自20世纪50年代Irwin提出采用应力强度因子K描述裂尖应力场以来,线弹性断裂力学(Linear Elastic Fracture Mechanics, LEFM)得到了迅猛发展,为含裂纹缺陷材料和结构剩余强度及疲劳寿命分析提供了重要理论支撑,并在桥梁建筑、航空航天、船舶交通等工程领域得到广泛应用[1]。

在线弹性理论框架下,裂尖完整应力场由奇异项、常数项以及若干高阶项组成[2]。传统LEFM采用应力强度因子K单一参量表征裂尖应力场,并将K作为含裂纹材料和结构安全性评定和疲劳裂纹扩展分析的计算参量。工程实际结构中的裂纹可能为I型、II型和III型3种基本类型裂纹中的任意2种或3种组合而成的混合型裂纹。基于单一K参量建立的如最大环向应力准则[3](MTS)、最小密度因子准则[4-5](SED)和平均应变能密度准则[6](ASED)等断裂准则为混合型裂纹材料与构件断裂破坏提供了重要判据,解释了裂纹起裂偏折方向和起裂条件[7],并分别得到了印证和应用。

然而,研究表明当裂纹受到高约束时,裂尖应力场中与裂纹尖端距离无关、平行于裂纹面的常数项

本文对考虑裂尖应力场常数项影响的修正MTS准则[12-13]、修正SED准则[14-15]和修正ASED准则[16]进行介绍,给出计及裂尖应力场常数项影响的裂纹偏折角和断裂判据表达式;在此基础上,对比分析应力场常数项以及泊松比对工程中常见的I型裂纹起裂扩展行为的影响,研究应力场常数项对I型裂纹偏折、起裂扩展影响阀值及一般规律,为含裂纹材料及结构断裂力学评估提供一定参考。

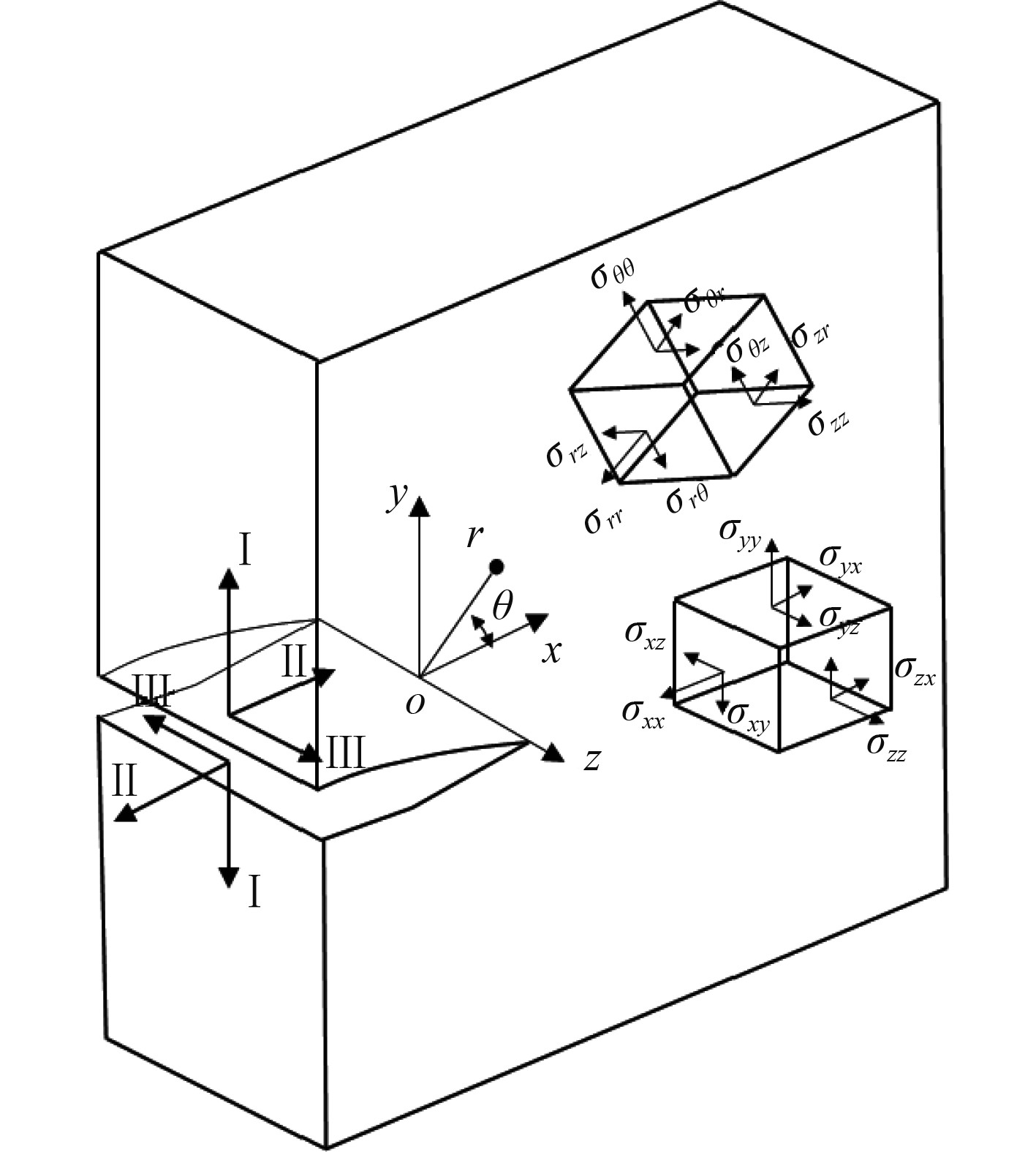

1 裂纹尖端应力场裂纹尖端应力场示意如图1所示。任意线弹性裂纹体中裂纹尖端附近应力场特征级数展开包括奇异项(

|

图 1 裂纹尖端应力场示意 Fig. 1 Stress field around crack tip |

| $ \begin{aligned}[b] & {\sigma }_{ij}=\frac{{K}_{\mathrm{{\rm I}}}}{\sqrt{2{\text π} r}}{f}_{ij}^{\mathrm{I}}\left(\theta \right)+\frac{{K}_{\mathrm{{\rm I}}\mathrm{I}}}{\sqrt{2{\text π} r}}{f}_{ij}^{\mathrm{I}\mathrm{I}}\left(\theta \right)+\frac{{K}_{\mathrm{{\rm I}}\mathrm{I}\mathrm{I}}}{\sqrt{2{\text π} r}}{f}_{ij}^{\mathrm{I}\mathrm{I}\mathrm{I}}\left(\theta \right)+\\ & T{\delta }_{1i}{\delta }_{1j}+\left(\upsilon T+E{\varepsilon }_{33}\right){\delta }_{3i}{\delta }_{3j}+O\left({r}^{\frac{1}{2}}\right) 。\end{aligned} $ | (1) |

式中:

极坐标系下,考虑裂纹尖端应力场特征级数展开前2项(奇异项和常数项)的混合型裂纹尖端应力场表达式为[2]:

| $ \left[ \begin{array}{l}{\sigma }_{rr}\\ {\sigma }_{\theta \theta }\\ {\sigma }_{r\theta }\\ {\sigma }_{zz}\end{array} \right] = {\left[ \begin{gathered}{c} \frac{1}{\sqrt{2{\text π} r}}\mathrm{cos}\frac{\theta }{2}\left[{K}_{\mathrm{I}}\left(1 + {\mathrm{sin}}^{2}\frac{\theta }{2}\right) + {K}_{\mathrm{{\rm I}}\mathrm{I}}\left(\frac{3}{2}\mathrm{sin}\theta - 2\mathrm{tan}\frac{\theta }{2}\right)\right] + T{\mathrm{cos}}^{2}\theta \\ \frac{1}{\sqrt{2{\text π} r}}\mathrm{cos}\frac{\theta }{2}\left[{K}_{\mathrm{I}}{\mathrm{cos}}^{2}\frac{\theta }{2}-\frac{3}{2}{K}_{\mathrm{I}\mathrm{I}}\mathrm{sin}\theta \right]+T{\mathrm{sin}}^{2}\theta \\ \frac{1}{2\sqrt{2{\text π} r}}\mathrm{cos}\frac{\theta }{2}\left[{K}_{\mathrm{I}}\mathrm{sin}\theta +{K}_{\mathrm{I}\mathrm{I}}\left(3\mathrm{cos}\theta -1\right)\right]-T\mathrm{sin}\theta \mathrm{cos}\theta \\ {\upsilon }^{'}\left({\sigma }_{rr}+{\sigma }_{\theta \theta }\right)\qquad\qquad\qquad \qquad\qquad\qquad\qquad\qquad\qquad \end{gathered}\right]。} $ | (2) |

式中:参数

一般通过引入无量纲参数

反映裂纹应力场常数项

| $ B\alpha =\frac{T\sqrt{2{\text π} {r}_{\mathrm{c}}}}{{K}_{{e}{f}{f}}}=\frac{{K}_{{{I}}{c}}T}{{\sigma }_{\mathrm{t}}\sqrt{{K}_{\mathrm{I}}^{2}+{K}_{\mathrm{I}\mathrm{I}}^{2}+{K}_{\mathrm{I}\mathrm{I}\mathrm{I}}^{2}}} 。$ | (3) |

对于I型裂纹(

断裂准则可为混合型裂纹材料与构件断裂破坏提供重要判据,能够解释裂纹起裂偏折方向和起裂条件[7]。本章对工程中常用的最大环向应力准则(MTS)、最小应变能密度因子准则(SED)和平均应变能密度准则(ASED)考虑应力场常数项修正的断裂准则理论进行介绍,给出相应断裂准则裂纹偏折角度和起裂扩展判据计算式。

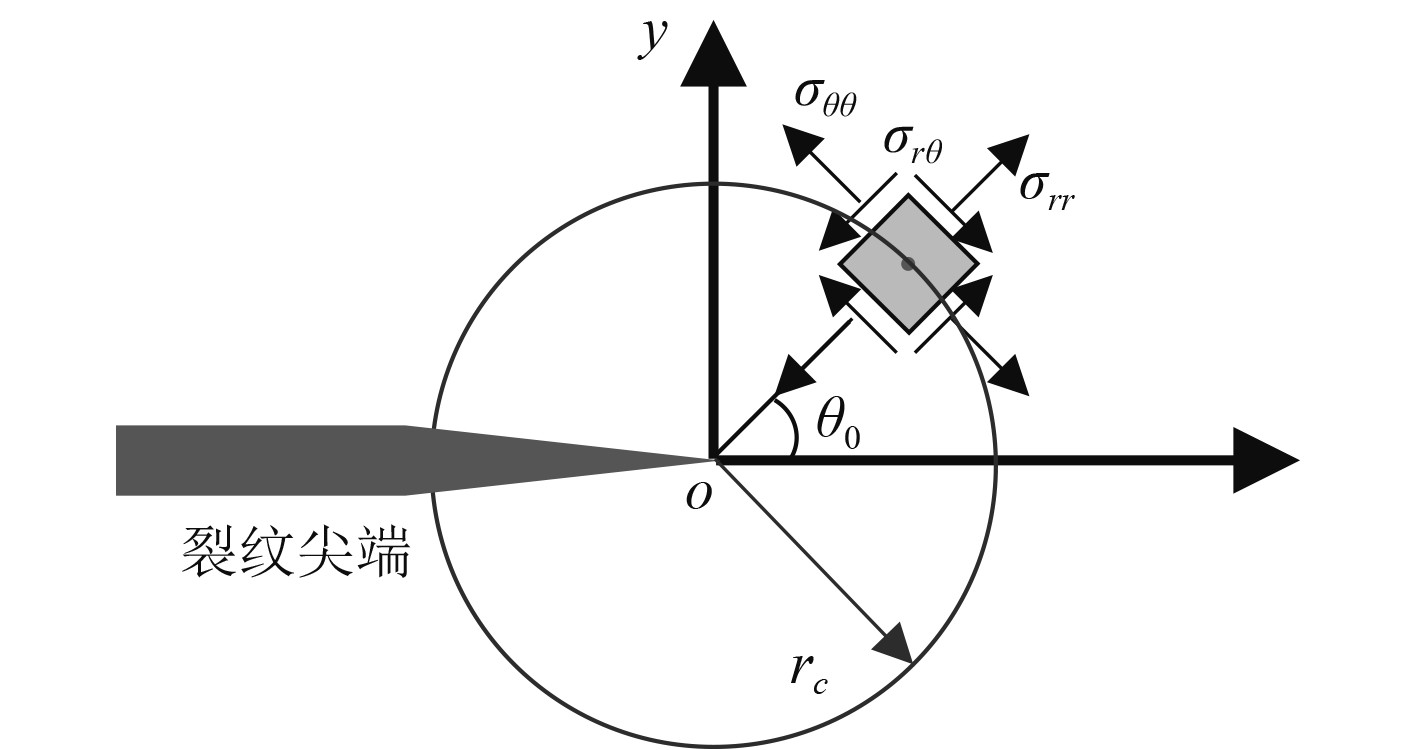

2.1 修正MTS准则Erdogan等[3]根据具有中心斜裂纹树脂玻璃板均匀拉伸试验结果提出了著名的最大环向应力准则(MTS准则),MTS准则认为裂纹沿临界距离

|

图 2 最大环向应力准则裂纹偏折示意 Fig. 2 Schematic diagram of MTS criterion |

| $ \left\{\begin{array}{c} {\left.\displaystyle\frac{\partial {\sigma }_{\theta \theta }}{\partial \theta }\right|}_{\begin{subarray}{c}\theta ={\theta }_{0}\\ r={r}_{{c}}\end{subarray}}=0,\\ {\left.\displaystyle\frac{{\partial }^{2}{\sigma }_{\theta \theta }}{\partial {\theta }^{2}}\right|}_{\begin{subarray}{c}\theta ={\theta }_{0}\\ r={r}_{{c}}\end{subarray}} < 0,\end{array}\right. $ | (4) |

| $ {\left({\sigma }_{\theta \theta }\right)}_{\mathrm{m}\mathrm{a}\mathrm{x}}={\left.{\sigma }_{\theta \theta }\right|}_{\begin{subarray}{c}\theta ={\theta }_{0}\\ r={r}_{{c}}\end{subarray}}={\sigma }_{{c}}。$ | (5) |

式中,断裂应力

| $ {\left.{\sigma }_{\theta \theta }\right|}_{\begin{subarray}{c}\theta =0\\ r={r}_{{c}}\end{subarray}}=\frac{1}{\sqrt{2{\text π} {r}_{{c}}}}{K}_{{Ic}}={\sigma }_{{c}}。$ | (6) |

将式(2)中环向应力

| $ \left[ {K}_{\mathrm{I}}\mathrm{sin}{\theta }_{0} + {K}_{\mathrm{I}\mathrm{I}}\left(3\mathrm{cos}{\theta }_{0} - 1\right) \right] - \frac{16}{3}T \sqrt{2{\text π} {r}_{{c}}}\mathrm{sin}\frac{{\theta }_{0}}{2}\mathrm{cos}{\theta }_{0} = 0 。$ | (7) |

然后,将求解得到裂纹偏折角

| $ \mathrm{cos}\frac{{\theta }_{0}}{2}\left({K}_{\mathrm{I}}{\mathrm{cos}}^{2}\frac{{\theta }_{0}}{2} - \frac{3}{2}{K}_{\mathrm{I}\mathrm{I}}\mathrm{sin}{\theta }_{0}\right) + T\sqrt{2{\text π} {r}_{{c}}}{\mathrm{sin}}^{2}{\theta }_{0} = {K}_{{Ic}}。$ | (8) |

引入参数

| $ \left[ {K}_{\mathrm{I}}\mathrm{sin}{\theta }_{0} + {K}_{\mathrm{I}\mathrm{I}} \left(3\mathrm{cos}{\theta }_{0} - 1\right) \right] - \frac{16}{3} \left( B\alpha \right) {K}_{{e}{f}{f}}\mathrm{sin}\frac{{\theta }_{0}}{2}\mathrm{cos}{\theta }_{0} = 0 ,$ | (9) |

| $ \mathrm{cos}\frac{{\theta }_{0}}{2}\left( {K}_{\mathrm{I}}{\mathrm{cos}}^{2}\frac{{\theta }_{0}}{2} - \frac{3}{2}{K}_{\mathrm{I}\mathrm{I}}\mathrm{sin}{\theta }_{0} \right) + \left( B\alpha \right){K}_{{e}{f}{f}}{\mathrm{sin}}^{2}{\theta }_{0} = {K}_{\mathrm{I}\mathrm{c}} 。$ | (10) |

修正MTS准则裂纹起裂偏折角及等效应力强度因子计算式包含临界半径

根据修正MTS准则,考虑裂纹应力场常数项

| $ \mathrm{sin}{\theta }_{0}-\frac{16}{3}\left(B\alpha \right)\mathrm{sin}\frac{{\theta }_{0}}{2}\mathrm{cos}{\theta }_{0}=0 ,$ | (11) |

| $ \left[{\mathrm{cos}}^{3}\frac{{\theta }_{0}}{2}+\left(B\alpha \right){\mathrm{sin}}^{2}{\theta }_{0}\right]{K}_{\mathrm{I}}={K}_{{Ic}}。$ | (12) |

可知,考虑裂纹尖端应力场常数项

Sih[4-5]基于裂纹尖端应力应变场能量理论提出了最小应变能密度因子准则(SED准则)。SED准则利用应变能密度因子

| $ S=wr=\frac{r}{2G}\left[\frac{1+\kappa }{8}{\left({\sigma }_{rr}+{\sigma }_{\theta \theta }\right)}^{2}-{\sigma }_{rr}{\sigma }_{\theta \theta }+{\sigma }_{r\theta }^{2}\right]。$ | (13) |

式中:

SED准则假设当裂纹尖端临界距离

| $ \left\{ \begin{array}{c}{\left.\displaystyle\frac{\partial S}{\partial \theta }\right|}_{\begin{subarray}{c}\theta ={\theta }_{0}\\ r={r}_{{c}}\end{subarray}}=0,\\ {\left.\displaystyle\frac{{\partial }^{2}S}{\partial {\theta }^{2}}\right|}_{\begin{subarray}{c}\theta ={\theta }_{0}\\ r={r}_{{c}}\end{subarray}} > 0,\end{array}\right. $ | (14) |

| $ {S}_{\mathrm{m}\mathrm{i}\mathrm{n}}={\left.S\right|}_{\begin{subarray}{c}\theta ={\theta }_{0}\\ r={r}_{{c}}\end{subarray}}={S}_{\mathrm{c}} 。$ | (15) |

将式(2)代入式(13)可得到考虑裂尖应力场奇异项和常数项的应变能密度因子

| $\begin{aligned}[b] S= & \frac{1}{16{\text π} G} [{a}_{1}{K}_{\mathrm{I}}^{2}+{a}_{2}{K}_{\mathrm{I}\mathrm{I}}^{2}+{a}_{3}{K}_{\mathrm{I}}{K}_{\mathrm{I}\mathrm{I}}+{a}_{4}\sqrt{2{\text π} {r}_{c}}{K}_{\mathrm{I}}T+ \\ & {a}_{5}\sqrt{2{\text π} {r}_{{c}}}{K}_{\mathrm{I}\mathrm{I}}T+{a}_{6}\left(2{\text π} {r}_{{c}}\right){T}^{2} ]。\end{aligned} $ | (16) |

式中,系数

| $ \left\{\begin{gathered}{a}_{1}=\left(1+\mathrm{cos}\theta \right)\left({{k}} -\mathrm{cos}\theta \right) ,\\ {a}_{2}=\left[{{k}} \left(1-\mathrm{cos}\theta \right)+\mathrm{cos}\theta \left(3\mathrm{cos}\theta +1\right)\right],\\ {a}_{3}=2\mathrm{sin}\theta \left(2\mathrm{cos}\theta -{{k}} +1\right),\\ {a}_{4}=2\mathrm{cos}\frac{\theta }{2}\left(\mathrm{cos}2\theta -\mathrm{cos}\theta +{{k}} -1\right),\\ {a}_{5}=-2\mathrm{sin}\frac{\theta }{2}\left(\mathrm{cos}2\theta +\mathrm{cos}\theta +{{k}} +1\right),\\ {a}_{6}=\left({{k}} +1\right)/2。\qquad\qquad\qquad\qquad\quad \end{gathered}\right. $ | (17) |

式(15)中临界值

| $ {S}_{\mathrm{m}\mathrm{i}\mathrm{n}}={\left.S\right|}_{\begin{subarray}{c}\theta =0\\ r={r}_{{c}}\end{subarray}}=\frac{{\text{κ}} -1}{8{\text π} \mu }{K}_{{Ic}}^{2}={S}_{{c}} ,$ | (18) |

将式(16)代入式(14),求解得到考虑裂尖应力场常数项的修正SED准则裂纹偏折角

| $ \begin{aligned}[b] & {b}_{1}{K}_{\mathrm{I}}^{2}+{b}_{2}{K}_{\mathrm{I}\mathrm{I}}^{2}+{b}_{3}{K}_{\mathrm{{\rm I}}}{K}_{\mathrm{{\rm I}}\mathrm{{\rm I}}}+{b}_{4}\left(B\alpha \right){K}_{\mathrm{I}}{K}_{{e}{f}{f}}+\\ & {b}_{5}\left(B\alpha \right){K}_{\mathrm{I}\mathrm{I}}{K}_{{e}{f}{f}}+{b}_{6}{\left(B\alpha \right)}^{2}{K}_{{e}{f}{f}}^{2}=0。\end{aligned}$ | (19) |

式中,系数

| $ \left\{\begin{gathered}{b}_{1}=\left(2\mathrm{cos}{\theta }_{0}-\kappa +1\right)\mathrm{sin}{\theta }_{0},\\ {b}_{2}=\left(\kappa -1-6\mathrm{cos}{\theta }_{0}\right)\mathrm{sin}{\theta }_{0},\\ {b}_{3}=2\left[2\mathrm{cos}2{\theta }_{0}-\left(\kappa -1\right)\mathrm{cos}{\theta }_{0}\right],\\ {b}_{4}=-\mathrm{sin}\frac{{\theta }_{0}}{2}\left[5\left(\mathrm{cos}2{\theta }_{0}+\mathrm{cos}{\theta }_{0}\right)+\kappa +1\right],\\ {b}_{5}=-\mathrm{cos}\frac{{\theta }_{0}}{2}\left[5\left(\mathrm{cos}2{\theta }_{0}-\mathrm{cos}{\theta }_{0}\right)+\kappa +3\right],\\ {b}_{6}=0。\qquad\qquad\qquad\qquad\qquad\qquad\quad \end{gathered}\right. $ | (20) |

将式(19)求解得到的裂纹偏折角

| $ {\sqrt{{c}_{1} {K}_{\mathrm{I}}^{2} + {c}_{2} {K}_{\mathrm{I}\mathrm{I}}^{2}+{c}_{3}{K}_{\mathrm{{\rm I}}}{K}_{\mathrm{{\rm I}}\mathrm{{\rm I}}} + {c}_{4}\left( B\alpha \right){K}_{\mathrm{I}}{K}_{e f f} + {c}_{5}\left( B\alpha \right){K}_{\mathrm{I}\mathrm{I}}{K}_{e f f} + {c}_{6}{\left( B\alpha \right)}^{2}{K}_{e f f}^{2}} = {K}_{Ic} }。$ | (21) |

式中,系数

| $ \left\{\begin{gathered}{c}_{1}=\frac{1}{2\left({k} -1\right)}\left(1+\mathrm{cos}{\theta }_{0}\right)\left({k} -\mathrm{cos}{\theta }_{0}\right),\\ {c}_{2}=\frac{1}{2\left({k} -1\right)}\left[{k} \left(1-\mathrm{cos}{\theta }_{0}\right)+\mathrm{cos}{\theta }_{0}\left(3\mathrm{cos}{\theta }_{0}+1\right)\right],\\ {c}_{3}=\frac{1}{\left({k} -1\right)}\mathrm{sin}{\theta }_{0}\left(2\mathrm{cos}{\theta }_{0}-{k} +1\right),\\ {c}_{4}=\frac{1}{\left({k} -1\right)}\mathrm{cos}\frac{{\theta }_{0}}{2}\left(\mathrm{cos}2{\theta }_{0}-\mathrm{cos}{\theta }_{0}+{k} -1\right),\\ {c}_{5}=-\frac{1}{\left({k} -1\right)}\mathrm{sin}\frac{{\theta }_{0}}{2}\left(\mathrm{cos}2{\theta }_{0}+\mathrm{cos}{\theta }_{0}+{k} +1\right),\\ {c}_{6}=\frac{\left({k} +1\right)}{4\left({k} -1\right)}。\qquad\qquad\qquad\qquad\qquad\qquad\qquad \end{gathered}\right. $ | (22) |

根据式(19)和式(20)可知,修正SED准则裂纹偏折角及裂纹起裂判据计算式中不仅包含临界半径

根据修正SED准则,I型裂纹(

| $ {b}_{1}+{b}_{4}\left(B\alpha \right)=0 ,$ | (23) |

| $ \sqrt{{c}_{1}+{c}_{4}\left(B\alpha \right)+{c}_{6}{\left(B\alpha \right)}^{2}}{K}_{\mathrm{I}}={K}_{\mathrm{I}\mathrm{c}} 。$ | (24) |

称式(24)左端为修正SED准则I型裂纹等效应力强度因子

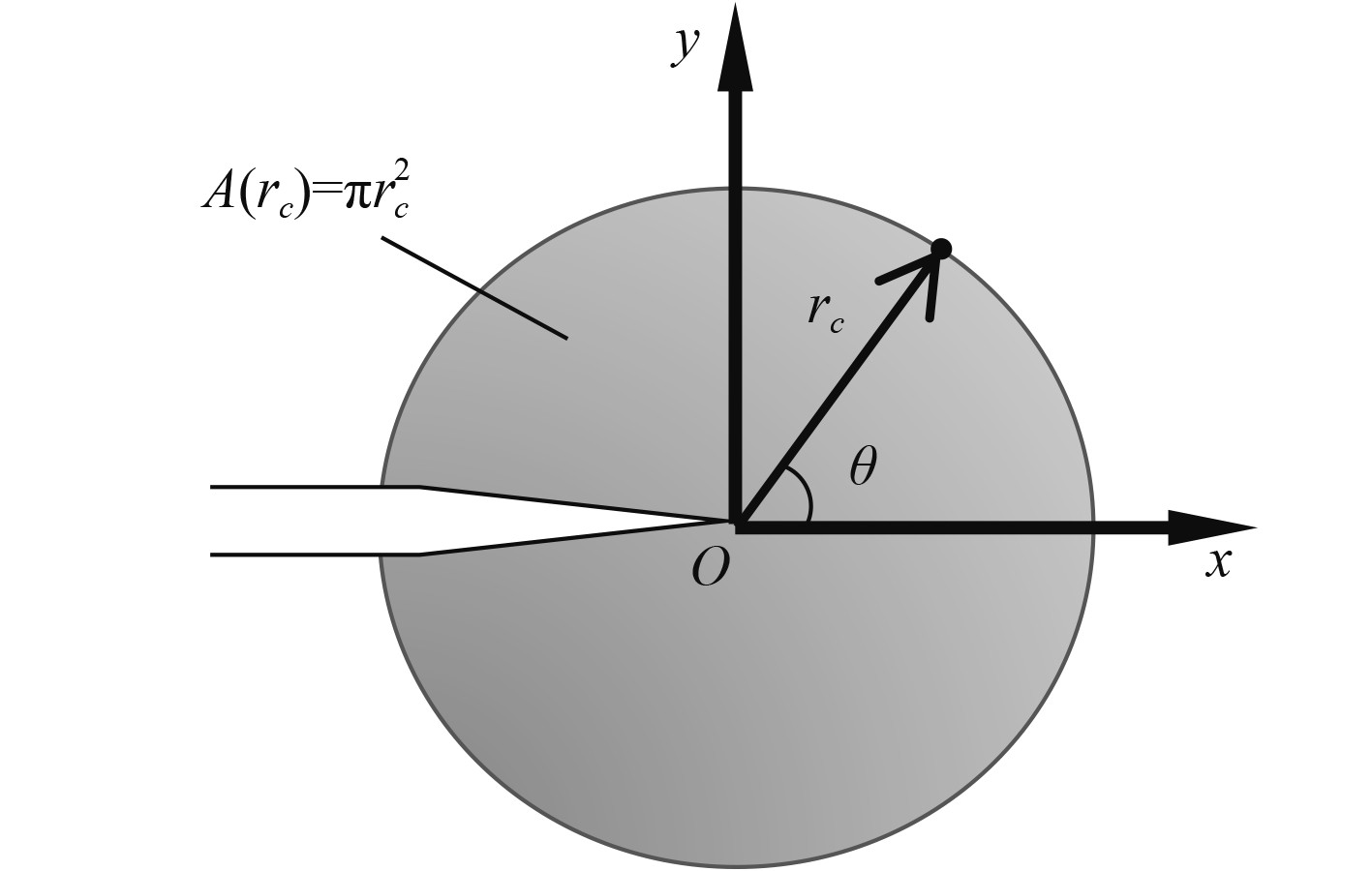

Lazarrin等[6]提出基于能量观点的平均应变能密度准则(ASED准则),该准则认为裂纹尖端临界距离

|

图 3 裂纹尖端断裂控制区域 Fig. 3 Fracture progress zone |

ASED准则可表示为:

| $ \bar {E}\left({r}_{{c}}\right)=\frac{{\displaystyle\int }_{0}^{{r}_{\mathrm{c}}}{\displaystyle\int }_{-{\text π} }^{{\text π} }S\mathrm{d}\theta \mathrm{d}r}{{\text π} {r}_{{c}}^{2}}={\bar {E}}_{{c}},$ | (25) |

将应变能密度因子表达式(16)代入式(25),可得到考虑裂尖应力场奇异项和常数项的平均应变能

| $ \bar{E}\left( {r}_{{c}} \right) = \frac{\left( -1 + 2{k} \right)}{16\mu {\text π} {r}_{\mathrm{c}}} {k}_{\mathrm{I}}^{2} + \frac{\left(3 + 2{k} \right)}{16\mu {\text π} {r}_{\mathrm{c}}} {k}_{\mathrm{I}\mathrm{I}}^{2} + \frac{\sqrt{2}\left(-7 + 5{k} \right)}{15\sqrt{{\text π} }\mu {\text π} \sqrt{{r}_{\mathrm{c}}}} {k}_{\mathrm{I}}T + \frac{\left( 1 + {k} \right)}{16\mu }{T}^{2}。$ | (26) |

式(25)中临界值

| $ {\bar{E}}_{{c}}=\frac{\left(2{k} -1\right)}{16{\text π} G{r}_{{c}}}{K}_{{I}{c}}^{2}。$ | (27) |

结合式(25)~式(27)便可得到修正ASED准则混合型裂纹断裂判据表达式为[16]:

| $ {{ \sqrt{{K}_{\mathrm{I}}^{2} + \displaystyle\frac{3 + 2{k} }{-1 + 2{k} }{K}_{\mathrm{I}\mathrm{I}}^{2} + \displaystyle\frac{16\left( -7 + 5{k} \right)}{15{\text π} \left( -1 + 2{k} \right)}\left(B\alpha \right){K}_{\mathrm{I}}{K}_{e f f} + \displaystyle\frac{\left(1+{k} \right)}{2\left( -1 + 2{k} \right)}{\left(B\alpha \right)}^{2}{K}_{e f f}^{2}} = {K}_{Ic} }}。$ | (28) |

根据式(28)可知,修正ASED准则同样能够考虑泊松比的影响,可区分平面应力及平面应变状态。当

根据修正ASED准则,I型裂纹(

| $ \sqrt{1+\frac{16\left(-7+5{k} \right)}{15{\text π} \left(-1+2{k} \right)}\left(B\alpha \right)+\frac{\left(1+{k} \right)}{2\left(-1+2{k} \right)}{\left(B\alpha \right)}^{2}}{K}_{\mathrm{I}}={K}_{Ic} 。$ | (29) |

称式(29)左端为修正ASED准则I型裂纹等效应力强度因子

工程结构中最常见的裂纹形式为I型裂纹,对于不考虑裂尖应力场常数项

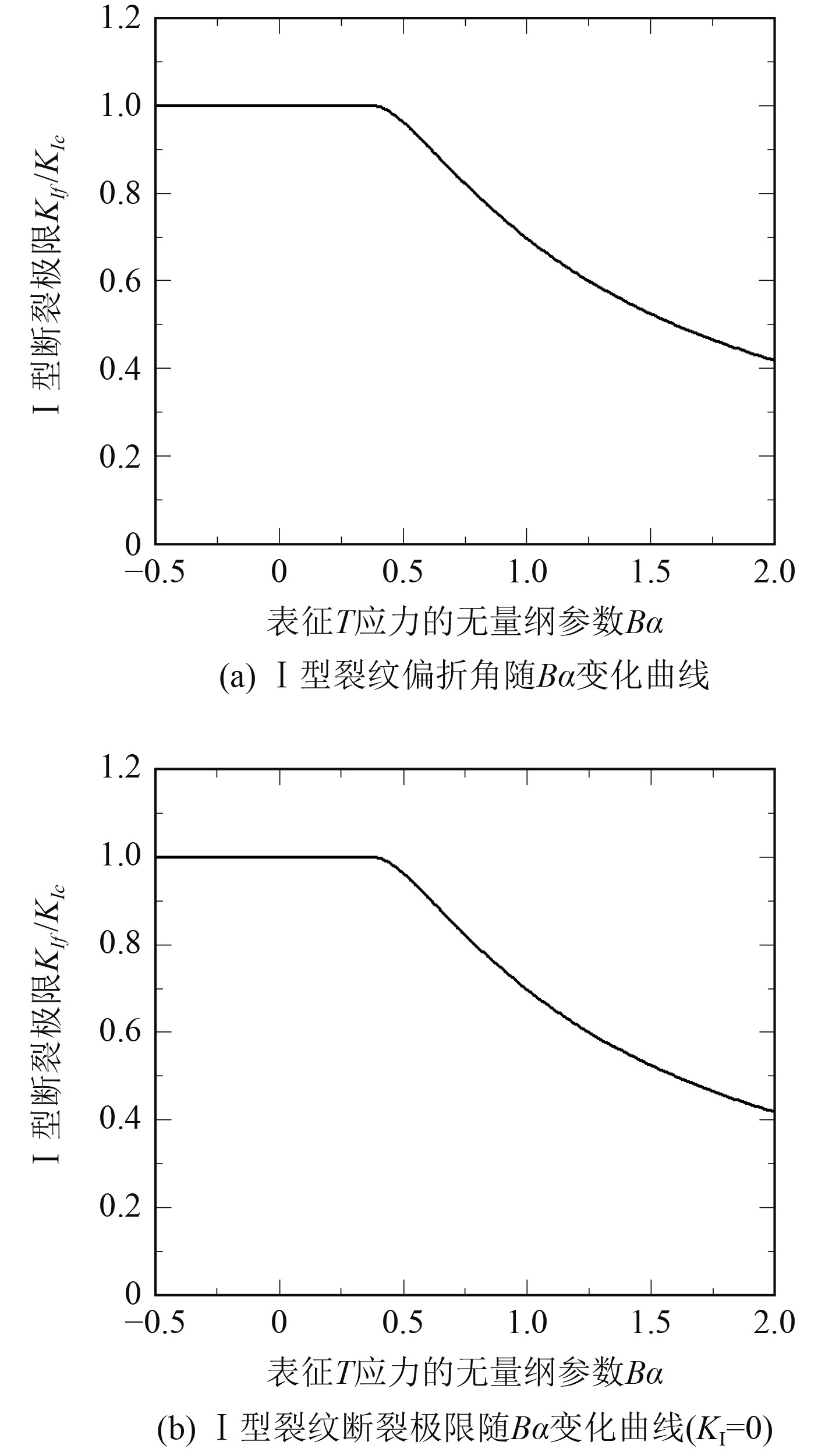

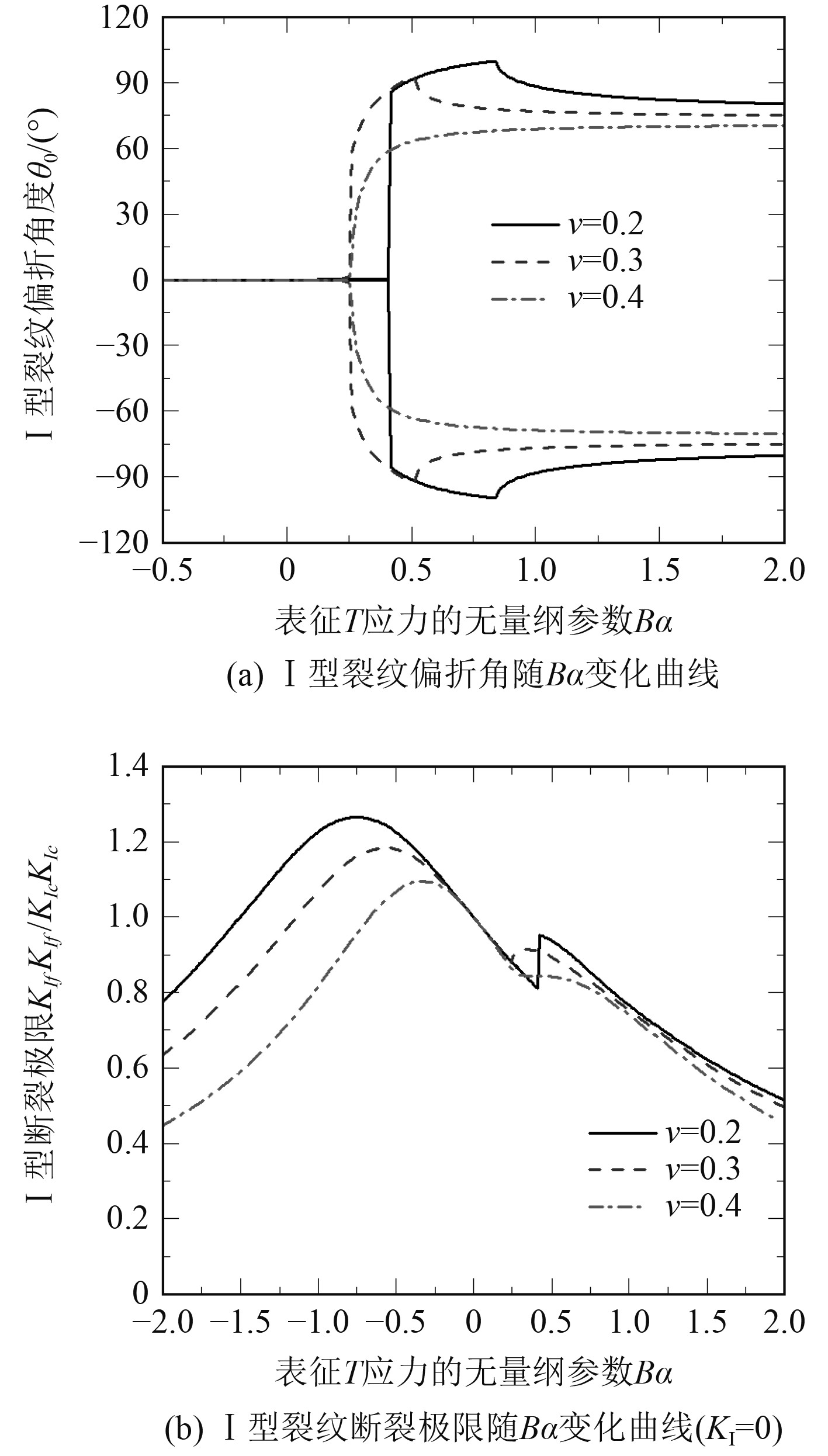

图4为基于修正MTS准则得到的I型裂纹初始偏折角度

|

图 4 T应力对I型裂纹起裂扩展行为影响(基于修正MTS准则) Fig. 4 The effect of T stress on mode I crack fracture behavior based on modified MTS criterion |

由图4(a)可知,当

由图4(b)可知:当

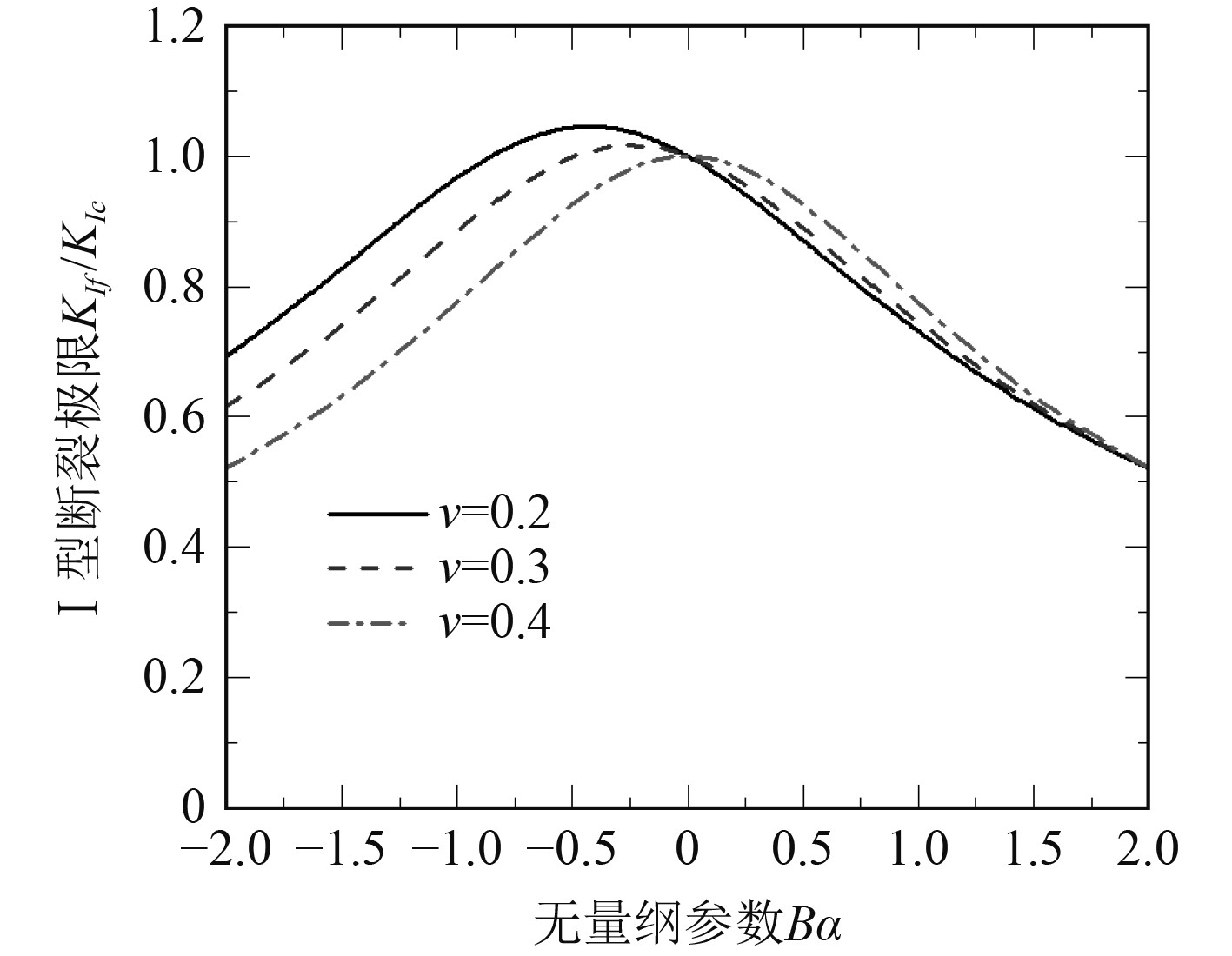

图5为基于修正SED准则得到的平面应变状态、不同泊松比

|

图 5 基于修正SED准则的I型裂纹起裂扩展行为 Fig. 5 The effect of T stress on mode I crack fracture behavior based on modified SED criterion |

由图5(a)可知,泊松比

由图5(b)可知,对于某一给定泊松比情况下(如泊松比

由图5(b)可知基于修正SED准则理论的泊松比

图6为基于修正ASED准则得到的平面应变状态、不同泊松比

|

图 6 基于修正ASED准则的I型裂纹起裂扩展行为 Fig. 6 The effect of T stress on mode I crack fracture behavior based on modified ASED criterion |

可知,对于某一给定泊松比情况下(如以泊松比

由图6可知,基于修正ASED准则理论的泊松比

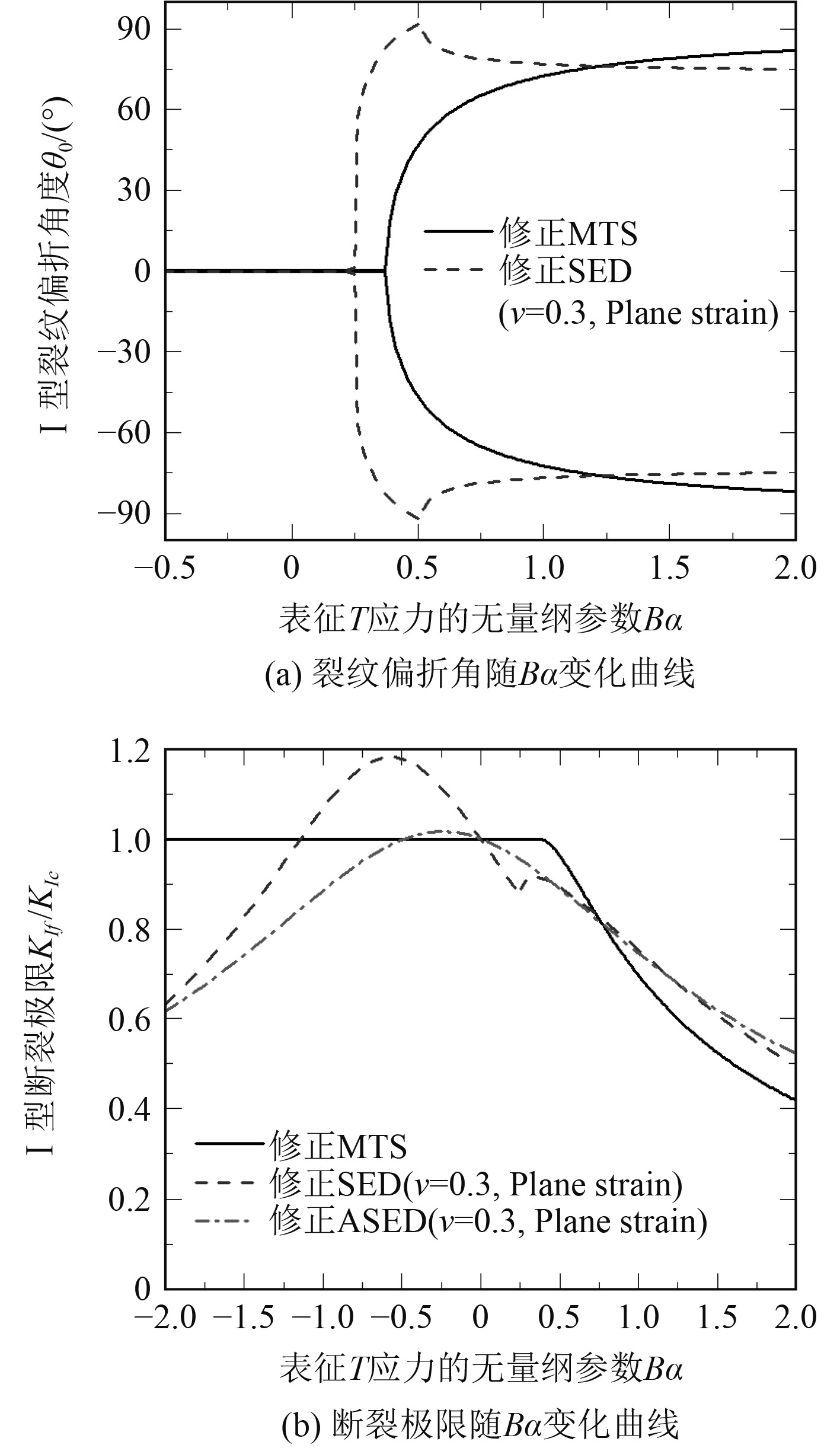

将基于修正MTS准则、修正SED准则以及修正ASED准则获得的I型裂纹断裂极限与断裂韧性的比值

|

图 7 考虑裂尖应力场常数项影响的I型裂纹起裂扩展行为 Fig. 7 The effect of T stress on mode I crack fracture behavior |

由图7(a)可知,1)根据修正MTS准则,当

由图7(b)可知,1)当裂尖应力场常数项

分别基于修正MTS准则、修正SED准则和修正ASED准则,对比分析了裂尖应力场常数项及泊松比对I型裂纹偏折、起裂扩展影响,得到以下结论:

1)根据修正MTS准则,当参数

2)根据修正SED准则,当

3)根据修正ASED准则,裂尖应力场常数项

4)当裂纹尖端应力场常数项为负值时,修正ASED准则断裂判据为最保守;当裂纹尖端应力场常数项为正值时,修正SED准则和修正ASED准则断裂判据基本一致;当

在进行材料与结构I型裂纹断裂力学评估时,应具体结合材料断裂特性实验结果最终确定相应的断裂准则。

| [1] |

吴学仁, 徐武. 裂纹体分析的权函数理论与应用: 回顾和展望[J]. 力学进展, 2022, 52(3): 415-507. WU Xueren, XU Wu. Weight function theory and applications for crack analysis: A review and outlook[J]. Advances in Mechanics, 2022, 52(3): 415-507. DOI:10.6052/1000-0992-21-060 |

| [2] |

WILLIAMS M L. On the stress distribution at the base of a stationary crack[J]. Journal of Applied Mechanics, 1957(24): 109-114. |

| [3] |

ERDOGAN F, SIH G C. On the crack extension in plates under plane loading and transverse shear[J]. Journal of Basic Engineering, 1963(85): 519-25. |

| [4] |

SIH G C. Some basic problems in fracture mechanics and new concepts[J]. Engineering Fracture Mechanics, 1973(5): 365-377. |

| [5] |

SIH G C. Strain energy density factor applied to mixed mode crack problem[J]. International Journal of Fracture, 1974(10): 305-321. |

| [6] |

LAZZARIN P, ZAMBARDI R. A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-shaped notches[J]. International Journal of Fracture, 2001, 112(3): 275-298. DOI:10.1023/A:1013595930617 |

| [7] |

杨立云, 韦鹏, 王青成, 等. 基于ABAQUS平台考虑T应力的I型裂纹扩展模拟开发[J/OL]. 工程力学: 1−9[2023-05-29]. YANG Liyun, WEI Peng, WANG Qingcheng, et al. Development of mode-I crack propagation simulation considering T-stress based on abaqus platform[J/OL]. Engineering Mechanics: 1−9[2023-05-29]. |

| [8] |

华文, 潘欣, 淦志强, 等. 基于广义最大周向应变准则的断裂特性研究[J]. 西南石油大学学报(自然科学版), 2021, 43(6): 42-53. HUA Wen, PAN Xin, GAN Zhiqiang, et al. A study on the fracture characterisc analysis based on the generalized maximum tangential strain criterion[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2021, 43(6): 42-53. |

| [9] |

LARSSON S G, CARLSSON A J. Influence of non-singular stress terms and specimen geometry on small-scale yielding at crack tips in elastic-plastic materials[J]. Journal of Physics and Mechincs, 1973(21): 263-277. |

| [10] |

AYATOLLAHI M R, MOGHADDAM M R, RAZAVI S M J, et al. Geometry effects on fracture trajectory of PMMA samples under pure mode-I loading[J]. Engineering Fracture Mechanics, 2016(163): 449-461. |

| [11] |

ASTM International, E2899-15. Standard test method for measurement of initiation toughness in surface cracks under tension and bending[S]. West Conshohocken: ASTM International, 2015.

|

| [12] |

SMITH D J, AYATOLLAHI M R, PAVIER M J. The role of T-stress in brittle fracture for linear elastic materials under mixed-mode loading[J]. Fatigue Fracture Engineering Material Structure, 2001(24): 137-150. |

| [13] |

赵艳华, 陈晋, 张华. T应力对I-II复合型裂纹扩展的影响[J]. 工程力学, 2010, 27(4): 5-12. ZHAO Yanhua, CHEN Ji, ZHANG Hua. Influence of T-stress on crack propagation for I-II mixed mode loading[J]. Engineering Mechanics, 2010, 27(4): 5-12. |

| [14] |

MOGHADDAM M R, AYATOLLAHI M R, BERTO F. Mixed mode fracture analysis using generalized averaged strain energy criterion for linear elastic materials[J]. International Journal of Solids and Structures, 2017(120): 137-145. |

| [15] |

高文, 王生楠. T应力对线弹性材料脆性断裂的影响[J]. 西北工业大学学报, 2015, 33(6): 928-935. GAO Wen, WANG Shengnan. Effect of T-stress on the brittle fracture for linear elastic materials[J]. Journal of Northwestern Polytechnical University, 2015, 33(6): 928-935. DOI:10.3969/j.issn.1000-2758.2015.06.010 |

| [16] |

黄如旭, 谢晓忠, 谢锋, 等. 基于平均应变能密度准则的裂纹断裂扩展特性分析[J]. 舰船科学技术, 2020, 42(3): 20-24. HUANG Ruxu, XIE Xiaozhong, XIE Feng, et al. Crack fracture and growth behavior based on averaged strain energy density criterion[J]. Ship Science and Technology, 2020, 42(3): 20-24. DOI:10.3404/j.issn.1672-7649.2020.02.003 |

2024, Vol. 46

2024, Vol. 46