文章信息

- 邓培淼, 宁洪龙, 谢伟广, 刘贤哲, 邓宇熹, 姚日晖, 彭俊彪

- DENG Pei-miao, NING Hong-long, XIE Wei-guang, LIU Xian-zhe, DENG Yu-xi, YAO Ri-hui, PENG Jun-biao

- 氧化亚锡薄膜晶体管的研究进展

- Research progress in stannous oxide thin film transistors

- 材料工程, 2020, 48(4): 83-88

- Journal of Materials Engineering, 2020, 48(4): 83-88.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2019.000065

-

文章历史

- 收稿日期: 2019-01-18

- 修订日期: 2019-08-21

2. 暨南大学 广东省真空薄膜技术与新能源材料工程技术中心, 广州 510632

2. Guangdong Vacuum Film Technology and New Energy Material Engineering Technology Center, Jinan University, Guangzhou 510632, China

目前,p型氧化物半导体在透明、柔性电子、忆阻器、电致变色、传感器、光伏电池等领域有着很好的发展前景[1]。但与n型氧化物半导体相比,由于产生空穴(如阳离子空位)的本征受主形成能高以及湮灭空穴(如阴离子空位)的本征施主形成能低,使得p型氧化物半导体的载流子浓度低、性能差从而阻碍了新型电子器件的发展[2-3];因此,开发性能与n型氧化物半导体相近的p型氧化物半导体成为当前研究的重点,从而为实现低功耗,低余热,高噪声裕度,高电路集成密度,结构简单的互补金属氧化物半导体器件(complementary metal-oxide-semiconductor, CMOS)的制备提供可能性[3-5]。在各种p型氧化物半导体中,如SnO(或SnOx)[6-7],Cu2O[8-10]和NiO[11-12],SnO由于本征受体的Sn空位(VSn)的形成能低,以及通过Sn5s与O2p轨道的杂化,形成了易于空穴传输的载流子通道,使得其空穴浓度高,有效质量低,霍尔迁移率高,从而比其他p型氧化物半导体更有可能实现互补电路的制备[13-15]。本文重点介绍SnO材料的微观结构、光电性能及薄膜材料和晶体管制备的研究进展。

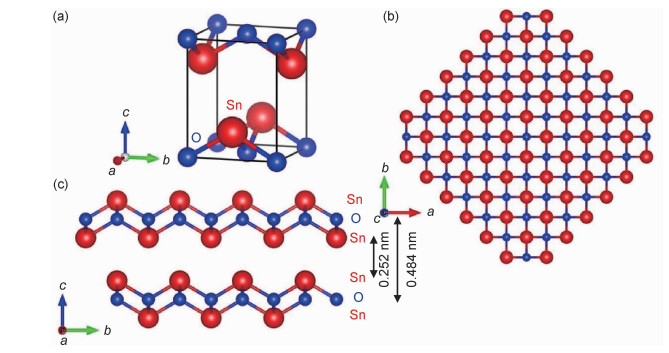

1 氧化亚锡微观性能分析 1.1 晶体结构Sn在锡单硫族化合物(Snx;x=O,S,Se或Te)中的电子构型为4d105s25p0,电负性强的硫族原子容易获得到Sn5p轨道上的两个电子,并且从SnTe到SnO,晶体结构依次从立方结构到二维层状结构转化,SnS,SnSe属于中间态。在这类材料中,SnO在[001]晶体方向与Sn1/2-O-Sn1/2序列形成层状结构。SnO的稳定相为四方晶体结构,4个O原子和1个Sn原子形成一个金字塔结构,如图 1(a)所示,晶格参数a=b=0.38 nm和c=0.484 nm;SnO晶格排列属于p4/nmm空间群,如图 1(b)所示;在SnO中,Sn5s壳外电子对不参与成键过程,构成一对孤对电子。这些孤对电子对指向层间距,由此产生的偶极-偶极相互作用导致SnO层间的范德华键间隙为0.252 nm,如图 1(c)所示[13, 15-16]。

|

图 1 SnO晶体结构 (a)晶胞;(b)[001]晶向;(c)[100]方向俯视图 Fig. 1 Crystal structure of SnO (a)unit cell; (b)[001]crystal orientation; (c) top view of [100] direction |

在发现SnO具有p型半导体性质之后,SnO在薄膜晶体管中的应用潜能得到了研究者们极大的关注。这是因为锡空穴(VSn)的形成能较低,以及由O2p与球形Sn5s轨道杂化而形成的一种更分散的空穴传输通道-价带顶杂化能级(valence-band maximum, VBM),其中在VBM的形成中Sn5s轨道起主导作用,由于Sn5s轨道呈球形,电子云重叠的方向性不强,更有利于空穴的传输,因而SnO具有较高的空穴迁移率。随后,Ogo等[7, 17]利用外延生长法在(001)钇氧化锆衬底上制备了SnO薄膜,霍尔迁移率为2.4 cm2·V-1·s-1,场效应迁移率为1.3 cm2·V-1·s-1。自此之后,由于其相对较高的霍尔迁移率和锡金属的丰富和无毒性,SnO受到了越来越多的关注[18]。通过研究Ogo等在(001)钇氧化锆衬底上利用外延生长的SnO薄膜的物理性质,发现SnO存在双带隙,光学带隙为2.7 eV,基本带隙为0.7 eV[7]。Ogo等还研究了SnO更详细的电子性质,包括电离势(5.8 eV)、空穴有效质量(2.05 me)和热激活能(45 meV)[17]。

由于SnO晶体是层状结构,因此它的电子结构表现出各向异性,导带在平行(001)晶面(沿X-Γ-M)和垂直(001)晶面(沿M-A)发生色散;其中,在Γ点处,价带顶能级的能量标定为0 eV,能量最高占据状态位于Γ点和M点之间,给出了M点处的最低未占状态,能带结构和部分态密度谱(partial density of states, PDOS)的背景表示价带中的3个特征能级区域[1, 15, 19]。同时,SnO的价带底能级(the conduction band minimum, CBM)主要来自Sn5p轨道,其PDOS曲线显示出一个自由电子带,表明如果存在足够多的电子,电子也可以在SnO中运动从而产生电流,此时,SnO表现出n型半导体性质[15, 20]。

2 氧化亚锡薄膜材料 2.1 氧化亚锡薄膜材料制备方法目前,氧化亚锡薄膜常用的制备方法是通过物理气相沉积(physical vapor deposition, PVD)路线来沉积薄膜,包括脉冲激光沉积(pulsed laser deposition, PLD)[7, 17, 21-22]、电子束沉积(electron beam evaporation, EBE)[23-25]、射频磁控溅射(radio-frequency magnetron sputtering, RFMS)[26-28]、直流磁控溅射(direct current magnetron sputtering, DCMS)[29]。表 1总结出氧化亚锡薄膜的研究进展,内容包括薄膜制备方法、衬体材料、沉积条件、霍尔迁移率、载流子(空穴)浓度、薄膜光透过率以及带隙等。在表 1中,Han等[30]提出了原子层沉积(atomic-layer deposition, ALD)方法,生长的SnO薄膜属于多晶结构,霍尔迁移率为2.9 cm2·V-1·s-1。除ALD外,化学气相沉积(chemical vapor deposition, CVD)和气溶胶辅助化学气相沉积(aerosol-assisted chemical vapor deposition,AACVD)等化学路线也被成功地应用于氧化亚锡薄膜的制备[31-33]。

| Method | Substrate | T/℃ | μHall/(cm2·V-1·s-1) | Nh/cm-3 | T/% | Eg/eV | Time | Reference |

| PLD | (001)YSZ | 200 | 2.4 | 2.5×1017 | - | 2.70 | 2009 | [17] |

| EBE | SiO2 | 600 | 1.4 | 2.8×1016 | 70 | 2.77 | 2010 | [23] |

| PLD | Si/SiO2 | 250 | 1.9 | 1.0×1017 | - | - | 2011 | [22] |

| EBE | Si/SiO2 | 350 | 3.9 | 5.6×1015 | 60 | 2.70 | 2012 | [24] |

| DCMS | ITO/HfO2 | - | 18.7 | 2.18×1017 | - | 2.65 | 2013 | [29] |

| RFMS | Glass | 500 | 0.64 | 4.3×1017 | - | - | 2014 | [27] |

| ALD | Si/SiO2 | - | 2.9 | 3.4×1017 | 60 | 2.60 | 2014 | [30] |

| PLD | (001)YSZ | - | 2.3 | 1.0×1017 | 40 | 2.80 | 2015 | [21] |

| RFMS | Glass | 265 | 0.78 | 4.28×1017 | 40 | 2.83 | 2015 | [26] |

| EBE | Quartz | 700 | 16.0 | 5.0×1014 | 90 | 2.20 | 2016 | [25] |

从表 1中可以明显看出,关于SnO基本(间接)带隙方面的报道非常少,而能带带隙Eg是半导体最重要的参数之一;主要原因是由于间接跃迁产生的弱光吸收现象造成间接带隙计算非常困难,因为要实现间接跃迁,不仅需要光子,还需要声子[1]。Ogo等[7]用漫反射光谱法测定粉末SnO样品的间接带隙为Eg=0.7 eV;在此之后,人们尝试用不同方法来测量氧化亚锡薄膜样品中的间接带隙值Eg,Liang等[34]用光吸收测量Al2O3覆盖的多晶SnO薄膜,测出其间接带隙值为0.5 eV;Toyama等[35]成功地用光声光谱和光热偏转光谱法测试SnO薄膜的间接带隙,其测量结果分别为0.7 eV和0.6 eV。表 1还列出了SnO薄膜的光学特性,包括可见光范围内的平均透过率和能带带隙(直接带隙和间接带隙);以及使用Seebeck测试方法用于检测SnO薄膜中多数电荷载流子类型。关于Seebeck系数(S)有很多相关报道:Ogo等[17]测出S=1.99 mV·K-1,Hayashi等[21]测出S=763 μV·K-1,Han等[30]测出S=1.69 mV·K-1;这种差异可能是由于载流子浓度以及能带结构的差异造成的,而能带结构的差异则来源于不同的沉积方法、薄膜的结晶度和晶粒生长取向[1]。

3 氧化亚锡薄膜晶体管制备目前,氧化亚锡薄膜晶体管常见制备方法包括原子沉积(atomic layer deposition, ALD)[36]、电子束蒸发(electron beam evaporation, EBE)[37-38]、脉冲激光沉积(pulsed laser deposition, PLD)[22]、射频(直流)磁控溅射(radio-frequency(direct current) magnetron sputtering, RF(DC)MS)[5, 6, 18, 39-43]、热蒸发(thermal evaporation, TE)[44-45]等;下面分别对脉冲激光沉积法,磁控溅射法以及原子沉积法进行详细介绍。

3.1 脉冲激光沉积法在2008年,Ogo等[7]制备出具有p型性质的SnO TFT器件。通过脉冲激光沉积法(PLD)外延生长(001)取向的SnO薄膜,厚度为20 nm,所用衬体为(001)晶向钇基氧化锆衬体(yttria-stabilized zirconia, YSZ),沉积温度为575 ℃。器件结构为共面顶栅结构,绝缘层a-Al2Ox采用脉冲激光沉积法沉积在有源层SnO薄膜上,沉积厚度为210 nm,源、漏和栅极Au/Ni采用电子束蒸发法(e-beam evaporated,EBE)沉积在绝缘层上。器件阈值电压Vth为4.8 V、场效应迁移率μFE为1.3 cm2·V-1·s-1、饱和迁移率μsat为0.7 cm2·V-1·s-1以及电流开关比Ion/Ioff为102;导致沟道耗尽工作模式以及电流开关比小的原因是器件沟道空穴密度非常大,对沉积的SnO薄膜进行霍尔测试,发现空穴浓度为2.5×1017 cm-3。此外,从SnO粉末样品的漫反射光谱中确定了SnO的基本带隙约为0.7 eV。

在2011年,Nomura等[22]证明SnO具有双极传导特性,通过施加正负不同栅偏压,沟道层中载流子分别为电子和空穴。双极传导TFT器件具有很大的优势,因为它可以将p型和n型半导体的沉积工艺结合起来,从而简化互补电路的制作过程。采用室温脉冲激光沉积法沉积SnO沟道层,厚度为15.4 nm,在250 ℃空气中退火30 min后,薄膜从非晶态转变为多晶态;SiO2(15 nm)/Si作为绝缘层和栅极,ITO作为源、漏电极,器件结构为交错底栅结构;此外,在SnO薄膜层上镀一层330 nm厚的Y2O3作为顶栅构成双栅结构。器件p型沟道饱和迁移率为0.81 cm2·V-1·s-1,n型沟道饱和迁移率为5×10-4 cm2·V-1·s-1。将表现双极性的SnO TFT器件组合在一起,构成一种CMOS型逆变器,增益值为2.5,这是使用单通道氧化物半导体应用于CMOS型逆变器。

3.2 磁控溅射法2013年,Caraveo-frescas等[46]报道了在柔性衬体上制备高性能SnO TFT器件的详细研究。实验采用刚性(玻璃)和柔性(聚酰亚胺)衬体,器件结构为交错底栅TFT结构,沟道层为迁移率更高的混合相SnO,栅极采用ITO,源、漏电极采用ITO/Ti,绝缘层采用HfO2,器件在空气下采用180 ℃退火30 min处理。在透明玻璃衬体上的器件阈值电压Vth为-1V,迁移率μFE为6.75 cm2·V-1·s-1,开关比Ion/Ioff为6×103,亚阈值摆幅SS为7.63 V·dec-1;在柔性衬体上的器件阈值电压Vth为-1.2 V,迁移率μFE为5.87 cm2·V-1·s-1,开关比Ion/Ioff为6×103,亚阈值摆幅SS为7.63 V·dec-1。

2018年,Ryu等[6]采用单壁碳纳米管(single walled carbon nanotubes,SWCNTs)作为SnO薄膜晶体管源、漏电极,具有聚合物刻蚀钝化层的SnO TFT的器件结构使SWCNTs能够在期望的区域内进行选择性刻蚀,而不受SnO沟道层的不利影响,器件栅极采用重掺杂n型Si,绝缘层采用SiO2,厚度为18 nm,SnO采用射频磁控溅射法(RF magnetron sputtering)制备,厚度为10 nm。以SWCNTs为源、漏电极的SnO TFT器件表现出良好的电接触性能(1.49 kΩ/cm), 器件迁移率μFE为0.69 cm2·V-1·s-1,开关比Ion/Ioff接近3.5×103,亚阈值摆幅SS为0.4 V·dec-1。系统温度依赖性测量表明,与传统的Ni电极相比,SnO通道在几十meV内具有活化能传输,同时具有良好的接触电阻。

3.3 原子层沉积法2017年,Kim等[36]通过采用原子层沉积法(atomic layer deposition, ALD)制备出高性能SnO TFT器件,探究了不同沉积温度对器件性能的影响,最终发现在210 ℃下沉积的SnO薄膜相较低温沉积的薄膜性能更优,这是由于在高温条件下SnO薄膜晶粒尺寸更大且杂质含量更少。器件栅极采用重掺杂p型Si,绝缘层采用厚度为100 nm的SiO2,用光刻法对SnO活性层进行图形化处理,用0.05%(质量分数)HF溶液化学刻蚀活性层的外围,源、漏电极采用Pt,采用15 nm厚的Al2O3钝化层对SnO活性层的背沟道表面进行钝化处理,随后,器件在氩气环境下进行250 ℃退火1 h。器件迁移率μFE为1.0 cm2·V-1·s-1,开关比Ion/Ioff接近2.0×106,亚阈值摆幅SS为1.8 V·dec-1。

表 2列出了近年来氧化亚锡薄膜晶体管的研究进展,对器件重要性能参数:阈值电压、开态电压、迁移率、电流开关比、亚阈值摆幅等进行了汇总;从表 2中可以看出器件制备方法一般采用磁控溅射法;目前,器件最大迁移率为10.83 cm2·V-1·s-1,基本能达到n型晶体管的水平。氧化亚锡薄膜晶体管现在最大的问题是电流开关比太低,关态电流难以抑制的问题还需进一步研究解决。

| Method | Vth/V | Von/V |

μFET/ (cm2·V-1·s-1) |

μsat/ (cm2·V-1·s-1) |

Ion/Ioff | SS/(V·dec-1) | Time | Reference |

| TE | 30.4 | - | - | 0.011 | 1.0×103 | 2 | 2008 | [44] |

| RFMS | -5 | - | 1.2 | - | 1.0×103 | - | 2010 | [39] |

| PLD | 3.1 | 2 | 0.48 | 0.78 | 1.0×104 | 1.9 | 2011 | [22] |

| EBE | -20.5 | -7 | - | 0.16 | 9.0×101 | - | 2012 | [37] |

| DCMS | -1.06 | 2 | 10.83 | - | 1.0×103 | 0.76 | 2013 | [46] |

| RFMS | -2.3 | 0 | 4.86 | - | 3.0×104 | 0.7 | 2014 | [41] |

| RFMS | 4.1 | 10 | 1.2 | 1.1 | 2.5×104 | 1.1 | 2014 | [42] |

| DCMS | 0.87 | - | 2.39 | - | 1.0×103 | 7.5 | 2015 | [5] |

| RFMS | 0.24 | 5 | 1.8 | - | 1.0×105 | 0.55 | 2015 | [43] |

| ALD | - | - | 1.0 | - | 2.0×106 | 1.8 | 2017 | [36] |

| RFMS | 3.0 | - | 0.69 | - | 3.5×103 | 0.4 | 2018 | [6] |

由于其特有的光学和电学性质,以SnO为代表的p型金属氧化物半导体材料引起越来越多研究者们的关注,并且已经在薄膜晶体管、传感器、催化剂、新能源电池等领域取得突破。相对于其他p型氧化物半导体材料,SnO具有锡空位VSn形成能低以及更为分散的载流子传输通道两大优点,从而在薄膜晶体管中的应用有着先天优势,基于SnO沟道层的薄膜晶体管器件性能更优,迁移率更高。本文对SnO微观性能分析、SnO薄膜材料制备以及晶体管研究进展等进行了详细介绍,目前SnO TFT器件迁移率能达到10.83 cm2·V-1·s-1,基本能实现与n型半导体器件性能相近。但SnO TFT器件所面临的最大问题是沟道空穴浓度高导致器件电流开关比(Ion/Ioff)太小, 一般不超过103量级,这严重影响了器件性能的提升。为此常用解决手段有:覆盖一层钝化层,选用功函数相匹配的绝缘层以及表面优化处理;采用这些优化手段旨在有效降低器件沟道空穴浓度从而提升器件性能。因此,在薄膜制备工艺以及器件结构方面的优化值得深入研究。

| [1] |

WANG Z, NAYAK P K, CARAVEO-FRESCAS J A, et al. Recent developments in p-type oxide semiconductor materials and devices[J]. Advanced Materials, 2016, 28(20): 3831-3892. DOI:10.1002/adma.201503080 |

| [2] |

SECOR E B, SMITH J, MAEKS T J, et al. High-performance inkjet-printed indium-gallium-zinc-oxide transistors enabled by embedded, chemically stable graphene electrodes[J]. ACS Applied Materials & Interfaces, 2016, 8(27): 17428-17434. |

| [3] |

LI Y S, HE J C, HSU S M, et al. Flexible complementary oxide-semiconductor-based circuits employing n-channel ZnO and p-channel SnO thin-film transistors[J]. IEEE Electron Device Letters, 2016, 37(1): 46-49. DOI:10.1109/LED.2015.2501843 |

| [4] |

WANG Z, Al-JAWHARI H A, NAYAK P K, et al. Low temperature processed complementary metal oxide semiconductor (CMOS) device by oxidation effect from capping layer[J]. Scientific Reports, 2015, 5: 9617-9620. DOI:10.1038/srep09617 |

| [5] |

MARTINS R F P, AHNOOD A, CORREIA N, et al. Recyclable, flexible, low-power oxide electronics[J]. Advanced Functional Materials, 2013, 23(17): 2153-2161. DOI:10.1002/adfm.201202907 |

| [6] |

RYU J H, BAEK G W, KIM S Y, et al. Spray-coated single walled carbon nanotubes as source and drain electrodes in SnO thin-film transistors[J]. Semiconductor Science and Technology, 2018, 33(7): 075013-075016. DOI:10.1088/1361-6641/aac675 |

| [7] |

OGO Y, HIRAMATSU H, NOMURA K, et al. P-channel thin-film transistor using p-type oxide semiconductor, SnO[J]. Applied Physics Letters, 2008, 93(3): 032113-032116. DOI:10.1063/1.2964197 |

| [8] |

LIU A, ZHU H, PARK W T, et al. Room-temperature solution-synthesized p-type copper (Ⅰ) iodide semiconductors for transparent thin-film transistors and complementary electronics[J]. Advanced Materials, 2018, 30(34): 1802379-1802381. DOI:10.1002/adma.201802379 |

| [9] |

LI B S, AKIMOTO K, SHEN A. Growth of Cu2O thin films with high hole mobility by introducing a low-temperature buffer layer[J]. Journal of Crystal Growth, 2009, 311(4): 1102-1105. DOI:10.1016/j.jcrysgro.2008.11.038 |

| [10] |

MATSUZAKI K, NOMURA K, YANAGI H, et al. Epitaxial growth of high mobility Cu2O thin films and application to p-channel thin film transistor[J]. Applied Physics Letters, 2008, 93(20): 202107-202110. DOI:10.1063/1.3026539 |

| [11] |

LIU A, MENG Y, ZHU H, et al. Electrospun p-type nickel oxide semiconducting nanowires for low-voltage field-effect transistors[J]. ACS Applied Materials & Interfaces, 2017, 10(31): 25841-25849. |

| [12] |

LIU A, LIU G, ZHU H, et al. Hole mobility modulation of solution-processed nickel oxide thin-film transistor based on high-k dielectric[J]. Applied Physics Letters, 2016, 108(23): 233506-233509. DOI:10.1063/1.4953460 |

| [13] |

WATSON G W. The origin of the electron distribution in SnO[J]. The Journal of Chemical Physics, 2001, 114(2): 758-763. |

| [14] |

WALSH A, WATSON G W. Electronic structures of rocksalt, litharge, and herzenbergite SnO by density functional theory[J]. Physical Review:B, 2004, 70(23): 235114-235117. DOI:10.1103/PhysRevB.70.235114 |

| [15] |

TOGO A, OBA F, TANAKA I, et al. First-principles calculations of native defects in tin monoxide[J]. Physical Review:B, 2006, 74(19): 195128-195131. DOI:10.1103/PhysRevB.74.195128 |

| [16] |

SAJI K J, TIAN K, SNURE M, et al. 2D tin monoxide-an unexplored p-type VAN DER WAALS semiconductor:material characteristics and field effect transistors[J]. Advanced Electronic Materials, 2016, 2(4): 1500453-1500457. DOI:10.1002/aelm.201500453 |

| [17] |

OGO Y, HIRAMATSU H, NOMURA K, et al. Tin monoxide as an s-orbital-based p-type oxide semiconductor:electronic structures and TFT application[J]. Physica Status Solidi:A, 2009, 206(9): 2187-2191. DOI:10.1002/pssa.200881792 |

| [18] |

WAGER J F, YEH B, HOFFMAN R L, et al. An amorphous oxide semiconductor thin-film transistor route to oxide electronics[J]. Current Opinion in Solid State and Materials Science, 2014, 18(2): 53-61. DOI:10.1016/j.cossms.2013.07.002 |

| [19] |

MILLER S A, GORAI P, AYDEMIR U, et al. SnO as a potential oxide thermoelectric candidate[J]. Journal of Materials Chemistry:C, 2017, 5(34): 8854-8861. DOI:10.1039/C7TC01623A |

| [20] |

YAN LIANG L, TAO CAO H, BOCHEN X, et al. Ambipolar inverters using SnO thin-film transistors with balanced electron and hole mobilities[J]. Applied Physics Letters, 2012, 100(26): 263502-263506. DOI:10.1063/1.4731271 |

| [21] |

HAYASHI H, KATAYAMA S, HUANG R, et al. Selective fabrication of n-and p-type SnO films without doping[J]. Physica Status Solidi (RRL)-rapid Research Letters, 2015, 9(3): 192-196. DOI:10.1002/pssr.201510016 |

| [22] |

NOMURA K, KAMIYA T, HOSONO H. Ambipolar oxide thin-film transistor[J]. Advanced Materials, 2011, 23(30): 3431-3434. DOI:10.1002/adma.201101410 |

| [23] |

LIANG L Y, LIU Z M, CAO H T, et al. Microstructural, optical, and electrical properties of SnO thin films prepared on quartz via a two-step method[J]. ACS Applied Materials & Interfaces, 2010, 2(4): 1060-1065. |

| [24] |

LIANG L Y, LIU Z M, CAO H T, et al. The structure, optical and electrical properties of Y-doped SnO thin films and their p-type TFT application[J]. Journal of Physics:D, 2012, 45(8): 085101-085104. DOI:10.1088/0022-3727/45/8/085101 |

| [25] |

PEI Y, LIU W, SHI J, et al. Fabrication and characterization of p-type SnO thin film with high c-axis preferred orientation[J]. Journal of Electronic Materials, 2016, 45(11): 5967-5973. DOI:10.1007/s11664-016-4816-7 |

| [26] |

JIANG Y H, CHIU I C, KAO P K, et al. Influence of rapid-thermal-annealing temperature on properties of RF-sputtered SnOx thin films[J]. Applied Surface Science, 2015, 327: 358-363. DOI:10.1016/j.apsusc.2014.11.115 |

| [27] |

HSU P C, CHEN W C, TSAI Y T, et al. Sputtering deposition of p-type SnO films using robust Sn/SnO2 mixed target[J]. Thin Solid Films, 2014, 555: 57-61. DOI:10.1016/j.tsf.2013.06.059 |

| [28] |

HSU P C, HSU C J, CHANG C H, et al. Sputtering deposition of p-type SnO films with SnO2 target in hydrogen-containing atmosphere[J]. ACS Applied Materials & Interfaces, 2014, 6(16): 13724-13729. |

| [29] |

CARAVEO-FRESCAS J A, NAYAK P K, Al-JAWHARI H A, et al. Record mobility in transparent p-type tin monoxide films and devices by phase engineering[J]. ACS Nano, 2013, 7(6): 5160-5167. DOI:10.1021/nn400852r |

| [30] |

HAN J H, CHUANG Y J, PARK B K, et al. Growth of p-type tin (Ⅱ) monoxide thin films by atomic layer deposition from bis (1-dimethylamino-2-methyl-2propoxy) tin and H2O[J]. Chemistry of Materials, 2014, 26(21): 6088-6091. DOI:10.1021/cm503112v |

| [31] |

WILDSMITH T, HILL M S, JOHNSON A L, et al. Exclusive formation of SnO by low temperature single-source AACVD[J]. Chemical Communications, 2013, 49(78): 8773-8775. DOI:10.1039/c3cc45676e |

| [32] |

SHIMIZU M, USUI H, SAKAGUCHI H. Electrochemical Na-insertion/extraction properties of SnO thick-film electrodes prepared by gas-deposition[J]. Journal of Power Sources, 2014, 248: 378-382. DOI:10.1016/j.jpowsour.2013.09.046 |

| [33] |

HILL M S, JOHNSON A L, LOWE J P, et al. Aerosol-assisted CVD of SnO from stannous alkoxide precursors[J]. Dalton Transactions, 2016, 45(45): 18252-18258. DOI:10.1039/C6DT02508K |

| [34] |

LIANG L Y, LIU Z M, CAO H T, et al. Improvement of phase stability and accurate determination of optical constants of SnO thin films by using Al2O3 capping layer[J]. ACS Applied Materials & Interfaces, 2010, 2(6): 1565-1568. |

| [35] |

TOYAMA T, SEO Y, KONISHI T, et al. Optical absorption spectra of p-type tin monoxide thin films around their indirect fundamental gaps determined using photothermal deflection spectroscopy[J]. Thin Solid Films, 2014, 555: 148-152. DOI:10.1016/j.tsf.2013.05.141 |

| [36] |

KIM S H, BAEK I H, KIM D H, et al. Fabrication of high-performance p-type thin film transistors using atomic-layer-deposited SnO films[J]. Journal of Materials Chemistry:C, 2017, 5(12): 3139-3145. DOI:10.1039/C6TC04750E |

| [37] |

SUNG S Y, JO K M, KIM S Y, et al. Structural, optical, and electrical properties of p-type SnO thin films deposited by reactive rf magnetron sputtering[J]. Journal of Nanoelectronics and Optoelectronics, 2012, 7(5): 475-478. DOI:10.1166/jno.2012.1384 |

| [38] |

YAN LIANG L, TAO CAO H, BO CHEN X, et al. Ambipolar inverters using SnO thin-film transistors with balanced electron and hole mobilities[J]. Applied Physics Letters, 2012, 100(26): 263502-263507. DOI:10.1063/1.4731271 |

| [39] |

FORTUNATO E, BARROS R, BARQUINHA P, et al. Transparent p-type SnOx thin film transistors produced by reactive rf magnetron sputtering followed by low temperature annealing[J]. Applied Physics Letters, 2010, 97(5): 052105-052109. DOI:10.1063/1.3469939 |

| [40] |

LEE H N, KIM H J, KIM C K. P-channel tin monoxide thin film transistor fabricated by vacuum thermal evaporation[J]. Japanese Journal of Applied Physics, 2010, 49(2R): 020202-020206. |

| [41] |

NAYAK P K, CARAVEO-FRESCAS J A, WANG Z, et al. Thin film complementary metal oxide semiconductor (CMOS) device using a single-step deposition of the channel layer[J]. Scientific Reports, 2014, 4: 4672-4676. |

| [42] |

HAN Y J, CHOI Y J, CHO I T, et al. Improvement of long-term durability and bias stress stability in p-type SnO thin-film transistors using a SU-8 passivation layer[J]. IEEE Electron Device Letters, 2014, 35(12): 1260-1262. DOI:10.1109/LED.2014.2363879 |

| [43] |

HAN Y J, CHOI Y J, JEONG C Y, et al. Environment-dependent bias stress stability of p-type SnO thin-film transistors[J]. IEEE Electron Device Letters, 2015, 36(5): 466-468. DOI:10.1109/LED.2015.2409854 |

| [44] |

OU C W, DHANANJAY, HO Z Y, et al. Anomalous p-channel amorphous oxide transistors based on tin oxide and their complementary circuits[J]. Applied Physics Letters, 2008, 92(12): 122113-122117. DOI:10.1063/1.2898217 |

| [45] |

AL-JAWHARI H A, CARAVEO-FRESCAS J A, HEDHILI M N, et al. P-type Cu2O/SnO bilayer thin film transistors processed at low temperatures[J]. ACS Applied Materials & Interfaces, 2013, 5(19): 9615-9619. |

| [46] |

CARAVEO-FRESCAS J A, ALSHAREEF H N. Transparent p-type SnO nanowires with unprecedented hole mobility among oxide semiconductors[J]. Applied Physics Letters, 2013, 103(22): 222103-222106. DOI:10.1063/1.4833541 |

2020, Vol. 48

2020, Vol. 48