2. China Electricity Council Technical and Economic Consulting Centre of Electric Power Consturction, No. 13, Baiguang Road, Xicheng District, Beijing, China

With the expansion of the global industrial scale, problems such as environmental degradation, global warming, and excessive energy consumption have become increasingly prominent [1, 2]. Many countries have mentioned energy conservation and energy efficiency as their primary strategic position. The massive access of distributed generation (DG), multi-energy interconnection and energy marketization are effective ways to promote energy efficient and clean utilization [3, 4]. The diversity of load and energy types makes energy interconnection an inevitable trend, and multi-energy complementary parks become one of the typical forms of comprehensive energy utilization. Park is a gathering place for urban energy consumption. It is composed of multiple individuals with similar energy characteristics, and has the characteristics of energy concentration, large energy demand, and collection of electric/heat/cold loads [5-10].

In this paper, a multi-energy complementary park integrated energy supply center optimization considering P2G planning is proposed, the electric/heat/cold energy flow difference and the energy conversion, space-time translation characteristics of power to gas (P2G) equipment in multi-energy complementary parks are combined. Based on the annual planning cycle, the economic, environmental and reliability impacts of the integrated multi-energy complementary park energy supply system are based on the minimum objective function, with the lowest annual operating cost, the highest annual energy supply reliability and the most DG output characteristics. Excellent for the lower objective function, a two-layer multi-objective optimization configuration model including multiple energy supply devices is established.

2 Construction of Two-Level Multi-objective Optimization Configuration Model for Multi-energy Complementary Park Integrated Energy Supply CenterAs a complex energy system, the multi-energy complementary park involves the production, transfer, storage and utilization of electric/heat/cold multiple energy sources, with complex load characteristics, large load demand and high energy supply reliability requirements. In the park, the energy production unit usually includes wind turbine (WT), photovoltaic (PV), micro-turbines (MT), gas-fired boiler (GB), etc. The energy conversion unit includes heat pump. (heat pump, HP), air conditioner (AIR), heat-exchanger (HE), electric chiller (EC), absorption chiller (AC), and electric ventilating Power to gas (P2G), etc. The energy storage unit includes electric energy storage device (ES), thermal energy storage device (HS), cold energy storage device (CS) And the gas energy storage device (GS); The energy utilization unit includes electric load (Eload), heat load (Hload), and cold load (Cload).

2.1 Objective Function(1) Upper objective function: The upper layer has the minimum annual cost as the objective function, including equipment installation fee, fuel cost, operation and maintenance fee, interaction with the grid cost and environmental cost.

| $ {\rm{Min}}{C_{year}} = {\rm{Min}}\left( {{C_{inves}} + {C_{fuel}} + {C_{grid}} + {C_{opera}} + {C_{envir}}} \right) $ | (1) |

| $ {C_{inves}} = \sum\limits_{i = 1}^{{N_I}} {\beta _i^{equ}\left( {C_i^{inves}w_i^{equ}} \right)\gamma _i^{equ}} $ | (2) |

| $ {C_{fuel}} = {N_J}\sum\limits_{t = 1}^{{N_T}} {\left( {\frac{{P_t^{Gas}\Delta t}}{{{\eta _{Gas}}{v_{LHV}}}}{C_{gas}} + {\xi _{P2G}}{C_{P2G}}P_t^{P2G\_out}\Delta t} \right)} $ | (3) |

| $ {C_{grid}} = {N_J}\sum\limits_{t = 1}^{{N_T}} {\left[ {\left( {\frac{{{C_{t,sale}} + {C_{t,buy}}}}{2}} \right)P_t^{grid}\Delta t + \left( {\frac{{{C_{t,buy}} - {C_{t,sale}}}}{2}} \right)\left| {P_t^{grid}} \right|\Delta t} \right]} $ | (4) |

| $ {C_{opera}} = {N_J}\sum\limits_{t = 1}^{{N_T}} {\sum\limits_{i = 1}^{{N_I}} {C_i^{main}P_{t,i}^{equ}\Delta t} } $ | (5) |

| $ \begin{array}{l} {C_{envir}} = {N_J}\sum\limits_{t = 1}^{{N_T}} {\sum\limits_{u = 1}^{{N_U}} {\left[ {{R_u}\left( {k_u^{MT}\frac{{P_t^{MT}}}{{\eta _t^{MT}}} + k_u^{GB}\frac{{Q_t^{GB}}}{{\eta _t^{GB}}}} \right.} \right.} } \\ \;\;\;\;\;\;\;\;\;\;\left. {\left. { + k_u^{grid}\frac{{P_t^{grid}}}{{{\eta _{grid}}}}\psi _t^{grid}} \right)\Delta t - {R_{{\rm{C}}{{\rm{O}}_2}}}{k_{{\rm{C}}{{\rm{O}}_2}}}P_t^{P2G\_out}\Delta t} \right] \end{array} $ | (6) |

where: Cyear, Cinves, Cfuel, Cgrid, Copera, Cenvir are the multi-energy complementary park annual cost, equipment investment cost, fuel cost, and grid Interaction cost, operation and maintenance cost, and environmental cost; Ni is the type of investment equipment; Ciinves, wiequ, γiequ are the unit cost investment cost, installation capacity and installation factor of equipment i, respectively. If the device is installed, γiequ = 1, otherwise 0; βiequ is the present value coefficient of device i, as in Eq. (7):

| $ \beta _i^{equ} = \frac{{r_i^{equ} + {{\left( {1 + r_i^{equ}} \right)}^{Lf_i^{equ}}}}}{{{{\left( {1 + r_i^{equ}} \right)}^{Lf_i^{equ}}} - 1}} $ | (7) |

where: riequ, Lfiequ are the discount rate of equipment i (generally taken as 7%) and the whole life cycle; Nj is the total number of days in the planning period; Nt is the total number of periods of a typical day; PtGas, PtP2G_out, Ptgrid, Ptequ, i, PtMT, QtGB, ηtMT, ηGB, Ψtgrid are the power of the daily interaction with the natural gas network, the natural gas power value of the P2G output, and the interaction with the grid. Electric power, output power of device i, electric/thermal power value of MT, GB and its efficiency and interaction power factor with the grid, if Ptgrid > 0, then Ψtgrid = 1, and vice versa 0; Δt is the time interval, taken here as 1 h; ηGas is the power transmission efficiency of the natural gas network; Cgas, νLHV is the natural gas purchase price and the low calorific value of natural gas combustion; ξP2G, CP2G are the CO2 coefficient and CO2 price required for the production of unit natural gas in the P2G process, respectively; Ct, sale, Ct, buy are the time-division power distribution and time respectively. Purchase electricity price; Cimain is the unit capacity operation and maintenance cost of equipment i; Nu is the number of pollutant types, including CO2, SO2, NOx, etc.; Ru is the environmental value of pollutant u; ηgrid, kuMT, kuGB, kugrid respectively the emission intensity of pollutants u for MT, GB and interaction with the grid; ηgrid is the transmission efficiency of the grid; RCO2 is the environmental value of the pollutant CO2; kP2G CO2 is the CO2 during the process of P2G consumption intensity.

(2) Lower objective function: The lower layer has the lowest annual operating cost, the highest annual energy supply reliability, and the optimal DG output characteristic as the objective function.

| $ {\rm{Min}}{C_{year\_opera}} = {\rm{Min}}\left( {{C_{fuel}} + {C_{grid}} + {C_{opera}} + {C_{envir}}} \right) $ | (8) |

| $ {\rm{Max}}{f_{REL}} = {\rm{Max}}\left\{ {\frac{{\sum\nolimits_{t = 1}^{{N_T}} {\left( \begin{array}{l} P_t^{WT} + P_t^{VT} + P_t^{MT} + P_t^{grid} + P_t^{ES} - P_t^{EC\_in} - P_t^{HP\_H}\\ \left. { - P_t^{HP\_C} - P_t^{AIR\_H} - P_t^{AIR\_C} - P_t^{P2G\_in}} \right)\Delta t\\ + \left( {Q_t^{MT\_HE} + Q_t^{GB} + H_t^{HS} + Q_t^{HP\_H} + Q_t^{AIR\_H} - Q_t^{AC\_in}} \right)\Delta t\\ + \left( {Q_t^{EC\_out} + Q_t^{AC\_out} + Q_t^{CS} + Q_t^{HP\_C} + Q_t^{AIR\_C}} \right)\Delta t \end{array} \right)} }}{{\sum\nolimits_{t = 1}^{{N_T}} {\left( {P_t^{load} + H_t^{load} + C_t^{load}} \right)} }}} \right\} $ | (9) |

| $ {\rm{Max}}{f_{DG\_uti}} = {\rm{Max}}\left[ {\sum\limits_{t = 1}^{{N_T}} {\left( {P_t^{WT} + P_t^{PV}} \right)} /\sum\limits_{t = 1}^{{N_T}} {\left( {P_t^{WT} + P_t^{PV}} \right)} } \right] $ | (10) |

where: Cyear_opera, fREL, fDG_uti are the annual operating costs, annual energy supply reliability and wind output characteristics of the multi-energy complementary park, respectively. If the energy supply value is greater than the load value at a certain time, the power supply reliability at this time is taken as 1; P PtWT, PtPV, PtEC_in, PtHP_H, PtHP_C, PtAIR_H, PtAIR_C, PtP2G_in are the output power of WT and PV for typical intraday time t, the input electric power value 344 M. Chen et al. of EC refrigeration, HP, AIR heating and cooling, and P2G equipment, respectively. The electric power value consumed; QtMT_HE, QtAC_in, QtHP_H, QtAIR_H are the MT output thermal power of the MT at a typical intraday time t, respectively. AC input thermal power and HP and AIR heating output thermal power values; QtEC_out, QtAC_out, QtHP_C, QtAIR_C are Output cold power values for EC, AC, HP, and AIR cooling at typical intraday time t; PtES, HtHS, CtCS are the net energy value, as follows:

| $ \left\{ \begin{array}{l} P_t^{ES} = \left( {p_t^{dis}/{\eta _{pdis}}} \right)z_t^{p,dis} - p_t^{ch}{\eta _{pch}}z_t^{p,ch}\\ H_t^{HS} = \left( {h_t^{dis}/{\eta _{hdis}}} \right)z_t^{h,dis} - h_t^{ch}{\eta _{hch}}z_t^{h,ch}\\ C_t^{CS} = \left( {c_t^{dis}/{\eta _{cdis}}} \right)z_t^{c,dis} - c_t^{ch}{\eta _{cch}}z_t^{c,ch} \end{array} \right. $ | (11) |

where: ptdis, htdis, ctdis and ptch, htch, ctch. The charge and discharge rate values of ES, HS, and CS for a typical intraday time t; zp, dist, zh, dist, zc, dist and zp, cht, zh, cht, zc, cht respectively For the typical day-to-day time t, the charge and discharge energy flag of ES, HS, CS, if put, zp, dist, zh, dist, zc, dist is 1, and vice versa, if charged, zp, cht, zh, cht, zc, cht is 1, and vice versa 0; ηpch, ηhch, ηcch, ηpdis, ηhdis, ηcdis are respectively ES, HS, CS charge and discharge efficiency; PWT_pret, PPV_pret are the typical intraday time t WT and PV predicted output value.

2.2 Constraints| $ \left\{ \begin{array}{l} P_t^{load} = P_t^{WT} + P_t^{PV} + P_t^{MT} + P_t^{grid} + P_t^{ES} - P_t^{EC\_in}\\ \;\;\;\;\;\;\;\;\;\; - P_t^{HP\_H} - P_t^{HP\_C} - P_t^{AIR\_H} - P_t^{AIR\_C} - P_t^{P2C\_in}\\ H_t^{load} = Q_t^{MT\_HE} + Q_t^{GB} + H_t^{HS} + Q_t^{HP\_H} + Q_t^{AIR\_H} - Q_t^{AC\_in}\\ C_t^{load} = Q_t^{EC\_out} + Q_t^{AC\_out} + C_t^{CS} + Q_t^{HP\_C} + Q_t^{AIR\_C}\\ \left( {G_t^{MT}\eta _t^{MT} + G_t^{GB}{\eta ^{GB}}} \right){v_{LHV}} = P_t^{P2G\_out} + P_t^{Gas} + \left( {g_t^{dis}/{\eta _{gdis}}} \right)z_t^{g,dis} - g_t^{ch}{\eta _{gch}}z_t^{g,ch} \end{array} \right. $ | (12) |

| $ \gamma _i^{equ}w_{i,\min }^{equ} \le w_i^{equ} \le \gamma _i^{equ}w_{i,\max }^{equ} $ | (13) |

| $ \mu _t^iS_t^{i,\min } \le S_t^i \le \mu _t^iS_t^{i,\max } $ | (14) |

| $ \left\{ \begin{array}{l} P_t^{MT} - P_{t - 1}^{MT} \le R_{up}^{MT}\\ P_{t + 1}^{MT} - P_t^{MT} \le R_{down}^{MT} \end{array} \right. $ | (15) |

| $ P_{\min }^{grid} \le \left| {P_t^{grid}} \right| \le P_{\max }^{grid} $ | (16) |

| $ P_{\min }^{P2G} \le P_t^{P2G\_out} \le P_{\max }^{P2G} $ | (17) |

| $ P_{\min }^{Gas} \le P_t^{Gas} \le P_{\max }^{Gas} $ | (18) |

| $ - en_t^{dis,\max } \le E{N_t} \le en_t^{ch,\max } $ | (19) |

| $ SOC_{\min }^{En}{C_{En}} \le E_t^{En} \le SOC_{\max }^{En}{C_{En}} $ | (20) |

| $ z_t^{En,dis} + z_t^{En,ch} \le 1 $ | (21) |

where: Eq. (12) is the electrical/heat/cold/gas power balance constraint at each time; Eq. (13) is the equipment capacity configuration constraint; Eq. (14) is the energy unit's output constraint; Eq. (15) is the MT climb Slope rate constraint; Eq. (16) is the grid interaction power constraint; Eqs. (17) and (18) are the P2G equipment output at each time and the gas source point supply flow upper and lower limits respectively; Eqs. (19) and (20) are respectively stored It can set the maximum storage energy rate and energy storage capacity constraint; formula (21) is (0, 1) variable constraint, ensuring that the energy storage device can not store energy (gas) and energy (gas) at the same time. Among them, Ptload, Htload, Ctload are the electric/thermal/cold load values in the multi-energy complementary park in the typical intraday time t; gtdis, gtch, ztg, dis, ztg, ch are the GS charge and discharge rate value and the charge and discharge gas mark at a typical intraday time t. If deflated, ztg, dis = 1, otherwise it is 0. If inflated, ztg, ch = 1, otherwise 0; GtMT, GtGB are the natural gas consumption of MT and GB for a typical intraday time t; wi, minequ, wi, maxequ are the upper and lower limits of the installation capacity of equipment i, respectively; Sti, μti is the output value and scheduling factor of the energy unit i in the typical intraday time t, respectively, if the energy unit is scheduled, the value is 1 and vice versa 0; Pt + 1MT, PtMT, Pt-1MT is the MT output value of typical intraday time t + 1, t, t − 1; Sti, min, Sti, max, RupMT, RdownMT, Pmingrid, Pmaxgrid, PminP2G, PmaxP2G, PminGas, PmaxGas are the output of each energy unit, MT climbing rate, grid transmission power, P2G generation natural gas power and upper and lower limits of interaction power with natural gas network at each moment; En is the type of energy storage and gas storage device, including ES, HS, CS and GS; Ent, EtEn, entdis, max, entch, max, SOCminEn, SOCmaxEn, CEn, ztx En, ztEn, ch are the energy storage device change rate, the energy storage device capacity, the maximum charge and discharge energy (gas) rate, the charge energy upper and lower limits, and the energy storage (gas) capacity values of a typical intraday time t, respectively. And the storage and release energy (gas) flag; ηgch, ηgdis are the charge and discharge efficiency of GS, respectively.

2.3 Model SolutionFor the multi-objective two-layer optimal configuration model of the multi-energy complementary park integrated energy supply center established in this paper, the improved immune genetic algorithm [9] based on fuzzy membership and variance weighting is used for nesting solution.

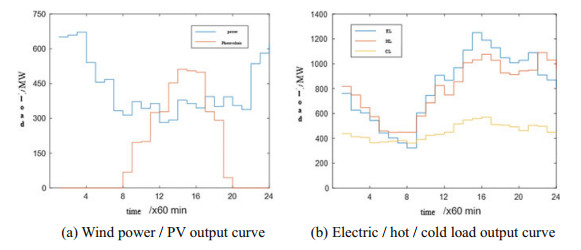

3 Case Analysis 3.1 Overview of the CaseThe planned area of the park is about 230, 000 m2, which is composed of industrial, commercial, municipal, and residential areas. Electrical/heat/cold load demand requirements in all areas, the park has a large demand for electric/heat load, and the demand for cold load is relatively small. Moreover, due to the integrated pipe gallery inside the park, the electric/heat/cold load is mostly concentrated. The maximum installed capacity of wind power and photovoltaic in the park are 780 and 600 MW respectively, and the maximum electric/heat/cold annual loads are 1260, 1140 and 680 MW respectively. The maximum power for interaction with the grid and natural gas network is 400 and 120 MW respectively. The energy time-sharing price is shown in Table 1. The relevant parameters of pollutants in each equipment are shown in Table 2. The upper and lower limits of the climbing rate of the micro gas turbine are taken as 30 MW/h, the heat loss coefficient is taken as 0.15, the minimum load rate is taken as 0.3, the minimum load rate of other equipment is taken as 0, and the maximum load rate is taken as 1; The CO2 coefficient and CO2 price required to produce a unit of natural gas are taken as 0.2 and 0.36$/MW h respectively. A typical daily wind/photovoltaic output curve and electricity/heat/cold load curve in the park as shown in Fig. 1:

| Table 1 Energy time-sharing price |

| Table 2 Related parameters of pollutants in each equipment operation |

|

Fig.1 Typical daily wind power/photovoltaic and electric/hot/cold load output |

3.2 Optimized Configuration Results and Analysis of Multi-energy Complementary Park Integrated Energy Supply Center

(1) Comparison of optimized configuration results under different energy supply strategies

Based on a typical daily wind power/photovoltaic output and electric/heat/cold load curve, the proposed two models and the algorithm are used to optimize the following two multi-energy complementary park energy supply strategies. Energy supply strategy 1: traditional energy supply mode, i.e. distribution network supply power, GB supply heating, EC supply cooling; Energy supply strategy 2: Combined Cooling Heating and Power (CCHP), consider the addition of DG and P2G equipment; The optimal configuration results and objective function pairs under two different energy supply strategies are shown in Tables 3 and 4.

| Table 3 Optimized configuration results under different energy supply strategies |

| Table 4 Comparison of objective functions under different energy supply strategies |

Comparing the two energy supply strategies, it can be seen that the addition of the cold joint supply system can realize the coordinated and complementary utilization of the electric/heat/cold multi-energy flow in the multi-energy complementary park, reduce the system energy supply cost, and improve the system power supply reliability; The DG satisfies part of the system's electrical load demand, and the energy supply cost is further reduced. However, considering the DG output has a certain degree of confidence, its energy supply reliability is slightly reduced. In addition, the coordinated use of P2G equipment and MT has played the role of "shaving peaks and filling valleys". To some extent, it has suppressed the uncertainty of DG output, and the characteristics of various objective functions have been improved to varying degrees.

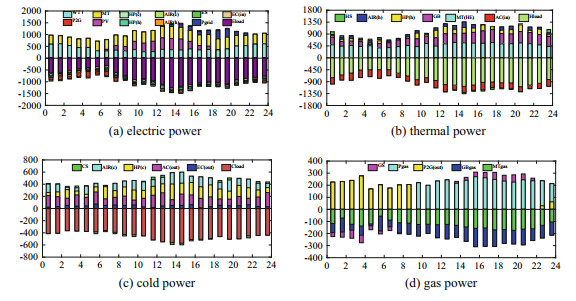

(2) Typical day optimization scheduling results analysis

Based on the typical daily optimization configuration results of the multi-energy complementary park, the optimal scheduling of electric/heat/cold/ gas power at each time is shown in Fig. 2:

|

Fig.2 Typical daily electric/thermal/cold/gas power balance diagram |

4 Conclusion

For the optimal configuration of multi-energy complementary park integrated energy supply center, this paper combines the electric/heat/cold multi-energy flow difference and the energy conversion and spatio-temporal shift characteristics of P2G equipment, proposes a two-layer multi-objective optimization configuration model with multiple energy-providing devices affected by system economy, environmental protection and reliability. Combined with the relevant examples, the correctness and feasibility of the proposed optimal configuration model are verified.

| 1. |

Malinowski M, Leon JI, Abu-Rub H (2017) Solar photovoltaic and thermal energy systems:current technology and future trends. Proc IEEE

(99): 1-15. (  0) 0) |

| 2. |

Deng L, Sun H, Chen R, et al (2016) Study on node energy price of cogeneration system for energy internet. Power Syst Technol

40(11): 3375-3382. (  0) 0) |

| 3. |

Dall'Anese E, Mancarella P, Monti A (2017) Unlocking flexibility:integrated optimization and control of multi energy systems. IEEE Power Energ Mag

15(1): 43-52. DOI:10.1109/MPE.2016.2625218 (  0) 0) |

| 4. |

Correa-Posada CM, Sánchez-Martín P (2015) Integrated power and natural gas model for energy adequacy in short-term operation. IEEE Trans Power Syst

30(6): 3347-3355. DOI:10.1109/TPWRS.2014.2372013 (  0) 0) |

| 5. |

Galbusera L, Theodoridis G, Giannopoulos G (2015) Intelligent energy systems:introducing power-ICT interdependency in modeling and control design. IEEE Trans Industr Electron

62(4): 2468-2477. DOI:10.1109/TIE.2014.2364546 (  0) 0) |

| 6. |

Lin C, Jing Z, Renle H, et al (2017) Case analysis of multi-scenario planning for integrated energy systems based on multi-energy complementation. Electr Power Autom Equip

37(6): 282-287. (  0) 0) |

| 7. |

Wu C, Tang W, Bai M, et al (2017) User-side energy Internet planning based on two-tier planning. Trans China Electrotech Soc

32(21): 53-62. (  0) 0) |

| 8. |

Huang W, Ge L, Hua L, Chen Y (2019) A recent comprehensive optimization of regional integrated energy systems participating in the dual market. Autom Electr Power Syst: 1–8 [2019-05-10]

(  0) 0) |

| 9. |

Fang Z, Song S, Lin Y, Lin X, Cheng G (2019) State estimation of active power distribution system with photovoltaic power station and battery energy storage system. Autom Electr Power Syst: 1–9[2019-05-10]

(  0) 0) |

| 10. |

Sun H, Guo Q, Wu W, Wang B, Xia, Zhang B (2019) Multi-energy integrated energy management system for energy Internet: design and application. Autom Electr Power Syst 1– 8 [2019-05-10]

(  0) 0) |

2020 : 341-351 DOI: 10.1007/978-981-13-9783-7_27

2020 : 341-351 DOI: 10.1007/978-981-13-9783-7_27