An Evaluation of the Effects of Human Factors on Pilotage Operations Safety

https://doi.org/10.1007/s11804-021-00222-1

-

Abstract

In recent years, marine pilotage accidents occurring on a worldwide basis as a result of human error have not been ceased to transpire, despite advances in technology and a significant set of international conventions, regulations, and recommendations to reduce them. This paper aims to investigate the effect of human factors on the safety of maritime pilotage operations. The human factors that affect the operators who are performing ships' berthing operations have also been examined in detail. In this study, in order to determine the causes of human-related errors occurred in maritime pilotage accidents, a comprehensive literature review is carried out, and a considerable number of real past case examples and an analysis of the maritime accident investigation reports regarding pilotage operations events that occurred between 1995 and 2015 have been reviewed. To validate the identified human-related risk factors (HCFs) and explore other contributory factors, survey questionnaires and semi-structured interviews with domain experts have been conducted. A structural hierarchy diagram for the identified risk factors (HCFs) has been developed and validated through experienced experts belonging to the maritime sector. A questionnaire for pair-wise comparison is carried out and analysed using the analytic hierarchy process (AHP) approach to evaluate the weight and rank the importance of the identified human causal factors. The findings of this study will benefit the maritime industry, by identifying a new database on causal factors that are contributing to the occurrence of maritime pilotage disasters. The database can be used as a stand-alone reference or help implement effective risk reduction strategies to reduce the human error, that might occur during pilotage operations.Article Highlights• Use of the AHP method to rank the importance of the identified human causal factors;• An effective pilotage risk/safety assessment tool to help implement effective risk reduction strategies, and prevent human errors from the incident/accident occurrence during marine pilotage operation.• The contributory human causal factors (HCFs) influencing the safety of marine pilotage operations; -

1 Introduction

Over the past decade, despite new technologies, modern bridge navigational equipment (Ugurlu et al. 2015c), and the implementation of safety-related regulations (Hetherington et al. 2006; Ćorović and Djurovic 2013), the impact of the human factor on maritime accidents has remained on average at about the same level (Noroozi et al. 2014), and the safety of ship's operations has not significantly changed (Eliopoulou et al. 2016; Kandemir and Celik 2021). There are many causes that can result in maritime accidents such as organisational, mechanical, electrical problems, and external factors such as adverse weather conditions; however, studies estimate that around 80% of maritime accidents are attributable to human error (Uğurlu et al. 2015a, b). And most of these accidents occur in narrow channels, and during berthing and unbreathing manoeuvres (Uğurlu et al. 2015a), resulting in damage to the environment and property (Erol and Başar 2015).

Gard (2014) reported that, in recent years, the number of maritime accidents occurring worldwide has been increasing, involving significant contact damage to fixed objects include berths, docks, locks, and shore side equipment such as cranes by vessels manoeuvring in confined waters, mostly within the port. The contact damage has resulted in many claims for the repair and/or loss of use of such objects. Consequently, the appropriate way to reduce the frequency and risk of maritime accidents is by identifying the root causes of the accidents occurring in these regions.

Despite the presence of marine pilot onboard ships to avoid human error involved in marine accidents, and to ensure the safety of navigation of visiting ships, it is, however, a fact that a considerable number of accidents still occur (Gard 2014).

Gill and Wahner (2012) pointed out that the major contributory factor for many maritime disasters has been caused by captains of the ships, deck officers, and marine pilots. And according to Graziano et al. (2016), 96.5% of the errors have been performed on the ship's bridge where the main actor is involved. These accidents have raised questions on how risk/ safety is reviewed in pilotage operations.

Pilotage operations are categorised as one of the most complex tasks, which are predominantly performed under a dynamic and uncertain working environment, extreme weather conditions, and heavily congested areas. Pilotage operations are liable to diverse risks due to their interaction and interdependence, and the multiplicity of the entities who are performing ships' berthing operations. It is conducted by multiple operators with different responsibilities including the pilot, ship's crewmembers, tugboats and mooring boat crews, shoreline personnel, and VTC regulators who are required to work cooperatively together as one team to guide the ship safely to its berth (Murdoch et al. 2012). It is worth mentioning that, during pilotage operations, high levels of operational uncertainties exist, especially, when a shipmaster is unfamiliar with the pilotage area and the master may be entering the port for the first time or the port pilot is not qualified. Pilotage operations involve managing high-risk situations that require intense concentration and high standard levels of competence and skills. The issue is complex, and there is an imperative need to focus on this issue in more detail.

Handling a large vessel in congested and restricted areas, such as straits, canals, and docks, is high-risk, making pilotage operations more challenging and complex (Uğurlu et al. 2016). Ships have changed over the years, and ship handling has to evolve in line with these changes, e.g. ship sizes have increased, whereas, ports have not always increased in size accordingly (Armstrong 2007, p.1). According to Xi et al. (2017), the technological innovations, developments in the shipping industry, and the emergence of complex systems and Very Large Crude Carrier (VLCC) make the consequences of disasters more and more serious. The complication and the difficulties that the matter represents today in the shipping industry in terms of structural adjustments, technological changes, and operational requirements reveal the necessity for further research to address this issue.

The incredible growth of international trade and the introduction of new technologies mean that shipping industry risks are evolving. As one serious accident caused by the grounding or collision of ships at sea or upon entering the port because of human error can endanger the port, crew, ships, and cargoes and damage the maritime environment, causing a substantial financial impact on coastal countries and companies (David, 2008). Therefore, operators must maintain a consistently high standard of human performance to maintain the ship's piloting safety, as any decrease in performance can potentially lead to a disaster (CAMSS 2012).

Overall, the above concerns indicate that seafarers' conduct at sea contributes to maritime safety and is of great importance to seafarers and all stakeholders interested in maritime affairs. The quality of performance and safety of ship's operations during pilotage operations has a significant effect on the port's productivity, safety, and reputation. Providing high-quality and safe port service that meets customers' needs leads to an increase in the port attractiveness to attract shipping carriers to berth at the port and enhance the port competitiveness (Ding et al. 2019).

In light of these considerations, and based on the above reasons, the need for the maritime industry to improve its operations safety can be justified. It is now assumed that the assessment of the human-related risk associated with pilotage operations needs to be established in the maritime industry, and threats to human performance must also be understood and mitigated to maintain pilotage operations safety, and achieve enhanced safety for international shipping and reduce consequent injuries, loss of life, and damage to the maritime environment and properties. Identifying and mitigating these risks are crucial as the shipping industry's successes or failures can have far-reaching impacts on global trade and the economy.

In this regard, in recent years, many research projects regarding maritime safety and maritime transportation-related risks have been conducted from various perspectives. However, little research has been done in the maritime domain on pilotage operation safety issues, and until now, few studies have employed a multiple criteria decision-making method to examine how human factors contribute to the maritime pilotage accidents. Few studies have employed advanced modelling techniques such as multiple criteria decision-making methods to examine how human factors contribute to maritime pilotage accidents. Therefore, to proactively address pilotage operations safety, this study aims to investigate the effect of human factors on maritime safety within this context, emphasising pilotage operations.

To address this research need, the human causal factors that contribute to pilotage accidents are identified. Furthermore, it is to determine the relative weights and rank the importance of the human factors that affect pilotage operation safety by an Analytical Hierarchy Process (AHP) method.

The rest of this paper is organised as follows: Section 2 describes the relevant literature review, Section 3 describes the research methodologies, Section 4 describes the process of identifying maritime pilotage accident causal factors and their classification, and Section 5 describes the process of the AHP method. The main results and discussion of the study are presented in Sections 6 and 7. The last section contains conclusions and the contribution of the study to the marine industry.

2 Literature Review

Studying human factors and accident analysis has always been an important research topic among maritime professionals and scientists (Özdemir and Güneroğlu 2015). According to IMO (2003), "the human element is a complex, multi-dimensional issue that affects maritime safety and marine environmental protection. It involves the entire spectrum of human activities undertaken by a ship's crew, shore-based management, regulatory bodies, recognised organisations, shipyards, legislators, and other relevant parties, all of whom need to cooperate to address human element issues effectively". The human factor plays a significant role in maritime safety (Berg et al. 2013).

Many studies on human factors in the past decade focused on how to reduce human error influencing maritime operations' safety. However, the early work on the human-related risk assessment in maritime transport has been changed due to the evolution of new technolgies, and the scientists in the maritime field came to recognise that the old ways are not capable of meeting the new challenges faced by maritime stakeholders.

Furthermore, they also realised the need for new approaches to the identification and quantification of human errors to address various human-related risks within a system has become increasingly one of the most important maritime safety issues, as it has been widely acknowledged to be the most frequent cause that leads towards marine accidents.

The increased numbers of maritime accidents during the last view decades have forced maritime professionals and scientists to conduct numerous studies to identify human risk factors and to analyse their impact on maritime safety (Özdemir and Güneroğlu 2015). For instance, Macrae (2009) discussed the human factor in terms of two types of shipping accidents: groundings and collisions between 1995 and 2000. The author defined the common causal patterns including organisational factors, unsafe acts, and cognitive and situational aspects.

Similar research had been carried out by Tzannatos and Kokotos (2009), where all accidents involving Greek-flagged ships during the period 1993–2006, accidents were examined according to the vessel type, cargo, and location. The findings showed that 63.9% of the pre-ISM accidents were due to human error. Tzannatos (2010) has also conducted studies on different incidents of Greek-flagged ships during 1993 to 2006. The findings provided useful insights for the formal enquiries conducted by the Hellenic Coast Guard. According to the investigation, 57.1% of ship accidents were attributed to the human element. Furthermore, it was discovered that the captains of the ships were responsible for almost all of the frequently encountered groundings and collisions, and were involved in 80.4% of the accidents. On the other hand, the engine officers were responsible for 8.1% of the incidents, and the bridge officers and crew were responsible for 6.8% and 4.7%, respectively.

A comprehensive review of literature was conducted by Hetherington et al. (2006) to identify the relative contributions of individual and organisational factors to shipping accidents. They found that fatigue, stress, health, situation awareness, teamwork, decision-making, communication, automation, and safety culture are the most frequent contributing factors to maritime accidents. Furthermore, Ferguson et al. (2008) examined the impact of brief, unscheduled naps during work periods on alertness and vigilance in coastal pilots along the Great Barrier Reef, as the duration of the work period could extend well beyond 24 h. In this study, Seventeen coastal pilots were volunteered; they found that a pilot's work environment, irregular and lengthy working hours without a decent nap, working at night without rest period, and travelling to and from their jobs impact on the alertness of marine pilots and can significantly contribute to fatigue.

Similarly, a survey-based study had been conducted by Darbra et al. (2007), through an interview of 20% of the Australian and New Zealand maritime pilots in order to assess the safety culture and hazard risk perception of the maritime pilots from the two countries. They found that starting/steering/anchoring equipment failures when manoeuvring or navigating, poor boarding arrangements, failure of tug lines, failure of ships master and/or personnel to correctly follow pilots, ships master and/or personnel to correctly follow pilots directions, navigating and ship handling in marginal operating conditions when subject to commercial pressure, the efficiency of navigation/propulsion equipment misrepresented to pilot by the master, pilots navigating vessels outside published guidelines or limits, incorrect operation of ships equipment, failure of the regulator to enforce efficient regulations for safe navigation, and incorrect ship details provided to pilot/port prior to pilotage are the most hazardous events in marine pilotage.

Uğurlu (2016) used questionnaires and interviews involving 71 pilots to investigate the pilots' profile and structure of existing pilotage organisations in Turkey, and as a result, it developed an effective pilotage organisation model. They found that the commercial–political pressures and low salaries negatively affect maritime pilot performance. They concluded that the structural deficiencies in pilotage organisations caused commercial pressure on pilots, which has negative impact on task management and should be reduced. Moreover, they found that dense and irregular working conditions reduced job satisfaction and caused physical and social problems; they also found that the working schedule or job rotation is one of the most important factors affecting fatigue management, and maritime pilot performance.

Ćorović and Djurovic (2013) investigated human factor and its impact on maritime safety from psychological and organisational aspects. They reported that health is considered one of the most important factors that influence the professional efficiency of seafarers and correlated to psychophysical strength, duration of resting, seafarers' job satisfaction, internal relationships, and stressful situations. They also found that, psychological problems such as impatience, dissatisfaction, and lack of motivation may stimulate intolerance between crewmembers, which could also be a result of cultural and religious differences. In addition, they pointed out that working and living on a ship with employees of an array of nationalities and backgrounds could lead to misunderstanding and operational problems which will have a negative effect on crew performance. And consequently influence vessel safety.

The human error during ship manoeuvring in restricted waters had been studied by Gerigk and Hejmlic (2015). The results aid the solution to the question on how stress and the stressing factors influence on the decision making process of ship's masters and marine pilots during ship manoeuvring in restricted area. Erol and Basar (2015) examined marine accidents occurring in the Turkish search and rescue area in the period between 2001 and 2009 by using a Decision Tree method. They found that 60% of marine accidents happening in the Turkish search and rescue area was due to human error. The main causes leading to the ocurnace of the human error included navigational, manoeuvring failure, and carelessness.

Uğurlu et al. (2015a) analysed the role of human errors in shipping accidents using a fault tree analysis (FTA) method. They found that the main reasons for the accidents originating from human error are as follows: for collision accidents, Convention on the International Regulations for Preventing Collisions at Sea (COLREG) violation and the lack of communication between vessels; and for grounding accidents, the interpretation failure of the officer on watch and lack of communication in the bridge resource management.

Recently, Chen (2020) used why-because analysis, Human Factors Analysis and Classification System (HFACS) for Maritime Accidents (HFACS-MA), and grey relational analysis (GRA), to identify the human and organisational factors (HOFs) in marine accidents. Kandemir and Celik (2021) analysed and determined the conditions under which errors in marine engineering maintenance and operations occur using a Human Factors Analysis and Classification System (HFACS) approach. Demirel (2020) utilised Cognitive Reliability Error Analysis Method (CREAM) to evaluate the failures in auxiliary systems of marine diesel engines that may be caused by human. Islam et al. (2018) identified the most important environmental factors affecting seafarers' performance during maintenance operation on-board ship using experienced seafarers' feedbacks and literature analysis. In addition, a study related to human error assessment had been conducted by Kandemir et al. (2019). This study extended the shipboard operation human reliability analysis (SOHRA) through the marine auxiliary machinery maintenance operations.

In recent years, maritime risk and safety assessment research have undergone many essential changes, and a considerable number of new approaches have been developed to facilitate human error quantification in order to improve maritime safety (Luo and Shin 2016). For example, Chauvin et al. (2013), utilised a Human Factor Analysis and Classification System (HFACS) method to evaluate human and organisational factors in marine accidents. Furthermore, several methods have been employed in studies on accident analysis and risk analysis, and safety assessment, including Cognitive Reliability Error Analysis Method (CREAM) (e.g. Demirel (2020), Yang et al. (2019)), Fuzzy AHP (FAHP) (e.g. Hsu 2012), Bayesian network (BN) (e.g. Akhtar and Utne 2014).

Within this context, the use of combined methods and coupled analysis becomes emerging in recent years. For instance, Yang et al. (2013) extended the CREAM approach by incorporating Bayesian reasoning in a fuzzy environment. Xi et al. (2017) modified CREAM methodology based on an Evidential Reasoning (ER) approach and a Decision-making Trial and Evaluation Laboratory (DEMATEL) technique for making human error probability quantification in CREAM rational.

Akyuz and Celik (2014) using a hybrid accident analysis approach by combing HFACS and cognitive map (CM), to analyse the role of the human factor in marine accidents. Additionally, an extended accident analysis model was introduced by Wang et al. (2013) to identify the leading accident causes and, thereafter, to propose the most cost-efficient safety measures to prevent the occurrence of such accidents. This model consisted of two parts: a quantitative accident analysis model that was built by integrating HFACS with BN, and the proposed prevention measures that were ranked according to cost-effectiveness through an Evidential Reasoning (ER) approach.

Akyuz (2015) presented a new method, using a novel hybrid accident analysis approach to analyse marine accident causes that occurred for complex social and technical reasons. It involved Accident Analyze Mapping (AcciMap) and an Analytical Network Process (ANP) method to determine the accident main contributory factors and provide a solution to evaluating the causes of accidents in the marine industry. Moreover, two methods DEMATEL and ANP, were proposed by Özdemir and Güneroğlu (2015) to evaluate the importance level of the human factors in maritime casualties.

Although showing some attractiveness from a methodological perspective, previous studies on human factors in the maritime industry still revealed some applicable problems in practice. Many of them focused on seafarers (including both officers and marine engineers) while few on pilots and fewer using advanced techniques than basic surveys to investigate the risk factors influencing pilot reliability. Given the fact that a large amount of maritime accidents occur in restrict waters where pilots often present, this study aiming to analyse the human factor-related risks that affect the operators responsible for executing pilotage operations is important and significant.

In this paper, an Analytical Hierarchy Process (AHP) method has been utilised. AHP approach is an effective tool proven to be appropriately applied for dealing with MCDM problems in an uncertain and complex operations environment. AHP was recognised as the most effective method of decision-making in management engineering after the 1980s. Professor Saaty of the University of Pittsburgh developed the method in the 1960s (Lee and Kim 2013). The AHP approach is common and widely used in rating tasks and an appropriate application when comparing the importance of a criterion against other criteria at the same level in the hierarchy decision tree (Saaty 1980).

It is worth mentioning that many studies have been conducted utilising the AHP method. It was applied by Celik and Cebi (2009) in order to identify the role of human errors in shipping accidents and by Zhang et al. (2013) to establish a hierarchical risk structure and to identify the significant influencing factor of an inland waterway transportation system. Lee and Kim (2013) used AHP to analyse the relative importance of the risk factors of marine traffic environment, while Pak et al. (2015) employed it to identify the factors that can affect port navigational safety. Ugurlu et al. (2015b) used the method to determine the causes of ships' collisions. Fu et al. (2018) utilised it to investigate the relative importance of potential risk influencing factors of Arctic maritime transportation systems, and by Saeed et al. (2019) in the development of a taxonomy of merchant marine deck officers' non-technical skills (NTS).

3 The Methodology

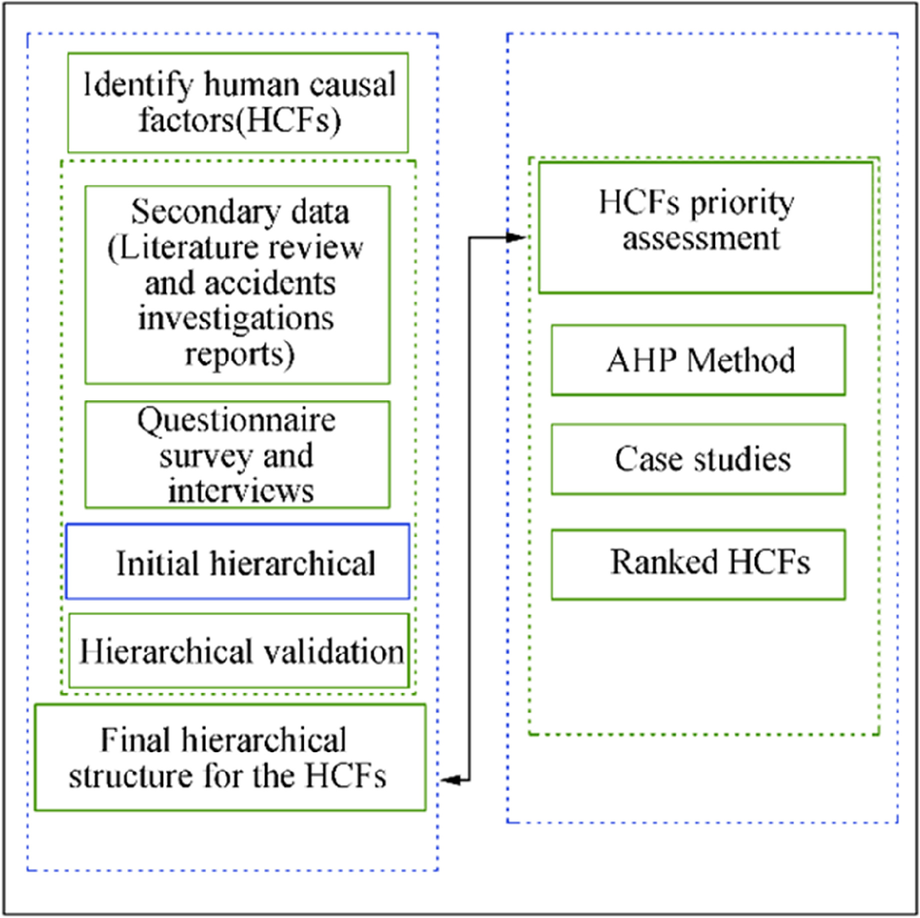

This section describes the methods and techniques used in this study. The study consists of three main steps as shown in Figure 1. Firstly, based on the information collected from the literature review, analysis of marine accidents investigation reports, and questionnaire surveys with experienced marine experts, the contributory human causal factors (HCFs) that can lead to maritime accidents during pilotage operations were identified.

After identifying the risk factors (HCFs) and based on previous maritime safety studies related to human factors with maritime experts' assistance, a preliminary hierarchical structure as a taxonomy for these factors (HCFs) was developed. The developed hierarchical structure of the identified risk factors is then modified and further validated through experienced marine experts. An AHP approach for evaluating these factors is then employed. These processes will be further discussed in the following sections.

4 The Process of Pilotage Accident Causal Factors Identification and Classification

In this study, as mentioned previously, identifying the human-related risk factors contributing to pilotage accidents was accomplished using secondary and primary source data.

4.1 Secondary Source Data

In this paper, to identify the risk factors as entirely as possible, a comprehensive and updated literature review was carried out. Besides, to provide additional evidence of contributing factors to maritime accidents, an analysis of investigation reports related to a number of occurring actual worldwide maritime accidents during pilotage operations between the period 1995 and 2015 has been reviewed and examined. These reports were investigated and published via web sites by countries and relevant institutions and organisations such as the Marine Accident Investigation Branch (MAIB) of the UK, the National Transportation Safety Board (NTSB) of the USA, and the Transportation Safety Board of Canada (TSB). Accident investigation reports are considered the most reliable sources of evidence to identify the ships' accidents' root causes (Mazaheri et al. 2015).

4.2 Primary Source Data

Identifying critical risk for pilotage operations is a challenging problem due to insufficient data availability and information limitation. It is also challenging to investigate the risks that influence ship's crewmembers and marine pilot's personality characteristics on their attitudes towards risk and the probability of error in maritime pilotage operations due to the lack of evidence.

Therefore, to ensure that all the human causal factors (HCFs) contributing to pilotage accidents are identified, semi-structured interviews and questionnaire survey with experienced marine experts were carried out in this study, attempting to validate and test the feasibility of the selected factors, as well as to explore new potential causes that may negatively influence mooring operations' safety and play a central role in the causal chain of maritime accidents. A structured questionnaire was developed for data collection. The questionnaire consisted of closed and open-ended questions. Questionnaires were sent by email to around 50 experienced experts belonging to various maritime sectors, and 25 responses were received.

The number of participants was deemed acceptable for this study. Saaty (2001) reported that just a small sampling size is required if the data collected are gathered from experienced specialists. This is because experts should share consistent beliefs and thus reduce the necessity for a large sample size.

The participants were all experienced professionals who possessed master's certificates and had worked for a long time in the marine sector, including ten professional ships' captains who had served long periods onboard a variety of vessels in shipping companies; eight experienced senior marine pilots; and two tug masters who had been working extended periods in different ports companies. They were selected as the study focuses on pilotage operations, and they are the leading operators who play a significant role in achieving safe and successful piloting and berthing operations. Thus, they are vital for avoiding marine accidents to provide views on their performance through their long practical experience and observations during maritime pilotage operations and give important information regarding the human element factors contributing to maritime accidents.

Also, the participants included two maritime educational institution staff who have a good understanding of marine operations risk research and are highly knowledgeable of human-related risk associated with pilotage operations. Moreover, one insurance and two port company managers, who are professionals in assessing and managing risks and who could provide factual information and broader data regarding human errors and causes of maritime pilotage accident that might occur during pilotage operations, were included.

The aforementioned steps lead up to in a composite of the 25 human causal factors (HCFs) affecting safety performance in the marine pilotage environment. These factors are shown in Table 1.

Table 1 The list of human causal factors contributing to maritime accidents in pilotage operationsNo Human causal factors (HCFs) of pilotage accidents 1 Lack of team work (poor bridge team-pilot integration, cooperation, coordination, and close loop) 2 Lack of effective communication and language barriers 3 Failure to exchange the information between pilot and ship's master prior to the commencement of the manoeuvre 4 Failure to establish a proper manoeuvring plan prior to piloting vessel 5 Distraction during the manoeuvring 6 Lack of situation awareness 7 Lack of familiarity with the electronic navigational equipment knowledge 8 Failure to proceed with safe speed as stipulated in COLREG 9 Pilot boarding and disembarking too close to breakwater 10 Mental and physical work load 11 Stress 12 Fatigue 13 Lack of ship handling skills due to lack of experience and improper training 14 Failure of pilot to give precise instructions 15 Failure of the ship's master to correctly follow the pilot directions (e.g. incorrect interpretations, refusal, rejection, intervention by master 16 Improper/inadequate use of tugs 17 Lack of skills of the crewmember on ship board, tugs, and shore mooring personnel 18 Orders regarding anchoring, steering, and engine requests, are not followed out by ship's crewmembers correctly 19 Failure of tug's masters to carry out the pilot's instructions precisely 20 Failing to inspect the tugs towing equipment 21 Pilot failing to think ahead for developing situations 22 The master's and pilot's ineffective monitoring of the tug boats masters, mooring boats, and shore mooring personnel performance and vessel's progress 23 Navigating vessels outside published rules and guidelines (e.g. piloting ships in bad weather condition or limits draft due to subject to commercial pressure) 24 The blind trust and reliance on the pilot during berthing operations 25 Using mobile phones during berthing operations 4.3 Sample Characteristics

In this study, to obtain reliable views on a wider scale and get multiple points of view, the participants of this study were selected from various backgrounds and different geographical areas within the maritime industry. The main factor in selecting these experts was based on their expertise that they have contributed in the fields related to the human element factors and causes of maritime pilotage accidents. The criteria ensure that the professionals are sufficiently senior and knowledgeable to answer the questions and provide reliable technical information and opinions on the research topic. Thus, their responses will give robustness to the study and explain the study objectives.

4.4 The Classification and Validation Process of HCFs

To develop the taxonomy for the contributory causal factors of pilotage accidents (HCFs), the following steps were performed in this study:

After identifying the twenty-five contributory factors of the pilotage accidents (HCFs) and based on previous maritime safety studies related to human factors and risk classification model, with the assistance of two experienced ship's captains, a hierarchal structure as a taxonomy is initially constructed. The experts were academics with education level PhD degree from an educational institution, staff who have more than 10 years of teaching and researching experience and a good understanding of marine operations risk research. They had also served long periods on-board various vessels that are navigating and visiting seaports worldwide.

First of all, the two experts were invited to review and evaluate the preliminary taxonomy and provide their opinion concerning each factor's level. They were asked how the grouped factors should be presented in a hierarchy properly and categorising and placing the accident causal factors in the taxonomy's correct position. The main questions in the interviews were asked to classify twenty-five factors which can represent their main associated factors (categories) and sub-factors and the questions were the following:

"Do you think the main group factors (categories) and their sub-factors are well classified?"

"Could you classify the main factors to represent their associated sub-factors?" and if necessary, modification, removal, division, and combination are allowable. Through the feedbacks, some factors (HCFs) were modified, removed, and combined.

For instances, they combined the error factors with the same meaning accidents' causal factors into a new one. This research found that the factors "using mobile phones" and "distraction" have a relatively similar meaning with regard to error factors which are more likely to influence the occurrence of an accident. Hence, these two factors were combined into one factor named distraction, also the blind trust and reliance on the pilot during berthing operations and lack of team work. In addition, improper/inadequate use of tugs and failing to inspect the tug's towing equipment. Finally, instead of twenty-five factors identified, the experts selected only twenty-one factors and classified them into five main factor groups; each group was then divided into several (4 or 5) sub-factors as illustrated in Table 2.

Table 2 Human causal factors of pilotage accidents (HFCFs)Factors Sub-factors Nontechnical skills shortcoming (BTM failure) (F1) Lack of teamwork (F11)

Lack of effective communication and language barriers (F12)

Failure to exchange the information prior to pilotage operation (F13)

Lack of situation awareness (F14)

The master's and pilot's ineffective monitoring of the tugboats masters, mooring boats, and shore mooring personnel performance and vessel's progress (F15)Technical skills shortcoming (F2) Lack of ship handling skills due to improper training and lack of experience (F21)

Lack of familiarity with the electronic navigational equipment knowledge (F22)

Lack of skills of the crewmember onboard ship, tugs, and shore mooring personnel (F23)

Improper/inadequate use of tugs (F24)Instructions and orders failure (F3) Failure of pilot to give precise instructions (F31)

Failure of the ship's master to correctly follow the pilot directions (F32)

Failure of tug's masters to carry out the pilot's instructions precisely (F33)

Orders regarding anchoring, steering, and engine requests, are not followed out by ship's crewmembers correctly (F34)Rules and regulations noncompliance (F4) Failure to establish a proper manoeuvring plan prior to piloting vessel (41)

Failure to proceed with safe speed as stipulated in COLREG (42)

Navigating vessels outside published rules and guidelines (e.g. piloting ships in bad weather condition or limits draft due to subject to commercial pressure) (F43)

Pilot boarding and disembarking too close to breakwater (F44)Individual- task interaction factors (F5) Fatigue (51)

Mental and physical workload (F52)

Distraction during the time of berthing operations (53)

Stress (54)After that, to assure the validity and confirm the developed hierarchy diagram's reliability, a panel consisting of six experienced experts belonging to the maritime sector were consulted. Emails distributed and face-to-face and telephone interviews with the validation team were subsequently conducted. The experts were all experienced ship masters who had served long periods on-board a variety of vessels, including two academics with education level PhD degree from a maritime educational institution staff who have good experience in maritime risk assessment research, two senior pilots currently working in different ports companies in the UK, one who has more than 25 years of marine experience and one senior pilot who has worked for an extended time on a variety of ships, 4 years as a ship's captain 2 years as marine operations and safety manager, and 20 years as a senior marine pilot.

One expert is a Master Mariner with an education level of a bachelor degree, who has vast experience as a director in the maritime sector. He also worked for an extended period as a sea pilot. Besides, he has held many positions such as harbour master, director of maritime affairs, assistant chairman of port, and acting chairman of a port management. One expert is an insurance company manager. He sailed as a master mariner on gas tankers, consequently worked as a marine superintendent for an oil/gas/chemical ship management company, followed by a spell as independent external surveyor. For the last 5 years, he worked as an internal surveyor for Standard P & I Club and took over as Director of Loss Prevention in 2013.

The experts were asked to review and validate the developed taxonomy's effectiveness and confirm if the identified factors were grouped according to their characteristics. Finally, the experts agreed, and the developed hierarchy diagram was accepted without any modification as shown in Table 2, that is, the most contributory causal human factors of maritime pilotage accidents. Risk classification enables the interpretation and enables complexity to be simplified (Ugurlu et al. 2015b). It also facilitates the evaluation and helps risk managers to understand the events and the circumstances from which they arise (Pak et al. 2015).

5 HCFs Priority Assignment Using AHP

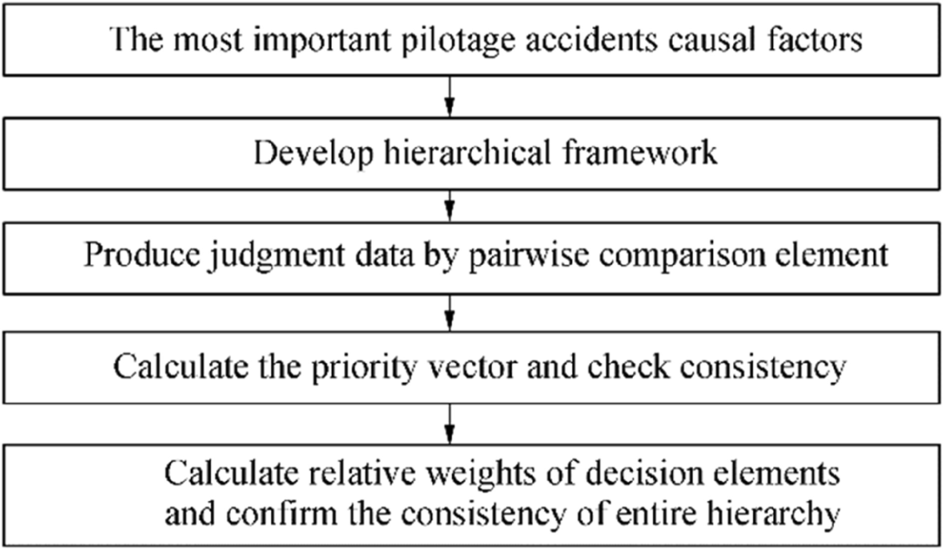

To determine the most important human causal factors that contribute to the occurrence of maritime accidents during pilotage operations, the AHP approach was used. Generally, AHP consists of three fundamental principles: firstly, hierarchy framework, secondly, priority analysis and finally, consistency verification. Figure 2 shows the AHP method in five steps: (1) determine the objective of the problem, (2) form the hierarchical structure of the problem, (3) produce judgement data by pairwise comparison (4) calculate the priorities vector and check the consistency, and (5) calculate the relative weight and confirm the consistency of the entire hierarchy. The process is presented in the following subsections.

5.1 The Goal

This study aims to determine the most critical factors that contribute to the occurrence of maritime accidents during pilotage operations. These factors are considered to affect the safety of pilotage operations. Therefore, the factors and sub-factors listed in Table 2 are the parameters that need to be evaluated.

5.2 Develop a Hierarchal Structure for Pilotage Accidents' Causal Factors

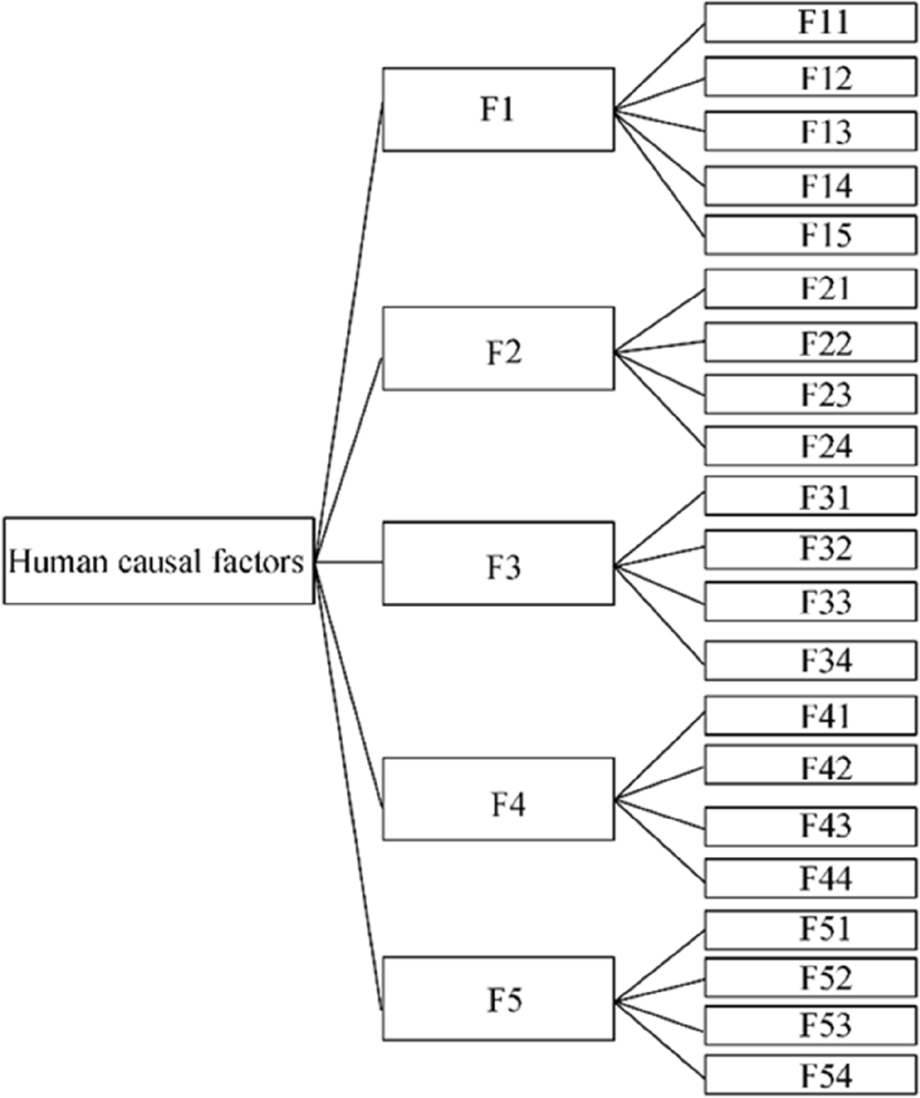

The Analytical Hierarchy Process (AHP) method in this study is employed to evaluate the weight and rank the importance of human factors that influence pilotage operation safety performance and cause maritime accidents. The first step is to develop a generic hierarchical structure based on the identified risk factors to achieve this aim. According to Saaty (2001), the AHP method recommends a maximum of seven comparative factors simultaneously because human beings have limited capacity to process information simultaneously with reliable accuracy and validity (Saaty and Ozedemir 2003). Therefore, based on the information presented in Table 2, the hierarchical structure for maritime pilotage accident causal factors is constructed in this study and corresponds to the basic AHP structure. Figure 3 illustrates the three levels of hierarchy for the decision process in this study.

In the hierarchical model, the overall goal is illustrated on the first level. That is the most contributory causal human factor of maritime pilotage accidents. This structure consists of five main group factors, and each one is divided into sub-factors. The main factors are the criteria, which are, (F1, F2, F3, F3, F4, and F5). The sub-factors are sub criteria which are, F1: (F11, F12, F13, F14, and F15), F2: (F21, F22, F23, and F24), F3: (F31, F32, F33, and F34), F4: (F41, F42, F43, and F44), and F5: (F51, F52, F53, and F54).

5.3 Constructing a Pairwise Comparison and Performing Judgement

Pair-wise comparisons between the causal factors are conducted to assign a weight.

Once a hierarchical framework is created, pair-wise comparisons between the causal factors are conducted to assign a weight. AHP uses a simple Pair-wise Comparison technique to determine weights and ratings (Saaty 2008), so that the decision-makers can focus on just two factors simultaneously (Mahmoodzadeh et al. 2007). The ratio scale of assessment for the pairwise comparison between factors of each hierarchy is used for comparing factors with each other (Saaty 1994), as shown in Tables 3 and 4. These tables describe the numerical assessment together with the linguistic meaning of each number. The first table explains "IMPORTANT", while the second table describes "UNIMPORTANT".

Table 3 Pairwise Comparison Scale (Saaty 1994)Numerical assessment Linguistic meaning 1 Equally important 3 A little important 5 Important 7 Very important 9 Extremely important 2, 4, 6, 8 Intermediate value of important Table 4 Pairwise Comparison Scale (Saaty 1994)Numerical assessment Linguistic meaning 1 Equally important 1/3 A little unimportant 1/5 Unimportant 1/7 Very unimportant 1/9 Extremely unimportant 1/2, 1/4, 1/6, 1/8 Intermediate value of unimportant The decision-makers should compare each element with the other by using the fundamental scale for pair-wise comparisons. The pair-wise comparison starts with a comparison between two selected elements at the same level to get the relative importance between them.

To select the most important factor, the expert will be asked to underline the importance of each factor and sub-factor in the given column accordingly. It is important to note that the respondents have to be careful not to get logical contradiction on these questionnaires for pairwise comparison. These logical contradictions of a respondent are measured as inconsistency ratio in the AHP method. It was pointed out that the AHP method is a subjective methodology, and a large number of experts are not required if the data collected are gathered from the experts (Saaty 2001). Therefoe, pairwise questionnaires were sent to only seven experts belonging to various maritime sectors to give their judgements, and each expert had to understand it before completing the pair-wise comparisons.

Experts are required to give a possible judgement to all questions based on their expertise and experience. The experts were experienced shipmasters who had served long periods onboard a variety of vessels, including five senior pilots currently working in different port companies in the UK and Mediterranean, one expert who is an insurance company manager, and one ship's captain with education level PhD degree from a maritime educational institution staff, with more than 10 years of working experience.

All responses were collected and recorded, but while feedback of seven experts was received in this study, only five participants' results were considered as two participants' weighting data was disregarded as a result of a lack of consistency in light of the AHP formula. Once a pairwise judgement is performed, comparisons of the decision elements are organised into matrices.

In this step, to conduct the pair-wise comparison matrix, at first, set up n criteria in the row and column of an n × n matrix. The number of matrixes at each level depends on the number of elements at that level of the hierarchy and the matrixes' order at every level depending on the number of elements at the lower level that it connects to.

Comparison of the decision elements is organised into matrices. These matrixes consist of n columns and n rows; it is a square matrix (i.e. A matrix) as shown in Eq. (1). Each element of the matrix represents the factor's preference in row i to the factor in column j, where i, j = 1, 2, 3, …, n and each aij is the relative importance of attribute Ai to attribute Aj. For a matrix of order n, n (n-1)/2 a comparison is necessary.

If i = j on the comparison matrix, then the value will be 1, because in this case, the related factor is compared with itself. If Ai is judged to be of equal relative importance to Aj, then aij = aji = 1. If aij = α, then aji = 1/α, α ≠ 0

$$ {\boldsymbol {A}}a_{ij}=\left[ \begin{array}{l}1& a_{12}& \cdots& a_{1n}\\a/a_{12}& 1& \cdots& a_{2n}\\\cdot& 1& \cdots& \cdot\\1/a1n& 1/a2n& \cdots& 1\end{array} \right] $$ (1) Then, to determine the priorities from each pair-wise matrix and to obtain the importance of each factor, the eigenvector method was used. The weight vector of the comparison matrix provides the priority, then the consistency ratio is calculated.

5.4 Eigenvector (Priority)

To determine the priorities from each pairwise matrix and to obtain the importance of each factor, the eigenvector method was used. The eigenvector (priorities) could be calculated as described in Eq. (2). According to Saaty (1980), the eigenvector approach is the most proper method to determine the priorities. The eigenvectors for priorities can be calculated by average of normalised column (ANC) method. After the comparison matrix was completed, the process of normalisation started. According to Muhisn et al. (2015), the ANC process can be done by applying three steps as follows:

(1) Sum of each column in matrix;

(2) Each element of the matrix is divided by the sum of its column; and

(3) Normalised eigenvector principle, which can be done by adding the element in each resulting row and then dividing this sum by the number of elements in the row (n).

Generally, weights w1, w2…, wn can be calculated by using the following equation:

$$ {W}_{i}=\frac{1}{n}{\sum }_{j=1}^{n}\left(\frac{{a}_{ij}}{{\sum }_{i=1}^{n}a_{ij}}\right),\left.i,j=\mathrm{1,2},\dots ,n\right) $$ (2) where $ {a}_{ij} $ represents the entry of row i and column j in a comparison matrix of order n. For example, to calculate the priority of main factor F1, it can be done by applying three steps as follows:

(1) $ \sum\nolimits_j^na_{ij}1+1/2+1/3+1/3+3=5 $

(2) $ \frac{{a}_{ij}}{{\sum }_{i}^{n}{a}_{ij}}\bullet \frac{1}{9.33}=0.11 $

(3) $ {\sum }_{j}^{n}\frac{{a}_{ij}}{{\sum }_{i}^{n}{a}_{ij}}\bullet 0.11+0.13+0.09+0.09+0.20=0.62 $ and divided this sum by the number of elements (n = 4) Thus, $ \frac{0.62}{5}==0.12 $.

Each value of the matrix in Table 5 is based on one expert's opinion. If several experts are involved, the geometric mean is used to find the judgements' averages before calculating the eigenvectors. The weight value of the factor F1is found as 0.12, and the same process to calculate the weight of the other factors F2, F3, F4, and F5 was applied (Table 5).

Table 5 Normalised status of the fife main causal factors comparison matrix and weightMain factors F1 F2 F3 F4 F5 Eigenvector (priority), w (%) F1 0.11 0.13 0.09 0.09 0.20 0.12 F2 0.21 0.26 0.27 0.28 0.20 0.25 F3 0.32 0.26 0.27 0.28 0.20 0.27 F4 0.32 0.26 0.27 0.28 0.33 0.29 F5 0.04 0.09 0.09 0.06 0.07 0.07 SUM 1.00 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.02 5.5 Perform the Consistency

Since the normalised matrix is performed to confirm the consistency of the pairwise judgement, the consistency verification is employed, which is considered as one of the essential tasks of the AHP approach according to Muhisn et al. (2015). It is included to compute the consistency ratio among the pairwise comparisons (Riahi et al. 2012).

When the Consistency Ratio (CR) of pairwise comparison is zero, the respondent keeps consistency perfectly. A good consistency is (a score < 0.1). If CR is more than 0.10, it means a lack of consistency (Saaty 1980). A decision-maker should review the pairwise judgements and should be repeated or disregarded.

To calculate CR, each column of the comparison matrix is multiplied to calculate the weighted aggregate matrix (Aw) as follows:

$$ {A}_{w}=0.12\left[\begin{array}{c}1\\ 2\\ \begin{array}{c}3\\ 3\\ 1/3\end{array}\end{array}\right]+0.25\left[\begin{array}{c}1\\ 2\\ \begin{array}{c}3\\ 3\\ 1/3\end{array}\end{array}\right]+0.27\left[\begin{array}{c}1/3\\ 1\\ \begin{array}{c}1\\ 1\\ 1/3\end{array}\end{array}\right]+0.29\left[\begin{array}{c}1/3\\ 1\\ \begin{array}{c}1\\ 1\\ 1/5\end{array}\end{array}\right]+0.07\left[\begin{array}{c}3\\ 3\\ \begin{array}{c}3\\ 5\\ 1\end{array}\end{array}\right] $$ Then, each element of the weighted Aw is divided by the priority vector element to calculate the Aw /w value. The CR value is calculated according to the following equations (Saaty 1980):

$$ \begin{array}{c}CR=\frac{CI}{RI}\\ C1=\frac{{\lambda }_{max-n}}{n=1}{\lambda }_{max}=\frac{{\sum }_{j=1}^{n}\left[\left({\sum }_{k=1}^{n}{w}_{k}{a}_{jk}\right)/wj\right]}{n}\\ \lambda =\frac{\left(5.1+5.1+5.2+5.2+5.0\right)}{5}=\frac{25.6}{5}\end{array} $$ (3) Lambda max λ = 5.12.

$$ \begin{array}{c}\mathrm C1=\frac{5.12-5}{5-1}=0.03\\\mathrm{CR}=\frac{0.03}{1.12}=0.02\end{array} $$ where CI represents the consistency index, RI is the average Random Index (Table 6), n is the matrix order, and λmax represents the maximum weight value of the n-by-n comparison matrix A.

Table 6 Values of random index (RI) of (AHP) processSize of matrix n 1 2 3 4 5 6 7 8 9 10 Random consistency index RI 0 0 0.58 0.9 1.12 1.24 1.32 1.41 1.45 1.49 Determining the suitable value of (RI) from the table of random index of AHP as shown in Table 6, for the matrix size of five, the random index will be RI = 1, 12, after that calculate Consistency Ratio (CR). For instance, the calculation to consistency test for the main $ \mathrm{CR}=\frac{\mathrm{CI}}R $, $ \mathrm{CR}=\frac{0.03}{1.12}=0.02 $. As the value of CR is less than 0.1, the judgements are acceptable.

In this study, to evaluate the weight of the five main causal factors and the twenty-one sub-factors presented in the hierarchical structure, a comparison matrix was created. Each value of the matrix in the tables is the geometric mean of five expert judgements. The geometric mean is used to find the averages of the judgements before calculating the eigenvectors. In this paper, exile software was used to calculate the priority (Eigenvector) and consistency.

6 Results

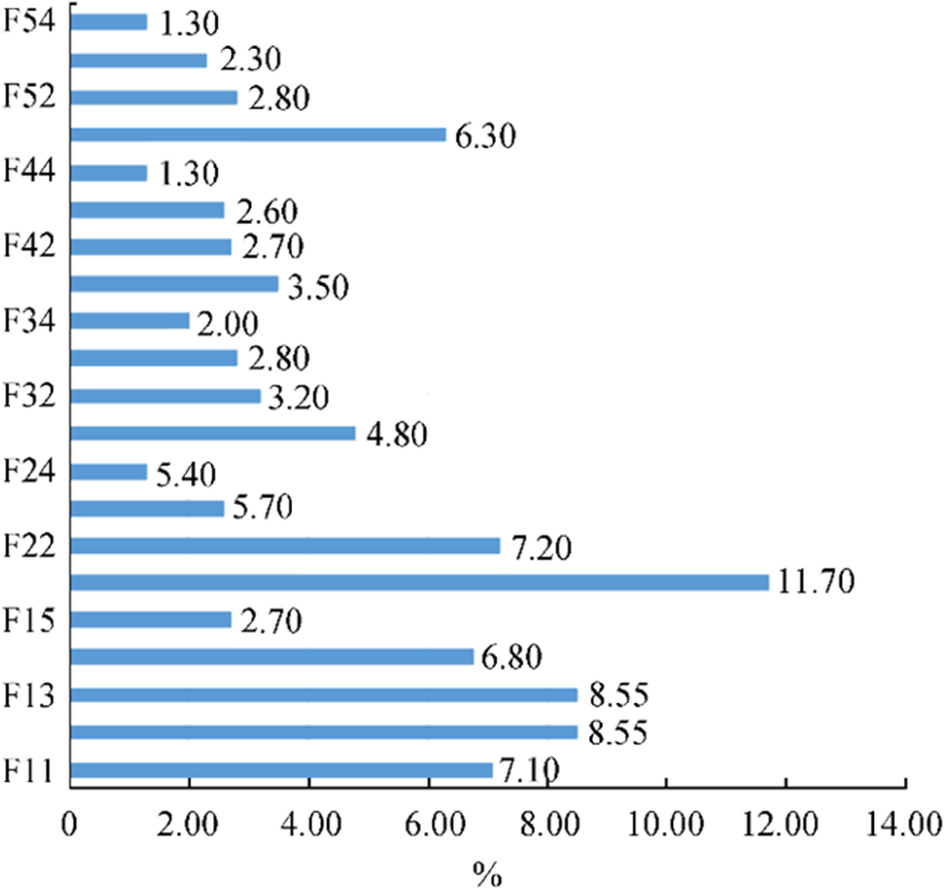

Tables 7–12 represent the priority weight and the relative importance among the five main causal factors categories and the twenty-one sub-factors contributing to pilotage accidents. It is important to mention that the weights obtained are local weights at the same level, it is necessary to obtain global weight for each of the sub-factor, which affects the main goal and forms the basis for further analysis. This has been conducted by multiplying the local weights of sub-factor by main factors weight value, which is the one of their associated whit upper-level factors. For example, the weight of F21 (lack of ship handling skills) can be obtained by multiplying F2 × F21 (= 0.30 × 0.39 = of 0.117 (11.7%)). Figure 4 illustrates the global weight of the 21 factors contributing to pilotage accidents.

Table 7 Weight and consistency ratio of 5 main factorsMain factor F1 F2 F3 F4 F5 Weight, w (%) F1 0.34 0.33 0.38 0.35 0.29 33.84 F2 0.31 0.31 0.32 0.31 0.27 30.48 F3 0.10 0.11 0.11 0.19 0.13 12.72 F4 0.08 0.09 0.05 0.09 0.18 9.71 F5 0.17 0.16 0.13 0.07 0.14 13.25 Sum 1.00 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.04 Table 8 Weight and consistency ratio of sub-factor (F1)Sub-factor (F1) F11 F12 F13 F14 F15 Weight, w (%) F11 0.21 0.28 0.23 0.15 0.19 2I.32 F12 0.19 0.25 0.27 0.30 0.26 25.38 F13 0.23 0.24 0.25 0.30 0.23 24.87 F14 0.27 0.16 0.16 0.19 0.24 20.40 F15 0.09 0.08 0.09 0.06 0.08 08.03 Sum 1.00 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.01 Table 9 Weight and consistency ratio of sub-factor (F2)Sub-actor (F2) F21 F22 F23 F24 Weight, w (%) F21 0.39 0.46 0.39 0.33 39.20 F22 0.20 0.23 0.25 0.28 24.04 F23 0.19 0.17 0.19 0.21 18.93 F24 0.22 0.15 0.17 0.18 17.83 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.01 Table 10 Weight and consistency ratio of sub-factor (F3)Sub-factor (F3) F31 F32 F33 F34 Weight, w (%) F31 0.38 0.43 0.41 0.27 37.13 F32 0.21 0.24 0.29 0.24 24.68 F33 0.18 0.16 0.20 0.33 21.90 F34 0.23 0.16 0.10 0.16 16.10 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.04 Table 11 Weight and consistency ratio of sub-factor (F4)Sub-factor (F4) F41 F42 F43 F44 Weight, w (%) F41 0.36 0.42 0.37 0.23 34.58 F42 0.22 0.26 0.29 0.33 27.26 F43 0.24 0.22 0.25 0.32 25.61 F44 0.19 0.10 0.09 0.12 12.55 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.03 Table 12 Weight and consistency ratio of sub-factors (F5)Sub-factor (F3) F31 F32 F33 F34 Weight, w (%) F51 0.51 0.60 0.45 0.41 49.35 F52 0.16 0.19 0.30 0.22 21.94 F53 0.20 0.11 0.17 0.26 18.50 F54 0.13 0.09 0.07 0.11 10.21 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.04 The results in Table 7 show the relative weights among the five main causal factors of pilotage accidents: F1 bridge team management failure (non-technical skills shortcoming), F2 (technical skills shortcoming), F3 (instructions and orders failure), and F4 (rules and regulations noncompliance), and F5 individual-task interaction factors. The data revealed that the most significant causes of human error-related pilotage accidents can be ranked as follows: The top three factors are F1, F2, and F5 with total weight rate 33.84%, 30.48%, and 13.25%, respectively.

In Table 8, it can be seen that the sub-factor F12 (lack of effective communication and language barriers) was ranked as the most contributing causal factor among the F1 sub-factors, 25.38%, whereas the sub-factor F13 (failure to exchange the information between pilot and ship's master) was ranked as the second most causal factor with a total weight rate of 24.87%. The sub-factor F11 (lack of teamwork) was the third critical contributing causal factor with the third-highest priority weight among the F1 sub-factors while F14 (lack of situation awareness in the bridge team), was in the fourth place. The sub-factor F15 (The master's and pilot's ineffective monitoring of the external parties and vessel's progress) was ranked as the least important at 8.03%.

The results in Table 9 show that the sub-factor F21 (lack of ship handling skills due to improper training and lack of experience) is the most significant causal factor for pilotage accidents since it has the highest priority weight among the F2 sub-factors with a total weight rate of 39.20%. It is followed by the sub-factor F22 (lack of familiarity with the navigational systems) which was ranked as the second most causal factor at 24.04%. The sub-factor F23 (lack of skills of crew members onboard ship, tugs and mooring boats masters, and shore mooring personnel) is ranked in third place at 18.93%, and F24 (improper/ inadequate use of tugs) is ranked in the fourth place at 17.83%.

Table 10 shows that the priority weights of the causal factor F31 (failure of pilot to give precise instructions) is the highest among the F3 sub-factors at 37.31%, followed by the causal factor F32 (failure of the ship's master to correctly follow the pilot directions) at 24.68%, which ranked as the second-largest cause of piloting accidents. The causal factor F33 (failure of tug masters to carry out the pilot's instructions precisely) was ranked as the third most important cause with a total weight rate of 21.90%. F34 (failure of ship's crewmembers to follow orders regarding anchoring, steering, and engine requests correctly) was ranked in the fourth place at 16.10%.

Table 11 shows that the sub-factor F41 (failure to establish a proper manoeuvring plan prior to piloting vessel) is the most significant causal factor among the F4 sub-factors for pilotage accidents since it has the highest priority weight of 34.58%. The sub-factor F42 (failure to proceed with safe speed as stipulated in COLREG) was ranked as the second most important causal factor among the F4 sub-factors, with total weight rate of 27.26%. The sub-factor F43, navigating vessels outside established rule and published guidelines (piloting ships in bad weather condition or limits draft) was ranked in third place with a total weight rate 25.61%. F44 (pilot boarding and disembarking too close to breakwater) was ranked in the fourth place at 12.55%.

Table 12 shows the priority weights of the F5 sub-factors. The data reveals that the most contributory causal factors of pilotage accidents among the F5 sub-factors, can be ranked as follows: F51 (fatigue), F52 (mental and physical workload), F53 (distraction during the time of berthing operations), and F54 (stress). The top three factors are F51, F52, and F53 which have a total weight rate of 49.35%, 21.49%, and 18.50%, respectively.

Derived from the results of AHP and according to the global weight of the 21 factors contributing to pilotage accidents, lack of ship handling skills due to improper training and lack of experience (F21) are the most important causal factors among the entire hierarchy, with total weight ratio of 11.7%, followed by lack of effective communication and language barriers (F12) 8.5%, failure to exchange the information between pilot and ship's master (F13) 8.5%, lack of familiarity with the electronic navigational equipment knowledge (F22) 7.2%, lack of teamwork (F11) 7.1%, lack of situation awareness in the bridge team (F14) 6.8%, fatigue (F51) 6.3%, lack of skills of crewmembers onboard ship, tugs and mooring boats masters, and shore mooring personnel (F23) 5.7%, failure of pilot to give precise instructions (F31) 4.8%, and failure to establish a proper manoeuvring plan prior to piloting vessel (F41) 3.5% as illustrated the top 10 highest scores in a bar graph 5.5.

This study corroborates the findings of the Marine Accident Investigation Branch (MAIB) of the UK, who investigated the accidents that occurred in the UK territorial waters during the period 2005 to 2013 in which a pilot was on board (Pennock 2015). The results also support some existing findings, e.g. findings from Darbra et al. (2007), Chauvin et al. (2013), who investigated the risks contributing to maritime accidents during pilotage operations.

This finding is also in line with some results of research conducted by the Transportation Safety Board of Canada (TSB) (1995) who found that the inadequate interpersonal communications among the bridge team, lack of adequate information exchange, incomplete understanding of the intended manoeuvre, and loss of situational awareness were the most important factors.

Based on these results, it can be easy to nominate the most crucial risks that significantly impact the safety of the maritime pilotage operations. The higher the value of human causal factors is, the higher the risk of pilotage safety performance. Therefore, effective measures should be applied to reduce or mitigate their risks and effects.

7 Discussion

Ship piloting is considered as one of the most complex tasks in maritime transport. It requires high standards of professional skills. Marine pilots who should possess high levels of local area knowledge, ship handling skills, and navigational experience, are employed onboard ships to give navigational advice to captains and guide vessels into and out of port safely, or wherever navigation may be considered hazardous, especially when a shipmaster is unfamiliar with the area (IMO 2016).

Lack of ship handling skills due to insufficient experience and improper training were identified as the most significant factors that affect manoeuvring's safety adversely. It is considered among the most important causes for accidents in pilotage operations. Ship handling is an art rather than a science. However, a ship handler who is familiar with the science will be better at their art and more easily identify a ship's manoeuvring characteristics and assess the skills needed to control the ship (Murdoch et al. 2012).

In this study, marine experts asserted that efficient pilotage is mainly dependent upon the effectiveness and understanding of the communications between the pilot and the bridge team members, between the master and crewmembers, as well as between pilot and assistant parties when manoeuvring. It is also concluded that, during ship berthing if crewmembers, the captain, and pilot onboard a ship do not speak the same language, and common English language communication ability is insufficient, the risk of misunderstandings often increases. It can cause lack of communication, and hence negatively affect the safety of the pilotage operations.

Good communication aided by appropriate English language ability can ensure the ship's master and crewmembers to keep track of any actions taken by the pilot and any external parties (such as the VTS, Vessel Traffic System's operators).

In order to ensure effective berthing operations, both the ship's master and the pilot should exchange information prior to the commencement of a manoeuvring operation. It is noteworthy that the feedback from marine experts, showed that inappropriate information sharing between masters and pilots will result in a dangerous and ambiguous situation on-board. Such shared information includes vessel characteristics (e.g. draft, the efficiency of readiness, and efficiency of navigation/propulsion equipment) from masters to pilots and berthing/sailing information (e.g. port and channel depth of water, tugboats' power, and number of tugboats used, and etcetera) prior to the pilotage operation from pilots to masters.

Marine pilots and shipmasters need to obtain the right information regarding the details of a ship's passage and berthing plan. This is especially important for both parties to be aware of the whole situation and enable them to easily identify the ship's manoeuvring characteristics, and quickly assess the skills needed to control the ship and prepare a proper and effective berthing plan to handle the ship to its destination safely.

Wrong handling of electronic navigational equipment when entering or leaving the port can negatively affect pilotage operation safety and lead to marine accidents. Ineffective use of the navigational electronic equipment such as ECDIS, AIS, Echo Sounder, RADAR, and GPS, and etcetera is considered to be highly risky and has a greater potential to cause major accidents. It plays a significant role in obtaining and maintaining situation awareness. It can result in being entirely unaware of the ship's position and leading to loss of the whole situation awareness, particularly when the vessel navigates through narrow canals or while underway, inbound/outbound from/to ports and channels under poor visibility conditions.

Due to the complexity and unfamiliarity of the tasks involved, operators are distracted and overloaded with information. They might therefore not be able to make proper decisions during berthing operations. Therefore, controlling workload is a key factor especially when new technologies involve. In addition, training and other forms of procedural guidance are needed to make seafarers aware of both the capabilities and limitations of the new technologies.

Good teamwork is considered as one of the most significant factors for achieving effective and safe mooring operations. Effective teamwork relies on effective closed-loop communication, cooperation, and coordination, all of which together play a significant role in obtaining and maintaining situation awareness (Chauvin et al. 2013). Therefore, in order to create efficient teamwork, the pilot, ship's crewmembers, and assisting parties (tugs masters, VTS, and shore personnel) should work with each other cooperatively. This is crucial, particularly when a vessel is operating in intense fog and poor visibility conditions in restricted waters or congested areas.

During berthing operations, operators' work characteristics such as professional skills and work attitudes, are very significant factors that can affect ships' navigation safety. For instance, the failures of crewmembers and/or assistance parties to carry out the pilot's instructions precisely is of a high risk, and negatively influence on the safety of the pilotage operation, and contribute to maritime accidents.

A delay between a pilot's order and the order's execution can affect the safety of manoeuvring. In addition, failure of the tug's masters to carry out the pilot's instructions precisely with respect to position and towing power could also affect manoeuvring safety or delays in securing a tug as a result of lack of skills of mooring parties, putting time pressure on the crew and thereby increasing the risk of the vessel sailing in unsafe conditions. As a result, the compliance of the tugs' masters, ship's staff, shore-side mooring personnel, and mooring boats with the given instructions will support a safe and efficient mooring operation.

Improper and inadequate use of tugboats is one of the causes of marine accidents in ports. It is considered among the most substantial causes for accidents in pilotage operations. Practically, the factors affecting the quality of tugboat operations include the number of tugboats, the horsepower of the tugboats, and the operating skills of tugboat drivers. Tugboats play a significant role in assisting vessels in berthing and detaching from the berth. As a result, failures of using sufficient numbers and powerful tugboats, lack of skills of tugboats' masters, or tugs' crewmembers are highly risky, and can affect the manoeuvring negatively and contribute to a ship's berthing accidents. Therefore, these causal factors should be emphasised to reduce the risks of accidents.

It is important to mention that nowadays, maritime pilots on the bridge are exposed to extensive information from multiple sources including crew verbal instructions, multiple instrument displays, and communication systems. The introduction of the new communication and navigation devices on the bridge requires increasing knowledge and skills from pilots, higher levels of accuracy, proficiency, and intelligence. In addition, the complexity of maritime pilotage operations and the large number of tasks involved, such as extensive monitoring of navigational equipment, speaking on handheld radios to guide the tugs' operators, mooring boats, and communicating with shore personnel, all of them require high levels of skill and concentration and need to be carried out simultaneously. Moreover, the short time allocated to achieve the tasks has increased the work burden, the level of stress and also fear for pilotage operators. Therefore, to mitigate operators' errors during pilotage operations and reduce accidents, these causal factors have been clearly identified and priorities to aid the development of effective countermeasures against each of them in a cost-effective manner.

8 Conclusions

This paper investigates the effect of human factors on the safety of pilotage operations. The causes of human-related errors in maritime pilotage accidents are examined in detail. A comprehensive and updated literature review is carried out, including an analysis of pilotage accident investigation reports. It is followed by questionnaires and interviews with experienced marine experts.

To evaluate each causal factor's importance, AHP is utilised. According to the AHP results, the most significant causes of human error-related pilotage accidents are lack of ship handling skills due to improper training and lack of experience, lack of effective communication and language barriers, failure to exchange the information between pilot and ship's master, lack of familiarity with the electronic navigational equipment knowledge, and lack of teamwork.

Establishing a new database on human causal factors that contribute to maritime pilotage accidents can assist in implementing effective risk reduction strategies to mitigate operator errors during pilotage operations. Moreover, this study can help relevant stakeholders, such as port authorities and shipping companies, to develop safety guidelines and risk control measures to improve the performance of operators and the safety of maritime pilotage operations.

Identification of human-related risk factors for pilotage operations is a challenging problem, due to insufficient data availability and the limitation of information. It is also very difficult to investigate the risks that influence shipmasters and marine pilots' personality characteristics on their attitudes towards risk, and the probability of error in maritime pilotage operations, due to the lack of evidence. For this reason, some of the critical phases of the study depend on expert judgement.

In future, more studies can be carried out to develop the present classification schemes, by including organisational factors, policy implications, and natural and political issues that may affect pilotage operations safety.

Acknowledgements: The authors would like to express their utmost gratitude to the ships' captains and pilots who participated in this research for being very enlightening, cooperative, and helpful with their prompt replies to the constant questions. The authors are also grateful for the support of all the maritime organisations, professionals, and managers of the shipping companies who participated in this project and have provided vital information to complete this study. -

Table 1 The list of human causal factors contributing to maritime accidents in pilotage operations

No Human causal factors (HCFs) of pilotage accidents 1 Lack of team work (poor bridge team-pilot integration, cooperation, coordination, and close loop) 2 Lack of effective communication and language barriers 3 Failure to exchange the information between pilot and ship's master prior to the commencement of the manoeuvre 4 Failure to establish a proper manoeuvring plan prior to piloting vessel 5 Distraction during the manoeuvring 6 Lack of situation awareness 7 Lack of familiarity with the electronic navigational equipment knowledge 8 Failure to proceed with safe speed as stipulated in COLREG 9 Pilot boarding and disembarking too close to breakwater 10 Mental and physical work load 11 Stress 12 Fatigue 13 Lack of ship handling skills due to lack of experience and improper training 14 Failure of pilot to give precise instructions 15 Failure of the ship's master to correctly follow the pilot directions (e.g. incorrect interpretations, refusal, rejection, intervention by master 16 Improper/inadequate use of tugs 17 Lack of skills of the crewmember on ship board, tugs, and shore mooring personnel 18 Orders regarding anchoring, steering, and engine requests, are not followed out by ship's crewmembers correctly 19 Failure of tug's masters to carry out the pilot's instructions precisely 20 Failing to inspect the tugs towing equipment 21 Pilot failing to think ahead for developing situations 22 The master's and pilot's ineffective monitoring of the tug boats masters, mooring boats, and shore mooring personnel performance and vessel's progress 23 Navigating vessels outside published rules and guidelines (e.g. piloting ships in bad weather condition or limits draft due to subject to commercial pressure) 24 The blind trust and reliance on the pilot during berthing operations 25 Using mobile phones during berthing operations Table 2 Human causal factors of pilotage accidents (HFCFs)

Factors Sub-factors Nontechnical skills shortcoming (BTM failure) (F1) Lack of teamwork (F11)

Lack of effective communication and language barriers (F12)

Failure to exchange the information prior to pilotage operation (F13)

Lack of situation awareness (F14)

The master's and pilot's ineffective monitoring of the tugboats masters, mooring boats, and shore mooring personnel performance and vessel's progress (F15)Technical skills shortcoming (F2) Lack of ship handling skills due to improper training and lack of experience (F21)

Lack of familiarity with the electronic navigational equipment knowledge (F22)

Lack of skills of the crewmember onboard ship, tugs, and shore mooring personnel (F23)

Improper/inadequate use of tugs (F24)Instructions and orders failure (F3) Failure of pilot to give precise instructions (F31)

Failure of the ship's master to correctly follow the pilot directions (F32)

Failure of tug's masters to carry out the pilot's instructions precisely (F33)

Orders regarding anchoring, steering, and engine requests, are not followed out by ship's crewmembers correctly (F34)Rules and regulations noncompliance (F4) Failure to establish a proper manoeuvring plan prior to piloting vessel (41)

Failure to proceed with safe speed as stipulated in COLREG (42)

Navigating vessels outside published rules and guidelines (e.g. piloting ships in bad weather condition or limits draft due to subject to commercial pressure) (F43)

Pilot boarding and disembarking too close to breakwater (F44)Individual- task interaction factors (F5) Fatigue (51)

Mental and physical workload (F52)

Distraction during the time of berthing operations (53)

Stress (54)Table 3 Pairwise Comparison Scale (Saaty 1994)

Numerical assessment Linguistic meaning 1 Equally important 3 A little important 5 Important 7 Very important 9 Extremely important 2, 4, 6, 8 Intermediate value of important Table 4 Pairwise Comparison Scale (Saaty 1994)

Numerical assessment Linguistic meaning 1 Equally important 1/3 A little unimportant 1/5 Unimportant 1/7 Very unimportant 1/9 Extremely unimportant 1/2, 1/4, 1/6, 1/8 Intermediate value of unimportant Table 5 Normalised status of the fife main causal factors comparison matrix and weight

Main factors F1 F2 F3 F4 F5 Eigenvector (priority), w (%) F1 0.11 0.13 0.09 0.09 0.20 0.12 F2 0.21 0.26 0.27 0.28 0.20 0.25 F3 0.32 0.26 0.27 0.28 0.20 0.27 F4 0.32 0.26 0.27 0.28 0.33 0.29 F5 0.04 0.09 0.09 0.06 0.07 0.07 SUM 1.00 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.02 Table 6 Values of random index (RI) of (AHP) process

Size of matrix n 1 2 3 4 5 6 7 8 9 10 Random consistency index RI 0 0 0.58 0.9 1.12 1.24 1.32 1.41 1.45 1.49 Table 7 Weight and consistency ratio of 5 main factors

Main factor F1 F2 F3 F4 F5 Weight, w (%) F1 0.34 0.33 0.38 0.35 0.29 33.84 F2 0.31 0.31 0.32 0.31 0.27 30.48 F3 0.10 0.11 0.11 0.19 0.13 12.72 F4 0.08 0.09 0.05 0.09 0.18 9.71 F5 0.17 0.16 0.13 0.07 0.14 13.25 Sum 1.00 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.04 Table 8 Weight and consistency ratio of sub-factor (F1)

Sub-factor (F1) F11 F12 F13 F14 F15 Weight, w (%) F11 0.21 0.28 0.23 0.15 0.19 2I.32 F12 0.19 0.25 0.27 0.30 0.26 25.38 F13 0.23 0.24 0.25 0.30 0.23 24.87 F14 0.27 0.16 0.16 0.19 0.24 20.40 F15 0.09 0.08 0.09 0.06 0.08 08.03 Sum 1.00 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.01 Table 9 Weight and consistency ratio of sub-factor (F2)

Sub-actor (F2) F21 F22 F23 F24 Weight, w (%) F21 0.39 0.46 0.39 0.33 39.20 F22 0.20 0.23 0.25 0.28 24.04 F23 0.19 0.17 0.19 0.21 18.93 F24 0.22 0.15 0.17 0.18 17.83 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.01 Table 10 Weight and consistency ratio of sub-factor (F3)

Sub-factor (F3) F31 F32 F33 F34 Weight, w (%) F31 0.38 0.43 0.41 0.27 37.13 F32 0.21 0.24 0.29 0.24 24.68 F33 0.18 0.16 0.20 0.33 21.90 F34 0.23 0.16 0.10 0.16 16.10 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.04 Table 11 Weight and consistency ratio of sub-factor (F4)

Sub-factor (F4) F41 F42 F43 F44 Weight, w (%) F41 0.36 0.42 0.37 0.23 34.58 F42 0.22 0.26 0.29 0.33 27.26 F43 0.24 0.22 0.25 0.32 25.61 F44 0.19 0.10 0.09 0.12 12.55 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.03 Table 12 Weight and consistency ratio of sub-factors (F5)

Sub-factor (F3) F31 F32 F33 F34 Weight, w (%) F51 0.51 0.60 0.45 0.41 49.35 F52 0.16 0.19 0.30 0.22 21.94 F53 0.20 0.11 0.17 0.26 18.50 F54 0.13 0.09 0.07 0.11 10.21 Sum 1.00 1.00 1.00 1.00 100.00 Consistency ratio (CR) = 0.04 -