The Malaysia fisheries sector plays a continuing and important role in fulfilling the nation’s nutritional needs. The production value of the national fisheries sector is worth 10.26 billion ringgit,and inshore fishing constitutes about 53.71% of the total value. However,the rapid increase in fuel prices is affecting the profitability of fisheries,as fuel costs for the industry have risen substantially over the last forty years(Suuronen et al., 2012). The use of fuel represents a substantial component of the costs involved in fishing in all nations,and although the actual proportion varies between fisheries it can reach up to 50%,for example in the motorized canoe fleet in Senegal(Dahou et al., 2001)and for canoe purse-seiners in NW Africa(FAO,1995). This is similar to the Malaysian scenario,as mentioned by Mohd Pauzi et al.(1991); the cost of fuel for fishing boats normally accounts for more than 50% of annual operating expenses. For many important fisheries,high fuel costs create major constraints to economic viability. In addition,fishermen working for inshore fisheries have low incomes and live in poverty(Suhaimi et al., 2011),and therefore future scenarios with further rises in fuel prices imply that the inshore fisheries sector has an uncertain future.

Increasing fuel prices often result in goverments establishing fuel-subsidies to support the viability of fishing operations(Suuronen et al., 2012; Sumaila et al., 2008; Kelleher et al., 2008),and in Malaysia a government initiative provides subsidies to this sector. Subsidies are given in various forms,including fuel subsidies,grants,loans,and monthly allowances. However,depending on fuel subsidy might not be a viable solution. This is because the decision to provide fuel subsidies is influenced primarily by political and social concerns,rather than on the sustainability of fisheries resources(Sumaila et al., 2008). There are some cases where fuel subsidies are only given to members of certain political parties and mostly influenced by political interests.Therefore it can be said that this approach is not viable and sustainable. Therefore,other efforts are required to reduce fuel costs,such as improving fuel efficiency,which not only reduces fuel consumption and operating costs,but also reduces the harmful effects of burning fossil fuels and minimizes greenhouse gas emissions. Kelleher et al.(2008)determined that the global fishing fleet consumes approximately 41 million tonnes of fuel anually at a cost of $22.5 billion; it also generates approximately 130 million tonnes of CO2(Buhaug et al., 2009).

The continual rise in fuel prices has promoted researchers to study various energy savings technologies to enable a reduction in fuel consumption(Sherbaz and Duan, 2012; Seddiek et al., 2013; Banawan et al., 2013),and achieving this in fishing boats could be realized by improving or replacing the current fuel engines. The most popular engine used for an FRP small fishing boat is an outboard engine,and nearly half of all vessels are powered by petrol outboard motors,as reported by the Department of Fisheries Malaysia(2011). Outboard engines have the advantage of being easy to install,and they are designed to achieve high speeds,which is important for fishing vessels,as reaching the fishing grounds and returning to port in the shortest time ensures that the catch is supplied to the market fresh. There are several types of outboard engines available on the market,and the most popular is a standard 2-stroke gasoline/petrol engine which has all these advantages(Wilson,1999).

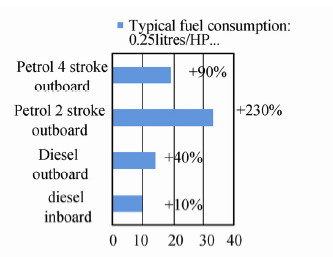

However,petrol outboard engines have a higher fuel consumption than diesel engines. Wilson(1999)determined that a diesel engine is about 2.4 times more fuel-efficient than a petrol engine. This result was similar to that concluded in the study of Gulbrandsen(1986),which desribes fuel consumption trials of petrol driven outboard engines and inboard diesel engines at speed of 5.5 kn. Fuel consumption data show that inboard diesel engines and petrol enginges consume 1 liter and 2.5 liters per hour at 4 and 7 HP,respectively,which shows that using a diesel engine delivers savings of about 60%. Fig. 1 shows a comparison of the fuel consumption rates of diesel and other engines. The data highlight that a diesel engine promises fuel savings when compared to a petrol outboard motor,and thus the petrol outboard engine is a heavy fuel consumer compared to the diesel outboard or diesel inboard engine. However,it is only possible to purchase petrol outboard engines on the market. It is therefore necessary to promote the use of inboard diesel engines to facilitate their possible production and to thus enable a potential solution to the growing fuel price crisis. Diesel engines also have the advantage of being able to run on fuel from renewable sources(Nagi and Nagi, 2008; Jaichandar and Annamalai, 2011),such as biodiesel,which has properties similar to those of conventional diesel. This strengthens the argument for the use of diesel engines; they represent a more stable aternative as they do not require fossil resources. However,even if they were freely available on the market,the use of inboard diesel engines in small scale fishing boats presents a problem in terms of propeller matching.

|

| Fig. 1 Comparison of fuel consumption between diesel inboard engines and others(Wilson,1999) |

In addtion to requiring major hullform modification and extra expenditure,when conventional propellers are used with inboard diesel engines they suffer from propeller loss. According to Wilson(1999),losses related to the use of conventional propellers in small fishing vessels are as high as 24%. These propeller losses may increase dramatically at higher speeds due to cavitation phenomena. In addition,poor propeller sizes also contribute significantly to fuel inefficiency in fishing boats,where,in general,a larger propeller diameter is more efficient. The surface-piercing propeller(SPP),which is also known as the partially-submerged propeller,is recognized as an efficient propulsion device for use with shallow draft crafts(Ferrando et al., 2002). According to Allison(1978)cited in,Wilson(1999),results of a large scale experiment carried out in 1976 by the U.S. Navy confirmed that partially submerged propellers can achieve efficiencies comparable to that of fully submerged propellers. In addition,Handler(1996)found that the fixed-pitch surface propeller is a very efficient propulsion option for vessels operating at a speed range of 30 to 50 kn. Although small-scale fishing boats may not operate within that speed range,SPP has additional positve features,and Ghassemi(2009)cited several reasons why the SPP is more efficient than using submerged propellers. For example,the SPP reduces the use of power by minimizing appendage drag related to shafts,struts,and the propeller hub. In addition,the SPP provides the possibility of using a larger propeller diameter,as its size is not limited by the blade tip clearance from the hull or the maximum vessel draft. Furthermore,the reduction of cavitation provided is remarkable.

This paper describes a proposal to introduce an inboard diesel engine for fishing vessels using an SPP.

2 MethodologyA preliminary field survey and collection of onboard data were carried out to identify factors required in the concept development of the proposed system. Onboard data collection was conducted to record speed and fuel consumption through a speed test in a current,small-scale fishing boat. These baseline data are used to make a comparison with the boat that was retrofitted in this study with the proposed system. The development of the proposed system was divided into three phases; firstly hull resistance was determined,secondly powering estimation to identify the correct propeller engine matching to achieve fuel savings was conducted and thirdly a general outline of the system was compiled. The calculation of fuel consumption and the powering analysis were conducted using NavCad Software. The general outline of the proposed system was compiled to show the location of engine and propeller. Finally,a techno economic analysis was conducted to validate the overall monetary savings.

3 Data collectionThis research applied two methods of data collection,a preliminary field survey and onboard data collection.

3.1 Preliminary site surveyA study was conducted to determine the current propulsion systems used and to identify the views of fishermen in relation to fuel costs. A questionnaire was developed as a survey tool based on the Likert scale,and was divided into three parts: cost factor,engine system,and operational factors. The questionnaire was distributed to respondents within a community of fishermen in Manjung,Perak. In total,50 questionaires were distributed and 30 responses were obtained. Data were processed using Statistical Package for Social Science(SPSS).

Table 1 shows the mean and standard deviation for the three parts using descriptive frequencies analysis. The first part of the questionnaire related to the economic element,and this was used to identify effects from using an outboard engine in terms of the various costs involved. Most respondents stated that they disagreed with the assumption that they are not burdened with an initial cost,operational costs,and maintenance costs,even though some had received government subsidies. In addition,it was clarified that the burden of high fuel costs for outboard engines limits the operating range of the fishing vessels.

| Constructs | Mean | Std. Deviation |

| Outboard motors are economical | 1.09 | 0.09 |

| Outboard motors give a good performance | 2.08 | 0.21 |

| Fishing operation is influenced by engine performance | 4.03 | 0.27 |

The second part of questionnaire related to the engine system,and this identified fishermen’s perceptions of the performance and reliability of outboard engines. Based on descriptive results,it was clarified that fishermen are not satistified with the performance of their current engines. With an engine power of less than 100 HP,most respondents are unable to venture far from shore and they therefore need a more powerful engine to go further safely. However,most respondents are unable to afford an engine with a higher capacity because of the price involved in doing so.

The third part of questionnaire related to fishing operation elements to identify the influence of engine performance on the practice of fishing. A number of different fishing gears can be used in inshore fishing,such as gill nets,bag nets,and barrier nets,and each type influences the fishing operation and boat performance in terms of the location of the engine and its power usage. Different types of fishing gears require different type of nets,equipment and number of workers and these affect boat weight and general arrangement. The proposed system require an inboard engine to be located inside the boat stern region. Although it takes more space,this is not an issue because the survey results showed that most respondents use gill nets,which will not be affected by the engine location. In summary,results suggested that inshore fishermen are receptive to a different type of fuel saving propulsion system.

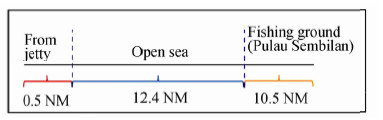

The survey also revealed that most inshore fishing boats have lengths in the range of 5.8 metres to 7.9 metres,and have average cruising speeds of around 22 kn up to a maximum speed of 26 kn. Therefore,in this study,a fiberglass fishing boat measuring 7.1 metres was chosen as the boat in which to obtain data. This boat which belongs to a local fisherman represent a typical fishing boat popular in this region. The boat was used for the case study,and on-board measurement was carried out on-board this boat. The survey also determined the operational profile of fishing boats in this area,as shown in Fig. 2,which shows that the trip route is divided into three phases: journeying from port,in the open sea,and in the fishing ground.

|

| Fig. 2 Fishing route |

In the study area,the distance from the jetty to the river mouth is approximately 0.5 nautical miles. The common fishing ground for the selected boat is Pulau Sembilan,which is located 12.4 nautical miles from the shore. From observations,the fishing route used to access the fishing grounds varies and depends on the availability of fish stock and sea conditions. Some fishermen who have boats with a higher engine capacity may journey to Pulau Jarak,which is located around 30 nautical miles to the west.

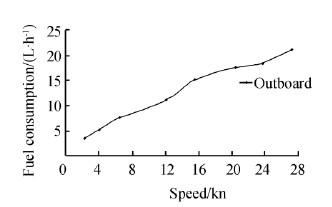

3.2 On-board data collectionThe survey reveals that outboard motors have a high fuel usage and are inefficient. To validate this result,onboard data collection was carried out to record the fuel consumption at a given speed of the 7.1 metres study boat(Fig. 3),the specifications of which are provided in Table 2. The fishing boats usually operate on daily trips,and the length of time that inshore fishing boats spend on the sea varies depending on the type of fishing gear used. To determine the accurate amount of fuel actually consumed per trip,measurements were carried out while the boat was in a typical fishing operation. byusing a fuel management meter.

|

| Fig. 3 Fishing boat (23 ft) used for data collection |

| Length overall LOA/m | 7.10 |

| Length between perpendicular LBP/m | 6.18 |

| Length water line LWL/m | 6.18 |

| Breadth/m | 1.53 |

| Draught amidships T/m | 0.23 |

| Displacement volume/m3 | 1.02 |

| Engine horsepower/HP | 60 |

|

| Fig. 4 Results of fuel consumption test |

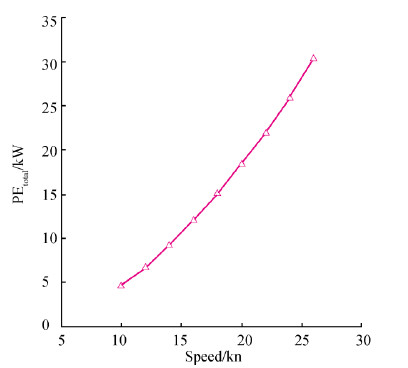

The concept of a fuel saving boat is proposed,and this is achieved using a combination of an inboard diesel engine and an SPP. In this study,only the engine and propeller characteristics are determined. A preliminary prediciton of power was carried out to determine the resistance and powering characteristic of the chosen boat,as it is important to select an appropriate propulsion configuration to meet the required speeds and operational conditions. The use of contemporary software,such as NavCad,reduced the time consumed in design and analysis. This software is a program tool used in the prediction and analysis of vessel speed and power performance; where the algorithm of the software is based on a collection of various resistance and power predictions. NavCad can thus perform analysis on optimization of resistance,power,propeller,and engine selection.

4.1 Hull resistance characteristicsVarious methods have been introduced to predict the resistance of a boat,such as model testing,full-scale trials,systematic series data,and statistical analysis. Statistical analysis uses large databases of results from model tests and full-scale ship trials. The database is then analysed using a regression based method and empirical formulae are developed. Statistical analysis is cost effective in comparison with other methods. For a given hull parameter,the resistance characteristic can be predicted.(Savitsky and Brown, 1976)introduced a well-known statistical analysis that predicted resistance when planning a hull. They presented results of hydrodynamic study of several fundamental planning phenomena in a form that is used by small-boat naval architects. According to Schneiders(1990),the level of statistical prediction accuracy is comparable with that achieved in tank tests.. The process of resistance prediction starts with entering hull form parameters. The hull characteristic of the fishing boat was obtained by measuring the hull form manually,and the data obtained were used in NavCad software(Hydrocompinc Inc.,2007)to predict and analyse the boat speed and its power performance.

Resistance analysis in this study was carried out using statistical analysis data proposed by Savitsky and Brown(1976),The analysis was performed for sea state 2 and wind speed of 8.5 kn. Design margin was set as 4% for all drags and the effective power is shown in Fig. 5 with respect to boat speeds. To achieve a maximum speed of 26 kn,the boat requires a power of 30 kW to overcome hull resistance.

|

| Fig. 5 Speed power curves |

The objective of the design of a propulsion system is to achieve the best characteristics and capabilities of the engine and propeller,as well as to ascertain that the system meets the required performance and is fuel-efficient. The power required to propel a boat is influenced by the boat’s hull shape,type of propeller,and transmission. By assuming an overall propulsive coefficient of 0.55,as mentioned in MacPherson(2003),the brake power is estimated to be 55kW(73 HP).

4.3 Propeller and engine profilesThe propeller profile is determined based on a propeller series developed from the free-surface cavitation channel analysis of five 4-bladed Rolla SSPs(Radojcic and Matic, 1997). The delivered thrust of the propeller needs to match the drag at each given speed,and it is therefore essential to identify characteristics that provide the correct amount of thrust at the right rpm. The selection of propeller size needs to achieve the maximum propulsive efficiency and maximum boat speed for the rated engine power and rpm. Using NavCad propeller sizing,profiles were obtained,as shown in Table 3. Propeller profiles need to be properly defined as to identify the correct engine capacity to achieve fuel savings.

| No. | Parameter | Value |

| 1 | Number of blades,Z | 4 |

| 2 | Pitch/diameter ratio,P/D | 1.4 |

| 3 | Open water propeller efficiency,ηO | 0.64 |

| 4 | Diameter,D/m | 0.5 |

| 5 | Inclination angle,Ψ/(°) | 6 |

Fig. 6 illustrates the open water propeller efficiency,ηO,against speed. As can be seen from the graph,for a speed of 26 kn,the propeller efficiency is 0.64,which is slightly higher than the conventional propeller efficiency of 0.55(Hadler,1996). This shows that the SPP gives better results at high speeds,and thus contributes to fuel saving.

|

| Fig. 6 Open water propeller efficiency |

The engine profiles are selected based on power demand from the propeller. The engine was selected from those available in the market which had different power at different rpm. Thus,power and rpm demands have to be compared with the entire rpm range of the engine characteristics to meet the design point. The delivered thrust of the propeller needed to match the drag at each given speed. Therefore,it was essential to identify the characteristic that could provide the correct amount of thrust,which means finding the right rpm. This can be attained by making a correct match between the engine and the propeller,the aim of which is to apply the principle of conservation energy that demands that the power produced by the engine is equal to that absorbed by the propeller. This is to prevent reaching a condition of overload or overspeed,which results from poor propeller matching.

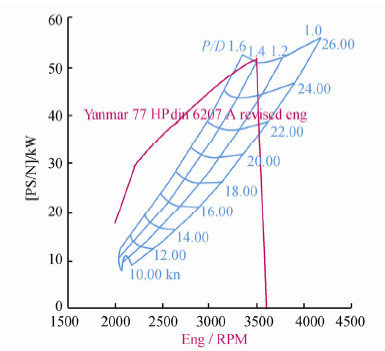

The propeller performance is directly affected by the value of the propeller pitch diameter ratio(P/D). As can be seen from Fig. 7,shaft power is plotted against engine rpm for different P/D ratios given as 1.0,1.2,1.4 and 1.6. For a P/D ratio of 1.4,the power curve meets the design point. Thus,taking a shaft efficiency of 0.97,as mentioned in MacPherson(2003),the amount of brake power required by the engine is 51 kW at a maximum speed of 26 kn,which is quite close to the assumed value of 55 kW.

|

| Fig. 7 Propeller-engine relationships |

As can be referred from the graph,using an inboard diesel engine of around 51 kW will give a maximum speed of 26 knots. The diesel engine is typically rated at 85%-90% of Maximum Continuous Power(MCR),and thus the capacity of the engine to be installed should be 58 kW(77 HP),as specified in Table 4. Therefore,a 77 HP Yanmar diesel engine was selected in this study.

| No. | Specifications | Value |

| 1 | Number of engines | 1 |

| 2 | Brake power | 58 |

| 3 | Engine rate of rotation per minute (RPM) | 3 500 |

| 4 | Reduction gear ratio | 2.78 |

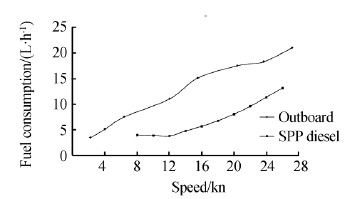

A fuel consumption analysis was carried out to compare the fuel rate of the proposed system to that of the present system,and to confirm that fuel saving can be gained. Fuel consumption rates for a 77 HP Yanmar(4JHDTE)diesel engine obtained from an engine performance curve(provided by the manufacturer and comparing fuel consumption rates)are plotted against the boat speed in Fig. 8. The fuel consumption curve shows that the inboard diesel engine with the SPP(the SPP diesel)consumes 13 litres per hour at a speed of 26 kn,while the outboard petrol consumes 20.5 litres per hour. The data reveal that a fuel saving of up to 44% can be gained using the proposed system.

|

| Fig. 8 Fuel consumption curve comparison |

A design of the proposed system was compiled to show a detailed layout; as shown in Fig. 9,the plan specifies the location of the engine and propeller. Space within the selected fibreglass fishing boat is mainly occupied by four fish holds and two compartments for the fuel tank. Minimal modifications were made to the layout to allow installation of the inboard engine,and in this respect one of the fish holds was removed. It is considered that removal of a single fish hold would not affect the overall fish holding capacity,as this is rarely optimised on a day trip. Observations show that only one of the fish holds is used for fish storage,and that the rest are used to store fishing equipment or nets. In addition,according to(Ahmad et al., 2003)the average quantity of fish landed by drift netter fishing boats is around 30 kg per day,and this amount only occupies one fish hold.

|

| Fig. 9 Design of engine and propellers |

The 77 HP Yanmar diesel engine was selected for this study. According to the engine manual,the minimum area required for the engine bed is 490 mm×888 mm,and this space should be located aft of the boat. The surface propeller is mounted close to the transom,and the propeller shaft is extended aft of the transom at a 6 degree inclination angle from the base line. For steering,a combination of tunnel and rudder are used for maximum thrust and maneuvering.

5 Techno-economic analysisThe techno-economic analysis starts by identifying overall costs,such as the initial cost,operational costs,maintenance costs,and salvage value. Other data required for the economic analysis,such as fuel consumption data,fishing routes,and fish catch,were based on estimations using findings and surveys. These data were then used to determine the Net Present Value for both systems. The following assumptions were made to simplify the economic analysis as follows:

a)The duration of every trip is constant.

b)The total fuel consumption of both systems is constant for every trip.

c)The price of petrol and diesel is constant throughout the year.

d)The operational life is estimated as 10 years.

e)The maintenance costs are equal for both systems.

The analysis also takes into account the fuel price including a government subsidy and that without subsidy,to further investigate the benefits of the proposed system.

5.1 Fuel saving analysisThe fuel consumption analysis is a key factor in this study,and the fuel consumption is proportional to the power used. The more power used to achieve a desired speed,the more fuel is consumed. Therefore,a calculation of power used indicates an accurate amount of fuel consumed for every trip. The best approach for determining an accurate amount of total fuel consumed is to calculate the actual speed used throughout a particular fishing trip route,as shown earlier in Fig. 5. From the figure,it can be seen that the boat is propelled at different speeds in every phase. Therefore,the fuel consumption curve in Fig. 6 was employed to calculate fuel consumption for each phase using the interpolation method,and the results are presented in Table 5.

| Item | From port | Open sea | Fishing ground | Total |

| Average speed/kn | 15.56 | 25.40 | 20.50 | |

| Fuel consume of outboard petrol l/h | 15.22 | 19.71 | 17.62 | 17.52 |

| Fuel consume of SPP diesel l/h | 5.50 | 12.66 | 8.51 | 8.89 |

| Travelling time per trip | 0.01 | 2.00 | 1.00 | 3.01 |

| Total fuel per trip Outboard petrol liter | 0.15 | 39.42 | 17.62 | 57.19 |

| Total fuel per trip SPP diesel liter | 0.06 | 25.32 | 8.51 | 33.89 |

| Fuel savings/liters | 0.10 | 14.10 | 9.11 | 23.31 |

| Fuel savings/% | 63.86 | 35.77 | 51.70 | 40.75 |

The fuel consumption for each phase was determined and calculated. A fishing boat using an outboard petrol engine consumes 57.19 liters of fuel per trip,and if it uses SPP diesel it consumes approximately 33.89 liters of fuel per trip. For overall fuel consumption,the percentage of fuel reduction is determined by obtaining the difference between the amount of fuel used by both the outboard petrol engine and that of the SPP diesel. Use of SPP diesel would achieve a saving of 23.31 liters,or 40.75%,and such saving in fuel would enable fishermen to travel further.

The government gives a subsidy to fishermen as an incentive to reduce their fuel burden,and currently the fishing industry receives subsidies for fuel prices for both petrol and diesel at RM 1.25. The market fuel price for petrol and diesel without subsidy is RM 2.10 and RM 2.00 respectively. However,the government is now starting to reduce the subsidies; for example,in 2011 the government cut off subsidies for offshore fishing boats. Therefore,to assess monetary savings,our calculations consider both subsidized prices and unsubsidized prices of fuel. Table 6 shows the total fuel cost per trip for both systems,where the total amount of subsidized fuel for the outboard petrol is RM 82.93,and for the SPP diesel is RM 49.13; the total unsubsidized fuel cost of both systems is RM 120.10 and RM 67.77 respectively. Therefore,if the government cuts fuel subsidies,the fuel cost for SPP diesel would be RM 67.77,which is still lower than the fuel cost of outboard petrol with a subsidy.

| Item | Total fuel per trip/ liters | Total fuel cost with subsidy per trip (RM) | Total fuel cost without subsidy per trip (RM) | |

| Outboard petrol | 57.19 | 82.93 | 120.10 | |

| SPP diesel | 33.89 | 49.13 | 67.77 | |

| Cost savings | 33.80 | 52.33 | ||

| Cost savings/% | 40.75 | 43.57 |

The economic analysis is carried out to determine the profitability of using SPP diesel compared to outboard petrol. Table 7 shows the Net Present Value of both cases for comparison. For an operational life of 10 years,the SPP diesel gives a NPV of RM64636 which is more than twice that of the outboard engine. This result proves that using the SPP diesel is more economical and delivers monetary savings.

| Item | Outboard petrol engine | SPP diesel engine |

| Initial cost,PO | RM 21000 | RM 23200 |

| Annual operation cost,A1 | RM 22971 | RM 16213 |

| Salvage value,FO | RM 7322 | RM 8099 |

| Annual income,A2 | RM 30000 | RM 30000 |

| Interest rate,i | 0.1 | 0.1 |

| Lifespan,n | 10 | 10 |

| (P/A/i/n) at 10% | 6.144 6 | 6.144 6 |

| (P/F/i/n) at 10% | 0.385 5 | 0.385 5 |

| Net Present value | RM 25010 | RM 64636 |

Although the initial cost of SPP diesel engine is much higher than that of an outboard engine,the expenditure can eventually be reduced in relation to operational costs. The operational cost per year for the SPP diesel engine can provide a significant reduction of as much as RM 6758,mainly due to the reduction of fuel cost. The use of the SPP diesel instead of the petrol outboard motor results in considerable cost savings,and thus an improved economic performance.

6 Concluding remarksThis paper proposes the concept of a propulsion system for inshore fishing boat using diesel fuel and an SPP propeller(SPP diesel). A survey was conducted,and results show that the present system causes a high fuel consumption. However,there is currently no alternative propulsion available for the outboard motor. Studies in literature show that using the SPP diesel is more economical and fuel-efficient compared to the present system,and results from data collection in this study show that fuel saving can be gained using the proposed system. This research therefore proposes an alternative propulsion system that offers a reduced fuel consumption. In addition,a techno economic analysis reveals that adapatation of the proposed system would be financially viable,and that it would increase the turnover of fish landed and represent a significance contribution to sustaining the livlihoods of fishermen.

| Ahmad AT, Salim K, Ean CP, Isa MM, Fong LC, 2003. An overview of the socioeconomic status of fisheries in Malaysia. The world fish center working papers. Retrieved from http://www.worldfishcenter.org/resource_centre/AMF_Chapter-23-FA.pdf. |

| Allison JL (1978). Propellers for high-performance craft. Marine Technology Society Journal, 15(4), 335-380. |

| Banawan AA, Mosleh M, Seddiek IS, 2013. Prediction of the fuel saving and emissions reduction by decreasing speed of a catamaran. Journal of Marine Engineering & Technology, 12(3), 40-48. DOI: 10.1080/20464177.2013.11020287 |

| Buhaug Ø, Corbett JJ, Endresen Ø, Eyring V, Faber J, Hanayama S, Yoshida K, 2009. Second IMO GHG study. International Maritime Organization (IMO), London, UK. |

| Dahou K, Déme M, Dioum A, 2001. Socio-economic and environmental impact of Senegalese fishery support mechanisms. UNEP, Geneva, 34. |

| Department of Fisheries Malaysia, 2011. Annual Fisheries Statistics Book. Retrieved from http://www.dof.gov.my. |

| FAO, 1995. Summary report of the CRODT/FAO CECAF ad hoc technical meeting on economic aspects of the exploitation of sardinellas and other small pelagic species off the Northwest African coast CRODT, Dakar. FAO, Rome. Retrieved from http://www.fao.org/docrep/003/V6444F/V6444F00.htm |

| Ferrando M, Crotti S, Viviani M, 2002. Performance of a family of surface piercing propellers. Royal Institution for Naval Architects (RINA) Transactions Part A, 11. |

| Ghassemi H, 2009. Hydrodynamic characteristic of the surface-piercing propellers for the planning craft. Journal of Marine Science and Application, 8(4), 267-274. DOI: 10.1007s11804-009-8076-2 |

| Gulbrandsen O, 1986. Reducing the fuel costs of small fishing boats. FAO Bay of Bengal Programme, 28. |

| Hadler JB, 1996. On partially submerged propeller propulsion. Workshop on Unconventional Propulsion, ITTC, 186-190. |

| Hydrocompinc Inc., 2007. NavCad manual. Retrieved from http://hydrocompinc.com/software/navcad. |

| Jaichandar S, Annamalai K, 2011. The status of biodiesel as an alternative fuel for diesel engine-An Overview. Journal of Sustainable Energy & Environment, 2, 71-75. |

| Kelleher K, Arnasson R, Willmann R, 2008. The Sunken Billions: the economic justification for fisheries reform. World Bank, Agriculture and Rural Development Department – and Food and Agriculture Organization, Washington, DC, 80. |

| MacPherson DM, 2003. Comments on reliable prediction accuracy. A HydroCamp Technical Report. Retrieved from www.hydrocompinc.com/knowledge/whitepapers/HC103-ReliablePrediction.pdf. |

| Mohd Pauzi AG, Yaakob O, Ahmad Fuaad AS, 1991. Powering estimates of deep sea fishing boat. National Seminar on Fishing Technology, Universiti Pertanian Malaysia, Kuala Terengganu. |

| Nagi J, Nagi SKAF, 2008. Palm biodiesel an alternative green renewable energy for the energy demands of the future. International Conference on Construction and Building Technology (ICCBT), 79-94. |

| Radojcic D, Matic D, 1997. Regression analysis of surface piercing propeller series. Paper presented at NAV & HSHV International Conference. Naples-Sorento, Italy. Retrieved from http://mararchief.tudelft.nl/catalogue/entries/13132/. |

| Savitsky D, Brown P, 1976. Procedures for hydrodynamic evaluation of planning hulls in smooth and rough water. Marine Technology, 13(1), 381-400. |

| Schneiders CC, 1990. Should ship performance be predicted by calculation? Naval Architect, 6, E250-E261. |

| Seddiek IS, Mosleh MA, Banawan AA, 2013. Fuel saving and emissions cut through shore-side power concept for high-speed crafts at the red sea in Egypt. Journal of Marine Science and Application, 12(4), 463-472. DOI: 10.1007/s11804-013-1218-6 |

| Sherbaz S, Duan W, 2012. Operational options for green ships. Journal of Marine Science and Application, 11(3), 335-340. |

| Suhaimi NAM, Hussein MA, Latiff I, Mohayidin G, 2011. The level of technical efficiency of the inshore fishermen in Kuala Terengganu. Economic and Technology Management Review, 6, 83-91. |

| Sumaila UR, Teh L, Watson R, Tyedmers P, Pauly D, 2008. Fuel price increase, subsidies, overcapacity, and resource sustainability. ICES Journal of Marine Science: Journal du Conseil, 65(6), 832-840. DOI: 10.1093/icesjms/fsn070 |

| Suuronen P, Chopin F, Glass C, Løkkeborg S, Matsushita Y, Queirolo D, Rihan D, 2012. Low impact and fuel efficient fishing—looking beyond the horizon. Fisheries Research, 119, 135-146. DOI: 10.1016/j.fishres.2011.12.009 |

| Wilson JD, 1999. Fuel and financial savings for operators of small fishing vessels. Food and Agriculture Organization of the United Nations, Rome. |