Review of Experimental-Numerical Methodologies and Challenges for Floating Offshore Wind Turbines

https://doi.org/10.1007/s11804-020-00165-z

-

Abstract

Due to the dissimilar scaling issues, the conventional experimental method of FOWTs can hardly be used directly to validate the full-scale global dynamic responses accurately. Therefore, it is of absolute necessity to find a more accurate, economic and efficient approach, which can be utilized to predict the full-scale global dynamic responses of FOWTs. In this paper, a literature review of experimental-numerical methodologies and challenges for FOWTs is made. Several key challenges in the conventional basin experiment issues are discussed, including scaling issues; coupling effects between aero-hydro and structural dynamic responses; blade pitch control strategies; experimental facilities and calibration methods. Several basin experiments, industrial projects and numerical codes are summarized to demonstrate the progress of hybrid experimental methods. Besides, time delay in hardware-in-the-loop challenges is concluded to emphasize their significant role in real-time hybrid approaches. It is of great use to comprehend these methodologies and challenges, which can help some future researchers to make a footstone for proposing a more efficient and functional hybrid basin experimental and numerical method.Article Highlights• Several basin experiments, industrial projects and numerical codes are summarized and discussed.• Discussion of the state-of-the-art real-time hybrid approaches.• Integrated new challenges that distinguish them from traditional ones in basin model experiments and those in wind tunnel experiments. -

1 Introduction

1.1 Background

In the face of rapidly growing energy demands and increasingly harsh environmental conditions, traditional energy supply will hardly meet the demand for sustainable development. Offshore wind has its enormous potential in renewable energy markets, worldwide (James and Ros 2015). Compared with conventional fixed-bottom offshore wind, the floating offshore wind turbines (FOWTs) can take the merits of abundant wind resources over the deeper sea, also as the capacity of being dragged out to the wind site and assembly in port (Stewart and Muskulus 2016a). Meanwhile, reduction of visibility impacts if their distance far from the coast (Musial et al., 2003; Sclavounos 2008).

The concept of FOWTs was firstly proposed by Heronemus (1972). Being dependent on the way of supporting the platform to obtain stability and restoring force, three mainly basic concepts were proposed which are (Butterfield et al. 2007): spar-buoy, tension-leg platform (TLP) and semi-submersible. General design details of offshore structures can be found in the literature (Chakrabarti 2005). The economics are also essential to consider when comparing different floaters or improve the original design, not just wave, current and wind-induced motions of performance.

Under this demand, different levels of concepts were presented (Table 1), some of them have been realized with the remarkable progress of the wind industry. As a leading role, the world's first floating wind farm, Hywind, has been settled about 15 miles from Peterhead in Aberdeenshire, Scotland, in 2017 (González and Diaz-Casas 2016). For basin model tests, Tri-Floater (Bulder et al. 2002; Courbois 2013; Huijs et al., 2014; Huijs et al., 2013), HiPRWIND (Ishihara et al. 2009), NauticaWindpower AFT, WindSea (Windsea 2010), Poseidon Floating Power, by the Netherlands' Floating Power Plant AS, Pelastar TLP (Vita et al. 2015), Vertiwind, Nautilus (Fernandez et al. 2013), Iberdrola (Amate et al., 2014) and VolturnUS (Viselli et al. 2015) have been tested in a wave tank in a scale between 1/130 and 1/2 in Europe (Müller et al. 2014).

Table 1 Different levels of conceptsConcepts Year Pertinent literature Hywind 2005–2009 (OC3 IEA Task 23, Subtask 3) Myhr et al. (2011); Nielsen et al. (2006) WindFloat 2009 (project start) Cermelli et al. (2009); Roddier et al. (2009) DeepCwind 2010–2013 (OC4 IEA Task 30) Robertson et al. (2013) Sway 2012 (1/6.5th scale prototype) Koh et al. (2016) Blue H 2009 (75% Prototype) Ng and Ran (2016) FOWTs are highly complex systems. The dynamic models of FOWTs, which account for the coupling between aerodynamics loads (turbine) and hydrodynamics loads (floater and mooring lines), flexible structural components (turbine and floater), elasticity, blade pitch controls and restoring effect of the mooring lines, are needed to validate their technical and economic feasibility (Jonkman 2009). In these scenarios, how to predict and validate a new or improved full-scale concept (Butterfield et al. 2007; Liu et al. 2017a, b) under high coupling effects has also been receiving great attention and lead to rapid research progress by both academia and industry, for their sophistication in the design process (Butterfield et al. 2007).

1.2 Validation of the Technical Feasibility

Generally, scaled model experiments, numerical analysis and on-site measurements are three reasonable methods to demonstrate the technical feasibility of the FOWTs.

1.2.1 On-site Measurements

For on-site measurements, the first truly floating wind turbine system Hywind (Jonkman and National Renewable Energy L 2010) was installed in the Norwegian waters in 2009, achieving a historic breakthrough in operation (Stiesdal 2009). Figure 1 shows the world's first floating wind farm (Hill 2018).

Figure 1 The world's first floating wind farm (Hill, 2018)

Figure 1 The world's first floating wind farm (Hill, 2018)Later, Principle Power installed WindFloat on the Portuguese coast. Aubault et al. (2009), Cermelli et al. (2009) and Roddier et al. (2010) conducted a comprehensive feasibility analysis of WindFloat, the first published design criteria for this concept. Principle Power (2019) provided the 3D visualization of the prototype, which attaches related component description (Figure 2).

Figure 2 The 3D Windfloat (Principle Power, 2019)

Figure 2 The 3D Windfloat (Principle Power, 2019)In 2010, one half-scale and one full-scale semi-type FOWTs were demonstrated in Japan (Ishida et al. 2013). The MOE Project (Figure 3) was the first grid-connected FOWT in Japan (100-kW half-scale model) and the full-scale FOWT has also been installed (2 MW). The survivability of the spar type FOWT against typhoon attack has been proven (Arakawa 2015).

However, the published data of these on-site measurements can be used for validating new concepts of FOWTs which is still scarce and limited, due to the exclusive rights of data by various companies and research institutes.

1.2.2 Numerical Simulation and Model Scale Experiment

In contrast, the numerical analysis method is time saving and low cost. However, the numerical fidelity of different software is still under testing in terms of innovative optimization methodologies, computational efficiency and accuracy. Despite there are numerous sophisticated numerical tools arising (Jonkman and Buhl Jr 2005), the experiment of a scale model with a controlled environment can still be seen as an essential validation step of the qualification process of system behaviour, non-linear phenomena, extreme and detailed loads and validating codes (Bachynski et al. 2016). For example, extreme wave and viscous loads, or wave-current interaction effects on floating moored structures are impossible to be simulated or modelled in numerical simulation in the current state (Sauder et al. 2016). Therefore, experimental assessments in terms of preliminary platform, turbine controller and mooring lines have been regarded as a useful and reliable method to predict global dynamic response of floating structures in the overall design and validation process apart from novel challenges. In addition, time efficiency and risk assessment have been required while demonstrating better controls and repeatable environmental conditions and accurate data than in front of the two (Chen et al. 2018).

Nonetheless, there are critical challenges when conducting a basin experiment of FOWTs. For hydrodynamic similarity of general loads acting on typical offshore structures, the Froude scale method needs to be applied (Chakrabarti 1998; Faltinsen 1993; Sarpkaya and Isaacson 1981). During the early stage of investigations, scholars applied the customary Froude scale method to recreate the dynamics of full-scale FOWTs in basin experiment. However, the dominance of the non-dimensional surrounding medium (aero-hydro) in two different phases which pose general critical challenges in FOWTs' experiments makes scaling without compensation cause discrepancies in the results (Hall and Goupee 2018). In this case, the scaling of the Reynolds number leads to an error inevitable for both hydrodynamics and aerodynamics. As a result, the Reynolds number of a model in the experiment will be much smaller than the full-scale value and significantly changing on aerodynamic performance (rotor) is therefore out of scale. Therefore, it is a great challenge for FOWTs' basin experiments to simulate accurate aerodynamic force and performance under the Froude scale and low Reynold number. Especially, for not advanced and fully equipped facilities, even wind generation techniques over the wave basin may be impractical (Martin et al. 2014). A brief comparison of these three methods is provided in Table 2.

Table 2 Comparison of three different methodsMethods Advantages Disadvantages On-site measurement More accuracy;

The actual sea state;Limit published data;

Difficult to measurement;

Expansive cost and high risk;

Time-consuming high resources required;Numerical simulation Faster;

Cheaper;

ConvenientHigh fidelity of numerical model;

Hard to simulate non-linear phenomena;Model scale experiment Non-linear hydro-aero phenomena;

Better controls and repeatable environmental conditions;Scaling issues;

High specific facilities required;Several approaches have been proposed by using a tuned drag disk or redesigned rotor and blade to deal with scaling issue (José et al. 2014). Also, several code-to-code approaches have arisen in recent years to counter these challenges (Cordle and Jonkman 2011) and many hybrid basin experimental methods have been proposed, but there is limited academic literature to pertain to provide comparisons and conclusions on these methods in recent years.

Regarding the research of China's FOWTs, in recent years, Chinese scholars have made great efforts and achievements worthy of attention. Chen et al. (2019) systematically studied the dynamic mechanism and the fully coupled time domain simulation program for offshore floating wind turbines; Ma et al. (2015) systematically analysed the dynamic performance of single-column FOWTs through numerical calculations; Hu et al. (2016) compared the motion of semi-submersible FOWTs under working and downtime conditions; Duan et al. (2016a, b) systematically completed a series of model experiments of spar-type and semi-type FOWTs; Li et al. (2018a, b) analysed the short-term fatigue characteristics of the tower base under a random wind and wave load. Wan developed the CFD solver NAOE-FOAM-OS-SJTU for marine and marine engineering based on OpenFOAM and overlapping grid technology (Ai and Wan 2017; Cheng and Wan, 2017; Huang et al. 2017). This solver has been used widely to carry out a series of research and analysis on semi-submersible FOWTs, including studying the coupled dynamic characteristics under different blade tip speed ratios, the platform motion under the combined wind and waves, and the impact of towers on the aerodynamic performance of FOWTs. Cao et al. (2013), Tang et al. (2014), Tang et al. (2013) and Li et al. (2017) designed a new type of semi-submersible FOWTs and carried out analysis and research on its hydrodynamic motion performance and overall structural strength. The results demonstrate that the wind turbine system has good performance, and its mooring system has sufficient ability to resist extreme sea conditions, but the two ends of the diagonal support of the tower and the pillar are relatively stressful and critical parts. In addition, Liu et al. (2018) designed a new type of semi-submersible-pillar hybrid FOWTs and used SESAM and FAST software to perform time domain calculations. That research also extended to the calculation method of a fixed vertical axis wind turbine to floating type and compiled corresponding calculation programs (Li et al. 2017). Zhang et al. (2013) studied the dynamic response under turbulent wind. Subsequently, they also independently designed a three-buoy floating platform foundation for the 5-MW wind turbine and carried out design research on its hydrodynamic performance such as stability, wave resistance and anchor positioning (Zhang and Deng 2011). In addition, Zhao et al. (2012) also designed and calculated a 3-MW offshore floating vertical axis wind turbine. Lu et al. (2016b) used FAST-Orcaflex software to conduct a series of analyses on FOWT mooring systems, and proposed a set of mooring systems design methods (Lu et al. 2016a, b; Lu et al. 2018). Lu et al. (2017) also made a frequency domain response analysis of the aerodynamic damping performance and designed the concept of reinforced concrete FOWTs. Jin and Teng (2016) developed a time domain coupled numerical program for FOWTs, which has been utilized to calculate the OC3-Hyiwnd. Shi (2015) performed an analysis of the overall motion characteristics and structural dynamic response of the single-column extension tension leg FOWTs, and optimized the structural size based on its fatigue characteristics.

1.3 Theoretical Analysis and Experiment of FOWTs

The theoretical analysis results need to be compared with the basin model test and on-site measurement to determine the availability and accuracy, and promote the development of the theory. Conversely, theoretical guidance can improve the methodology of the experiment and numerical simulation. In short, the three methods are of great importance, which are required for different research stages.

In the preliminary design stage of FOWTs, the theoretical analysis and the calculation can be used to quickly complete the selection work. In the stage of fine design, numerical calculation and wind tunnel or basin model test are the main research methods. After the physical design, the experiment becomes the main force.

This review article aims to critically compare and conclude these state-of-the-art approaches in terms of the horizontal axis floating offshore wind turbines to help future researchers to make a footstone for proposing a more efficient and functional hybrid basin experimental method.

2 Progress of Model Tests on FOWTs

It is well acknowledged that basin experiment for FOWTs can predict non-linear aero-hydro phenomena and also better controls and repeatable environmental conditions. In this chapter, several basin experiments and typical industrial projects are discussed in terms of validation and progress.

In an earlier stage, the significant R & D effort of FOWTs has been made with the appearance of coupled hydro-aero tools (Jonkman et al., 2009; Jonkman and Sclavounos 2006; Wayman et al. 2006). Several concepts for FOWTs have been proposed in Japan in the early stage (Fukumoto et al. 2006; Iijima et al. 2013; Ishihara et al. 2007; Ishihara et al. 2006; Ishihara et al. 2009; Kitamura et al. 2006; Ohkawa et al. 2004; Sukegawa et al. 2006; Van Phuc and Ishihara 2007; Yago et al. 2007). And a national demonstration project of FOWTs was conducted by the Ministry of the Environment of Japan in 2010. A half-sized floater with a 100-kW wind turbine and a full-sized floater with a 2-MW turbine were monitored in the same position and the measured record including huge typhoon condition is also presented, respectively (Arakawa 2015).

The safety and performance of their type of concept were investigated by Utsunomiya et al. (2013a) based on one a 1/100 scale model (Utsunomiya et al. 2009a) and a 1/22.5 scale model (Utsunomiya et al. 2009b). In a 1/10th scale model (Utsunomiya et al. 2013b), the static catenary line theory and modified Morison's equation are used in time domain code analysis which shows discrepancies in drag force without damping of mooring lines will induce significant motion responses. In a 1/22.5 campaign, Utsunomiya et al. (2009b) examined the model under the regular and irregular wave and combing a steady horizontal force corresponding to a steady wind to replicate a steady thrust force from the blade in the aerodynamic part.

This experiment focused only on the wave loading and generating of steady force in open basin space instead of wind. But there was lost of sight of the coupling effect between wind and wave, especially blade rotating and scaling issues in aerodynamic load simulation. And the validation for half size was in parked condition at NMRI (Kokubun et al. 2012). Experimental descriptions aiming at a full scale have been given by their paper (Utsunomiya et al. 2014), which introduced one dynamic analysis tool including MSC Adams (Jonkman and Buhl Jr 2005), NREL/AeroDyn (Laino and Hansen 2002), SparDyn (in-house) and Moorsys (in-house). His tests cover dynamic analysis and simulation validation of simplified scale model tests under extreme condition. Utsunomiya et al. (2013a, b) also compared the numerical calculations. In summary, full-scale tests have been conducted at the ocean (Ishida et al., 2013; Utsunomiya et al. 2013a, b) and the derivation of their numerical model was provided by Matsukuma and Utsunomiya (2008).

In 2012, Sethuraman and Venugopal (2013) performed a model experiment in a curved wave tank in the University of Edinburgh. Their model was fundamentally comparable with the work of Utsunomiya et al. (2013a, b). The surge motions have a significant reduction by comparing the mooring line and four-point mooring configuration which was compared with the former's work. The OrcaFlex software has been applied to the numerical modelling analysis. Later, Chujo et al. (2013) conducted a basin test, based on the Fukushima project (Forward 2014) with various phases including model and prototype tests as well as the blade pitch control. Continue to part of the work of Duan et al. (2016a, b), several studies on FOWTs are summarized in Tables 3 and 4. In the next part of this chapter, a few projects will be briefly introduced.

Table 3 Summary of several studiesAuthor/org Year Classification Model type Scale ratio José et al. (2014) 2014 Hybrid model test Concrete Star Wind Floater 1:40 Bayati et al. (2018a) 2014 Hybrid model test - 1:25 Sauder et al. (2016) 2016 Real-time hybrid model test Braceless semi-type 1: 30 Hall and Goupee (2018) 2018 Real-time hybrid model test DeepCwind semi-type 1:50 Table 4 ContributionsAuthor/org Contributions José et al. (2014) Using a ducted fan mounted at the tower top to provide the required thrust force. Bayati et al. (2018a, b) Test in the wind tunnel and simplified the 6DOF motions by the actuator Sauder et al. (2016) Using actuators to provide the transient simulated force rather than a ducted. Considered effects between the wind forcing, wave forcing and the blade pitch control algorithm Hall and Goupee (2018) Using the actuation system combined numerical wind turbine model was set to simulate thrust force by winch and cables, pulling fore and aft on the nacelle. 2.1 OC Projects

As the leading projects, the phase Ⅳ of OC3 (Jonkman and Musial 2010), phase Ⅱ of OC4 (Robertson and National Renewable Energy L 2014) and OC5 Project phase Ⅱ (Robertson et al. 2017) operated under IEA Wind Tasks for the NREL are the most illustrative projects (Table 5).

Table 5 OC ProjectsAuthor/org Abbr. Year Content IEA Wind Annex 30 OC3 2005–2009 Phase Ⅳ: Hywind IEA Wind Annex 30 OC4 2010–2013 Phase Ⅱ: DeepCwind NREL and Fraunhofer IWES OC5 2014–2018 Phase Ⅱ: DeepCwind NREL OC6 2019–2022 - 2.1.1 Hywind

The Hywind was the first large-capacity FOWTs which has been installed 10 km away from the southwest coastline of Norway in 2009 by Statoil, achieving a historic breakthrough in the operation of FOWTs (Stiesdal 2009). It adopted a single-column floating body as a support structure with a rated power of 2.3 MW. The water depth is 200 m and is moored by the anchor chain connected by 3 sets of delta connection. Statoil has done a lot of actual measurements on their response and operation under wind and wave loads.

As early as 2006, Nielsen et al. (2006) and Skaare et al. (2007) performed model tests for a 5-MW Spar-hull for Hydro Oil & Energy at MARINTEK based on a 1/47 scale where Froude scaling was applied. Couple wave and wind load cases were conducted and the control strategy consistent with the actual FOWTs was applied in testing when the wind speed is less or higher than the rated wind speed. They conducted code-to-experiment validation by comparing SIMO/RIFLEX and HywindSim and the integration of SIMO/RIFLEX/HAWC2. And also a new blade pitch control strategy with an active damping algorithm has been used because the loads will amplify or damp the motions of FOWTs if conventional control strategies were adopted (Knauer et al. 2006).

In 2011, Shin (2011) conducted a 1/128 scale model test in 2D and 3D wave tanks and the physical model was built on the Froude number at the Ocean Engineering Wide Tank at the University of Ulsan. The simulation used model blade replicate, the thrust disks of the Hywind, and set a rotating and fixed rotor under regular and irregular wave cases which provided a reference for researchers who later conducted experiments and simulation of Hywind. The FAST (Fatigue, Aerodynamics, Structures, and Turbulence) code and MOSES code also were utilized for validation. Myhr et al. (2011) conducted one 1/100 scaled model test which compared Tension-Leg-Buoy (TLB) and Hywind by experiment and code analysis (3D float and ANSYS). The smaller motions have been found in experiments and computations may be resulted in calibration.

Duan et al. (2016a, b) examined two different blade systems based on a 1/50 scale spar type: the thrust matched (TMBS) and the geometry matched (GMBS) under different environmental conditions at Deepwater Offshore Basin of SJTU. Two different blades have been discussed in more details by Chen et al. (2018) and an improved deficient thrust force correction approach has been proposed by Li et al. (2018a, b).

2.1.2 DeepCwind

In 2011, 1/50 scale model tests on three types floater of FOWTs have been performed by Goupee et al. (2012) by using a geometrically scaled reference turbine (NREL 5 MW). They changed the wind speed from 11.4 m/s (rated speed) to 21.8 m/s to offset of the turbine force. It allows the thrust to match the desired value for the low performance of the original geometric scale wind turbine model. Martin (2011) outlined the details of the test and procedure. The examination of the test data is provided by Robertson et al. (2013), which also shows a very thorough insight available on the practical capability of FAST (Jain et al. 2012) and experimental investigation of the three major FOWTs.

Goupee et al. (2014b) demonstrated the unique advantages and disadvantages of three concepts which are TLP, Spar and Semi. The study proposed a new model blade with better Ct and Cp aerodynamic performance at the Froude scale model wind speed, and the control strategy was applied in this experiment. The test matrix of the global performance of three FOWTs and system identification were concluded by Koo et al. (2014) in terms of hammering test, free decay test and white noise test. In 2011, as part of the DeepCwind, Gueydon and Xu (2011) conducted a 1/50 geometrically identical to Hywind test with a full-scale modified mooring system in a water depth of 200 m. The multi-body time domain simulation program aNySIM created by MARIN was utilized to calibrate by matching during the decay test. However, the horizontal drift motions could not be simulated in software, because of the error of notable differences in motion response statistics.

In 2013, de Ridder et al. (2013) conducted the same Semi model which has been conducted under improved testing conditions in the MARIN. This experiment was designed with a comparison to the previous campaign. Besides, another 1/130 scale model has been used to assess the reliability which can be noted by Kimball et al. (2014). The proper scaling methodology is as follows: Adopting a redesigned 125% NREL 5-MW reference turbine (Fowler et al. 2013; Martin et al. 2014) to satisfy the performance-matched turbine (MSWT) which can be seen as a significant Landmark exploration. Masciola et al. (2013) compared the numerical results of interacted mooring dynamics with MARIN test data for a 1/50 scale Froude model subjected to equivalent sea states. And a full-scale model has been calibrated and validated within FAST (Stewart et al. 2012).

2.2 INNWIND.EU

A 1/60 scale OC4 DeepCWind semi-submersible model was used to perform a recent test led by INNWIND.EU project (Sandner et al., 2015). A Froude-scaled rotor was designed with the characteristics of:

· Constant rpm;

· Feedback controlled ducted fan;

· Real-time hardware-in-the-loop (HIL) controlled;

· No wind generator.

Although the Reynolds numbers between the models and full scale do not match, they are still necessary for experiments with high-chord blades to match the rotor thrust. And also, a research of the 1/60 Froude-scaled DTU 10-MW (Bak et al., 2013) TLP is detailed in Bredmose et al. (2015) and Laugesen and Hansen (2015). It also has been presented by Pegalajar-Jurado et al. (2016) as a part of INNWIND.EU. The numerical model (Ramachandran 2013) is implemented in Flex5 (Øye, 1996) on the scale of 1/60 as well.

2.3 LIFES50+

In the LIFES50+ project, some innovative new substructure concepts have been proposed which focus on water depths from 50–200 m and the 10-MW FOWT. There is an interesting campaign testing the performance of FOWTs but not in basin tank. Bayati et al. (2013) performed a 2-DoF (pitch and surge motion) experimental rig-HexaFloat at Politecnico di Milano Wind Tunnel to simulate a 1/25 scale DTU 10-MW wind turbine model. This combined hydrodynamic and aerodynamic loads within the LIFES50+ project (Bayati et al. 2016). Next year, HexaFloat has been expanded to 6DOFs (Bayati et al. 2014). In 2017, they proposed an aerodynamic design methodology and a scaled model technology for a 1/75 scale DTU 10-MW wind turbine rotors (Bayati et al. 2017a).

2.4 WindFloat

In October 2011, Principle Power installed a semi-type WindFloat in Portugal, with a rated power of 2 MW and a working water depth of 45 m. The foundational predecessor of WindFloat is MiniFloat. Fulton et al. (2006) and Zambrano et al. (2006) proposed this Semi-type floater MiniFloat (Roddier et al. 2009). Cermelli et al. (2010) conducted a 1/67th scale-scale model testing campaign in 2010 at the University of California Berkeley Ship Model Testing Facility in the first phase of the WindFloat platform which is based on the hydrodynamic and structural studies of MiniFloat (Aubault et al. 2007; Aubault et al. 2006; Cermelli and Roddier 2005; Cermelli et al. 2008; Cermelli et al. 2004). One disk with a diameter of 27 m was used to provide the same thrust force (using Froude scaling) to simply the issues of different Reynolds and turbine control (Larsen and Hanson, 2007). After the experiment, extensive finite-element analyses and the FAST code were carried out. In the same year, Roddier et al. (2010) performed a 1/105 small-scale model test which combined with the numerical analysis tools including TIMEFLOAT and FAST. In this experiment, one electrical motor was placed to model the gyroscopic effect and the disk still was utilized to replace the wind turbine under the selected drag coefficient 1.2, wind speed 12 m/s and 0.4 after that up to 25 m/s, respectively.

2.5 Winflo and AFOSP

To predict the global dynamic responses of an innovative concept, Le Boulluec et al. (2013) conducted scaled model tests and included an adapted rotor to validate the floater and mooring within the Winflo project in 2010 (Henderson and Witcher 2010). And experimental results show the moored floater has a superior ability to hand the hydro/aero coupling and gyroscopic effects induced by FOWTs.

Within the European KIC AFOSP project, a monolithic concrete spar was developed and the experiment was presented by Molins et al. (2011) and Molins i Borrell et al. (2014). The exemplary design and methodology of the experiment of this novel spar have been demonstrated by Matha et al. (2015) who provide a brief review of the AFOSP project.

2.6 Floating Wind Offshore Structures

Philippe et al. (2013) performed a model test of the Dutch Trifloater based on Froude similarity (Courbois, 2013) in ECN. The wind generation system in his experiment can be found in the paper of Courbois et al. (2011a, b). The numerical model (Philippe et al. 2014) they used in the experiment showed a good agreement for three degrees of motions. José et al. (2014) validated a 1/40 scale 6-MW Concrete Star Wind Floater designed by Dr.techn.Olav Olsen AS (Lunde 2013), which used a concrete model in the ECN wave tank in 2014. A new methodology was proposed for the scaling of aerodynamic force by combining the Ducted Fan and hardware iteration to obtain the correct thrust force at the low Reynolds regime.

3 Challenges in Basin Experiment Technologies

Due to the blade rotation and the elasticity of the tower and structure, the FOWTs' experimental model has become complicated. Compared with the traditional floating structure model test, there are numerous key challenges.

Several intrinsic challenges are summarized here, which will affect the accuracy of the wave-wind coupling effects in the basin experiment, as well as making the FOWT basin experiments different from traditional offshore engineering experiments and wind tunnel testing. These challenges include:

Scaling issues:

Froude number and Reynolds number cannot be satisfied simultaneously; aerodynamic performance simulation; reflecting of coupling effects between aero-hydro and structural dynamic responses.

Blade pitch control strategies:

Increase of the loads, negative thrust sensitivity and resonant amplification of platform pitch motion.

Experimental facilities and calibration methods:

Mass property adjustment, installation of measurement devices and wind-wave generator techniques.

3.1 Scaling Issues

The first challenge has been regarded as the crucial one which extends the problems of blade design and control strategies caused by dissimilar low Reynolds scaling issue. This involves the consideration of the dynamic similarity criterion.

Generally, the exact simulation of hydrodynamic and aerodynamic forces depends on the similarity of Froude numbers and Reynolds numbers, respectively. And scaling incompatibility is induced by these two factors. The appropriate scale rule and eliminating scale effect as much as possible can be regarded as a very important point to obtain a reasonable overall dynamic response of the whole system.

In response to these existing challenges, early scholars have summarized the existing experiments. Müller et al. (2014) listed some representative basin experiments and projects in the past and put forward a methodology for the existing problems by redesigned model scale rotor. However, aerodynamic torque and gyroscopic momentum are not scaled correctly with his software-in-the-loop procedure. Alternatively, rotating scaled mass was used to represent the rotor inertia to match the gyroscopic effects. Stewart and Muskulus (2016a, b) reviewed 9 experiments of FOWTs in details, as a preliminary preparation for the Integrated Research Program on Wind Energy (IRPWind).

3.1.1 Hydrodynamic Simulation

For the basin model experiment of the traditional floating structure, the Froude scale is usually the priority because the gravitational forces are the main factor to impact hydrodynamics of floater rather than viscous forces (Brown, 2006). And the gravitational and inertial forces in the wave force components can be accurately simulated, which are the dominant external loads for ships or floating offshore structures.

A steady thrust force has been replicated by using a steady horizontal force corresponding to a steady wind from Utsunomiya et al. (2009a, b). Myhr et al. (2011) performed a 1/100 scale TLP platform in 2011. As further work in 2014, they exploited another 1/40 scale TLP and tested at IFREMER to validate the hydro-elastic of three different Tension-Leg-Buoy (TLB) floaters, compared with an aero-servo-hydro-elastic simulation tool (3DFloat). In 2012, a simplified 1/80 scaled TLP model testing has been performed by Wehmeyer et al. (2013) under the ultimate limit state (ULS), therefore no aerodynamic loading and gyroscopic effects. Sethuraman and Venugopal (2013) conducted a 1/100 scaled stepped-spar basin experiment at the University of Edinburgh. Their model was fundamentally comparable with the one of Utsunomiya et al. (2013a, b). Bayati et al. (2015) presented a method to study hydrodynamic loads on the OC4 Semi-type platform with the effects of water depth which has been inspired by previous studies (Naciri et al. 2004; van Essen et al. 2013). Based on the data of previous basin model tests, Gueydon (2016) carried out the validation (without control). Two numerical models were established to examine the design concept and the small-scale constructed physical model which were matched at operating speed, wave and steady wind at a fixed speed.

However, these experiments were focused only on hydrodynamic parts and did not consider the coupling effect induced by another aerodynamic performance including the rotor, blade or other actuators in the experiment. Therefore, the coupling effects between aero-hydro cannot be presented well, especially controller induced platform unstable phenomena.

3.1.2 Aerodynamic Simulation

The Reynolds number is usually adopted in wind tunnel tests to validate the size and parameters of the blade and rotor (Jamieson 2018), and to ensure that the viscous forces and inertial forces in the correct airflow field can be obtained. However, the Reynolds number will become much smaller in the basin experiment of FOWTs under the Froude scale, for example, the Reynolds number will reduce to 1/350 under a 1/50th Froude scale (Hall et al. 2014). Therefore, the Reynolds number cannot be considered simultaneously with the Froude number in FOWTs' experiment which means a difficulty in replicating the coupling between aero-hydro dynamic forces (Bayati et al. 2017a, b).

If the similarity of the Reynolds number cannot be simulated inappropriately, there will be a significant impact on the aerodynamic performance such as blade performance (lift and drag forces) and aerodynamic damping, resulting in dissimilar thrust force, thus affecting the dynamic response performance of the entire system. Currently, the Froude number is still adopted in the experiment of FOWTs to simulate the correct wave force and inertial force effect which are also the premise rather than the Reynolds number. For this composite model test, the density and dynamic viscosity of the airflow field are unlikely to simulate. Despite having some aerodynamic-related properties that are affected by the Reynolds number, it mainly reflects the relative relationship between the viscous force and the inertia force (Martin 2011). As a result, the viscid effect usually is neglected in the model test to equate the Froude similarity between the model and full scale to satisfy the gravitational and the inertial similarity.

Nonetheless, the most critical and significant aerodynamic loads are selected out, namely, gyroscopic momentum, thrust force and torque. These three loads are transmitted from the blade to the floater which can represent the main aerodynamic performance (Martin et al. 2014). Gyroscopic momentum can be obtained through satisfying the weight, center of gravity of the blade and rotating speed under the Froude scale. Gyroscopic effect (Gyro-effect) has been studied by many scholars (Bahramiasl et al. 2018; Fujiwara et al. 2011; Murai and Nishimura 2010; Suzuki et al. 2004). The Gyro-effect of rotating blades that induced yaw motion has been proved that will not reduce generator power sharply (Suzuki et al. 2004). Upon the idea of Suzuki et al. (2004), one 1/158 scale model test was conducted by Murai and Nishimura (2010), which adopted an automatic revolving disk rather than blades. And an examined experiment and numerical simulation of Gyro-effect on coupled dynamic responses have been done by Fujiwara et al. (2011), as well as derivation of formulas of gyroscopic damping and motions. In addition, 6 DOFs' equations in the frequency domain have been provided in terms of aerodynamic loads (Semi) (Blusseau and Patel 2012), model test and numerical simulation (TLP) (Bahramiasl et al. 2018). Karimirad (2011) demonstrated the instability of FOWTs, due to high amplitude in yaw and pitch motion coupled by the Gyro-effect.

If the thrust and torque are not corrected, it cannot meet the requirements for correctly simulating the corresponding relationship of the full scale. In addition, it is necessary to determine the priority relationship between thrust force and torque if they cannot be satisfied simultaneously. The thrust force is directly transmitted to the tower and platform which have a significant impact on the whole system. Therefore, providing correctly scaled thrust force is easier and feasible to do since torque is less important for global dynamic responses (Martin et al. 2014) in the case where the rotation axis of the blade is driven by the motor instead of wind.

The platform will undergo 6DOF motions under the action of wind and waves. The aerodynamic load of the wind turbine aggravates the motion responses of the platform. At the same time, the movement of the platform is induced by the speed of the rotor to change the flow field. With unsteady distribution, the aerodynamic load of the rotor changes accordingly. As the rotor rotates continuously, its aerodynamic loads generally change with the rotational position, and the platform motion affects this periodically varying load. Therefore, the platform motion and the rotor load are mutually coupled processes.

This coupling problem poses a challenge for the design and analysis of FOWTs and has received much attention in recent years. Based on the free wake vortex method (FVM), Sebastian and Lackner (2012) analysed the interaction between the rotor and the downwind vortex under the pitch motion of the platform. It is considered that the change of the aerodynamic load caused by the platform pitching motion is not negligible. Sebastian and Lackner (2013) also considered that the platform motions caused an unsteady flow field, compared the aerodynamic loads of fixed and studied the freedom of motions of the platform with different influences on aerodynamics under different platform forms. Jeon et al. (2014) also analysed the effects of pitch motion using the vortex lattice method (VLM). Farrugia et al. (2014) carried out experimental research on the aerodynamic performance of the floating platform, measured the load and wake state of the rotor, and proposed that the FOWTs should reduce the longitudinal motion to avoid running at a relatively high tip speed. Rockel et al. (2014) studied the influence of the platform's pitch motion on the wake through wind tunnel tests. The movement of other degrees of freedom of the floating body may also make the wake more complicated.

Sant and Cuschieri (2015) analysed the rotor properties of the platform at different heading angles according to various models. Wu et al. (2015) used the CFD method to study the effects of platforms' sway, pitch and yaw motions on the aerodynamic loads of the whole rotor and single blade, combined with the velocity distribution of the disk surface and wake. Power and load changes are brought by the platform motion. The analysis was carried out and these changes will be considered as important challenges in the study of control systems, structural fatigue and strength. However, these studies are only for the part of the degree of freedom of the platform motions, lack of comprehensive analysis and comparison of the 6DOF.

3.2 Rotor Simulation and Blade Pitch Control

The dissimilarity of direct geometric scale blades cannot match the aerodynamic performance as expected. To avoid the discussed dissimilar problem, several researchers have proposed a more sophisticated "non-geometrical" scaling approaches. The new Froude scale rotor and blade have been redesigned to make up to performance reductions of the aerodynamic load modelling in the experiment, including drag disk by Wan et al. (2015) and Cermelli et al. (2010) or a modified low-Reynolds number airfoils with enlarged chord lengths (Duan et al. 2016a, b) to only match the full-scale thrust force (de Ridder et al. 2014; de Ridder et al. 2013; Fowler et al. 2013; Make, 2014).

3.2.1 Drag Disk

Principle Power conducted a 1/67 scale model test in the first phase of WindFloat (Cermelli et al. 2010; Cermelli et al. 2009). Taking excessive complexity of simulation control execution into account, a compromise approach was adopted, even disk instead of blades to get enough thrust. In 2010, the Reynolds number has been considered to be well overcome by using enlarged blades in terms of special airfoils and roughened leading edge (Martin 2011). The NREL 5-MW blade was the prototype of that Froude scale rotor. They increased a higher wind speed to match the thrust force to keep the balance in the relationship of aero-hydro dynamic force between the model and full scale. And then in 2013, a second-round testing was conducted based on a semi-type platform and the hybrid combination of potential flow theory and Morison's equation has been considered in this specific experiment. The detailed parameters, the definition of external wave conditions and specification of installation (sensors) have been provided in their papers; however, limited experimental results have been published. Although MARIN tested FOWTs equipped with such blades in basin model tests, it was only applied to a semi-submersible platform until this project ended.

Based on phase Ⅳ of OC3, Shin (2011) used model blades in replicating the thrust disks to conduct a 1/128 scale model test under stochastic wind and wave. And motions of the platform and rotating rotor effect include linear hydrostatics, excitation force (incident waves), radiation (outgoing) and non-linear effects (added mass effects and viscous forces) that have been discussed in their research. In addition, the spar torus combination (STC) proposed at NTNU (Wan et al. 2015; Wan et al. 2016a, b; Wan et al. 2017) and semi-wind energy and flap-type wave energy converter (SFC) (Gao et al. 2016; Luan et al. 2014; Michailides et al. 2016; Michailides et al. 2014) have been studied by model tests and numerical validation based on EU FP7 MARINA Platform project. They adopted a drag disk on the top of the tower to replicate the mean thrust on the rotor because it is mainly to validate the structural integrity of STC under severe sea states.

3.2.2 Re-design Rotor and Blade

In 2014, three scale relationships including prototype to model (Chakrabarti 1998), Froude-scaled wind and tip speed ratio (TSR) (Jonkman and National Renewable Energy L 2010) have been mentioned by Martin et al. (2014). Hansen et al. (2014) concluded a 1/200 scale TLP with an optimized rotor and low Reynolds number through an alternative pitch angle distribution. Duan et al. (2016a, b) conducted 1/50 scale spar-type model tests by comparing the testing results of the TMBS and GMBS under different environmental conditions. Du et al. (2016) examined a similar geometrical blades' aerofoils which show only 24.3% of the target. He optimized the thrust force of the model and the lift and drag coefficient was obtained by the RANS method. The improved blade referenced by Fowler et al. (2013) has better aerodynamic performance than the original geometrically similar blade and is more in line with the target value, which largely compensates for the inability of the geometrically similar blade to accurately simulate the rotor's performance. And a quasi-static and unsteady methodology has been proposed by Salehyar and Zhu (2015) to analyse the aerodynamic dissipation effect. Although MARIN and SJTU based on geometrically reduced model blades have taken relevant remedial measures at low Reynolds number, its structure for non-rotor parts (such as towers) and parts of the float above the water surface will also produce unwanted extra thrust. To ensure the correct simulation of the axial thrust, the accurate collection of other aerodynamic loads, such as torque, was abandoned.

Ahn and Shin (2017) conducted a 1/128 scale 3-leg catenary spread mooring system with a delta connection. The water depth of the entire system is matched numerically and experimentally in various combinations including wind and rotor rotation to predict platform performance. By comparing the significant motion and RAOs with conventional and irregular waves, the validity of the numerical simulation they proposed can be assured. Due to the small size, the blade must be re-corrected for the thrust force and surge excursion, because the flapwise surface of the 3D blade model was the only one matched in their project. For this reason, 3D printing can be used as another optimal solution for the construction of a small-scale experimental physical model.

In general, the geometric downsizing of the rotor effectively alters the aerodynamics of the scaling issues (Jain et al. 2012). And also, in this method, gyroscopic forces can be provided by a correct mean thrust force and aerodynamic damping, if spinning. However, whether it is a drag disk or a modified blade, the thrust force is the only condition which has been considered in the previous experiment. More detailed investigations' fidelity will lose if the torque, rotor blades' load, scalability for aerodynamic damping at different wind speed and advanced blade pitch control cannot be considered.

3.2.3 Blade Pitch Control Strategies

How to simulate the rotation of the rotor is related to control technology. Adjusting the blade pitch angle and generator torque is one of the most significant requirements in most wind turbines (Pao and Johnson 2011), which are discussed above briefly. In general, under different wind speed region, the control strategies vary.

Wind speed < rated: The maximum power is the priority and the generator torque will adjust (pitch angle keeps 0).

Wind speed > rated: The generator torque constant by adjusting pitch angle to maintain stable power output.

It is appropriate for both land-based and floating types. However, due to the particularity of FOWTs, the standard land-based control strategies cannot apply on the floating turbine blade directly (Jonkman 2008). It is a challenge to apply the controller on a floating platform which will lead the floater unstable especially when the damping and the controller mode are within the same bandwidth (Savenije and Peeringa 2014). This is exactly what was mentioned above, the poly-trope of thrust force on the rotor. In this case, good control strategies for active turbine blades and generator control ensure stable operation of FOWTs including maintaining appropriate rotating speed and power regulation (Pardalos et al. 2013), as well as reducing the motions and a substantial load of floater (Savenije and Peeringa 2014). In general, not only the motions of the floater have impacted the superstructure but also controllers will influence the floaters which are also the coupled effects.

Many scholars did numerous researches in these specific blade pitch control strategies (Bakka and Karimi 2012; Christiansen et al. 2013; Lackner Matthew 2013; Larsen and Hanson 2007; Lindeberg et al. 2012; Namik and Stol, 2010, 2011, 2013; Oh et al. 2015; Ramos 2012; Schlipf et al. 2013; Wang et al. 2014). Namik and Stol (2013) provide a detailed review of FOWTs' controllers and introduce an IBP controller. Savenije and Peeringa (2014) provided a brief review of control development for FOWTs and compared four different controllers including FPfloat (fixed pitch), OC3float, ECNland (without modifications) and ECNfloat. Some researchers investigated the active blade pitch control and generator control based on global dynamic responses of FOWTs (Bredmose et al. 2017; Goupee et al. 2017; Yu et al. 2017). Hara et al. (2017) proposed a system identification approach. Their approach adopted an H∞ method (Zhou and Doyle 1998) which was applied by Tsujimoto et al. (2014). Although some blade pitch control systems have been investigated in this area and achieved certain results, there are still few references available in the field of how the control strategies are combined with a real-time hybrid experiment, especially the influence of active turbine controls.

José et al. (2014) proposed another approach that performed a 1/40 scale test of a semi-type FOWTs. They applied a ducted fan to provide the required thrust force. Although it was controlled via a real-time numerical simulation with active controls, it still had a limited ramping rate and good results integrated with simulation results very well. Goupee et al. (2014a, b) compared two campaigns using a geometrically similar and improved performance-matched DeepCwind model (OC4 Phase Ⅱ), which have been conducted in 2011 and 2013, respectively. As a corrective measure, the wind speed has been increased to obtain the correct mean thrust force in the 2011 campaign and the coupled aero-hydro-elastic response in region three and active blade pitch control has been tested in 2013 which were not executed in 2011.

Yu et al. (2017) conducted a 1/60 scale Triple Spar floater, a hybrid between a spar-buoy and semi-submersible tri-floater which was tested with an active blade pitch control in DHI Denmark for the first time (Bredmose et al. 2017; Yu et al., 2017). The aerodynamic damping, interaction effects induced by wind, and wave and blade pitch control are discussed in their work. They applied a real-time active controller on the model (Yu et al. 2017). In this campaign, different methodologies of the controller related to negative aerodynamic damping and simulation have been investigated to show the possibility of a low Reynolds rotor to control the rotor speed by adjusted the blade pitch angle. The calibration of the simulation model has also been proposed, due to the lift and drag coefficients and aerodynamic losses and drivetrain mechanical friction.

3.2.4 Summary

The model size of the blade is large, and the scaled mass is very light, at the same time it needs to bear various wind loads in the test to meet sufficient strength and rigidity, which involves the blade manufacturing technology.

The upper structure of the FOWTs is very lightweight and at the same time the most complicated part of the arrangement and installation. Especially, it needs to install the motor, connect the hub, the six-component force sensor, the accelerometer sensor and the various components.

Meeting the objective scale quality is a challenging task that involves not only control strategies but also mass control techniques.

In summary, the mass adjustment of the blade pitch physical model (gear and motor) and a wind speed estimation are the primary consideration. And the coupling effect of controller induced dynamic behaviour in terms of platform pitch motion damping (Goupee et al. 2017) and extra aerodynamic damping (e.g., negative damping phenomenon (Larsen and Hanson 2007; Thiagarajan and Dagher 2014)) which still does not have the final conclusion, because of the limited researches.

3.3 Experimental Facilities and Calibration Methods

To accurately measure the coupling response of FOWTs under the action of both aerodynamic and hydrodynamic loads, a set of controlled wind field rectification system has to be specially designed for the experiment to achieve spatial and temporal uniformity. Wind generation techniques may not be feasible in an open basin (Martin et al. 2014), especially for less advanced facilities. To accurately measure the coupling response of FOWTs under wind and wave, a wind-making rectification system with a controllable wind field is often designed to achieve uniformity in space and time. Improved wind generation systems have been proposed by Courbois et al. (2011a, b), Newton et al. (2015) and Philippe et al. (2013).

Before the experiment, other key factors are calibrated which will influence the whole experiment directly, involving tuning the platform, tower and aerodynamic parameters. Wind turbine geometry, mass properties, aerodynamic losses and the drivetrain mechanical friction in the simulated rotor and blade model should be examined. Decay tests are required to determine approximate constants of the initial conditions. Through the decay test, the stiffness, mass and added mass, the moment of inertia and damping accuracy of the model system can be verified. Stewart et al. (2012) and Browning et al. (2014) proposed a method called further decay tests and also gave some details for calibration and validation (physical and numerical). The natural frequency of the tower can be tested by the hammer test. Rotor and nacelle parts are not included in the hammer test. However, the influence of the sensor and cable is not negligible. For this reason, the mass of the wind turbine has a certain difference from the design value in the basin model test. Yu et al. (2017) and Bredmose et al. (2017) discussed partly calibration in the Triple spar campaign. Based on the previous work of Duan et al. (2016a, b), Li et al. (2018a, b) proposed an improved deficient thrust force correction approach which used the wind to drive the rotor rather than the motor.

4 Real-Time Hybrid Approach

Under the premise mentioned above, many scholars selectively avoided the simulating aerodynamic issues when studying the dynamic responses of FOWTs, focusing mostly on the effects of hydrodynamic forces or they may use the original disk to replicate the required thrust force in a much easier way. With the limitations of methods and facilities, these practices were popular in early research. However, seldom details have been thoroughly opened to the public. Through the improvement of theoretical and numerical models' fidelity and increased computational power, the real-time hybrid approaches (RTHA) have been proposed recently. It consists of physical and virtual subsystems that can be defined as a combination of basin experiment and hardware-in-the-loop (HIL). A numerical model in HIL simulation accounted for the transient and degraded responses, interfacing with scale model through sensors and actuators (Plummer 2006). This presented the method applied in all aerodynamic load components (thrust force and torque) on a wind turbine model in a new way, while unlike previous similar champions, only satisfied thrust force.

In RTHA, the wind turbine or floating platform will be replaced with some actuation systems. And a full range of transient aero-hydro-servo-elastic dynamics force, which is calculated in a numerical model simulation in real-time, will be applied on the model by these actuators. A thorough introduction of the working mechanism of RTHA in the context of floating structures and proposes its use in basin experiment of FOWTs has been provided by Chabaud et al. (2013). Different from a usual numerical simulation, delays and dynamics are undesired compensation in this alternative approach which means one feedback-controlled facility was settled to emulate aerodynamic forces (Hall et al. 2018; Hall and Goupee 2018; Hall et al., 2014) or wave forces (Bayati et al. 2014; Bottasso et al. 2014; Filippo et al. 2014). The aero-elastic response of the tower and blades is usually neglected in basin experiment. However, these can be simulated with a scale model in software by using BEMT and beam bending models in RTHA. Additionally, this method created an easy way to effectively solve the wind generator techniques at model scale, and relatively simple in utilizing non-generic designs.

4.1 Code Development

It is because of the rapid development of software technology that it promoted the birth of RTHA. Moreover, hardware and software play significant roles in the experiment. Therefore, it is necessary to give a brief overview of numerical simulation before discussing RTHA. Currently, researchers have been exploiting numerous numerical simulation tools for analysing the full-scale FOWTs which can be classified into two categories (Liu et al. 2016): frequency domain and time domain analysis. Many new numerical simulation tools have been created in recent years and most related experiments are undergoing code-to-code or code-to-experiment validation, especially in hybrid basin experiment. This section will provide a brief introduction and summary of the numerical simulation tools.

4.1.1 Frequency Domain Analysis

Grant proposed BEMT to apply the aerodynamic forces of the wind turbine, based on the one-dimensional momentum theory proposed by Rankine et al. (Ingram 2005). According to Cordle and Jonkman (2011), BEMT is an aerodynamic model currently used to calculate aerodynamic loads. However, the presence of significant low-frequency motion in FOWTs makes the flow field around the blade more complex than a fixed wind turbine. Therefore, researchers have proposed many correction methods for this theory (Hansen 2015; Hansen et al. 2006): Prandtl's tip loss correction factor and Glauert's correction.

The calculation of the hydrodynamic load of FOWTs usually depends on the structure of the floater. For a spar type, the calculation of hydrodynamic loads is a complex coupling problem that requires consideration of incident wave excitation force, potential flow radiation damping and additional mass. In 1950, to simplify the computational complexity of the project, Morison et al. (1950) proposed the Morison empirical formula to solve the hydrodynamic load calculation of the floating structure. Subsequently, the formula is widely used in the calculation of hydrodynamic loads in cylinders (Faltinsen 1993; Wei et al. 2014). This formula is also the earliest model for hydrodynamic calculation of FOWTs (Faltinsen 1993; Maniar and Newman 1997). But it is mainly applied to the calculation of hydrodynamic loads of offshore fixed wind turbines. The Morison formula is primarily suitable for applications on small-scale structures since it ignores the memory effect of the free surface and uses G.I.Taylor's long-wave approximation to simplify the diffraction problem (Cummins 1962; Ogilvie 1964). All these make the Morison formula not applicable on large-scale structures. Later, the researchers tried to numerically analyse the FOWTs in the frequency domain under the linear assumption.

For linear systems, when a periodic load of a single frequency is applied to the system, such as a floating body under the action of a regular wave, the excitation response should be a single frequency. The response amplitude operator (RAO) defined in the traditional ship and ocean engineering is based on this linear input-output hypothesis to reflect the responses of the floating body by the wave excitation load. Therefore, for the traditional floating platform, the frequency function can be solved by direct frequency domain calculation to predict the responses of the floating body under the wave excitation load (Ma et al. 2014). However, for FOWTs, its normal operating state is subject to both wind and wave loads. And in the case of turbine blades rotating at a specific speed, the wave load of a single frequency can no longer be seen as a single input. At the same time, a single frequency wave load excitation can also result in multiple frequency responses. This non-linear characteristic is mainly caused by the rotation effect of the blade and the system instability induced by the blade pitch controller (Jonkman et al. 2010).

Therefore, for FOWTs, first of all, the response of the system to wave excitation cannot directly solve the frequency function or the RAO from the traditional frequency domain equation. Secondly, when evaluating the responses of the system induced by wave excitation, the normal operation of the wind turbine, that is, the rotation effect of the blade and the wind load effect, cannot be ignored. This is determined by the system characteristics of the FOWTs itself. Otherwise, only the response characteristics of the wave load are considered. The forecast is of little significance in practice. To better evaluate the response of the system to wave excitation, Jonkman et al. (2010) proposed the concept of "effective RAO" with the definition of the traditional marine floating platform RAO.

Inspired by the technologies of offshore O & G industries in the field, some researchers have studied the dynamical characteristics of FOWTs using frequency domain analysis tools. For example, Lee (2005) and Wayman et al. (2006) performed a series of investigations on TLP and analysed shallow-drafted barge and the MIT/NREL TLP, respectively. Wang et al. (2017) proposed a frequency domain approach to analyse the coupling effects of FOWTs. However, FOWTs are the typical non-linear system which is not capable of modelling and involves the influence of coupling between aerodynamic loads, structural elastic deformation and the movement modes.

4.1.2 Time Domain Analysis

In traditional ocean engineering, the floating structure is considered to be a single rigid body, which can be used to establish the dynamic equation of the structure. And this rigid body must have no relative motion between the various mass points inside the structure. However, when the FOWTs is working, the rotor rotates continuously, and there are relative motions between the rotor, blade, nacelle structure and platform which do not meet the conditions for the single rigid body dynamic theory. Therefore, the FOWTs could be regarded as a fully coupled aero-hydro-servo-elastic model by solving the dynamical equations of numerous degrees of freedom (DOF) in the time domain. And the DOF of FOWTs' systems (except mooring system) mainly are:

· 6DOF motions of the platform.

· Modal coordinates of the elastic deformation of the tower in all directions.

· The rotation of the nacelle relative to the top of the tower.

· The rotation of the rotor relative to the nacelle.

· The rotation of each blade relative to the hub of the end of the transmission rotor.

· Modal coordinates of the elastic deformation of each blade.

To study a simple system consisting of a small number of rigid bodies, it is convenient and feasible to use any kind of mechanical method. However, for a plurality of rigid bodies, even systems containing flexible bodies, a more general mechanical model needs to be established. In multi-body systems, some objects are assumed to be rigid bodies, and some objects must consider flexible deformation. The mechanical model is called the rigid-flexible multi-body system.

The traditional hybrid coordinate model ignores the quadratic coupling term when considering the coupling between the large-scale rigid body motion and the high-frequency elastic deformation motion of the flexible body at low frequencies, and directly uses the analysis results suitable for small deformation displacement in structural dynamics. It is not only unable to deal with the dynamic stiffening phenomenon brought by the rigid body motion to the flexible body but also causes the negative stiffness phenomenon when the large-scale rigid body motion is very large or the flexible beam is long, which affects the solution of the flexible beam motion displacement. The longer the length of the flexible beam, the more obvious the phenomenon of dynamic stiffening, and the elastic deformation is reduced. Therefore, for the large and slender flexible structure, the coupling effect of high-order elastic deformation and large-scale rigid body motion should be considered. And also, it is because of non-linear behaviour, transient effects and coupling effect, which cannot be simulated accurately in frequency domain analysis. Therefore, the time domain analysis method has come into the mainstream gradually.

Karimirad and Moan (2011) conducted an extreme structural response and fatigue loads of a spar-type FOWTs. Bachynski et al. (2013) did the research on transient events in time domain analysis. In addition to special R & D, some researchers made improvements from O & G industries or some other existing codes. For example, Jonkman and Buhl Jr (2005) added hydrodynamic mooring loads into FAST code which has been developed for onshore bottom-mounted wind turbines, originally by Wilson et al. (1999). Fylling et al. (2009) employed SIMO (structural dynamics and hydrodynamics) and RIFLEX (model mooring lines with FEM) to carry out the research, combined with a separate aerodynamic subroutine.

Several time domain numerical tools have been developed from commercially available general-purpose multi-body system (MBS) codes. ADAMS and SIMPACK have been used by combing with additional aerodynamic, mooring and hydrodynamic subroutines for Withee (2004) and Matha et al. (2011), respectively. Ormberg and Bachynski (2012) described the RIFLEX extension of aerodynamic load on elastic structural components. Also, aNySIM has been developed and validated by MARIN to provide clients with a more integrated simulation package including multi-body side-by-side, the mooring system and dynamic positioning capability studies (De Wilde et al. 2009; Naciri et al. 2007; Serraris 2009). Another integrated code DARwind has been proposed by Chen et al. (2019). And also some theoretical background can be found in his papers which also were verified code-to-experiments (Chen et al. 2017).

With the development of computer technology, computational fluid dynamics (CFD) has become one of the strong tools to analyse global dynamic responses of FOWTs. Zhao and Wan (2014) and Liu et al. (2015) conducted a series of investigations by their own CFD tool NAOE-FOAM-SJTU. And comparisons of wave load effects of TLP by combining potential flow theory approaches and CFD were conducted by Nematbakhsh et al. (2015). Tran et al. (2014) applied the CFD method to study the influence of periodic pitching motion on the aerodynamics of FOWTs and compared other calculation models. In the simulation of large-scale pitch motion, the CFD method has a smaller load than the traditional aerodynamic model and can be a more accurate calculation of the effects of unsteady loads and random motion of the platform. The Offshore Code Comparison Collaboration (OC3, OC4 and OC5) project (Jonkman and Musial 2010; Robertson and National Renewable Energy L 2014; Robertson et al. 2017) can be regarded as a series successful comparison.

In summary, the previous work has concluded the different numerical simulation tools in each module, based on Liu et al. (2016). Nonetheless, very limited studies have been performed that elaborate on the rigid-flexible coupling multi-body methodologies implemented in FOWTs. And detailed test data hardly being openly available to the public.

The development of CFD technology has played a certain role in promoting the research of FOWTs. However, due to the high requirements of hardware or software, long time consumption and lack of accurate verification, compared with the traditional numerical simulation method, still need to be improved. Although some of these tools have been used in a wide range and even have been benchmarked through code-to-code check work, for instance, FAST and HAWC2, few of these numerical tools have been accepted consistently for their reliabilities if these tools are used solely to predict global responses of FOWTs. In addition, in the numerical tools, the coupling effect is truly a challenge to be considered in an integrated way. Due to some assumptions or simplifications introduced in theoretical calculations, such as hydrodynamic calculations without considering second-order wave forces, and potential flow calculations neglecting viscous effects, etc., it will bring inaccuracies in some aspects of the simulation results of numerical simulation tools. For example, the hydrodynamic calculation linearization cannot account for the second-order difference frequency wave force, which causes the oscillation of the surge, pitch and heave under wave excitation to be correctly simulated at the natural frequency; the second-order harmonic wave force cannot be considered. It is possible that the vibration of the tower at its natural frequency cannot be sufficiently excited. But this coupling effect can be reflected and obtained in a basin model test.

4.2 Hybrid Basin Experiment

A real-time hybrid method was first applied to the earthquake of civil engineers in the 1970s in Japan by Carrion and Spencer Jr (2007). They tried to validate the assumption of large-scale structural behaviour which can be realized and interface experiments with simultaneous simulation. And various pathfinder improved tremendously as this method became a criterion for buildings and bridges' damage simulation (Horiuchi et al., 1999; Nakashima et al., 1992). A detailed review up to 2007 has been given in Carrion and Spencer Jr (2007). A review of this RTHA has been applied to simulate aerodynamic forces within the automotive car industry, which was made by Plummer (2006) and the individual parts (de Klerk, 2009; Klerk et al., 2008; Li, 2014). The development of this method has been promoted in the USA by Shao and Griffith (2013) and in Europe by Pinto et al. (2004) as well. With the development of RTHA, the challenges arose because of its interaction between multi-disciplinary simulation including software, hardware, fabricating measurement, experimental methods, signal processing, control engineering and data acquisition which required instantaneity and precision for real-time coupling.

Some examples of each discipline's fundamental progress or advanced methods have been provided by Sauder et al. (2016) including control strategies (Carrion and Spencer Jr, 2007) and stability analyses (Kyrychko et al., 2006). The application of RTHA in renewable energy and marine technology can be found in Cao and Tahchiev (2013), Chabaud et al. (2013), Li et al. (2006), Munteanu et al. (2010), Signorelli et al. (2011) and references therein. The objective aerodynamic thrust and generator torque should be considered or actuated which are the most significant effects on floaters when using a modified numerical simulation.

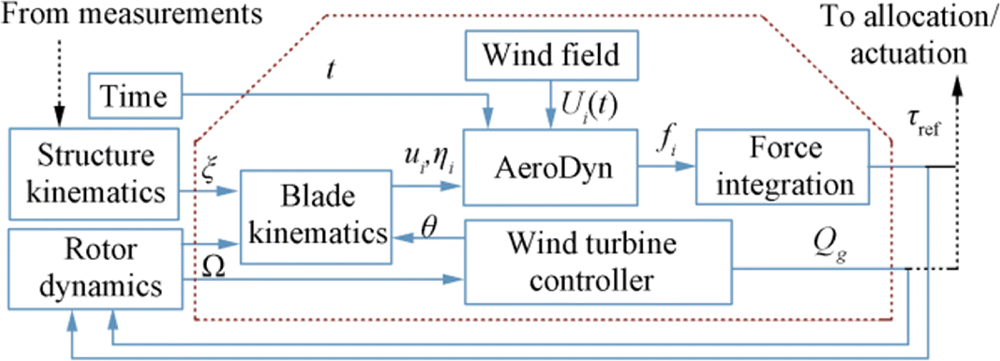

As to gyroscopic moments, non-thrust loads (pitch and yaw moment, sway and heave force), dynamic torque and thrust directionality have been neglected in RTHA (Bachynski et al., 2015). Bachynski et al. (2016) and Sauder et al. (2016) also offered a brief review of the RTHA testing which is adopted for FOWTs' experiments by limiting a part of the environment to avoid the discussed scaling problem (Figure 4).

Figure 4 Block diagram of the numerical substructure (Bachynski et al., 2016)

Figure 4 Block diagram of the numerical substructure (Bachynski et al., 2016)In their experiment, they proposed one method to apply wind-wave-induced forces and the blade pitch control algorithm by using a series of tensioned wires to connect the turbine and actuators to provide the transient simulated force rather than a ducted. The specific process of this hybrid method on a 1/30 scale 5-MW braceless semi-type wind turbine has been proposed in terms of qualification, quantification, possible error sources and performance of FOWTs. In the last stage, Berthelsen et al. (2016) introduced a methodology of using experimental data to calibrate the numerical model and quantify and mitigate equipment. Karimirad et al. (2017) used SIMA to extend previous work by Berthelsen et al. (2016) in terms of the BEM model for rotor forces and second-order loads compared with experimental data. In addition, coupled aerodynamic simulations were conducted to avoid potentially incorrect modelling of the aerodynamic damping (Stewart and Muskulus 2016a, b). Results of experimental data and full-scale numerical simulation from hybrid testing of 1/50th scale FOWTs have been provided by Hall et al. (2014) and five considerations of RTHA have been proposed:

· Actuator displacement.

· Velocity and acceleration envelopes.

· Actuator force envelopes.

· Motion tracking accuracy.

· Force actuation accuracy and system latency.

Bayati et al. (2013) performed a 2-DoF (Pitch and Surge motion) experimental rig-HexaFloat in a wind tunnel to simulate the motion of a 1/25 scale DTU 10-MW wind turbine model which combined hydrodynamic and aerodynamic loads within the LIFES50+ project (Bayati et al. 2016). Next year, HexaFloat (Figure 5) has been expanded to 6DOF (Bayati et al. 2014; Delbene et al. n.d.). In 2017, they proposed an aerodynamic design methodology and a scale model technology for a 1/75 scale DTU 10-MW wind turbine rotors (Bayati et al. 2017a, b).

In general, the technical issues and methodologies of this hybrid/HIL test can be found in Bayati et al. (2018a, b). More challenges for performing this method can be found in Bayati et al. (2018a, b). In the former case, Bayati illustrated the methodology of blade design. But he did not put the turbine system in real water and simplified the 6DOF motions of the supporting platform to a large extent. But Bayati ignored the coupling effect between the blade pitch controller–induced instability of the floater and the aerodynamic load due to blade rotation and wave excitation. Therefore, it can be pointed out that the model test in a wind tunnel is a promising way to predict global responses of floating wind turbine but still in the face of many challenges.

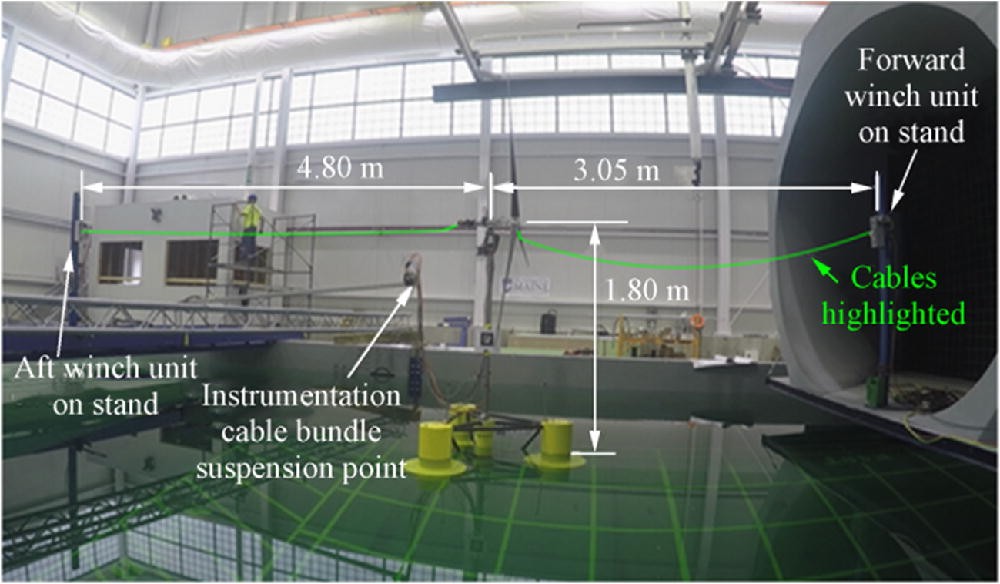

Another real-time hybrid approach was validated by Hall et al. (2018), and Hall and Goupee (2018), which can be seen in Figure 6. In their experiment, an actuation system combined numerical wind turbine model was set to simulate the thrust force by winch and cables, pulling fore and aft on the nacelle. Three controls are integrated which was executed by changing cable length.

Figure 6 Arrangement of cable system in basin (Hall and Goupee 2018)

Figure 6 Arrangement of cable system in basin (Hall and Goupee 2018)He also demonstrated the benefit and possible disadvantages of some hybrid approaches and compared with physical wind-wave tests which show a satisfactory agreement. However, some other aerodynamic force and moment have been neglected. And also, the mean value of platform surge motion has a great difference up to 17% (no wind) and 14% (steady wind), respectively. This may be due to unidirectional dynamic forces on the nacelle by the actuation system. More specifications and detailed methodologies have been given in Hall et al. (2018).

Vittori et al. (2018) proposed one hybrid experimental method by using software-in-the-loop (SIL) method. Different from HIL, SIL validates that generated code has the same behaviour as tested in the model simulation and does not need a hardware interface. This SIL method was applied on OC4 to integrate the aerodynamic performance. The results of all the cases in the experiment are compared with numerical software. However, since the setting of the data type accuracy is done in the SIL, all the calculations inevitably cause calculation errors.

In summary, the scalability and fidelity of basin experiment can be improved by RTHA potentially. The dissimilar scaling issue can be avoided and any scale can be modelled. Requirements of experimental facilities can be reduced and blade pitch control can be modelled without the limitations of small-scale actuation. These make the model test of FOWTs more accessible and flexible to researchers. However, there still have been possible disadvantages. The significant difficulty in numerical modelling of FOWTs is the accurate estimation of the influence of sensor cables (Coulling et al. 2013). Since the model of FOWTs is very light, the influence of the sensor cable can be said to be non-negligible and even very important. In addition, sensor cables of various test institutions in the world are not the same, and the arrangement of cables in basin test cannot be unified. The influence of cables may even be non-linear, so it is difficult to accurately estimate the impact of the cable. The errors may also arise due to the various inaccuracies and delays. And also, the quality of virtual subsystems will influent the results. In addition, almost all the theories are adopted in numerical simulation which relies on assumptions (Farrugia et al. 2016; Jeon et al. 2014; Sebastian and Lackner 2013). Most importantly, more problems (design, manufacture and optimization) may come due to the need to find alternatives actuation system.

5 Conclusions

5.1 Summary

This paper aims to present academic literature pertaining to provide comparisons and conclusions to make a further footstone for proposing an efficient, economic and simplified method to predict the global dynamic responses of FOWTs. Three methods (on-site measurement, basin model test and numerical analysis) to validate the technical and economic feasibility of FOWTs have been compared and discussed the importance of experimenting to validate the full scale. Some previous work and typical industrial projects combined model tests have been introduced. A summary of several model tests to optimize the experimental methods have been provided in terms of drag disk, re-design rotor and blade, and hybrid method briefly. Some common challenges have been concluded: scaling issues, blade pitch control strategies, experimental facilities and calibration methods. Brief code development has been provided. And some new real-time hybrid approaches have been discussed also which are conducted by one feedback-controlled facility to emulate aerodynamic forces or wave forces, the scalability and fidelity of the basin experiment can be improved by RTHA potentially.

5.2 Future Work

With the commercialization of FOWTs and the promotion of its engineering applications, more academic issues will emerge. For example, the current OC6 project aims to understand the reason for the under-prediction of loads/motion in floating semisubmersibles in pitch/surge natural frequencies. In addition, it is also aimed to develop and employ more rigorous validation practices through OC6, in terms of identifying a specific validation objective, using metrics to assess validation success and calculating associated experimental uncertainty of metrics.