2. Department of Marine Engineering, Federal University of Petroleum Resources, P.M.B. 1221, Effurun, Delta State, Nigeria;

3. Department of Mechanical Engineering, Federal University of Petroleum Resources, P.M.B. 1221, Effurun, Delta State, Nigeria

1 Introduction

The use of Liquefied Natural Gas (LNG) as a major energy source has resulted in an increase in the demand for LNG. In recent years, there has been a growing number of LNG carriers transporting LNG to meet global demands. LNG carriers are specialized vessels designed, constructed, and equipped to carry cryogenic LNG stored at a temperature of −162℃ at atmospheric pressure (Moon et al., 2009). While the carriers all have similar features, they differ in their tank designs (Nwaoha et al., 2013). These carriers can either have a membrane tank design, a structural prismatic tank design, or a spherical (moss) tank design (Nwaoha et al., 2013). Loading and discharging operations of LNG carrier cargo at LNG terminals is more complex than those of other vessels. The connection of loading arms, pressurizing and purging of the arms, securing the vessel, and checking the safeguard systems must be carried out prior to loading and discharging at the LNG terminal. These operations expose the involved personnel and environment to various high-risk hazards. Knowledge about the LNG carrier cargo-related precautions to be taken during loading and discharging operations can optimize the outcome of LNG carrier cargo operations and identify potential high-risk hazards.

Therefore, a viable qualitative and quantitative technique is necessary for this type of research. The analytic hierarchy process (AHP) has been demonstrated to be a useful qualitative and quantitative multi-criteria decision-making technique for application in various fields (Mishra et al. 2015; Socaciu et al. 2016; Singh and Nachtnebel, 2016; Arslan, 2009; Cheng, 1997; Liu and Hai, 2005; Shang and Sueyoshi, 1995; Takamura and Tone, 2003; Wang et al. 2008; Zhang and Cui, 1999; Rocha et al. 2016). Arslan (2009) utilized the AHP technique in a quantitative evaluation of the precautions used on chemical tanker operations. Cheng (1997) adopted the AHP method in combination with the fuzzy logic approach to evaluate a naval factual missile system. Liu and Hai (2005) employed the AHP method in their determination of the voting weighting criteria in the selection of suppliers. Shang and Sueyoshi (1995) used AHP methodology to quantify the elusive benefits associated with a manufacturing company’s cooperative and longterm objectives for a Flexible Manufacturing System (FMS). Takamura and Tone (2003) applied the AHP method to determine the weight criteria in a site evaluation study for relocating the Japanese government from Tokyo. Wang et al., (2008) incorporated the AHP method in determining the weight of criteria for a risk assessment of bridge structures. Zhang and Cui (1999) employed AHP in the development of a project evaluation system to determine a reasonable investment ratio in China.

Since the usefulness of AHP has been clearly demonstrated, we selected this method for use in this study. We detail the precautions associated with LNG carrier cargo operations in section 2, and describe the AHP methodology in section 3. In section 4, we apply AHP in the prioritization of the precautions of LNG carrier cargo operations, and in section 5 we draw our conclusions.

2 LNG Carrier cargo operation precautionsNegligence with respect to taking necessary precautions during LNG carrier cargo operations can result in adverse consequences. The safety and optimization of the operation must begin with a thorough understanding of the precautions required in order to avoid hazards and system failures. In this study, the necessary precautions to be taken by personnel involved in the LNG carrier cargo operations at the LNG terminal are specified in the ship/shore safety checklist, and are summarized as follows (ISGOTT, 2006):

● Berthing-related precautions: These are the actions required to be taken as the vessel comes alongside the terminal prior to cargo operations. They involve securing the vessel mooring lines, ensuring that the vessel is within an adequate distance in relation to the terminal loading arms, providing a safe access between the ship and terminal, and ensuring the ship-to-shore safety checklist is reviewed and signed by both vessel and shore representatives.

● Personnel and procedural precautions: These are the procedural precautions required by both shore and ship personnel before commencing LNG carrier cargo operation. Shore and ship personnel must ensure that the communication system is tested and understood, that the Emergency Shutdown Device (ESD) test procedures have been checked and are in place, and that the ship and shore smoking regulations pertaining to the operation are understood by all the personnel and a notice is clearly displayed that is visible to all.

● Cargo equipment precautions: These are the precautions necessary on the cargo equipment before operation commences. This includes correctly setting the cargo tank relief valve and gas detection equipment, confirmation of the stoppage of any gas burning operation, and ensuring the ship and shore loading arms are fitted with filters.

● Procedural precautions during operation: These are the precautions required when cargo operation commences, including the inerting of the hold and inter-barrier spaces, ventilating, and ensuring that all alarms are working in the compressor room, and monitoring the vessel shear forces, bending moment, and stability conditions during operation.

● Precautions regarding probable emergency situations: These are the precautions related to the readiness of the ship and shore personnel in the event of any emergency. They call for the presence of personnel onboard and ashore to address any emergency situation and that all emergency equipment is in position and ready for use.

In this study, we denote these precautions with the labels: LNG PRE1, LNG PRE2, LNG PRE3, LNG PRE4 andLNG PRE5 respectively. Other precautions relating to the LNG carrier cargo operations that are linked to LNG PRE1, LNG PRE2, LNG PRE3, LNG PRE4 andLNG PRE5 were identified by LNG experts. The list and meaning of the precautions associated with the LNG PRE1, LNG PRE2, LNG PRE3, LNG PRE4 andLNG PRE5 are as follows:

● Berthing-related precautions, LNG PRE1includes LNG PRE11 (is the ship securely moored), LNG PRE12 (is there safe access between the ship and shore), LNG PRE13 (is the ship/shore safety checklist agreed upon and signed), and LNG PRE14 (is the vessel in position relative to shore loading).

● Personnel and procedural precautions: LNG PRE2 includes LNG PRE21 (is the agreed ship/shore commutation system operative), LNG PRE22 (are the smoking regulations and agreed smoking area/notices displayed), LNG PRE23 (is the ESD valve timing carried out), and LNG PRE24 (confirmation of ship/shore ESD test procedure and checks).

● Cargo equipment precautions, LNG PRE3, includes LNG PRE31 (is the cargo tank relief valve set correctly), LNG PRE32 (is the gas detection equipment properly set), PRE33 (are filters fitted to the ship manifold and shore loading arm), and LNG PRE34 (is the stoppage of any gas burning operation confirmed).

● Procedural precautions during operation, LNG PRE4, include LNG PRE41 (are the hold and inter-barrier space properly inerted), LNG PRE42(is the compressor room properly ventilated and alarm working), LNG PRE43(is the stability of the shear force and bending moment/metacentric height (GM) during operation maintained), and LNG PRE44 (is the agreed maximum manifold pressure maintained).

● Precautions regarding probable emergency situations, LNG PRE5, include LNG PRE51 (are there sufficient personnel onboard and ashore to deal with an emergency), LNG PRE52 (is the ship emergency fire control plan located externally), LNG PRE53 (is there provision for emergency escape), and LNG PRE54 (are the fire hose and firefighting equipment onboard and ashore in position and ready for immediate use).

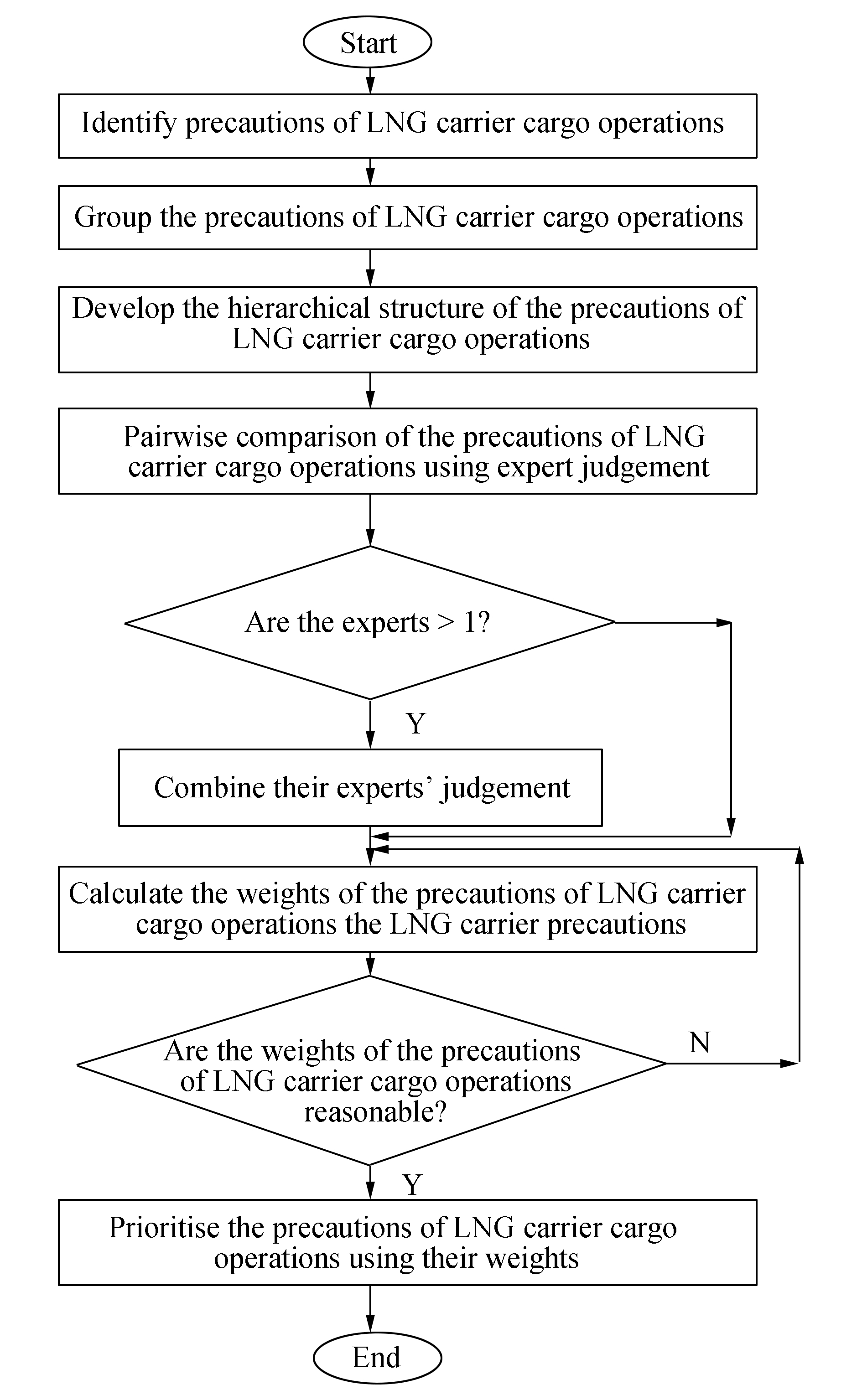

3 MethodologyThe safety record of LNG is associated with the technical competence of the personnel and their operational procedures (Hyde, 2006). The purpose of this research is to prioritize the precautions being taken during LNG carrier cargo operations to facilitate the identification of an appropriate management tool that can increase the level of operational safety. To this end, we propose an analytical tool such as the AHP technique for the prioritization of the precautions of LNG carrier cargo operations used to improve cargo operation safety and prevent the occurrence of accidents to personnel and the environment. The methodology used in this research is outlined in Fig. 1.

|

| Figure 1 Research methodology |

The information flow in Fig. 1 begins with the identification of precautions regarding the LNG carrier cargo operations, followed by the grouping of these precautions. The next step is to develop a hierarchical structure of the precautions, followed by the pairwise comparison of the precautions by expert judgement. If more than one expert is used in the pairwise comparison exercise, then their judgments are first combined and the weights of the precautions then calculated. In situations involving just one expert, no combination of judgements is needed prior to calculating the weights of the precautions. The next step is to check whether the weights of the precautions of the LNG carrier cargo operations are reasonable. If yes, the precautions are prioritized, otherwise the weights of the precautions are re-estimated before prioritization.

Analytic Hierarchy Process (AHP)

The AHP technique was developed by Satty (1980) to address complex multi-criteria decision-making problems. According to Wang et al. (2008), the AHP technique involves the ranking of a complex multi-criteria decision-making problem into a hierarchy, the provision of judgments about the relative importance of each criterion in the hierarchical structure by decision makers, determination of the overall priority, and the ranking of each criterion. This technique is based on the provision of judgments by a pairwise comparison of criterion (Anderson et al., 2015).

Procedures of the AHP methodology

The steps involved in the AHP methodology are described as follows:

● Define the decision-making problem.

● Develop a hierarchical structure of the defined decision-making problem.

● Using the pairwise comparison scale shown in Table 1, carry out a pairwise comparison of each level of criteria in the hierarchical structure of the defined decision-making problem.

| Numerical Value | Definition | Description |

| 1 | Equal importance | The level of importance of two LNG precautions is equal in LNG carrier cargo operations. |

| 2 | Between moderate and equal importance | The level of importance of two LNG precautions is between equal and moderate importance in LNG carrier cargo operations. |

| 3 | Moderate importance | LNG precaution is slightly important than another LNG precaution in LNG carrier cargo operations. |

| 4 | Between moderate and equal importance | LNG precaution is between moderately and strongly more important than another LNG precaution in LNG carrier cargo operations. |

| 5 | Strong importance | LNG precaution is strongly favored/more important than another LNG precaution in LNG carrier cargo operations. |

| 6 | Between strong and very strong importance | LNG precaution is between strongly and very strongly more important than another LNG precaution in LNG carrier cargo operations. |

| 7 | Very strong importance | LNG precaution is very strongly more important than another LNG precaution in LNG carrier operations. |

| 8 | Between very strong and extreme importance | LNG precaution is between strongly and very strongly more important than another LNG precaution in LNG carrier cargo operations. |

| 9 | Extreme importance | LNG precaution is extremely more important than another LNG precaution in LNG carrier cargo operations. |

| 2, 4, 6, 8 | Intermediate values | Intermediate values |

| 1/2, 1/3, 1/4, 1/5, 1/6, 1/7, 1/8, 1/9 | Reciprocals | Indicates the dominance of the second LNG precaution as compared with the first in LNG carrier cargo operations. |

● Using Eq. (1), combine the decision makers’judgements in the pairwise comparison exercise.

● Using Eq. (2), develop the pairwise decision matrix.

● Calculate the weight of each criterion using Eq. (3).

Average numerical value rating:

| $ X = \frac{{\sum\limits_{i = 1}^n {{a_i}} }}{n} $ | (1) |

ai=each value estimated by decision makers/experts for the same criterion.

n=total number of decision makers/experts involved in the pairwise comparison exercise.

| $ {\bf{{\rm \boldsymbol{H}}}} = \left[ {\begin{array}{*{20}{c}} 1&{{a_{12}}}& \cdots &{a{}_{1L}}\\ {1/{a_{12}}}&1& \cdots &{a{}_{2L}}\\ \vdots & \vdots & \cdots & \vdots \\ {1/{a_{1L}}}&{1/{a_{2L}}}& \cdots &1 \end{array}} \right] $ | (2) |

H=pairwise comparison n-by-n matrix.

The n-by-n matrix H serves as the quantified judgements of decision makers/experts on pairs of the LNG precautions Ai and Aj. In Eq. (2), two entry rules are utilized in the definition of the entries aij (i, j=1, 2…L). According to Riahi et al. (2012), these rules are as follows:

Rule 1. If aij=α, then aji=1/α, α ≠ 0.

Rule 2. If Ai is judged to be of equal relative importance as Aj, then aij=aji=1.

| $ {{\bf{\boldsymbol{w}}}_k} = \frac{1}{n}\sum\limits_{j = 1}^n {\left( {\frac{{{a_{kj}}}}{{\sum\limits_{i = 1}^n {{a_{ij}}} }}} \right)} \;\;\;\;\;\left( {k = 1,2,3 \ldots ,n} \right) $ | (3) |

wk=weight of a specific LNG precaution k in the pairwise comparison matrix.

aij=entry of row i and column j in a comparison matrix of order n.

The benefit of adopting the AHP technique is the ability to achieve consistency in the pairwise comparison exercise conducted by the decision makers/experts by the use of a consistency ratio (CR). If the value of the CR is less than or equal to 0.1, a reasonable consistency is indicated in the pairwise comparison of the judgment (Saaty, 1980). However, there is no mathematical proof supporting the idea that a CR value of less than or equal to 0.1 is the only acceptable solution (Karahalios et al., 2011). In view of this, Saaty suggested that the CR value could be near 0.2 when any attempt to reduce this value does not necessarily improve the judgement (Dadkhah and Zahedi, 1993; Wedley, 1993). Furthermore, it is difficult to achieve this value in real world problem-solving, because of the different opinions of the decision makers/experts (Karahalios et al., 2011). The CR is defined as follows:

| $ {\rm{CR = }}\frac{{{\rm{CI}}}}{{{\rm{RI}}}} $ | (4) |

where, CI=consistency index value and RI=random index value.

The RI values are shown in Table 2, and the CI values can be calculated using Eq. (5).

| $ {\rm{CI = }}\frac{{{\lambda _{\max }} - n}}{{n - 1}} $ | (5) |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| RI | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

where, n=matrix order and λmax=maximum weight value of the n-by-n comparison matrix H.

| $ {\lambda _{\max }} = \frac{{\sum\limits_{j = 1}^n {\frac{{\sum\limits_{k = 1}^n {{w_k}{a_{kj}}} }}{{{w_k}}}} }}{n} $ |

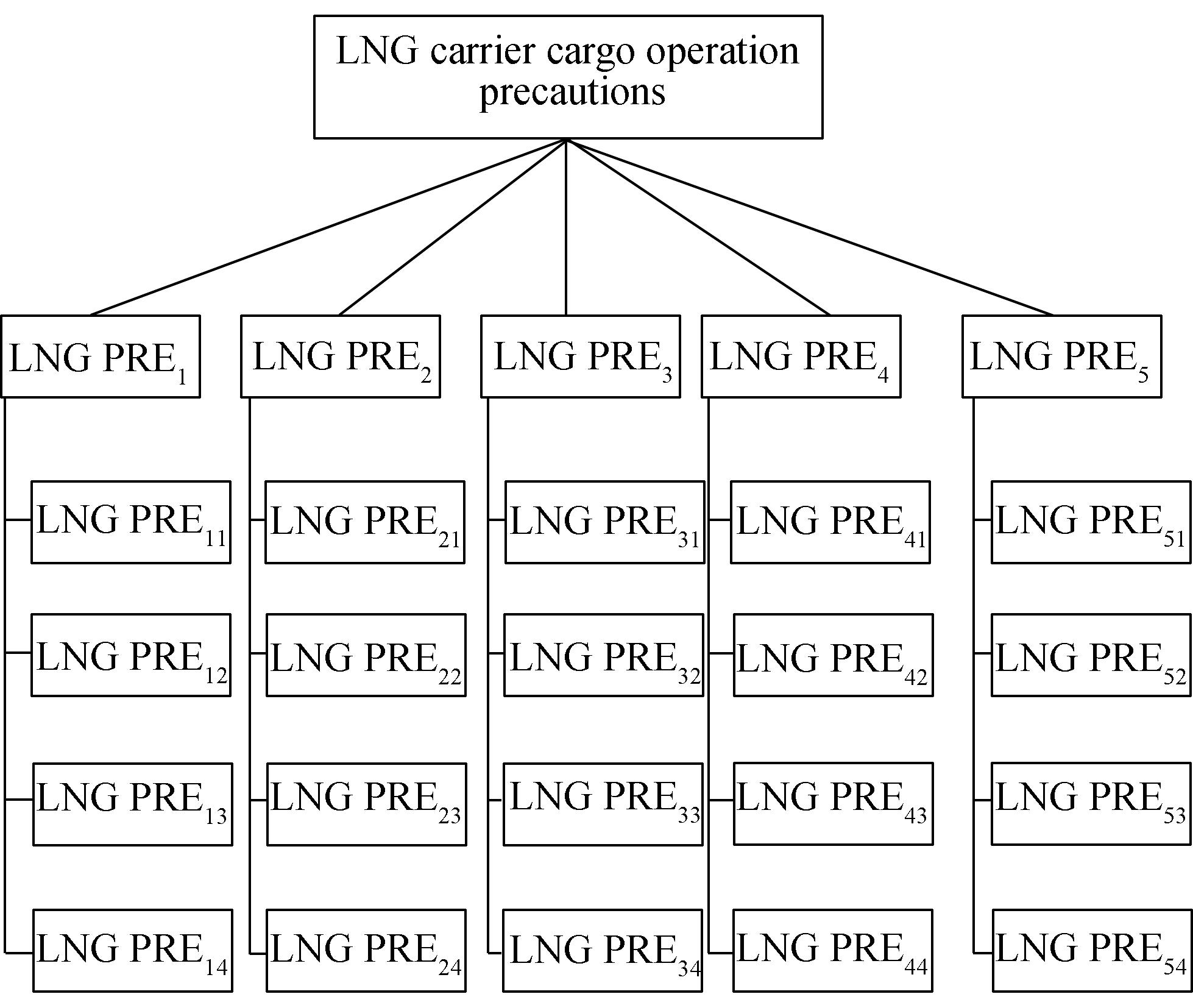

In this sutdy, we used the AHP technique to address the decision-making problems associated with the precautions of LNG carrier cargo operations. It serves as both a qualitative and quantitative method. The qualitative analysis is based on the opinion of personnel with experience in the study area and the data gathered is used to establish the basis for further quantitative analysis (Sapsford and Jupp, 2006). Since this study evaluates the precautions used on the LNG carrier cargo during loading and unloading operations, qualitative method are used to examine the experts’judgment experiences relating to the individual precautions of the LNG carrier cargo operations. As identified and described in section 2, the hierarchical structure of the precautions of the LNG carrier operations are illustrated in Fig. 2, which is used to facilitate the estimation of the weights of these precautions. The experts employed in this study were a gas engineer (expert A), two LNG superintendents (expert B and expert C), and a master mariner (expert D) with a minimum of four years experience in LNG carrier cargo operations.

|

| Figure 2 Hierarchical structure of precautions of LNG carrier cargo operations |

The information flow in Fig. 2 begins with the precautions of the LNG carrier cargo operations, which is the first level of the hierarchical structure. The LNG carrier cargo operation precautions consist of LNG PRE1, LNG PRE2, LNG PRE3, LNG PRE4 andLNG PRE5at the second level of the hierarchical structure. The third level of the hierarchical structure includes LNG PRE11, LNG PRE12, LNG PRE13 and LNG PRE14, which are associated with LNG PRE1; LNG PRE21, LNG PRE22, LNG PRE23, and LNG PRE24 which are associated with LNG PRE2; LNG PRE31, LNG PRE32, LNG PRE33, and LNG PRE34, which are associated with LNG PRE3; LNG PRE41, LNG PRE42, LNG PRE43and LNG PRE44, which are associated with the LNG PRE4; and LNG PRE51, LNG PRE52, LNG PRE53 and LNG PRE54, which are associated with LNG PRE5.

4.1 Gas engineer (Expert A) judgmentThe decision results of expert A in making a pairwise comparison judgment between the precautions of the LNG carrier cargo operations are illustrated in Table 3. In the table, LNG PRE1has equal importance with LNG PRE2 andis moderately more important than LNG PRE3;LNG PRE4 is between moderately and strongly more important than LNG PRE1; LNG PRE1is between moderately and strongly more important than LNG PRE5; LNG PRE3is between moderately and strongly more importantthan LNG PRE2; LNG PRE4is moderately more important than LNG PRE2; LNG PRE2 is between moderately and strongly more important than LNG PRE5; LNG PRE4is between equally and moderately more important than LNG PRE3; LNG PRE3is strongly more important than LNG PRE5; and LNG PRE4is between strongly and very strongly more important than LNG PRE5.

| LNG precaution | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | LNG precaution |

| LNG PRE1 | X | LNG PRE2 | ||||||||||||||||

| LNG PRE1 | X | LNG PRE3 | ||||||||||||||||

| LNG PRE1 | X | LNG PRE4 | ||||||||||||||||

| LNG PRE1 | X | LNG PRE5 | ||||||||||||||||

| LNG PRE2 | X | LNG PRE3 | ||||||||||||||||

| LNG PRE2 | X | LNG PRE4 | ||||||||||||||||

| LNG PRE2 | X | LNG PRE5 | ||||||||||||||||

| LNG PRE3 | X | LNG PRE4 | ||||||||||||||||

| LNG PRE3 | X | LNG PRE5 | ||||||||||||||||

| LNG PRE4 | X | LNG PRE5 |

Following Table 1, experts B, C, and D also carried out pairwise comparisons of precautions LNG PRE1, LNG PRE2, LNGPRE3, LNG PRE4, andLNG PRE5. Similarly, experts A, B, C, and D carried out a pairwise comparison of precautions including:

● LNG PRE11, LNG PRE12, LNG PRE13, LNG PRE14 andLNG PRE15 associated with LNG PRE1.

● LNG PRE21, LNG PRE22, LNG PRE23, LNG PRE24 andLNG PRE25 associated with LNG PRE2.

● LNG PRE31, LNG PRE32, LNG PRE33, LNG PRE34 andLNG PRE35 associated with LNG PRE3.

● LNG PRE41, LNG PRE42, LNG PRE43, LNG PRE44 andLNG PRE45 associated with LNG PRE4.

● LNG PRE51, LNG PRE52, LNG PRE53, LNG PRE54 andLNG PRE55 associated with LNG PRE5.

4.1.1 Pairwise comparison matrixThe determination of the weighting values of the precautions of LNG carrier cargo operations can be facilitated by the use of the average judgments of the experts’pairwise comparison. We also used a pairwise comparison matrix to facilitate the calculation of λmax and the CR values in the expert judgment exercise. The matrix consists of rows and columns of precautions, as shown in Table 4. The average numerical rating of experts is entered into the row and column of each precaution.

| LNG carrier operations precautions | LNG PRE1 | LNG PRE2 | LNG PRE3 | LNG PRE4 | LNG PRE5 |

| LNG PRE1 | 1 | 1 | 2.25 | 1/2 | 4.67 |

| LNG PRE2 | 1 | 1 | 1/3.5 | 1/3.25 | 4 |

| LNG PRE3 | 1/2.25 | 3.5 | 1 | 1/2 | 3.75 |

| LNG PRE4 | 2 | 3.25 | 2.0 | 1 | 4.25 |

| LNG PRE5 | 1/4.67 | 1/4 | 1/3.75 | 1/4.25 | 1 |

| SUM | 4.658 | 9 | 5.81 | 2.55 | 17.67 |

In the LNG PRE1-LNG PRE3 pairwise comparison exercise, Experts A and B estimated that LNG PRE1is moderately more important (i.e., 3) than LNG PRE3. Expert C estimated that both are equally important (i.e., 1). Expert D estimated that the LNG PRE1is between equally and moderately more important (i.e., 2). Therefore, we calculated the LNG PRE1-LNG PRE3 average numerical rating as (3+3+1+2)/4=2.25, and inserted 2.25 into the row LNG PRE1and column LNG PRE3in Table 4. This implies that the LNG PRE3-LNG PRE1comparison has a reciprocity of 2.25 i.e., 1/2.25, as evidenced in Table 4. We used this same process to compute the other values in Table 4. Similar pairwise comparison exercises were also used for the precautions associated with LNG PRE1, LNG PRE2, LNG PRE3, LNG PRE4, andLNG PRE5, as shown in Figure 2.

| $ {w_{{\rm{LNGPR}}{{\rm{E}}_{\rm{1}}}}} = \frac{1}{5}\left( {\frac{1}{{4.66}} + \frac{1}{9} + \frac{{2.25}}{{5.81}} + \frac{{0.5}}{{2.55}} + \frac{{4.67}}{{17.67}}} \right) = 0.235 $ |

In a similar way, wLNGPRE2, wLNGPRE3, wLNGPRE4 and were calculated to be 0.145, 0.213, 0.353 and 0.054 respectively. The values of, wLNGPRE11, wLNGPRE12, wLNGPRE13, wLNGPRE14, wLNGPRE21, wLNGPRE22, wLNGPRE23, wLNGPRE24, wLNGPRE31, wLNGPRE32, wLNGPRE33, wLNGPRE34, wLNGPRE41, wLNGPRE42, wLNGPRE43, wLNGPRE44, wLNGPRE51, wLNGPRE52, wLNGPRE53 and wLNGPRE54 were calculated in the same way and have the values 0.179, 0.178, 0.322, 0.321, 0.451, 0.106, 0.194, 0.249, 0.233, 0.399, 0.108, 0.260, 0.327, 0.245, 0.297, 0.131, 0.474, 0.104, 0.145, and 0.277, respectively.

4.1.2 Calculation of CR values for LNG carrier cargo operations precautionsThe wLNGPRE1, wLNGPRE2, wLNGPRE3, wLNGPRE4 and values are reasonable if the CR value is less than or equal to 0.2. The CR value is calculated as follows:

| $ \begin{array}{c} \sum\limits_{k = 1}^n {{w_k}{a_{kj}}} = 0.235\left[ \begin{array}{l} 1\\ 1\\ 1/2.25\\ 2\\ 1/4.67 \end{array} \right] + 0.145\left[ \begin{array}{l} 1\\ 1\\ 3.5\\ 3.25\\ 1/4 \end{array} \right] + 0.213\left[ \begin{array}{l} 2.25\\ 1/3.5\\ 1\\ 2\\ 1/3.75 \end{array} \right] + \\ 0.353\left[ \begin{array}{l} 1/2\\ 1/3.25\\ 1/2\\ 1\\ 1/4.25 \end{array} \right] + 0.054\left[ \begin{array}{l} 4.67\\ 4\\ 3.75\\ 4.25\\ 1 \end{array} \right] = \left[ \begin{array}{l} 1.287\\ 0.764\\ 1.202\\ 1.948\\ 0.280 \end{array} \right] \end{array} $ |

| $ \begin{array}{l} {\lambda _{\max }} = \frac{{\sum\limits_{j = 1}^n {\frac{{\sum\limits_{k = 1}^n {{w_k}{a_{kj}}} }}{{{w_k}}}} }}{n} = \\ \;\;\;\;\;\;\;\frac{{\frac{{1.287}}{{0.235}} + \frac{{0.764}}{{0.145}} + \frac{{1.202}}{{0.213}} + \frac{{1.948}}{{0.353}} + \frac{{0.28}}{{0.054}}}}{5} = 5.425 \end{array} $ |

| $ {\rm{CI}} = \frac{{5.429 - n}}{{n - 1}} $ |

n=5, because the number of criteria is 5.

Therefore,

| $ {\rm{CR = }}\frac{{{\rm{CI}}}}{{{\rm{RI}}}} = \frac{{0.106}}{{{\rm{RI}}}} $ |

1.12 is the RI value because the number of criteria (n) is 5, and 5 has a corresponding RI number of 1.12, as evidenced in Table 2.

Therefore,

The value of CR is less than 0.2, therefore the wLNGPRE1, wLNGPRE2, wLNGPRE3, wLNGPRE4 and wLNGPRE5 values are acceptable and can be adopted in the prioritization exercise of the precautions of the LNG carrier cargo operations.

In a similar way, the CR values associated with (wLNGPRE11, wLNGPRE12, wLNGPRE13, wLNGPRE14), (wLNGPRE21, wLNGPRE22, wLNGPRE23, wLNGPRE24), (wLNGPRE31, wLNGPRE32, wLNGPRE33, wLNGPRE34), (wLNGPRE41, wLNGPRE42, wLNGPRE43, wLNGPRE44) and (wLNGPRE51, wLNGPRE52, wLNGPRE53 and wLNGPRE54) are 0.152, 0.018, 0.071, -0.006 and 0.066, respectively. Since the CR values are less than 0.2, the weights are acceptable and can be used in the prioritisation exercise.

4.1.3 Prioritization of the precautions of LNG carrier cargo operationsThe identified weights of all the precautions of the LNG carrier cargo operations in sub-section 4.1.1 can then be used to prioritize them in order to optimize the system cargo operations and reduce risk of accidents/system failure. We prioritized the precautions as follows:

● wLNGPRE4 > wLNGPRE1 > wLNGPRE3 > wLNGPRE2 > wLNGPRE5. This means that LNG PRE4requires more attention thanLNG PRE1; LNG PRE1requires more attention than LNG PRE3; LNG PRE3 requires more attention than LNG PRE2; and LNG PRE2 requires more attention than LNG PRE5.

● wLNGPRE13 > wLNGPRE14 > wLNGPRE11 > wLNGPRE12. This means that for precautions associated with the LNG PRE1, LNG PRE13requires more attention thanLNG PRE14; LNG PRE14requires more attention than LNG PRE11; and LNG PRE11 requires more attention than LNG PRE12.

● wLNGPRE21 > wLNGPRE24 > wLNGPRE23 > wLNGPRE22. This means that for precautions associated with LNG PRE2, LNG PRE21requires more attention thanLNG PRE24; LNG PRE24requires more attention than LNG PRE23; and LNG PRE23 requires more attention than LNG PRE22.

● wLNGPRE32 > wLNGPRE34 > wLNGPRE31 > wLNGPRE33. This means that for precautions associated with LNG PRE3, LNG PRE32requires more attention than LNG PRE34; LNG PRE34requires more attention than LNG PRE31; and LNG PRE31 requires more attention than LNG PRE33.

● wLNGPRE41 > wLNGPRE43 > wLNGPRE42 > wLNGPRE44. This means that for precautions associated with LNG PRE4, LNG PRE41requires more attention thanLNG PRE43; LNG PRE43requires more attention than LNG PRE42; and LNG PRE42 requires more attention than LNG PRE44.

● wLNGPRE51 > wLNGPRE54 > wLNGPRE53 > wLNGPRE52. This means that for precautions associated with LNG PRE5, LNG PRE51requires more attention thanLNG PRE54; LNG PRE54requires more attention than LNG PRE53; and LNG PRE53 requires more attention than LNG PRE52.

Therefore, for the optimal and successful discharging and loading operations of a LNG carrier cargo, LNG precautions should be given attention in the order of importance described above.

5 ConclusionsBased on its application in previous studies, the mechanism of the AHP technique has been shown to be appropriate for incorporation into the prioritization exercise for the precautions of LNG carrier cargo operations. Using the AHP technique can help to optimize LNG carrier cargo operations and reduce the risk of system failure or any form of marine accident. In this study, we carried out pairwise comparison exercises for LNG PRE1, LNG PRE2, LNG PRE3, LNG PRE4, andLNG PRE5; LNG PRE11, LNG PRE12, LNG PRE13 and LNG PRE14; LNG PRE21, LNG PRE22, LNG PRE23 and LNG PRE24; LNG PRE31, LNG PRE32, LNG PRE33and LNG PRE34; LNG PRE41, LNG PRE42, LNG PRE43and LNG PRE44; and finally on LNG PRE51, LNG PRE52, LNG PRE53 and LNG PRE54so as to facilitate the estimation of their weight values. We then used their weight values to determine which precautions require more attention than others.

The pairwise comparison exercise of LNG PRE1-LNG PRE5 revealed that LNG PRE4 requires more attention than others, while LNG PRE5 requires less attention than others. The study results also identified LNG PRE13, LNG PRE21, LNG PRE32, LNG PRE41 and LNG PRE51as the precautions requiring more attention of the LNG PRE11-LNG PRE14, LNG PRE21-LNG PRE24, LNG PRE31-LNG PRE34, LNG PRE41-LNG PRE44, and LNG PRE51-LNG54groups, respectively. Furthermore, LNG PRE12, LNG PRE22, LNG PRE33, LNG PRE44, and LNG PRE52 are the precautions that require less attention. This research technique can be adopted by oil and gas companies in their decision-making processes with respect to the loading and discharging operations of LNG carrier cargo.

| Anderson DR, Dennis JS, Williams TA, Camm JD, Cochran JJ, 2015. An introduction to management science: quantitative approaches to decision making. 4th Edition, South-Western College Publisher, ISBN: 1111823618. |

| Arslan O, 2009. Quantitative evaluation of precautions on chemical tanker operations. Process Safety and Environmental Protection, 87, 113–120. DOI:10.1016/j.psep.2008.06.006 |

| Cheng CH, 1997. Evaluating naval tactical missiles system by fuzzy ahp based on grade value of membership function. European Journal of Operational Research, 96(2), 343–350. DOI:10.1016/S0377-2217(96)00026-4 |

| Dadkhah KM, Zahedi F, 1993. A mathematical treatment of inconsistency in the analytic hierarchy process. Mathematical Computing Modeling, 17(415), 111–122. DOI:10.1016/0895-7177(93)90180-7 |

| Hyde P, 2006. LNG Operational practice.Witherbys Seamanship, ISBN 1856093212. |

| ISGOTT, 2006. International safety guide for oil tanker and terminal. 5th Edition, Witherby & Co Ltd, ISBN 1856092917. |

| Karahalios H, Yang ZL, Williams V, Wang J, 2011. A proposed system of hierarchical scorecards to assess the implementation of maritime regulations. Safety Science, 49, 450–462. DOI:10.1016/j.ssci.2010.11.001 |

| Liu FHF, Hai HL, 2005. The voting analytic hierarchy process method for selecting supplier. International Journal of Production Economics, 97(3), 308–317. DOI:10.1016/j.ijpe.2004.09.005 |

| Mishra AK, Deep S, Choudhary A, 2015. Identification of suitable sites for organic farming using the AHP and GIS. The Egyptian Journal of Remote Sensing and Space Science, 18(2), 181–193. DOI:10.1016/j.ejrs.2015.06.005 |

| Moon K, Song S, Ballesio J, Fitzgerald G, Knight G, 2009. Fire risk assessment of gas turbine propulsion system for LNG carriers. Journal of Loss Prevention in Process Industries, 22, 908–914. DOI:10.1016/j.jlp.2008.11.008 |

| Nwaoha TC, Yang Z, Wang J, Bonsall S, 2013. Adoption of new advanced computational techniques to hazards ranking in LNG carrier operations. Ocean Engineering, 72(1), 31–44. DOI:10.1016/j.oceaneng.2013.06.010 |

| Riahi R, Bonsall S, Jenkinson I, Wang J, 2012. A seafarer's reliability assessment incorporating subjective judgements. Journal of Engineering for Maritime Environment, 226(4), 313–334. DOI:10.1177/1475090212438480 |

| Rocha PMD, Barros APD, Silva GBD, Costa HG, 2016. Analysis of the operational performance of Brazilian airport terminals:a multicriteria approach with De Borda-AHP integration. Journal of Air Transport Management, 51, 19–26. DOI:10.1016/j.jairtraman.2015.11.003 |

| Saaty TL, 1980. The analytic hierarchy process. McGraw-Hill, New York, 1. |

| Sapsford R, Jupp V, 2006. Data collection and analysis. 2nd Edition, SAGE Publications Ltd, ISBN 0761943633. |

| Shang J, Sueyoshi T, 1995. A unified framework for the selection of a flexible manufacturing system. European Journal of Operational Research, 85. DOI:10.1016/0377-2217(94)00041-A |

| Singh RP, Nachtnebel HP, 2016. Analytical hierarchy process (AHP) application for reinforcement of hydropower strategy in Nepal. Renewable and Sustainable Energy Reviews, 55, 43–58. DOI:10.1016/j.rser.2015.10.138 |

| Socaciu L, Giurgiu O, Banyai D, Simion M, 2016. PCM selection using AHP method to maintain thermal comfort of the vehicle occupants. Energy Procedia, 85, 489–497. DOI:10.1016/j.egypro.2015.12.232 |

| Takamura T, Tone K, 2003. A comparative site evaluation study for relocating Japanese government agencies out of Tokyo. Social-economic Planning Services, 37(2), 85–102. DOI:10.1016/S0038-0121(02)00049-6 |

| Wang YM, Liu J, Elhag TM, 2008. An integrated AHP-DEA methodology for bridge risk assessment. Computer and Industrial Engineering, 54(3), 513–525. DOI:10.1016/j.cie.2007.09.002 |

| Wedley WC, 1993. Consistency prediction for incomplete AHP matrices. Mathematical Computing Modeling, 17(415), 151–161. DOI:10.1016/0895-7177(93)90183-Y |

| Zhang XS, Cui JC, 1999. A project evaluation system in the state economic information system in china and operations research practice in public sector. International Transaction in Operational Research, 6(5), 441–452. DOI:10.1016/S0969-6016(99)00009-X |