文章信息

- 王志战, 魏杨旭, 秦黎明, 郑奕挺, 赵 明, 向蜀平, 惠成峰

- WANG Zhi-zhan, WEI Yang-xu, QIN Li-ming, ZHENG Yi-ting, ZHAO Ming, XIANG Shu-ping, HUI Cheng-feng

- 油基钻井液条件下油层的 NMR

- Oil Layer Identification by NMR with the Use of Oil-Based Drilling Fluid

- 波谱学杂志, 2015, 32(3): 481-488

- Chinese Journal of Magnetic Resonance, 2015, 32(3): 481-488

- http://dx.doi.org/10.11938/cjmr20150309

-

文章历史

- 收稿日期: 2014-07-21

- 收修改稿日期: 2015-07-21

2. 西安石油大学 地球科学与工程学院,陕西 西安 710065;

3. 中石化西北油田分公司 勘探项目管理部,新疆 乌鲁木齐 830011;

4. 中石化华北石油工程有限公司 录井分公司,河南 郑州 450042

2. Xi'an Shiyou University, School of Earth Science and Engineering, Xi'an 710065, China;

3. Exploration Project Department, Northwestern China Petroleum Corporation of SINOPEC, Urumqi 830011, China;

4. Logging Branch Company, North China Petroleum Engineering Corporation of SINOPEC, Zhengzhou 450042, China

油基钻井液具有抗高温、抗盐、润滑性好、抑制性强、对地层伤害小等优良性能[1, 2],有利于井壁稳定和油气层保护[3, 4],在非常规油气水平井、深井超深井、水敏性复杂的地层中广泛使用[5-9].油基钻井液分为油包水钻井液(含水量一般为10%~60%)和全油基钻井液(含水量不超过7%)[10].油基钻井液具有较强的荧光背景和全烃基值,掩盖了地层油气的真实信息,给荧光录井、气测录井发现油气带来了严重影响[11];同时,油基钻井液具有较强的亲油性,钻开油层后,侵入井筒的原油快速与钻井液中的基础油融合,给油层的识别带来了极大困难;而且,油基钻井液条件下的岩屑难以清洗出岩石本色[12],基于岩屑的油气分析手 段也失去了作用.为了解决这道难题,在对自由流体核磁共振弛豫特性进行分析的基础上,采用高分辨率低场核磁共振分析技术对油基钻井液混油前、后的弛豫特性进行研究,建立了油基钻井液含油性及含油率的精细评价方法.通过现场应用,实现了油基钻井液条件下的油层准确识别,对于推动录井技术的发展和促进勘探开发效益的提高具有重要的意义.

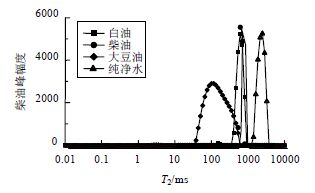

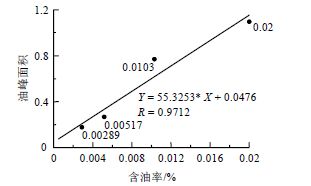

1 自由流体的核磁共振特性核磁共振是获得诺贝尔奖最多的科学专题[13],是最有效的储层评价和流体分析技术之一[14, 15, 16].对于低场核磁共振而言,在岩样孔隙的受限空间内,表面弛豫起主要作用;而对于不受限的自由流体,体弛豫起主要作用[17].自由流体的低场核磁共振特性表现在4个方面:一是一种纯流体的T2谱只有一个峰,如纯油、纯水等(图 1);二是谱峰最高点所对应的T2(或T1)或T2(T1)的几何平均与流体的黏度(或密度)成反比[18, 19];三是流体的质量或体积与T2谱的谱峰面积成正比(图 2);四是由于物化性质的差异,水比油更容易受外加弛豫试剂(如MnCl2)的影响,水峰的峰面积或峰高随弛豫试剂浓度的增加呈指数式降低,水峰的弛豫时间随弛豫试剂浓度的增高在<8000 mg/L的范围内呈指数式衰减,超过这个范围将保持不变(图 3).根据这4个特性,低场核磁共振广泛应用于含水率 或 含油 率的检测[20, 21],根据弛豫时间定性,根据峰面积或峰高定量.若流体赋存于岩石内部,还可检测流体分布,评价储层物性、孔喉分选性等[22, 23].

|

| 图 1 不同流体的T2谱 Fig. 1 T2 spectrum of different fluids |

|

| 图 2 含油率与油峰面积的关系 Fig. 2 Relations between oil content and oil peaks |

|

| 图 3 锰离子溶液的核磁共振特性 Fig. 3 NMR characteristics of manganese cations solution |

对于石油录井,荧光级别超过6级(相等于20 mg/L)就要参与岩石定名,所以相比于农业及石油试采等领域,录井需要更高的仪器信噪比、分辨率与稳定性.为此,采用苏州纽迈科技有限公司生产的共振频率为22.621 MHz、磁体强度为0.53 T的核磁共振录井仪,回波时间(TE)为0.1 ms,等待时间(TW)为500 ms,恢复时间(TR)为1 000 ms,所采用的脉冲序列为CPMG < /span>序列(图 4),仪器温度控制在31.99 ℃~32.00 ℃.为此,保证了仪器的检测下限达到了20 mg/L(图 2),仪器的重复性相对误差<5%.

|

| 图 4 CPMG序列及其参数 Fig. 4 CPMG sequence and parameters |

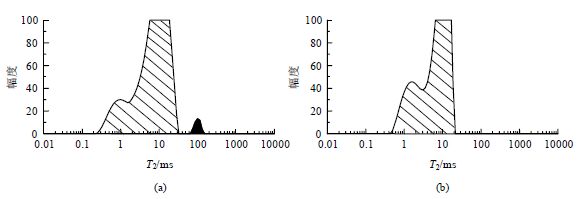

油基钻井液的基础油包括白油、柴油、植物油等,油基钻井液的核磁共振特性不同于水基混油钻井液,后者为水包油体系[24],钻井液、添加油、地层油在T2谱上表现为彼此分离的峰;而前者,水被油包裹[9],处于束缚状态,添加油、地层油进入钻井液后,会迅速与油基钻井液的峰进行叠合,给判识油层带来很大困难.实验过程中,地层油刚刚加入油基钻井液后会出现新峰[图 5(a),100 ms的小峰],但搅拌后,新峰消失[图 5(b)].

|

| 图 5 全油基钻井液加入地层油搅拌前、后的核磁共振T2谱.(a) 不搅拌;(b) 搅拌后 Fig. 5 NMR T2 spectra of oil based drilling fluids before or after adding oils in the layer (a) no blending,(b) blending |

核磁共振相比于定量荧光、岩石热解、气测等录井技术,具有不细分到组分、定量准确、对油质反应灵敏等优势.尽管地层油侵入井筒后,不会引起钻井液T2谱形态的明显变化,但对T2谱按钻井液质量进行标准化处理后,通过弛豫时间(判断含油性)和含油面积(计算含油率)的细微变化仍能准确识别是否有地层油侵入井筒,即是否钻遇油层.

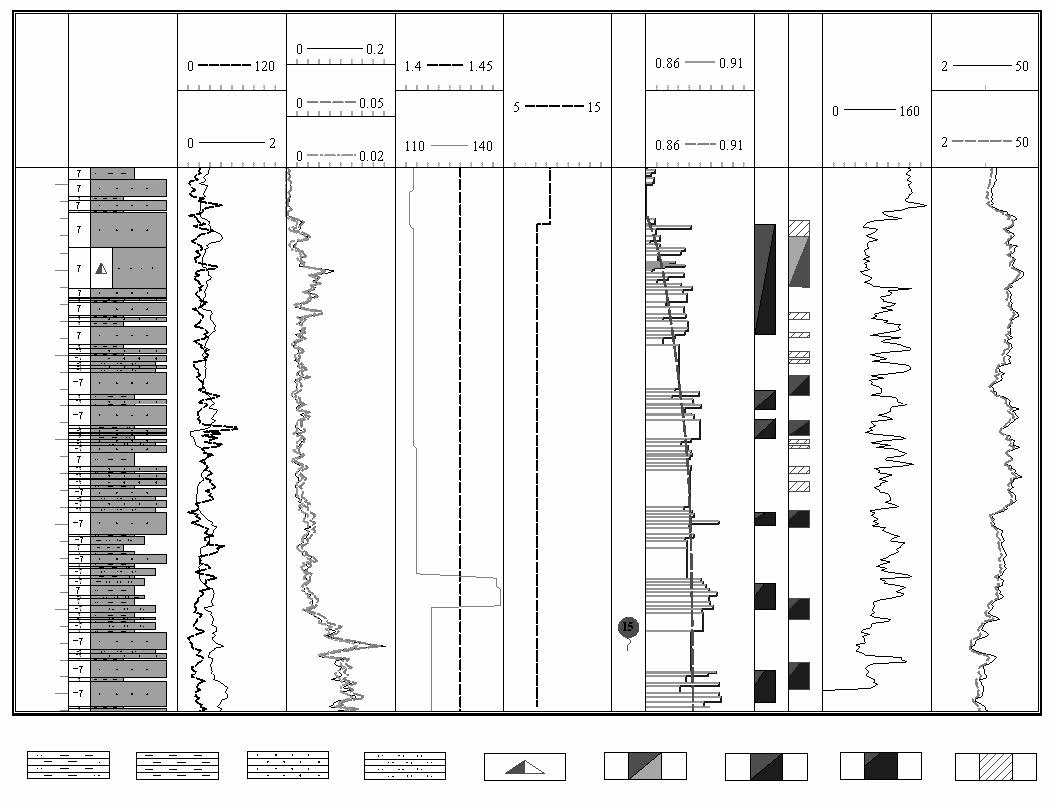

3 油基钻井液条件下的油层识别西部探区的S903H井是一个超深水平井,目的层为志留系柯坪塔格组,岩性为细粒岩屑砂岩,邻井S9井相同层位的原油密度为0.87 g/cm3,属轻-中质油.该井先用水基钻井液钻的直导眼,后用全油基钻井液钻斜导眼,基础油为白油和柴油,钻井液密度为1.43 g/cm3,黏度为105 s~115 s.井段5 408 m~5 568 m为沥青质砂岩;& lt; /span>5 700 m~6 000 m为目的层段,岩屑录井仅描述一层23 m厚的油迹显示,气测值极低,甲烷最高为0.094%,乙烷最高0.018%,丙烷最高0.007%,丁烷和戊烷的含量均为0%.三维定量荧光技术被录井公认为解决混油问题最有效的手段,但在该井实验后发现该方法并不适用于油基钻井液.由于沥青的油质较重,进入钻井液后引起油峰T2弛豫时间的降低,据此在沥青质砂岩段解释2层含油水层(图 6).在轻-中质油砂岩段,由于地层油的油质与油基钻井液的基油接近,不能引起油峰T2弛豫时间的变化,根据标准化后钻井液相对含油率偏离基线的高低,解释油水同层3层、含油水层3层(图 7).完钻后,测井在井段5 408 m~5 568 m解释含油水层2层;在井段5 700 m~6 000 m解释油气层1层、油水同层2层、含油水层3层.由于钻具与测井电缆的误差及迟到时间的误差,导致解释深度上有误差,但总体看来,二者的解释比较吻合,证明了钻井液核磁共振录井技术在油基钻井液条件下识别油层的有效性.由于斜导眼的显示还不如直导眼,决定不钻水平段、不下油层套管完井.该井的实验结果表明,由于轻质油和重质油含氢分子数的差异,前者比较容易引起含油率的变化,而后者则比较容易引起含油性的变化;在油气显示较差的极端条件下,该项技术仍然实现了油基钻井液条件下含油层的有效判识.

|

| 图 6 S903H 井沥青质砂岩段测、录井综合对比图 Fig. 6 Comparison between logging charts in bitumen section of Well S903H |

|

| 图 7 S903H井目的层段测、录井综合对比图 Fig. 7 Comparison between logging charts in target section of Well S903H |

(1) 核磁共振技术是最有效的流体识别技术之一,不仅适用于岩样分析,也适用于自由流体的分析.高分辨率低场核磁共振录井技术具有检测下限低、定量准确等特点,是一项有效的钻井液荧光背景下的油层识别与评价技术.

(2) 油基钻井液为油包水体系,地层油侵入井筒后,与钻井液基础油融合,在钻井液核磁共振T2谱上不形成新峰,但通过含油性及含油率的变化,能够准确判识所钻遇的各类油层,在页岩油、致密油水平井及深井、超深井中具有广阔的应用前景.

致谢:该项目实施过程中得到中国石化石油工程技术研究院、中石化西北油田分公司勘探项目管理部、中石化华北石油工程有限公司录井分公司、中石化胜利石油工程有限公司地质录井公司领导和同事们的大力支持,在此一并表示深深的谢意!

| [1] | Wang Zhong-hua(王中华). Research and application progress of oil-based drilling fluid at home and abroad(国内外油基钻井液研究与应用进展)[J]. Fault-Block Oil & Gas field(断块油气田), 2011, 18(4): 533-537. |

| [2] | Feng Ping(冯萍), Qiu Zheng-song(邱正松), Cao Jie(曹杰), et al. Progress on study and application on rheology modifier for oil-based mud aboard(国外油基钻井液提切剂的研究与应用进展)[J]. Drilling Fluid and Completion Fluid(钻井液与完井液), 2012, 29(5): 84-88. |

| [3] | Zhang Zhen-hua(张振华), Zhang Hai-yan(张海严), He Tao(何涛), et al. Application of whole oil base drilling fluid in BARINAS block of Venezuela(全油基钻井液在委内瑞拉BARINAS 区块的应用)[J]. Drilling Fluid and Completion Fluid(钻井液与完井液), 2011, 28(5): 20-22. |

| [4] | Wang M S, Sun M B, Shang H Y, et al. Biodiesel-Based Drilling Fluids[C]. IADC/SPE 155578, 2012 |

| [5] | Hou Ye-gui(侯业贵). Application on low aromatic hydrocarbon oil-based drilling fluid in shale oil and gas wells(低芳烃油基钻井液在页岩油气水平井中的应用)[J]. Drilling Fluid and Completion Fluid(钻井液与完井液), 2013, 30(4): 21-24. |

| [6] | Liu Ming-hua(刘明华), Sun Ju(孙举), Wang Zhong-hua(王中华), et al. Oil-based drilling fluid technology in horizontal wells with unconventional oil-gas reservoir(非常规油气藏水平井油基钻井液技术)[J]. Drilling Fluid and Completion Fluid (钻井液与完井液), 2013, 30(2): 1-6. |

| [7] | Wang Zhong-hua(王中华). Difficulty and applicable principle of the drilling fluid technology of horizontal wells for shale gas(页岩气水平井钻井液技术的难点及选用原则)[J]. Sino-Global Energy(中外能源), 2012, 17(4): 43-47. |

| [8] | He Zhen-kui(何振奎). Oil base drilling fluid technology applied in well Biye HF1(泌页HF1井油基钻井液技术)[J]. Petroleum Drilling Techniques(石油钻探技术), 2012, 40(4): 32-37. |

| [9] | Huang Hong-xi(黄红玺), Zhang Feng(张峰), Xu Ming-biao(许明标), et al. Main influence factors of water-in-oil emulsion stability(油包水乳状液稳定性影响因素分析)[J]. Fault-Block Oil & Gas Field(断块油气田), 2009, 16(6): 99-101. |

| [10] | Liu Xiao-dong(刘晓东). Study on chemical analysis based on oil-base drilling fluid (油基钻井液的化学分析测试研究)[J]. Journal of Oil and Gas Technology(石油天然气学报), 2012, 34(1): 146-148. |

| [11] | Cao Feng-jun(曹凤俊), Wang Li(王力). Gas and water zone distinguishing and evaluating in oil-based drilling fluid(油基钻井液钻井气水层识别与评价)[J]. Mud Logging Engineering(录井工程), 2006, 17(1): 25-27. |

| [12] | Tang Jin-xiang(唐金祥), Meng Ling-pu(孟令蒲), Han Zhi(韩志), et al. Mud logging technique improvement and practice with oil-base drilling fluid(油基钻井液环境下的录井方法及实践)[J]. Mud Logging Engineering(录井工程), 2006, 17(3): 38-42, 46. |

| [13] | Fu Jie-qing(傅杰青). Nuclear Magnetic Resonance—The subject that won the most Nobel prizes(核磁共振—获得诺贝尔奖次数最多的一个科学专题)[J]. Ziran Zhazhi(自然杂志), 2003, 25(6): 357-361. |

| [14] | Wang Z Z, Martinez Y, Strack K, et al. Applications of NMR Mud Logging Technology in China[C]. SPWLA 2007 Annual Logging Symposium, 444294X. |

| [15] | Wang Zhi-zhan(王志战), Zhai Shen-de(翟慎德), Zhou Li-fa(周立发), et al. Application of nuclear magnetic resonance logging technology in physical property analysis of rock(核磁共振录井技术在岩石物性分析方面的应用研究)[J]. Petroleum Geology & Experiment(石油实验地质), 2005, 27(6): 619-623. |

| [16] | Wang Zhi-zhan(王志战), Xu Xiao-qiong(许小琼), Zhou Bao-jie(周宝洁). Relaxation features of pore fluid and water/oil bed recognition with NMR technology(孔隙流体核磁共振弛豫特征及油水层识别方法[J]. Petroleum Geology and Recovery Efficiency(油气地质与采收率), 2011, 18(2): 41-44. |

| [17] | Li Zhi-tao(李志涛), Wang Zhi-zhan(王志战), Zhao Lei(赵蕾). Nuclear Magnetic Resonance(NMR) Rock Sample Analysis Technology and the Application(核磁共振岩样分析技术及应用)[M]. Beijing(北京): Petroleum Industry Press(石油工业出版社), 2011. |

| [18] | Freedman R, Heaton N. Fluid characterization using nuclear magnetic resonance logging[J]. Petrophysics, 2004, 45(3): 241-250. |

| [19] | Xie Ran-hong(谢然红), Xiao Li-zhi(肖立志), Fu Shao-qing(傅少庆), et al. Experimental study on nuclear magnetic resonance relaxation characteristic of crude oil at variable temperature(原油的变温核磁共振弛豫特性实验研究)[J]. Journal of China University of Petroleum[中国石油大学学报(自然科学版)], 2007, 31(4): 34-37. |

| [20] | Xu Xiao-qiong(许小琼), Wang Zhi-zhan(王志战), Pu Deng-gang(普登岗), et al. Detecting oil content in drilling fluid with NMR(利用磁共振技术检测钻井液含油量的方法探讨)[J]. Chinese J Magn Reson(波谱学杂志), 2011, 28(2): 237-243. |

| [21] | Li Ran(李然), Chen Shan-shan(陈珊珊), Yu Jie(俞捷), et al. Determination of water content of tea by Low Field Nuclear Magnetic Resonance technology(应用低场核磁共振技术测定茶叶含水量)[J]. Journal of Tea Science(茶叶科学), 2010, 30(6): 440-444. |

| [22] | Xiao Li-zhi(肖立志). Magnetic Resonance Image Logging and Rock Nuclear Magnetic Resonance and its Application(核磁共振成像测井与岩石核磁共振及其应用)[M]. Beijing(北京): Science Press(科学出版社), 1998. |

| [23] | Wang Zhi-zhan(王志战), Xu Xiao-qiong(许小琼). Quantitative evaluation of reservoir separation with MR-ML technology(利用核磁共振录井技术定量评价储层的分选性)[J]. Chinese J Magn Reson(波谱学杂志), 2010, 27(2): 214-220. |

| [24] | Qian Dian-cun(钱殿存), Wang Qing(王晴), Wang Hai-tao(王海涛), et al. Study and application of oil-in-water drilling fluid(水包油钻井液体系的研制与应用)[J]. Drilling Fluid and Completion Fluid(钻井液与完井液), 2001, 18(4): 3-6. |

2015, Vol. 32

2015, Vol. 32