Review of Risk Analysis Studies in the Maritime LNG Sector

https://doi.org/10.1007/s11804-023-00376-0

-

Abstract

This research presents a review and classification of the published work related to applied risk analysis and risk management in the maritime liquefied natural gas (LNG) sector from 2000 to 2023. The papers are categorised under two primary contexts. The first is the risk analysis theory context which represents the classification with respect to (w. r. t.) the used risk analysis method, the used risk analysis tool, and the objective of risk analysis, whereas the second is the presented case in the risk analysis context which represents the classification w. r. t. the analysed LNG ship type, the analysed operation, and the inclusion level of human error in risk analysis. The above process has revealed that the interest in this domain of research has increased significantly during the past decade. In addition, the use of dynamic risk analysis (DRA) tools, and the inclusion of human error in the risk analysis model have been observed significantly in the past five years, in particular, for modelling the risk of external LNG transfer operations. It is concluded that the inclusion of the effect of human and organisational factors (HOFs) in risk analysis, and the use of DRA methods for modelling the risk of the daily routine operations of the complex maritime LNG systems can improve the management of the operational risk of these systems.Article Highlights● The global efforts of decarbonisation have been major contributors in the rapid growth of the maritime LNG sector.● The number of the relevant publications to risk analysis in the maritime LNG sector has increased significantly in the past decade.● Improving the incorporation of HOFs in risk analysis will improve risk prediction and management in the maritime LNG context.● The use of DRA tools in modelling the risk of routine operations will improve the operational risk management of the critical marine LNG units. -

1 Introduction

The harmful impacts of global warming and climate change on earth have been posing significant challenges to governments and policy makers for decades for finding sustainable solutions for the reduction of the continuing growth of greenhouse gases (GHGs) (UNEP 2007). Accordingly, sectors, where activities/products are responsible for the release of GHGs to the atmosphere (e.g., energy, industrial, and transport sectors), have been encouraged by the above-mentioned parties to implement sustainable measures for limiting their impacts on increasing global warming and climate change (UNEP 2007).

As the responsible entity of the sector that transports more than 80% of the worldwide trade (UNCTAD 2021), the International Maritime Organisation (IMO) has been concerned about reducing the produced air emissions from ships since the introduction of Annex VI of the MARPOL convention (The International Convention for the Prevention of Pollution from Ships) in 1997 (IMO 1997, p96; IMO 2019a).

Further focus on reducing GHG emissions from the maritime sector has started since the introduction of the energy efficiency regulation of ships in 2011 (IMO 2011, MEPC. 203(62)). Seven years later, the IMO has released the initial strategy for reducing GHGs from ships which proposes a set of measures for achieving finite and time-bound targets of reducing Carbon Dioxide (CO2) and other GHG emissions from ships regarding 2008 levels (IMO 2018; Tadros et al. 2023a). In response to the IMO's emission reduction efforts, stakeholders of the shipping industry have been actively working during recent decades in different directions for finding reliable and sustainable solutions for improving the environmental performance of ships. Examples of these solutions are improving the design of hulls and propulsion systems, using alternative fuels, developing exhaust emission abatement solutions, and optimising ship operations (Tadros et al., 2023b).

When considering alternative fuels, the use of LNG as a marine fuel has been recognised as one of the efficient solutions for reducing GHG emissions from ships. Although the use of LNG as a ship fuel has received criticism due to the effect of methane slip on the atmosphere, the newly developed LNG-fuelled marine engines could successfully cut 50% of methane slip and achieve 20%–25% reduction of the CO2 and CO2 equivalent emissions (WinDg 2020). LNG is also deemed to be a safe, and economic ship fuel due to the current maturity level of the marine LNG fuel systems, as well as, the cost-effectiveness of LNG when compared with the other fossil fuels that are used in marine diesel engines along with emissions' abatement solutions (Ampah et al. 2021; Hansson et al. 2019; Wang et al. 2021a).

Therefore, the use of LNG as a marine fuel is considered to be a suitable solution for reducing GHG emissions during the ongoing energy transition period till further reliable and cost-efficient carbon-neutral solutions become available. Other than that, the global demand for LNG has increased significantly during the past decade due to its low emissions value, availability, and reasonable price (GIIGNL 2021; Jaramillo et al. 2007).

The above factors have had direct effects on increasing the number of ships that carry LNG as cargo or fuel during the past two decades. As reported in Abdelmalek and Guedes Soares (2022), as of the end of 2020, the number of ships that carry LNG as cargo or fuel has reached 844 ships in operation and 427 ships on order. These numbers represent the related ships to the shipping industry i.e. LNG carriers (LNGCs), bunkering vessels (LNGBVs), and LNG-Fuelled Ships (LNGFSs), in addition to the related ships to the oil and gas industry, i.e., Floating LNG units (FLNGs).

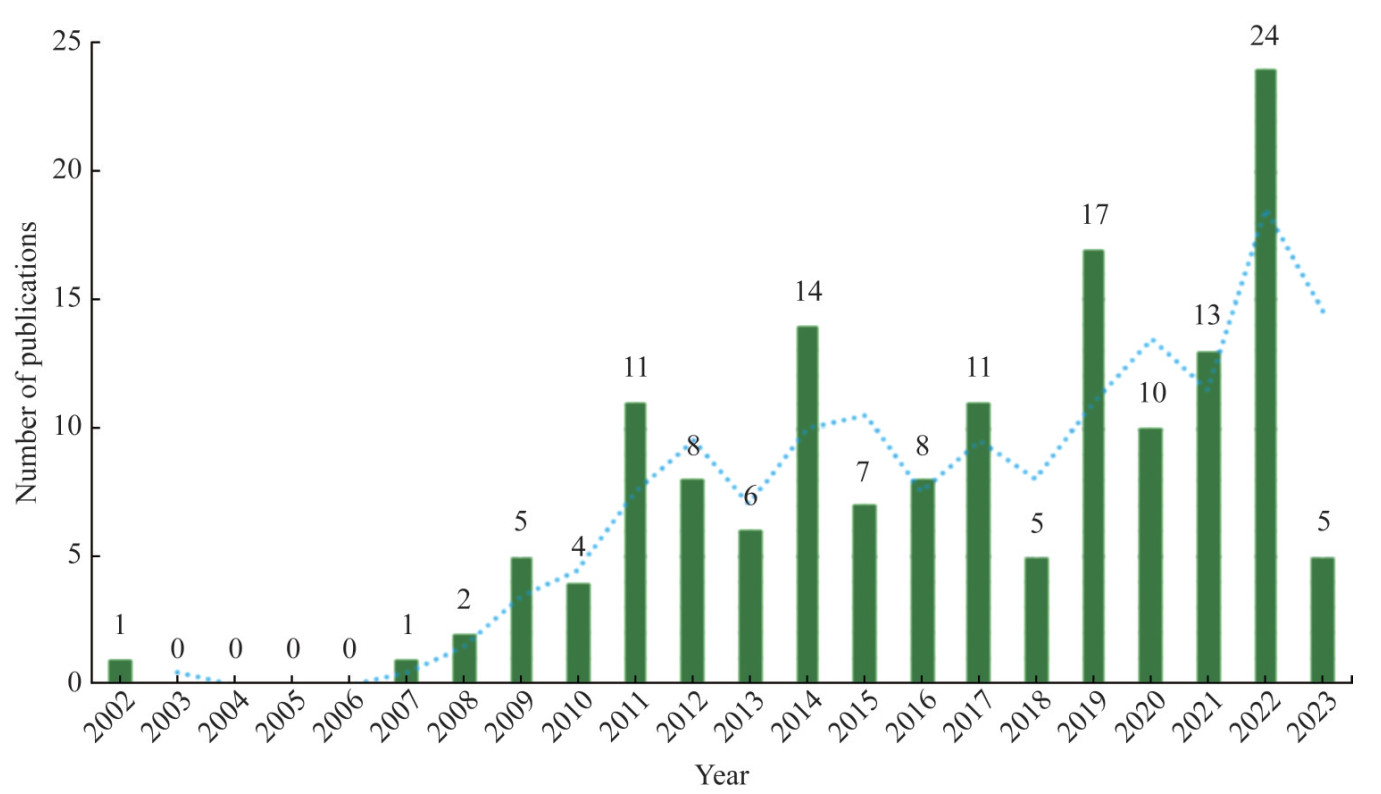

However, on one hand, the rapid and continuous increase in the number of ships that belong to the maritime LNG sector presents significant environmental benefits in terms of reducing the produced GHG emissions from the shipping industry and the other sectors. But on the other hand, maintaining the safe performance of this sector in terms of the absence of significant LNG leaks, or more optimistically ensuring a leak-free future for the maritime LNG sector is a primary operational safety challenge to the increasing growth in this sector. This challenge is primarily originated from the importance of avoiding the severe hazards of LNG leaks which can lead to harmful consequences in case of ignition or non-ignition as mentioned in Alderman (2005) and Pitblado et al. (2005). Therefore, the related research domain to applied risk analysis in the maritime LNG context has received significant interest during the past ten years. This fact is supported by the presented statistics later in this paper which reveals that the average number of relevant publications to this research domain has increased from 2.5 articles per year between 2000 and 2012, to 10.9 articles per year between 2013 and July 2023.

This paper presents a review of the related publications on applied safety risk analysis and risk management of maritime LNG units. The objectives of this review are to indicate the progress of this research domain in the period 2000 – 2023, in addition to, classifying the reviewed articles concerning the following six dimensions; ⅰ) the used risk analysis methods, ⅱ) the used risk analysis tools; ⅲ) the objective of risk analysis; ⅳ) the analysed LNG ship type; ⅴ) the analysed ship operation; and finally, ⅵ) the inclusion level of human error in risk analysis.

The first three dimensions are classified under the risk analysis theory context, while the remaining dimensions are categorised under the presented case in the risk analysis context. However, further review and classification of the related articles to risk analysis in the maritime and onshore LNG sectors have been presented in Animah and Shafiee (2020), which has presented important information to the interested parties in this domain of research regarding the practical application, and possible improvements in risk analysis in the LNG sector.

However, in the present work, the classification process aims to check to what extent the included information in the reviewed articles is addressing the operational safety challenges that are confronting the development of the maritime LNG sector. Examples of these challenges are the high complexity of the used LNG systems onboard FLNGs which represent both LNG Floating Production Storage and Offloading units (FPSOs) and LNG Floating Storage and Regasification Units (FSRUs), and the rapid increase in the number of LNGCs and LNGFSs in comparison to the limited numbers of crewmembers with sufficient experience in operating these types of ships (Abdelmalek and Guedes Soares 2022).

The current paper consists of seven sections including an introduction. Sections two and three present information on the two primary motivations behind the recent increase in interest in the related research to safety risk analysis and risk management domain in the maritime LNG sector which are the rapid expansion in the maritime LNG sector and its driving factors, and the resulting hazards from the accidental LNG leaks, respectively. Subsequently, the methodologies used for searching, selecting, and classifying the reviewed articles are introduced in section four. Section five presents the results of the articles' review and classification. Afterwards, discussions on the development of the relevant articles to the scope of the present research and the driving factors of this development, and the main findings from the articles' review and classification process are presented in section six, in addition to, recommendations for improving the risk modelling and management in the field of interest. Lastly, section seven presents a conclusion of the conducted work.

It is assumed that the readers of this research have prior knowledge of the theory, methods, and practical applications of risk analysis and risk management so that backgrounds on these topics are not presented herein. But for readers who have no or limited prior knowledge on the topics above, information on all of the ⅰ) processes, methods, and tools of risk analysis and risk management can be found in (ISO 2009; Rausand 2011), ⅱ) dynamic methods in risk management in (Raveendran et al. 2022; Villa et al. 2015), ⅲ) applications of risk assessment in the maritime and offshore oil and gas industry in (Vinnem 2007), and ⅲ) human error and human reliability analysis (HRA) in (NASA 2006; Wu et al. 2022).

2 Growth of the maritime LNG sector

The last decade has witnessed significant development in the maritime LNG sector. As of the end of 2020, the total number of maritime LNG units has reached, approximately 844 ships in operation and 427 ships on order (Abdelmalek and Guedes Soares 2022). These numbers are representing the transporting LNG ships (i.e. LNGCs, LNGBVs, and LNGFSs) and the in-situ FLNGs. The number of ships in operation and on order of each class of the maritime LNG units, as of the end of 2020, is presented in Table 1.

Table 1 Number of the various maritime LNG units in operation and on orderSegment Transporting units In-situ units Subclass LNGCs1 LNGBVs1, 2 LNGFSs3 FSRUs4 FPSOs4 In operation 576 23 198 43 4 On order 119 21 277 7 3 Sources: 1GIIGNL 2021; 2MOL 2021; 3Nerheim et al. 2021; 4Songhurst 2019. The rise in the number of LNGCs and FSRUs has resulted from the rapid development in the worldwide demand for natural gas (NG) due to its economic competitiveness, and low environmental footprint compared to other fossil energy sources such as coal and crude oil (GIIGNL 2021; Jaramillo et al. 2007) since the volume of LNG imports has increased from 224 million tonnes per year (MTPA) in 2010 to 356.1 MTPA in 2020 (GIIGNL 2021; IGU 2010). Furthermore, according to GIIGNL (2020), the global imports of LNG are expected to reach around 600 MTPA by 2025. Other than that, the ability of LNG FPSOs to unlock small-scale NG offshore projects has increased the attractiveness of this class of production facilities to several oil and gas producers (KPMG 2014).

On the other side, the growth in the number of LNGFSs and LNGBVs is attributed to two important factors. The first is the compatibility of LNG, as a ship fuel, with the present IMO requirements for reducing exhaust emissions from the shipping industry (IMO 2018, 2019b, c), while the second is the long-term economic competitiveness of using LNG as a ship fuel in comparison to the other conventional marine fuels (Wang et al. 2021a; WARTSILA 2017).

In detail, according to IMO (2019b), starting from January 2020 all ships had to comply with the 0.5% sulphur cap in all areas, while in the emission control areas (ECAs) the sulphur cap is reduced to 0.1%. The IMO has also stated further requirements to control the emissions of Nitrogen oxide (NOx) from the shipping industry. According to Annex VI of the MARPOL convention, starting from January 1st 2000, all ships equipped with diesel engines with more than 130 kW output power other than ships that are used for emergency purposes had to comply with the presented requirements in Table 2 (IMO 2019c). As indicated in Table 2, there are three different tiers of NOx emissions limits where the limit of each tier applies based on the construction date and engine-rated speed of the ship.

Table 2 The limits of the IMO NOx emissions tiers (IMO 2019c)Tier Ship construction date on, or after Total weighted cycle emission limit (g/kWh) n < 130 n=130-1999 n≥2 000 Ⅰ January, 1st 2000 17.0 45n(- 0.2) 9.8 Ⅱ January, 1st 2011 14.4 44n(- 0.23) 7.7 Ⅲ January, 1st 2016 3.4 9n(- 0.2) 2.0 Note: n=engine's rated speed (r/min). Other than SOx and NOx emissions, fossil fuel-driven ship engines are also emitting further harmful emissions such as Greenhouse Gases (GHG) which refers to Carbon Dioxide (CO2), methane (CH4), and Nitrous Oxide (N2O) (Winnes et al. 2015), and Particulate Matters (PM) including Black Carbon (BC) (Lindstad et al. 2020). However, in 2018 the IMO adopted the initial strategy for reducing GHG emissions from the maritime sector (IMO 2018). In this initial strategy, the IMO has presented several short-, mid-, and long-term candidate measures to achieve the following objectives. According to IMO (2018), regarding 2008 levels, the industrial average of CO2 emissions per transport work should be reduced by 40% and 70% by 2030 and 2050, respectively. Also, the annual GHG emissions level should be reduced to at least 50% by 2050 regarding 2008 levels.

The primary motivation behind these requirements is the control of the continuous increase of the emitted GHGs and most importantly CO2 emissions from the maritime transport sector. According to the fourth IMO GHG Study, the emitted CO2 from the maritime transport industry had increased from 962 MTPA in 2012 to 1 056 MTPA in 2018, which approximately accounts for a 10% increment in 6 years (IMO 2020). In addition, Serra and Fancello (2020) represented that, the expected continuous growth in the seaborne trade could result in a 50% to 250% rise in the resulting CO2 emissions from the shipping industry by 2050.

In light of the presented information above, LNG is deemed to be the most reliable alternative marine fuel in the meantime due to several reasons. Firstly, marine LNG-fuel systems are mature, and safe, and have been in service onboard ships since 2000 without resulting in any significant accident (DNV 2019, 2020). Also, LNGFSs that are designed according to the requirements of the IMO IGF code (International code of safety for ships using gases and other low-flashpoint fuels) (IMO 2016), are assumed to be as safe as their similar conventional oil-fuelled ships (Fan et al. 2021).

Secondly, a ship that is powered by LNG will release almost zero SOx emissions and can reduce NOx and CO2 emissions by 80% and 20%, respectively, with reference made to the resulting emissions from its similar heavy oil-fuelled ship (Ampah et al. 2021; Wang et al. 2021a). However, the reduction in NOx emissions from LNGFSs ranges between 25% and 90% depending on the type of the used engine(s) onboard the ship (SINTEF 2017; Wang et al. 2021a). Therefore, LNGFSs can comply with the 0.1% sulphur cap, and Tier Ⅲ NOx emissions without being equipped with any emission reduction technologies such as Exhaust Gas Recirculation (EGR), Scrubbers, or Selective Catalytic Reduction (SCR) (Deng et al. 2021; Wang et al. 2021a).

Moreover, LNGFSs will release 96% less PM emissions than their similar conventional oil-fuelled ships (Elgohary et al. 2015). The reduction in PM emissions is significant to the environment because PM includes BC which has 20-year and 100-year Global Warming Potentials (GWPs) equal to 3200 and 900, respectively (ICCT 2017 p.10).

Thirdly, from the economic perspective, the Capital Expenditures (CAPEX) of the LNGFSs is approximately 15– 25% higher than that of the oil-fuelled vessels (Aymelek et al. 2015; Wang et al. 2021a), but their average payback period is around 7 years regarding the Operational Expenditures (OPEX) of their similar oil-fuelled vessels (European Commission 2017; Fan et al. 2021). In addition, the presented case study in WARTSILA (2017) showed that LNGFSs can save 20% of the Life Cycle Cost (LCC) over 20 years regarding the LCC of their similar heavy oil-fuelled ships which are equipped with SOx abatement solutions. Other than that, a study conducted by Hansson et al. (2019) concluded that LNG is prioritised over other alternative low-carbon marine fuels when considering the current economic, technical, environmental and social aspects.

In contrast to the information above, the growth in relying on LNG as a ship fuel is expected to be negatively influenced in the near future if the proposed IMO's 70% reduction requirement of CO2 emissions comes into force in 2050 (DNV 2020). Therefore, renewable Methanol (Bio-Methanol or E-Methanol) (IRENA 2021), and Liquefied Ammonia (LNH3) (ABS 2020), are expected to become the dominating carbon-neutral marine fuels in the near future (DNV 2020).

Liquid Hydrogen (LH2) is expected to become one of the reliable zero-carbon fuels in the short-sea shipping segment (DNV 2020; Nerheim et al. 2021). In Table 3, a comparison between the resulting emissions from using LNG as a ship fuel versus the other carbon-neutral fuels is given with reference made to the resulting emissions from heavy fuel oil-powered engines. In this comparison, LNG is assumed to be used in an engine that complies with NOx Tier Ⅲ requirements. In addition, the presented emission values of LH2 is related to using it in a fuel cell (FC), which in that case according to DNV (2019) has zero NOx emissions. Further information on the produced NOx emissions from using Hydrogen in internal combustion engines can be found in (Heffel 2003).

Table 3 Comparison between LNG and the other carbon-neutral fuelsFuel Price (USD/GJ) Energy (MJ/kg) (lhv)* Density (liquid) (kg/m3) SOx (%m/m) NOx reduction (%) CO2 reduction (%) Technical maturity4** Safety level4** HFO 10 36 991 3.5 0 (Tier Ⅰ) 0 V. High V. High LNG 7.85 483 4308 traces2 85–90 (Tier Ⅲ)9 204 High V. High L.NH3 22.95 18.610 600 null10 no info. yet (Tier Ⅰ or Ⅱ)10 10010 Low Low Ren. methanol 29.855 201, 7, 8 7961, 7, 8 null8 Up to 80 (Tier Ⅲ)8 up to 958 Medium Medium LH2 40–506*** 1209 719 null3 100 (FC) (Tier Ⅲ)3 100 Low V. Low Sources: 1Bazaluk et al. 2020; 2Deng et al. 2021; 3-5DNV 2019, 2020, 2021; 6Hydrogen Council 2021; 7IRENA 2021; 8Methanol Institute 2018; 9Nerheim et al. 2021; 10OEKO 2021.

Notes: *Lower heating value. **Information extracted from(DNV 2020, p85). ***Rough estimate based on the presented hydrogen prices in (Hydrogen Council 2021, p18).3 Hazards of LNG leaks

LNG is liquefied at atmospheric pressure at -162 ℃ (Nerheim et al. 2021). In addition, LNG is odourless, colourless, non-toxic, and non-corrosive (Alderman 2005). The flammability range of LNG vapours falls between 4.5% and 16.5%, and its minimum ignition energy is 0.28 mJ both at atmospheric pressure at 20 ℃ (Vandebroek and Berghmans 2012). However, ignited and non-ignited accidental LNG leaks can lead to severe consequences to humans, the environment, and assets (Alderman 2005; Pitblado et al. 2005).

3.1 Hazards of non-ignited LNG leaks

3.1.1 Hazards to the environment

LNG releases to the sea will evaporate without causing any effect on the marine environment. However, massive releases of LNG vapours, which are mainly consisting of methane, will have adverse effects on the surrounding atmosphere to the source of release (Lindstad et al. 2020). Because methane is one of the GHGs, as well as one of the harmful volatile organic compounds (VOCs) that act as a precursor to tropospheric ozone (ground-level ozone) (Mohajan 2012). According to Royal Society (2008), ground-level ozone is a major cause of acute and chronic respiratory diseases to humans, in addition, it is one of the causes of reducing the yield of staple crops. Besides, the release of methane into the atmosphere will consume hydroxyl radicals (OH) which act as a natural cleaner to the troposphere from the various urban hydrocarbon pollutants (Sanderson 2008).

Ignition and burning of the released LNG vapours will produce further GHGs such as CO2 and N2O, in addition to producing precursors to tropospheric ozone such as NOX and N2O (Mohajan 2012; World Bank Group 1998a). The GWP of the nitrous oxide (i.e. N2O) is approximately 300 times of that of the CO2 (ICCT 2017). Other than that, N2O is also acknowledged as one of the major causes of stratospheric ozone depletion (European Commission 2016). Furthermore, around 7% of the emitted N2O to the stratosphere is transported back to the troposphere in the form of NOX emissions (Portmann et al. 2012). The presence of NOX emissions in the troposphere will contribute to the formation of acid rains and PMs which have harmful effects on human health and plants (ECGEB n.d.; EPA 1999; Leibensperger et al. 2011; World Bank Group 1998b).

3.1.2 Hazards to the human body

Direct exposure to LNG and its cold vapours can lead to several severe effects on the human body. The major hazards of LNG leaks to the human body are hypothermia, lung damage, frostbite, and asphyxiation. According to Mayo Clinic (2020), "Hypothermia is a medical emergency that occurs when the human body loses heat faster than it can produce heat, causing a dangerously low body temperature". Hypothermia can occur in unprotected workers who are exposed to cold LNG vapours. Hypothermia becomes dangerous when the human core temperature reaches 35 ℃ and below, and at very low temperatures, hypothermia can rapidly lead to unconsciousness and death (IHSA n.d.; Mayo Clinic 2020). The only reported fatality event that has occurred in the maritime LNG sector was due to the exposure of a terminal worker to an LNG leak during a cargo loading operation at Arzew, Algeria in 1977, where the leaked LNG caused him to freeze to death (Cabrillo Port 2007). Other than that, human lungs can be severely damaged due to the inhalation of cryogenic vapours (TUN 2013).

Human skin that comes in contact with cryogenic fluids will suffer from frostbite. According to Sever et al. (2010) "frostbite is an acute freezing of tissues when exposed to temperature below the freezing point of intact skin". Consequences of frostbite can develop beyond the temporary skin damage of slight cold burns to causing permanent damage to skin and numbness of the affected area, and also can lead to damage to muscles and bones (Mayo Clinic 2022). IHSA (n.d.) stated that human flesh may freeze in less than 30 seconds at a temperature equal to -46 ℃, which is quite warmer than the temperature of LNG. The therapy of frostbites can take a very long time (30 days in the hospital, and 3 to 16 months for follow-up), and often the damaged part is amputated (Sever et al. 2010). Furthermore, oxygen deficiency can occur in the surrounding area to LNG leaks due to the large expansion ratio of the vaporised LNG (i.e. 1∶600). However, an area is classified as unsafe for human beings when oxygen level falls below 18%, due to the risk of oxygen deficiency asphyxiation (ESS 2016). Furthermore, if oxygen concentration falls below 11% in a particular area, 100% fatality will occur in 8 minutes to any person located in that area (OSHA 2018).

3.1.3 Brittle fracture

The cooling effect of the spilt LNG will reduce the temperature of the affected ship structural steel below its Ductile-to-Brittle Transition Temperature (DBTT), and accordingly the behaviour of the low carbon steel alloys of ship structure will change from ductility to brittleness (Knott 2015; Petti et al. 2013).

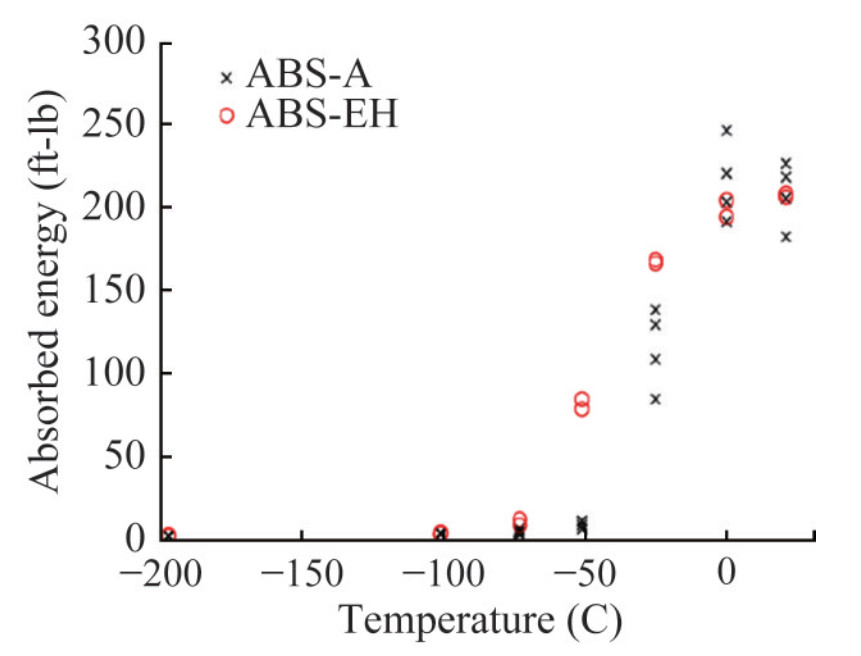

In more detail, when structural steel is exposed to cryogenic liquid spills the steel will experience excessive transient thermal stresses (Lu and Fleck 1998), in addition to a significant reduction in fracture toughness (Knott 2015). As reported by Keseler et al. (2015), the combination of both conditions resulted in brittle fractures to a platform's deck which had been exposed to a spill of liquid nitrogen. In addition, Ostvik et al. (2005) reported that historical accidental LNG leaks onboard ships were always associated with local fractures to the affected structural elements. However, the conducted study by Petti et al. (2013) examined the effect of exposing two different grades of ship steel, namely ABS Grade A and ABS Grade EH, to various low-temperature levels on fracture toughness and concluded that both steel grades will reach nearly zero fracture toughness at -100 ℃ as indicated in Figure 1.

Figure 1 Charpy V-Notch energy absorbed for ABS Grades A and EH steels (Petti et al. 2013)

Figure 1 Charpy V-Notch energy absorbed for ABS Grades A and EH steels (Petti et al. 2013)Other studies have revealed that the DBTT of high strength low carbon steel alloys ranges between -100 ℃ to -150 ℃, (Inoue et al. 2021; Zia-Ebrahimi 1985). The value of the DBTT of ferritic steel is controlled by several factors such as; material composition, material geometry, material condition, and grain size (Bayley and Sterjovski 2019; Inoue et al. 2021).

Recent results have provided information on the mechanical properties of steels under low temperatures (Wang et al. 2021b; Zhang et al. 2023; Zhao et al. 2020).

3.1.4 Rapid phase transition

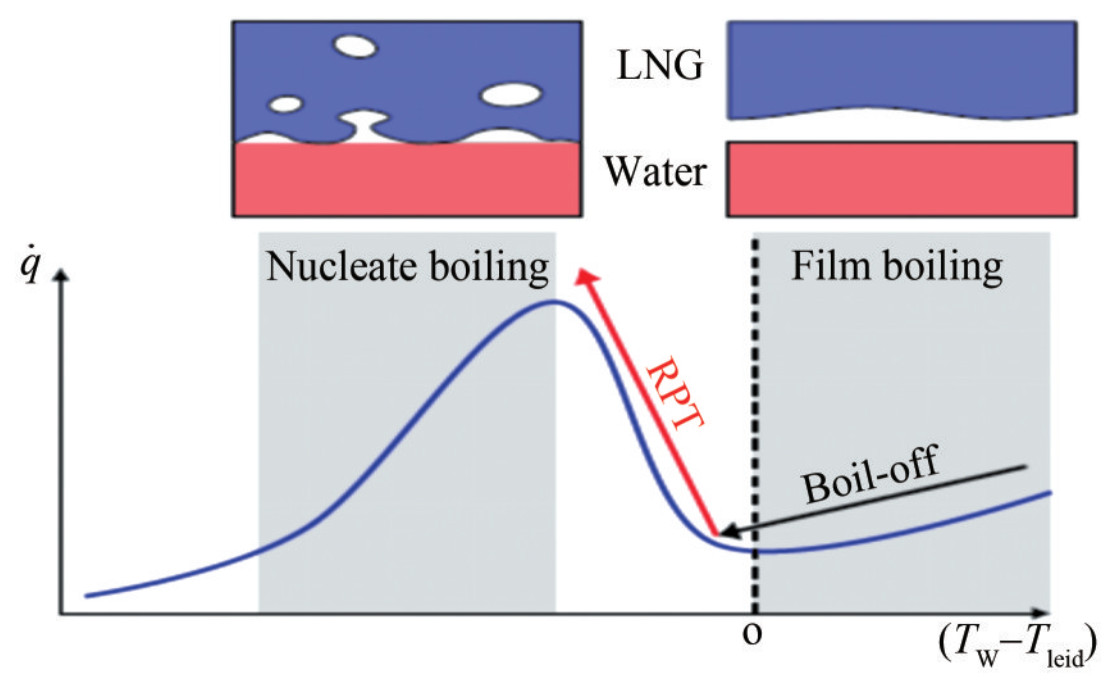

The pouring of LNG on warmer surfaces (e.g. seawater) introduces a potential risk of physical explosion when rapid vaporisation of LNG occurs, however, this phenomenon is known as rapid phase transition (RPT) (Alderman 2005). RPT is classified as early RPT (i.e. droplet boiling) and delayed RPT (i.e. pool boiling) (Aursand et al. 2020).

Early RPT occurs immediately below the leakage point due to the boiling of the submerged LNG droplets, while delayed RPT occurs when the LNG spill reaches the Leidenfrost point (Luketa-Hanlin 2006). In detail, when LNG spills into the sea, the difference between seawater temperature (TW) and LNG temperature will lead to rapid boiling accompanied by the propagation of bubbles which will create a vapour layer at the interface between both mediums (Ustolin et al. 2020a). The low thermal conductivity of the intermediate vapour layer will allow a small amount of heat flux to transfer from seawater to the spilt LNG. In this case, LNG will continue to vaporise under the film boiling regime. During the film boiling, methane will preferentially boil-off due to its lower molecular weight compared to the heavier alkanes of the LNG composition (e.g. ethane and propane) (Luketa-Hanlin 2006; Melhem et al. 2006).

The continuous vaporisation of methane will gradually rise the Leidenfrost temperature (TLeid) of the remaining LNG composition (Aursand and Hammer 2018). However, the film boiling regime will persist until the vapour layer collapses at the Leidenfrost point (i.e. TW - TLeid = 0). The Leidenfrost point is defined as the onset of the transition from the film boiling regime to the nucleate boiling regime (Bernardin and Mudawar 1999; Embach 2006). At this point, the liquid-liquid contact will occur at various locations leading to the sudden increase in heat flux transfer from seawater to LNG.

The sudden rise of the heat flux transfer will rapidly lead the LNG to reach the superheating limit. In this condition, the evaporation rate of LNG will not be sufficient to release the added heat flux, and then homogeneous nucleation will occur leading to explosive expansion (i.e. RPT) which occurs to return the LNG vapour to its equilibrium state (Aursand and Hammer 2018; Aursand et al. 2020).

In Figure 2, the transition process from film boiling to nucleate boiling of LNG is illustrated. Other than that, accidental ingress of seawater inside LNG tanks can trigger internal RPT (Melhem et al. 2006). The primary concern from the RPT occurrence is the consequent over-pressure wave of this event which can result in damage to the objects located in the vicinity of the RPT origin (Pitblado et al. 2005). The estimated explosion energy from an RPT ranges between 50–80 kJ/kg which is approximately 10–20 g TNT equivalent (Aursand and Hammer 2018; Aursand et al. 2020).

Figure 2 Transition from film boiling regieme to nucleate boiling regieme vs. the associated heat flux (q.) of each boiling regeime (Aursand and Hammer 2018)

Figure 2 Transition from film boiling regieme to nucleate boiling regieme vs. the associated heat flux (q.) of each boiling regeime (Aursand and Hammer 2018)3.2 Hazards of ignited LNG leaks

Ignited LNG leaks are highly undesirable events due to their high potential of causing severe consequences to humans, environment, and assets. The severity of LNG fire and explosion events depends on several factors such as the releasing rate and the released quantity of LNG, the time (i.e. immediate or delayed) and location of ignition, the duration of fire, and the weather condition.

The immediate and delayed ignition of LNG leaks can result in various fire and explosion outcomes. There are two scenarios of the immediate ignition of LNG leaks which are pool fires (Betteridge et al. 2014), and jet fires (Zhang et al. 2019), while delayed ignition can result is flash fires (Cracknell and Carsley 1997), or Vapour Cloud Explosions (VCE) (Atkinson et al. 2017). Other than that, pressurised LNG equipment that is subjected to extensive pool or jet fire loads to the level that makes its internal pressure exceeds its structural integrity will fail and release a massive fire ball or, in other words, will trigger Boiling Liquid Expanding Vapour Explosion (BLEVE) (Pitblado 2007). However, cold BLEVEs can occur to pressurised LNG equipment due to non-fire related structural failures, failures of the pressure relief system (PRS), or insulation failure (Patricio et al. 2012; Ustolin et al. 2020b).

The severity of LNG fires originates from the resulting thermal loads, and the produced smoke from burning the other combustible materials. According to Petti et al. (2013), an external pool fire with surface emissive power of 290 kW/m2 will rise the temperatures of the outer and inner hulls of the impacted ship to 1 000 ℃, and 775 ℃, respectively, in 15 minutes. This condition will result in a 75% reduction in the strength of ship steel. On the other side, jet fires will result in severe damage due to their high heat flux, and high mechanical erosive effect, but this kind of fire will cause local damage to the affected area (ABS 2004; Roberts et al. 2001). In addition, in some of the escalated scenarios fire and smoke loads can obstruct human beings from reaching the designated mustering area (Vinnem 2007, section 6.9).

Furthermore, flash fires occur within almost 3 seconds and will radiate heat without causing significant overpressures (Margolin 2013; Pitblado et al. 2005). The harmful effect of flash fires is restricted to human beings who are located within their harmful radiation zone (SINTEF 2003). But in case of the presence of obstructions or confinements in the flash fire zone, the flame propagation speed will accelerate from the subsonic to the supersonic speed and then deflagration to detonation transition (DDT) will occur leading to VCE (ABS 2004; Oran et al. 2020). The expected outcomes of VCEs are more destructive than those of flash fires due to the resulting blast waves and missiles etc. (ABS 2004; Vinnem 2007). A well-known example of the severity of VCEs in the LNG industry is the accident that occurred in the Skikda LNG plant in Algeria in 2004 that has resulted in 27 fatalities, 56 injuries, and $900 million in terms of financial loss (Ouddai et al. 2012).

4 Methodology

4.1 Searching and selection of the reviewed articles

The reviewed articles in this study are obtained from Web of Science (WoS) and Scopus databases. WoS and Scopus are selected due to the stringent evaluation criteria that both databases are using for assessing the selected articles compared to the other database sources (Ampah et al. 2021; LSE 2019). In addition, the use of WoS and Scopus collectively will ensure the acquisition of sufficient amount of high-quality research data. Therefore, the use of both databases is highly recommended when conducting studies related to Bibliometric analysis, meta-analysis, and systematic review (Donthu et al. 2021; Pranckutė 2021; Zhu and Liu 2020).

In addition, for ensuring proper searching on the related publications to applied risk analysis in the maritime LNG domain, the provided searching procedures in Clarivate (2020) were used. However, further information regarding WoS and Scopus and the difference between them can be found in Stahlschmidt and Stephen (2020).

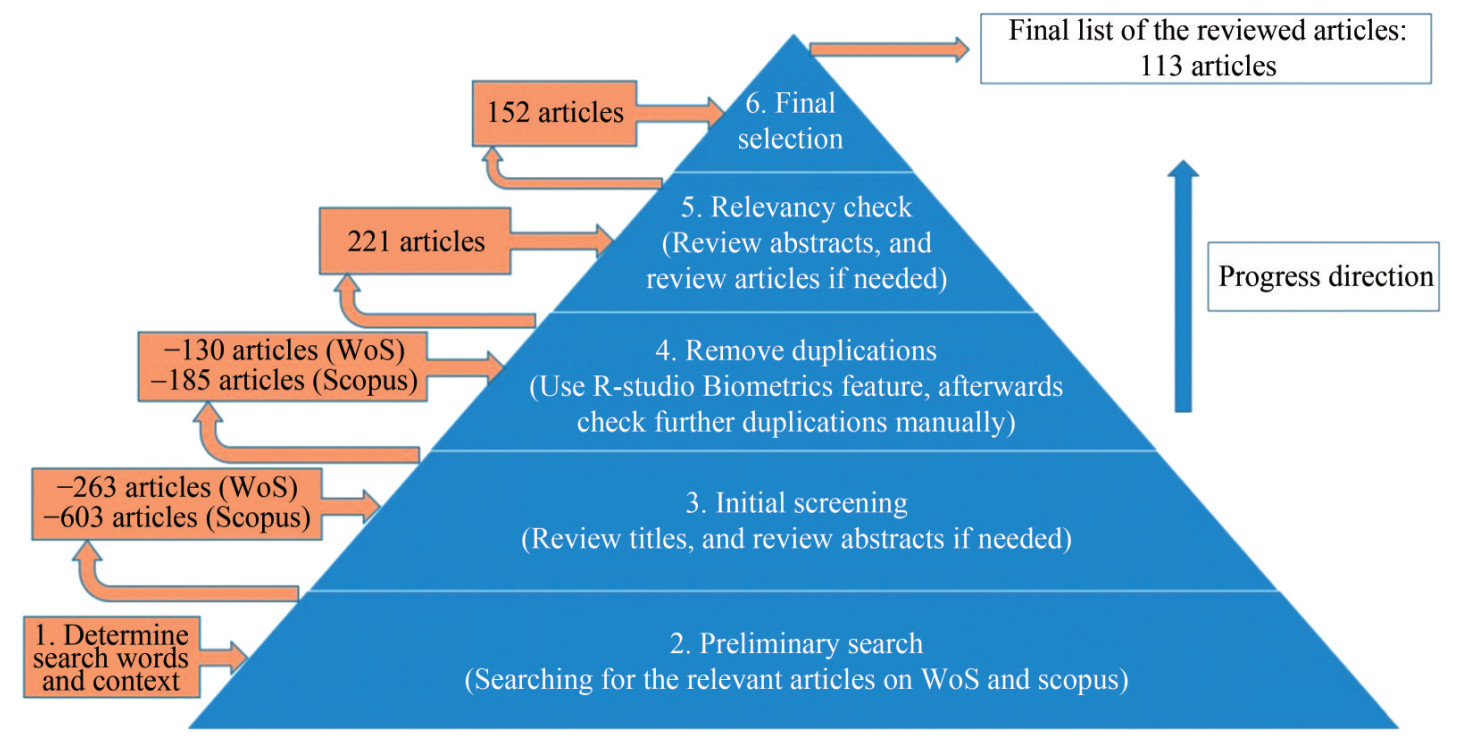

In the performed search in WoS and Scopus the following searching words were used TS= (LNG) AND (RISK OR SAFETY OR RESILIENCE) AND (DYNAMIC OR ASSESSMENT OR ANALYSIS) AND (SHIP OR FUELLED-SHIP OR FSRU OR FLNG), however, these searching words are denoted as the main search. Other searching words were used to capture the remaining publications that contain information on including HOFs in risk analysis in the maritime LNG domain. The other searching words are denoted as the complementary search. The search was performed on the "topic" of the articles which includes the article's title, abstract, and keywords. The application of the main search on WoS, and Scopus has resulted in finding 263, and 603 publications, respectively.

Afterwards, in the initial screening, the titles of the obtained articles were checked for excluding the irrelevant articles to the risk analysis domain of the maritime LNG sector. Some abstracts were also checked whenever needed to confirm the relevancy of these articles to the above-mentioned scope. The number of the selected articles after the initial screening is 130 and 185 from WoS and Scopus, sequentially. Table 4 presents more details regarding the number of the selected publications for the following detailed review and selection processes.

Table 4 Number of articles found on WoS and Scopus (post-initial screening)Searching elements WoS Scopus Main search 130 185 Complementary search 3 5 Manually included 0 2 Total 133 192 Subsequently, the R-studio Bibliometrix feature is used following the instructions by Goel (2021) to merge the WoS and Scopus lists without duplications. Accordingly, 104 duplicated publications were removed from the merged list. Therefore, the number of the remaining articles is 221. Afterwards, further selection criteria were applied for ensuring that the reviewed articles are relevant to the scope of the current study. In more detail, the focus of this study is on the publications that include applied safety risk assessments and management of systems and/or operations of the various LNG ship types.

Examples of the included studies in this review are the ones that present comprehensive risk analysis of LNGCs (Vanem et al. 2007), risk-based layout optimisation (Ji et al. 2017), calculation of human error probabilities (Fan et al. 2022a), or risk-based identification of the operational conditions such as the determination of LNG bunkering safety exclusion zone (Jeong et al. 2018). The related articles to the field of maritime LNG safety that do not include applied risk analysis are excluded. Examples of irrelevant articles to the scope of this research are the articles that present a literature review only (e.g. Aneziris et al. 2020), articles that contain failure analysis of mechanical LNG equipment only (e.g. Pil et al. 2008; Wan et al. 2014), or the related studies to describing the behaviour of a particular LNG hazard outside of the applied risk analysis context (e.g. Han et al. 2010).

In the detailed evaluation step, the abstracts of the 221 articles are reviewed for excluding the articles that are not relevant to the scope of the present study. In addition, the contents of some of the 221 articles were reviewed for verifying their relevancy/irrelevancy to the scope of the paper. From the detailed evaluation process, 69 articles were excluded. Consequently, 152 publications are found to be relevant to the scope of the present research. Out of the 152 articles, 113 papers are selected in the articles' classification and reviewing process. However, the process of searching and selecting the reviewed articles is illustrated in Figure 3. In addition, the illustrated trend in Figure 4 reflects the development in the entire sample of the related publications to applied risk analysis and risk management of the various LNG ship types (i.e. 152 publications) from January 2000 till July 2023.

4.2 Articles' classification

In the present study, two general contexts are used for categorising the dimensions used for classifying the selected 113 articles for the review and classification process. The two reference contexts are ⅰ) The risk analysis theory context, and ⅱ) The presented case in the risk analysis context. The first context covers generic aspects of the risk analysis model that has been used in each article, which is independent of the related information and data to the applied case study in that model (i.e. it covers what has been used to model the case study). On the other side, the second context covers relevant aspects to the included information in the risk analysis model (i.e. it covers what have been analysed by the presented risk analysis model). In addition, in each of the above contexts, the articles are classified w. r. t. three classification dimensions. The word "dimension" in the current study refers to "An aspect or feature of a situation" (Lexico 2022). The situation here represents the presented risk analysis study in each of the reviewed publications, and the aspects or features represent the sub-categorised classification dimensions under each of the following classification contexts.

1) The risk analysis theory context

ⅰ) The used risk analysis methodology (e.g., qualitative or quantitative),

ⅱ) The objective of risk analysis (e.g. fire and explosion, or layout optimisation) and,

ⅲ) The used risk analysis tool (e.g. risk matrix, fault tree analysis (FTA), Bayesian network (BN), etc.).

2) The presented case in the risk analysis context

ⅰ) The analysed ship type in risk analysis (e.g. LNGFS, or LNG FPSO),

ⅱ) The analysed LNG ship operation in risk analysis (e.g. cargo transfer, or LNG processing) and,

ⅲ) The level of inclusion of human error in risk analysis. The description of the sub-criteria of each classification dimension and the count and percentage of the relevant articles to each sub-criterion are presented in Tables 5 – 10. The process of describing the underlying sub-criteria of the classification dimensions is conducted according to the presented methodology in Banae Costa and Beinat (2005) which is used for describing the performance of the underlying levels of the used criteria in the context of the multicriteria decision making (MCDM).

Table 5 Classification w.r.t. the risk analysis methodology's dimensionSub-criteria Description Count (%) Qualitative Probabilities and consequences are determined purely qualitatively (Rausand 2011). (e.g. Ivanišević et al. 2017; Sultana et al. 2019a). 5(4%) Quantitative Probabilities and consequences are expressed numerically and sometimes along with associated uncertainties (Rausand 2011). (e.g. Kim et al. 2021; Zhu et al. 2022). 87(77%) Semi-quantitative A hybrid method of qualitative and quantitative methods (Radu 2009). (e.g. Elsayed 2009; Ovidi et al. 2018). 9(8%) Dynamic quantitative Quantitative risk analyses are used for representing the changes in the ship/facility risk level dynamically according to the resulting operational changes and disturbances. (e.g. Vairo et al. 2021; Yeo et al. 2016). 12(11%) Table 6 Classification w.r.t. the objective (or scope) of risk analysis dimensionSub-criteria Description Count (%) FERA The scope of analysis is to calculate the fire and explosion risk of the ship/facility. (e.g. Wu et al. 2021; Xie et al. 2022). 40 (35%) RBD Risk analysis is used to support decision making such as layout optimisation (Ji et al. 2017), comparison between concepts (Ramos et al. 2011), or determining safety exclusion zones (Jeong et al. 2018). 25 (22%) NRA Risk analyses related to navigation safety during sailing or manoeuvring. (e.g. Li et al. 2021). 21 (19%) HEP Human error or HEPs calculation are the main or the dominating topic of risk analysis (e.g. Fan et al. 2022a; Ge et al. 2022). 5 (4%) CRA Comprehensive risk analysis that modelling various hazardous events in the risk analysis study (e.g. fire and explosion, collision, structural failure etc.) to estimate the total risk of the ship/facility. (e.g. Elsayed et al. 2014; Daryanto et al. 2020). 6 (5%) EEERA Risk analysis of emergency escape and evacuation (Kim et al. 2021). 1 (≈1%) LRA Leakage (LNG spill only) risk assessment. (e.g. Zhou et al. 2017). 8 (7%) SRA Structural risk analysis is the main focus of the study. (e.g. Hu et al. 2017; Li and Tang 2019). 4 (4%) HAZID The objective of the study is hazard identification only. (e.g. Hu et al. 2019; Sultana et al. 2019b). 3 (3%) Table 7 Classification w.r.t. the risk analysis tools' dimensionSub-criteria Description Count (%) HAZID tools Tools that are used for hazard identification only such as HAZID lists (e.g. Ivanišević et al. 2017; Paltrinieri et al. 2011). 3 (3%) Risk Matrix Two dimensions matrix (frequency X consequence) is used to indicate the risk level. (e.g. Elsayed 2009; Dogliani 2002). 5 (4%) Dynamic tools Represents tools which indicate the risk level continuously based on the current state of the assessed ship. (e.g. Fan et al. 2022b; Yeo et al. 2016). 11 (10%) MCDM MCDM method is used in the context of risk analysis. (e.g. Elsayed et al. 2014; Ji et al. 2017). 7 (6%) Risk indicators or Risk indexes Qualitative or quantitative indexes/indicators are used to present the level of risk. (e.g. Ahn et al. 2022; Iannaccone et al. 2019; Sultana et al. 2019a). 7 (6%) Consequence modelling only The objective of the study is to determine the consequences of a particular accidental scenario. This group represents consequence modelling tools such as CFD, FEA, and DNV Phast. (e.g. Cao et al. 2022; Kim et al. 2011). 26 (23%) ConQRA- Risk analysis that includes HAZID and/or historical data and risk presentation. (e.g. Gucma et al. 2019; Martins et al. 2015). Or risk analysis that includes HAZID and/or historical data and interrelation model of the underlying failure causes of systems (e.g. FTA and BN). (e.g. Fan et al. 2022a; Kuzu et al. 2019). 9 (8%) ConQRA Risk analysis that includes HAZID and/or historical data, and using accident development and/or interrelation model of the underlying failure causes of systems (e.g. ETA, BN, or FTA), in addition to the use of, a non-sophisticated consequence modelling approach. (e.g. Wu 2021; Zhou et al. 2017). 23 (20%) ConQRA+ Same as ConQRA in addition to the use of sophisticated consequence modelling methods such as CFD and FEA. (e.g. Lv et al. 2017; Zhu et al. 2022). 10 (9%) Others (non-conventional) Non-frequently used risk analysis tools (e.g. evidential reasoning, FRAM (Functional Resonance Analysis Method), or Delphi). (e.g. Nwaoha 2014; Sultana and Haugen 2023; Zhang et al. 2019). 12 (11%) Table 8 Classification w.r.t. the analysed ship type in risk analysis dimensionSub-criteria Description Count (%) LNGC LNG tankers. (e.g. Kuzu et al. 2019; Ovidi et al. 2018). 39 (35%) LNGBV LNG bunkering vessels (e.g. Kong et al. 2023) 3 (≈ 2%) LNGFS Ships that are powered by LNG other than LNGCs. (e.g. Vairo et al. 2021; Wu 2021). 38 (34%) LNG FPSO Represents risk analyses of LNG PFSOs only without interactions with other ship types. (e.g. Yang et al. 2020; You et al. 2019). 6 (5%) LNG FSRU Represents risk analyses of LNG FSRUs without interactions with other ship types. (e.g. Ji et al. 2017; Lee 2020). 9 (8%) FLBT Floating LNG bunkering terminal (FLBT) (i.e. Fan et al. 2013; Kim et al. 2021). 2 (2%) Others Studies that involve joint operations between two different ship types such as LNGC and (FPSO or FSRU) (e.g. Abdussamie et al. 2018; Daryanto et al. 2020). Or risk analyses that do not involve a particular LNG ship/facility in the case study (e.g. Sultana et al. 2019b). 16 (14%) Table 9 Classification w.r.t. the analysed ship operation dimensionSub-criteria Description Count (%) LNG bunkering Bunkering operations of LNGFSs. (e.g. Fan et al. 2022a; Vairo et al. 2021). 22 (≈19%) FGSS operations Fuel gas supply system operations of LNGFSs i.e. LNG storage, regasification and internal transfer. (e.g. Cao et al. 2022; Milioulis et al. 2022). 15 (13%) Navigation Sailing and/or manoeuvring operations. (e.g. Li et al. 2021; Xie et al. 2022). 36 (32%) Cargo transfer External LNG transfers i.e. cargo operations between LNGCs ( & BVs) and FLNGs or onshore terminals. (e.g. Hu et al. 2021; Zhu et al., 2022). 21 (19%) LNG processing Internal operations that are carried out onboard FSRUs and LNG FPSOs which are LNG storage, transfer, regasification or NG liquefaction. (e.g. Baskoro et al. 2021; You et al. 2019). 13 (12%) Others Involves studies that are not developed to assess the risk of one of the above activities. Such as the related studies to emergency escape during a hypothetical fire scenario or generic HAZID studies. (e.g. DiMattia 2011; Paltrinieri et al. 2011). 6 (5%) Table 10 Classification w.r.t. the inclusion level of human error in risk analysis' dimensionSub-criteria Description Count (%) HE+ Human error is the main or the dominating topic in the presented risk analysis (i.e. Ahn et al. 2022; DiMattia 2011; Fan et al. 2022a; Ge et al. 2022; Uflaz et al. 2022; Zhou et al. 2017). 6 (5%) HE Human error is sufficiently included and/or explained, but, without being the main nor the dominating topic of risk analysis. (e.g. Hu et al. 2021; Li et al. 2021). 15 (13%) HE- Human error is simply represented (directly or indirectly) with numerical values or described in the HAZID study without further explanation. (e.g. Kuzu et al. 2019; Xie et al. 2022). 22 (20%) No No information was provided regarding the human error in the failure development and accident development models. (e.g. Fadhil et al. 2020; Vairo et al. 2021). 35 (31%) NA Human error is out of the scope of the study. Or the study is based on consequence analysis only so that no failure development nor accident development models are included in risk analysis. (e.g. Martins et al. 2016). 35 (31%) Furthermore, the reviewed 113 publications contain a large diversity of risk analysis tools. In addition, some of the reviewed articles utilise more than one risk analysis tool such as Hazard Identification (HAZID) and other failure analysis tools (e.g. failure mode effect and criticality analysis (FMECA) and FTA) (Milioulis et al. 2022), or accident development modelling tool, in addition to, sophisticated consequence modelling tool (e.g. event tree analysis (ETA) and computational fluid dynamic (CFD) analysis) (e.g. Lee et al. 2015). Therefore, three common sub-criteria have been created to classify the articles that involve the utilisation of more than one Conventional Quantitative Risk Analysis (QRA) tool. The presented three common sub-criteria are ConQRA-, ConQRA, and ConQRA+.

Two more common sub-criteria, namely, dynamic tools and consequence modelling only, have been created to represent the risk analyses that are based on dynamic risk analysis tools (e.g. dynamic BN (DBN), and system dynamics (SD)) (Hu et al. 2019; Milioulis et al. 2021; Vairo et al. 2021), and risk analyses that utilise only consequence modelling methods (e.g. CFD, finite element analysis (FEA), and DNV Phast) (Li and Tang 2019; Ramos et al. 2011; Xie et al. 2022), respectively.

However, in this research, the term DRA represents the studies that are conducted specifically for developing risk analysis models that are used for presenting the changes of the facility risk dynamically according to the resulting operational changes and disturbances (e.g. Hu et al. 2021; Xuan et al. 2019; Yeo et al 2016). On the other hand, studies that are adopting risk analysis tools with the ability to update the belief about the underlying parameters of the risk analysis model given new evidence or data such as BN (Ibrahim and Patruni 2019), or can model the temporal or sequence-dependent behaviour of mechanical systems such as DFT (Milioulis et al. 2021), but are not developed specifically for the defined purpose of DRA above are classified in this research under their relevant Conventional QRA category. In addition, the studies that are presenting time-dependent models for the development of accidental events, for example (Montekwa et al. 2010; Yang et al. 2020) are also classified in this article under the conventional QRA groups.

5 Results

5.1 Articles' classification w.r.t. the risk analysis context

As given in Table 5 it is found that QRA methodology is used in 87 (77%) of the reviewed articles. The scopes of the presented risk analyses in these 87 articles are distributed as follows, 31% are fire and explosion risk analysis (FERA) studies, 28% and 20% belong to risk based design (RBD) and navigation risk analysis (NRA) studies, respectively. The remaining 21% is distributed on the remaining objectives of risk analysis as follows; leakage risk analysis (LRA) (8%), structural risk analysis (SRA) (3%), Human error probabilities (HEP) calculation (6%), comprehensive risk analysis (CRA) (3%), and emergency escape and evacuation risk analysis (EEERA) (1%).

Dynamic QRA methodology falls in second place as it has been used in 12 (11%) articles. DBN is used in 7 of the dynamic QRA studies, whereas SD (Xuan et al. 2019), and Infrastructure Resilience-Oriented Modelling Language (IRML) (Hu et al. 2021) are used in the remaining 4 publications. In addition, Park et al. 2022 has utilised deep neural networks (DNN) for developing a dynamic model for predicting fire consequences, dynamically, during LNG bunkering operations. In the rest of the articles, semi-QRA has been used in 9 (8%) articles, while Qualitative risk analysis is applied in 5 (4%) articles.

However, port operations of LNGCs which represent cargo transfer and ship manoeuvring are the analysed operations in 78% of the articles that are based on semi-QRA (i.e. 7 out of 9 articles) (e.g. Daryanto et al. 2020; Elsayed 2009; Sultana and Haugen 2023), while the remaining 2 articles used the semi-QRA methodology to analyse the fire and explosion risk of LNG regasification operation onboard FSRUs (Dogliani 2002), and to assess the structural safety of LNG membrane ship tanks while sailing in Baltic sea (Han et al. 2008).

In the 5 articles that are based on qualitative risk analysis, 3 papers utilised this method in hazard identification (Ivanišević et al. 2017; Paltrinieri et al. 2011; Sultana et al. 2019b), while qualitative risk analysis is used in the other 2 articles on RBD of FSRUs (Sultana et al. 2019a), and FERA on an LNGFS (Shao et al. 2022).

The distribution of the articles' classification w.r.t. the objective or the scope of risk analysis is presented in Table 6. From this table, it is found that 40 (35%) articles are developed for calculating the risk of fire and explosion. LNGFSs are analysed in 17 of those studies. The remaining 23 articles are distributed as follows 9, 7, 5, 1, and 1 studies are based on the FERA of LNGCs, FSRUs, LNG FPSOs, LNGBVs, and other ship types, sequentially. The articles that present risk analysis studies with the objective of RBD come in second place with 22% of the total number of articles (i.e. 25 articles). Subsequently, NRA studies come in third place as they are representing 19% of the reviewed publications (i.e. 21 articles).

Studies that are based on CRA, which aim to calculate the total risk of the ship (e.g. Elsayed et al. 2014; Hu et al. 2021; Vanem et al. 2008) are representing 5% of the reviewed articles (i.e. 6 articles). The number of publications with the purpose of SRA and HAZID is 4 and 3, respectively. The objectives of the remaining risk analyses studies are distributed as follows 8, 5, and 1 article(s) with the scope of LRA, HEPs calculation, and EEERA, in the same order.

Table 7 presents the distribution of the used risk analysis tools in the reviewed articles. In this table, ten sub-criteria are used to classify the 113 articles concerning the used risk analysis tool. The three Conventional QRA common sub-criteria include 42 (37%) of the reviewed 113 articles. In detail, 9 (8%), 23 (20%), and 10 (9%) of the reviewed articles, belong to the ConQRA-, ConQRA, and ConQRA+ groups, respectively.

ETA is the risk analysis tool with the highest presence in the 42 articles, which has been used for modelling the development of accident scenarios in 20 articles. Subsequently, FTA is the risk analysis tool that has the second highest contribution share in the three ConQRA groups since it has been used in 10 of the 42 articles. BN comes in third place among the used conventional risk analysis tools. BN has been used in 7 of the 42 articles. In Fan et al. (2022a), fuzzy BN was used to calculate HEPs of bunkering operations of LNGFSs. Also, two articles have utilised BNs as converted forms of FTAs (Ibrahim and Rao 2019; Martins et al. 2014).

In addition, two articles have utilised BNs in modelling grounding and collision risk of LNGCs (Li and Tang 2019; Montewka et al. 2010), whereas in further two articles, BNs are used in FERA studies of LNG processing onboard LNG FPSO (Ibrahim and Patruni 2019), and LNG bunkering operation (Wu et al. 2021). In the most of the remaining articles of the three ConQRA groups, the risk is calculated by using mathematical models (e.g. Gucma et al. 2019; Ligteringen et al. 2006). It is also observed that advanced HAZID tools such as FMECA and hazard and operability studies (HAZOP) are used only in five of the articles that using conventional QRA tools (e.g. Baskoro et al. 2021; Fadhil et al. 2020; Kang et al. 2022; Milioulis et al. 2022). The rest of the classified articles under the three ConQRA groups are using historical accidental frequencies and hazard lists in the HAZID step of risk analysis.

Regarding the ConQRA+ group, CFD is used in 8 of the classified articles under this group. In addition, in Jeong et al. (2017), CFD and FEA have been adopted for modelling the effect of fire and explosion loads on structures of the fuel preparation room of LNGFSs. In Li and Tang (2019), FEA is used separately for modelling the effect of grounding on membrane tanks of LNGCs. Other than that, Dynamic QRA tools were used in 11 (10%) of the 113 articles. DRA tools are utilised for reflecting the dynamic changes in the system's underlying variables and parameters on the risk level of the system (Parhizkar et al. 2021; Rokseth and Utne 2015). This feature of DRA tools makes them suitable for analysing the dynamic risk of critical operations of maritime LNG units.

For example, the authors of 9 of the 11 articles that classified under the DRA tools sub-category have been developed for modelling the risk of critical LNG operations such as; cargo transfer between LNGCs and LNG FPSOs (e.g. Hu et al. 2021; Yeo et al. 2016), and LNG bunkering of LNGFSs (e.g. Vario et al. 2021; Xuan et al. 2019).

Moreover, 26 (23%) of the reviewed publications utilise consequence modelling risk analysis tools only in the presented risk analyses. CFD and FEA are used in 14 and 3 of these studies, respectively. In addition, CFD and FEA had been combined for modelling the consequence of LNG leaks on an LNGBV in Nubli et al. (2022). The remaining 8 studies are including consequence modelling that is based on mathematical models or less-sophisticated consequence modelling methods such as DNV Phast (Nwaoha and Adumene 2020; Ramos et al. 2011). Most of the classified articles under this group are developed to compare alternative designs (Ramos et al. 2011), identify the safe operational limit such as identifying the safety exclusion zone of LNG bunkering operations (Jeong et al. 2020), and verification of the design suitability during emergencies such as emergency escape and evacuation, or fire scenarios (Baalisampang et al. 2017; Kim et al. 2021).

In addition, MCDM tools are applied in 7 (6%) of the reviewed articles. Analytical-Hierarch Process (AHP) MCDM method is used in 4 articles (e.g. Alaba et al. 2016; Ji et al. 2017), whereas in the remaining three articles, a safety value function has been developed by Ji et al. (2023), Fuzzy TOPSIS (Technique for Order Preference by Similarity to Ideal Situation) method is utilised in Elsayed et al. (2014), and DATA MCDM software is utilised in Elsayed et al. (2009). Furthermore, risk indexes and risk indicators are used in 7 (6%) of the 113 articles (e.g. Iannaccone et al. 2018; Iannaccone et al. 2019). The used risk analysis tools in the remaining 20 articles are distributed as follows, 3 (3%) articles use HAZID tools, 5 (4%) articles are using risk matrices, and 12 (11%) articles are utilising non-conventional (Others) risk analysis tools such as Delphi and simulator programs.

5.2 Articles' classification w. r. t. the presented case in the risk analysis context

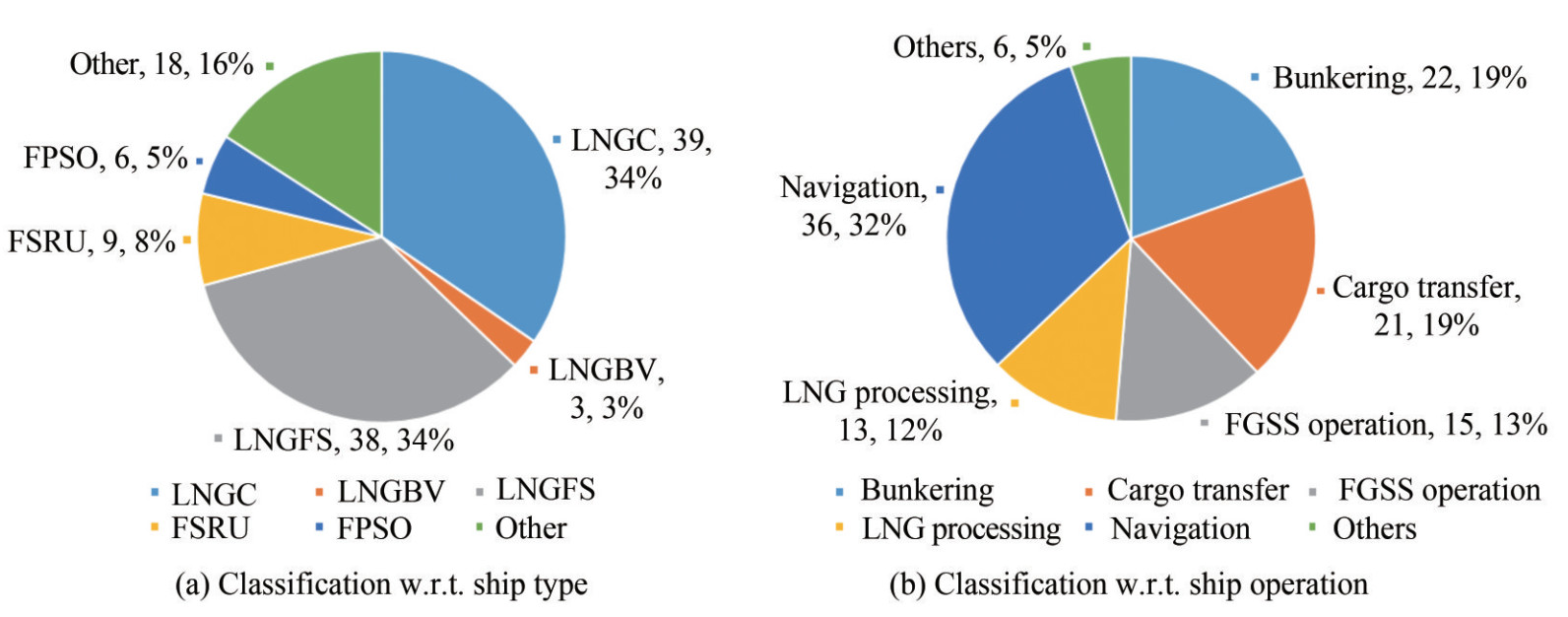

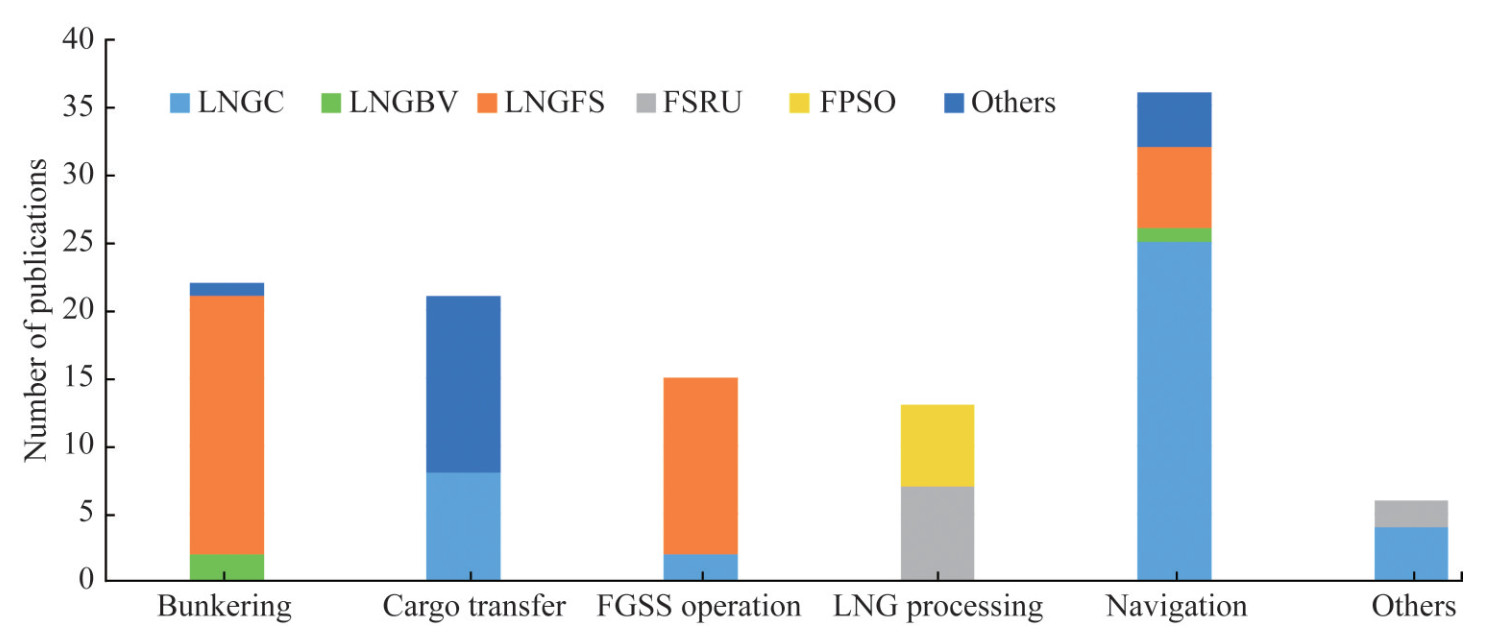

According to the presented results in Table 8 and Figure 5(a), the related articles to risk analysis of LNGCs represent 39 (35%) of the reviewed 113 articles. Risk analysis studies of LNGFSs come in second place with 38 (34%) publications. On the other hand, the number of articles that present risk analyses of FSRUs and LNG FPSOs, are 9 (8%) and 6 (5%), respectively. The remaining 21 (19%) articles include risk analyses of joint operations between two different types of ships such as LNGC and FSRU, and LNGC and LNG FPSO (e.g. Abdussamie et al. 2018; Daryanto 2020), risk analysis of LNGBVs (e. g. Kong et al. 2023) in addition to studies that applied on non-conventional ship type i.e. FLBT (Kim et al. 2021) or studies that do not include a particular ship type (e.g Sultana et al. 2019b).

Other than that, as given in Table 9 and Figure 5(b), the related operations to the in-port and overseas ship navigation or in other words manoeuvring and sailing are the most operational activities that have been assessed in the reviewed research work, where it is accounting for 36 (32%) out of 113 articles. LNG bunkering, and Cargo transfer operation of LNGCs come in second and third place of the involved operations in the performed risk analyses in the reviewed articles with 22 (≈19%) and 21 (19%) publications, sequentially. It is also observed that articles belonging to LNG bunkering of LNGFSs and LNGBVs include 58% of the articles that are classified under the dynamic QRA method (i.e. 7 out of 12 articles).

Furthermore, risk analyses of LNG FGSS operations, and LNG processing onboard FLNGs come in the fourth and fifth places with 15 (13%) and 13 (12%) articles, respectively. Lastly, the remaining 6 studies include risk analyses that are conducted during the preliminary design phase such as HAZID studies (Paltrinieri et al. 2011), and selection between alternatives (Ramos et al. 2011), in addition to, CRA studies(Vanem et al. 2007, 2008), and EEERA studies (DiMattia 2011).

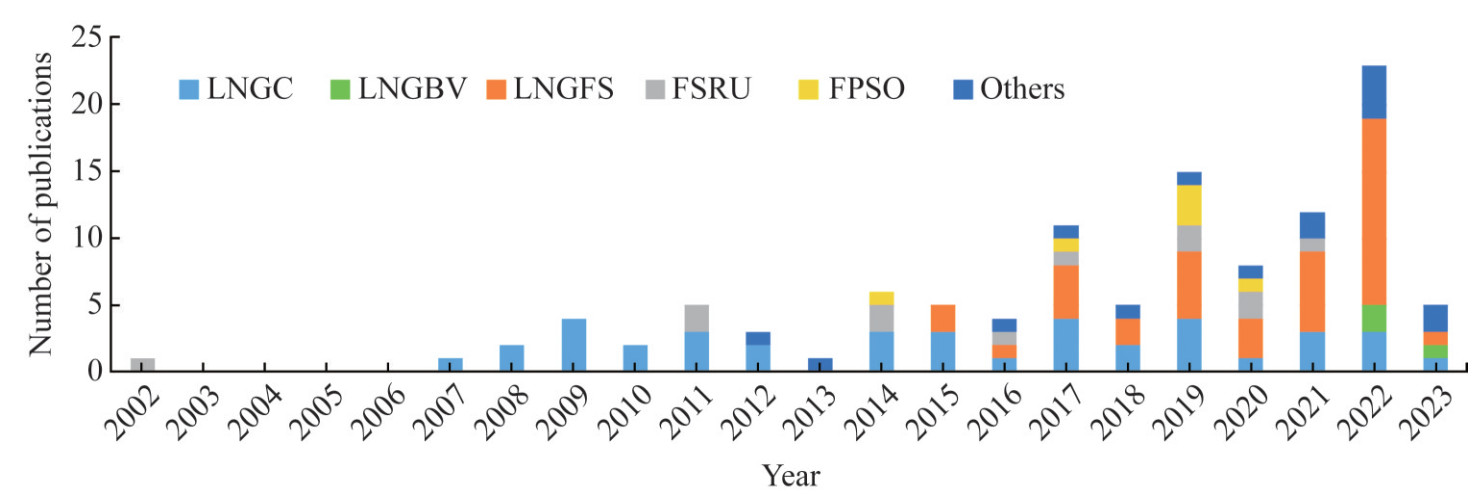

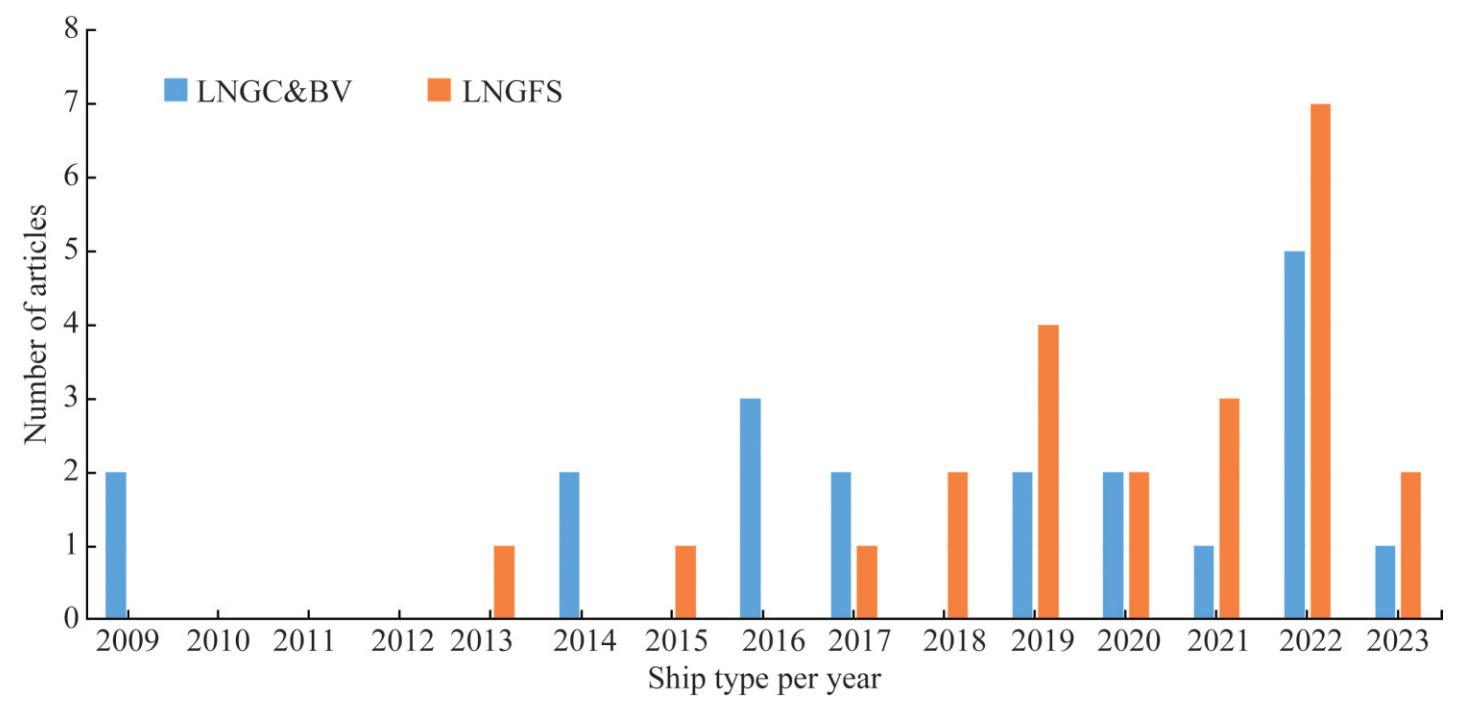

Furthermore, as shown in Figure 6, 74% of the published articles from 2002 to 2013, (i. e. 14 out of 19 articles), belong to risk analysis studies of LNGCs, while the remaining 26% of the articles, (i. e. 5 out of 19 articles), are related to FSRUs, FLBT, and joint operation between an LNG FPSO and an LNGC. It is also observed in the reviewed research sample that, there are no corresponding articles to risk analysis of LNGFSs published before 2015. But two years later, a noticeable increase in the risk analysis studies of LNGFSs is observed.

Moreover, from 2017 to 2020, there are at least 2 publications on the risk analysis of LNGFSs per year, while the highest number is observed in 2022 which includes 13 publications related to the risk analysis of LNGFSs. Furthermore, the vast majority (i. e. 6 out of 9, 67%) of the corresponding articles on risk analysis of FSRUs are published between 2014 and 2021, whereas 100% of the risk analysis research of LNG FPSOs are published during the same period. As also illustrated in Figure 6, 2019 include 50% of the related publications to risk analysis of LNG FPSOs. However, the relationship between the included ship type in risk analysis, and the analysed operational activities is described in the form of the distribution of the various ship types per each operational activity in Figure 7.

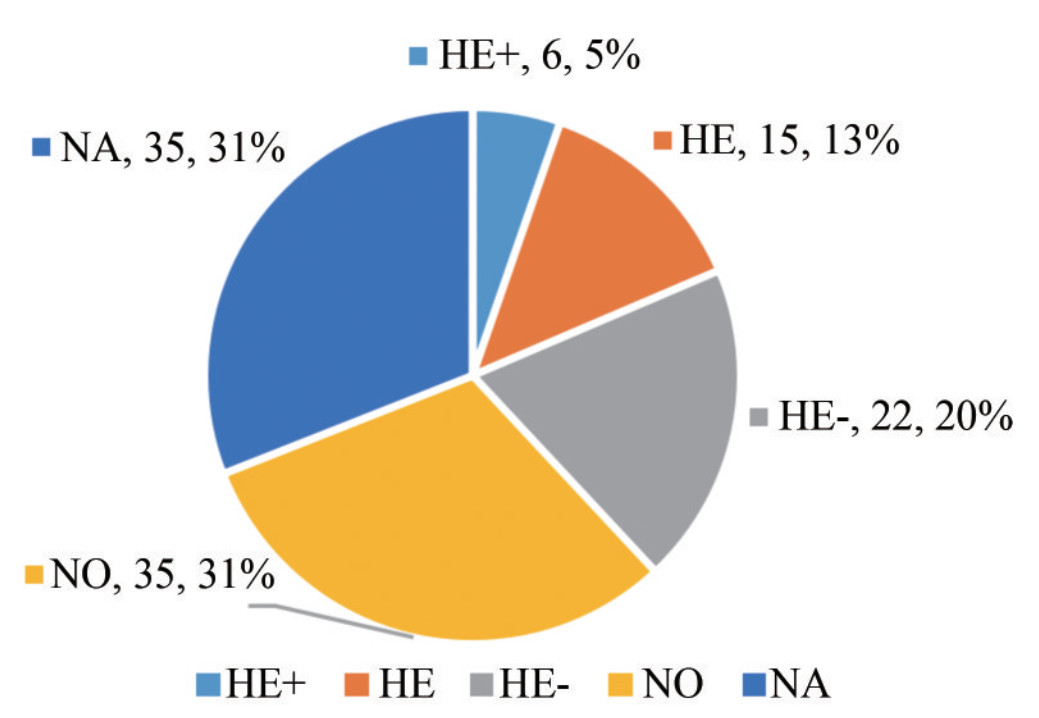

In Table 10, the reviewed articles are classified concerning the inclusion level of human error in risk analysis. In this classification, articles are classified based on the described five levels of human error inclusion in Table 10, and depicted with numbers in Figure 8. The classification approach of the human error inclusion dimension in risk analysis is an adapted form of the presented classification in Skogdalen and Vinnem (2011) that has been used for classifying a sample of QRA studies concerning the level of inclusion of HOFs in risk analysis. However, the classification of the human error inclusion dimension concluded that 35 (31%) of the reviewed articles are classified under the (not applicable) (NA) group due to the irrelevancy of human error to the presented risk analysis in these articles. For example, studies that using CFD and FEA for design verification and selection purposes are classified under the NA group (e.g. Cao et al. 2022; Nubli and Sohn 2021).

In the remaining 78 publications, 6 (5%) articles are mainly developed for calculating human error probabilities, and accordingly, these articles are classified under the HE+ category. The first article is developed by DiMattia (2011) for predicting human error probabilities of mustering actions during emergencies onboard LNGCs. In Zhou et al. (2017), besides the conventional FTA of mechanical systems, the cognitive reliability and error analysis method (CREAM) of HRA is applied to calculate the human error probabilities' contribution to the related risk to fire and explosion of LNGCs' cargo handling operations. Thirdly, in Fan et al. (2022a), the fuzzy BN CREAM model is used to predict HEPs of LNG bunkering operations of LNGFSs.

Furthermore, Ge et al. (2022) utilised the grey relational analysis for ranking the critical performance shaping factors (PSFs) to human reliability during LNG offloading operations. In addition, the system theoretic process analysis (STPA) and success likelihood index method (SLIM) have been used in Ahn et al. (2022) for predicting HEPs of the emergency shutdown task during LNG ship-to-ship operations. Lastly, in Uflaz et al. (2022), the human error assessment and reduction technique (HEART) HRA method was used for calculating HEPs of LNG bunkering operation.

Other than that, 15 (13%) publications are classified under the HE category. The classified publications under this category are not developed primarily for calculating HEPs, however, HEPs in these articles are sufficiently included/ explained. For instance, in Xuan et al. (2019), human error is described qualitatively in the HAZID step and also reflected quantitatively on the leakage risk results of the LNG bunkering operation. On the other hand, in the HE-category, human error was simply represented as a basic event of a fault tree, or mentioned briefly in the text. The classified articles under this group are accounting for 22% of the reviewed publications (i. e. 20 out of 113 articles). Examples of the classified articles under the HE- group can be found in Kuzu et al. (2019), and Xie et al. (2022). In the earlier, human errors are introduced as basic failure events without further explanations or comments, whereas in the latter, human error is included in the text among the causes of leakage of an LNG FGSS. Other than that, 35 (31%) publications are found to be lacking the inclusion of any information regarding human error, for instance, Fadhil et al. (2020), and Vairo et al. (2020).

6 Discussions and recommendations

6.1 Motivations behind the increasing interest in risk analysis research in the maritime LNG sector

The increasing interest and evolution in the related research work to risk analysis and risk management of the maritime LNG sector can be attributed to two aspects. The primary one is the rapid expansion of and the introduction of new ship concepts to the maritime LNG sector, whereas the other important aspect is the high severity of the associated hazards of accidental LNG leaks. In detail, the economic, safety, and environmental benefits of using LNG in comparison to other fossil fuels in light of the current global decarbonisation efforts have had a significant impact on increasing the number of ships that carry LNG as a cargo or ship fuel during the past decade.

For instance, the increasing global demand for LNG resulted in a doubling of the worldwide fleet of LNGCs between 2010 and 2020 (Shakirov 2021, p2). Similarly, since the introduction of the firstLNG FSRU in 2005, this concept of ships has become more popular with several LNG importing countries due to its ability to fulfil the short-, and medium-term energy demand with significantly lower costs than those of the shore-based LNG regasification facilities.

In addition, LNG FPSOs have recently become an interesting concept to oil and gas producers due to their ability to unlock the potential of the small scale and remote offshore NG projects with lower costs and environmental footprint in comparison with the alternative concepts of producing and liquefying offshore NG (KPMG 2014). Also, ship owners have become more confident to use LNG as a ship fuel due to the excellent safety records of the LNG FGSSs since the launch of the first non-LNG tanker LNGFS Glutra in 2000 (SEA-LNG 2020), in addition to the economic attractiveness of LNG, and its compliance with the present IMO environmental requirements (Hansson et al. 2019; Sharma et al. 2022; Wang et al. 2021a). Therefore, there has been a significant need for assessing the emerging risks from the related operations to the newly introduced ship concepts to the sector of interest, as well as, for exploring the associated risks of using conventional LNG ship concepts in new operational circumstances for ensuring their operational safety.

On the other side, LNG accidental releases are highly undesired events due to the associated hazards and high escalation potential of uncontrolled LNG leaks. As described earlier in section three, when LNG leaks occur onboard ships, LNG will cause damage to the ship structure, while the released leaks to the sea can lead to explosive waves when RPT occurs (Luketa-Hanlin 2006; Petti et al. 2013).

In addition, the exposure of human skin to the cold temperature of LNG will result in severe burns, or damage to muscles and bones, whereas if a human being is engulfed by an LNG leak or its vapour, fatality will possibly occur in a limited time due to hypothermia or oxygen deficiency asphyxiation (ESS 2016; IHSA n. d.; Mayo Clinic 2020; Sever et al. 2010). Other than that, immediate and delayed ignitions of LNG vapours can lead to severe damage to ships as well as to humans who are exposed to the resulting fire and explosion loads of the ignited vapours [see Vinnem (2007) for further information on the consequences of the fire and explosion loads]. Therefore, the severity of LNG leak accidents has been an important motivator to interested researchers in risk analysis and risk management of the maritime LNG sector for developing advanced techniques and studies for improving the prediction and modelling of the associated risks to critical LNG operations.

6.2 Progress in risk analysis research of the maritime LNG sector

There was a noticeable increase in interest during the last decade in the related research to risk analysis of the various LNG ship types. The increasing interest in this research domain is depicted earlier in Fig 4 which represents the entire sample of the relevant research work to the scope of this article (i.e. 152 articles). From that figure, it is found that the average number of relevant publications on applied risk analysis and risk management of the maritime LNG units had increased from 2.5 articles per annum between 2000 and 2012, to 10.9 articles per annum between 2013 and July. 2023.

This noticeable increase in the number of articles was driven by the introduction of new concepts of facilities to this sector such as FSRUs, LNG FPSOs, as well as the increasing number of LNGFSs. The percentage of the related research work to risk analysis of FSRUs, LNG FPSOs, including the ship-to-ship operations (e. g. Varela et al. 2015), and LNGFSs and FLBTs from 2012 to July 2023 in the "reviewed" articles that have been published in the same interval is 63% (i. e. 62 out of 98 articles). Furthermore, the high criticality of the external LNG transfer operations which represent LNGCs' cargo transfer with marine terminals, FSRUs, and FPSOs, in addition to, LNGFSs' bunkering operations, was a primary cause for these operations to occupy an important share in the relevant risk analysis studies to the maritime LNG sector since 2016. In Figure 9, the development trend in the related studies to risk analysis of external LNG transfer operations from 2009 till July 2023 is illustrated. The period between 2000 and 2008 is not illustrated in that Figure because there are no articles developed specifically for analysing the risk of these operations in that interval.

6.3 Status of dynamic risk analysis in the reviewed articles

Recently, DRA methodologies found their way to being suitable candidates for modelling the risk of critical operations and complex systems in the maritime sector (Parhizkar et al. 2021; Rokseth and Utne 2015). However, when concentrating on the maritime LNG domain, the period between 2019 till July 2023 has witnessed the publication of 11 articles related to DRA studies. DRA of external LNG transfer operations was the dominating topic in the DRA studies since 8 out of the 11 DRA publications have been developed for modelling the risk of external LNG transfers.

Furthermore, the assessment of the resilient performance of the marine LNG systems was the main objective of 3 of the DRA-related articles (i.e. Hu et al. 2019, Vairo et al. 2020, 2021). In these articles, two different approaches to resilience assessment were adopted. In Hu et al. (2019), a resilience assessment was conducted according to the indicated concept by Linkov et al. (2016) which follows the resilience definition by the United States National Academy of Science (NAS). Based on Linkov et al. (2016), the resilience assessment of systems is meant by assessing the ability of such systems to absorb and recover from shocks and disturbances without exceeding a threshold, in addition to, learning from what has happened and adopting new measures for avoiding the reoccurrence of such disturbances.

Alternatively, the adopted resilience perspective in Vairo et al. (2020, 2021), is based on the presented resilience definition by Hollnagel (2016), which supports the increasing focus on how the system can work efficiently under the expected and unexpended conditions by improving anticipation of future events rather than concentrating only on hardening the system against a predefined set of threats and hazards (Hollnagel 2022). From Hollnagel's point of view, the resilient performance of systems should have four abilities which are how the system can ⅰ) respond (i.e. what to do), ⅱ) monitor (i.e. what to look for), ⅲ) learn (i.e. learning from the observed event or opportunity), ⅳ) anticipate (i.e. how to predict future adverse events or opportunities) (Hollnagel 2015). However, several advantages have been presented in the literature regarding the assessment of the resilient performance of systems in the safety context. For instance, the performance of resilience assessment for modelling systems with high complexity and multiple components allows a better understanding of the relationships between the various components, accordingly, new failure patterns or potential improvements can be anticipated (Hollnagel 2015). In addition, as represented in Vairo et al. (2021), resilience assessment plays a key role in unlocking the potential of using Artificial Intelligence (AI) methods, i. e. Machine Learning (ML) data-driven models, in the context of risk analysis.

6.4 Inclusion of human error in the reviewed articles

It has been observed that the inclusion of the human factor in the presented risk analyses in the reviewed articles has received increasing interest during the past 5 years since 81% of the classified articles under the HE and HE+ groups (i.e. 17 out of 21 articles) are published after 2018. But on the other hand, the prevailing majority of the classified articles under the HE (i. e. 10 out of 15, 67%) group do not address the reflection of the effect of the HOFs that are currently deemed to be significant on the performance of human element in the maritime LNG sector.

The remaining 5 (33%) of the HE group´s articles utilise risk analysis models that allow for the adjustment of HEPs or risk indicators based on the facility-specific HOFs (Sultana et al. 2019a; Zhuang and Guo 2021). In addition, the lack of using HRA for predicting specific HEPs to a particular LNG operation or ship type is one of the important research gaps in this domain of research, since HRA was performed only in 5 of the 113 articles (i.e. Ahn et al. 2022; DiMattia, 2011; Fan et al. 2022a; Uflaz et al. 2022; Zhou et al. 2017).

6.5 Recommendations

Since 2019, there has been a remarkable innovation and evolution in the used methods and tools in the presented risk analyses in the reviewed articles. For instance, the adoption of DRA methods for analysing the risk and resilience of the critical LNG processes, where such methods unlock the potential for using state-of-the-art tools (e. g. ML data-driven models) for emulating the dynamic risk of such processes. Adding to that the wide agreement among the various researchers regarding the importance of including the impact of HOFs in risk analysis for improving the prediction of risk. For instance, Fan et al. (2022a) have presented an important research contribution to overcoming the lack of specific HEPs for the LNG bunkering operations. In Fan et al. (2022a), a qualitative survey involved the opinions of 137 experts from a wide diversity of experience and academic levels was utilised as the input of a fuzzy BN-CREAM HRA model to predict specific HEPs to the LNG bunkering operations based on the present state of knowledge.

Nonetheless, there are considerable potential improvements in the related research to risk analysis of the maritime LNG sector. One of the foreseeable improvements is the accounting for the effect of the various HOFs other than the intra-job factors (e.g. fatigue and stress) on the underlying variables of risk analysis models since human and organisational errors are the primary factors of 65% of the catastrophic accidents as mentioned in Fan et al. (2022a). In addition, extending the use of DRA models beyond the modelling of the non-routine critical operations (e.g. external LNG transfers), to involve the dynamic emulation of the daily routine operations will improve the management of the operational risk onboard the various maritime LNG units. In particular, for modelling the dynamic risk of the critical maritime LNG systems such as LNG FPSOs' liquefaction and cargo transfer systems, and FGSSs of LNGFSs, due to the high complexity of the former, and the lack of human and organisational operational experience of the latter (Abdelmalek and Guedes Soares 2022).

For example, monitoring the changes in the conditions of the performance influencing factors (PIFs) of the various technical, operational, and organisational barrier elements (Hauge and Øien 2016), during the operations phase can provide the required input data for the DRA model of the ship. In this process, potential degradations (or weak signals of disturbance (Hollnagel 2022)) in the performance of the included barrier elements in the DRA model can be determined by measuring the real-time changes in the status of the underlying PIFs of these barrier elements. Accordingly, the output of the risk analysis model can be updated, continuously, based on the resulting changes in the model input variables, which result from system degradation or improvement.

7 Conclusions

In this paper, a review and classification of the related publications of applied risk analysis and risk management of the maritime LNG sector is presented. The 113 selected articles were thoroughly reviewed, resulting in the identification of several important observations. For instance, it is observed that the introduction of new ship types to the maritime LNG sector i. e. LNG FPSOs and FSRUs, and the increasing number in the LNGFSs had a significant effect on increasing the number of related research work to risk analysis and risk management in this sector during the past decade.

Furthermore, it is also observed that in the past five years there was a noticeable increase in the related publications to DRA in the maritime LNG sector, as well as, a wide agreement among researchers on the importance of reflecting the effect of HOFs on risk analysis models for improving risk prediction in the related research domain to the maritime LNG sector.

The role of DRA methodologies for improving risk modelling and failure anticipation and their possibility for assessing the resilient performance of the various systems are discussed. Further discussion is presented to highlight the importance of improving the inclusion of the HOFs in risk analysis models.

Another conclusion is the identification of two potential improvements in the context of risk analysis and risk management in the maritime LNG sector. Firstly, improving the analysis of the effect of the HOFs on the underlying elements of the risk analysis model will improve risk prediction.