-preserving effectiveness of chitosan-metal.salts against wood decaying fungi. The Society for Antibacterial and Antifungal Agents, Japan, 23(5): 14-20. |

2008, Vol. 44

2008, Vol. 44