A Review of the Design and Feasibility of Intelligent Water-Lubrication Bearings

https://doi.org/10.1007/s11804-022-00296-5

-

Abstract

Water-lubrication bearings are critical components in ship operation. However, studies on their maintenance and failure detection are highly limited. The use of sensors to continually monitor the working operation of bearings is a potential approach to solve this problem, which is collectively called intelligent bearings. In this literature review, the recent progress of electrical resistance strain gauges, Fiber Bragg grating, triboelectric nanogenerators, piezoelectric nanogenerators, and thermoelectric sensors for in-situ monitoring is summarized. Future research and design concepts on intelligent water-lubrication bearings are also comprehensively discussed. The findings show that the accident risks, lubrication condition, and remaining life of water-lubricated bearings can be evaluated with the surface temperature, coefficient of friction, and wear volume monitoring. The research work on intelligent water-lubricated bearings is committed to promoting the development of green, electrified, and intelligent technologies for ship propulsion systems, which have important theoretical significance and application value.Article Highlights• Operation condition monitoring is essential in predicting a water-lubricated bearing failure before it happens;• Potential accident risks, lubrication conditions, and remaining useful life are three important evaluation indicators for water-lubricated bearings;• The addition of conductive fillers into a bearing matrix can be used for wear volume monitoring;• A high surface contact temperature effectively indicates poor lubrication conditions and potential accidents. -

1 Introduction

The marine industry's history is over 5 000 years, which began with the first trade routes between modern-day India and Pakistan. Although new transport modes have been increasingly invented, the marine industry keeps its importance for maritime transport, resource development, and sovereignty defense. The marine propulsion system is one of the most important segments for ship operation. To improve its reliability and security, the use of bearings as critical support components is highly valuable for research. However, traditional oil-lubricated bearings have many disadvantages, including high vibration and wear, high energy and metal resource cost, low reliability and work life, and risk of oil leaking, which dramatically limit their development. With these reasons and the increasing environmental protection requirements, green ship technology has been considered the future target, where water-lubrication nonmetal bearings will replace oil-lubrication ones (Quirapas and Araz, 2021; Sun et al., 2018).

To solve the problems mentioned above, improving the properties of water-lubricated bearings is the leading solution. This purpose has three primary strategies: The first strategy is designing new materials for bearings, such as polyurethane-polyethylene wax composite material (Huang et al., 2021; Wu et al., 2019), guaiacum, and high-density polyethylene (HDPE)-based biomimetic materials (Guo et al., 2017), microcapsule/ultra-high molecular weight polyethylene composite materials (Yang et al. 2021), modified glass fiber-HDPE composite material (Liang et al., 2020), and rubber materials (Litwin, 2015). The second strategy is improving the structure of water-lubrication bearings, such as designing different textures on the surface of bearings (Chang et al., 2019) or a three-layer composite (Litwin, 2015). The last strategy is researching the general principles of water-lubricated bearings, such as micro interface lubrication regimes (Xie et al., 2021), failure analysis (Wasilczuk and Wasilczuk, 2020), the influence of friction and wear on vibration (Wang et al., 2017; Litwin, 2016), and interface lubrication regime transition (Xie and Liu, 2020). These improvements are effective for recently manufactured water-lubricated bearings but cannot ensure their high properties stably in realistic harsh working environments for several years. This view can be proven by numerous ship accidents caused by the damage in their water-lubricated bearings every year.

Failure detection during operation is essential to predict water-lubricated bearing failures before they happen and take reasonable actions to avoid accidents. However, it is a challenging task. Different types of structures and materials are applied in water-lubrication bearings, so the current knowledge cannot accurately predict the failure and working life of each specific bearing. Litwin (2009) emphasized that bearings need to overcome harsh environmental factors, such as low temperatures, sediments, pollutants, and accidents, which dramatically increase the risks of sudden failures. A bearing failure can lead to the whole power system's failure, which is devastating for ships. To ensure the safety and reliability of machines, regular inspection and maintenance are essential. Due to the complex interactions among components, the prediction of the working life has not achieved high accuracy, and the regular inspection cost is high. Hence, to continuously and effectively monitor a specific machine or whole system, continuous, reliable, and accurate data should be obtained. Therefore, a general method for the online in-situ monitoring of water-lubrication bearings is highly crucial.

With the rise of the Fourth Industrial Revolution and the Internet of things, there has been a rapid increase in requirements for sensing and monitoring systems in realtime (Tomaz et al., 2021). Studies related to bearing fault diagnosis have been fully researched for decades (Zhang et al., 2022; Yao et al., 2022; Liu et al., 2022). Although some out-situ sensors have been used for traditional bearings' monitoring tasks (Ali et al., 2015; Xu et al., 2021; Wang et al., 2021), their sensors are too large to establish an online in-situ monitoring system. In addition, most monitoring processes are based on vibration and noise signals. The generated noise makes it hard to be used in practical applications, especially for water-lubricated bearings. Therefore, an effective method with a high signal-to-noise ratio, simple structure, and low maintenance is required. Moreover, the power support and data transfer plan should be considered. Bearings considering all these requirements are called intelligent bearings.

Intelligent bearings integrate a series of sensors without decreasing their tribological properties, which can directly access different parameters in operation. With the combination of sensors, real-time operating information can be recorded and transferred to an extensive database, which can evaluate their conditions and issue a warning when a failure occurs. In addition, the data are valuable in training intelligent bearing health monitoring systems (Yang et al., 2022).

Currently, intelligent commercial bearings are achieved by just bonding sensors on the bearing surface, which is unsuitable for water-lubricated bearings. Embedding sensors directly into the bearing bush may be the only method to acquire high accuracy data. However, related studies are only focused on limited fields, such as construction materials (Strangfeld and Kruschwitz, 2018; Ahmadi et al., 2020; Roopa et al., 2020; Kocherla et al., 2021) and human health (Nguyen et al., 2021; Singh et al., 2021; Qi et al., 2020; Han et al., 2021). This phenomenon is attributed to the different factors that limit the installation of sensors in other products, such as the high properties and reliability requirements, harsh manufacturing environment (high pressure and temperature), and water working environment. Therefore, in this review, the design and feasibility of intelligent water-lubrication bearings are systematically discussed. First, the current evaluation approach of the water-lubricated bearing performance and the difficulty of in-situ monitoring are introduced in detail. Then, various potential types of embedded sensors are analyzed to determine their availability for intelligent water-lubricated bearings. Other typical successful monitoring systems are classified into categories and reviewed. Finally, the design concept for the water-lubricated bearing is presented and comprehensively discussed. Although the topic of this review is intelligent water-lubricated bearings, it also explores potential general approaches to other related intelligent products.

2 Evaluation approaches

To continuously and effectively monitor a specific machine or whole system, constant, reliable, and accurate data should be obtained. Researchers have attempted to perform this objective in broad areas, such as monitoring a chronic wound (Sharifuzzaman et al., 2020), fatigue of flax fiber (Kuang et al., 2013), damage to concrete (Nguyen et al., 2016), condition of cylinder liner-piston rings (Rao et al., 2022), and solid railway axles (Carboni and Crivelli, 2020). However, the monitoring of water-lubricated bearings is still challenging work. To achieve this work, the existing experimental test for evaluating water-lubricated bearings will be reviewed to determine the parameters that should be measured. Then, a short discussion on the challenges of monitoring water-lubricated bearings is presented to summarize existing monitoring issues.

2.1 Experimental test

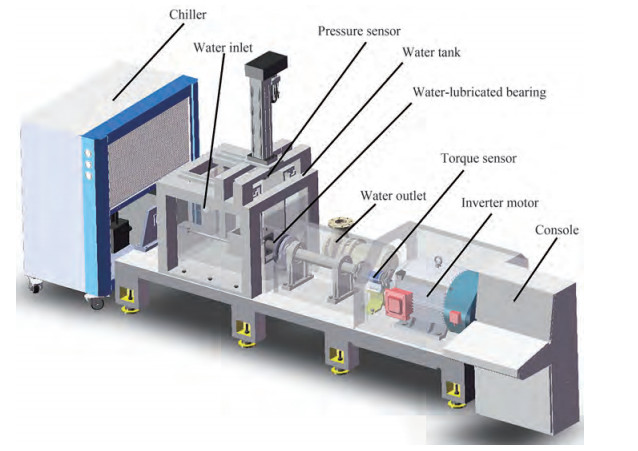

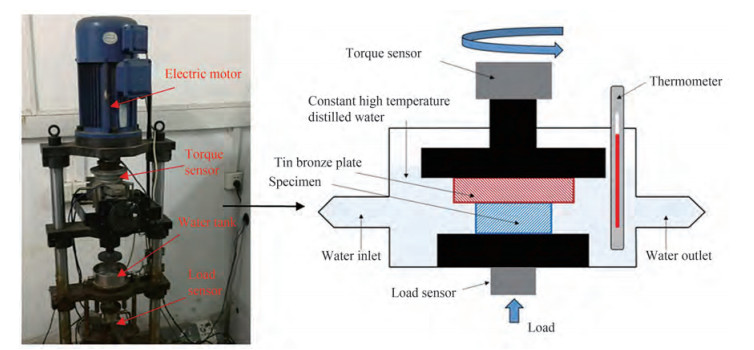

To improve the tribological properties of water-lubricated bearings, various materials have been examined as potential ones. The coefficient of friction (COF), wear volume loss, and wear surface topographies are three major experimental test parameters that correspond to the evaluations of antifriction, wear resistance, and friction mechanism. Considering the cost and efficiency, small samples of bearings (typical shape of cuboid or circle) are used for the tests. To measure the COFs of materials in the underwater environment, the use of a friction and wear tester is a common method. Specimens are placed in a water tank and rubbed against stern bearing bushing discs (commonly made of bronze), as shown in Figure 1. During the test, the pressure, speed, torque, and other parameters are continually collected in real time, and the following equation calculates the COF.

$$ \mu=\frac{T}{r \times F} $$ (1)  Figure 1 Friction and wear tester (Huang et al., 2021)

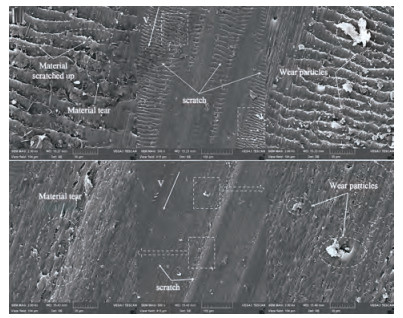

Figure 1 Friction and wear tester (Huang et al., 2021)where μ is the COF, T (N·m) is the friction torque, r (m) represents the rotation radius, and F (N) indicates the applied load. COF analysis is the most basic test to evaluate the tribological properties of materials. Wear volume loss analysis is also a typical test to evaluate the wear resistance ability of materials. The wear volume is calculated by the dimensional change of the specimen after testing. Comparing the weight changes is another method. However, Yang et al. (2021) present that materials can absorb water during the wear test, which impacts volume loss results. To explore the wear mechanism, scanning electron microscopes (SEMs) can be used to observe the surface of samples (Figure 2). The wear surface morphology, type of wear mode, deformation, mass loss, and other information can be clearly shown in these images.

Figure 2 SEM micrographs of specimens (Wu et al., 2019)

Figure 2 SEM micrographs of specimens (Wu et al., 2019)Although the above experiments can evaluate the performance of specimens, more advanced experimental equipment is essential for testing whole water-lubricated bearings. A water-lubricated bearing test bench is drawn in Figure 3. A pressure sensor and torque sensor were installed to calculate the COF using Equation 1. A water recycling system was designed so that water was siphoned from the chiller and flowed back into the constant-temperature water tank. Thermometers were fixed to monitor the difference between water temperatures in the inlet and outlet. The experimental bench is much bigger than the above ones, which is approximately 10 m in length. Compared with using small samples, this approach can comprehensively evaluate the performance of water-lubricated bearings, such as water film pressure, axis orbit, and variation curve (Liu et al., 2022). However, the whole test needs several uninterrupted experiments with different speeds and loads, which leads to a high cost of energy and human resources. A high cost means that this kind of experiment cannot easily study the fatigue of bearings that are needed hundred hours. In addition, the amount of data collected in the test is more limited compared with a real condition, resulting from the variable and complex marine environment in the real world.

2.2 Challenges and methods of the online monitoring of water-lubricated bearings

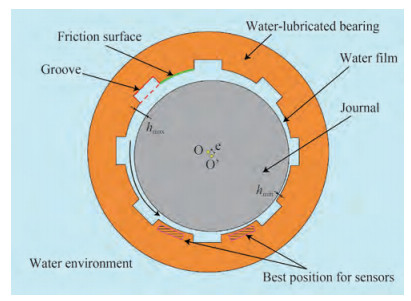

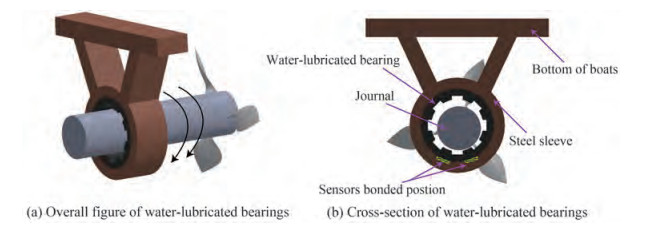

The primary drawbacks of the experimental test of water-lubricated bearings are the high cost and large difference from real working conditions. Online in-situ monitoring is an effective method to solve this problem, but it also has big challenges. The geometry of the cross-section of water-lubricated bearings is shown in Figure 4. Grooves were designed to promote the generation of water films between bearings and journals. Therefore, the bearings were surrounded by water, which means that protecting sensors from the water environment is essential. In addition, there is a short distance (e) between the centers of bearings (O) and shaft (O'), which leads to high vibrations during the operation. The impacts could damage the sensors if they are placed on the bearing surface. Finally, gaps between the bearings and shafts are small and change while the bearing works (hmin and hmax), so sensors with big sizes or complex structures cannot be used due to vibrations (Zhang et al., 2019), luminescence spectra (Fang et al., 2017; He et al., 2018), and electromagnetic testing (Palenčár et al., 2017). For these issues, one possible solution is integrating permanent sensors in the materials for monitoring. Because of gravity, the lower part of the bearings has the highest friction, making it the best place to embed sensors for increased sensitivity.

Accident risks and the remaining working life are two critical aspects for evaluating the condition of water-lubricated bearings. Wodtke and Litwin (2021) presented the current failure causes of assembly errors, severe operating conditions, improper lubrication, and overheating of bearing materials. Deformation, surface temperature (Wodtke and Litwin, 2021), and COF (Xie and Liu, 2020) are three valuable pieces of information to determine if the above problems happened. The remaining working life can be clearly calculated with the wear volume. Therefore, the following content discusses the sensors suitable to measure the parameters online and their energy supply methods.

3 Sensor selection

This section introduces the principle of different types of sensors, including electrical resistance strain gauges (SGs), fiber Bragg grating (FBG) sensors, piezoelectric (PZT) sensors, thermoelectric (TE) sensors, resistance thermometers (RTDs), and triboelectric sensors (TENGs). Features and current research works are reviewed to discuss if they are potential sensors for intelligent water-lubricated bearings. In addition, some typical case studies are reviewed and discussed.

3.1 Electrical resistance SGs

3.1.1 Working principle

The first electrical resistance SGs were designed in 1938. The primary sensing principle behind them is the variation of the electrical resistance when the conductor is stretched and its geometry changes. The resistance R can be presented as

$$ R=\rho L / S $$ (2) where ρ is the material's resistivity, L is the length, and S is the cross-sectional area (Figure 5a). An ideal SG can easily and reliably monitor strain changes caused by various factors, such as force, pressure, tension, and weight.

3.1.2 Current research status

There are still many limitations to SGs' practical applications, including shear lag, heat dissipation, performance deterioration during installation, inability to work on a curved surface, and resistance change resulting from the transverse strain (Yi et al., 2012). Moreover, the traditional SG has a relatively thick (~1 μm) metal foil and low-resistance material (commonly 120–350 Ω), which results in high power consumption. Thus, high resistivity, large elastic limit, and thin thickness material are hoped to solve this problem as the ideal solution for SGs, which is concentrated on nanoscale materials, such as graphene (Zhao et al. 2013), polymer (Kondratov et al., 2020), and metallic glasses (Yi et al., 2012). Kwak et al. (2017) presented a flexible, thin, polymer-based SG manufactured with polymer and metal via double-sided fabrication. This sensor is only 40 nm thick and has high resistance (~6 kΩ), whose energy cost is approximately 6% that of the conventional ones. Lee et al. (2017) designed another SG that was fabricated by a nanoparticle (NP) printer. Conductive NPs were printed onto carbon and glass fiber-reinforced composites, which can be used to measure composites' strain with 5 to 30 gauge factors (GFs). Metal NPs are another potential material for SGs, responding to a minimum mechanical strain of 0.000 94% (Jiao et al., 2014). However, these sensors can only work with a maximum of 2%–10% deformation, limiting particular areas, such as the medical industry and industrial robots. Therefore, an improved flexible SG has been presented to design a new SG for measuring large reversible deformations. Yi et al. (2015) solved the detectable hysteresis problem by assembling an Au NP monolayer on a polyethylene terephthalate film, detecting a frequency range of 1 to 20 000 Hz. The major problem for these SGs is the limitation on manufacturability. Kondratov et al. (2020) designed a new method and machine to print an electrically conductive coating on elastic polymer films, measuring the tensile deformation up to 70%. Min et al. (2019) showed that an aerodynamically focused nanomaterial printing system is another possible solution for high sensitivity and large-stretchability strain sensors, which presents a GF of 58.7 and a maximum strain limit of 74%. Other materials, such as graphene/ZnO composite films (Hassan et al., 2018), silver-coated polystyrene spheres (PS@Ag) (Hu et al., 2018)., metallic glass (Ignakhin et al., 2019), AIN (Schmid et al., 2020), and liquid polydimethylsiloxane (PDMS) have also been used for similar SGs, which have potential in flexible and wearable electronics (Han et al., 2021), microelectromechanical systems (MEMSs) (Yi et al., 2012), and biomedical industry (Ferreira et al., 2018).

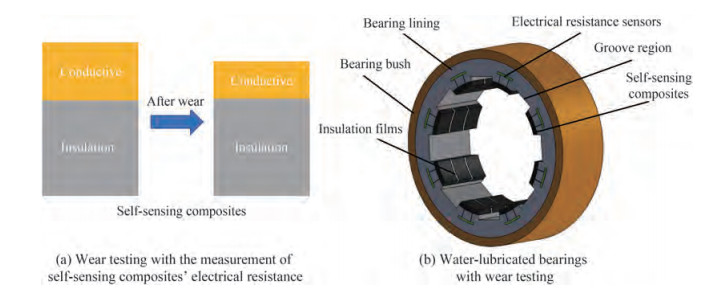

Compared with the traditional SG, adding conductive fillers for material self-sensing is a new approach. The stress, deformation, and cracks of materials can be detected with electrical measurement parameters, such as voltages, currents, and other signals. Metals are the most common conductive materials. However, environmental factors, such as water and oxygen, can corrode them, reducing the accuracy of the sensing performance. Carbon conductive fillers are more potential than metal because of their durability, excellent alkali resistance, and conductive performance (Han et al., 2020). For instance, Lee et al. (2020) designed a wireless self-monitoring of concrete infrastructures for railways. Sonicator (Qsonica Q500) was used to mix 1.0 vol% amount of conductive carbon nanotubes (multi-walled carbon nanotubes (MWCNTs)) into cement paste. MWCNTs were tiny particles with only a 15 nm diameter, keeping the cement-based sensor's mechanical properties. When there were external loads on sensors, their electric resistance changed, and the transmission module generated and transmitted sensing signals from sensors to the reception module. Lee et al. (2020) proved that stable sensing data can be transmitted up to 100 m, and the life of sensors was 3.5 years without maintenance in practical use. The significant advantage of self-sensing is reducing the cables and wires, which can reduce the cost and weight and simplify the structure of the sensing system (Li et al., 2018). Although self-sensing has enough potential, some challenges include the lack of basic theory, property reduction, weak anti-interference ability, and relatively low signal-to-noise ratio (Han et al., 2020; Zhang et al., 2020). To solve these limitations, the method of adding conductive fillers without agglomeration is critical. Additive manufacturing (AM) (Wang et al., 2019) and electrospinning (Lee et al., 2018) are two effective methods to promote stable conductivity in materials.

3.1.3 Applicability of intelligent water-lubricated bearings

Several issues should be considered when designing intelligent water-lubricated bearings based on SGs. First, the traditional SG is not an ideal sensor for its high energy cost. When embedding sensors into the bearing, the battery change could lead to a high cost, which means that the power used by sensors should be extremely low. Although high resistance thin thickness SGs have an energy cost of just around 5% of the conventional ones, this kind of SG is too thin, which could be damaged by the continuing impact and vibration during operation. Therefore, using SGs is only suitable for the research on intelligent water-lubricated bearings in the early stage. For practical applications, adding conductive fillers into the bearing matrix to promote self-sensing can be sensible. The self-sensing approach is a relatively new method of diffusing conductive fillers into a material. With the wear process, the volume change of materials can be calculated with the local electrical resistance. By using self-sensing composites in water-lubricated bearings, the whole bearings can be divided into several self-sensing areas by insulation films (Figure 5). With the electrical resistance measurement of each region, the wear volume can be determined for a specific position, and a wear monitoring system can be established, which significantly increases the efficiency of troubleshooting, maintenance, and repair. In addition, some conductive substances (e.g., carbon nanotubes) can enhance heat dissipation and reduce the friction of bearings. By using self-sensing composites in water-lubricated bearings, the whole bearings can be divided into several self-sensing areas by insulation films. With the electrical resistance measurement of each region, the wear volume can be determined for the specific position, and a wear monitoring system can be established, which significantly increases the efficiency of troubleshooting, maintenance, and repair.

3.2 FBG sensors

3.2.1 Working principle

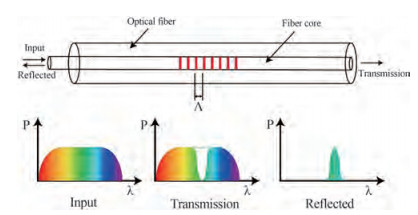

FBG sensors gained attraction in the 1990s. Their advantages include lightweightness and compactness, high precision, intelligence, immunity to electromagnetic interference, safety and biocompatibility, fast response for realtime monitoring, and suitability for harsh environments (Tosi, 2018; Liu et al., 2018; Chen et al., 2011). Currently, FBG sensors, as one of the most prominent fiber optic sensors, have been applied in board fields in geotechnical engineering (Zheng et al., 2019; Hong et al., 2016), fatigue monitoring (Szebényi et al., 2020), structural health monitoring (Qiu et al., 2013; Kuang and Cantwell, 2003), and commercial applications (Broadway et al., 2019). The primary sensing principle behind the FBG is based on the Fresnel reflection, which means that reflection and refraction can happen when light travels between media of different refractive indices. Therefore, a short optical fiber segment is created to reflect a particular wavelength of light but transmit all others. Then, a periodic variation of the refractive index is designed to establish a wavelength-specific dielectric mirror. The Bragg wavelength of the grating is calculated using the following formula:

$$ {\lambda _B} = 2{n_{{\rm{eff }}}}\mathit{\Lambda } $$ (3) where neff is the effective refractive index of the core mode propagating in the fiber, Λ is the grating pitch, and λB represents the Bragg wavelength of the FBG (Figure 6). Any change in neff or Λ results in an equivalent shift in λB, which can be used to measure various physical parameters, including temperature, strain, voltage/current, and index of refraction (Chen et al., 2011; Deepa and Das, 2020). However, according to the above expression, the temperature and strain can directly impact the wavelength change. Therefore, to monitor the shift of strain, the wavelength variation caused by temperature should be eliminated, and vice versa. Under actual conditions, the temperature change usually leads to a shift in strain, which will cause measurement errors. Thus, to solve this problem, using another FBG sensor that measures only strain or temperature is a practical method. This extra sensor is isolated from the other parameters' effects and located near the origin. Chen and Zhang (2011) introduced that the typical strain responses of FBGs can reach 0.64 pm/με (με = micro-strain) and 6.8 pm/℃. However, a higher resolution has been achieved for the other advanced FBGs (Tosi, 2018; Deepa and Das, 2020). Tosi (2017) designed different algorithms to obtain valuable information from the limited resolution and noise from FBGs, improving their accuracy and noise ratio resilience. In the future, FBGs can be widely used in research and practical applications.

3.2.2 Current research status and typical cases

The use of optical fiber sensors is a potential and common method for monitoring the condition of materials due to their sufficient sensitivity. In addition, FBGs can be embedded in the material without a high negative impact on mechanical properties.

FBGs can be used for pressure, strain, and fatigue monitoring. Leal-Junior et al. (2020) designed a temperature-insensitive pressure sensor by embedding a pair of FBGs in a polyurethane diaphragm. Dynamic mechanical analysis was used to compensate for the cross-sensitivity between temperature and pressure. Rufai (2020) identified that an embedded FBG has a good strain measurement sensitivity during the complete curing process of laminate. Optical fiber sensors can also be used to monitor the entire life cycle of composites (Szebényi et al., 2020). When FBG sensors are used for health monitoring, bare FBG sensors are fragile, so protection is essential. Polymer curing (Gómez et al., 2020) and 3D printing (Manzo et al., 2019) are two methods for these purposes. However, many factors can affect the slope calibration factor, such as Young's modulus and the casing's thickness. In addition, the adhesion between the casing and structure and the surface contact area between the casing and fiber are also not ideal for practical applications, which should be solved in the future (Manzo et al., 2019).

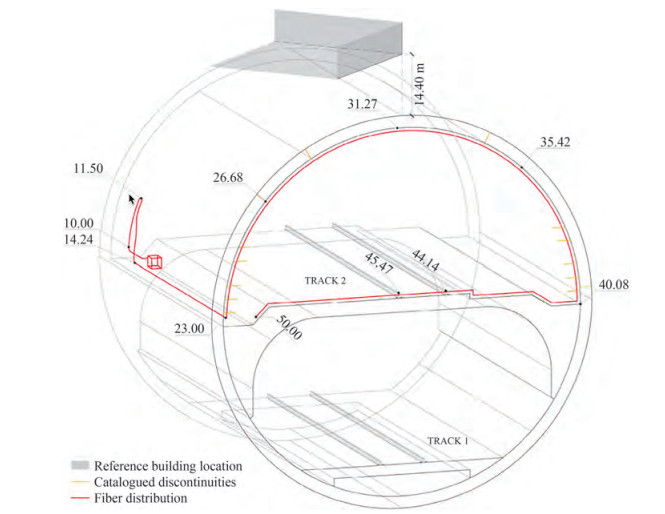

FBG sensors are also widely used for structural health monitoring of civil structures, such as bridges (Tennyson et al., 2001) and tunnels (Dreyer et al., 2013). Among them, one typical case is the monitoring of a tunnel in Barcelona. The effects of nearby construction on the tunnel's whole sections were continually detected during the excavation works. Although the FBG has good performance for this test, each sensor can only perform vivid measurements in a limited area. Thus, many similar sensors should be used to make a sensing network for global monitoring, called the degree of freedom (DOF). To ensure the performance of an optical fiber, they were bonded to the concrete surface (shown in Figure 7). Tape dots were used to fix fibers temporarily. A thin layer of epoxy resin was covered and bonded to the concrete lining. The results show that the DOF measurement has high accuracy in responding to nearby construction and ensuring safety during the whole monitoring. Although some geometrical discontinuities occurred due to the failure of the fiber-concrete bonding and the lack of a continuous monitoring tool, complex algorithms were applied to identify and substitute the lack of raw data, which provided smooth data on surface strain tendencies. Nonetheless, this case still has some limitations, including fiber bonding to the structure, temperature affections on the measurement, and post-processing of raw data (Gómez et al., 2020).

Figure 7 3D representation of the DOF monitoring scheme (Broadway et al., 2019)

Figure 7 3D representation of the DOF monitoring scheme (Broadway et al., 2019)FBG sensors have great potential in commercial applications. The first area is wearable and embedded applications, including exoskeleton torque analysis, gait and movement analysis, conventionally employed sensors, accelerometers, transverse forces sensors, and curvature sensors. The second area is (bio)chemical applications, including pH sensing, refractive index sensing, and humidity sensing. The third area is biomedical applications, including ultrasound or photo-acoustic and ultrasonic tomography, ultrasonic detection, breathing rate, and heartbeat sensors. The last area is radiative environments, including hydrogen sensors, X-ray detection, and the effects of gamma radiation on materials. The above applications show that FBG sensors are gaining popularity in complex and practical applications. The primary reason for this is their accessibility and low production cost. These enormous numbers of applications can also promote the research of more advanced FBGs and offer practical experience for their use (Deepa and Das, 2020).

3.2.3 Applicability of intelligent water-lubricated bearings

A number of problems should still be solved to integrate FBG sensors into water-lubricated bearings for monitoring. Among all the limitations, the fragility of bare FBGs is the biggest one. In a previous study, Szebényi et al. (2020) embedded FBG sensors into composite plates with 0.2 MPa of injection pressure and 70 ℃. However, some FBG sensors were still fractured. How to protect FBGs in the highpressure and high-temperature manufacturing process of water-lubricated bearings is critical. The package processing of FBG sensors can achieve this purpose, but the protective layer could absorb part of the strain and temperature change, which could reduce their sensitivity. In addition, the cost and volume of monitoring devices are so enormous that they cannot be integrated into bearings, so online monitoring cannot be achieved (Gómez et al., 2020). Finally, the temperature and external load can impact the wavelength shift compensation of fiber. Therefore, the method to separate these impacts is essential. Despite these drawbacks, FBGs have high potential owing to their accurate readings, high sensitivity, reliability under electromagnetic, compactness, and fast response. These characteristics make them a reasonable choice not only for monitoring the fatigue of bearings but also for manufacturing errors (manufacturing error is one of the common reasons for bearing failure) (Litwin, 2009).

3.3 PZT sensors

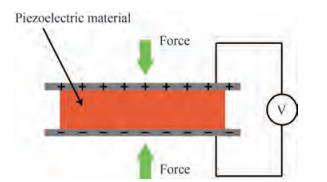

3.3.1 Working principle

The PZT material was discovered in 1880. The primary principle is the change in polarization in the crystal structure without a center of symmetry due to mechanical deformation. An electrical charge can be accumulated across its boundaries in response to applied mechanical stress (Figure 8). Moreover, the electrical field can lead to mechanical deformations in the PZT material. Energy harvesting and sensing are the two primary applications for the PZT material. For these purposes, sandwiching structure materials are commonly used. PZT is fabricated between elastomeric substrates, which can protect it and offer enough flexibility. Then, the electric charge can be collected for energy or data sensing from the top and bottom electrodes.

The electric flux density of the PZT material is presented by the following equation:

$$ D_i=\sum_j \varepsilon_{i j} E_j $$ (4) where D is the electric flux density, ε is the dielectric constant, and E is the electric field strength. Piezoceramics are typical materials for their large dielectric constants, which means that they can convert electrical energy into mechanical energy or convert mechanical energy into electrical energy with high efficiency. However, they are so brittle that they cannot stand immense strain before being damaged. On the contrary, piezopolymers can entirely overcome the limitations of piezoceramics with a highly flexible but low electromechanical coupling factor. To combine the two materials' advantages, PZT composites have the potential for specific applications. Its significant advantages include high-frequency resonant structures, easy fabrication, design flexibility, low weight, low cost, broad dynamic ranges, low power consumption, and no magnetic field generated while converting mechanical energy into electrical energy (Gupta et al., 2010).

3.3.2 Current research status and typical cases

Currently, PZT is mainly used for energy harvesting (Zhou et al., 2020) and sensing (Tuloup et al., 2019) in the engineering field. In terms of sensing, PZT has been widely used in acoustic emission monitoring, ultrasound monitoring, electrical monitoring (including electrical measurements and impedance meter), and frequency response and analysis monitoring (Tuloup et al., 2019). In addition, different materials were found to have PZT characteristics, such as crystalline materials, polymers, semiconductors, and ceramics. Furthermore, PZT can be formed in various shapes, including films, discs, and fibers. Because of these advantages, PZT material-based sensors can be embedded into materials to monitor operation data in different situations. Flexible PZT materials are potential PZT sensors with their advantages, including self-powered, high sensitivity, and flexible multifunctional. For instance, due to the electromechanical coupling and the possibility of being micromachined, PZT thin films have been applied in developing nanoscale and microscale devices, including MEMSs and nanoelectromechanical systems (Khan et al., 2016).

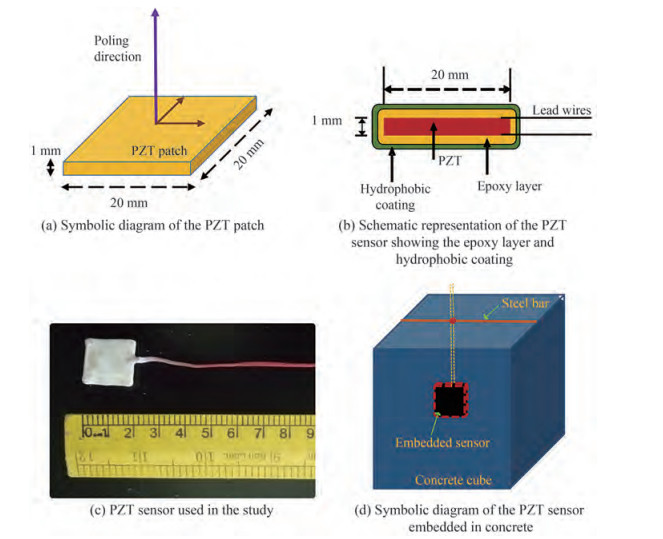

Another major application area for embedded PZT-based sensors is civil engineering, which focuses on monitoring the internal damage of concrete structures, architecture structures, and asphalt pavements. The internal damage in these structures is mainly generated from internal cracks, which grow into macro cracks and lead to failure. Compared with traditional surface-bonded sensors, the embedded one is more sensitive to detecting internal cracks. To embed the sensor, environmental protection should be considered, such as physical protection and insulation. However, in some practical working applications, environmental factors, such as temperature changes, rain, and seawater, can cause PZT deterioration. Thus, to solve this problem, PZT has been embedded into structures for internal damage detection, including concrete (Kocherla and Subramaniam, 2020) and asphalt pavements (Di et al., 2020). Another method is covering them up with silicone or epoxy. Although it can protect PZT, the cover can change the impedance signatures of PZT and testing results. Therefore, compensation algorithms or more PZT should be used to eliminate these influences. One typical example is the monitoring of concrete conducted by Kocherla et al. In this case, three epoxy layers were used to cure by placing PZT patches on a hot plate. Then, plastic enclosures were used as a hydrophobic coating to ensure the long-term stability of the epoxy in concrete (shown in Figure 9). When cracks are generated, the damping and compliance of the material decrease, which leads to a decrease in the peak conductance and a small leftward shift in the resonant frequency. Unlike other sensors, high sensitivity for crack detection has been achieved with the combination of embedded sensors and electrical impedance measurement. Currently, sensors are only installed in a particular direction. Another limitation of PZT is the low sensing range. Its effective range is only several meters. For this reason, monitoring large structures has a high cost, and the combination of PZT and other sensors is essential. With sensors in a different direction and installed in the whole concrete structures, global monitoring can be achieved (Kocherla and Subramaniam, 2020).

Figure 9 Embedded smart PZT-based sensor for internal damage detection in concrete under applied compression(Kocherla and Subramaniam, 2020)

Figure 9 Embedded smart PZT-based sensor for internal damage detection in concrete under applied compression(Kocherla and Subramaniam, 2020)3.3.3 Applicability on intelligent water-lubricated bearings

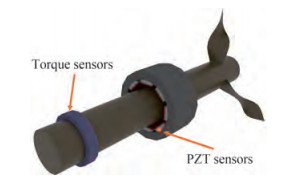

Self-powered and pressure-measuring capabilities make PZT an ideal sensor for water-lubricated bearings. Compared with FBG and SG, PZT is a passive sensor without energy cost problems. PZT transducers can meet the energy requirement of sensors and wireless antennas from the constant vibration generated in the bearing work. The pressure value is also a critical parameter for the calculation of the COF. Formula 1 shows that the COF is determined by the friction torque, rotation radius, and applied load. The first two can be easily measured with sensors in the engine. The integration of PZT allows recording the applied load to calculate the COF during operation (Figure 10).

3.4 TE sensors

3.4.1 Working principle

TE materials can directly convert temperature differences to electric voltage and vice versa. In this kind of material, the temperature gradient leads to the transfer of charge carriers from the hot side to the cold side, which causes electric voltage (Figure 11). Therefore, by designing suitable TE devices, the harmful heat from the working process and the heat in the environment can be harvested for various purposes, such as electricity generation, sensing, and temperature control of objects. Currently, low cost, high-conductivity, flexible, and nontoxic organic TE materials gain their attractiveness for their compatibility with wearable applications (Ruan et al., 2020). Moreover, based on the TE effect, the detection of specific ions can be achieved.

Similar to SGs, an RTD is another sensor used in the testing method according to electrical resistance changes. Currently, most RTDs are made from pure materials, such as nickel, platinum, and copper, for the relationship between resistance and temperature. Compared with other sensors, high accuracy and low drift are their critical advantages. With the increasing number of research works on measurement and calibration, RTDs have gained popularity in industries and research areas (Rao et al., 2022; Parali et al., 2018; Estacio et al., 2019).

3.4.2 Current research status and typical cases

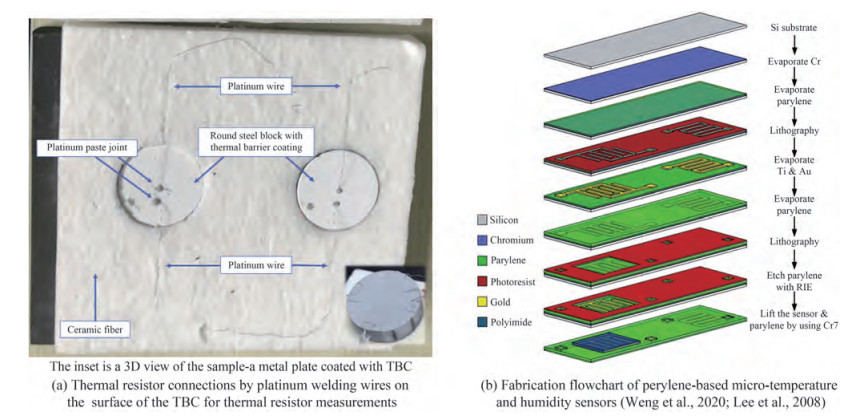

Temperature data are one of the typical signals used for system monitoring. High temperatures can cause dramatic damage to materials and even fire disasters. Moreover, the temperature change can indicate other issues, such as energy support problems, material fatigue, and extreme working load. In most cases, temperature monitoring is inexpensive and easy to implement. However, traditional sensors have limitations, including their large size and heavy weight. Therefore, the current research focuses on completing this mission in harsh environments and tiny spaces. For instance, Weng et al. (2020) used MEMS thin film sensors to monitor the temperature on the surface of turbine blade metals in aeroengines, which operate in over 500 ℃ working environments. To avoid the short-circuit effect resulting from the decrease in the electrical insulation performance of sensors, an improved thermal barrier coating (TBC) technology has been used to make an insulation layer (Figure 12(a)). A platinum thermocouple was installed on the TBC surface to measure the surface temperature. Guha et al. (2012) embedded micro-thin film thermocouples into a polycrystalline cubic boron nitride for a tool behavior study. To obtain the internal temperature of micro fuel cells, thin film sensors were integrated into a stainlesssteel base with microchannels (Figure 12(b)). This technique can record temperature data to perfect the operation parameters of fuel cells (Lee et al., 2008). Temperature sensors have also been applied to other fields, such as thermal conductivity measurement (Yu et al., 2013), medical engineering (Menz and Bonanno, 2021), and thermo-fluidic systems (Cho et al., 2017), and concrete structures (Norris et al., 2008).

3.4.3 Applicability on intelligent water-lubricated bearings

Water's inherently poor heat dissipation led to heat-aged or even carbonized water-lubricated bearings in the high temperature working environment. Findings show that high temperatures harm the COF of all types of water-lubricated bearings (Huang et al., 2021). Thus, temperature monitoring is a standard method to evaluate the lubrication condition and potential failure. Thermocouples and RTDs are the two most common sensors for measuring machine temperatures. The high energy requirement and measurement lag make RTDs a worse choice between the two. A thermocouple is an ideal sensor whose advantages include compactness, fast response, and non-energy requirement. In addition, it can work in high temperatures and high pressure without protection. However, due to the intense friction on the bearing surface, it can only be embedded for internal temperature monitoring. A heat distribution theoretical model of water-lubricated bearings considering frictional heat-generating and thermal balance effects and a contact temperature measurement method based on an internal temperature test should be proposed to determine the bearing lubrication condition by heat monitoring.

3.5 TENGs

3.5.1 Working principle

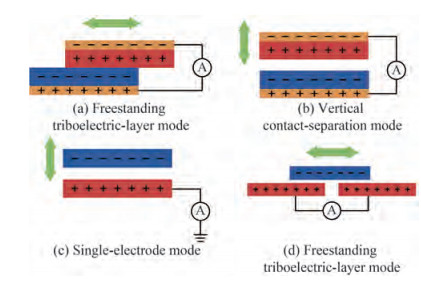

The phenomenon of contact electrification was discovered thousands of years ago, and it has been considered a valuable energy source for engineering until recently. The triboelectric effect is a kind of contact electrification generated from the contact and separation of two certain materials. The rubbing of materials can increase the contact area and hence the triboelectric effect. Although triboelectrification mechanisms have not been clearly researched (Xu et al., 2018; Duchene et al., 2018), Fan et al. (2012) designed triboelectric nanogenerators based on this phenomenon in 2012. The triboelectric effect is used to generate the potential between two thin films having two electrodes. TENGs can convert different types of mechanical energies to electrical signals (Figure 13), which has great potential in various fields, including engineering technology, biomedical techniques, and material science in the future (Mathew et al., 2021).

3.5.2 Current research status and typical cases

In recent years, various methods have been used to enhance the performance of TENGs. Different materials have been discussed, providing specific properties, including transparency, stretchability, thermal stability, and flexibility (Mahapatra et al., 2021). The significant advantages of triboelectric nanogenerators include their simple structure and process, low manufacturing cost, excellent robustness and flexibility, reliability, and environmental friendliness. One of the major applications of triboelectric nanogenerators is energy harvesting from the environment, such as wind speed, temperature, heartbeat, mechanical triggering, rotation energy, moving automobiles, flowing water, raindrop, tide, and ocean waves (Zhang et al., 2021; Mahapatra et al., 2021). Its area power density can reach 1 200 W/m2, and the conversion can achieve 85% (LináWang, 2014). Another application is the self-powered sensor, which has great potential in medical monitoring, acceleration, environmental humidity detection, human-machine interface, and chemical monitoring. For these purposes, the application has two major types. One is using the nanogenerators directly as sensors. Although this method can reduce the cost and simplify the structure, it is highly essential to stabilize the performance of sensors. The other one uses nanogenerators as the power for the test of other sensors. Although capturing valuable signals is much easier because of environmental adaptability, the costs of sensor manufacturing, energy, and maintenance are high (Zhang et al., 2021).

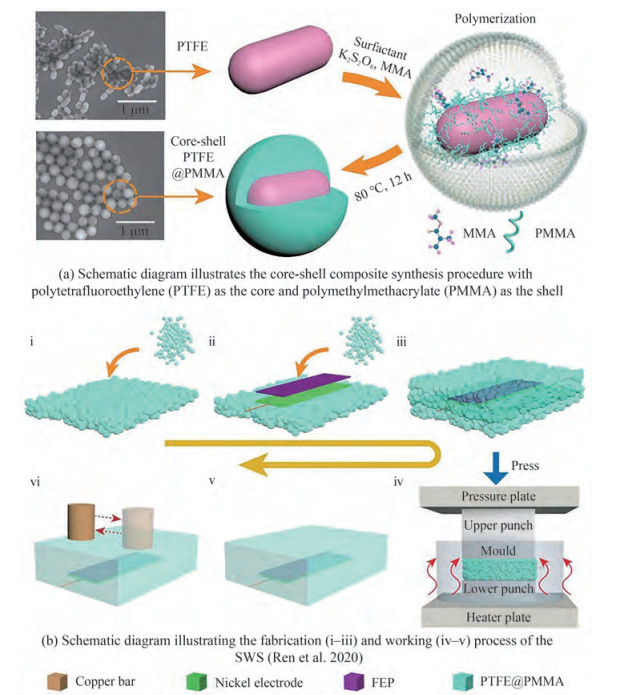

Ren et al. (2020) developed a sensor array based on single-electrode triboelectric nanogenerators for dynamic wear monitoring. In this case, electrodes were embedded into a core-shell composite with the combination of polytetrafluoroethylene (PTFE) as the core and polymethylmethacrylate (PMMA) as the shell. The wear sensor unit was manufactured by a hot press, where the pretreated electrode was placed between the bottom and upper PTFE@PMMA powder in a mold (shown in Figure 14). Then, a copper bar was reciprocated on it, and an electrometer was used to record the output signal. To simultaneously monitor a global area, an array of sensors is essential. Therefore, a 3×3 cross-electrode array with six outputs was installed, and each output contains two electrodes. Then, a fluorinated ethylene propylene film was used to prevent the electrostatic shielding effect between the upper and lower electrodes. The open-circuit voltage increased with the sliding displacement, copper bar diameter, and electrode width within a specific range, which achieved wear monitoring.

3.5.3 Applicability on intelligent water-lubricated bearings

Although traditional sensors can complete sensing tasks with high accuracy and reliability, their reliance on batteries limits their long-term sustainability and shrinkage of device size. With the aid of 5G technology, massive computable devices can be connected through networks, enabling the use of an enormous number of low-power sensors; their power consumption could be reduced by several orders of magnitude (Zhou et al., 2021). Therefore, harvesting energy from the environment is a reasonable strategy, making self-powered sensors a future trend (Zhao et al., 2020).

Many researchers have successfully used PENGs, TENGs, and TE sensors to make self-powered sensors (Zhou et al., 2021; Zhu et al., 2021; Salehi et al., 2021; Gao et al., 2020). However, various challenges should still be solved to use these technologies for water-lubrication bearings. First, the measurement of these sensors is challenging. There is a considerable internal resistance of these sensors, making the generating charge and information minimal. Second, the change in the external load usually occurs quickly, which cannot be captured by a common ammeter. Currently, the electrostatic transducer can overcome these issues, but its cost is too high to be widely applied in the industry. Third, there is also a specific shortage for each kind of sensor, owing to the vast area of manufacturing of PENGs and the low power density of TENGs (Zhu et al., 2021). Therefore, TENGs can only be used for the energy requirement of intelligent water-lubricated bearings. At the same time, artificial intelligence (AI) technology is essential, which can manage the energy for the sensor system and recover incomplete data when the environmental energy is not enough (Zhou et al., 2021).

4 Installation of sensors

Although sensors can meet different monitoring requirements, their installation is challenging. Accordingly, three steps are followed for this process: The first one is embedding the sensor precisely in the designed position. Sensor arrays in different geometries may be used for the advanced monitoring system's high accuracy in later research. In addition, embedded sensors' highly precise position is beneficial for repeatable results and enormous manufacturing for commercial applications. The second step is reducing the negative influence of mechanical properties. Tensile, bending, creep, and friction properties should not be dramatically reduced to implement this step. Otherwise, materials cannot keep their original application, and the purpose of monitoring is lost. The final step is keeping the integrity of the sensors after embedding. For some types of farming methods, such as hot pressing, high temperatures and pressures are encountered during manufacturing. Therefore, if the sensor will be embedded into a material during this period, it is critical to protect it from the manufacturing environment. After the sensors are embedded, the fix and maintenance are nearly impossible, or the cost is too high. Four approaches to embedding sensors will be presented in the following sections.

4.1 Bonded on the surface

Bonding sensors on the surface of a measured object is the most common method. The biggest advantages of this strategy are that it will not damage the object and it is easy to set up. The structure of the water-lubricated bearings is shown in Figure 15. Metallic bearing sleeves protect and connect water-lubricated bearings to the bottom of boats. Thus, holes can be made on the surface of the steel sleeve and fixed sensors into it. Magnet and epoxy resin are the typical materials for this purpose. However, water-lubricated bearings are non-metallic materials, so the magnet can only be fixed on the surface of the sleeve that is made of metal, which is presented as the green area in Figure 15. However, the distance between this area and the measured surface is too large for some sensors. For instance, TE sensors need to be close enough to monitor the temperature of materials that water can cool quickly, making them helpful only in monitoring surface temperature. Because the sensors are not embedded into the materials, their maintenance is convenient, which is the most significant advantage. Therefore, using this method to set up batteries is reasonable to avoid water and change when dead. The current major problem is how to separate the sleeve and bearing after mounting. Liquid nitrogen is used to cool down water-lubricated bearings and then mount them into the sleeve. However, this operation causes damage to the bearing and is irreversible. To avoid the accumulation of damages, the repeat mounting must be safe for bearings.

4.2 Embedding with microchannels

As there is a considerable distance between the measured surface and sensors, embedding sensors directly near the object is essential. Among all the embedding approaches, making microchannels and installing sensors into them are among the most influential and accessible ways. Figure 16 presents the steps. First, a suitable position to place sensors is decided, and a microchannel is made, whose size can be just crossed by sensors. Then, sensors are embedded into the microchannel, where only their leads are located outside. Finally, fillers, such as waterproof rubber and epoxy resin, are used to fill the microchannels. Compared with other approaches, the greatest benefit of this method is the highly effective research study of intelligent water-lubricated bearings. Nearly all kinds of sensors can be embedded with this approach in any position in materials. However, continuous vibration and damage caused by microchannels lead to the main limitation of using this method in practical applications.

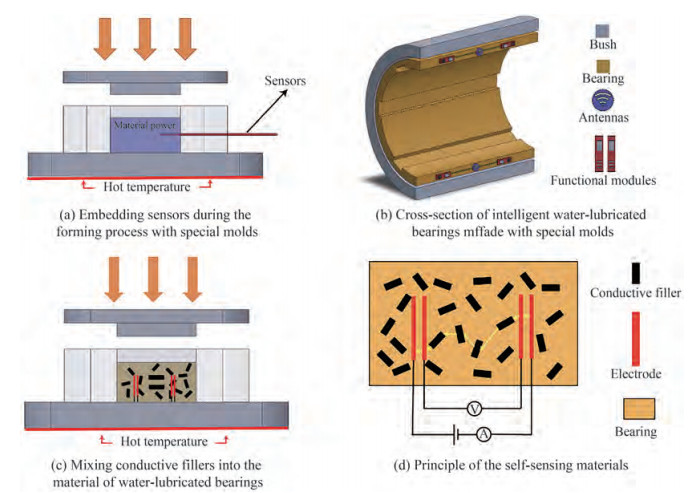

4.3 Special molds

Embedding sensors during the forming process of bearings is another method. The relatively low damage for bearings from the embedding process can be expected for this method, which is the main advantage. Hot press forming is a typical power metallurgy process for polymers, diamondmetal, and technical ceramics, which can embed sensors during the forming process (Ren et al., 2020). Although this method could almost keep the performance of the original materials, the high temperature and pressure could damage the sensors (Sousa et al., 2020). Moreover, it is not easy to position the sensors in materials because they will move during the forming process. This problem is serious while embedding precise and complex designed geometry sensing arrays and can significantly impact the reliability of obtained data. A general method that can precisely embed sensors into materials without any damage is hoped to solve these issues. Making a particular hot press mold is a reasonable method. For example, Sakka et al. (2018) added polyester fiber to polyethylene composites in different directions. Therefore, another hot press mold can be designed to embed sensors, which is shown in Figure 17. Polyester fiber can be used to locate and fix the sensors anywhere in the mold. During the polymer powder filling of the mold and the hot pressing process, the sensors can keep their position and be embedded in bearings. However, the manufacturing process usually has a harsh environment, such as high temperature and high pressure, damaging most sensors. Therefore, designing protection packing for sensors is a solution to this problem. However, this method may negatively affect the sensitivity of captured data. Another solution is using sensors that can generally work in this harsh processing environment, such as SGs. However, this method highly limits the selection of the types of sensors. Designing a particular mold is one of the most suitable methods in the current stage, where not only sensors but batteries and antennae can be embedded without negative impacts on water-lubricated bearings.

The self-sensing approach is a relatively new method that diffuses conductive fillers into a dielectric polymer (Figure 17(c)). By measuring the change in the local electrical resistance, the transient dynamic strain can be determined (Figure 17(d)). When applied in intelligent water-lubrication bearings, the significant benefits are the removal of unnecessary cables and the degradation of adhesive layers between the matrix material and sensors. In addition, the most conductive filler is made of carbon. MWCNTs have been proven to improve the stability of the friction interface and reduce the COFs and their fluctuation amplitudes.

Moreover, it is a potential method to measure the wear loss of water-lubricated bearings, where the loss of conductive fillers can dramatically change the electrical resistance of bearings. It can also be used to estimate the remaining life of bearings. However, the low ability to respond to low-frequency signals (lower than kilohertz) makes it hard to identify the embryonic damage of small dimensions (Wasilczuk and Wasilczuk, 2020). The change in the temperature, strain of materials, and water absorbed during the working process can also change the electrical resistance of conductive fillers, which leads to difficulties in determining specific factors.

4.4 AM

AM offers higher design freedom for customized parts and can solve the limitations of embedding sensors. Similar to using special molds, AM can embed sensors during the manufacturing process with good integration between the sensors and materials (Tomaz et al., 2021). The fused deposition method (Gupta et al., 2010), selective laser melting (Lee et al., 2020), multi-jet printing (Mieloszyk et al., 2020), stereolithography (Gupta et al., 2010), and directed energy deposition (Sakka et al., 2018) have been successfully applied in embedding FBGs in ceramics, polymers, and metals, which allows monitoring the temperatures and strains of materials. Figure 18 illustrates the three steps of embedding sensors by AM. The first step is manufacturing the bottom section of intelligent water-lubricated bearings. Leads and designed cavities are also simultaneously made (Figures 18(a) and (b)). Then, sensors are placed into the cavities, and cover plates are inserted to protect sensors if essential (Figure 18 (c)). Finally, the manufacturing of the upper section of the intelligent water-lubricated bearings is restarted (Figure 18 (d)). However, water-lubricated bearings are commonly designed for over ten years of working life with extremely high tribological performance and reliability. How to use AM to produce bearings is the major issue to be solved. The AM technology has a high possibility of being the best method for manufacturing intelligent water-lubricated bearings.

5 Design concept

Recently, the continuous increase in global sea trade has resulted in an increasing quantity of vessels. Technological development, including machinery, automation, and electrification, are critical factors for the improvement of efficiency and environmental impact and cost saving (Mieloszyk et al., 2021). Compared with traditional water-lubricated bearings, intelligent water-lubricated bearings can continuously monitor their working parameters and examine structural damages. In the above review, various sensors and embedding methods have been presented. This section will offer a comprehensive discussion of the design concept of intelligent water-lubricated bearings.

5.1 Research steps on intelligent water-lubricated bearings

To continuously and effectively monitor a specific machine or whole system, continuous, reliable, and accurate data are essential to be obtained. Different potential sensors have been introduced and discussed in Chapter 3. Table 1 shows a summary of the advantages and limitations of the sensors. Potential accident risks, lubrication conditions, and remaining useful life are three important evaluation indicators for water-lubricated bearings. Based on the analysis results, the sensor selection and proposed research steps are shown in Figure 19. The surface contact temperature is an effective indicator as the failure of water-lubricated bearings is mainly caused by the high temperatures caused by poor lubrication conditions when a ship starts and stops. Temperature sensors, such as thermocouples, can be used for monitoring the internal temperature and calculating the surface temperature. The COF is the most critical parameter of tribological properties, which can characterize the lubrication condition of bearings. The COF can be measured with torque and pressure monitoring. Measuring the wear volume is one of the best methods to estimate the remaining life. Adding conductive fillers not only can make the composites self-sensing for volume monitoring but also increases their thermal conductivity, which promotes the dissipation of frictional heat from the bearing surface. Therefore, self-powered load and temperature sensors should be embedded into self-sensing bearings and torque sensors in engines. The real-time evaluation of water-lubricated bearings can be achieved. In the future, research works should focus on sensor selection based on their measuring range, resolution, and working age and the influence of sensor integration on the bearing characteristics, such as strength, age, lubrication properties, and vibration properties. The management of specific equipment for processing sensing signals is also a critical research hotspot for making water-lubricated bearings intelligent.

Table 1 Summary of the advantages and limitations of potential sensorsTypes Energy requirement Advantages Limitation Electrical resistance strain gauges Active sensor Conductive filler could reduce the COFs of bearings High energy cost Fiber Bragg grating sensors Active sensor High sensitivity, fatigue, and manufacturing error monitoring Unable for online monitoring; Protection requirement Piezoelectric sensors Passive sensor Measured pressure can be used for calculating COFs High measurement cost Triboelectric sensors Passive sensor Energy harvesting High measurement cost Thermoelectric sensors Passive sensor Energy and protection free Indirect measurement of bearing properties 5.2 Signal processing

The signal processing for data obtained from embedded sensors is still a challenging task. For signal processing, three major parts of information should be identified: operation condition, fault risks, and remaining life. However, due to the enormous amount and the variability and richness of the response signals obtained by sensors during the test, directly diagnosing faults is almost impossible. Therefore, an automagical and general fault diagnosis system is essential, which focuses on the method that can identify a feature before it reaches a critical level and catastrophic failure. Effective feature extraction is essential to solve the fault pattern recognition problem with high accuracy.

Feature extraction and model construction are the critical steps in bearing fault diagnosis (Rufai et al., 2020). In the feature extraction period, statistical features, including Bayesian Statistics, correlation analysis, and time-frequency-domain methods, can reflect the essential characteristics of signals. However, specific domain knowledge and expertise are needed to obtain the statistical features. Moreover, only shallow information can be obtained from the statistical features, which cannot achieve feature extraction with the increasing complexity of machinery systems. This problem is attributed to the ignorance of their temporal characteristics. Thus, in-depth information can be extracted from the characteristics. Deep and shadow information can reflect the signal information from different perspectives, which means that their combination is potential (Mao et al., 2021a). During model construction, the use of AI tools is a major method, which includes k-nearest neighbor algorithms, Bayesian classifiers, support vector machines, artificial neural networks, and deep learning (Tosi, 2018; Mao et al., 2021b). Among them, hand-crafted feature extraction, expert knowledge, and human labor are essential for traditional machine learning diagnosis systems, but they cost too much time. Deep learning as the alternative method can learn high-level salient features from fault data. Then, it can determine salient high-level features from fault data. The primary limitation of deep learning is the narrow applicability that most research focuses on diagnosing a particular single fault but not a multiple-fault diagnosis system (Liu et al., 2018). Hence, an advanced fault diagnosis system is vital to increasing reliability and finding valuable information about testing signals (AlShorman et al., 2020). For instance, the novel convolutional neural network can work in a situation where the amount of training data is not big enough (Kumar et al., 2021a). Variational mode decomposition has significant advantages for defect degradation monitoring tasks (Kumar et al., 2021b). Although signal processing is critical for designing water-lubricated bearings, it is so complicated that this review will not be fully discussed.

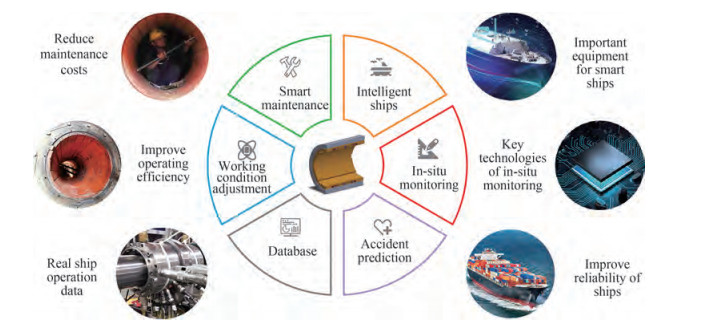

5.3 Applications and social significance

Due to the diversity of materials and structures in water-lubricated bearings, changing working conditions, and aging problems, implementing a standardized bearing performance evaluation system and bearing fault diagnosis method is difficult. Aiming at the limitations of working state monitoring and fault diagnosis of water-lubricated bearings and the difficulty of remaining life prediction, designing intelligent water-lubricated bearings with self-perception, self-decision, and self-regulation properties has a strong practical significance. With the increasingly close global trade, the volume of water transportation continuously increases, and ships are gradually developed in the direction of intelligence. The intelligence of marine systems and equipment is an important basis for the development of intelligent ships. As the core component of ships' power systems, intelligent water-lubricated bearings can monitor their running status in real-time, save it on the ship or upload it to the cloud, and build a database for the performance of water-lubricated bearings. Through the effective analysis of the database, we can evaluate the real-time status of water-lubricated bearings, predict their remaining effective life, and provide early warnings before an accident occurs, which significantly improves the reliability of ships. Valuable real ship data for the design and research of water-lubricated bearings can also be gained, which provides effective help for water-lubricated bearings and even tribology-related research. In addition, through the accurate judgment of faults, intelligent water-lubricated bearings can effectively reduce their maintenance costs, providing a research basis for intelligent maintenance and unmanned ships. In conclusion, the research on real-time monitoring and fault diagnosis of water-lubricated bearings has significant social significance. Relevant research can not only improve the reliability of ships but also meet the increasing demand for water transportation. It is also the main component of the development of intelligent ships. The research work is oriented to the frontier needs of international science and technology and is committed to promoting the development of green, electrified, and intelligent technologies for ship propulsion systems, which have important theoretical significance and application value.

6 Conclusions

In summary, this paper proposes possible solutions for intelligent water-lubricated bearings. With a review of similar tasks and a comprehensive discussion, the following conclusions can be drawn:

1) Compared to traditional bearings, intelligent bearings can continuously monitor themselves and predict features before they reach a critical level and catastrophic failure. Embedding sensors into machines is a practical approach to this requirement. However, there is little research about embedding sensors into intelligent water-lubrication bearings. Therefore, more research is hoped to embed sensors into bearings with the integrity of both, which is the future marine industry trend.

2) The water working environment and high vibration make the design of intelligent water-lubricated bearings a challenging task. Embedding sensors into bearings can be an effective method. Various types of sensors and four embedding methods are presented, and the advantages and drawbacks of embedding sensors are discussed.

3) The research work on intelligent water-lubricated bearings is committed to promoting the development of green, electrified, and intelligent technologies for ship propulsion systems, which have important theoretical significance and application value.

-

Figure 1 Friction and wear tester (Huang et al., 2021)

Figure 2 SEM micrographs of specimens (Wu et al., 2019)

Figure 7 3D representation of the DOF monitoring scheme (Broadway et al., 2019)

Figure 9 Embedded smart PZT-based sensor for internal damage detection in concrete under applied compression(Kocherla and Subramaniam, 2020)

Table 1 Summary of the advantages and limitations of potential sensors

Types Energy requirement Advantages Limitation Electrical resistance strain gauges Active sensor Conductive filler could reduce the COFs of bearings High energy cost Fiber Bragg grating sensors Active sensor High sensitivity, fatigue, and manufacturing error monitoring Unable for online monitoring; Protection requirement Piezoelectric sensors Passive sensor Measured pressure can be used for calculating COFs High measurement cost Triboelectric sensors Passive sensor Energy harvesting High measurement cost Thermoelectric sensors Passive sensor Energy and protection free Indirect measurement of bearing properties -