| 2种安梨渣粉理化性质分析及其对火腿肠制作的影响 |

In order to improve the utilization rate of P. Ussurian pear resources, PUPP as a source of dietary fiber was used in ham sausage, and improve the nutrition structure of ham sausage to explore the feasibility of developing high fiber ham sausage. This paper studied basic components and physicochemical properties of peeled P. Ussurian pears pomace (PPUPP) and whole-fruit P. Ussurian pears pomace (WFPUPP) as well as PUPP as a source of dietary fiber added to ham sausage.

The results showed that the moisture, ash content, fat content, water-holding capacity, oil-holding capacity, water solubility index and chroma L* & b* value of the two kinds of PUPP were significantly different, the differences in protein, starch, dietary fiber content, pH value, chroma a* value were not significant. The effect of ham sausage physicochemical properties of the two kinds of PUPP in different levels is not significant, and PUPP has significant effect on the textural properties. The hardness and chewiness increased with PUPP level. The hardness of the treatments added with WFPUPP and PPUPP ham sausage was increased from 3.16 N of the control group to 4.74 N and 5.00 N, respectively. While the chewiness was increased from 21.70 mJ of the control group to 32.45 mJ and 28.73 mJ, respectively. Ham sausage glue viscosity and elasticity decreased with the level of PUPP, which the viscosity in the treatment of WFPUPP and PPUPP ham sausage was reduced from 8.33 mJ in the control group to 3.67 mJ and 6.04 mJ and from 14.67 N elasticity in the contrast group to 12.05 N and 12.81 N, respectively. Different addition levels of PUPP showed significant influence on ham sensory properties including color, texture and taste, but there was no significant difference in flavor. The overall acceptability of ham added with 0.5% PUPP was the closest to the control group. 0.5%-2.0% PUPP showed no significant effect on the overall acceptability of ham, and the highest level of two kinds of PUPP incorporated into ham was 2.0%.

膳食纤维是指不被人体消化的多糖类碳水化合物和木质素的总称。膳食纤维 (dietary fiber, DF) 可预防心血管疾病、便秘、过敏性结肠、结肠癌和糖尿病[1-4]。膳食纤维通过影响胆汁酸代谢使机体胆固醇排出增加, 从而降低血清胆固醇, 预防由冠动脉硬化引起的心脏病[5]。膳食纤维根据其溶解性的不同分为可溶性膳食纤维 (soluble dietary fiber, SDF) 和不溶性膳食纤维 (insoluble dietary fiber, IDF), 二者共同构成总膳食纤维 (total dietary fiber, TDF)。近年来,随着“健康食品”观念日益深入人心, 膳食纤维以其丰富的来源, 显著的生理活性和良好的保健作用引起了国际食品研究领域的关注, 相关学者进行了大量的研究, 使其成为国际研究热点[1, 6]。膳食纤维具有促进钙、铁、镁吸收的作用[7], 成人每天膳食纤维摄入量一般为25~38 g[8]。安梨 (Pyrus Ussurian), 俗称酸梨, 是秋子梨系统的代表品种之一, 主要分布于中国冀东北、辽西及京津等地的燕山一带, 年产量在10万t以上, 是一个古老的栽培品种[9-10]。安梨的加工主要是榨汁制作饮料和酿造安梨酒, 其加工副产物安梨渣富含膳食纤维却往往被废弃, 不仅污染环境而且浪费了膳食纤维资源。因此,将安梨渣粉通过加工处理, 作为食品功能性成分纳入到肉类制品中, 不仅解决了污染问题, 而且实现了膳食纤维资源的再利用。CHOI等[11]研究了米糠纤维对猪肉盐溶性肉类蛋白质的影响, 添加米糠纤维提高了保水能力, 降低了质构特性。此外,还分别探讨了小麦纤维、胡萝卜纤维、黄色西番莲纤维、葡萄抗氧化纤维等对肉类制品的影响[12-17]。火腿肠是将瘦肉和脂肪斩碎以后, 混合盐、硝酸盐或亚硝酸盐、糖、香辛料并灌入肠衣后, 经过加工而得到的肉制品[18]。火腿肠具有营养丰富、风味独特、携带方便、货架期长等特点, 得到很多人的认可[19]。膳食纤维的添加可以改善火腿肠营养结构, 提高其营养价值[20]。本研究探讨了去皮安梨渣粉 (peeled Pyrus Ussurian pears pomace, PPUPP) 和全果安梨渣粉 (whole-fruit Pyrus Ussurian pears pomace, WFPUPP) 基本组成成分、理化特性以及以安梨渣粉 (Pyrus Ussurian pears pomace, PUPP) 作为膳食纤维源添加到火腿肠中, 对火腿肠理化和感官性质的影响。截至发稿前未见相关研究报道, 此研究为安梨加工副产物作为功能性原料在肉制品方面的应用提供了理论基础, 具有理论价值和现实指导意义。

1 材料与方法 1.1 试验材料 1.1.1 原料安梨购自市场, 全果安梨渣粉和去皮的安梨渣粉由实验室自制。

1.1.2 试剂化学试剂:氢氧化钠、醋酸、95%乙醇、盐酸、硫酸、丙酮、氯化钠、硝酸钾、硝酸钠、三氯甲烷、无水硫酸钠、硝酸、三氯化铁、硼酸、甲基红-溴甲酚绿混合指示剂、硫酸钾、硫酸铜、无水乙醚或石油醚、二氧化硅、甲基红乙醇指示溶液 (2 g/L)、乙酸铅、酒石酸钾钠、1%次甲基蓝指示剂、标准葡萄糖、2-吗啉乙磺酸 (2-morpholine ethyl sulfonic acid, MES)、三羟甲基氨基甲烷 (three hydroxy methyl amino methane, TRIS)、磷酸二氢钾。生物试剂:α-淀粉酶 (30 U/mg)、蛋白酶 (60 U/mg)、淀粉葡糖苷酶 (100 U/mg)。

1.1.3 主要仪器设备电子天平,购自上海良平仪器仪表有限公司; 101-1-S型电热恒温鼓风干燥箱,购自上海跃进医疗器械厂; 电热恒温水浴锅,购自上海医疗器械五厂; 78-1型磁力加热搅拌器,购自江苏金坛市中大仪器厂; 九阳榨汁机,购自浙江九阳股份有限责任公司; JSP-200高速多功能粉碎机,购自浙江省永康金穗机械制造厂; 雷磁PHS-3C pH计,购自上海精密科学仪器有限公司; KSW-5-12A马弗炉,购自天津市中环实验电炉有限公司; 水平振荡器, 真空抽滤机, SKD-100凯氏定氮仪,购自上海沛欧分析仪器有限公司; DL-1万能电炉,购自北京中兴伟业仪器有限公司; KEO-20AS11TC电磁炉,购自康佳集团; 质构仪, SMY-2000测色色差计, 购自北京盛名扬科技开发有限公司。

1.2 方法 1.2.1 安梨渣粉制备工艺安梨→榨汁→梨渣40 ℃蒸馏水洗15 min→烘箱干燥6 h (60 ℃)→粉碎→过100目筛→全果安梨渣粉。

安梨→削皮→榨汁→梨渣40 ℃蒸馏水洗15 min→烘箱干燥6 h (60 ℃)→粉碎→过100目筛→去皮安梨渣粉。

1.2.2 安梨粉化学性质测定水分的测定:直接干燥法; 灰分:高温灼烧法; 脂肪:索式提取法; 淀粉:GB5009.9—2008酶解法; 蛋白质:微量凯氏定氮法; 总膳食纤维、可溶性膳食纤维、不溶性膳食纤维:参照Association of Official Analytical Chemists 991.43方法; pH值的测定:pH计法。

1.2.3 安梨粉物理性质测定 1.2.3.1 持水力参考RAGHAVENDRA等[21]采用的方法。精确称取样品250 mg为m0, 放入25 mL的蒸馏水, 电磁搅拌1 h, 烘干至恒量, 测离心管质量m1, 在3 000~4 000 r/min的转速下离心20 min, 弃去上清液, 称样品的湿时质量为m2, 持水力/(g/g)=(m2-m1-m0)/m0。

1.2.3.2 持油力参考GARAU等[22]的研究方法。精确称取样品250 mg为W0, 放入25 mL的食用油, 电磁搅拌1 h, 干燥至恒量,测离心管质量W1, 在3 000~4 000 r/min的转速下离心20 min, 倾去上层油, 称量样品的湿质量为W2, 持油力/(g/g)=(W2-W1-W0)/W0。

1.2.3.3 溶胀力参考GARAU等[22]的研究方法。精确称取样品1 g为m1, 置于10-mL的具塞试管内, 摇动, 使上液面保持平坦, 记录干样品的体积V1, 然后加入5 mL的蒸馏水, 摇匀, 在室温 (18±3) ℃下放置24 h, 读取膨胀后湿物质的体积V2, 溶胀力/(mL/g)=(V2-V1)/m1。

1.2.3.4 水溶性指标精确称取样品m置于100-mL烧杯中, 加50 mL蒸馏水, 室温下搅拌4 h, 离心10 min, 将上清液置于培养皿 (已恒量m0) 中, 在60 ℃下干燥18 h后再在105 ℃烘2 h至恒量, 称其质量为m1, m0、m1的差值即为所溶解的质量。水溶性 (S)/%=[(m1-m0)/m]×100。

1.2.3.5 色度安梨渣粉样品的颜色测量是建立在L*、a*和b*值的基础上, 使用色度计进行的[23]。L*值表示明亮度, 其中0表示黑色,而100表示白色;a*值表示红-绿色度, 其中较高的a*值指示更红;b*值表示黄-蓝色度, 其中较高的b*值指示更黄。

1.2.4 火腿肠的制作 1.2.4.1 材料安梨渣粉、猪肉 (肥瘦比为1:4)、盐 (2.8%)、白糖 (1.0%)、白胡椒 (0.1%)、味精 (0.15%)、淀粉 (10%)、生姜 (0.5%)、料酒。

1.2.4.2 火腿肠制备工艺参考EIM等[24]的研究。猪肉 (肥瘦比1:4)→清洗→绞碎→腌制 (盐、白糖、白胡椒、味精、生姜、料酒, 4 ℃下24 h)→斩拌 (淀粉)→灌肠→熟制杀菌 (121 ℃下30 min)→冷却→成品。

1.2.4.3 常规营养成分分析水分的测定:直接干燥法; 灰分:高温灼烧法; 脂肪:索式提取法; 蛋白质:微量凯氏定氮法。

1.2.4.4 水分活度测定水分活度的测定采用康卫氏皿扩散法

1.2.4.5 pH的测定样品采用1.5 g的火腿肠在10 mL蒸馏水中匀浆, 静止30 min取上清液,用pH计测定样品pH值, 同一个试样进行3次测定取平均值[25]。

1.2.4.6 感官分析感官分析是为了测试食品感官特性的一种广泛使用的方法[26]。火腿肠的感官特性由35名成员进行评价, 要求每个成员评价火腿肠的气味、颜色、质地、味道和整体可接受性, 评分标准为10分, 每个感官特性从10(非常愉快) 到1(厌恶至极)。

1.2.4.7 质构分析参考VISESSANGUAN等[27]的研究。采用物性测定仪 (质构仪) 测定火腿肠质构特性。样品高度20 mm, 参数设定:探针高度30 mm, 样品形变量40%, 向下速度60 mm/min, 向上速度60 mm/min, 接触力0.1 N。参数设定后利用程序测得火腿肠的硬度、弹性、凝聚力、胶黏性、咀嚼性[28]。

1.2.5 统计分析试验中的数据均为3个或3个以上试验样本平均值, 使用软件DPS 12.50对数据进行统计分析。

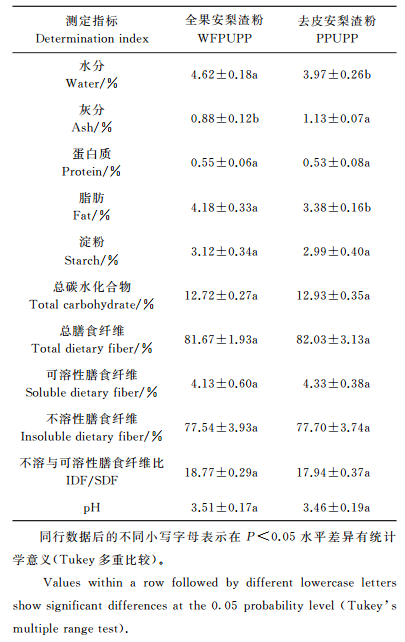

2 结果与分析 2.1 PUPP理化特性分析 2.1.1 PUPP基本组成成分及化学特性由WFPUPP和PPUPP的基本组成成分及化学特性 (表 1) 可知, WFPUPP和PPUPP的水分、灰分和脂肪含量存在显著性差异 (P < 0.05), 二者的蛋白质、淀粉、膳食纤维含量及pH差异不显著。二者的蛋白质、脂肪和灰分含量均低于柑橘皮和虎坚果副产物相应成分的含量[29-30], 这可能与膳食纤维源所属的植株及果品种类差异有关。

| 表1 安梨渣粉基本组成成分及化学特性 Table 1 Basic components and chemical properties of PUPP |

|

| 点击放大 |

WFPUPP和PPUPP的pH值分别为3.51和3.46, 二者的pH均低于橙子膳食纤维[31]的pH 4.06和柠檬膳食纤维[22]的pH 3.96, 导致PUPP pH值略低的原因可能是其中富含苹果酸、枸橼酸和草酸等有机酸[32]。PPUPP的SDF含量为4.33%, 略高于WFPUPP的SDF含量4.13%, WFPUPP脂肪含量达4.18%, 明显高于PPUPP脂肪含量3.38%。PUPP的TDF含量达81%以上, 显著高于石榴渣粉[33]45%~50%的TDF含量。WFPUPP和PPUPP的IDF/SDF值分别为18.77和17.94, 较高的IDF/SDF值表明PUPP中含有大量的纤维素和半纤维素, PUPP中较高的IDF比例是一种优势, 因为IDF可以作为一种营养成分应用于食品工业以增加食品中不溶性化合物的含量。此外, 高IDF含量能增加饱腹感, 增加粪便的体积质量从而利于排便, 促进消化系统功能的改善, 有利于身体健康[1-4]; 同时应用于某些食品中有利于调节TDF中SDF和IDF的比例平衡。

2.1.2 物理性质PUPP的物理性质见表 2, 其中水合性质包括持水力 (water-holding capacity, WHC)、溶胀力 (swelling capacity, SWC) 和水溶性指标 (water solubility index, WSI),此外还有持油力 (oil-holding capacity, OHC) 和色度。植物纤维的物理特性受不溶性和可溶性膳食纤维比例、纤维粒度、提取条件及植物多糖的结构和植物来源等因素影响。无论从生理还是技术角度, WHC都是膳食纤维的一个重要性质, 它表示一个潮湿的材料在保持水的能力时所受到的外部离心力或压缩。WHC所表示的保持水分主要由物理限制水、结合水和水动力水组成。OHC也是与植物多糖化学结构密切相关的技术特性, 主要受植物多糖的化学和物理结构影响, OHC是纤维与油混合一定时间并离心后, 纤维所能保持油的数量。SWC是另一个和纤维的成分直接相关的重要的水合性质。WSI与可溶性分子的存在相关。由表 2可知,PUPP的WHC和OHC较低, 这可能与SDF含量较低有关[34]。WFPUPP和PPUPP的WHC、OHC和WSI都存在明显差异 (P < 0.05)。WFPUPP的WHC、OHC和SWC较高,但WSI略低于PPUPP, 这可能与安梨膳食纤维含量及组成成分结构有关。

| 表2 安梨渣粉物理性质 Table 2 Physical properties of PUPP |

|

| 点击放大 |

颜色是食品中最重要的品质参数之一。膳食纤维的颜色是制约其在食品方面的潜在应用价值[33]。颜色受许多因素的影响, 其中包括水果品种和成熟度, 尤其是果肉的干燥处理工艺, 在脱水过程中果肉经历高温, 导致酶促和非酶褐变 (美拉德反应), 使产品颜色变暗。食品中的亮度与许多因素有关, 包括颜料的含量和类型,以及含水量和可用的表面水。由表 2可知WFPUPP和PPUPP的L*值和b*值差异显著 (P < 0.05), 而a*值差异不显著 (P > 0.05)。PPUPP的L*值、a*值、b*值分别达42.74、5.53和12.69, 显著高于WFPUPP的相应指标34.00、4.12和9.71, 说明PPUPP比WFPUPP更亮、更红、更黄。同时PPUPP比WFPUPP的颜色值相对适中, 使得它们很容易添加到其他产品中。WFPUPP和PPUPP的黄-蓝坐标b*值均低于其他已报道的水果纤维, 如柠檬纤维的b*值达25.89[33], 橘子纤维的b*值达38.8[35], 这些高b*值可能是由于出现在水果中的胡萝卜素没有被清洗掉所致。

2.2 安梨渣粉的添加对火腿肠性质的影响 2.2.1 理化分析由火腿肠的理化性质 (表 3) 可知,WFPUPP和PPUPP各添加水平火腿肠的水分、灰分、蛋白质、脂肪含量以及pH、水分活度与对照组相比均无显著性差异[36](P > 0.05)。WFPUPP和PPUPP各添加水平火腿肠的水分基本稳定在58%左右, 灰分稳定在2.2%左右, 蛋白质稳定在16%左右, 脂肪稳定在11%左右, pH基本稳定在5.30左右, 水分活度基本稳定在0.85左右。由此可知, WFPUPP和PPUPP各添加水平对火腿肠理化性质均无显著影响。

| 表3 安梨渣粉的添加对火腿肠理化性质的影响 Table 3 Effects of adding PUPP on the physicochemical properties of ham sausage |

|

| 点击放大 |

由火腿肠的质构性质 (表 4) 可知,PUPP的添加对火腿肠的硬度、胶黏性、弹性和咀嚼性均有显著影响 (P < 0.05), 对火腿肠的凝聚力影响不显著 (P > 0.05)。比较WFPUPP和PPUPP各添加水平火腿肠和对照组火腿肠的质构性质表明, 随着PUPP添加量的增加, 火腿肠的硬度逐渐增大, 从对照组的3.16 N分别增加到4.74 N和5.00 N。但是弹性和胶黏性均逐渐减小[24, 37], 弹性从对照组14.67 N分别降至12.05 N和12.81 N, 而胶黏性从对照组的8.33 mJ分别降到3.67 mJ和6.04 mJ, 这可能与安梨渣粉中含有较高的不溶性膳食纤维有关[38]。随着PUPP添加量的增加, 火腿肠的咀嚼性逐渐增强, 咀嚼性从对照组的21.70 mJ分别增加到32.45 mJ和28.73 mJ。可见,在相同添加水平下, 添加WFPUPP火腿肠的咀嚼性比添加PPUPP火腿肠的咀嚼性更强, 这可能是由于WFPUPP和PPUPP的膳食纤维组成及结构差异所致。WFPUPP和PPUPP各添加水平火腿肠的凝聚力均低于对照组的凝聚力0.53, 且均稳定在0.50左右。

| 表4 安梨渣粉的添加对火腿肠质构性质的影响 Table 4 Effects of adding PUPP on the texture characteristics of ham sausage |

|

| 点击放大 |

由火腿肠的感官性质 (表 5) 可知,添加PUPP对火腿肠的感官性质具有显著影响 (P < 0.05)。随着WFPUPP和PPUPP添加水平的增加, 对火腿肠的颜色、质地及味道有显著影响 (P < 0.05), 火腿肠的颜色、质地、味道等感官评分逐渐下降, 火腿肠颜色从对照组的6.37分别降至3.90和3.56, 质地从对照组的6.90分别降至3.63和3.67, 味道从对照组的5.97分别降至2.93和3.13。EIM等[24]在研究胡萝卜纤维对发酵干香肠感官性质的影响时也发现了相似的结果。

| 表5 安梨渣粉的添加对火腿肠感官性质的影响 Table 5 Effects of adding PUPP on the sensory properties of ham sausage |

|

| 点击放大 |

随着WFPUPP和PPUPP添加水平的增加, 对火腿肠的气味影响不显著 (P > 0.05), 对照组气味评分6.20, WFPUPP和PPUPP各添加水平火腿肠的气味评分值范围为5.73~6.40, 且气味评分随PUPP添加水平的增加逐渐上升。对照组火腿肠整体上是可接受的, 在10分的评价标准上, 对照组整体可接受的评分是6.63。其中2.5% WFPUPP和PPUPP添加水平的火腿肠与对照组存在显著差异, 被感官评价员评定为差,并认为是不可接受的;0.5% WFPUPP和PPUPP添加水平的火腿肠的整体可接受性最接近对照组;2.0% WFPUPP和PPUPP添加水平对火腿肠的影响不显著, 评价小组可接受且有类似于对照火腿肠的感官特性, 因而WFPUPP和PPUPP可纳入火腿肠的最高水平为2.0%。EIM等[24]报道胡萝卜纤维可纳入发酵干香肠的最大水平为3.0%。

3 结语 3.1PUPP的理化分析结果表明, WFPUPP和PPUPP的水分、灰分、脂肪含量以及持水力、持油力、水溶性和色度L*值与b*值存在差异显著, 它们的淀粉、蛋白质、膳食纤维含量以及pH、溶胀力和色度a*值无差异显著。两者的灰分、脂肪、蛋白质含量以及pH值均较低, TDF和IDF含量均较高, 分别达81.67%、82.03%和77.54%、77.70%, 因此两者均为潜在的优质膳食纤维资源, 可以作为营养强化剂或填充剂广泛应用于食品工业。

3.2PUPP对火腿肠的理化性质影响研究结果表明, PUPP对火腿肠的理化性质无显著影响, 各WFPUPP和PPUPP添加水平火腿肠的理化性质指标与对照组基本相近。

3.3PUPP对火腿肠的质构和感官性质影响研究结果表明, PUPP对火腿肠的质构和感官性质有显著影响。随着WFPUPP和PPUPP添加水平的增加, 对火腿肠的硬度、咀嚼性、弹性和胶黏性影响显著 (P < 0.05),而对凝聚力影响不显著。火腿肠硬度从对照组的3.16 N分别增加到4.74 N和5.00 N, 咀嚼性从对照组的21.70 mJ分别增加到32.45 mJ和28.73 mJ, 弹性从对照组14.67 N分别降低到12.05 N和12.81 N。而胶黏性从对照组的8.33 mJ分别降低到3.67 mJ和6.04 mJ, 凝聚力稳定在0.50左右。

3.40.5%的WFPUPP和PPUPP添加水平火腿肠的整体可接受性最接近对照组。2.0%的WFPUPP和PPUPP添加水平对火腿肠影响不显著, 整体可接受且有类似于常规火腿肠的感官性质, 而2.5%的WFPUPP和PPUPP添加水平对火腿肠影响显著, 被评价小组评定为最差且不可接受, WFPUPP和PPUPP可纳入火腿肠的最高水平为2.0%。

| [1] |

POCIO R, ANA J, JUAN F B, et al. Dietary fibre from vegetable products as source of functional ingredients.

Journal of Trends in Food Science and Technology, 2006,17 (1):3–15. DOI: 10.1016/j.tifs.2005.10.002. |

| [2] |

ANTONIO J E, MARIA D T, IRENE E M, et al. Health promoting effects of a dietary fiber concentrate from the soybean byproduct Okara in rats.

Journal of Agricultural and Food Chemistry, 2008,56 (16):7495–7501. DOI: 10.1021/jf800792y. |

| [3] |

FUENTES-ZARAGOZA E, RIQUELME-NAVARRETE M J, SÁNCHEZ-ZAPATA E, et al. Resistant starch as functional ingredient: a review.

Journal of Food Research International, 2010,43 (4):931–942. DOI: 10.1016/j.foodres.2010.02.004. |

| [4] |

MANN J I, CUMMINGS J H. Possible implications for health of the different definitions of dietary fibre.

Journal of Nutrition, Metabolism and Cardiovascular Diseases, 2009,19 (3):226–229. DOI: 10.1016/j.numecd.2009.02.002. |

| [5] |

VENKATESAN N, DEVARAJ S N, DEVARAJ H. Increased binding of LDL and VLDL to apo B, E receptors of hepatic plasma membrane of rats treated with Fibernat.

European Journal of Nutrition, 2003,42 (5):262–271. DOI: 10.1007/s00394-003-0420-8. |

| [6] |

LEILA P S, MARIA D L S C. Total insoluble and soluble dietary fiber measured by enzymatic gravimetric method in cereal grains.

Journal of Food Composition and Analysis, 2005,18 (1):113–120. DOI: 10.1016/j.jfca.2003.12.005. |

| [7] |

OSAMU K, YOSHIO A, AKIRA A, et al. Effect of germinated barley foodstuff administration on mineral utilization in rodents.

Journal of Gastroenterology, 2000,35 (3):188–194. DOI: 10.1007/s005350050329. |

| [8] |

ROMO M, MIZE C, WARFEL K. Addition of Hi-maize, natural dietary fiber, to a commercial cake mix.

Journal of the American Dietetic Association, 2008,108 (9):A76. |

| [9] |

齐永顺, 刘金, 宋金耀, 等.安梨新品种"燕安1".

园艺学报,2004,31 (3):417.

QI Y S, LIU J, SONG J Y, et al. "Yan'an 1", a new pear variety. Acta Horticulturae Sinica, 2004,31 (3):417. (in Chinese with English abstract) |

| [10] |

齐永顺, 刘金, 宋金耀, 等.安梨新品种"燕安2".

园艺学报,2004,31 (4):555.

QI Y S, LIU J, SONG J Y, et al. "Yan'an 2", a new pear variety. Acta Horticulturae Sinica, 2004,31 (4):555. (in Chinese with English abstract) |

| [11] |

CHOI Y S, CHOI J H, HAN D J, et al. Effects of rice bran fiber on heat-induced gel prepared with pork salt-soluble meat proteins in model system.

Journal of Meat Science, 2011,88 (1):59–66. DOI: 10.1016/j.meatsci.2010.12.003. |

| [12] |

WASZKOWIAK K, SZYMANDERA-BUSZKA K. The application of wheat fibre and soy isolate impregnated with iodine salts to fortify processed meats.

Journal of Meat Science, 2008,80 (4):1340–1344. DOI: 10.1016/j.meatsci.2008.06.011. |

| [13] |

GROSSI A, SØLTOFT-JENSEN J, KNUDSEN J C, et al. Synergistic cooperation of high pressure and carrot dietary fibre on texture and colour of pork sausages.

Journal of Meat Science, 2011,89 (2):195–201. DOI: 10.1016/j.meatsci.2011.04.017. |

| [14] |

LÓPEZ-VARGAS J H, FERNÁNDEZ-LÓPEZ J, PÉREZ-ÁLVAREZ J Á, et al. Quality characteristics of pork burger added with albedo-fiber powder obtained from yellow passion fruit (Passiflora edulis var. flavicarpa) co-products.

Journal of Meat Science, 2014,97 (2):270–276. DOI: 10.1016/j.meatsci.2014.02.010. |

| [15] |

EIM V S, SIMAL S, ROSSELLÓ C, et al. Optimisation of the addition of carrot dietary fibre to a dry fermented sausage (Sobrassada) using artificial neural networks.

Journal of Meat Science, 2013,94 (3):341–348. DOI: 10.1016/j.meatsci.2013.02.009. |

| [16] |

SÁYAGO S G, BRENES A, GOÑI I. Effect of grape antioxidant dietary fiber on the lipid oxidation of raw and cooked chicken hamburgers.

Journal of LWT-Food Science and Technology, 2009,42 (5):971–976. DOI: 10.1016/j.lwt.2008.12.006. |

| [17] |

KTARI N, SMAOUI S, TRABELSI I, et al. Chemical composition, techno-functional and sensory properties and effects of three dietary fibers on the quality characteristics of Tunisian beef sausage.

Journal of Meat Science, 2014,96 (1):521–525. DOI: 10.1016/j.meatsci.2013.07.038. |

| [18] |

SAVADKOOHI S, HOOGENKAMP H, SHAMSI K, et al. Color, sensory and textural attributes of beef frankfurter, beef ham and meat-free sausage containing tomato pomace.

Journal of Meat Science, 2014,97 (4):410–418. DOI: 10.1016/j.meatsci.2014.03.017. |

| [19] |

VUJIĆ J M, VRANIĆ D V, VESKOVIĆ S M, et al. Antioxidant and antimicrobial activity of Kitaibelia vitifolia extract as alternative to the added nitrite in fermented dry sausage.

Journal of Meat Science, 2014,97 (4):459–467. DOI: 10.1016/j.meatsci.2014.03.012. |

| [20] |

GANDEMER G. Lipids in muscles and adipose tissues, changes during processing and sensory properties of meat products.

Journal of Meat Science, 2002,62 (3):309–321. DOI: 10.1016/S0309-1740(02)00128-6. |

| [21] |

RAGHAVENDRA S N, SWAMY S R R, RASTOGI N K, et al. Grinding characteristics and hydration properties of coconut residue: a source of dietary fibre.

Journal of Food Engineering, 2006,72 :281–286. DOI: 10.1016/j.jfoodeng.2004.12.008. |

| [22] |

GARAU M C, SIMAL S, ROSSELLO C, et al. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium cv. Canoneta) byproducts.

Journal of Food Chemistry, 2007,104 (3):1014–1024. DOI: 10.1016/j.foodchem.2007.01.009. |

| [23] |

LEON K, MERY D, PEDRESCHI F, et al. Color measurement in L*, a*, b* units from RGB digital images.

Journal of Food Research International, 2006,39 (10):1084–1091. DOI: 10.1016/j.foodres.2006.03.006. |

| [24] |

EIM V S, SIMAL S, ROSSELLÓ C, et al. Effects of addition of carrot dietary fibre on the ripening process of a dry fermented sausage (Sobrassada).

Journal of Meat Science, 2008,80 (2):173–182. DOI: 10.1016/j.meatsci.2007.11.017. |

| [25] |

SAMARANAYAKE C P, SASTRY S K. In-situ pH measurement of selected liquid foods under high pressure.

Journal of Innovative Food Science & Emerging Technologies, 2013,17 :22–26. |

| [26] |

CASABURI A, ARISTOY M C, CAVELLA S, et al. Biochemical and sensory characteristics of traditional fermented sausages of Vallo di Diano (southern Italy) as affected by the use of starter cultures.

Journal of Meat Science, 2007,76 (2):295–307. DOI: 10.1016/j.meatsci.2006.11.011. |

| [27] |

VISESSANGUAN W, BENJAKUL S, RIEBROY S, et al. Changes in composition and functional properties of proteins and their contributions to NHAM characteristics.

Journal of Meat Science, 2004,66 (3):579–588. DOI: 10.1016/S0309-1740(03)00172-4. |

| [28] |

HERRERO A M, ORDÓÑEZ J A, DE AVILA R, et al. Breaking strength of dry fermented sausages and their correlation with texture profile analysis (TPA) and physico-chemical characteristics.

Journal of Meat Science, 2007,77 (3):331–338. DOI: 10.1016/j.meatsci.2007.03.022. |

| [29] |

CHAU C F, HUANG Y L. Comparison of the chemical composition and physicochemical properties of different fibres prepared from the peel of Citrus sinensis L. cv. Liucheng.

Journal of Agricultural and Food Chemistry, 2003,51 (9):2615–2618. DOI: 10.1021/jf025919b. |

| [30] |

SÁNCHEZ-ZAPATA E, FUENTES-ZARAGOZA E, FERNÁNDEZ-LÓPEZ J, et al. Preparation of dietary fibre powder from tiger nut (Cyperus esculentus) milk ("Horchata") byproducts and its physicochemical properties.

Journal of Agricultural and Food Chemistry, 2009,57 (17):7719–7725. DOI: 10.1021/jf901687r. |

| [31] |

LARIO Y, SENDRA E, GARCÍ J, et al. Preparation of high dietary fiber powder from lemon juice by-products.

Journal of Innovative Food Science and Emerging Technology, 2004,5 (1):113–117. DOI: 10.1016/j.ifset.2003.08.001. |

| [32] |

STINTZING F C, CARLE R. Cactus stems (Opuntia spp.): a review on their chemistry, technology, and uses.

Journal of Molecular Nutrition & Food Research, 2005,49 :175–194. |

| [33] |

VIUDA-MARTOS M, RUIZ-NAVAJAS Y, MARTIN-SÁNCHEZ A, et al. Chemical, physico-chemical and functional properties of pomegranate (Punica granatum L.) bagasses powder co-product.

Journal of Food Engineering, 2012,110 (2):220–224. DOI: 10.1016/j.jfoodeng.2011.05.029. |

| [34] |

FIGUEROLA F, HURTADO M L, ESTÉVEZ A M, et al. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment.

Journal of Food Chemistry, 2005,91 (3):395–401. DOI: 10.1016/j.foodchem.2004.04.036. |

| [35] |

GRIGELMO-MIGUEL N, MARTINA-BELLOSO O. Characterization of dietary fibre from orange juice extraction.

Journal of Food Research International, 1998,31 (5):355–361. DOI: 10.1016/S0963-9969(98)00087-8. |

| [36] |

GARCÍA M L, DOMINGUEZ R, GALVEZ M D, et al. Utilization of cereal and fruit fibres in low fat dry fermented sausages.

Journal of Meat Science, 2002,60 (3):227–236. DOI: 10.1016/S0309-1740(01)00125-5. |

| [37] |

BORDERÍAS A J, SÁNCHEZ-ALONSO I, PÉREZ-MATEOS M. New application of fibre in foods: Addition to fishery products.

Journal of Trends in Food Science and Technology, 2005,16 (10):458–465. DOI: 10.1016/j.tifs.2005.03.011. |

| [38] |

SANCHEZ-ALONSO I, HAJI-MALEKI R, BORDERIAS A J. Effect of wheat fibre in frozen stored fish muscular gels.

Journal of European Food Research Technology, 2006,223 (4):571–576. DOI: 10.1007/s00217-005-0242-4. |

2017, Vol. 43

2017, Vol. 43