2. IVL Swedish Environmental Research Institute, PO Box 5302, 400 14 Gothenburg, Sweden;

3. Department of Applied Mechanics, Chalmers University of Technology, 412 96 Gothenburg, Sweden

The emission of particles from different combustion sources has an adverse impact on human health, the climate, and the environment. One of these sources is the combustion of marine fuel oils in marine diesel engines installed on ships. These emissions occur close to coastal areas and are consequently a significant source of air pollution in such areas (Corbett et al., 2007) and mainly consist of small particles with a diameter below 150 nm (Kivekäs et al., 2014; Merico et al., 2016).

Particle emissions from ships have been shown to relate to the Fuel Sulfur Content (FSC) (Kasper et al., 2007; Lack et al., 2011; Lack et al., 2009), and therefore a reduction in the FSC within marine fuel oils reduces particle emissions from ships. The FSC is now regulated through MARPOL Annex Ⅵ Regulation 14 (Svensson, 2011), with regulations considering both at global level and at regional level involving designated Sulfur Emission Control Areas (SECAs). At a global level, 3.5 wt% S is permissible, although from 2020 this amount will be limited to 0.5 wt% S. The percentage allowance of FSC in SECAs has been specified as 0.1 wt% S since 1 January, 2015 (IMO, 2013).

However, it appears evident that other fuel characteristics besides the FSC have an impact on particle formation and growth, and consequently emissions. Plume measurements have shown that sulfate particles represent 10%–22% of total particle mass. Furthermore, a correspondence with FSC has only been found for Particle Mass (PM) but not for Particle Number (PN) emissions (Beecken, 2015). Measurements conducted using a test-bed engine (Anderson et al., 2015) and in ship plumes (Lack et al., 2011) have emphasized that both the FSC and other fuel characteristics need to be considered when evaluating particle emissions from ship operations. For example, other factors influencing particle emissions such as engine type, engine load, and the exhaust system should also be considered (Diesch et al., 2013).

In this study, the relationship between particle emissions and the aromatic content of the fuel is investigated. Aromatics are a group of organic compounds containing one or more ring structures with conjugated double bonds, e.g. benzene or xylene. Polyaromatic Hydrocarbons (PAHs) consist of fused aromatic rings. Aromatics, for example benzene and its derivatives, are known compounds in crude oil and PAHs in diesel fuel oils (Stone, 2012). Some PAHs are carcinogenic and other aromatics (such as benzene) are toxic to humans (Hart et al., 1999). Aromatics are seen as precursors in soot formation in fuel-rich zones within the cylinders during combustion (Brem et al., 2015) and have a higher soot formation tendency than other hydrocarbons in fuels (Ladommatos et al., 1996). The impact on particle emissions has previously been investigated in several studies (Brem et al., 2015; Den Ouden et al., 1994; Fukuda et al., 1992; Kidoguchi et al., 2000; Neill et al., 2000; Tan et al., 2013; Tsurutani et al., 1995). However, few studies have considered particle size and number concentrations (Brem et al., 2015) and none have applied the maritime aspect. Furthermore, no consensus can be found in literature on the connection between fuel aromatic concentration and particle emissions (Tree and Svensson, 2007). This is likely due to the use of variations in the aromatic content in the studies while maintaining other fuel properties; however, inter-correlations are considered to provide more significant results (Lee et al., 1998; Miyamoto et al., 1991).

This study has a maritime perspective to investigate whether a higher content of aromatics in fuel influences particle emissions with respect to PN, mass, and size distribution. Engine bench experiments were conducted using fuels containing varying amounts of aromatics but which were otherwise similar. The impact of operational conditions (here engine load) were also studied to relate the particle emissions to operations of real ships and the impact on air quality in coastal areas.

2 Material and methodsThe measurements in this study were made in two different test-bed engine labs; firstly, in the test-bed engine lab at the Department of Shipping and Marine Technology, Chalmers University of Technology (Campaigns 1 and 2). After analyzing results, additional measurements were conducted in the test-bed engine lab at the Department of Applied Mechanics at Chalmers University of Technology (Campaign 3). The aim of these measurements was to further investigate the impact of aromatics on combustion processes such as heat release, peak pressure, and temperature.

2.1 Test-bed engines, fuels, and test cycleThe first measurements were conducted in two separate Campaigns in the test-bed engine lab at the Department of Shipping and Marine Technology: Campaign 1 in November 2012 and Campaign 2 in March 2014. The engine lab is equipped with a 2.4 liter, 4-stroke, turbocharged, Volvo Penta D3-110 marine diesel engine with five cylinders, a crankshaft power of 81 kW, and a maximum engine speed of 3000 r/min. The engine has a common rail system and four separate heated fuel tanks, which gives the opportunity to change fuel during operation of the engine and control the viscosity of the fuel, although the engine was originally designed to operate using Swedish environmental class 1 diesel (MK1). The engine is connected to a hydraulic brake, which enables operation at different loads. During Campaign 1, the engine was restricted to operating at a maximum engine load of 35% at 1800 r/min, and for Campaign 2 the engine was operated at a maximum load of 50% at 2000–2010 r/min, after changes had been made to the hydraulic brake and cooling system.

Measurements conducted in the test-bed engine lab at the Department of Applied Mechanics (Campaign 3) were conducted in January 2016. This engine rig was equipped with a 2-liter single cylinder heavy-duty diesel engine (Volvo D12), providing possibilities for detailed cylinder pressure analysis (rate of heat release analysis). The engine has a common rail system and Exhaust Gas Recirculation (EGR) system, and the rail pressure (Pinj), start of injection, and duration of injection were controlled using ATI Vision software. The cylinder pressure was measured using a system from Osiris, and the rate of heat release was calculated using an in-house Matlab code. The engine and system are further described in Zhang et al., (2015) and Sjöblom (2015).

The reference fuel used in Campaigns 1 and 2, was MK1 with a viscosity of 2.0 cSt at 40℃, a flash point between 61–71℃, heating value of 43.1 MJ/kg, and density of 800–830 kg/m3 at 15℃. The ash content for MK1 during Campaign 1 was < 0.01 wt% and the fuel contained 5%–7% RME (Rapeseed methyl esters). MK1 used during Campaign 2 did not contain RME. The same type of lubrication oil was used during Campaigns 1 and 2, with major compounds of calcium (2 850 mg/kg fuel), zinc (1 150 mg/kg fuel), and iron (20 mg/kg fuel). In Campaign 3, a VSD10 diesel was used as the reference fuel; this diesel meets the EN590 standard and contains no biofuel. To increase the content of aromatics in the reference fuels, a fuel additive consisting of aromatics (mainly mono-and diaromatics, > 93%, Caromax 28) was used and mixed into MK1 in tanks. During Campaign 1, fuel blends with aromatic concentrations of 23% and 30% by volume (%vol) were tested; for Campaign 2, measurements were repeated using a fuel-blend of 30%vol aromatics; and for Campaign 3 fuel blends with aromatic volumes of 20% and 30% were tested (i.e. the experiments conducted during Campaigns 1 and 2 were repeated). The properties of the reference fuels, fuel blends, and Caromax 28 are presented in Table 1. Furthermore, during Campaign 3, an ignition improver (Cepro 100, 2-ethylhexyl nitrate) was added to the fuel blends with aromatic volumes of 20% and 30% to achieve a cetane number (CN) close to that of the value of the reference fuel. The amount of Cepro 100 to be added was decided from results of CN analysis tests of fuel blends at the accredited laboratory, Saybolt, which also made the fuel analyses using standard SS115166-93 for content of aromatics, EN-ISO 8754 for sulfur content, and ASTM D 7111-11 for metals.

|

|

Table 1 Properties of reference fuels (MK1 and VSD10), fuel blends with higher content of aromatics (arom.), and aromatic mixture Caromax 28. (n.a = "not analyzed") |

For Campaign 1, measurements were conducted at engine loads of 10%–12%, 27%–29%, and 38%–40% of the Maximum Continuous Rate (MCR), with engine speeds of 1780–1790 r/min and at idle with 700 r/min. For Campaign 2, measurements were conducted at engine loads of 10%, 26%–27%, and 50%–51% of MCR at 2010 r/min and at idle with 700 r/min. At each load, the engine worked for 30–40 minutes. Engine loads were selected to be representative of those used in coastal and port areas and when ships operate at sea and run more than one main engine.

Several operating conditions were investigated during Campaign 3. Only two operating conditions are presented here to demonstrate the effects of aromatics. These points are named A25 and C75. For A25 the torque was 78 N·m, engine speed 1200 r/min, injection pressure 1800 bar, injection duration 660 μs, start of injection 4.5° before to dead center and EGR was 29%. For C75 the torque was 186 Nm, engine speed 1800 r/min, injection pressure 1800 bar, injection duration 1300 μs, start of injection 4.5° before to dead center and EGR was 22%. These operating points have earlier been used for this test-bed engine (see Zhang et al., 2015). Due to the difference in the size and number of cylinders (multi-cylinder vs. single-cylinder) between the test-bed engines used, it was not possible to use the same operating points during Campaign 3 as for Campaigns 1 and 2. The load profile used during Campaign 3 was part of that used for the European Stationary Test Cycle.

2.2 Experimental set-upSimilar experimental set-up was used for Campaigns 1 and 2. The aerosol instruments used were an Engine Exhaust Particle Sizer (EEPS, Model 3090, TSI Inc.) that measures particles in a size range of 5.6–560 nm, and a Dust Monitor (Model 1.108, Grimm) that measures particles in a size range of 300 nm to over 20 μm in diameter. The EEPS classifies particles in relation to their differential electrical mobility (TSI, 2006). The Grimm, an optical instrument, uses light scattering to count the number of particles and classify them into different sizes (Grimm Aerosol Technik GmbH & Co KG, 2010). The instruments were simultaneously used to make the measurements. A thermodenuder (TD, Dekati) heated to 300℃ was used to study thermal characteristics of emitted particles, and was coupled in a series before the EEPS and Grimm with a bypass option. Measurements at each load were made both with and without the TD. For Campaign 3, a DMS500 (Differential Mobility Spectrometer) from Cambustion was used to conduct particle measurements. This instrument measures particles in a size range of 4.87–1000 nm. Similar to the EEPS, this instrument also use the differential electrical mobility of particles to classify them into different sizes (Symonds, Reavell, Olfert, Campell, & Swift, 2007). A TD, developed at the Department of Chemistry and Molecular Biology, University of Gothenburg, was heated to 300℃ and used to study the thermal characteristics of the emitted particles during these measurements. In addition, filter sampling using Teflon filters (PTFE filters) was conducted during Campaign 1 and 2 at the highest engine loads. These filters were used for subsequent gravimetric analyses of Total Suspended Particles (TSP) (conducted at an accredited lab); analysis of black carbon (BC) content using a visible light reflectometer (part of the beta gauge monitor FH62 I-N, ESM Emberline, Germany) (Pettersson et al., 2011); and in elemental analyses using Energy Dispersive X-Ray Fluorescence (EDXRF) (Boman, 2009).

For all three Campaigns, a fine particle sampler (FPS, Model 4000, Dekati) was used as the dilution system and connected directly to the exhaust gas channel. The FPS extracted the aerosol samples via a fixed inlet (Apex instruments) in Campaigns 1 and 2, and via a perforated sampling pipe (6 mm in diameter) placed in a perpendicular position to the exhaust gas flow in Campaign 3. The FPS diluted the raw exhaust gas sample in two steps: the primary dilution step in a perforated tube with preheated, clean and dry air (240-300℃, i.e., the temperature of the raw exhaust gas) and the second dilution step with clean air of ambient temperature. In addition, an ejector diluter drew the sample from the primary dilution section. Residence time in the system was below 0.5 seconds (Dekati, 2010). The dilution ratios used during Campaign 1 varied from 30 to 82 for the different tests and for Campaign 2 37-57. In Campaign 3 the dilution ratio during experiments with VSD10 diesel was 209-400, and for experiments with aromatics 133-184.

Measurements of standard gaseous emissions (NO, NOx, SO2, CO2, CO, and O2) were made in parallel with aerosol measurements (Fuji Electric Model ZRE NDIR-analyzer, Fuji Electric Systems Co, Ltd, Japan for Campaigns 1 and 2, and with an AVL AMA i60 exhaust measuring system for Campaign 3). To determine the correct dilution ratio, the concentration of NO and/or NOx was measured both in raw exhaust and in the diluted exhaust gases; for the latter, a chemiluminescence instrument (TH42i, Thermo Scientific) with a low range of 0–20 ppm was used.

2.3 Data analysisData obtained from measurements were analyzed for stable conditions. Data were corrected for the dilution ratio used, and size-dependent particle losses within the TD were accounted for by following manufacturer instructions (Campaigns 1 and 2) or from experimental studies (Campaign 3). Particle emissions were analyzed with respect to Particle Number (PN) concentration, Particle Mass (PM) concentration, size distribution by number, volatility, and for Campaign 1 the content of BC and inorganic compounds. Emission Factors (EFs) were calculated for both PN, PM, and size-resolved PN of total particle emissions and non-volatile fraction. The EFPM from online measurements was calculated with the assumption of spherical particles with unit density. However, the density of diesel-generated particles differs from unity and are dependent on particle size and content of condensable compounds (Ahlvik et al., 1998; Barone et al., 2011; Olfert et al., 2007; Park et al., 2003; Virtanen et al., 2002). Calculations were based on the IMO NOx Technical Code (IMO, 2009), and were made using the flow through the exhaust gas channel and included values for engine load and fuel consumption from readings of data in the engine control system.

As mentioned in Section 2.2, different aerosol instruments were used to obtain measurements in the two separate test-bed engine labs. The absolute values of particle emissions measured using these three different instruments are not compared here (for example, the size distributions shown in Figs. 2 and 5); firstly, because measurements were based on the use of different technologies that measure different particle sizes, and secondly because they were made using two different test-bed engines. Results from measurements made with the EEPS and Grimm were used to calculate the EFs of PN and PM in Campaigns 1 and 2 (Section 3.1). Data from measurements made with the DMS500 in Campaign 3 are mainly used to discuss how the combination of various engine parameters with the content of aromatics in fuel effect particle emissions (Section 3.2).

|

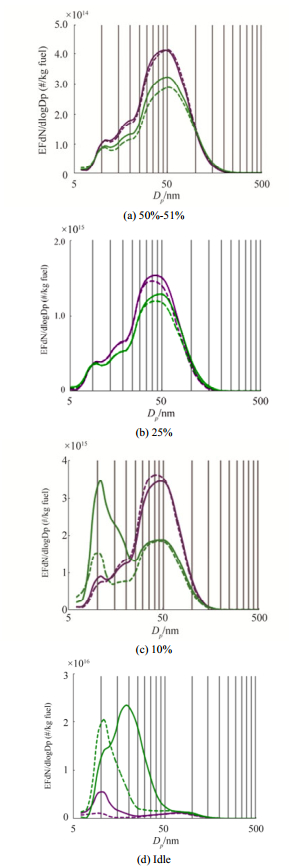

Figure 2 Size-resolved emission factors for PN (EEPS-measurements, 5.6–560 nm) at: a) 50% engine load; b) 25% load; c) 10% load; and d) idle during Campaign 2 for MK1 (purple) and fuel-blend with 30% aromatics (green) Solid lines represent total particle emissions and dashed lines are non-volatile fraction |

|

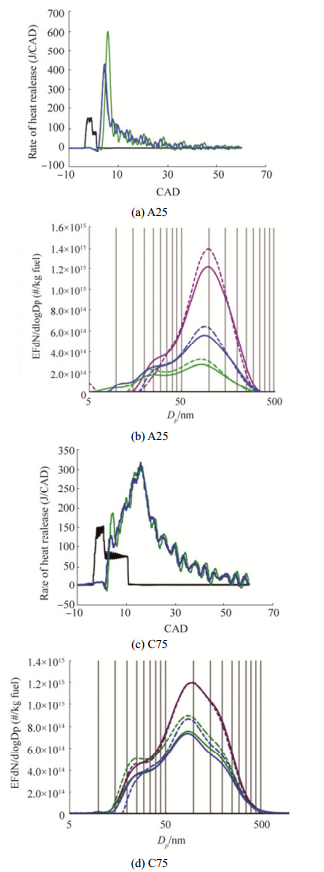

Figure 5 Rate of heat release (a, c) and size-resolved EFPN (b, d, DMS-measurements) during operation at load point A25 (a, b) and C75 (c, d) for reference fuel (purple), fuel-blend with 30% vol aromatics (green), and fuel-blend with 30% vol aromatics plus ignition improver (blue) Solid lines in (b) and (d) represent total particle emissions; dashed lines represent non-volatile fraction; solid black line in (a) and (c) represent injection signal at that engine condition |

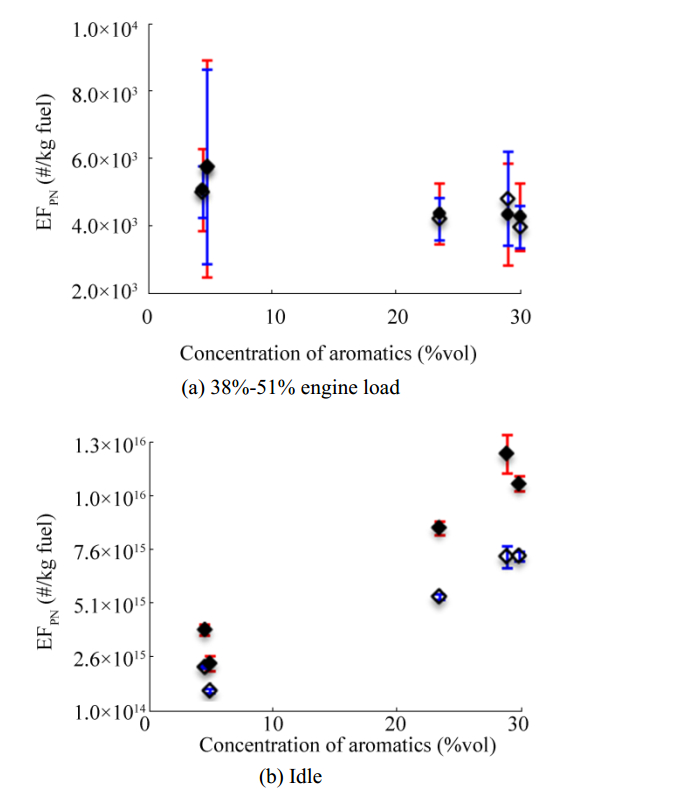

The measurements of particles (diameter (Dp) range 5.6–560 nm) show a higher PN emission tendency for MK1 than for the fuel blends with 23% or 30% aromatics (with respect to total particle number emissions and for the non-volatile fraction) for all engine loads (38%–51% (Fig. 1(a)), 26%–29%, and 10%–12%) except for idle. The same trend can be seen regardless of whether emissions are related to either engine load or fuel consumption (#/kWh vs. #/kg fuel). Furthermore, particle emissions consist mainly of a non-volatile fraction. Operation at idle resulted in the opposite trend: increased particle emissions with increased content of aromatics in the fuel, and a higher fraction of volatile compounds compared with at higher engine loads (Fig. 1(b)). For larger particles (in the size range 0.3 to > 20 μm) measured at a 38%-50% engine load and at idle, similar trends can be seen as for particles in the size range 5.6-560 nm..

|

Figure 1 Emission factors for PN (EEPS-measurements, 5.6–560 nm): total-PN (filled) and non-volatile fraction of PN, (unfilled) relate to content of aromatics at 38–51% engine load (a) and idle (b) The error bars represent one standard deviation (red for total emission and blue for non-volatile fraction). Note the scale on the y-axis |

The trends seen for EFPN are also seen for the size-resolved emission factors for PN presented in Fig. 2. Operation at the two higher engine loads (50% and 25%) using MK1 results in a higher emission of particles of all sizes between 5.6-560 nm; size distributions have a pronounced peak at 45-52 nm and a small peak at 10 nm (Fig. 2(a) and 2(b)). Fuel blends with a higher content of aromatics show a similar pattern. However, a decrease in engine load to 10% (Fig. 2c) or idle (Fig. 2d) changes the size distribution from that of a unimodal character to a more bimodal character, and an increased content of aromatics results in higher EFs for smaller particles, i.e., Dp 5.6-22 nm for a 10% engine load with peak at 10 nm for total particle emissions. Furthermore, at a 10% engine load the combustion of MK1 results in higher emissions for particles with Dp > 25 nm than the combustion of fuel blends. An increased content of aromatics at idle results in higher EFs for particles in the range 5.6-52 nm, with a peak at 19 nm for total particle emissions. A shift toward smaller particles can be seen for the non-volatile fraction, which shows a peak at 10 nm.

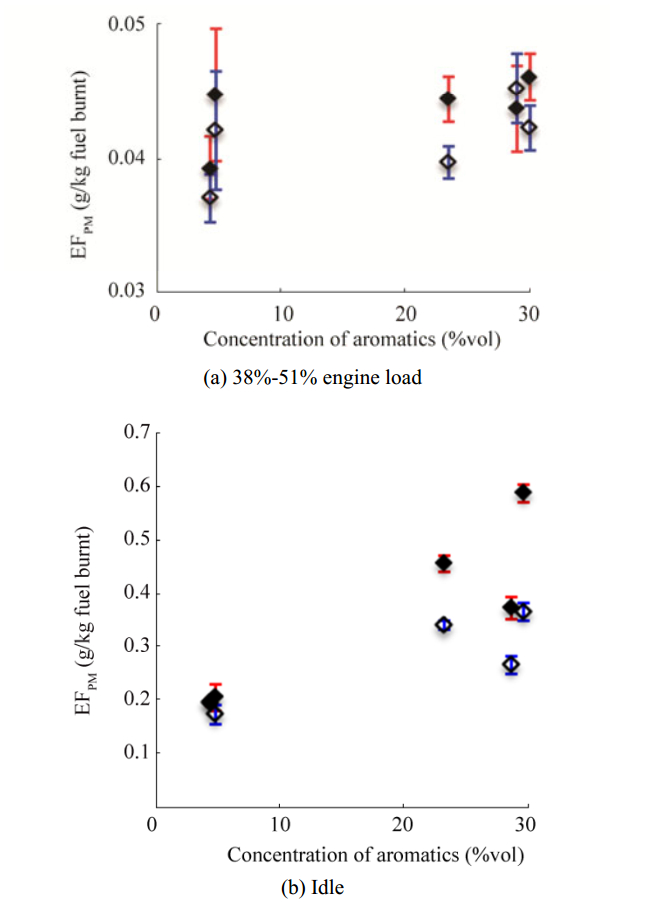

Operating at 38%–51% and 26%–29% engine loads results in no significant difference between EFPM values for MK1 or the fuel blends. At higher engine loads the EFPM values vary between 0.034–0.04 g/kg fuel for MK1 and 0.039-0.042 g/kg fuel for the fuel blends (Fig. 3(a)); corresponding values for engine loads of 26%–29% are 0.06-0.09 g/kg fuel for MK1 and 0.05-0.1 g/kg fuel for the fuel blends). EFs for TSP from filter sampling show a trend toward a lower mass of TSP for the fuel blends than for MK1 (0.06–0.08 g/kg fuel for fuel blends and 0.09–0.13 g/kg fuel for MK1).

|

Figure 3 Emission factors for PM (EEPS-measurements, 5.6 –560), total-PM (filled) and non-volatile fraction of PM, (unfilled) related to content of aromatics for 38%–51% engine load (a) and idle (b) The error bars represent one standard deviation (red for total emission and blue for non-volatile fraction). Note the scale on the y-axis |

At 10%–12% engine loads, there is a trend towards an increase in emissions for PM with a reduced content of aromatics (EFPM for MK1 0.2 g/kg fuel and for fuel blends 0.1–0.14 g/kg fuel). An increase of EFPM, both for total particle emissions and for the non-volatile fraction, with an increased content of aromatics is found while the engine is at idle (Fig. 3(b)); this is related to an increase in emissions of particles both with Dp 15–52 nm and around 100 nm (Fig. 4). The size distribution by mass for 50%, 25%, and 10% engine loads shows the same pattern, with a peak at 90–110 nm, but there is no significant difference between the different fuels at the two higher engine loads. At a 10% engine load, MK1 results in higher emissions than the fuel-blend. There are small differences in EFPM for the reference fuel. Small differences in EFPM for the reference fuel and fuel-blends with a higher content of aromatics were reported from other studies as well (Den Ouden et al., 1994; Neill et al., 2000). Other studies, however, show a tendency of an increase in EFPM for fuel blends with a higher content of aromatics (Kidoguchi et al., 2000; Tan et al., 2013; Tsurutani et al., 1995) as is seen in this study for idling (Fig. 3(b)).

|

Figure 4 Size-resolved emission factors for PM (EEPS-measurements, 5.6–560 nm) at idle during Campaign 2 for MK1 (purple) and fuel-blend with 30% aromatics (green) Solid lines represent the total particle emission and dashed lines the non-volatile fraction |

A higher content of aromatics does not result in higher emissions of BC (EFBC for MK1 34 mg/kg fuel and for fuel blends 33–36 mg/kg fuel). Furthermore, similar levels of inorganic elements are found in the emitted particles using MK1 and the fuel blends (zinc 0.25-0.29 mg/kg fuel, iron 0.34-0.39 mg/kg fuel and nickel 0.40-0.53 mg/kg fuel). The exception was Ca, for which a higher content of Ca was found in the particles from the fuel-blend with an aromatic concentration of 30% vol (0.13 mg/kg fuel for fuel blend compared to below detection limit for reference fuel). However, there are no differences in the content of inorganic elements between MK1 and the fuel blends (Table 1), and the higher content of Ca is therefore probably related to the lubrication oil.

Both EFPN and EFPM increase with a reduced engine load, independently of the fuel or the aromatic content. However, higher EFPN and EFPM can be seen for the fuel blends than for MK1 at idle (Figs. 1(b) and 3(b)). Furthermore, there is an increase in the difference between total particle emissions and the non-volatile fraction with reduced engine load. It is considered that the changes in EFs and the amount of volatile compounds in emissions may be related to reduced temperatures in the exhaust gases and increased incomplete combustion (due to over-leaning) with a reduced engine load; the reduced temperatures in the exhaust gases and the increased incomplete combustion enhance the formation of new particles (nucleation) from the unburnt fuel and lubrication oil. In addition, volatile compounds, such as organic compounds, may also condense and adsorb onto the existing particles (Kittelson, 1998) and cause increased PM. It is also considered that a high concentration of aromatics in the fuel blends may contribute to higher nucleation and a greater number of volatile compounds, which can condense on existing particles when the engine load is reduced. This explains why EFPN and EFPM are higher for the fuel blends than for MK1 at idle. A rather low dilution ratio, both primary and totally, may also have an influence on the increased amount of volatile compounds during idle (see section 2.2).

3.2 Campaign 3The measurements conducted in Campaigns 1 and 2 show that an increase in the content of aromatics in fuel does not necessarily increase the emissions of particles, except for when the engine is operating at idle. One possible explanation for these results is that the increased content of aromatics reduces the CN of the fuel, which increases the ignition delay and leads to a longer amount of time for pre-mixing of the fuel and the air injected into the cylinder and a therefore reduce the formation of soot (Kidoguchi et al., 2000). Furthermore, this would increase the temperature and pressure in the cylinder and consequently also increase the oxidation of the soot formed. To follow-up measurements made using the marine engine and investigate the impact of aromatics and CN on the combustion process, additional measurements were conducted (Campaign 3). In addition to comparing fuels with different aromatic contents, an ignition improver was used with the aim of separating the effect of combustion timing from the effect of the fuel itself. Fig. 5 presents the results for two load points (A25, low speed and low load; C75, high load and high speed) for the reference fuel (VSD10 diesel), the fuel-blend with 30 %vol. aromatics, both with and without ignition improver added. In Figs. 5(b) and 5(d), emissions of the non-volatile fractions are higher than total particle emissions. This may be because the differences between these two emissions were low and there were low amounts of volatile compounds in the emissions. Furthermore, the compensation factors used in experiments with TD add uncertainty, and it is thus considered that the small difference lies within the range of uncertainty implicit in experiments.

Measurements show a similar trend to those observed for the marine engine: combustion of reference fuel results in higher emissions of particles than fuel blends with a higher content of aromatics (Figs. 5(b) and 5(d)). The measurements confirm that an increased content of aromatics causes increased ignition delay, with a higher peak pressure in the cylinder during combustion and faster combustion (rate of heat release), which was also seen in a previous study (Fukuda et al., 1992) (Figs. 5(a) and 5(c)).

This effect is most evident at a low load (Fig. 5a); the low load case was dominated by pre-mixed combustion (injection ended before combustion began), and hence the effect of ignition delay (adjusted by addition of ignition improver) is evident.

The addition of an ignition improver to increase the CN to a similar level as that in the reference fuel (VSD10) results in a very similar pattern in the rate of heat release as with the reference fuel (Figs. 5(a) and 5(c)) (The graphs for reference fuel and fuel-blend with 30%vol aromatics plus ignition improver are quite similar in Figs. 5a and 5c and they are difficult to distinguish between.). However, there is not a similar increase in particle emissions as with the reference fuel (Figs. 5(b) and 5(d)). There is a low (or zero) impact on particle emissions when the ignition improver is added; as reported in an earlier study (Tsurutani et al., 1995). For the high load case, there is a reduction in the difference in PN emissions between when ignition improver is added and when it is not (Fig. 5d). As seen in the injection trace (solid black line in Figs. 5(a) and 5(c)), a large quantity of fuel is injected during combustion (i.e. mixing controlled combustion), which explains why the effect of the ignition improver is reduced. These results emphasize the impact of a multitude of factors on particle emissions. In addition, the physical properties of fuel (viscosity, heat of vaporization/volatility) are evidently important factors for mixing air and fuel prior to ignition. Furthermore, the density of fuel, in combination with the gas density, may affect the spreading angle of the injected fuel (Siebers, 1999). It is also considered that the chemical properties of the fuel mixture, including the composition and molecular structure of the aromatics and other hydrocarbons in the fuel, may also be important (Brem et al., 2015; Fukuda et al., 1992; Zannis et al., 2008).

4 Maritime implications and discussionThe objective of this study was to consider the results of above-described measurements from a maritime perspective. Therefore, it is necessary to draw firm conclusions from this study in relation to how aromatics in the fuel affect particle emissions from in-use marine diesel engines, and how such results depend on the engines and fuels used in this study. However, the two test-bed engines used do not represent main engines used on-board ocean-going ships, and the reference fuels used (MK1 or VSD10) are not typical marine fuels. Unfortunately, it is difficult to perform such experiments on-board actual ships due to safety concerns, and this necessitates the use of test-bed engine lab facilities. Furthermore, using marine fuel oil would increase the influence of other fuel characteristics on particle emissions, and would thus make it difficult to solely investigate the impact of aromatics. The use of MK1 as a reference fuel made the experiment possible, as it has a low fuel sulfur content and other compounds such as carbon residue that may influence the formation and growth of particles during and after combustion. The content of sulfur in marine fuel is at least 0.1 wt-%, compared to the amount (ppm) in MK1, and the carbon residue in a HFO can be around 7.00 wt-% (while it is below 0.20 wt-% for the MK1 used in the fuel-blend here).

The fuel blends investigated in this study have a comparable content of aromatics (total) to those in marine fuel oils, such as HFO and low-sulfur residual oils used on-board operating ships. The CN achieved in the fuel-blend with 29% aromatics is similar to that defined for marine diesel oil and marine gas oil, according to ISO 8217:2010 (Vermeire, 2012). However, for most cases it is unknown which types of aromatics are contained in marine fuel oils, and, as mentioned in Section 3.2, the molecular structure of the aromatics may affect the emissions. The aromatic solution used for the experiments in this study mainly consisted of mono and diaromatics. Although marine fuels have a considerable content of polyaromatics, which are thought to contribute to formation and growth of particles. However, the results from this study indicate that a higher content of aromatics does not necessarily result in increased particle emissions, and that other factors (such as engine operating parameters and other fuel characteristics) also need to be considered. For example, when ships change fuel upon entering or leaving a SECA, the engine operating parameters are not changed. This may affect the emissions, as different fuels result in different spray patterns (for example). A combination of all these parameters (the engine, its operating parameters, and fuels) make it difficult to provide an indication of how the combustion of marine fuel oils will affect particle emissions.

The validity of the results from this study is strengthened by the fact that measurements followed similar trends even though tests were conducted using two different test-bed engines. This trend can also be seen in earlier measurements conducted with marine fuel oils (HFO and MDO) using the same test-bed engine (with unchanged engine operating parameters between the fuels) as that used in Campaigns 1 and 2 in this study (Table 2) (Anderson et al., 2015). As shown in Table 2, the combustion of marine fuel oils with lower aromatic contents than a fuel-blend with 29 %vol. aromatics causes higher particle emissions. Furthermore, the combustion of HFO results in higher emissions of BC (112 mg/kg fuel for HFO, 10 mg/kg fuel for MDO and 33-36 mg/kg fuel for fuels included in these experiments). Consider the inorganic elements; combustion of HFO resulted in higher content of calcium, zinc, iron and vanadium in the particles than combustion of MK1 and the fuel blends used here. The content of nickel in the particles was on similar level independently of fuel type/blend (Anderson et al., 2015).

|

|

Table 2 Fuel properties for HFO, MDO, and the fuel-blend used in Campaign 2 and calculated emission factors for PN (total emissions (wo TD) and for non-volatile fraction (w TD)) for 35%-50% engine load and at idle |

The objective of this study is to investigate whether an increased content of aromatics influenced the number of particles emitted. The impact of the aromatic content of fuel on particle emissions is investigated through experiments in two different test-bed engine lab facilities. Measurements performed under the above-described conditions show that combustion of fuel blends with a higher content of aromatics results in a lower (or an unchanged) particle emissions compared to the reference fuel, for all engine loads except at idle. This is in part a consequence of the reduced CN in the fuel blends, which increase the ignition delay and consequently increase the time involved in pre-mixing of injected fuel and air, thereby reducing the formation of particles in the cylinder. However, the addition of ignition improver to retain the CN present in fuel blends presented the same results, but to a smaller extent. Thus, the physical properties of aromatic fuel blends result in lower particle emissions at the engine operating conditions presented here.

When the aim is to understand the implications of one specific factor (in this case the aromatic content in the diesel fuel), it is important to consider the interdependencies of the various fuel properties and the internal combustion engine. In this study, the effect of ignition delay (degree of pre-mixing) and the rate of heat release are analyzed to improve understanding. However, the detailed underlying phenomena involved in explaining (and possibly also predicting) particle emissions from marine engines are still far from understood. It is considered that these types of experiments are important from academic, industrial, and regulatory perspectives. Furthermore, this study indicates the importance of considering the combustion process and other fuel characteristics when conducting future particle emission studies.

AcknowledgmentThe authors would like to acknowledge Ǻngpanneföreningen's Foundation for Research and Development (11-164), the Foundation for Swedish Environmental Research Institute (SIVL), and Swedish Maritime Organization and Lighthouse for their financial support. Kjell Peterson and Håkan Salberg, IVL, are gratefully acknowledged for their assistance during the various experimental Campaigns. We would also like to thank Timothy Benham, of the Department of Applied Mechanics, Chalmers University of Technology, for operating the engine and for assistance during Campaign 3. Furthermore, Preem is acknowledged for their support with the aromatic mixture, Caromax28, and we would also like to thank Xiangyu Pei from the Department of Chemistry and Molecular Biology at Gothenburg University for providing the thermodenuder during Campaign 3.

Ahlvik P, Ntziachristos L, Keskinen J, Virtanen A. Real time measurements of diesel particle size distribution with an electrical low pressure impactor[J]. SAE Technical Paper Series, 1998: 980410. ( 0) 0)

|

Anderson M, Salo K, Hallquist ÅM, Fridell E. Characterization of particles from a marine engine operating at low loads[J]. Atmospheric Environment, 2015, 101: 65-71. DOI:10.1016/j.atmosenv.2014.11.009 ( 0) 0)

|

Barone TL, Lall AA, Storey JME, Mulholland GW, Prikhodko VY, Frankland JH, Parks JE, Zachariah MR. Size-resolved density measurements of particle emissions from an advanced combustion diesel engine:effect of aggregate morphology[J]. Energy & Fuels, 2011, 25(5): 1978-1988. DOI:10.1021/ef200084k ( 0) 0)

|

Beecken J, 2015. Remote measurements of gas and particulate matter emissions from individual ships. PhD thesis, Chalmers University of Technology, Göteborg, Sweden. http://trid.trb.org/view/1463109

( 0) 0)

|

Boman J. Trace element analysis of urban aerosol particles using X-ray fluorescence spectrometry[J]. Spectroscopy Europe, 2009, 21(6): 11-14. ( 0) 0)

|

Brem BT, Durdina L, Siegerist F, Beyerle P, Bruderer K, Rindlisbacher T, Rocci-Denis S, Andac MG, Zelina J, Penanhoat O, Wang J. Effects of fuel aromatic content on nonvolatile particulate emissions of an in-production aircraft gas turbine[J]. Environmental Science & Technology, 2015, 49(22): 13149-13157. DOI:10.1021/acs.est.5b04167 ( 0) 0)

|

Corbett JJ, Winebrake J, Green EH, Kasibhatla P, Eyring V, Lauer A. Mortality from ship emissions:a global assessment[J]. Environmental Science & Technology, 2007, 41(24): 8512-8518. ( 0) 0)

|

Dekati, 2010. Dekati FPS-4000, Fine Particle Sampler. Tampere, Finland

( 0) 0)

|

Den Ouden CJJ, Clark RH, Cowley LT, Stradling RJ, Lange WW, Maillard C. Fuel quality effects on particulate matter emissions from Light-and heavy duty diesel engines[J]. SAE Technical Paper Series, 1994: 942022. ( 0) 0)

|

Diesch JM, Drewnick F, Klimach T, Borrmann S. Investigation of gaseous and particulate emissions from various marine vessel types measured on the banks of the Elbe in Northern Germany[J]. Atmospheric Chemistry and Physics, 2013, 13(7): 3603-3618. DOI:10.5194/acp-13-3603-2013 ( 0) 0)

|

Fukuda M, Tree DR, Foster DE, Suhre BR. The effect of fuel aromatic structure and content on direct injection diesel engine particulates[J]. SAE Technical Paper Series, 1992: 920110. ( 0) 0)

|

Grimm Aerosol Technik GmbH & Co KG, 2010. Portable laser aerosol spectrometer and dust monitor model 1. 108/1. 109. Ainring, Germany.

( 0) 0)

|

Hart H, Craine LE, Hart DJ, 1999. Organic Chemistry, a Short Course. Stratton R, Blodget N, Eds. 10th ed. Houghton Mifflin Company, USA.

( 0) 0)

|

IMO, 2009. Revised MARPOL Annex Ⅵ and NOx Technical Code 2008: Regulations for the prevention of air pollution from ships.

( 0) 0)

|

IMO, 2013. MARPOL Annex Ⅵ and NTC 2008 with guidelines for implementation 2013 edition. London, UK.

( 0) 0)

|

Kasper A, Aufdenblatten S, Forss A, Mohr M, Burtscher H. Particulate emissions from a low-speed marine diesel engine[J]. Aerosol Science and Technology, 2007, 41(1): 24-32. DOI:10.1080/02786820601055392 ( 0) 0)

|

Kidoguchi Y, Yang C, Kato R, Miwa K. Effects of fuel cetane number and aromatics on combustion process and emissions of a direct-injection diesel engine[J]. JSAE Review, 2000, 21: 469-475. DOI:10.1016/S0389-4304(00)00075-8 ( 0) 0)

|

Kittelson DB. Engines and nanoparticles:a review[J]. Journal of Aerosol Science, 1998, 29(5-6): 575-588. DOI:10.1016/s0021-8502(97)10037-4 ( 0) 0)

|

Kivekäs N, Massling A, Grythe H, Lange R, Rusnak V, Carreno S, Skov H, Swietlicki E, Nguyen QT, Glasius M, Kristensson A. Contribution of ship traffic to aerosol particle concentrations downwind of major shipping lane[J]. Atmospheric Chemistry and Physics, 2014, 14: 8255-8267. DOI:10.5194/acp-14-8255-2014 ( 0) 0)

|

Lack DA, Cappa CD, Langridge J, Bahreini R, Buffaloe G, Brock C, Cerully K, Coffman D, Hayden K, Holloway J, Lerner B, Massoli P, Li SM, McLaren R, Middlebrook AM, Moore R, Nenes A, Nuaaman I, Onasch TB, Peischl J, Perring A, Quinn PK, Ryerson T, Schwartz JP, Spackman R, Wofsy SC, Worsnop D, Xiang B, Williams E. Impact of fuel quality regulation and speed reductions on shipping emissions:implications for climate and air quality[J]. Environmental Science & Technology, 2011, 45(20): 9052-9060. DOI:10.1021/es2013424 ( 0) 0)

|

Lack DA, Corbett JJ, Onasch T, Lerner B, Massoli P, Quinn PK, Bates TS, Covert DS, Coffman D, Sierau B, Herndon S, Allan J, Baynard T, Lovejoy E, Ravishankara AR, Williams E. Particulate emissions from commercial shipping:Chemical, physical, and optical properties[J]. Journal of Geophysical Research, 2009, 114: 2156-2202. DOI:10.1029/2008jd011300 ( 0) 0)

|

Ladommatos N, Rubenstein P, Bennett P. Some effects of molecular structure of single hydrocarbons on sooting tendency[J]. Fuel, 1996, 75(2): 114-124. DOI:10.1016/0016-2361(94)00251-7 ( 0) 0)

|

Lee R, Pedley J, Hobbs C. Fuel quality impact on heavy duty diesel emissions:a literature review[J]. SAE Technical Paper Series, 1998: 982649. ( 0) 0)

|

Merico E, Donateo A, Gambaro A, Cesari D, Gregoris E, Barbaro E, Dinoi A, Giovanelli G, Masieri S, Contini D. Influence of in-port ships emissions to gaseous atmospheric pollutants and to particulate matter of different sizes in a Mediterranean harbour in Italy[J]. Atmospheric Environment, 2016, 139: 1-10. DOI:10.1016/j.atmosenv.2016.05.024 ( 0) 0)

|

Miyamoto N, Ogawa H, Shibuya M. Distinguishing the effects of aromatic content and ignitability of fuels in diesel combustion and emissions[J]. SAE Technical Paper Series, 1991: 912355. ( 0) 0)

|

Neill SW, Chippior WL, Gülder ÖL, Cooley J, Richardson KE, Mitchell K, Fairbridge C, 2000. Influence of fuel aromatics type on the particulate matter and NOx emissions of a heavy-duty diesel engine. SAE Technical Paper Series, 2000-01-1856. http://papers.sae.org/2000-01-1856/

( 0) 0)

|

Olfert JS, Symonds JPR, Collings N. The effective density and fractal dimension of particles emitted from a light-duty diesel vehicle with a diesel oxidation catalyst[J]. Journal of Aerosol Science, 2007, 38: 69-82. DOI:10.1016/j.jaerosci.2006.10.002 ( 0) 0)

|

Park K, Cao F, Kittelson D, McMurry PH. Relationship between particle mass and mobility for diesel exhaust particles[J]. Environmental Science & Technology, 2003, 37(3): 577-583. ( 0) 0)

|

Pettersson JBC, Kovacevik B, Wagner A, Boman J, Laursen J. Elemental composition of fine particulate matter (PM2.5) in Skopje, FYR of Macedonia.[J]. X-Ray Spectrometry, 2011, 40: 280-288. DOI:10.1002/xrs.v40.4 ( 0) 0)

|

Siebers DL, 1999. Scaling liquid-phase fuel penetration in diesel sprays based on mixing-limited vaporization. SAE Technical Paper Series, 1999-01-0528. http://papers.sae.org/1999-01-0528/

( 0) 0)

|

Sjöblom J. Combined effects of late IVC and EGR on low-load diesel combustion[J]. SAE Int. J. Engines, 2015, 8(1): 60-67. DOI:10.4271/2014-01-2878 ( 0) 0)

|

Stone R, 2012. Introduction to internal combustion engines. 4th ed. Palgrave Macmillan, England. https://link.springer.com/book/10.1007/978-1-349-22147-9?no-access=true

( 0) 0)

|

Svensson E, 2011. The regulation of global SOx emissions from ships. IMO Proceedings 1988-2008. (Licentiate of Philosophy), Chalmers University of Technology, Göteborg, Sweden, 11: 127. http://publications.lib.chalmers.se/publication/140528

( 0) 0)

|

Symonds JPR, Reavell KSJ, Olfert JS, Campell BW, Swift SJ. Diesel soot mass calculation in real-time with a differential mobility spectrometer[J]. Journal of Aerosol Science, 2007, 38: 52-68. DOI:10.1016/j.jaerosci.2006.10.001 ( 0) 0)

|

Tan P-q, Zhao J-y, Hu Z-y, Lou D-m, Du A-m, Du D-m. Effects of fuel properties on exhaust emissions from diesel engines[J]. Journal of Fuel Chemistry and Technology, 2013, 41(3): 347-355. DOI:10.1016/s1872-5813(13)60021-3 ( 0) 0)

|

Tree DR, Svensson KI. Soot processes in compression ignition engines[J]. Progress in Energy and Combustion Science, 2007, 33(3): 272-309. DOI:10.1016/j.pecs.2006.03.002 ( 0) 0)

|

TSI, 2006. Model 3090 Engine Exhaust Particle Sizer Spectrometer, Operation and Service Manual, P/N 1980494, Revision E. Retrieved from USA.

( 0) 0)

|

Tsurutani K, Takei Y, Fujimoto Y, Matsudaira J, Kumamoto M. The effects of fuel properties and oxygenates on diesel exhaust emissions[J]. SAE Technical Paper Series, 1995: 952349. ( 0) 0)

|

Vermeire MB, 2012. Everything you need to know about marine fuels. Retrieved from Chevron Global Marine Products, Belgium.

( 0) 0)

|

Virtanen A, Ristimäki J, Marjamäki M, Vaaraslathi K, Keskinen J, 2002. Effective density of diesel exhaust particles as a function of size. SAE Technical Paper Series, 2002-01-0056. http://papers.sae.org/2002-01-0056/

( 0) 0)

|

Zannis TC, Hountalas DT, Papagiannakis RG, Levendis YA. Effect of fuel chemical structure and properties on diesel engine performance and pollutant emissions:review of the results of four European research programs[J]. SAE International Journal of Fuels and Lubricants, 2008, 1(1): 384-419. DOI:10.4271/2008-01-0838 ( 0) 0)

|

Zhang T, Munch K, Denbratt I. An experimental study on the use of butanol or octanol blends in a heavy duty diesel engine[J]. SAE International Journal of Fuels and Lubricants, 2015, 8(3): 610-621. DOI:10.4271/2015-24-2491 ( 0) 0)

|

2017, Vol. 16

2017, Vol. 16