| 苏南地区夏季浅层地热交换对大棚降温效果初探 |

我国设施农业面积居世界前列;江苏地区温室总面积达20.3万hm2,名列全国第四[1-2],其中塑料大棚为17.4万hm2。江苏为亚热带季风气候,从6月下旬到9月上旬温度普遍高于30 ℃,大棚内温度更是在40 ℃以上,导致夏季长达2个月无法进行作物生产。因此本试验引入浅层地热交换系统,意在探究系统在该地区夏季棚内的降温效果。

地源热泵技术是以浅层土壤或地下水作为热源或冷源的一种兼具加温和降温作用的技术,是近年来发展迅速和研究较多的节能空调工艺之一;与空气相比,土壤和水具有更好的热稳定性,因此,地源热泵比空气源热泵能效更高[3-5]。白义奎等[6]对辽沈Ⅰ型温室地下热交换系统进行了试验研究,提出了北方日光温室地下热交换系统设计的一般方法和原理;吴德让等[7]建立了日光温室数学模型,用于分析地下热交换系统热特性和土壤温度场的分布状况;王永维等[8]针对现行温室地下埋管式换热系统结构的缺点,提出了合理的设计和主动蓄热时长依据;方慧等[9]提出了基于热泵的日光温室浅层土壤水媒蓄放热方法,白天开启循环水泵,将后墙获得的太阳辐射储存到温室浅层土壤中,傍晚自然释放加热温室;柴立龙等[10]以性能系数(coefficient of performance, COP)为评价指标对系统降温性能进行分析,并提出了适用于该研究的能量传递和系统性能分析模型。可以看出,目前地热交换系统研究重心在温室大棚的增温效应方面,关于降温效应的研究很少。本试验针对南方地区夏季高温造成棚内作物生理障碍的情况,以降温为目的,分析了苏南地区浅层地热交换系统的温湿度、地温、焓差、蓄热量、能耗等变化情况,以分析此系统在苏南地区大棚内的降温效果及实用性。

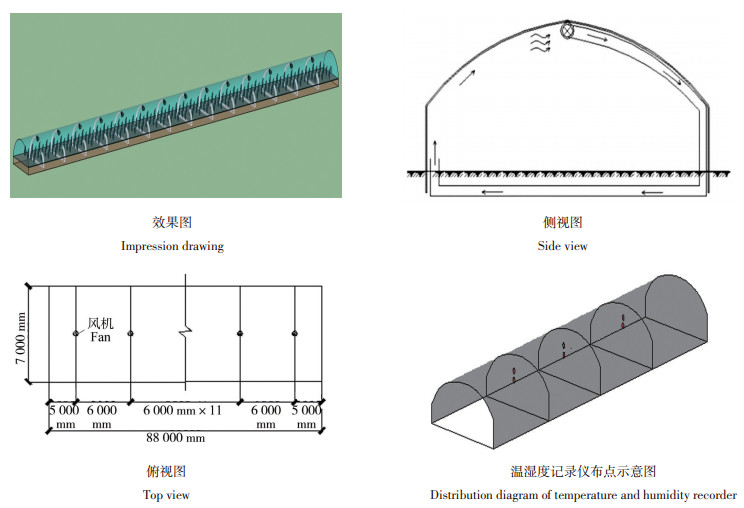

1 材料与方法 1.1 供试塑料大棚的结构参数及试验布置试验于2016年5-7月在江苏省苏州市张家港常阴沙现代农业示范园区(北纬31°52′,东经120°45′)内进行。塑料大棚南北走向,长88 m,跨度7 m,脊高3 m,为钢管装配式大棚,棚膜采用EVA膜,东西两侧棚面80 cm处设置底通风。选取2座外部环境条件、规格一致的塑料大棚作为处理和对照,土质为黏质土壤[11],处理大棚地中热交换管道埋深为60 cm,共14组。因棚面最高处为该截面温度最高的位置,故在屋脊处设置进风口,在棚体西侧距地面20 cm处设置出风口,聚氯乙烯(PVC)管道直径为110 mm,大棚每日06:00-18:00正常通风,夜间根据天气情况进行开闭,种植作物为西瓜,不启用遮阳网。温湿度记录仪布置在棚的4等分点处,记录此处高1.5 m和2.0 m的温度和湿度。在管道进入地下处(测点1)和伸出地面处(测点2),分别布置一台温湿度记录仪,记录此处的温湿度变化。地温测点布置在各个大棚中央管道的垂直面,距地表 15、40、60 cm的位置。风机输入功率为160 W,实测风量0.2 m3/s,转速40 r/s,上午6:00开启,下午6:00关闭,10 min记录一次棚内温度、湿度、地温、管道测点1和测点2的温湿度。

供试塑料大棚的效果图和部分视图如图 1所示。

|

| 图1 供试塑料大棚的效果图和部分视图 Fig. 1 Impression drawing and part views of tested plastic greenhouse |

热空气经过地下换热管道后从大棚的另一侧排入棚内,空气与换热管道间的换热量取决于空气流量与空气在换热管道进出口焓值的变化。

湿空气焓h计算公式[12]为:

| $ h=1.01T+d\left( 2\ 500+1.84T \right). $ | (1) |

式中:T为温度,℃;d为湿空气的含湿量,kJ/kg。

| $ \text{湿空气含湿量}d=\psi {{d}_{\text{b}}}. $ | (2) |

式中:ψ为相对湿度,%;db为饱和含湿量。

| $ \text{饱和含湿量}{{d}_{\text{b}}}=d=0.622\left( {{P}_{\text{v}}}/{{P}_{\text{a}}} \right). $ | (3) |

式中:Pv为温度在T ℃时的水蒸气饱和分压,kPa。Pa为自然压强,取值101.325 kPa。

主动蓄热系统白天蓄积的热量Q计算公式[13]为:

| $ Q=V\rho |\Delta h|\Delta t. $ | (4) |

式中:Q为地下蓄热量,kJ;V为空气总体积流量,m3/s;△t为时间段,s;ρ为△t时间内干空气密度,kg/m3;△h为△t时间内空气在测点1、2间的焓差,kJ/kg。

太阳能塑料大棚地下蓄热系统平均蓄热热流量或加温热流量Φ计算公式[14]为:

| $ \mathit{\Phi }=Q/\sum{\Delta t}. $ | (5) |

平均蓄热或加温热流密度q的计算公式为:

| $ q=\mathit{\Phi }/A. $ | (6) |

式中A为棚内土壤面积,m2。

| $ 鼓风机消耗的电能\ W=P\Delta t. $ | (7) |

式中P为风机的实际功率,W。

| $ \text{COP}={{Q}_{\text{p}}}/{{W}_{\text{p}}}. $ | (8) |

式中:Qp为空气与地下管道热交换功率,kW;Wp为风机的输入功率,kW。

| $ {{Q}_{\text{p}}}={{m}_\text{a}}\left| \Delta h \right|. $ | (9) |

式中:ma为地下管道空气流量,m3/s;△h同式(4)。

2 结果与分析在2016年5月5日-7月17日共74天的测定期间内,晴天11天,占14.9%,阴雨天35天,占47.3%,多云天28天,占37.8%。因此,温湿度变化趋势从晴天、阴雨天和多云天3种情况分析。

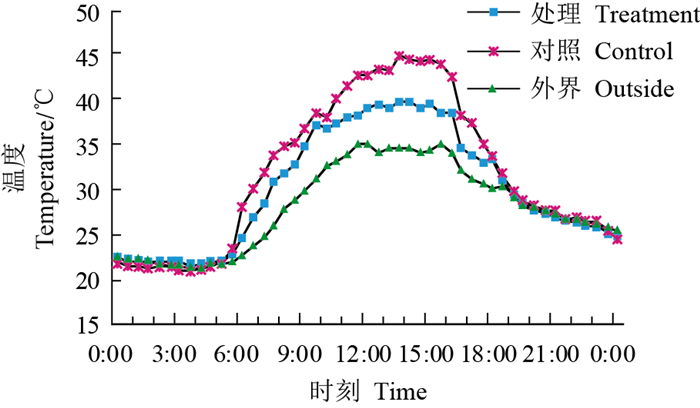

2.1 不同天气条件下塑料大棚内温度变化 2.1.1 晴天天气条件下塑料大棚内温度变化如图 2所示:在5:30(日出)之前,大棚内外温度处于平稳状态,在23 ℃上下波动;日出后,温度开始走高,6:00风机开启后,3组温度的上升速率出现差异。其中:外界温度上升幅度最小,白天温度低于大棚内温度;对照大棚温度上升幅度最快,中午12:00后上升趋缓,维持在44 ℃上下波动,16:00后温度开始下降,19:00后下降趋缓;埋设有浅层地热交换系统的大棚在风机开启后,温度介于对照和外界之间,上升速率比对照慢,中午12:00温度稳定在38 ℃左右,16:00温度开始下降,18:00风机关闭后下降速率与对照棚趋于一致,在通风时段,处理大棚的温度始终低于对照温度,平均降温效果为3.4 ℃。降温后的大棚可满足耐热作物和一些喜温作物的正常生长。

|

| 图2 晴天大棚内外温度的日变化 Fig. 2 Daily temperature variation inside and outside greenhouse in sunny days |

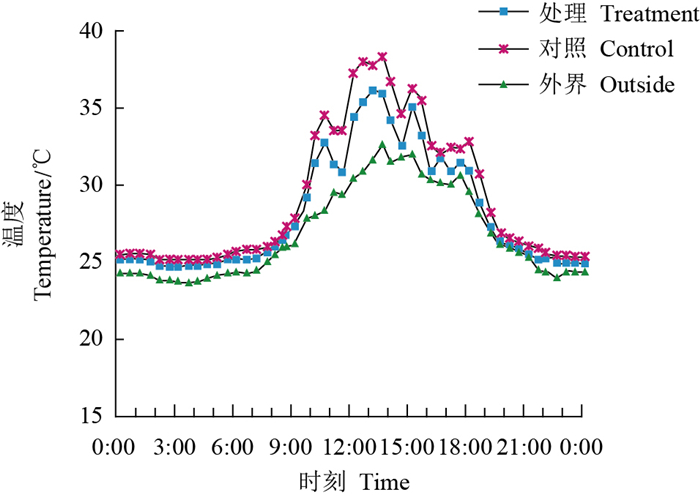

如图 3所示:在多云天,0:00-9:00,3者的温度平稳上升,但上升不明显,且6:00风机开启后降温效果也不明显;9:00开始,3者温度波段式上升,对照大棚温度上升最快,处理大棚次之,外界温度上升最慢;对照大棚的温度在13:30左右达到峰值,为38.3 ℃;处理大棚在13:00时达到峰值,为36 ℃,之后温室内外温度又呈波段式下降,从20:00开始在25 ℃横向波动。由于多云天的缘故,太阳不时被云遮挡,出现了温度呈波段式变化的情况,大棚内的温度变化幅度较晴天小,浅层地热交换系统平均降温效果为1.5 ℃。

|

| 图3 多云天大棚内外温度的日变化 Fig. 3 Daily temperature variation inside and outside greenhouse in cloudy days |

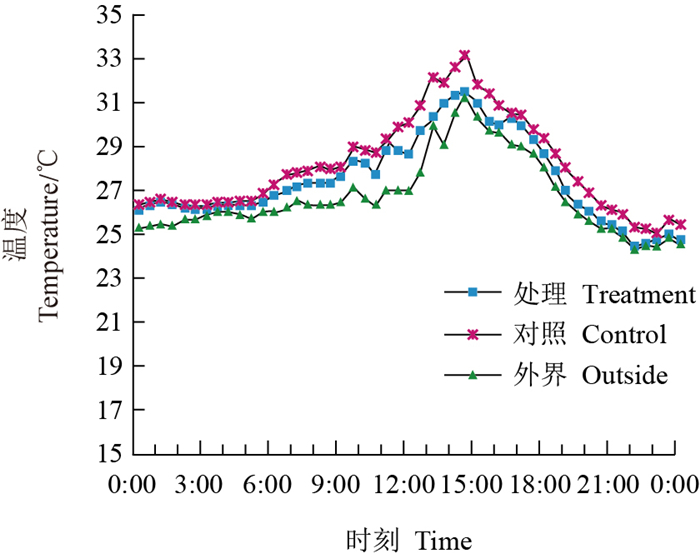

如图 4所示:在阴雨天气条件下,大棚内外温度波动不明显,0:00-15:00一直处于平稳上升状态,处理与对照大棚在风机开启前温度变化基本一致,都高于外界温度;6:00风机开启后,处理大棚温度上升速率减缓,介于对照与外界温度上升速率之间;3者的温度在15:00左右达到峰值,之后逐渐走低,直至20:00左右开始在25 ℃上下平稳波动。由于阴雨天大棚内外的温差小,所以浅层地热交换系统降温效果不显著,平均降温效果为0.8 ℃。

|

| 图4 阴雨天大棚内外的温度日变化 Fig. 4 Daily temperature variation inside and outside greenhouse in rainy days |

如图 5所示:在晴天条件下0:00-6:00,3者的湿度均处于80%以上,处理和对照大棚内湿度没有明显差异,从80%平稳增到近100%,而外界湿度在70%~80%平稳波动;6:00太阳升起和风机开启后,3者的湿度迅速下降,因对照大棚温度上升速率快于处理大棚,所以对照大棚湿度下降速率也快于处理大棚;9:00后3者湿度横向波动,外界在36%上下波动,大棚内在40%上下波动;15:00后大棚内外湿度开始上升,2座大棚内湿度上升幅度一致,差异不明显,最后维持在90%左右,外界湿度上升至77%左右开始稳定。综上表明,浅层地热交换系统对大棚内湿度的影响效果不明显,变化情况基本与对照一致。多云天和阴雨天棚内外的湿度变化趋势与晴天一致,多云天在60%~100%区间内波动,阴雨天在80%~100%区间内波动。另外,从图 5可以看出,夜晚棚内的湿度均处于80%以上,这种高湿环境易引起西瓜白粉病、蔓枯病、绵腐病等病害,所以夜间应打开侧通风进行通风,防止病害的产生和传播。

|

| 图5 晴天大棚内外湿度的日变化 Fig. 5 Daily humidity variation inside and outside greenhouse in sunny days |

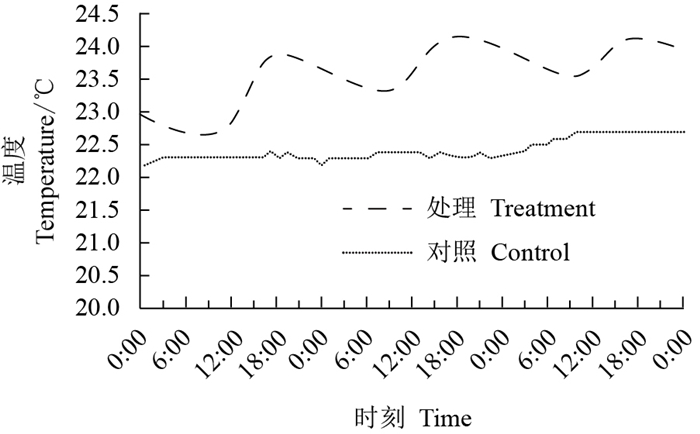

图 6为7月15日-17日连续3个晴天60 cm深处的地温变化。结果显示,没有浅层地热交换系统装置的对照大棚,其60 cm深土层处的温度基本处于21.3 ℃的恒温状态,而装有换热管道的大棚,由于管道与土壤的热交换作用,60 cm处地温在21.8 ℃±0.4 ℃范围内波动。

|

| 图6 60 cm处大棚内地温变化 Fig. 6 Soil temperature difference in the greenhouses at 60 cm depth |

图 7为7月15日-17日连续3个晴天大棚内40 cm深处地温变化。从中可以看出:对照地温变化甚微,呈缓慢上升的运行趋势,这是由于深层土壤受棚内温度的影响较小造成的。而处理大棚40 cm深处靠近地热交换管道,会接收来自管道的热量,所以地温高于对照;且温度的日变化较大,一天中最高温出现在18:00左右,最低温出现在6:00前的一段时间(由于此时风机关闭,无法继续进行热积累);连续晴天由于土壤的蓄热作用,地温呈波浪上升的情况,温度变化在1 ℃左右,变化幅度较小。每天的最低和最高温都高于前一天。因为40 cm深处接受大棚内的热量很小,所以处理大棚的大部分热量来源于管道换热,

|

| 图7 40 cm处大棚内地温变化 Fig. 7 Soil temperature difference in the greenhouses at 40 cm depth |

图 8为7月15日-17日连续3个晴天大棚15 cm深处的温度变化。从中可以看出,对照和处理大棚的地温变化趋势基本一致,二者每天的最高温出现在15:30;因为处理还会接收到来自换热管道的热量,所以平均地温比对照高0.8 ℃;二者每天最高温出现时间提前,且变化趋势一致的情况,说明15 cm深地温受换热管的影响减弱,受地表传热的影响较大。

|

| 图8 15 cm处大棚内地温变化 Fig. 8 Soil temperature difference in the greenhouses at 15 cm depth |

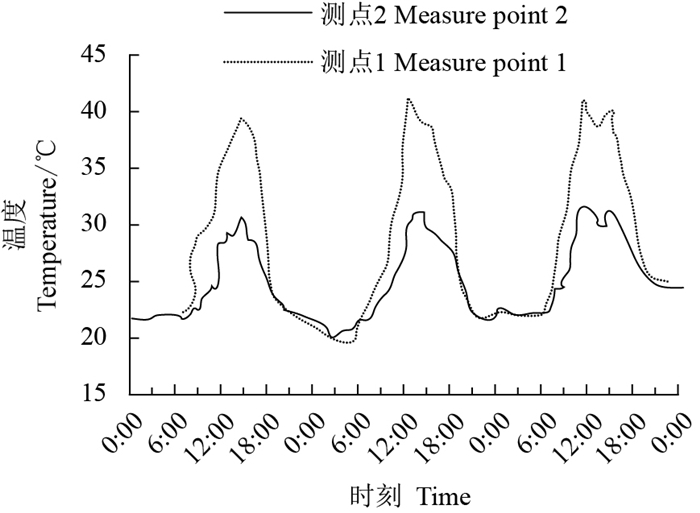

图 9为6月20日-22日连续3天测点1、测点2的温度变化情况。结果显示,6:00风机开启前,2个测点温度一致,6:00后2个测点温差逐渐拉大,12:00-14:30,管道换热效率最高,最高温差为10.8 ℃,平均温差7.3 ℃,16:00后2个测点温度开始下降,温差也逐渐缩小,18:00风机关闭后,二者温度达到一致。

|

| 测点1:管道进入地下处;测点2:管道伸出地面处。 Measure point 1: At the site of underground pipe; Measure point 2: At the site of Pipe out of the ground. 图9 管道测点1和测点2温度变化 Fig. 9 Temperature change of the measure point 1 and point 2 |

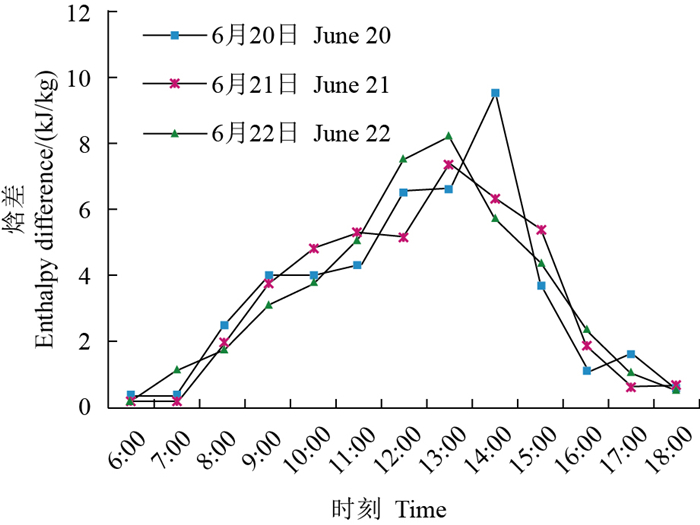

图 10为6月20日-22日连续3天6:00-18:00管道测点1和2间的焓值变化情况。可以看出:大棚的热空气流经换热管道后,焓值降低0.166~9.56 kJ/kg,3日平均焓差为3.37 kJ/kg,中午12:00-15:00时段达到较高水平,蓄热效率高;一天中焓差在风机开后和关前的1小时最低。

|

| 图10 管道测点1和测点2间的焓差 Fig. 10 Enthalpy difference between the measure point 1 and point 2 |

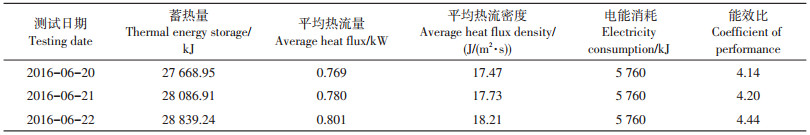

从表 1可以得出,每根管道日平均蓄热量为28 170.5 kJ,日平均热流量为0.783 kW,日平均热流密度为17.80 J/m2/s,系统平均能效比(COP)为4.21。计算可得,棚内14根管道每天总蓄热量约为3.94×105kJ,而每天风机消耗的总电能约为0.8×105kJ;因此,系统蓄积的热能远大于风机运行消耗的电能。

| 表1 蓄热性能计算结果 Table 1 Calculation results of heat storage performance |

|

| 点击放大 |

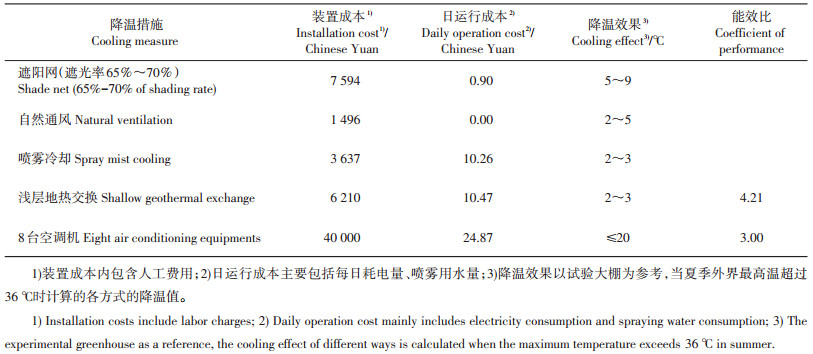

经统计分析,各降温措施装置成本、运行成本及降温效果如表 2所示。从中可以看出:遮阳网的装置成本较高,但运行成本较低,降温效果显著。自然通风成本最低,性价比高,但受外界气候影响较大,降温效果不稳定。喷雾成本较低,运行成本较高,降温不明显,在苏南地区高湿环境中,蒸发降温受到制约,而且喷雾导致棚内湿度增大,植株易染病;空调机降温效果极显著,但投入成本、运行成本高。浅层地下热交换系统在装置成本上略低于遮阳网,但同非能量消耗的遮阳网及自然通风等降温方式相比,其降温效果略差;同喷雾相比,二者的降温效果相当,虽浅层地下热交换系统的投入成本约增加70%,但可有效避免喷雾降温带来的棚内湿度升高对作物生长造成的影响;同最高能效标准空调机相比,浅层地下热交换系统投入成本仅达到其15.5%,且系统能效比约是空调机的1.4倍。

| 表2 各降温措施成本及降温效果 Table 2 Cost and cooling effect of the cooling measures |

|

| 点击放大 |

经研究发现,测试期间浅层地热交换系统在不同天气条件下降温效果为0.8~3.4℃,但降温后棚内温度仍处于30 ℃以上的高温状态。对于如何进一步改良温室内降温方式有待进一步研究。在试验中连续3个晴天处理大棚60 cm处地温在21.8 ℃±0.4 ℃平稳波动。戴巧利等[17]在主动式土壤蓄热试验中发现,主动式土壤蓄热系统具有明显的白天蓄热效果,且具有长期蓄热能力,可见土壤良好的蓄热性能是降温的关键。充分利用土壤的蓄热性能对棚内降温将是接下来的研究方向。此外,苏南地区雨水充沛且位于江畔,拥有丰富的地下水资源,经实测,夏季多雨时浅层地下水的水位距地表 50 cm左右;根据林俊等[18]及范蕊等[19]的研究可以发现,富水土壤会对管道的换热效果起到促进作用。在下一步研究中,可考虑地下水热渗流作用对管道换热效果的影响。

4 结论 4.1浅层地热交换系统晴天平均降温3.4 ℃,多云天平均降温1.5 ℃,阴雨天平均降温0.8 ℃。

4.2浅层地热交换系统日平均蓄热量3.94×105kJ,日消耗电能0.8×105 kJ,蓄积热量远大于耗电量,平均能效比4.21。

4.3浅层地热交换系统具有较好的降温效果,同其他降温措施相比各有优劣,存在初期投资较大等缺点,需进一步改进和完善。

| [1] |

魏晓明, 齐飞, 丁小明, 等. 我国设施园艺取得的主要成就. 农机化研究, 2010, 32(12): 227-231. WEI X M, QI F, DING X M, et al. Main achievements in China facility horticulture. Journal of Agricultural Mechanization Research, 2010, 32(12): 227-231. (in Chinese with English abstract) DOI:10.3969/j.issn.1003-188X.2010.12.055 |

| [2] |

蒋卫杰, 邓杰, 余宏军. 设施园艺发展概况、存在问题与产业发展建议. 中国农业科学, 2015, 48(17): 3515-3523. JIANG W J, DENG J, YU H J. Development situation, problems and suggestions on industrial development of protected horticulture. Scientia Agricultura Sinica, 2015, 48(17): 3515-3523. (in Chinese with English abstract) DOI:10.3864/j.issn.0578-1752.2015.17.017 |

| [3] | ZENG H Y, DIAO N R, FANG Z H. A finite line-source model for boreholes in geothermal heat exchangers. Heat Transfer—Asian Research, 2002, 31(7): 558-567. DOI:10.1002/(ISSN)1523-1496 |

| [4] | MICHOPOULOS A, BOZIS D, KIKIDIS P, et al. Three-years operation experience of a ground source heat pump system in Northern Greece. Energy and Buildings, 2007, 39(3): 328-334. DOI:10.1016/j.enbuild.2006.08.002 |

| [5] | KARLSSON F, FAHLExN P. Capacity-controlled ground source heat pumps in hydronic heating systems. International Journal of Refrigeration, 2007, 30(2): 221-229. DOI:10.1016/j.ijrefrig.2006.08.008 |

| [6] |

白义奎, 王铁良, 刘文和, 等. 东北型节能日光温室:辽沈Ⅰ型温室地下热交换系统试验研究. 节能技术, 2002, 20(2): 3-5. BAI Y K, WANG T L, LIU W H, et al. Experimental research on heat exchanger system of solar greenhouse of type Northeast China: Type Liaoshen I solar greenhouse. Energy Conservation Technology, 2002, 20(2): 3-5. (in Chinese with English abstract) |

| [7] |

吴德让, 李元哲, 于竹. 日光温室地下热交换系统的理论研究. 农业工程学报, 1994, 10(1): 137-143. WU D R, LI Y Z, YU Z. Theory research on earth tube heat exchangers in a sun-light greenhouse. Transactions of the Chinese Society of Agricultural Engineering, 1994, 10(1): 137-143. (in Chinese with English abstract) |

| [8] |

王永维, 苗香雯, 崔绍荣, 等. 温室地下蓄热系统换热特性研究. 农业工程学报, 2003, 19(6): 248-251. WANG Y W, MIAO X W, CUI S R, et al. Heat exchanging characteristics of underground heat storage system in greenhouses. Transactions of the Chinese Society of Agricultural Engineering, 2003, 19(6): 248-251. (in Chinese with English abstract) |

| [9] |

方慧, 杨其长, 张义. 基于热泵的日光温室浅层土壤水媒蓄放热装置试验. 农业工程学报, 2012, 28(20): 210-216. FANG H, YANG Q C, ZHANG Y. Experimental study on shallow soil assisted heat release-storage system with water-water heat pump in solar greenhouse. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(20): 210-216. (in Chinese with English abstract) |

| [10] |

柴立龙, 马承伟, 张晓蕙, 等. 地源热泵温室降温系统的试验研究与性能分析. 农业工程学报, 2008, 24(12): 150-154. CAI L L, MA C W, ZHANG X H, et al. Experimental investigation and performance analysis on ground source heat pump system for greenhouse cooling. Transactions of the Chinese Society of Agricultural Engineering, 2008, 24(12): 150-154. (in Chinese with English abstract) DOI:10.3321/j.issn:1002-6819.2008.12.032 |

| [11] |

刘付程, 史学正, 潘贤章, 等. 苏南典型地区土壤颗粒的空间变异特征. 土壤通报, 2003, 34(4): 246-249. LIU F C, SHI X Z, PAN X Z, et al. Characteristics of spatial variability of soil granules in a typical area of southern Jiangsu province. Chinese Journal of Soil Science, 2003, 34(4): 246-249. (in Chinese with English abstract) |

| [12] | TSAY J, OZKAN H E, FOX R D, et al. CFD simulation of mechanical spray shields. Transactions of the American Society of Agricultural Engineers, 2002, 45(5): 1271-1280. |

| [13] |

徐昶昕. 农业生物环境控制. 北京: 农业出版社, 1994: 10-12, 52, 187. XU C X. Agricultural Biological Environment Control. Beijing: Agriculture Press, 1994: 10-12, 52, 187. (in Chinese with English abstract) |

| [14] |

王永维, 苗香雯, 崔绍荣, 等. 温室地下蓄热系统蓄热和加温性能. 农业机械学报, 2005, 36(1): 75-78. WANG Y W, MIAO X W, CUI S R, et al. Study on the heat storing and heating performances of an underground heat storage system in greenhouse. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(1): 75-78. (in Chinese with English abstract) |

| [15] | OZGENER O, HEPBASLI A. A parametrical study on the energetic and exergetic assessment of a solar-assisted vertical ground-source heat pump system used for heating a greenhouse. Building and Environment, 2007, 42(1): 11-24. DOI:10.1016/j.buildenv.2005.07.003 |

| [16] |

严家騄, 王永青. 工程热力学. 3. 北京: 高等教育出版社, 2001: 36, 186-44, 190. YAN J L, WANG Y Q. Engineering Thermodynamics. 3. Beijing: Higher Education Press, 2001: 36, 186-44, 190. (in Chinese with English abstract) |

| [17] |

戴巧利, 左然, 李平, 等. 主动式太阳能集热/土壤蓄热塑料大棚增温系统及效果. 农业工程学报, 2009, 25(7): 164-168. DAI Q L, ZUO R, LI P, et al. Active solar heating system with soil heat storage for plastic film greenhouse and its effects. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(7): 164-168. (in Chinese with English abstract) |

| [18] |

林俊, 胡映宁, 刘涛, 等. 渗流对富水土壤传热特性影响的实验模拟研究. 暖通空调, 2007, 37(7): 7-10. LIN J, HU Y N, LIU T, et al. Simulating experiment on heat transfer characteristics of aqueous soil at seepage situation. Heating Ventilating & Air Conditioning, 2007, 37(7): 7-10. (in Chinese with English abstract) |

| [19] |

范蕊, 马最良. 地下水流动对地下管群换热器传热的影响分析. 太阳能学报, 2006, 27(11): 1155-1162. FAN R, MA Z L. Heat transfer analysis of geothermal hear exchanger under coupled conduction and groundwater advection. Acta Energiae Solaris Sinica, 2006, 27(11): 1155-1162. (in Chinese with English abstract) DOI:10.3321/j.issn:0254-0096.2006.11.016 |

2017, Vol. 43

2017, Vol. 43